Abstract

Unexpected worldwide disruptions brought various challenges to supply chain management thus manipulating the research direction towards resilience. Since the supplier is one of the important supply chain elements, the challenges can be overcome through resilient supplier selection. Supplier selection is a multi-criteria decision-making problem where several criteria are involved. In this study, GRA-BWM-TOPSIS was proposed to evaluate resilient suppliers. Seven resilience criteria which were Quality, Lead Time, Cost, Flexibility, Visibility, Responsiveness and Financial Stability have been proposed and five experts were selected to provide judgments for the selection process. By using the proposed method, the criteria importance levels were obtained using GRA and the criteria weights were computed using BWM, together with a consistency test. TOPSIS was applied to evaluate the suppliers’ performances. Through a case study in a food manufacturing company, 10 suppliers were evaluated and ranked. A validation process was carried out and the managerial implications were provided to ensure the effectiveness of the proposed model. GRA-BWM-TOPSIS is suitable for resilient supplier selection when there are uncertainties and incomplete data.

Keywords:

resilience; supply chain; supplier selection; multi-criteria decision-making; GRA; BWM; TOPSIS 1. Introduction

A Supply Chain (SC) consists of five main elements namely suppliers, manufacturers, distributors, retailers, and customers. Recently, uncertain global risks and disruptions have affected most of the manufacturing industries which forced them to focus on SC resilience. Generally, the risks associated with SC can be classified into two categories which are operational risk and disruption risk [1]. Operational risk refers to the inherent events that occur within a SC such as uncertainty in transportation cost, customer demand, and power outage [2]. Disruption risk refers to the major disruptive events such as natural disasters, human-made threats, or employee strikes including pandemics, tsunamis, earthquakes, floods, fires, transport accidents, and labor strikes. These events may cause short-term or long-term negative impacts to the financial performance of SC or even economic crisis in more serious cases. To deal with the economic issues, resilience is vital to be incorporated in a SC.

The literature [3] indicates that most of the previous supplier selection studies only focused on traditional, green and sustainable SC elements while overlooking resilience factors. The disruption of COVID-19 pandemic has forced the government to make significant restrictions on goods transportation, as well as labor migration. Many industries are facing the impact including food manufacturing industry. The food manufacturing SC is significantly affected by the absence of local or migrant workers due to their sickness and travel restrictions of lockdowns imposed by the government. As a consequence, many companies face economic challenges. A statistic by Companies Commission of Malaysia shows that 9675 Small and Medium Enterprises (SMEs) had shut down during the first phase of the Movement Control Order from 18 March to 9 June in 2020. During the recovery phase from June to September 2020, 22,794 SMEs had winded up [4]. To deal with this, resilience is required to overcome the sudden changes in the manufacturing SC. The less focus on resilience elements in previous supplier selection studies [3,5] causes a lack of investigation on resilience criteria and resilient suppliers’ evaluation. Today, globalization has brought problems of uncertainties and incomplete information due to risks and disruptions which cause inaccuracy to the decision-making. Thus, researchers are urged to shift their research direction towards SC resilience.

A resilient SC has a good flow of materials, information and capital, with the collaboration between the suppliers and customers by considering dimensions of being able to respond quickly to various disruptions and have a flexible contingency plan in place. An economically resilient SC is able to foresee, adapt to, and leverage the changing conditions to economic advantages as stated by the National Association of Counties (NACo) [5]. In this case, Rajesh and Ravi [6] reported that a supplier is the main element in SC while Munir et al. [7] stated that a supplier acts as the main source in developing SC economic resiliency. Therefore, suppliers are the main concern in building up a resilient SC. In this study, a supplier is a party that provides the raw materials by ensuring that the communications between all the parties are forthcoming and the stocks are of satisfactory quality. One of the most effective ways to deal with various economic challenges is resilient supplier selection.

Supplier Selection Process (SSP) consists of four sub-processes which are the definition of problems, identification of evaluation criteria, determination of potential suppliers, and selection of the best supplier. SSP is a Multi-Criteria Decision-Making (MCDM) problem since the process deals with more than one criterion. In previous studies, several MCDM methods have been utilized to evaluate and select the best supplier [8]. However, the previous techniques are found to have certain limitations in handling problems with uncertainties and incomplete information due to unexpected risks and disruptions, thus, resulting in inconsistent findings. Therefore, a better technique is proposed.

Generally, the purposes of this study are:

- To incorporate the element of resilience into supplier selection;

- To calculate the weights of resilience criteria with a higher consistency;

- To rank the performances of the resilient suppliers while taking into account uncertainties and incomplete data.

Hence, a Grey-MCDM model which is a new integrated Grey Relational Analysis (GRA)-Best Worst Method (BWM)-Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) model is proposed for resilient supplier selection. This new technique is a serial integration between three different techniques to generate better outcomes. It could be applied to determine the importance level of each criterion to be considered in resilient supplier selection. At the same time, it could provide highly consistent results of criteria weights and suppliers’ ranks by considering the problems with uncertainties and incomplete information. The paper is structured as follows: the literature review and research gaps are presented in Section 2. The research methodology is explained and defined in Section 3. The case study and results are presented in Section 4. Section 5 presents the validation of the proposed model, followed by Section 6 which presents the managerial implications. Finally, the conclusions and recommendations for future work are provided in the last section.

