Abstract

Nanocellulose has recently gained a significant level of attention from academic and industrial researchers due to its non-toxic, biocompatible, bio-degradable, low-cost, and easy availability that connects many applications. In this research, cellulose extracted from betel nut husk fiber (BNHF) was converted to nanocellulose by chemical technique to examine their potential for use as reinforcement in bio-composite applications. The cellulose isolated from BNHF was subjected to acid hydrolysis using 62% sulfuric acid under ultrasonic treatment to convert cellulose into nanocellulose. The particle size of nanocellulose was determined by particle size analyzer. The morphology, structure and thermal properties of nanocellulose were also determined by scanning electron microscope (SEM) and Fourier-transform infrared (FTIR), thermogravimetric analysis (TGA), and differential scanning calorimetric (DSC) analysis. The bio-composites of nanocellulose–polyvinyl alcohol (PVA) and cellulose–PVA were prepared with different weight percentages (1–5%) of nanocellulose and cellulose via casting methods. The tensile, thermal and morphological properties were characterized for all composites. Enhancement in the tensile, thermal, and morphological properties was found in the nanocellulose–PVA biocomposites.

1. Introduction

Cellulose has attracted much attention from many researchers due its availability and excellent properties, including special morphology and geometrical dimensions, crystallinity, high specific surface area, rheological properties, liquid crystalline behavior, alignment and orientation, mechanical reinforcement, barrier properties, surface chemical reactivity, biocompatibility, biodegradability, lack of toxicity etc., especially in the form of nano-fibers [1]. Cellulose existing in natural fiber is one of the most abundant, renewable, and biodegradable polymer resources produced by nature on the earth. It has been used as a manufacturing material for several commodities in the food and pharmaceutical industries, as well as in paint, textiles etc. [2]. However, cellulose application in high value-added areas is still limited due to its hygroscopic nature and lack of melting properties. For the past few years, the preparation of cellulose nano-crystals (CNCs) and their application in nano composite materials have gained increasing attention because of their inherent properties like elastic modulus (130–150 GPa), high specific area (up to several hundreds of m2/g), high length to width ratio (up to several hundred) combined with low density (1.6 g/cm2), low thermal expansion (0.1 ppm·K−1), biodegradability and renewability [3]. CNCs are mostly produced from various cellulosic materials, such as bleached pulp, cotton, micro crystalline cellulose (MMC) or plants [2]. Due to a special intrinsic nano structure and excellent properties, nano cellulose has wide application potentials, such as aero gels, biomedical materials, packing materials, optical or electro conductive materials and several mechanically reinforced nano composites [4,5,6,7,8].

In recent years, a wider application of cellulose has been proposed at the nanostructure level for developing various biocompatible products as well as a variety of commercial cellulose derivatives [9,10,11]. Although it is extracted from native cellulose, it possesses remarkably high physical properties with special surface chemistry. Nanocellulose has gained increasing interest for a wide range of applications relevant to the fields of materials science and biomedical engineering due to its renewable nature, anisotropic shape, excellent mechanical properties, good biocompatibility, tailor able surface chemistry, and interesting optical properties. A new scope of nanocellulose application is still under investigation in fields such as photonics, films and foams, surface modifications, nanocomposites, flexible optoelectronics, and medical devices like scaffolds for tissue regeneration. The most beneficial property of nanocellulose research is the green nature of the particles, their fascinating physical and chemical properties, and the diversity of applications that can be derived from this material [12].

Betel nut husk fiber (BNHF) is an important agricultural waste material which has high cellulose content. Cellulose can be extracted from BNHF. Numerous efforts have been focused on using from these renewable materials resources for composite reinforcement. The addition of cellulose nanofibers in polymer matrix is a great interest to replace the nanofiller from non-renewable materials. Thus, in order to use nanocellulose for universal application, it is necessary to develop a sustainable and environmentally friendly processing technique. In this study an improved new extraction procedure of cellulose from BNHF has been developed and the nanocellulose was successfully isolated by chemical treatment. Betel nut trees are available in Bangladesh region, so utilization of regional BNHF as a raw material to produce bio-composite materials will provide a new opportunity in innovative applications.

Polyvinyl alcohol (PVA) is a water-soluble polymer which has widespread use in many areas of industrial applications such as textiles, paints, and adhesive industries and it is also a very promising candidate for the preparation of biodegradable plastics. This is because of its biodegradability, biocompatibility, chemical resistance, and excellent physical properties. Hydrogen bonding between cellulose chains in cellulose nanofibers causes an agglomeration or entanglement of nanofibers in the polymer matrix. Therefore, to reduce the interaction between hydroxyl groups, the cellulose nanofibers are maintained in the form of a suspension in water. Thus, the use of cellulose nanofibers without modification for the composites is limited to water soluble polymer [13].

2. Materials and Methods

Betel nut fruit husk fibers were used as reinforcing material in this research work. Betel nut is the fruit of Areca palm tree (Areca catechu). Matured betel nuts were collected from local betel nut plantation field, Barisal, Bangladesh. The BNHF is the fibrous part of the fruit. The analytical grade sodium hydroxide (Merck, Germany), sulfuric acid (Merck, India), polyvinyl alcohol (Mw approx. 60,000, Merck, Germany), 90% ethanol, purified benzene, glacial acetic acid, and reagent grade acetone were used in this study.

