Abstract

The need for energy harvesters for various applications, including structural health monitoring (SHM) in remote and inaccessible areas, is well established. Energy harvesters can utilize the ambient vibration of the body on which they are mounted to generate energy, thus eliminating the need for an external source of power. One such type of harvester is designed using piezoelectric materials and using a cantilever type set-up. However, the challenge associated with cantilever-based Piezoelectric Vibration Energy Harvesters (PVEH) is that its output power reduces when the ambient vibration frequency deviates from the resonant frequency of the harvester. This calls for a mechanism to tune its resonant frequency to match with the ambient frequency. This article presents an innovative design of an electrically tunable PVEH. The PVEH is integrated with an Ionic Polymer Metal Composite (IPMC) as an actuator that loads the cantilever beam, changing the stiffness of the beam. IPMC utilizes low power, and the authors demonstrate in this paper that a net gain of power can be achieved by this novel design. For the configuration used, it is experimentally proven that a frequency shift from 5.9 Hz to 8 Hz is achieved with three actuation values. Typical power output from the harvester is 52.03 µW when the power spent on actuation is only 0.765 µW. On-going modeling of this system using simulation software is expected to lead to further optimization and prototyping of design.

1. Introduction

Due to the developments in microsystems [], very low power MEMS (Micro Electro Mechanical Systems) based sensors are already realized. Deployment of a large number of sensors on structures enables more comprehensive and interactive Structural Health Monitoring (SHM) for diagnosis and prognosis in the case of critical structures. In this present scenario of low power sensors and the resulting Internet of Things (IOT) and SHM, enabling autonomous power sources for the sensors by energy harvesting from ambient conditions is of great research interest. This will avoid the need for deploying batteries and the associated issues of recharging procedures. Of the different forms of ambient energy, vibrations of different frequencies are present on many systems and structures, during their operating life cycle. Hence a great deal of research has gone into vibration-based energy harvesting, especially when utilizing piezoelectric materials []. Vibration-based energy harvesters using piezoelectric materials have demonstrated good conversion efficiency. However, such harvesters have a poor response at all the frequencies of vibration other than their own resonant frequency. One method to overcome this limitation is to get a broader bandwidth by enabling tuning of the resonant frequency of the harvester closer to the ambient vibration frequency. The resonant frequency of a system can be changed only by two methods, by changing the mass or by changing the stiffness []. Some of the recent literature on this is presented below.

A reported method for mechanically tuning the harvester’s resonance frequency includes the introduction of notches [] that brings out the relation between the applied compressive preload and the corresponding resonance frequency. The structure consists of two additional thin arms to apply an axial preload to the tip of the beam. Similarly, studies by Leland et al. [] have proven that axially compressing a piezoelectric bimorph lowers its resonance frequency. It is reported that if an axial preload is given, the resonance frequency of a simply supported bimorph can be shifted to 24% below its resonance frequency. Qi et al. [] have designed a clamped-clamped piezoelectric harvester, having cantilevers mounted on the sides. Different masses added to these cantilevers make their resonant frequencies different, resulting in a wider bandwidth. However, this method can address a limited number of frequencies by this passive approach. Leadenham and Erturk [] have designed an M-shaped harvester in order to overcome the requirement of having high excitation levels in a nonlinear harvester. The device is made of spring steel on which piezoelectric laminates are bonded. Researchers have also worked with configurations where stretching strain is introduced by doubly clamped structures [,]. It should, however, be noted that the harvester is not in the conventional cantilever configuration.

Huang et al. [] have used polymer piezoelectric materials with a beating mechanism. The impact force created through the low-frequency vibratory motion by the beating mechanism excites the system’s natural frequency. A method of shifting of gravity center by a moving mass for tuning the resonance frequency of the harvester has been reported by Xiaoming et al. []. Experiments are carried out on a prototype and could achieve adjustment from 130 Hz to 180 Hz. A base-mounted piezoelectric (BMP) harvester is designed by Koven et al. [] with a piezoelectric transducer mounted below the base of a cantilevered beam resonator. The harvester behaves like a damped mass-spring system. Zhou et al. [] developed a design by introducing springs in between adjacent harvester beams. The time-varying relative displacement between two adjacent harvesters leads to broadening the bandwidth. Thus, the authors could achieve nonlinearity without introducing magnets, which is very important and relevant in some applications. Researchers have also worked on using magnets in the design in different configurations, in order to increase the bandwidth by the effect of attractive force on the cantilever [,,]. However, all of the above designs suffer from the limitations of the tunable frequency range. In this paper, the authors present an innovative design that overcomes these reported shortcomings.

