Abstract

Fire engineering endeavours to mitigate injury or the loss of life in the event of a fire. This is achieved primarily through fire prevention, containment, and extinguishment measures. Should prevention fail, the structural integrity of buildings, coupled with effective evacuation strategies, becomes paramount. While glass fibre-reinforced polymer (GFRP) materials have demonstrated efficacy in reinforcing concrete elements, their performance under fire conditions, notably in comparison to steel, necessitates a deeper understanding for structural applications. This study experimentally and numerically investigates the fire performance of GFRP-reinforced concrete (RC) columns subjected to only fire load without additional external loads. The research aims to ascertain the fire resistance based on the thickness of the concrete coating and the ultimate tensile strength of GFRP rebars after 90 min of fire exposure. Four GFRP-RC columns were subjected to a standardized fire curve on all sides in the experimental program. In the analytical program, a theoretical model was developed using the heat transfer module of the COMSOL software. The results of both analyses were very close, indicating the reliability of the procedure used. Based on the findings, recommendations regarding the fire resistance of GFRP-RC columns were formulated for structural applications. Results from this research provide the civil engineering community with data that will help them continue using FRP materials as internal reinforcement for concrete.

1. Introduction

Fire engineering primarily involves preventing injury or loss of life during a fire [1,2]. The best ways to achieve this are to prevent ignition, reduce the spreading of fire and smoke, and extinguish the fire before it develops fully. If these are impossible, the structural materials and elements must guarantee sufficient fire resistance when the fire is fully set. If all control measures fail, the structural integrity must be maintained for a sufficient time to allow the occupants to be evacuated and the firefighters to extinguish the fire.

Research on using fibre-reinforced polymer (FRP) materials as concrete reinforcements has been growing in recent years. However, there are several gaps in the literature suggesting that the fire performance of FRPs is a critical aspect that should be addressed. For example, Karbhari et al. presented a durability gap analysis of composites in civil infrastructure [3]. This analysis provided very instructive insights into the various concerns related to FRPs and fire, and the authors commented on the lack of data availability concerning each issue and the need for research in these areas.

It has long been evident that fire poses a potential risk to FRP-reinforced concrete (FRP-RC) elements. In a pioneering study on FRP-RC columns by Fardis and Khalili, several problems were identified that were associated with the flammability of the polymer matrix and the possible consequences for load-bearing structures. The authors suggested the inclusion of flame-retardant additives or fillers as a solution to improve the fire performance of the polymer matrices. However, they did not attempt to improve the behaviour of the composite [4].

Harries et al. presented a summary of current research needs related to FRP materials for use with concrete, compiled from a survey of the members of ACI Committee 440 [5]. In the resulting list of priorities for investigation, fire resistance was second only to durability, with a gap between the perceived need and the available information. Fire performance was found to be a critical area for research due to the lack of available data. Harries et al. stated that no FRP materials or FRP-RC had been tested against fire.

There is, however, a significant amount of information on the use of FRPs in aerospace and marine applications, although little of it describes their fire behaviour [6]. Given the few existing contributions, applying these results to the wide range of FRP composite materials used in civil engineering applications will take time. Moreover, it is not easy to generalise their behaviour at high temperatures due to the great variety of existing FRP formulations and systems. Therefore, research efforts on the fire performance of FRPs are needed before these materials can be used confidently in structural applications, where fire has always posed a significant risk.

The behaviour exhibited by FRPs at high temperatures differs radically from those of concrete or steel. All polymer matrix composites will burn when subjected to high heat flux. Furthermore, the composite matrix, usually polyester, vinyl ester, or epoxy, cannot withstand combustion; instead, it decomposes chemically, releasing energy as heat and emitting amounts of dense black smoke as it evolves (6). Even at moderate temperatures, FRPs experience a degradation of their strength, stiffness, and adhesion properties [7].

In general, the critical temperature for FRP is taken as the glass transition temperature of the polymer matrix, Tg [8]. According to ACI440-1R [9], for matrices used in structural applications, Tg is within the range 65–120 °C, although a degradation in strength and stiffness may be apparent even before these temperatures are reached [10]. Due to the anisotropy of the FRP material, the transverse properties are more affected by elevated temperatures than the longitudinal ones, with the stiffness and transverse strength decreasing rapidly upon reaching Tg.

The fire behaviour of steel-reinforced concrete has been extensively studied in the literature. Concrete has comparatively low thermal conductivity, and reinforced concrete (RC) elements can achieve correspondingly high fire resistance ratings without additional protection.

Adequate fire resistance of RC members is generally ensured by providing minimum cross-sectional dimensions with sufficient coverage, inside of established limits, to insulate the internal steel reinforcement. However, it is difficult to assess the fire performance of elements when the permissible temperature for the reinforcing material is unknown, as is the case for FRP rods [11]. Critical steel reinforcement and prestressing temperatures have been established as 593 °C and 426 °C, respectively; however, such critical temperatures have not been set for most of the currently available FRP rods. It can be assumed that these are within the wide range of 200–300 °C, making it difficult to establish the minimum coverage needed to guarantee adequate fire performance in most cases.