2.1. Analysis of the Constituent of Betel Nut Husk Fiber

The BNHF fibers were extracted from betel nut fruits manually by rejecting the hard portion of fruits. The fibers were washed with soap flake first and then with distilled water. Finally, the washed fibers were dried at 105 °C in an oven and stored. The chemical composition of BNHF samples in different processing stages were determined followed by Solvent Extractives of Wood and Pulp [TAPPI T204] standard method [14,15].

2.1.1. Estimation of Aqueous Extract

Dried fibers were heated with distilled water at 60 °C for 2 h and then the fibers were separated by filtration. Collected fibers were dried at 105 °C for constant weight. The calculated loss in weight gave the amount of aqueous extract in fiber.

2.1.2. Estimation of Fatty and Waxy Matters

Dried fibers were immersed in benzene-ethyl alcohol mixture (1 volume of ethanol and 2 volume of benzene) contained in a beaker in the ratio of 1 gm dried fiber per 100 mL of the mixture and then allowed to stand for 10 h then the fibers were washed several times with fresh benzene-ethyl alcohol mixture and finally with alcohol. Then, the fibers were dried at 105 °C for constant weight. The loss in weight on extraction with solvent mixture gives the amount of fatty and waxy matters present in betel nut fiber.

2.1.3. Estimation of Pectic Matters

The dried, de-waxed fibers were taken in a beaker and heated with 0.5% ammonium oxalate solution in the ratio of 1 g fiber per 100 mL of the solution at 70–80 °C for three days in a heating mantle. As evaporation went on the loss of water was compensated by adding hot distilled water to keep the level of the solution constant throughout the process. The fibers were then filtered, washed thoroughly with hot distilled water and then dried at 105 °C for constant weight. The loss in weight gave the amount of pectic matters in fiber.

2.1.4. Estimation of Lignin

De-waxed and de-pectinised fibers were dried at 105 °C and then treated with 72% H2SO4 (15 mL for 1 gm of fiber) with frequently stirring at ordinary temperature. The mixture was allowed to keep for 2 h and then diluted to 3% acid concentration. The mixture was refluxed for 4 h. Then, it was allowed to stand over-night and filtered through a sintered funnel, before being dried at 105 °C for constant weight. The weight of the residue gave the amount of lignin content in betel nut fiber.

2.1.5. Estimation of α-Cellulose and Hemicellulose

A suitable amount of de-waxed and de-pectinised fibers were taken to dry at 105 °C. Dried fibers were then treated with sodium chlorite (0.7%) solution buffered at pH 4 in the ratio of 1 g fiber 80 mL liquor at 90–95 °C for 90 min; 1 mL buffer solution of sodium acetate and acetic acid of pH 4 is added for every 10 mL of chlorite solution to stabilize the constant pH. In this process, the chlorite holo-cellulose was collected in the sintered funnel and dried at 105 °C until constant weight was obtained. Chlorite hollo-cellulose was treated with 24% KOH solution for 4 h with occasional stirring (1 g fiber in 100 mL of the alkali solution). By this treatment hemicellulose went into solution and α-cellulose remains undissolved. The α-cellulose was separated by filtration, washed thoroughly with 2% acetic acid solution, finally, with distilled water and dried at 105 °C for constant weight. The obtained weight of α-cellulose was deducted from the weight of holocellulose to calculate the amount of hemicellulose present in fiber.

2.2. Extraction of Cellulose from Betel Nut Husk Fibers

To extract cellulose from betel nut fiber, the fibers were immersed in de-ionized water, boiled at 100 °C for three hours, and then washed with de-ionized water. The fiber was then dried in an oven. 5 g of oven dried fiber was placed into a 500 mL Erlenmyner flask, to which 200 mL of de-ionized water (having a temperature of 90 °C) was then added followed by 10 mL of acetic acid and 7.5 g of 80% (w/w) NaClO2. for 60 min cycle which was repeated for up to 5 cycles. The reaction was stopped by adding cold water. The reaction mixture was then filtered, washed with cold water and acetone and dried at 105 °C in oven until the crucible weight was constant. The holo-cellulose content was calculated. The collected holo-cellulose was treated with 17.5% NaOH solution at room temperature for three hours with occasional stirring to obtain cellulose. The solution mixture was then filtered and washed several times with distilled water. Cellulose was then dried in open air and in oven at 80 °C for five hours.

2.3. Preparation of Nanocellulose

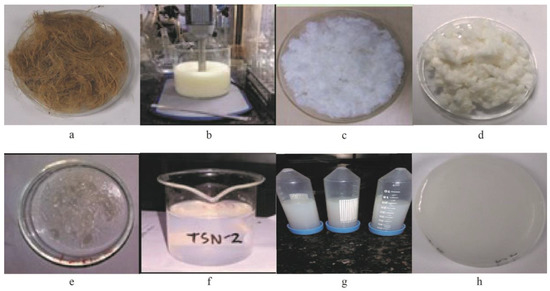

Cellulose extracted from betel nut fruit husk fibers was converted to cellulose nano fiber (Figure 1) by a chemical technique to examine their potential use as reinforcement in bio-composite applications. The cellulose isolated from betel nut fibers were subjected to acid hydrolysis using 62% (w/w) sulfuric acid. The ratio of fiber to acid was 1:8 (w/v) and hydrolysis proceeded under stirring (500 rpm) at 50 °C for 1 h. The reaction mixture was diluted ten times volume with de-ionized water to quench the reaction. The suspension was centrifuged at 8500 rpm for 21–23 min to remove excess acid and water. The precipitated was repeatedly rinsed and centrifuged with deionized water until the suspension remained at neutral pH. The suspension was then sonicated for three hours (optimized) to created cellulose crystals of colloidal dimensions. Cellulose nano fibers were characterized by FTIR, nano zeta seizer, and scanning electron microscopy.