2. Design of A Novel Tunable Piezoelectric Vibration Energy Harvester (TPVEH) and Experimental Work

The resonant frequency-based cantilever design of a piezoelectric vibration energy harvester gives better output at its resonant frequency, compared to the impact type device []. Hence, methods to tune its natural frequency to different values matching with the ambient frequency open up a wide range of applications. Several methods that are discussed in the literature so far are either passive or that require a higher power input []. This limitation led to the current work presented by the authors.

2.1. Materials Utilized and Design Concept of the Device

Materials:

The work presented below focuses on the design of PVEH targeted for low frequencies, which can be tuned to different ambient frequencies. The basic hypothesis is that the power spent on tuning the system should be much lower than the PVEH power output. The proposed design of PVEH integrates two smart materials, piezoelectric material and Ionic Polymer Metal Composite (IPMC), to achieve tuning over a wider frequency range. Henceforth, tunable PVEH is simply referred to as PVEH. The discovery by the authors of the right type of IPMC for PVEH tuning was preceded by the thought process described below.

Active tuning requires a smart element, which can be electrically controlled. Research into the range of smart materials available revealed that piezoelectric material actuator [] or shape memory alloy actuator [] doesn’t really meet the requirement of low power consumption. Magnetic shape memory alloys also require higher power than that we can expend in this application. Based on this work, it was found that IPMC meets all the essential requirements of power, size, and weight.

The piezoelectric material used in this study is Macro Fiber Composites (MFC) sourced from Smart Material Corporation, Sarasota, FL, USA. []. It has advantages over other piezoelectric elements, since it is flexible to a great extent, making it effective in high deflection scenarios. It can also be bonded to any surface effectively. MFC is also effective at energy conversion at its resonant frequency when used in cantilever mode.

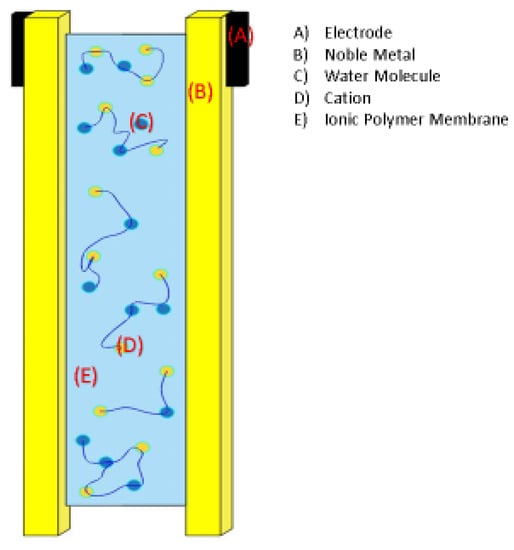

The design proposed by the authors involves the application of the actuation properties of IPMC to introduce load on the cantilever beam. IPMC is composed of an ionic polymer like Nafion, whose surfaces are coated with platinum or gold as conductors. When the IPMC is subjected to a low electric field (1 to 4 V), positively charged hydrated cations in the membrane network get repelled by the anode, and they migrate to the negative electrode. Hence, the water molecules also get shifted within the membrane. This leads to an osmotic pressure gradient, which results in the bending of the IPMC strip. Hence, it functions as an actuator with a low driving voltage, as reported by Shahninpoor and Kim []. Figure 1 shows a typical structure of an IPMC element. The actuation force associated with an IPMC can be utilized for applying a pre-defined force on the cantilever of the energy harvester. The force applied is a function of its mass and the applied voltage.

Figure 1.

Structure of Ionic Polymer Metal Composite (IPMC).

Assuming the mass remains the same, we can control the force by controlling the input voltage. Since the actuation mechanism is dependent on the water molecules in the polymer film, the hydration of the IPMC is of importance to achieve the correct load values.

Governing Equations:

The IPMC has a composite structure with a conductive medium. Its function depends on the cation concentration, the conductive medium, and the electric field. The actuation of the IPMC is essentially due to the hydrated cation transport across the membrane. IPMCs can be characterized using the governing Partial Differential Equations (PDE) as given below: []

where D, E, φ, and ρ denote the electric displacement, the electric field, the electric potential, and the charge density, respectively. κe is the effective dielectric constant of the polymer, F is Faraday’s constant, and C+ and C− are the cation and anion concentrations, respectively. The corresponding continuity equation is given by

where J is the ion flux vector.