2. Literature

The trend of research in supplier selection indicates that the SC focus has been shifted from conventional, green and sustainability elements towards resilience to deal with uncertainties and incomplete information caused by unexpected risks and disruptions. In previous studies [3,8], researchers have proposed different MCDM techniques for resilient supplier selection such as VlseKriterijumska Optimizacija I Kompromisno Resenje (VIKOR), Additive Ratio Assessment (ARAS), Weighted Aggregated Sum Product Assessment (WASPAS), Data Envelopment Analysis (DEA), Analytical Network Process (ANP), Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS), Multi-Choice Goal Programming (MCGP), Fuzzy Inference System (FIS) and Analytical Hierarchy Process (AHP). Some of the latest studies are presented in this section.

Mohammed et al. [3] proposed a hybrid MCDM approach towards resilient sourcing. They developed an efficient resilient supplier selection approach based on a new holistic framework that enables the identification of key resilience pillars (RPs) and traditional business criteria (TBC). The outcome was the measurement of the relative importance of TBC and RP by applying the DEMATEL method. This was followed by the integration of Multi-Attributive Border Approximation Area Comparison (MABAC) and Operational Competitiveness Rating Analysis (OCRA) with TOPSIS and VIKOR methods in verifying the suppliers’ ranking.

Pramanik et al. [9] presented a soft computing approach to mitigate uncertainties in resilient supplier selection. Considering both the tangible and intangible criteria, they presented a new integrated fuzzy AHP and fuzzy ARAS with fuzzy entropy using the linguistic values to solve the supplier selection problem with uncertain data. Fuzzy entropy was used to obtain the entropy weights of the criteria while fuzzy AHP-ARAS was applied to rank the suppliers.

A hybrid model was proposed by Xiong et al. [10] for green-resilient supplier selection which integrated BWM, WASPAS, and TOPSIS to select green-resilient suppliers. Firstly, the criteria weights were calculated by BWM and the intuitionistic fuzzy numbers were applied to rank the suppliers. Then, WASPAS-TOPSIS was applied to select the optimal resilient-green supplier.

Hasan et al. [11] developed a Decision Support System (DSS) to incorporate imprecise heterogeneous data to rank the resilient suppliers in a logistic 4.0 environment. They induced a triangular fuzzy number from large-scale temporal data by applying the probability-possibility consistency principle. The qualitative attributes were mapped by the fuzzy linguistic variables while the suppliers were ranked by the fuzzy-based TOPSIS method. These ranking scores act as the inputs of the MCGP model to determine the optimal order allocation for the suppliers.

In a latter study conducted by Mohammed [12], an integration between a grey theory with DEMATEL-VIKOR was proposed for the resilient supplier selection. After identifying the gresilience criteria, the DEMATEL algorithm was used to determine the importance levels of criteria based on the experts’ opinions. The gresilience performances of suppliers were then assessed by using the VIKOR algorithm. Next, the suppliers’ performances were revealed and the insights for the gresilience suppliers were discussed.

In another study, Piprani et al. [13] employed a two-stage methodology for the supplier selection process. Their aim was to determine the resilient capability factors at different stages of SC disruptions in Pakistan’s textile industry. In the first stage, the resilient capability factors were identified through the experts’ consultations. In the second stage, the factors needed for the textile industry were ranked by applying AHP.

Parkouhi et al. [14] considered two dimensions which were resilience enhancer and resilience reducer in selecting suppliers. The degrees of importance of the criteria were determined using the Grey DEMATEL technique for the two dimensions, while the scores of suppliers were determined using the Grey Simple Additive Weighting (GSAW) technique. The findings showed that customization was the most important enhancer criterion whereas the most significant reducer was the capacity limit of suppliers. Finally, the prioritized resilient suppliers were identified.

Davoudabadi et al. [15] presented a new integrated efficiency measurement model for resilient supplier analysis using the Principal Components Analysis (PCA) to reduce the criteria dimensions. Furthermore, DEA was employed to determine the criteria weights and suppliers’ ranks. The weights of criteria were simultaneously determined by using the DEA method, entropy index, and judgments of decision-makers.

A resilient-sustainable framework based on the supplier selection indicators was proposed by Amindoust [16]. A fuzzy set theory has been applied to deal with the uncertainties in supplier selection. Furthermore, a modular FIS was designed to determine the suppliers’ affinity indices to the resiliency and sustainability issues. It provided a comprehensive supplier selection model with any number of indicators and suppliers. The outcomes were analyzed using the Assurance Region DEA method (AR-DEA) in determining the indicators’ weights and suppliers’ ranks.

Some other studies that have applied MCDM methods in resilient supplier selection are summarized in Table 1.

Table 1.

Review on resilient supplier selection.

As presented in Table 1, the fuzzy theory was commonly applied rather than the grey theory to deal with uncertainties in supplier selection. It is evident that AHP and TOPSIS were the most common MCDM methods in resilient supplier selection. Among the industries covered by the previous studies above, the food manufacturing industry has not been considered.