Figure 1.

Production of nanocellulose from BNHF (a. BNHF, b. Cellulose preparation, c. Holocellulose, d. Cellulose, e. Nanocellulose, f. Nanocellulose) and nanocellulose reinforced nanocomposites with PVA (g. NC-PVA suspension, h. PVA-NC composite).

2.4. Preparation of Cellulose and Nanocellulose Reinforced Polyvinyle Alchohol Composites

Cellulose and nanocellulose of betel nut husk fiber were used to prepare PVA-cellulose and PVA-nanocellulose composites. 10 wt.% of PVA solution was prepared in hot water at 80 °C and the different weight fraction of cellulose and high dispersed nanocellulose suspension were mixed with this solution and stirred at 700 rpm for 30 min, then dispersed by using a homogenizer for 30 min. The mixtures were degassed by allowing them with caps at room temperature overnight. Subsequently, the mixtures were cast in petri dishes and dried at room temperature for several days. These procedures were followed for all the composites fabricated in the ratio of composition 5 (wt.%) cellulose and 95 (wt.%) PVA, 4 (wt.%) cellulose and 96 (wt.%) PVA, 3 (wt.%) cellulose and 97(wt.%) PVA, 2 (wt.%) cellulose and 98 (wt.%) PVA, 1 (wt.%) cellulose and 99 (wt.%) PVA, 5 (wt.%) nanocellulose and 95 (wt.%) PVA, 4 (wt.%) nanocellulose and 96 (wt.%) PVA, 3 (wt.%) nanocellulose and 97 (wt.%) PVA, 2 (wt.%) nanocellulose and 98 (wt.%) PVA, 1 (wt.%) nanocellulose and 99 (wt.%) PVA, 100 (wt.%) PVA. The resulting films were characterized by FTIR and SEM analysis. The mechanical property of the prepared sample was studied by tensile testing and thermal properties were analyzed by TGA and DSC.

2.5. Characterization of Betel Nut Cellulose, Nanocellulose and Composites

2.5.1. Particle Size and Zeta Potential Measurement

The particle size of prepared nano-cellulose was analyzed using Malvern Zeta sizer Nano ZS (Malvern Instruments, Malvern, UK). This equipment uses dynamic light scattering to measure the diffusion of particles moving under Brownian motion and convert this to size and size distribution. It also uses laser Doppler micro electrophoresis to apply an electric filed to the dispersion of particles which then move with a velocity related to their zeta potential.

2.5.2. FTIR Spectroscopy

The FTIR spectrum of cellulose, nanocellulose and their reinforced composites were taken by FTIR spectrometer. Cellulose, nanocellulose and betel nut husk microfibers were used to make pellet with potassium bromide to take FT-IR. On the other hand, FTIR spectra of cellulose, nanocellulose and their reinforced PVA composites were recorded over the frequency range 4000–700 cm−1 using an FTIR spectrometer (PerkinElmer, Boston, MA, USA, Model Forntier, serial no. 101393). FT-IR spectra were obtained in the printed form.

2.5.3. Scanning Electron Microscopy (SEM)

The surface of cellulose, nanocellulose and fracture surface of tensile test sample of cellulose and nanocellulose reinforced PVA composites samples were observed under the field emission scanning electron microscope (JEOL JSM-7600F). The samples were mounted on the carbon tape, which were taped into aluminum plates and coated with ultrathin film of gold with a sputter coater. The images were taken to observe the morphology of cellulose, nano-cellulose and fracture surface of tensile test sample of cellulose and nanocellulose reinforced PVA composites. The photographs are presented in the result and discussion section.

2.6. Mechanical Properties of Composites

Tensile Properties of the Composites

The tensile test of all prepared cellulose and nanocellulose reinforced PVA composites were measured using a universal tensile testing machine, model: 1410 Titans, England. Tensile tests were conducted following ASTM D 3039/D 3039M-00 (2002) standard method and the cross-head speed of the test was 10 mm/min and gauge length was 50 mm. Each test of the specimen was performed until tensile failure occurred. Six to ten specimens of each composition were tested, and the average values were reported by calculating the maximum five values. The load versus elongation curves were obtained by the instrument. The maximum load values were also recorded by the instrument which can be recalled after the completion of the test. The highest load in the tensile test gave the ultimate strength.

2.7. Thermal Properties of Composites

The thermal properties of optimized tensile tested sample were analyzed by Simultaneous 206 Thermal Analyzer (STA), Model No F3 Jupiter serial no STA 449 F-3A-1311-M NETZSCH, Sleb, Germany. The thermo gravimetric analysis and differential scanning calorimetric analysis of the cellulose, nanocellulose and betel nut husk micro fiber reinforced PVA composites were recorded on a STA 449F3 NETZSCH thermal analysis instrument in the temperature range of 30–950 °C and the heating rate was set as 30 °C/10 (K/min)/950 °C in a nitrogen atmosphere. Subsequently, 10 mg of the sample was heated in the aluminum sample pan.