E = D κe = −∇φ

∇ · D = ρ = F(C+ − C−)

∇ · J = −∂C+/ ∂t

Design concept:

In this investigation, as an initial step, the characteristics of IPMC was studied by applying several different steps of voltages, ranging from 0.5 V to 4 V. It should be noted that different actuation characteristics of IPMC can be selected by choosing the right thickness of the Nafion film.

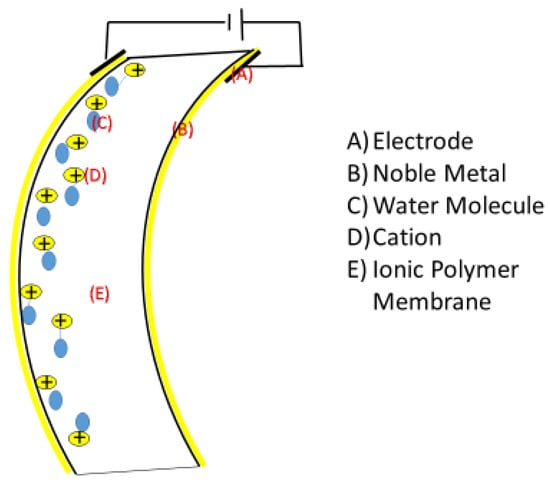

The IPMC strips can be easily miniaturized to introduce into the harvester design. It is biocompatible, in the case of applications in biological systems. The additional advantage of using IPMC is that its driving current is also very low. Hence the power required can be tapped from the generated power from the harvester itself. When a low voltage is applied to the IPMC, the cations tagged to the water molecules move towards the negative electrode. The migration of water molecules creates a bending in the film, as described earlier. Figure 2 depicts this bending effect of the IPMC strip. When the actuated IPMC gets in contact with the cantilever beam, the effective resonant frequency of the harvester changes; this function of IPMC is due to the change in energy associated with the harvester unit, when it gets in contact with the IPMC. A different shift in the resonant frequency of harvester can be achieved by changing the actuation level of IPMC, which is a function of the input voltage to IPMC.

Figure 2.

Structure of IPMC under applied voltage.

The MFC used in this study is made of piezoelectric fibers of the square cross-section, bonded together to form a piezoelectric sheet. This piezoelectric sheet is placed in between layers of adhesive, electrodes, and a polyimide film. The interdigitated pattern of electrodes enables better contact with the fibers and in-plane poling/actuation. This pattern also leads to a very low voltage drop at the interface. The electrical and mechanical properties of MFC used in this study are given in the manufacturer’s datasheet []. P2 and P3 type MFCs work on the d31 effect for actuation and are mostly used for energy harvesting []. The novel TPVEH consists of a cantilever beam on which MFC is bonded in the unimorph configuration, and an IPMC actuator integrated into the system. The IPMC specimens from Environmental Robots, USA, were used to actuate during the experiment. The properties of IPMC are provided by the manufacturer in their datasheet []. The force applied by the IPMC on the cantilever generates a compressive load component, which contributes to the stiffness change of the device.

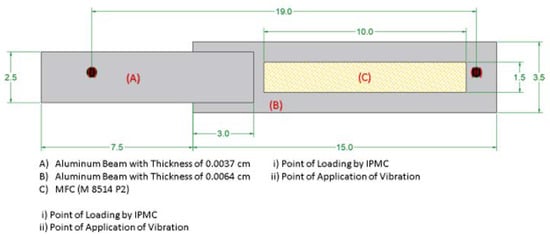

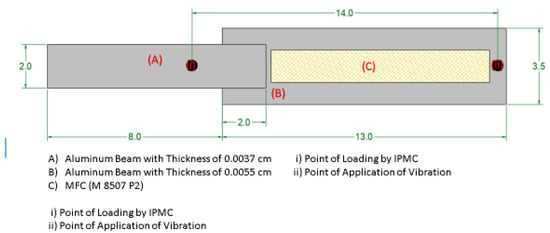

In this study, the authors chose an aluminum cantilever beam that consists of two sections, a 0.64 mm thick root section of 15 cm × 3.5 cm and 0.37 mm thick extension of 10.5 cm × 2 cm, with an overlap of 3 cm. (Figure 3). For these specimens, the thickness of the beam was intentionally kept low so as to allow effective control in the frequency shift using the applied load by IPMC.

Figure 3.

Plan view of the device-Configuration 1.

