Nanosecond Laser Cutting of Double-Coated Lithium Metal Anodes: Toward Scalable Electrode Manufacturing

Abstract

1. Introduction

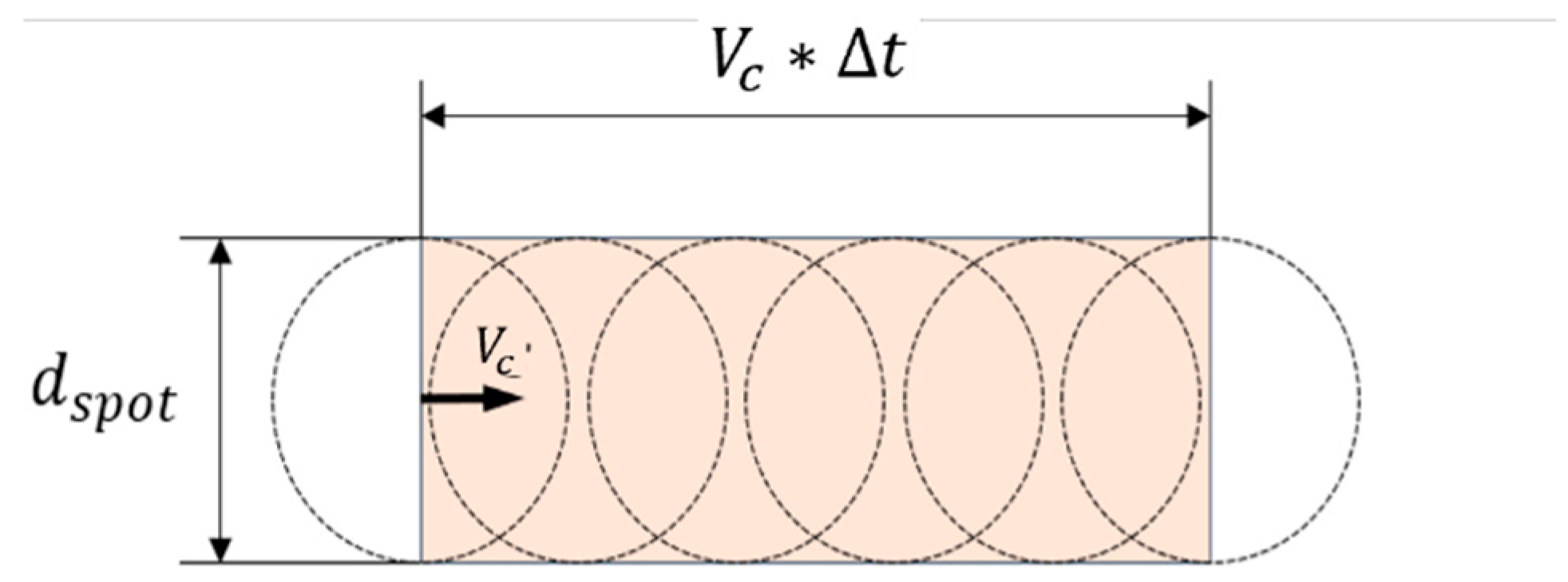