3. Results and Discussion

3.1. Chemical Constituent of Betel Nut Husk Fiber

Betel nut husk fibers (BNHF) contain cellulose, hemicellulose, lignin and others constituent in small amount. BNHF was extracted and analyzed. The ingredients found in BNHF are presented in Table 1.

Table 1.

Main chemical constituents of BNHF.

3.2. Characterization of Cellulose and Nanocellulose

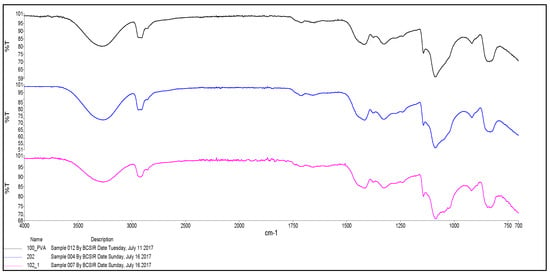

FTIR Analysis

Fourier transform infrared (FTIR) analysis is an advanced technique to obtain the structure of a sample. Figure 2 shows the comparative spectra of betel nut husk fiber, cellulose and nanocellulose. As depicted in Figure 2, the broad peak at 3330 cm−1 which appears in al spectra are attributed to the O-H frequency, whereas the peaks at 2893 cm−1, 2892 cm−1 and 2919 cm−1 predominantly arise from C-H stretching [16,17]. After chemical and ultrasonic treatment, the prominent peak of betel nut husk fiber at 1731 cm−1 corresponds to ester carbonyl vibrations from the acetyl, ferulic and pcoumeric acids of lignin or hemicellulose. Reducing the peaks at 3330 cm−1 and 1731 cm−1 indicates that most of the lignin has been removed from BNHF during the chemical treatment. A stretching peak detected at 1609 cm−1 for unbleached fiber is attributed to the carbonyl group of the acetyl ester in hemicellulose and the carbonyl aldehyde in lignin. The absence of this peak in cellulose and nanocellulose may be due to the removal of lignin and hemicellulose. The 1513 cm−1 and 1428 cm−1 peaks in the BNHF represent aromatic ring vibration and C-H deformation of lignin, respectively. The disappearance of this peak in cellulose indicates the removal of lignin. Peak at 1027 cm−1, 895 cm−1 in cellulose and 1024 cm−1, 894 cm−1 in nanocellulose are associated with the C-O stretching and C1-H deformation vibration of cellulose [18].

Figure 2.

FTIR spectra of cellulose (upper), nanocellulose (middle) and betel nut husk fiber (lower).

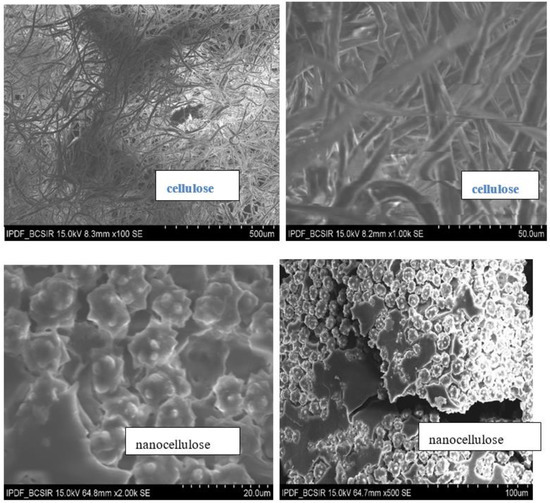

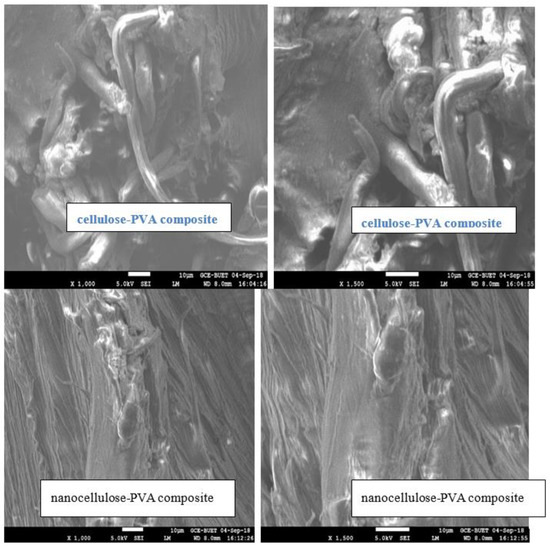

3.3. Scanning Electron Microscopy Analysis (SEM)

The surface of cellulose, nanocellulose and fracture surface of tensile test sample of cellulose and nanocellulose reinforced PVA composites samples were observed under the field emission scanning electron microscope (JEOL JSM-7600F). The SEM images of cellulose, nanocellulose shown in Figure 3 and fracture surface of tensile test sample of cellulose and nanocellulose reinforced PVA composites are shown in Figure 4. The microfibers of cellulose were found as disordered agglomeration position but nanofibers of nanocellulose were found as highly ordered and smooth disagglomeration position in the Figure 3. Disagglomeration of nanofibers makes uniform dispersion of nanofiber and matrix in the nanocomposites. Uniform and good interfacial bonding of fiber and matrix was observed in the nanocellulose–PVA composite in the Figure 4.