The dynamics of the cantilever beam can be described by the Euler–Bernoulli Beam equation as given below in Equation (4)

where w is the out of plane displacement of the beam, p is the force per unit length acting in the direction y (and w), E is Young’s modulus of the beam, and I represents the moment of inertia of the cross-section of the beam. The present case of a cantilever beam of two sections can be represented by a change in I.

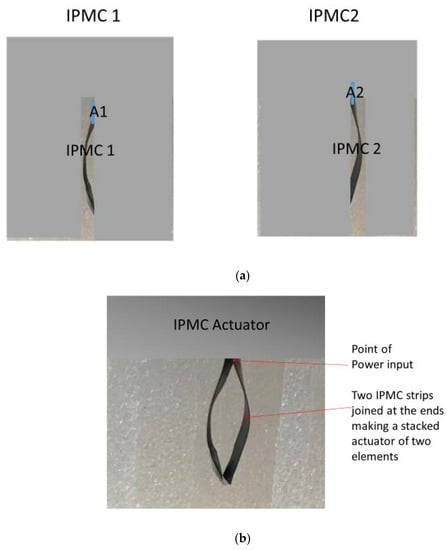

Configuration 1 consisted of an MFC M 8514 P2 that was bonded on the thicker cantilever section in the unimorph configuration (having a single active layer of piezoelectric material), as shown in Figure 3. This MFC has an active length of 85 mm, active width of 14 mm, a free strain of 630 ppm, and a blocking force of 76 N. The cantilever was subjected to vibration at point C using an electrodynamic exciter. Electrodynamic exciter-Miniature shaker model no. K2007E01-Modal shop was used to simulate the vibrations. The IPMC actuator was actuated at point D, perpendicular to the width of the beam. Two rectangular IPMC strips were joined at the tips, as in Figure 4. Figure 4a gives two individual IPMC strips. IPMC 1 is powered at A1, and IPMC 2 is powered at A2. The figure indicates the bending due to the actuation of the IPMC, and Figure 4b gives the combined structure and powered from a single power supply. The IPM C utilized had dimensions of 30 mm × 5 mm × 0.2 mm.

Figure 4.

Configuration of IPMC (a) Individual IPMC under actuation. (b) Two IPMC strips joined at the ends.

2.2. Experimental Setup

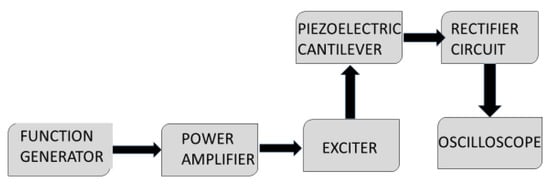

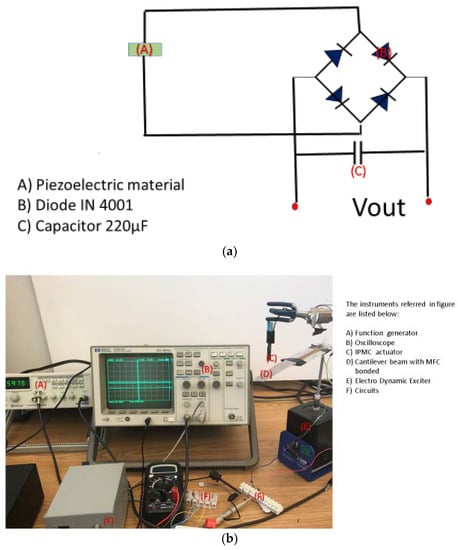

The block diagram explaining the experimental set up is shown in Figure 5. The exciter was driven by a function generator through a power amplifier. In the model used, the exciter has a built-in power amplifier. The output of the piezoelectric element was connected to a full-wave rectifier and then to an oscilloscope. The rectifier circuit is shown in Figure 6a and the experimental set up in Figure 6b. The full-wave rectifier circuit is designed using four diodes in Wheatstone’s bridge configuration. This is required to convert the AC output of the PVEH to DC. Diode IN 4001 and capacitor 220 µF was used in the full-wave rectifier circuit. In the experimental set up, a function the generator model no. GW Instek GFG 8250A and Oscilloscope model no. HP 54603 B were used.

Figure 5.

Block diagram of the experimental setup.

Figure 6.

(a) The rectifier circuit (b) The experimental setup.