Although several studies have presented results for the fire performance of FRP-RC elements, these are always conditioned by the fact that they are experimental data for specific FRP reinforcement systems, meaning that the conclusions cannot be extended to other materials or systems. For example, studies were conducted in Japan on RC panels with FRP grillage without loading [12]. The researchers tested concrete panel elements following Japanese standards. They found that they performed satisfactorily during a fire, with sufficient fire resistance characteristics to be used as curtain walls but not as structural elements. The panels were then subjected to fire exposures under self-weight loads. However, as these exposures were relatively short (less than one hour), little helpful information could be obtained, and the structural fire performance of the panels could not be investigated.

Hiroyuki and Sakashita compared the fire performance of steel-reinforced concrete beams with carbon, glass, and aramid FRP-RC beams with different surface finishes and fibre orientations. They reported that elements containing braided carbon or aramid rebars performed worse than conventional concrete, while those with straight rebars performed better. However, the results could not be easily compared due to differences between the amounts of reinforcement used and the placements within the section, and drawing general conclusions was therefore difficult [13].

Abassi and Hogg tested concrete beams reinforced with GFRP under loading conditions [14]. The flexural reinforcement of the beams consisted of longitudinal GFRP rebars, with GFRP shear reinforcement in some of the beams. Fire resistance of more than 1.5 h was achieved before collapse, despite the FRP rod reaching temperatures as high as 462 °C. The authors attributed the high fire performance of these beams to the 70 mm concrete topping of the FRP reinforcement.

Kodur et al. presented a review of the existing literature and a parametric study in which they calculated the fire resistance of concrete slabs reinforced with FRP rebars [15]. For this purpose, they used a heat transfer analysis to predict the fire resistance as a function of the time required to reach the critical temperature of 250 °C for the FRP reinforcement.

Subsequently, Kodur and Bisby presented the results of an experimental and analytical study of the fire behaviour of concrete slabs reinforced with steel, GFRP, or CFRP rebars [16]. They tested a series of steel- and FRP-reinforced concrete slabs under self-weight loading and applied a normalised fire curve. The heat transfer model given by Kodur and Baingo was used, and satisfactory agreement with the test results was reported. This study found that the reaction to fire and the qualitative heat transfer behaviour of FRP-RC slabs were similar to those of steel-reinforced slabs; however, FRP-RC slabs had a lower fire resistance than steel-reinforced slabs. The fire resistance was defined in terms of the critical temperature of the material, such as 250 °C for CFRP and 325 °C for GFRP, based on the assumption that the data presented in previous studies by Wang et al. were valid [17].

These authors noted that higher fire resistance for the slabs could be obtained by using a higher concrete topping or by using carbonate aggregates, although full-scale tests of slabs loaded with FRP reinforcement were needed to determine whether degradation of the bond between the concrete and FRP could lead to premature structural failure during a fire. They also noted the need for data on the mechanical properties of FRPs at elevated temperatures and further structural fire tests to validate their models.

Saafi conducted an analytical investigation of the fire performance of FRP-RC beams [18]. Although this analysis was instructive, it needed to be substantiated by experimental data, and the conclusions given required experimental verification.

Currently, several codes and guidelines exist for the design of FRP-RC elements. All of these documents comment on the susceptibility of FRP materials to fire; however, only the Canadian standard provides objective guidance for the designer. Based on the work of Kodur and Baingo, CSA S806-02 [19] includes a series of graphs that can be used to estimate the concrete cover required to achieve a specific fire resistance for an FRP reinforcement, known as its critical temperature. These graphs are not often easy to use in practice, since critical temperatures for most FRP members still need to be discovered, as there is so much variety. ACI 440.1R recommends that FRP reinforcements not be used in structures where fire resistance is essential to maintain structural integrity.

Recently, Abd Elsalam et al. studied the influence of the applied load ratio, concrete cover and column’s configurations on the fire resistance of RC columns with GFRP rebars [20]. Further work is needed in this area, particularly about the deterioration of FRPs at elevated temperatures and its consequences on the behaviour of FRP-RC elements under self-weight or while load bearing during a fire.

Therefore, there is a need for research on the fibre-reinforced polymer (FRP) composite materials used in structures in two areas: (i) the combustibility characteristics, smoke generation, flame propagation, and toxicity of the composite material and (ii) its ability to maintain its structural integrity at high temperatures when the fire has completely developed [11].

The current study addresses this second concern: the capacity of FRP-RC elements to resist a building fire. The main objective of this study is to investigate the deterioration of the mechanical properties of GFRP rebar and the influence of concrete cover to determine a time–fire resistance relationship.

The fire behaviour of FRP-RC elements is the starting point that defines the general objective of this work. To this end, a numerical finite element model is applied to determine the temperature reached by the GFRP reinforcement and the outer face of the concrete element under a fire load, simulating a real fire; it is also used to determine its relationship with the variation of the existing concrete covering. Also, experimental models are developed to determine the necessary covering and the ultimate tensile stress on internal rebars of the columns after fire load to determine the loss of strength of GFRP.

The numerical and experimental models are designed to be as similar as possible to enable a comparison of the results. Finally, some relevant conclusions are drawn from this work by comparing the experimental results with those obtained analytically.