Research Gaps

Previous researchers revealed that resilience is rare to be incorporated in SC compared to traditional, green and sustainable elements in supplier selection. In the early years, traditional criteria such as cost, quality and lead time were prioritized in selecting suppliers. After some time, the SC focus shifted to the indicators of green supplier evaluation due to the challenges of commensurate environmental degradation, such as the rise of consumer awareness and attendant shift of attitudes to purchasing greener products. Then, the rapid consumption of natural resources and the need for environmental protection led to the focus on SC sustainability by taking into account economic, social and environmental criteria. People are accustomed to surviving in their comfort zones as they enter the globalization period. As a result, there is a lack of preparedness and readiness in dealing with unforeseen risks and disruptions, which pose several important problems to the SC. In achieving the first objective of the study, resilience is incorporated into supplier selection to deal with various SC challenges.

By referring to the literature [8,9,10,11,12], AHP and TOPSIS are among the most convenient methodologies to provide the criteria weights and suppliers’ ranks since AHP is easy to be applied while TOPSIS provides a scalar value that accounts for the abilities of both the best and the worst alternatives. Peng and Xiao [22] and Sun et al. [23] pointed out that TOPSIS is a better decision-making technique for choosing alternatives because of its clear and understandable logic. TOPSIS can also deal with qualitative and quantitative problems [24]. Thus, it is preferred in this study. However, from the perspective of AHP, it becomes complicated when the number of variables is large thus causing inconsistency in experts’ judgments. To deal with this, researchers have discovered the Best Worst Method (BWM) as a substitute for weighing the criteria. BWM greatly reduces the complexity of calculation, and through more consistent comparisons, the final result will be more credible [25]. Due to its simplicity and ability to generate results with greater consistency, BWM has replaced AHP to be integrated with TOPSIS to determine the criteria weights and rank the suppliers in achieving the second objective. BWM is applied in this study for criteria weights calculation based on experts’ judgments and to ensure that the results are consistent.

On the other hand, there are problems of uncertainties and incomplete information in the supplier selection process. Unexpected risks and disruptions bring various uncertainties to the SC. In this case, the weights of criteria and the performances of suppliers are usually incommensurate and fuzzy in nature. At the same time, decision-makers may have varying levels of knowledge and opinions when it comes to evaluating the suppliers. In addition, there may be insufficient information due to data confidentiality which causes difficulties for the evaluation process. In this case, the uncertain and incomplete data might limit the function of BWM in producing an accurate result. In previous supplier selection studies [9,10,11,13], the fuzzy-based model was commonly applied to select the suppliers due to its strength to cope with uncertainties. However, in terms of handling incomplete data and information, the grey theory is an appropriate method. One of the major parts of the grey theory is Grey Relational Analysis (GRA) which is suitable for solving problems with complicated interrelationships between multiple factors and variables. In order to fulfill the third objective, GRA is integrated with BWM-TOPSIS to rank the resilient suppliers with the consideration of uncertainties and incomplete data.

Furthermore, this study is an original effort in improving SC resilience by applying GRA-BWM-TOPSIS to execute resilient supplier selection in the food manufacturing industry. This research can help decision-makers to improve the supplier selection process by identifying the most resilient supplier.

3. Methodology

In this section, the explanations of the proposed GRA-BWM-TOPSIS model and the research framework for resilient supplier selection are presented.

3.1. GRA for Obtaining the Relative Importance of Criteria

Grey relational analysis (GRA) technique was introduced by Deng [26] and has been effectively utilized in solving several MCDM complications. GRA is one of the effective analysis tools of grey theory, with the ability to address imprecise and incomplete information [27]. It analyzes the similarity relationship between the reference series and alternative series where the best scheme of the decision is the alternative series with the closest similarity to the reference series.

The steps are as follows [28]:

3.1.1. Listing of Questionnaire Responses

Experts’ judgments are used to determine the relative importance of each criterion to be applied in the supplier selection process. Table 2 shows the scoring scale assigned for GRA.

Table 2.

GRA scoring scale.

A decision matrix is formed based on the experts’ judgments for each criterion using Equation (1).

where i represents respondent and j represents criterion.

3.1.2. Determination of the Reference Score and the Differences from the Reference Score

The results are listed from the experts’ responses, and the reference score, r0 which is the largest value in the decision matrix is determined. Then, the differences between each score, ri and r0 are calculated using Equation (2)

3.1.3. Calculation of Grey Relational Coefficient

The grey relational coefficient is calculated based on Equation (3):

- where,

- ∆min = minⱯiminⱯj∆ri(j),

- ∆max = maxⱯimaxⱯj∆ri(j)

- where p is an identification coefficient.

In general, the value of p is set to 0.5 to provide good stability where its function is to increase or decrease the range of the grey relational coefficients.

3.1.4. Determination of Grey Relational Grade

The grey relational grade, Yi which is equal to the arithmetic mean of the grey relational coefficients, Zi is calculated based on Equation (4). The arithmetic mean of Zi determines the final grade of a particular criterion. Thus, the higher the Yi grade, the more important is the criterion.

where m is the total number of respondents.

3.2. BWM for Criteria Weights Calculation

The preferences of the best criterion over other criteria and other criteria over the worst criterion are determined either using a score between 1 and 9 or its reciprocal. The weights of criteria are computed using Equations (7) and (8). Finally, Equation (9) is applied to calculate the consistency ratio for the results. Table 3 shows the scoring scale for BWM.