2.3. Conduction of Experiments

The PVEH was subjected to continuously varying frequencies, and the resonant frequency was identified. Corresponding voltage and current outputs from PVEH were recorded. The current was measured, incorporating a load resistor of 1 KΩ. The IPMC actuator was given 1.5 V input at point D of the cantilever. This load shifted the resonant frequency of the device. Now, the frequency sweep was given again and located the new resonant frequency. This value and corresponding voltage and current output of the PVEH were recorded. These steps were repeated for 1.9 V and 2.1 V input to IPMC. These steps of voltage input to IPMC were selected to bring out a frequency shift of around 2 Hz. In all the cases, the current drawn by the IPMC was also recorded. For all the steps, power harvested from PVEH, as well as power spent on actuation of IPMC were calculated using Equation (5).

2.4. Results and Analysis: Configuration 1

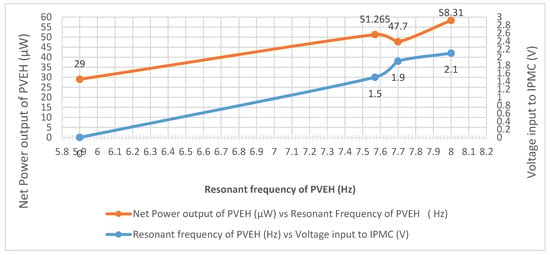

The results of the tests conducted on the designed harvester are presented in Table 1, Figure 7. In Table 1, the IPMC input value with the corresponding resonant frequency of the PVEH in Hz is included. For each input value, the corresponding measured values of power output, power spent in actuation, and the net resulting power is also included.

Table 1.

Input and Output values of Piezoelectric Vibration Energy Harvester (PVEH).

Figure 7.

The power output of PVEH and Voltage to IPMC vs. Resonant frequency.

When the power input to IPMC is 0, the power output of the PVEH is 29 µW, and the corresponding resonant frequency is 5.9 Hz. The power output of PVEH is 52.03 µW, when the power used for the IPMC actuation is 0.765 µW, shifting the resonant frequency from 5.9 Hz to 7.57 Hz. Similarly, the power output is 49.98 µW when the power for IPMC actuation is 2.28 µW, shifting the resonant frequency to 7.7 Hz. Further, a power input of 5.88 µW to IPMC shifted the resonant frequency to 8 Hz, giving a power output of 64.19 µW from PVEH.

Table 1 also gives the calculated net power gain of the PVEH at every stage of shifted resonant frequency. The net power output of PVEH is 29 µW at 5.9 Hz, 51.265 µW at 7.57 Hz, 47.7 µW at 7.7 Hz, and 58.31 µW at 8.0 Hz. It is evident that intervention by the IPMC results in gains of net power. It seems like the maximum net power is achieved at a resonant frequency of 8 Hz. As a first case, experiments were done until the IPMC input value of 2.1 V. It can be further increased to achieve still higher resonant frequencies, based on the characteristics of the specific IPMC specimen.

From the above data and graphs, it is evident that, by applying a low power to the IPMC, the resonant frequency of the harvester can be tuned to the ambient vibration frequency. The graphs show a near-linear trend. The force applied by the IPMC is a function of its mass also. Hence by selecting the IPMC of the required mass, the desired force application range can be achieved. For the above experiments, as stated earlier, commercially available IPMC samples were used. IPMC samples of different thickness can be fabricated to suit the specific requirement of force range.

It can be seen that at every stage of the shift of resonant frequency, the power output is much higher than the power spent on the actuation process. This comparison of power spent on actuation and power generated by PVEH in the process clearly indicates that there is a substantial gain in power harvested over a wider frequency range, applying this novel design. The design offers an effective tuning for low-frequency energy harvesters. This device can be tuned to practically many frequencies by varying the applied actuation load, whereas, many reported methods have limitations in the range of tuning.

The low power required for the IPMC actuation can be tapped from the harvested energy and hence can enable a closed-loop autonomous system in place. This can be achieved by integrating a low power microcontroller in the device, which looks for the ambient frequency change and changes the input to IPMC. The ambient vibration frequency can be detected from the voltage output of the harvester itself. In on-going work, a lookup table for PVEH output vs. ambient frequency is being programmed in the controller, using which ambient frequency can be identified. This makes the technology of self-powered sensors a reality since the inevitable variations in ambient frequency don’t affect the energy converted, in fact, could optimize it.