2. Fire Resistance

In the event of a fire in a building, the nature of the elements and materials that make up its construction and its contents have a decisive influence on the initiation, development, and spread of the fire, and can determine the time available for the evacuation of its occupants and the extent of material damage.

Once a fire starts, passive protection measures can slow down and contain the fire in the room of origin, thus allowing for the combined application of active protection means and the intervention of emergency firefighters.

Building elements are the components of a building that have a load-bearing or compartmentalising function, or both (such as columns, walls, and doors). Their behaviour in the event of fire is studied from the point of view of fire resistance. The reaction to fire of a construction element is its ability to perform its function in the event of a fire; if it is a load-bearing element, its capacity to maintain its load-bearing function while preventing the collapse of the building is expressed in minutes.

Fire resistance is evaluated using standardised criteria, relying on fire models simulated in laboratory furnaces represented by temperature–time curves. This method ensures the creation of a realistic and reproducible fire scenario regarding exposure conditions. Consequently, materials can be compared and chosen based on standardised acceptance criteria according to prevailing technical or administrative requirements.

Determination of Fire Resistance

The fire resistance of a building element (separating, load bearing, or both) is defined as the time during which it meets specific requirements for the load-bearing capacity (if applicable), integrity, and thermal insulation. Fire resistance is evaluated using standardised criteria, as data from real fires is unavailable. Standard UNE-EN 1363-1:2020 establishes the essential requirements for fire resistance tests in Spain [21].

The basic principle of this test consists of subjecting the construction element to a standardised furnace, which is heated according to a T–t [temperature–time] curve until failure of the element occurs. If the element is also expected to have a bearing capacity, it is loaded before the test begins until it is subjected to the same stress as it would bear within the structure under study.

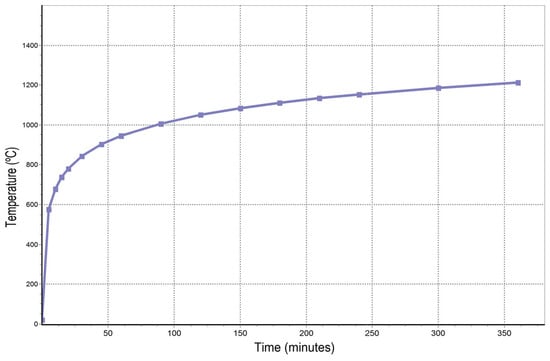

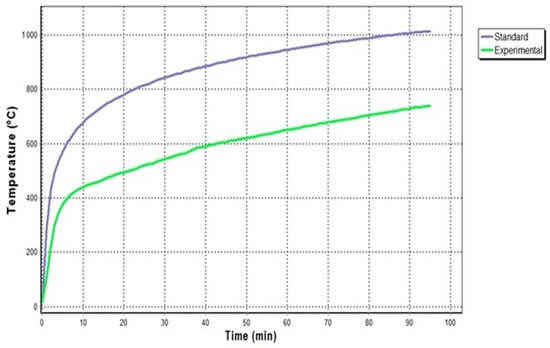

Traditionally, it has been considered that most building fires are caused or fuelled by combustible cellulosic materials. Consequently, the standard T–t curve has been selected based on this premise. For such fires, the T–t curve is defined by EN 1363-1:2020 as follows:

where T is the average oven temperature in degrees Celsius, and t is the time in minutes (Figure 1).

Figure 1.

Normalised temperature and time curve.

This test is very stringent, as the slope of the curve is very steep. In the first 5 min, the temperature inside the oven reaches 556 °C, and 15 min after the start of the test, the temperature is 721 °C. Subsequently, the temperature rise slows slightly, reaching approximately 1150 °C after 4 h of testing.

Among all the observable behaviours of a construction element subjected to a standardised fire, the most relevant ones are used to determine the level of safety that element provides. In this way, the fire resistance of a construction element is expressed using a physical property (i.e., a criterion) together with an indication of the time over which the element retains its resistance to the action of fire.

Fire resistance criteria are based on the loss of physical properties of the element under the action of fire, and research has focused mainly on the “fire resistance” (FR), which is defined as the capacity of a construction element to resist exposure to fire for some period of time without loss in structural stability. This capacity RF is expressed according to the categories defined in EN 1363-1:2020 [21], which is listed for the periods obtained by rounding down the time, expressed in minutes, over which the criterion has been fulfilled. These periods are standardised as 15, 20, 30, 30, 45, 60, 90, 120, 180, and 240 min.

As the tested specimens were not subjected to load, the structural stability was evaluated using an approximate method that calculated the ultimate flexural strength of the GFRP rebars used to reinforce the specimens after removing them from the concrete.

3. Description of the Structural Model

3.1. Theoretical Model

As Buttignol et al. explain [22], a better approximation is obtained through numerical heat flux analyses. Finite element models allow for the introduction of different fire curves, fire durations, cross-sections, and thermal properties.