Figure 3.

SEM of cellulose and nanocellulose.

Figure 4.

SEM of cellulose-PVA composite and nanocellulose-PVA composite.

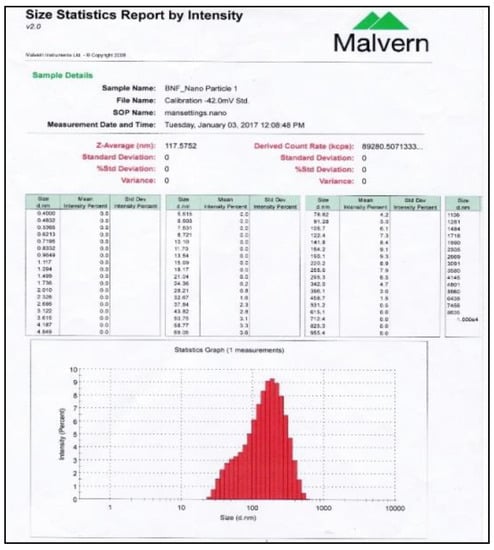

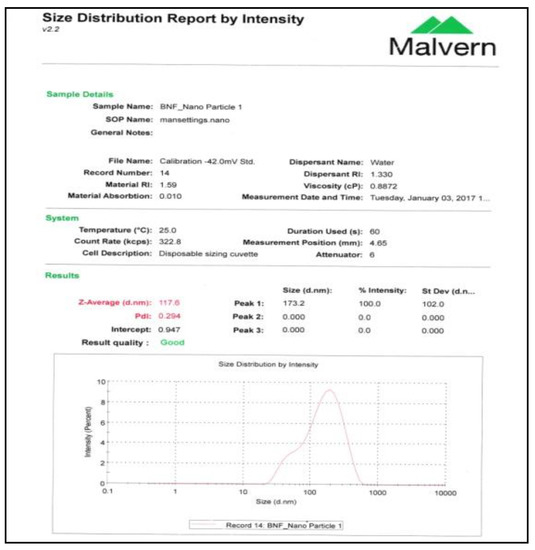

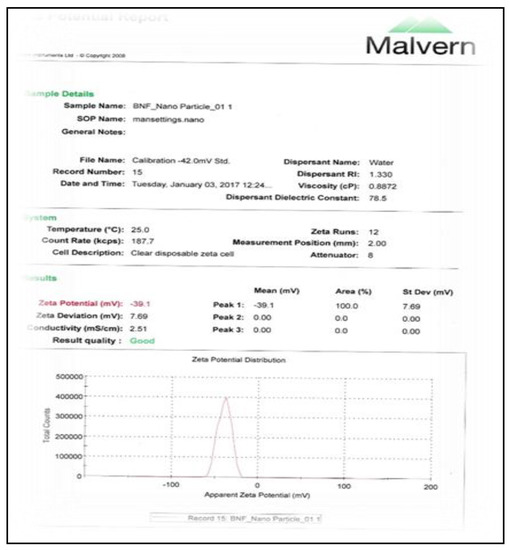

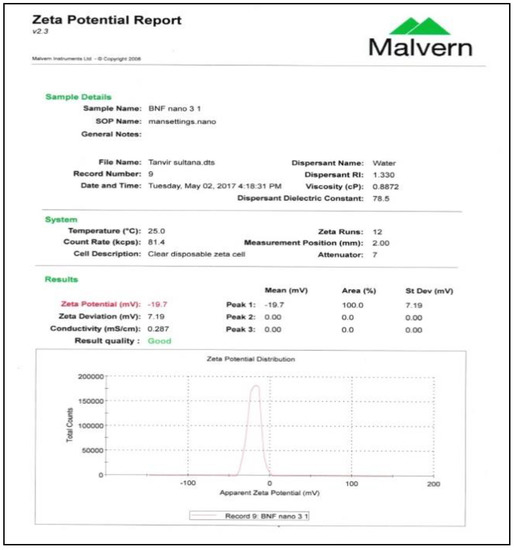

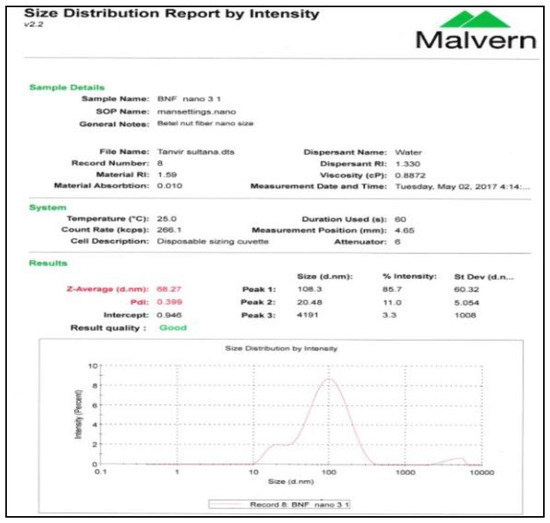

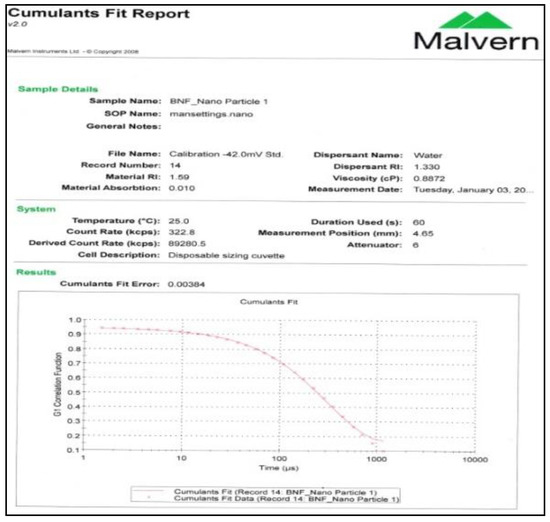

3.4. Measurement of Particle Size and Zeta Potential of Nanocellulose

The particle size of prepared nanocellulose and BNHF nano-fiber were analyzed using Malvern Zeta sizer Nano ZS (Malvern Instruments, UK). The particle size and zeta potential of prepared nano cellulose were measured by the instrument and the results were taken in printed form (Figure A1, Figure A2, Figure A3, Figure A4, Figure A5 and Figure A6 in Appendix A). The time of acid hydrolysis and effect of sonication on particle size was studied. In optimized acid concentration was 62% (w/w), reaction time one hour at 50 °C temperature. The reaction temperature, acid concentration and reaction time were optimized by conducting a series of reactions. If the reaction temperature is low (25 °C), then the reaction process toke place over a long time, and the particle size distribution report showed that without sonication the average particle size after hydrolysis was 117.6 nm. After three hours sonication, the average size was found 68.27 nm. The zeta potential of prepared nano cellulose was −39.1 mV and the colloidal nano suspension was very stable. The sonication time decreased the zeta potential and it was −19.7. Analytical reports of prepared nano cellulose are presented in appendix section (Figure A1, Figure A2, Figure A3, Figure A4, Figure A5 and Figure A6).