3. Effect of Distance of Loading Point from the IPMC Actuator: Configuration 2

The results reported above were focused on using a fixed point for actuation. Further work was conducted to investigate the effect of variation in loading point on the net power gain using the same set-up described above. Configuration 2 consisted of the MFC type M8507P2. This MFC has an active length of 85 mm, active width of 7 mm, a free strain of 605 ppm, and a blocking force of 38 N. A different MFC cantilever with different dimensions was used with a view of demonstrating the concept proof in different cases. This MFC was also bonded on an aluminum substrate (thicker root section) in unimorph configuration, as shown in Figure 8. The extension beam was bonded to the root section. The electrodynamic exciter was used to give controlled frequency vibrations to the harvester at point C.

Figure 8.

Plan view of the device-Configuration 2.

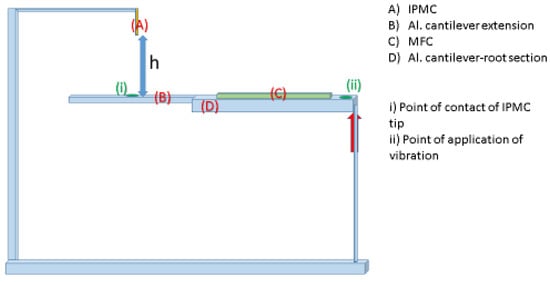

The schematic setup of the device is as given in Figure 9. The distance of the IPMC tip from the cantilever surface (h) is a variable. The fixture enables to fix the IPMC at different distances (h).

Figure 9.

Schematic setup of the device.

3.1. Conduction of Experiments

The resonant frequency of the device with no input to IPMC was determined by applying varying frequencies of input to the shaker through a function generator. The frequency of vibration at which the PVEH output voltage reaches a peak was identified, which corresponds to the resonant frequency of the harvester. Then IPMC input voltage of 1.5 V was given at a distance of 30 mm (h) above the cantilever. This maximum height was fixed based on the deflection of the beam, so that impact is enabled. The input to IPMC was given through a potential divider. It was found that the resonant frequency was shifted to a higher value. This was repeated for various values of h: 25 mm, 20 mm, 16 mm, and 10 mm. In each case, the new resonant frequency, the power output of PVEH, and the power input to IPMC were monitored. The point of IPMC contact on the cantilever beam was at a distance of 14 cm from the fixed end. This exercise was done in order to study the effect of the design variable “h” on the performance of the harvester.

3.2. Results and Analysis: Configuration 2

Table 2.

Piezoelectric Vibration Energy Harvester (PVEH) output and shift of resonant frequency for different Ionic Polymer Metal Composite (IPMC) loading points.

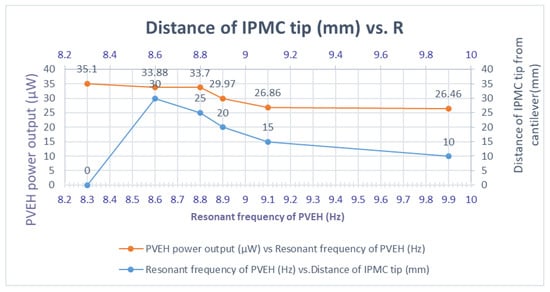

Figure 10.

PVEH power output vs. Resonant frequency and Resonant frequency vs. Distance of IPMC.

When no power is applied to IPMC, the resonant frequency of the harvester is 8.4 Hz. The voltage output is 3.9 V, and the current is 9 µA. When a voltage of 1.5 V is applied to IPMC at a distance of 30 mm above the cantilever surface, the impact load on the beam shifted the resonant frequency to 8.6 Hz. The PVEH output is 3.85 V and 8.8 µA. The IPMC drew a current of 0.51 µA. The net power output of PVEH was 33.11 µW. With the same power input to IPMC, the distance h was changed between 25 mm and 10 mm, and the resonant frequency changed further from 8.6 Hz to 9.9 Hz, with the net power output of PVEH maintained between 33.11 µW and 25.69 µW. These results show the dependence of the distance of the point of impact loading on the tuning of frequency.

The resonant frequency shifts to higher values, when the point of loading becomes closer to the cantilever. A marginal drop in the PVEH output is observed, which won’t affect the total charge generated over a period of varying frequencies.

From the plot of the frequency of vibration vs. the power output of PVEH, it can be seen that power output is maintained at the high value throughout a range of input frequencies spanning through 8.3 to 9.9 Hz. Hence this data can be effectively used along with variable power input to IPMC to increase the frequency bandwidth of the PVEH. This method is effective in tuning the resonant frequency of a PVEH in cantilever form.