Table 3.

BWM scoring scale.

The steps are as follows [29,30]:

3.2.1. Preferences of the Best Criterion over Others and Others over the Worst Criterion

The resulting Best-to-Others (BO) vector, AB would be:

where ABj indicates the importance of the best criterion B over criterion j.

Hence, ABB = 1.

The resulting Others-to-Worst (OW) vector, AW would be:

where AjW indicates the importance of criterion j over the worst criterion W.

Hence, AWW = 1

3.2.2. Computation of Criteria Weights

The optimization model is formulated to find the optimal weights of the criteria, wj. To determine the optimal weights, the absolute maximum differences between and for all j should be minimized, which can be written as:

Subject to:

Equation (7) can be converted into the following model:

min ξ

Subject to:

3.2.3. Calculation of Consistency Ratio

The level of consistency is calculated using a robust index called consistency ratio, CR:

where ξ* is the optimal objective value of the model and ξmax is the maximum possible value of ξ. The range of CR is [0, 1]. The closer the CR to 0, the more consistent are the judgments. In particular, CR = 0 means that the comparisons are cardinally consistent.

3.3. TOPSIS for Supplier Ranking

The Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) is a MCDM technique introduced by Hwang and Yoon in 1981 [31]. It aids the decision-makers in organizing and ranking alternatives by comparing their distances from the ideal solution and non-ideal solution. Hwang and Yoon [31] later proposed the alternatives’ ranking based on the closest distance from the positive ideal solution (PIS) and the furthest distance from the negative ideal solution (NIS). TOPSIS represents the mindset of human choice with a measurable value that accounts for both the ideal and non-ideal choices concurrently [32,33]. TOPSIS is an easy computation process and its high flexibility allows itself to be applied on various occasions. At the same time, this enables its further extension in multi-objective decision-making [34] and group decision-making. Table 4 tabulates the scoring scale for TOPSIS. The performances of suppliers are evaluated based on Equations (10)–(17).

Table 4.

TOPSIS scoring scale.

The steps are as follows [28]:

3.3.1. Formation of Decision Matrix

A decision matrix, uij is formed based on experts’ opinions as stated below:

where i represents supplier and j represents criterion.

3.3.2. Formation of Standardized Decision Matrix

For the purpose of standardization, the values in the decision matrix are divided by their respective root sum square values.

Standardized Decision matrix, Uij is formed based on experts’ opinions as stated below:

3.3.3. Calculation of Weighted Standardized Decision Matrix

Weighted standardized decision matrix, vij is formed by multiplying the standardized decision matrix with the criteria weights, wj.

where wj represents criteria weight and = 1.

3.3.4. Determination of Positive Ideal Solution (PIS) and Negative Ideal Solution (NIS)

The maximum value for each criterion is the PIS whereas the minimum value for each criterion is the NIS.

PIS, V+ can be expressed as:

NIS, V− can be expressed as:

where J is associated with the benefit criteria, and is associated with the cost criteria;

3.3.5. Calculation of Distance of Separation from the PIS and NIS

The separation of each alternative from the PIS, is given as:

The separation of each alternative from the NIS, is given as:

3.3.6. Calculation of Relative Closeness Coefficient

The relative closeness of the i-th supplier, Fi with respect to V+ is defined as:

where , .

3.3.7. Ranking of Suppliers

By comparing the relative closeness coefficients, the suppliers’ priorities are ranked. The larger the relative closeness coefficient, the better the selected supplier.

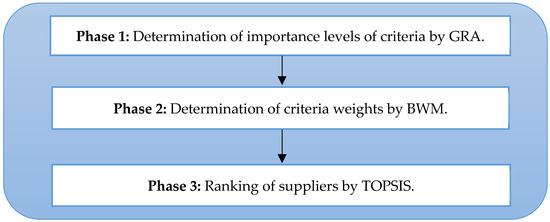

3.4. Proposed Framework of GRA-BWM-TOPSIS

The integrated model consists of three phases as presented in Figure 1. The first main part of the model is the identification and definition of the appropriate resilience criteria. These criteria are first collected from the related literature and then refined based on the SC requirements. A group of experts is selected from the case company to execute the data collection. The experts’ judgments are gathered and the importance levels of each criterion are obtained using GRA in phase 1. Then, the weight of each criterion is determined by applying BWM and the consistency ratio is calculated at the end of phase 2. After computing the weights, the evaluation of suppliers is carried out by applying TOPSIS in phase 3. In this phase, the experts are requested to provide their opinions about the suppliers based on each resilience criterion.

Figure 1.

Proposed framework of GRA-BWM-TOPSIS.