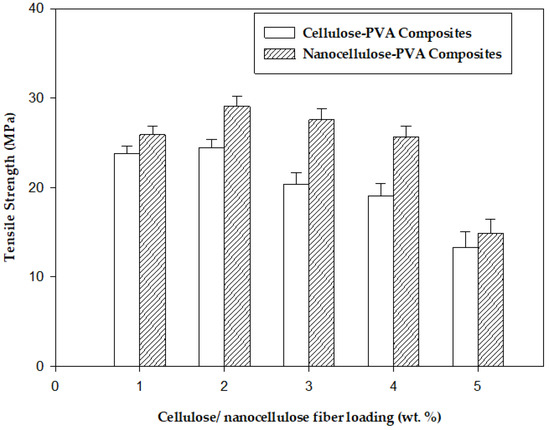

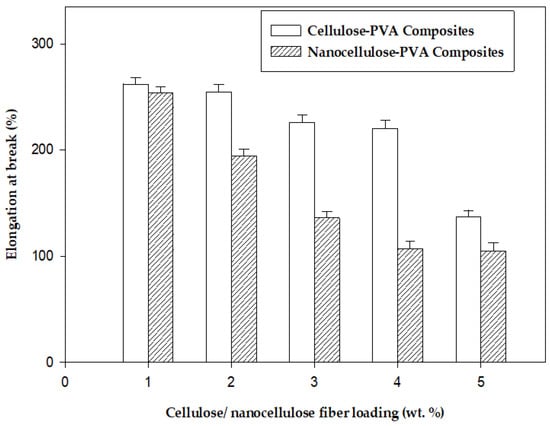

3.5. Tensile Properties of Composites

The effect of fiber loading (wt%) on tensile strength and elongation at break of cellulose and nanocellulose reinforced polyvinyle alcohol composites along with their error bars are given in Figure 5 and Figure 6. From these figure the increases of tensile strength with increasing the fiber loading (wt%) up to 2% fiber for both cellulose and nanocellulose reinforced PVA composite then decreases. Nanocellulose reinforced PVA composite showed higher tensile strength than cellulose–PVA composite which indicate the good dispersion of nano fiber in PVA matrix and good interfacial adhesion between PVA and nanocellulose. Nanocellulose reinforcement in PVA composite enhanced the tensile strength of composites. 2% cellulose and nanocellulose reinforced PVA composite give the highest tensile strength. Elongation at break decreases when increasing the fiber loading of composite, but cellulose reinforced PVA composites showed higher elongation at break.

Figure 5.

Tensile strength (MPa) vs. cellulose/nanocellulose fiber loading (wt.%) of cellulose/nanocellulose reinforces PVA composites.

Figure 6.

Elongation at break (%) vs. cellulose/nanocellulose fiber loading (wt.%) of cellulose/nanocellulose reinforced PVA composites.