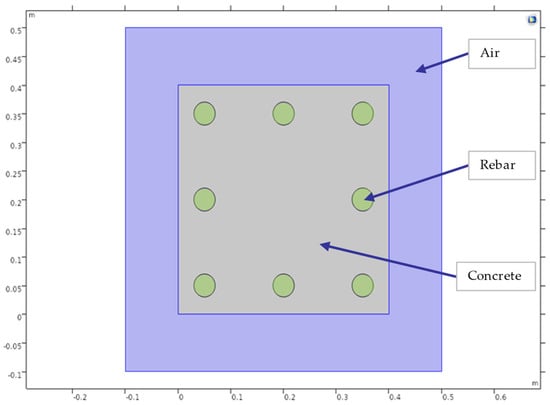

In this paper, to examine the behaviour of FRP-RC columns, a 2D theoretical model was developed using the Heat Transfer Module of COMSOL software [23], which is developed to handle any type of heat transfer you are looking to model (conduction, convection, and radiation) jointly with other physical properties to investigate the effects of heat loads.

The model was used to simulate the effects of fire on the four faces of a column without any load. The heat focus was situated at 100 mm on each concrete face through an air interface. Two cases that change internal reinforcement, a steel-RC and GFRP-RC column section, have been modelled. The section model is 400 × 400 mm, with a 50 mm cover and 8 ϕ 16 mm as internal reinforcement (Figure 2).

Figure 2.

Theoretical model.

A heat transfer model was devised to map the temperature distribution within the concrete and reinforcement rebars as the column was exposed to a standardized fire curve. Thermal contact resistance between the reinforcement and the concrete was dismissed, assuming that they conduct heat perfectly. Concrete conductivity and specific heat (λ, C) were determined following EC2 [24]. Nevertheless, due to discrepancies in the manufacturing methods and components of GFRP rebars globally, standardized values for their conductivity and specific heat are absent in the literature. Hence, values from the commercial product were employed [25].

3.2. Experimental Model

Following UNE-EN 1363-1:2020, test samples were columns with several exposed faces and different coatings. These samples were manufactured according to the dimensions of the existing furnace.

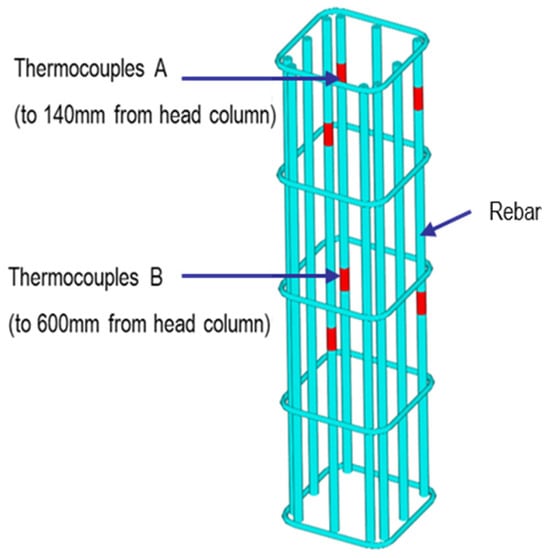

3.2.1. Full-Sided Exposed Elements (Columns)

The column samples (Figure 3) consisted of four concrete elements reinforced with GFRP rebars with the same diameter of 16 mm and the same height of 1000 mm, with variable concrete cover giving rise to different end sections. Tested rebars were provided by RTH Pultrusystems (RTHp) [25]. All rebars were manufactured by a pultrusion process and roughened using silica sand to increase the bond between GFRP rebar and the concrete. Vinyl-ester resin was used for all GFRP rebars and stirrups. The mechanical properties of concrete and GFRP rebars are shown in Table 1.

Figure 3.

Internal column reinforcements.

Table 1.

Mechanical properties.

The dimensions of each element are given in Table 2. Thermocouples were placed inside the rebars to measure the temperatures reached during the test.

Table 2.

Geometric dimensions of the tested columns.

Internal thermocouples have been placed in the columns to obtain the temperature values reached by each of them throughout the test. These internal thermocouples were placed at two different distances from the head of the column to record the changes in the temperature depending on the distance to the focus of the fire load. Location A was positioned 140 mm from the top of the column, and location B was at a distance of 600 mm (Figure 4). There were three internal thermocouples at each location. External thermocouples were also installed on the face of the concrete.

Figure 4.

Locations of the thermocouples on the column.

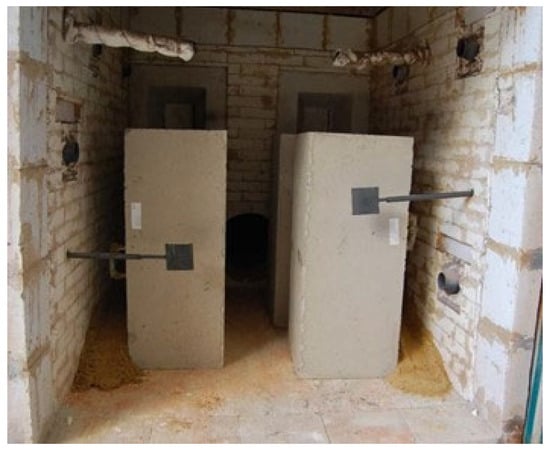

3.2.2. Test Equipment

The tests were carried out at the AIDICO Institute. This laboratory has been accredited since June 2006 by the National Accreditation Entity (ENAC), which awards certification for the fire resistance testing of construction elements (133/LE1215).