4. Case Study

The COVID-19 pandemic has brought a far-reaching global impact upon SC logistics, suppliers, and workforces especially in the manufacturing industries. As a result, there was a combination of typical and painful remedies against financial insolvency such as employee layoffs and budget cuts which finally ended up with bankruptcy [35]. However, Food and Agriculture Organization (FAO) [36] stated that the food manufacturing industry is slightly different from others because it works on the daily essential needs. In this case, factory closures have ramifications for the food manufacturing supply chain. If one of the factories closes, those who work there might lost their jobs and go hungry, whereas if the suppliers and manufacturers become infected, more people are at risk [37]. This demonstrates that the food manufacturing industry faces a variety of challenges, hence resilience is vital to be incorporated in the SC. Previously, the case company focused less on the element of resilience, resulting in the post-pandemic impact on its SC. Currently, the management level is shifting its main focus towards resilience in selecting suppliers to cope with the economic challenges. The proposed criteria and the new technique were applied in the case company to verify their effectiveness. This study presents a list of 7 resilience criteria to assess 10 suppliers’ performances in improving the SC performance of the company. The most common criteria from previous supplier selection studies [3,10,11,12,13] were combined to form a new set of resilience criteria. In this case, six common resilience criteria have been discovered based on previous research. However, there was a lack of financial consideration which was experienced by the case company. Financial concern tends to be one of the important factors in selecting suppliers since financial issues are often the root cause of deteriorating supplier performance, and suppliers often try to hide it from customers and buyers. Therefore, financial stability was proposed as one of the resilience criteria for this case study.

Table 5 shows the set of resilience criteria with their respective definitions to assess the suppliers.

Table 5.

Resilience criteria.

4.1. Data Collection

After defining the resilience criteria, five expert Respondents (R) which are the Supply Chain manager (Female, 10-year experience), Quality manager (Male, 20-year experience), Production manager (Male, 15-year experience), Procurement manager (Female, 14-year experience) and Finance manager (Male, 18-year experience) from the case company were requested to give their judgments on the importance levels of the criteria, and the suppliers’ performances based on the scoring scales assigned, respectively. All of them owned a bachelor’s degree except the Supply Chain manager with a Master degree. As shown in Table 5, the seven resilience Criteria (C) were Quality (C1), Lead Time (C2), Cost (C3), Flexibility (C4), Visibility (C5), Responsiveness (C6) and Financial Stability (C7). For this case study, 10 Suppliers (S) were evaluated based on the criteria. Table 6, Table 7, Table 8 and Table 9 present the data collected for each phase.

Table 6.

Experts’ opinions on criteria for GRA (Phase 1).

Table 7.

Experts’ opinions on comparison of best criterion over others for BWM (Phase 2).

Table 8.

Experts’ opinions on comparison of others over worst criterion for BWM (Phase 2).

Table 9.

Average experts’ opinions on suppliers for TOPSIS (Phase 3).

4.2. Weights Calculation

In this phase, five experts’ opinions on the criteria were collected, and the grey relational grades (GRG) which are the importance levels were determined using GRA as shown in Table 10. Following this, the weights of each criterion were computed using BWM as illustrated in Table 11. The result consistency was then determined by calculating the consistency ratio as shown in Table 12. To ensure the consistency, the consistency ratio should be close to 0.

Table 10.

Grey relational grade and rank for each criterion.

Table 11.

Weights of criteria.

Table 12.

Consistency test.

4.3. Ranking of Suppliers

After the determination of criteria weights, the experts were requested to evaluate the performance of each supplier based on each resilience criterion. By using the scoring scale, a decision matrix was created. Table 13 shows the decision matrix on suppliers obtained from the experts’ judgments with the root mean squares (RSS) for each supplier. Then, a standardized decision matrix was formed in Table 14. Table 15 illustrates the weighted standardized decision matrix by multiplying the criteria weights generated by BWM with the standardized decision matrix. After obtaining the weighted standardized decision matrix, the PIS and NIS were identified by applying TOPSIS. Lastly, the suppliers were ranked based on the relative closeness coefficients, F. Table 16 presents the results of the , sum of and , Fi and rank of the suppliers.

Table 13.

Average experts’ opinions on suppliers for TOPSIS (Phase 3).

Table 14.

Standardized decision matrix with respective criteria weights.

Table 15.

Weighted standardized decision matrix with respective PIS and NIS.

Table 16.

Computation of results.

4.4. Discussion

A food manufacturing company with the financial problem caused by the COVID-19 pandemic was selected to be assessed by the proposed model. In this case, 10 suppliers of the company were evaluated based on seven resilience criteria which were Quality (C1), Lead Time (C2), Cost (C3), Flexibility (C4), Visibility (C5), Responsiveness (C6) and Financial Stability (C7). Based on the proposed model, the results were generated and analyzed. In Table 10, GRA was applied to identify the importance level of each resilience criterion. The outcomes show that C3 which is Cost has the highest grey relational grade of 0.8667 at the 1st rank among the criteria, followed by C7, C5, C6, C4, C2 and lastly C1 with the lowest grade of 0.5133. The higher the grey relational grade, the more crucial is the criterion to be considered in the selection process. This implies that C3 is the most important criterion whereas C1 is the least important criterion to be applied for resilient supplier selection. By applying BWM, the best and the worst criteria were determined and the criteria weights were calculated. In this study, C3 is the best criterion whereas C1 is the worst criterion. From Table 11, the greatest weight is C3 with a value of 0.4225 whereas the smallest weight is C1 with a value of 0.0367. The weights were further applied for the evaluation of suppliers. To ensure the result consistency, a consistency test was carried out where Table 12 indicates that the consistency ratio generated is 0.09 which is close to 0. This implies that the result is consistent and the study could proceed to the next phase. Else, the process could be reversed to the scoring stage to improve the data collected. In this case, the criteria weights were carried to the supplier ranking phase by applying TOPSIS. Table 16 shows the outcomes of the supplier evaluation process. From the outcomes, Supplier 4 (S4) has the highest closeness coefficient which is 0.7512. This means that S4 has the nearest distance to the PIS and the furthest distance from the NIS which is the most ideal supplier for the case company. In contrast, Supplier 1 (S1) has the lowest closeness coefficient of 0.2222 which implies that S1 has the furthest distance from PIS and nearest distance to NIS. The suppliers’ rank starts from S4 with the best performance, followed by S3, S5, S10, S2, S7, S9, S6, S8 and lastly S1 showing the worst performance in the evaluation. Therefore, S4 is the most prioritized supplier for the case study. By applying the proposed resilience criteria and the validated technique of GRA-BWM-TOPSIS, the best resilient supplier is identified to improve the SC resilience of the company.