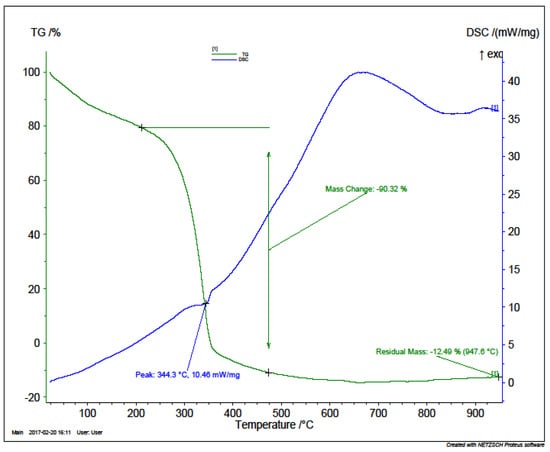

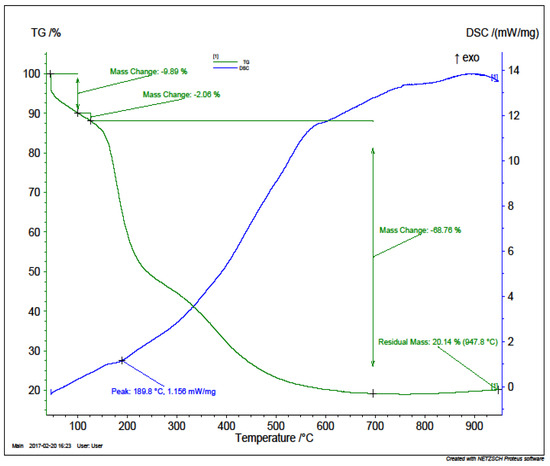

3.6. Thermal Properties of Composites

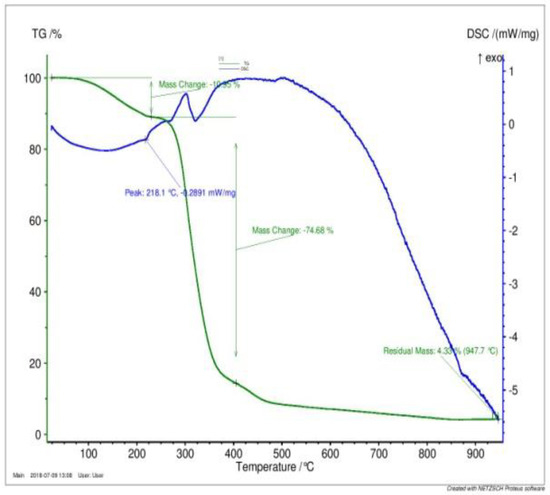

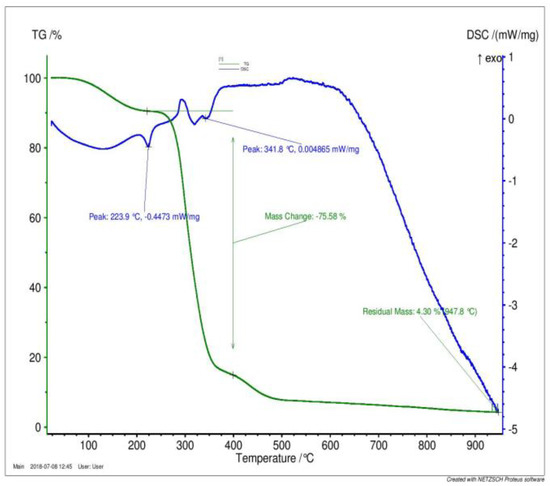

In order to understand the thermal stability of cellulose, nanocellulose, PVA, and its cellulose and nano-composites, TGA measurements were carried out. Both TGA thermographs of all PVA and their nano-composites show similar patterns, i.e., three main weight loss regions. The first region (75–160 °C) is due to the evaporation of water, and the weight loss of the film in these ranges is about 5–10 wt.%. The second transition region (260–390 °C) is due to the structural degradation of PVA nanocomposite films and the total of weight loss in this range was approximately 74 wt.%. The third region occurred above 390 °C due to the cleavage backbone of PVA bio composite films or the decomposition of carbonaceous matter. The total weight loss in this range was more than 95 wt.% at 500 °C. Figure 7, Figure 8, Figure 9 and Figure 10 shows that all PVA-cellulose and PVA–nanocellulose composites start to degrade at higher temperatures than those of PVA. This indicates that the addition of cellulose and nanocellulose fiber can improve thermal stability of PVA, thus confirming the enhanced thermal stability due to a strong hydrogen bonding between the hydroxyl groups of nanocellulose and the PVA matrix.

Figure 7.

TGA and DSC curve of cellulose.

Figure 8.

TGA and DSC of nanocellulose.

Figure 9.

TGA and DSC curve of cellulose-PVA composite.

Figure 10.

TGA and DSC curve of nanocellulose PVA composites.

4. Conclusions

The optimized parameters of the extraction and synthesis of nanocellulose from BNHF have been developed. Nanocellulose having a diameter of 68–117 nm were obtained from macroscopic and microscopic forms of cellulose following strong acid hydrolysis and a sonication method. This was proven by particle size analyses, FTIR, SEM, and thermal characterization. The effects of cellulose and nanocellulose reinforcing in PVA matrix have been investigated. Two series of bio composites of cellulose–PVA and nanocellulose–PVA were prepared and characterized. The tensile, thermal, and morphological properties of nanocellulose–PVA nanocomposites showed higher values than cellulose–PVA composites. These materials can be used for biomedical applications and provide an opportunity for the efficient utilization of waste betel nut husk fiber.