The instrumentation needed to be capable of subjecting the construction elements to the temperature conditions established by the standard and measuring them during the test. A furnace of nominal dimensions 1500 × 1500 × 1500 mm was used. Plate thermocouples were used to record the temperature of the furnace, and a T-sensor with a differential transmitter was used for pressure. To measure the internal temperature of each rebar, a type K thermocouple cable composed of 2 × 0.8 mm solid wires insulated individually and in conjunction with ceramic fibre was used. In addition, four thermocouples were used to record the furnace temperature. The placement of the samples inside the oven can be seen in Figure 5 and Figure 6.

Figure 5.

Fire test: columns placed in the furnace.

Figure 6.

Assembly of the columns in the furnace.

3.2.3. Test Procedure

The test started when the thermocouples inside the furnace registered a temperature above 50 °C. The test duration was measured from that instant, and all other systems, both automatic and manual for measurement and observation, began to operate. The pressure inside the furnace and the temperatures of the thermocouples were recorded at intervals of no more than 1 min throughout the fire exposure period.

The test was terminated after 95 min of exposure, which was considered sufficient time to determine the temperature–time–coating relationship. The data acquisition system was used to record the time, the temperatures reached in the thermocouples located in the different samples, and the temperature reached by the furnace. The recording data was used to obtain the temperature–time curves for each sample.

4. Results and Discussion

In this section, after carrying out the test campaign and the post-processing of the experimental data, the results of the fire tests on the performance of pultruded GFRP rebars are presented and discussed in detail.

4.1. Results

The results allowed us to analyse the behaviour of the GFRP rebars after the fire resistance test of both the furnace and the four columns.

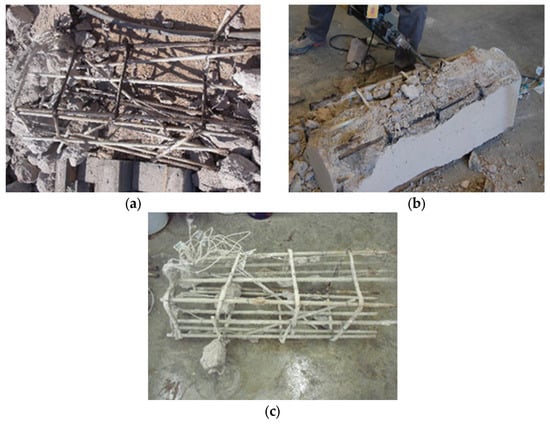

After the test, it was found that some faces of the columns exposed to fire suffered from ‘spalling’ (Figure 7). Small or significant parts of the exposed faces disappeared through detachment, resulting in the loss of the existing reinforcement coating. Consequently, the reinforcement may be directly exposed to heat, losing its load capacity [26].

Figure 7.

Spalling on the columns.

4.1.1. Oven

The average temperature recorded by the four thermocouples monitoring the oven was compared with the normalised curve, and a difference of around 300 °C was found between the theoretical and experimental temperatures of the oven throughout the test (Figure 8).

Figure 8.

Evolution of real and theoretical fire loads for the oven.

This difference, obtained from an analysis of the test results, the equipment used, and the data obtained, led to the conclusion that an excess load inside the test furnace prevented it from reaching the theoretical temperature at any time.

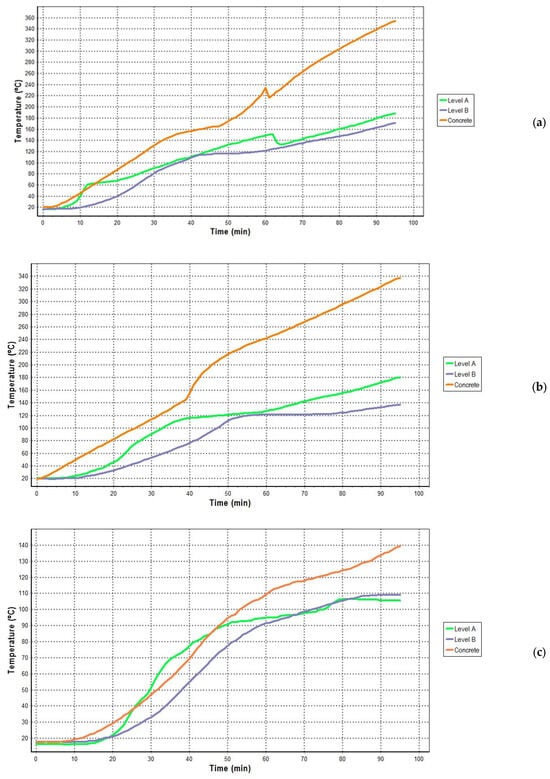

4.1.2. Columns

The data obtained from the fire resistance test of the different columns are presented below. The average values recorded by the three thermocouples at position A, 140 mm from the top face; the three thermocouples at position B, 600 mm from the top face; and the three thermocouples measuring the temperature at the concrete surface are calculated.