5. Validation of the Proposed Model

In this paper, the proposed model was validated by comparing it with another common MCDM technique in supplier selection. The technique selected for the comparison was AHP-VIKOR [28,39]. AHP was compared with the proposed GRA-BWM in determining the criteria weights whereas VIKOR was compared with the proposed TOPSIS to evaluate the suppliers’ performances and rank the suppliers. Hence, additional data were collected from the five experts in the case company in order to execute the AHP-VIKOR. Table 17 and Table 18 tabulate the results of applying AHP to the criteria weights and VIKOR to the suppliers ranking, respectively. The outcomes of GRA-BWM-TOPSIS and AHP-VIKOR are compared in Table 19 and Table 20, respectively.

Table 17.

Criteria weights by applying AHP.

Table 18.

Suppliers ranking by applying VIKOR.

Table 19.

Comparisons of results on criteria weights.

Table 20.

Comparisons of results on suppliers ranking.

6. Managerial Implications

In this study, the resilience element was incorporated in supplier selection to improve the SC ability to deal with unexpected risks and disruptions, consequently reducing the occurrence of financial issues. An effective Grey-MCDM model that integrated GRA with BWM and TOPSIS was proposed to measure the suppliers’ performances with respect to the set of 7 resilience criteria. To deal with SC risks and disruptions, GRA was applied due to its strength in coping with uncertainties and incomplete data in supplier selection. Then, BWM was applied to calculate criteria weights due to its simplicity. In addition, BWM was adopted to reduce the inconsistency of judgments with less pairwise comparisons needed. Thus, a more consistent result could be generated. Moreover, TOPSIS as one of the most common MCDM techniques was applied to evaluate the suppliers’ performances because it eases the computational work and has a better tolerance to a higher level of criterion weight change. Therefore, GRA-BWM-TOPSIS could be more effectively implemented to select the resilient suppliers. Other than that, the proposed set of resilience criteria was identified based on the review of literature and consideration of current SC needs. The proposed criteria do not only consider the basic traditional elements, but also resilience and financial elements. With this, the company’s managers could focus on different aspects by clearly identifying the resilience criteria with their importance to be prioritized in the assessment process. By applying the knowledge, the case company would be able to achieve its objective of building up a resilient SC through resilient supplier selection. The findings are not only useful to provide a clearer image for the decision-makers in selecting the best resilient supplier, but also to benchmark the performances of the suppliers with the consideration of uncertainties and incomplete data. In this case, the new technique was validated by comparing it with another common method to ensure its effectiveness in improving the performance of the SC, raising the satisfaction level of the customers and finally increasing the resiliency of the company. Overall, this study provides a reference for resilient supplier selection so that the company could remain alert towards the unexpected risks by focusing on the prioritized criteria with the consideration of uncertainties and incomplete data, thus, achieving a more robust SC.

7. Conclusions

This study has integrated GRA-BWM-TOPSIS to propose a framework for resilient supplier selection. Generally, there has been a lack of attention on resilient supplier selection, particularly with the presence of uncertain and incomplete data. Among the existing MCDM models, the integration of GRA-BWM-TOPSIS is novel. To implement the proposed model, seven resilience criteria (Quality, Lead Time, Cost, Flexibility, Visibility, Responsiveness, and Financial Stability) were determined based on the literature review and SC requirements. Subsequently, the importance levels for all the criteria were determined, the resilience criteria weights were computed, the consistency test was carried out, the suppliers’ performances were assessed and finally the supplier with the best performance was identified.

There are several contributions of this study. Firstly, the application of the serial-integrated MCDM method which is GRA-BWM-TOPSIS in the area of resilient supplier selection is new and has not yet been investigated in the literature. Secondly, grey theory rather than fuzzy theory is used in this study to improve the reliability of the supplier assessment process with the consideration of uncertainties and incomplete data. In addition, this is the first time where the resilience criteria for supplier selection in the food manufacturing industry have been investigated. In addition, the proposed criteria are generic and can be applied to different types of economic, operational and natural risks or disruptions.

Other than the contributions, there are also recommendations to be considered for future work. In this study, the proposed technique is a serial-integrated method. Further studies could be conducted with a different kind of integration of other methods [40] to select resilient suppliers. Next, the proposed technique has only been tested in the food manufacturing industry. In the future, the technique could be applied to select resilient suppliers in other industries. Furthermore, the proposed criteria set consists of only seven criteria and they may be varied depending on a company’s policy. Future studies could explore more criteria for resilient supplier selection.