The entire study was focused on making the best advantage of MFC and resolving the basic issue associated with it, the frequency dependence. MFC is suitable for this application since it is highly flexible and has a good conversion efficiency []. The IPMC is identified as the most suitable smart material for tuning, since the power requirement for its actuation is very low, compared to the typical PVEH output. The actuation of IPMC at different voltage inputs actually manifests as an effective change in its stiffness. The impact of the cantilever with the actuated IPMC modifies its resonant frequency. The IPMC is suitable for miniaturization and can be easily integrated with the PVEH design. Another salient feature is that the tailorable properties of IPMC [] makes it feasible to design the actuator according to the PVEH requirements. For instance, the thickness of the polymer membrane, the cation concentration, and the liquid molecules can be variable parameters, in order to achieve a particular actuation specification.

4. Conclusions and Future Work

A frequency tunable piezoelectric vibration energy harvester making use of low voltage-driven actuation properties of IPMC is designed, fabricated, and tested. The experimental results indicate that, the resonant frequency of the harvester was shifted to different values effectively using this configuration, and the power spent on tuning mechanism is much less than the power output of the PVEH, giving a substantial net power gain from the PVEH. In addition, the effect of the distance of the IPMC tip to the body of the harvester is established. The current work in progress is to integrate a low power microcontroller in the device in order to realize the autonomous function of the device.

Future work will focus on optimizing the design with reference to the actuation force and the topology. The IPMC unit behaves as a variable stiffness impact loading element. Its loading value can be changed by changing its position on the device. Different locations can be assigned, depending on the range of target design frequencies. Once the distance is fixed, the impact load is decided by the mass of the IPMC and the voltage input to it. Hence these two factors also become a part of the design parameters. Since stiffness change in IPMC is immediate and consistent in nature, the control circuit design can be realized, based on available experimental data. IPMC can be tailored to various characteristics during its fabrication by changing its anion/cation concentration and by maintaining the hydration level. The properties can also be changed by changing the thickness of Nafion film during fabrication. This makes it highly suitable for applications where variable loading is required. In the experiments discussed here, the IPMC is powered by a low power source. This power can be tapped from the PVEH output itself. In the present study, a stack of two IPMC elements in a diamond shape was used, which has resulted in stable operation. Further to this, the stack actuator can be designed with a greater number of elements. The integration of IPMC into a MEMS harvester is easy to achieve, due to its tailorable characteristics. An additional advantage is that it can be designed with multiple electrodes to enable the desired loading.

Another interesting aspect could be in exploring the feasibility of designing nanoscale devices of this design. The literature on IPMC indicates various new approaches in IPMC design, including the application of silver nano-powders []. Hence, the design of a nanoscale device, integrating IPMC into piezoelectric nano-fibers, could be a potential application, especially for biomedical applications.

Author Contributions

The formal investigation, analysis and initial writing has been done by S.R. The resources, supervision, project administration, writing- review and editing, funding acquisition have been led by R.G. The conceptualization, methodology, visualization have been done by both authors. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Natural Sciences and Engineering Research Council of Canada’s Discovery grant awarded to Dr. Rishi Gupta, Grant#RGPIN-2016-05219.

Acknowledgments

The authors acknowledge with thanks all the help offered by Patrick Chang of the Department of Mechanical Engineering, Armando Tura, Paul Kovacs, and Bruce of the Department of Civil Engineering at the University of Victoria. The authors also acknowledge the funding agency NSERC (Natural Sciences and Engineering Research Council) of Canada for providing the necessary financial support for this project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sahdom, A. Application of Micro Electro-Mechanical Sensors (MEMS) Devices with Wifi Connectivity and Cloud Data Solution for Industrial Noise and Vibration Measurements. J. Phys. Conf. Ser. 2019, 1262, 012025. [Google Scholar] [CrossRef]

- Berdy, D.; Srisungsitthisunti, P.; Jung, B.; Xu, X.; Rhoads, J.; Peroulis, D. Low-frequency meandering piezoelectric vibration energy harvester. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 846–858. [Google Scholar] [CrossRef] [PubMed]

- Alameh, A.; Gratuze, M.; Elsayed, M.; Nabki, F. Effects of Proof Mass Geometry on Piezoelectric Vibration Energy Harvesters. Sensors 2018, 18, 1584. [Google Scholar] [CrossRef] [PubMed]

- Eichhorn, C.; Goldschmidtboeing, F.; Woias, P. Bidirectional frequency tuning of a piezoelectric energy converter based on a cantilever beam. J. Micromech. Microeng. 2009, 19, 094006. [Google Scholar] [CrossRef]