Moreover, when the rebars were recovered by chopping the concrete (Figure 9a–c), the ultimate tensile strength for the reinforcing rebars of the columns was calculated based on a bending test. A simple bending test allowed us to determine the tensile strength of the GFRP rebars with sufficient precision [27] (Figure 10).

Figure 9.

Reinforcements recovered after the fire test: (a) column 1, (b) column 3, (c) column 4.

Figure 10.

Reinforcement bending test of column 2.

Column 1

Figure 11 shows the T–t curve for column 1. After recovering its reinforcement (Figure 12), we found it was impossible to carry out a bending test to obtain the residual ultimate strength of the GFRP rebar after the fire test. Column 1 had a 20 mm coating, designed to withstand a fire load for 30 min (FR 30) rather than the 95 min used in the test. Tg values were approximately 120 °C for vinyl-ester resins, which were used in these GFRP rebars, according to the manufacturer of the patented material. Hence, the resin of these rebars reached its glassy temperature Tg, dissolving and leaving only the fibres devoid of resistance.

Figure 11.

Evolution of the real fire load on column 1.

Figure 12.

GFRP rebar after the fire test: column 1.

Columns 2–4

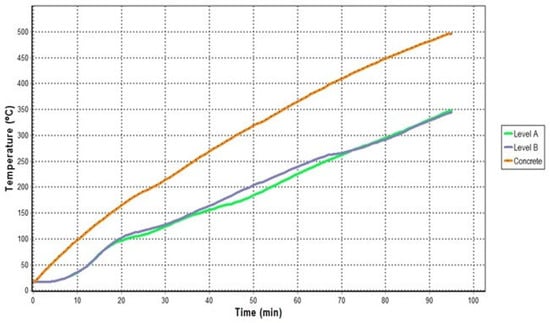

For each tested column, there was no substantial difference in the values measured by the thermocouples at levels A and B. Therefore, the height of the heat focus was not a determining variable (Figure 13a–c).

Figure 13.

Evolution of the actual fire load for (a) column 2, (b) column 3, and (c) column 4.

The 16 mm diameter of the GFRP rebar has 620 MPa as a tensile strength characteristic [25]. When the rebars were recovered by chopping the concrete, residual ultimate tensile strength values for GFRP rebars were obtained through the bending test [27] (Table 3).

Table 3.

Tensile strength for columns 2–4.

In Figure 13a, around the 60 min mark, there was a sudden drop for level A and concrete because an internal thermocouple in level A and an external thermocouple in the concrete for column 2 (390 × 390 mm) stopped measuring. However, measurements were continued for the other two thermocouples in each case.

4.1.3. Theoretical Model

Due to the diversity of dimensions, the theoretical analysis is conducted on an intermediate-sized model for both the total section and concrete cover (Figure 2).

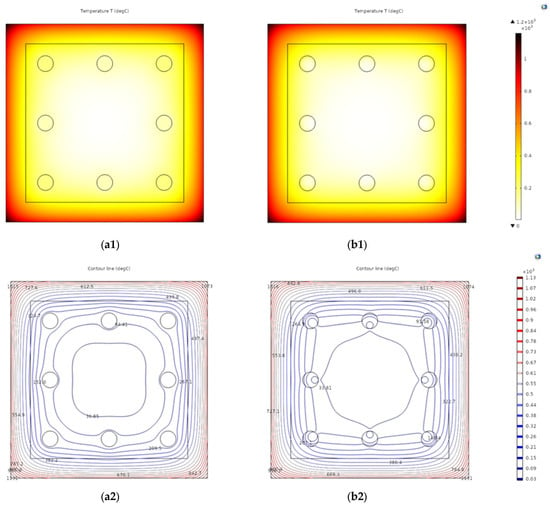

In this first theoretical study, following a 90 min exposure period under identical testing conditions (time, coating, and no applied load), the maximum temperature recorded at the surface concrete of the GFRP-RC section is lower than that of the steel-RC. Furthermore, the temperature reached by internal GFRP reinforcement is lower than that of the steel (Table 4). This study has been performed by applying the tested difference between the theoretical and experimental oven temperatures. The results are shown in Figure 14.

Table 4.

Theoretical temperature.

Figure 14.

Theoretical results: fire behaviour for (a1,a2) steel-RC, (b1,b2) GFRP-RC at 90 min.

Despite the disparate behaviour observed between steel and GFRP rebars, the temperature distributions within steel RC and FRP-RC elements during a fire are approximately the same (Figure 14).

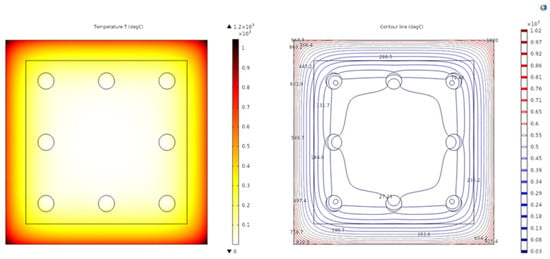

A second theoretical study is carried out for an exposure time of 60 min for GFRP-RC model (Figure 15).