Author Contributions

W.Y.L.: Writing; methodology; data collection; reviewing; editing of manuscript. K.Y.W.: Writing; supervision; reviewing; editing of manuscript. W.P.W.: Reviewing; editing of manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors are grateful to Universiti Teknologi Malaysia (UTM) (Vote Number: 20H69).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ivanov, D. Revealing interfaces of supply chain resilience and sustainability: A simulation study. Int. J. Prod. Res. 2018, 56, 3507–3523. [Google Scholar] [CrossRef] [Green Version]

- Hosseini, S.; Barker, K. Modeling infrastructure resilience using Bayesian networks: A case study of inland waterway ports. Comput. Ind. Eng. 2016, 93, 252–266. [Google Scholar] [CrossRef]

- Mohammed, A.; Yazdani, M.; Oukil, A.; Gonzalez, E.S. A Hybrid MCDM Approach towards Resilient Sourcing. Sustainability 2021, 13, 2695. [Google Scholar] [CrossRef]

- Carvalho, M.; Sivanandam, H.; Rahim, R.; Tan, T. 50,269 SMEs have closed down since March. The Star. 2020. Available online: https://www.thestar.com.my/news/nation/2020/11/10/50269-smes-have-closed-down-since-march#:~:text=A%20TOTAL%20of%2050%2C269%20small,Entrepreneurship%20Development%20and%20Cooperatives%20Ministry.&text=During%20the%20recovery%20MCO%20phase,September%2C%2022%2C794%20SMEs%20winded%20up (accessed on 10 November 2020).

- NACo. Strategies to Bolster Economic Resilience. Available online: https://www.naco.org/sites/default/files/documents/Strategies%20to%20Bolster%20Economic%20Resilience.pdf (accessed on 29 December 2020).

- Rajesh, R.; Ravi, V. Supplier selection in resilient supply chains: A grey relational analysis approach. J. Clean. Prod. 2015, 86, 343–359. [Google Scholar] [CrossRef]

- Munir, M.; Jajja, M.S.S.; Chatha, K.A.; Farooq, S. Supply chain risk management and operational performance: The enabling role of supply chain integration. Int. J. Prod. Econ. 2020, 227, 107667. [Google Scholar] [CrossRef]

- Pitchaiah, D.S.; Hussaian, M.; Govardhan, D. A review on multi attribute decision making for evaluation and selection. In Materials Today: Proceedings; Elsevier: Hyderabad, TS, India, 2020. [Google Scholar]

- Pramanik, D.; Mondal, S.C.; Haldar, A. Resilient supplier selection to mitigate uncertainty: Soft-computing approach. J. Model. Manag. 2020, 15, 1339–1361. [Google Scholar] [CrossRef]

- Xiong, L.; Zhong, S.; Liu, S.; Zhang, X.; Li, Y. An Approach for Resilient-Green Supplier Selection Based on WASPAS, BWM, and TOPSIS under Intuitionistic Fuzzy Sets. Math. Probl. Eng. 2020, 2020, 1–18. [Google Scholar]

- Hasan, M.; Jiang, D.; Ullah, A.S.; Alam, N.-E. Resilient supplier selection in logistics 4.0 with heterogeneous information. Expert Syst. Appl. 2020, 139, 112799. [Google Scholar] [CrossRef]

- Mohammed, A. Towards ‘gresilient’ supply chain management: A quantitative study. Resour. Conserv. Recycl. 2020, 155, 104641. [Google Scholar] [CrossRef]

- Piprani, A.Z.; Jaafar, N.I.; Ali, S.M. Prioritizing resilient capability factors of dealing with supply chain disruptions: An analytical hierarchy process (AHP) application in the textile industry. Benchmarking Int. J. 2020, 27, 2537–2563. [Google Scholar] [CrossRef]

- Parkouhi, S.V.; Ghadikolaei, A.S.; Lajimi, H.F. Resilient supplier selection and segmentation in grey environment. J. Clean. Prod. 2019, 207, 1123–1137. [Google Scholar] [CrossRef]

- Davoudabadi, R.; Mousav, S.M.; Sharifiba, E. An integrated weighting and ranking model based on entropy, DEA and PCA considering two aggregation approaches for resilient supplier selection problem. J. Comput. Sci. 2020, 40, 101074. [Google Scholar] [CrossRef]

- Amindoust, A. A resilient-sustainable based supplier selection model using a hybrid. Comput. Ind. Eng. 2018, 126, 122–135. [Google Scholar] [CrossRef]

- Pramanik, D.; Haldar, A.; Mondal, S.C.; Naskar, S.K.; Ray, A. Resilient supplier selection using AHP-TOPSIS-QFD under a fuzzy environment. Int. J. Manag. Sci. Eng. Manag. 2016, 12, 1–10. [Google Scholar] [CrossRef]

- Shanmugam, P.; Goh, M. Multi-objective supplier selection and order allocation under disruption risk. Transp. Res. Part E Logist. Transp. Rev. 2016, 95, 124–142. [Google Scholar]