Author Contributions

T.S. contributed on the experimental works. T.S. and S.S. contributed on the analytical works. H.P.N. and M.W.K. supervised the research works and discussed the data. T.S. wrote the paper discussing with all authors. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors would like to express their sincere gratitude to the Bangladesh University of Engineering and Technology (BUET), University Grant Commission (UGC), Ministry of Education, Bangladesh for supporting the research work. Special thanks to BCSIR Laboratories, Dhaka for providing different useful instruments along with other lab facilities.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Figure A1.

Size Statics Report of nano cellulose by Intensity.

Figure A2.

Size Distribution Report nano cellulose.

Figure A3.

Zeta Potential Report of Nanocellulose.

Figure A4.

Zeta Potential Reports (sonicated nano cellulose).

Figure A5.

Size distribution report.

Figure A6.

Cumulants Fit Report.

References

- Lin, N.; Dufresne, A. Nanocellulose in biomedicine: Current status and future prospect. Eur. Polym. J. 2014, 59, 302–325. [Google Scholar] [CrossRef]

- Eichhorn, S.J.; Dufresne, A.; Aranguren, M.; Marcovich, N.E.; Capadona, J.R.; Rowan, S.J.; Weder, C.; Thielemans, W.; Roman, M.; Renneckar, S.; et al. Review: Current international research into cellulose nanofibers and nanocomposites. J. Mater. Sci. 2010, 45, 1–33. [Google Scholar] [CrossRef]

- Iwamoto, S.; Kai, W.; Isogai, A.; Iwata, T. Elastic Modulus of Single Cellulose Microfibrils from Tunicate Measured by Atomic Force Microscopy. Biomacromolecules 2009, 10, 2571–2576. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Shi, K.; Zhitomirsky, I.; Cranston, E.D. Cellulose Nanocrystal Aerogels as Universal 3D Lightweight Substrates for Supercapacitor Materials. Adv. Mater. 2015, 27, 6104–6109. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; He, Z.; Mosseler, J.A.; Ni, Y. Production of highly electro-conductive cellulosic paper via surface coating of carbon nanotube/graphene oxide nanocomposites using nanocrystalline cellulose as a binder. Cellulose 2014, 21, 4569–4581. [Google Scholar] [CrossRef]

- Mueller, S.; Sapkota, J.; Nicharat, A.; Zimmermann, T.; Tingaut, P.; Weder, C.; Foster, E.J. Influence of the nanofiber dimensions on the properties of nanocellulose/poly (vinyl alcohol) aerogels. J. Appl. Polym. Sci. 2014, 132, 41740. [Google Scholar] [CrossRef]

- Lyubimova, O.; Stoyanov, S.R.; Gusarov, S.; Kovalenko, A. Electric Interfacial Layer of Modified Cellulose Nanocrystals in Aqueous Electrolyte Solution: Predictions by the Molecular Theory of Solvation. Langmuir 2015, 31, 7106–7116. [Google Scholar] [CrossRef] [PubMed]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J.P. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef] [PubMed]

- Lamaming, J.; Hashim, R.; Leh, C.P.; Sulaiman, O.; Sugimoto, T.; Nasir, M. Isolation and characterization of cellulose nanocrystals from parenchyma and vascular bundle of oil palmtrunk (Elaeisguineensis). Carbohydr. Polym. 2015, 134, 534–540. [Google Scholar] [CrossRef] [PubMed]

- Nasir, M.; Hashim, R.; Sulaiman, O.; Nordin, N.A.; Lamaming, J.; Asim, M. Laccase, an Emerging Tool to Fabricate Green Composites: A Review. BioResources 2015, 10, 6262–6284. [Google Scholar] [CrossRef]

- Abraham, E.; Deepa, B.; Pothan, L.A.; Jacob, M.; Thomas, S.; Cvelbar, U.; Anandjiwala, R. Extraction of nanocellulose fibrils from lignocellulosicfibers: A novel approach. Carbohydr. Polym. 2011, 86, 1468–1475. [Google Scholar] [CrossRef]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, M.N.K.; Beg, M.D.H.; Khan, M.R.; Mina, M.F. Synthesis of copper nanoparticles and their antimicrobial performances in natural fibers. Mater. Lett. 2013, 98, 26–29. [Google Scholar] [CrossRef]

- Kaxutoshi, Y.; Takeshi, K.; Toshiro, F.; Iso, A.A. Novel Modification of Klason Lignin Quantitaitve Method. Jpn. Tappi J. 1984, 38, 466–475. [Google Scholar]

- Park, C.-W.; Han, S.-Y.; Choi, S.-K.; Lee, S.-H. Preparation and Properties of Holocellulose Nanofibrils with Different Hemicellulose Content. BioResources 2017, 12, 6298–6308. [Google Scholar] [CrossRef]

- Wang, B.; Sain, M. Dispersion of soybean stock-based nanofiber in a plastic matrix. Polym. Int. 2007, 56, 538–546. [Google Scholar] [CrossRef]

- Marchessault, R.H. Application of infra-red spectroscopy to cellulose and wood polysaccharides. Pure Appl. Chem. 1962, 5, 107–130. [Google Scholar] [CrossRef]

- Luz, S.M.; Del, T.J.; Rocha, G.J.M.; Goncalves, A.R.; Del’Arco, A.P.J. Cellulose and lignin from sugarcane bagasse reinforced polypropylene composites: Effect of acetylation on mechanical and thermal properties. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1362–1369. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).