Figure 15.

Theoretical results: fire behaviour for GFRP-RC at 60 min.

4.2. Discussion

- A temperature of 160 °C (close to the glassy temperature of the resin in the columns);

- A temperature of 120 °C (the temperature at which the composite begins to lose its intrinsic properties under load, as indicated in the technical specifications of the resins);

a clear relationship can be found between the applied coating and the elapsed time until these temperatures are reached. Table 5 presents the relationship between the time needed to reach a specific temperature and the existing coating at each study point.

Table 5.

Times required to reach 120 °C and 160 °C.

Suppose we study the temperatures reached after specific periods of time, as established by the fire resistance term, without the rebar losing its resistance characteristics. In that case, we obtain the results in Table 6. These have been differentiated according to the time considered.

Table 6.

Temperatures reached after 90, 60, and 30 min.

For an exposure time of 60 min, it is possible to compare the theoretical results (Figure 15) with the experimental ones (Figure 13a,b). Table 7 shows the temperature reached by the concrete face and the internal GFRP reinforcement in the theoretical and experimental models. It can be seen that the starting hypothesis of this study is supported.

Table 7.

Temperatures reached after 60 min.

5. Conclusions

This study aimed to investigate the capacity of FRP-RC elements to resist a building fire, the deterioration of the mechanical properties of GFRP rebar, and the influence of concrete cover to determine a time–fire resistance relationship. According to the study’s results, some recommendations about the FR of GFRP-RC columns were developed.

- The experimental data from column 1 suggest that fibres of GFRP rebars experience a critical temperature of around 350 °C. Although glass fibres can resist high temperatures, they do not do their job perfectly in concrete elements without a binding material (resin), which begins to degrade upon reaching the glass transition temperature, dissolving and leaving only the fibres, devoid of resistance.

- For the other columns, the experiments were carefully and successfully conducted to determine the variations of tensile strength. A minimal loss of resistance appears in the rebars after a fire, which is within the range accepted by the safety factors of materials, and in no case has it reached more than a 5% loss of the characteristic value. Because of this, GFRP rebars are valid as internal reinforcement for reinforced concrete for load-bearing construction.

- The effect of the cover thickness is much more significant at temperatures below 300 °C.

- It can be seen that the concrete cover’s thickening has a significant effect on the fire resistance of the columns. Higher concrete cover thickness delays the temperature transmission to the reinforcement, enhancing fire resistance. It is possible to recommend the following coatings to achieve a specific fire resistance:

- For 90 min of exposure (FR 90), 80 mm is recommended as the optimum concrete cover.

- For 60 min of exposure (FR 60), we advise a 50 mm overlap.

- For 30 min of exposure (FR 30), the recommended coating is 30 mm.

- Based on these limited studies, for 120 min (FR 120), which is the exposure time considered valid for load-bearing structural elements such as columns, the GFRP rebar coating should be 120 mm.

Additional research is imperative to further develop the utilization of FRP materials in reinforced concrete columns. This is essential for enhancing the accuracy of predicting the structural responses of FRP-RC columns under fire exposure.

Author Contributions

Conceptualization, A.A.-C. and P.M.-C.; methodology, A.A.-C., P.M.-C., J.M.-P. and J.M.M.-C.; software, A.A.-C. and P.M.-C.; validation, A.A.-C., P.M.-C. and J.M.-P.; formal analysis, A.A.-C., P.M.-C. and J.M.M.-C.; writing—original draft preparation, A.A.-C.; writing—review and editing, A.A.-C., P.M.-C., J.M.-P. and J.M.M.-C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

Authors gratefully acknowledge RTH Pultrusystems (RTHp) company that supplied the GFRP rebars for the experimental tests.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Buchanan, A.H.; Abu, A.K. Structural Design for Fire Safety, 2nd ed.; John Wiley & Sons Inc.: West Sussex, UK, 2017. [Google Scholar]

- Lie, T.T. Structural Fire Protection: Manual of Practice No. 78; American Society of Civil Engineers: New York, NY, USA, 1992; Available online: https://ascelibrary.org/doi/pdf/10.1061/9780872628885.fm (accessed on 25 September 2023).

- Karbhari, V.M.; Chin, J.W.; Hunston, D.; Benmokrane, B.; Juska, T.; Morgan, R.; Lesko, J.J.; Sorathia, U.; Reynaud, D. Durability gap analysis for fiber-reinforced polymer composites in civil infrastructure. J. Compos. Constr. 2003, 7, 238–247. [Google Scholar] [CrossRef]

- Fardis, M.N.; Khalili, H. Concrete encased in fiberglass-reinforced plastic. ACI J. Proc. 1981, 78, 440–446. [Google Scholar] [CrossRef]

- Harries, K.A.; Porter, M.L.; Busel, J.P. FRP materials and concrete: Research needs. Concr. Int. 2003, 25, 69–74. [Google Scholar]

- Michael Davies, J.; Wang, Y.C.; Wong, P.M.H. Polymer composites in fire. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1131–1141. [Google Scholar] [CrossRef]

- Bisby, L.A. Fire Behaviour of Fibre-Reinforced Polymer (FRP) Reinforced or Confined Concrete. Ph.D. Thesis, Queen’s University, Kingston, ON, Canada, 2003. [Google Scholar]

- Bakis, C.E. FRP Reinforcement: Materials and Manufacturing. In Fiber-Reinforced-Plastic (FRP) Reinforcement for Concrete Structures; Nanni, A., Ed.; Elsevier Science Publishers: Amsterdam, The Netherlands, 1993; pp. 13–58. [Google Scholar]

- ACI 440.1R-2015; Guide for the Design and Construction of Structural Concrete Reinforced with Firber-Reinforced Polymer (FRP) Bars. American Concrete Institute: Farmington Hills, MI, USA, 2015.