- Sahu, A.K.; Datta, S.; Mahapatra, S. Evaluation and selection of resilient suppliers in fuzzy environment Exploration of Fuzzy VIKOR. Benchmarking Int. J. 2016, 23, 651–673. [Google Scholar] [CrossRef]

- Haldar, A.; Ray, A.; Banerjee, D.; Ghosh, S. A hybrid MCDM model for resilient supplier selection. Int. J. Manag. Sci. Eng. Manag. 2013, 7, 284–292. [Google Scholar] [CrossRef]

- Vinodh, S.; Anesh Ramiya, R.; Gautham, S. Application of fuzzy analytic network process for supplier selection in a manufacturing organization. Expert Syst. Appl. 2011, 38, 272–280. [Google Scholar] [CrossRef]

- Peng, A.H.; Xiao, X.M. Material selection using PROMETHEE combined with analytic network process under hybrid environment. Mater. Des. 2013, 47, 643–652. [Google Scholar] [CrossRef]

- Sun, X.; Gollnick, V.; Li, Y.; Stumpf, E. Intelligent Multicriteria Decision Support System for Systems Design. J. Aircr. 2014, 51, 216–225. [Google Scholar] [CrossRef]

- Mousavi-Nasab, S.H.; Sotoudeh-Anvari, A. A comprehensive MCDM-based approach using TOPSIS, COPRAS and DEA as an auxiliary tool for material selection problems. Mater. Des. 2017, 121, 237–253. [Google Scholar] [CrossRef]

- Rezaei, J. Best-worst multi-criteria decision-making method: Some properties and a linear model. Omega 2016, 64, 126–130. [Google Scholar] [CrossRef]

- Deng, J. Control problems of grey systems. Syst. Control Lett. 1982, 1, 288–294. [Google Scholar]

- Deng, J. Grey System Book; Science and Technology Information Services: Windsor, UK, 1988. [Google Scholar]

- Koganti, V.K.; Menikonda, N.; Anbuudayasankar, S.P.; Krishnaraj, T.; Athhukuri, R.; Vastav, M. GRAHP TOP model for supplier selection in Supply Chain: A hybrid MCDM approach. Decis. Sci. Lett. 2019, 8, 65–80. [Google Scholar] [CrossRef]

- Gan, J.; Zhong, S.; Liu, S.; Yang, D. Resilient Supplier Selection Based on Fuzzy BWM and GMo-RTOPSIS under Supply Chain Environment. Discret. Dyn. Nat. Soc. 2019, 2, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Raigar, J.; Sharma, V.S.; Srivastava, S.; Chand, R.; Singh, J. A decision support system for the selection of an additive manufacturing process using a new hybrid MCDM technique. SĀDhanĀ 2020, 45, 45–101. [Google Scholar] [CrossRef]

- Huang, C.; Yoon, K. Methods for Multiple Attribute Decision Making. Lecture Notes in Economics and Mathematical Systems; Springer: Berlin/Heidelberg, Germany, 1981; pp. 58–191. [Google Scholar]

- Kim, G.; Park, C.; Yoon, K. Identifying investment opportunities for advanced manufacturing systems with comparative-integrated performance measurement. Int. J. Prod. Econ. 1997, 50, 23–33. [Google Scholar] [CrossRef]

- Cheng, S.; Chan, C.; Huang, G. Using multiple criteria decision analysis for supporting decisions of solid waste management. J. Environ. Sci. Health Part A 2002, 37, 975–990. [Google Scholar] [CrossRef] [PubMed]

- Yoon, K.; Huang, C. Manufacturing plant location analysis by multiple attribute decision making: Part I—Single-plant strategy. Int. J. Prod. Res. 1985, 23, 345–359. [Google Scholar] [CrossRef]

- Ventura, L. The World’s Biggest Bankruptcies 2020. Global Finance Magazine; United States. 2020. Available online: https://www.gfmag.com/global-data/economic-data/worlds-biggest-bankruptcies (accessed on 29 December 2020).

- Kelly, S. Adjusting Business Models to Sustain Agri-Food Enterprises during COVID-19; also available in Chinese, Spanish, Arabic, French and Russian; FAO: Rome, Italy, 2020. [Google Scholar]

- Staniforth, J. COVID-19 Update: Worker Health, Absenteeism Present Largest Risks to U.S. Food Supply Chain. Food Quality and Safety. Available online: https://www.foodqualityandsafety.com/article/covid-19-update-worker-health-and-absenteeism-present-largest-risk-to-u-s-food-supply-chain/ (accessed on 15 March 2020).

- Parkouhi, S.V.; Ghadikolaei, A.S. A resilience approach for supplier selection: Using Fuzzy Analytic Network Process and grey VIKOR technique. J. Clean. Prod. 2017, 161, 431–451. [Google Scholar] [CrossRef]

- Jahan, A.; Mustapha, F.; Ismail, Y.; Sapuan, M.S.; Baharaminasab, M. A comprehensive VIKOR method for material selection. Mater. Des. 2011, 32, 1215–1221. [Google Scholar] [CrossRef]

- Behrouzi, F.; Wong, K.Y. An integrated stochastic-fuzzy modeling approach for supply chain leanness evaluation. Int. J. Adv. Manuf. Technol. 2013, 68, 1677–1696. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).