- Leland, E.; Wright, P. Resonance tuning of piezoelectric vibration energy scavenging generators using compressive axial preload. Smart Mater. Struct. 2006, 15, 1413–1420. [Google Scholar] [CrossRef]

- Qi, S.; Shuttleworth, R.; Olutunde Oyadiji, S.; Wright, J. Design of a multiresonant beam for broadband piezoelectric energy harvesting. Smart Mater. Struct. 2010, 19, 094009. [Google Scholar] [CrossRef]

- Leadenham, S.; Erturk, A. Nonlinear M-shaped broadband piezoelectric energy harvester for very low base accelerations: Primary and secondary resonances. Smart Mater. Struct. 2015, 24, 055021. [Google Scholar] [CrossRef]

- Huang, P.; Tsai, T.; Yang, Y. Wide-bandwidth piezoelectric energy harvester integrated with parylene-C beam structures. Microelectron. Eng. 2013, 111, 214–219. [Google Scholar] [CrossRef]

- Hajati, A.; Kim, S. Ultra-wide bandwidth piezoelectric energy harvesting. Appl. Phys. Lett. 2011, 99, 083105. [Google Scholar] [CrossRef]

- Huang, H.; Chen, K. Design, analysis, and experimental studies of a novel PVDF-based piezoelectric energy harvester with beating mechanisms. Sens. Actuators A Phys. 2016, 238, 317–328. [Google Scholar] [CrossRef]

- Wu, X.; Lin, J.; Kato, S.; Zhang, K.; Ren, T.; Liu, L. A frequency adjustable vibration energy harvester. In Proceedings of the Power MEMS 2008+ microEMS2008, Sendai, Japan, 9–12 November 2008. [Google Scholar] [CrossRef]

- Koven, R.; Mills, M.; Gale, R.; Aksak, B. Low-Frequency and Broadband Vibration Energy Harvesting Using Base-Mounted Piezoelectric Transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2017, 64, 1735–1743. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Yan, B.; Inman, D. A Novel Nonlinear Piezoelectric Energy Harvesting System Based on Linear-Element Coupling: Design, Modeling and Dynamic Analysis. Sensors 2018, 18, 1492. [Google Scholar] [CrossRef] [PubMed]

- Ma, H.; Liu, J.; Tang, G.; Yang, C.; Li, Y.; He, D. A Broadband Frequency Piezoelectric Vibration Energy Harvester. Key Eng. Mater. 2011, 483, 626–630. [Google Scholar] [CrossRef]

- Lu, Q.; Scarpa, F.; Liu, L.; Leng, J.; Liu, Y. An E-shape broadband piezoelectric energy harvester induced by magnets. J. Intell. Mater. Syst. Struct. 2018, 29, 2477–2491. [Google Scholar] [CrossRef]

- Fan, K.; Tan, Q.; Zhang, Y.; Liu, S.; Cai, M.; Zhu, Y. A monostable piezoelectric energy harvester for broadband low-level excitations. Appl. Phys. Lett. 2018, 112, 123901. [Google Scholar] [CrossRef]

- Jung, H.; Lee, S.; Jeong, S.; Yoo, H. Segmented impact-type piezoelectric energy harvester for self-start impedance matching circuit. Smart Mater. Struct. 2018, 27, 114006. [Google Scholar] [CrossRef]

- Anton, S.; Sodano, H. A review of power harvesting using piezoelectric materials (2003–2006). Smart Mater. Struct. 2007, 16, R1–R21. [Google Scholar] [CrossRef]

- Nah, S.K.; Zhong, Z.W. A microgripper using piezoelectric actuation for micro- object manipulation. Sens. Actuators A 2007, 133, 218–224. [Google Scholar] [CrossRef]

- Jaronie, M.J.; Martin, L.; Aleksandar, S.; Mark, A.G. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar]

- Smart Material, Energy Harvester. Available online: https://www.smart-material.com/ (accessed on 26 March 2020).

- Mohsen, S.; Kwang, J.K. Ionic polymer-metal composites: I. Fundamentals. Smart Mater. Struct. 2001, 10, 819. [Google Scholar]

- Environmental Robots Inc., Products. Available online: https://www.environmental-robots.com/ (accessed on 26 March 2020).

- Chung, C.K.; Hong, Y.; Wu, T.C. A novel fabrication of ionic polymer metal composites actuator with silver nano powders. In Proceedings of the 13th International Conference on Solid State Sensors, Actuators and Microsystems, Digest of Technical Papers, Seoul, Korea, 5–9 June 2005. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).