- Blontrock, H.; Taerwe, L.; Matthys, S. Properties of fiber reinforced plastics at elevated temperatures with regard to fire resistance of reinforced concrete members. In Proceedings of the 4th International Symposium on Fiber Reinforced Polymer Reinforcement for Reinforced Concrete Structures (FRPRCS-4), Baltimore, MD, USA, 31 October–5 November 1999; Dolan, C.W., Rizkalla, S.H., Nanni, A., Eds.; pp. 43–54. [Google Scholar] [CrossRef]

- Tanano, H.; Sakashita, M.; Tomosawa, F. Characteristics and performance evaluation methods of continuous fibre bars—State of the art studies on fire properties and durability of continuous fibre reinforced concrete in Japan. In Proceedings of the 4th International Symposium on Fiber Reinforced Polymer Reinforcement for Reinforced Concrete Structures (FRPRCS-4), Baltimore, MD, USA, 31 October–5 November 1999; Dolan, C.W., Rizkalla, S.H., Nanni, A., Eds.; pp. 523–531. [Google Scholar] [CrossRef]

- Fujisaki, T.; Nakatsuji, T.; Sugita, M. Research and development of grid shaped FRP reinforcement. ACI Symp. Pap. 1993, 138, 177–192. [Google Scholar] [CrossRef]

- Tanano, H.; Sakashita, M. Deflections of continuous fiber reinforced concrete beams under high-temperature loading. J. Struct. Constr. Eng. Trans. AIJ 1998, 63, 161–168. [Google Scholar] [CrossRef]

- Abbasi, A.; Hogg, P.J. A model for predicting the properties of the constituents of a glass fibre rebar reinforced concrete beam at elevated temperatures simulating a fire test. Compos. B Eng. 2005, 36, 384–393. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Bhatt, P.P.; Naser, M.Z. High temperature properties of fiber reinforced polymers and fire insulation for fire resistance modeling of strengthened concrete structures. Compos. B Eng. 2019, 175, 107104. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Bisby, L.A.; Green, M.F. Preliminary guidance for the design of frp-strengthened concrete members exposed to fire. J. Fire Prot. Eng. 2007, 17, 5–26. [Google Scholar] [CrossRef]

- Wang, Y.C.; Wong, P.M.H.; Kodur, V.K.R. Mechanical properties of fibre reinforced polymer reinforcing bars at elevated temperatures. In Proceedings of the SFPE/ASCE Specialty Conference: Designing Structures for Fire, Baltimore, MD, USA, 1 October 2003; pp. 183–192. [Google Scholar]

- Saafi, M. Effect of fire on FRP reinforced concrete members. Compos. Struct. 2002, 58, 11–20. [Google Scholar] [CrossRef]

- CAN/CSA S806; Design and Construction of Building Components with Fibre Reinforced Polymers. Canadian Standards Association: Toronto, ON, Canada, 2012.

- Abd elsalam, M.M.; Agamy, M.; Genidi, M.M.M.; Salem, M. Fire resistance of square concrete columns reinforced with GFRP bars, experimental and numerical investigation. Eng. Struct. 2024, 305, 117732. [Google Scholar] [CrossRef]

- UNE-EN 1363-1; Ensayos de Resistencia al Fuego Parte 1: Requisitos Generales. CTN 23 Seguridad Contra Incendios, Asociación Española de Normalización: Madrid, Spain, 2021.

- Buttignol, T.E.T.; Bittencourt, T.N. Simplified design procedures for the structural analysis of reinforced concrete columns in fire. Eng. Struct. 2021, 246, 113076. [Google Scholar] [CrossRef]

- COMSOL—Software for Multiphysics Simulation. Available online: https://www.comsol.com/ (accessed on 1 May 2024).

- EN 1992–1-2 (2004); Eurocode 2-Design of Concrete Structures, Part 1–2: General Rules for Structural Fire Design. Commission of European Communities: Brussels, Belgium, 2004.

- RTH Pultrusystems (RTHp). Available online: https://rthp.es/ (accessed on 1 May 2024).

- Anderberg, Y.; Forsén, N.E. Fire Resistance of Concrete Structures; Division of Building Fire Safety and Technology, Lund Institute of Technology: Lund, Sweden, 1982. [Google Scholar]

- Almerich-Chulia, A.; Fenollosa, E.; Cabrera, I. GFRP Bar: Determining Tensile Strength with Bending Test. Adv. Mat. Res. 2015, 1083, 90–96. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).