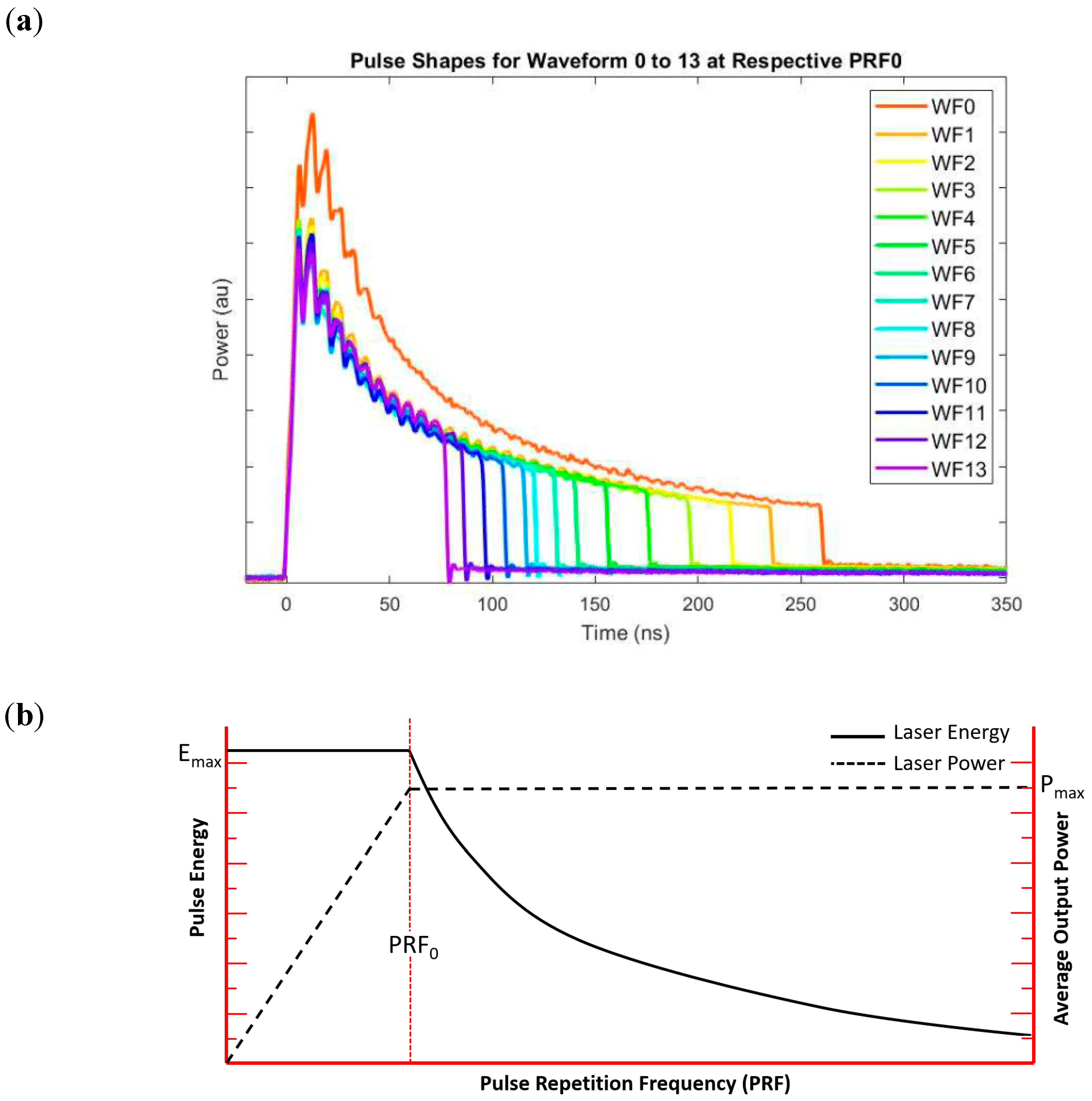

2. Ns-Pulsed Laser Cutting

3. Experimental Procedure

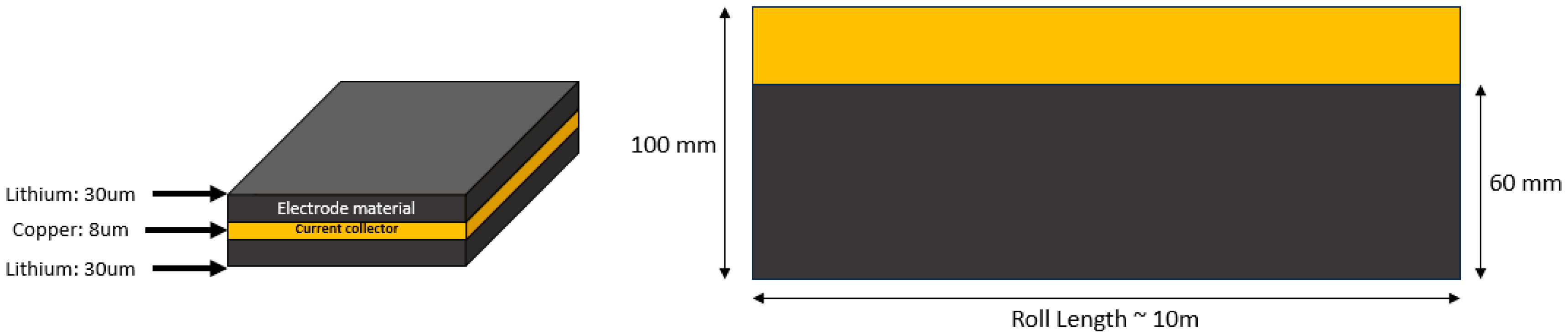

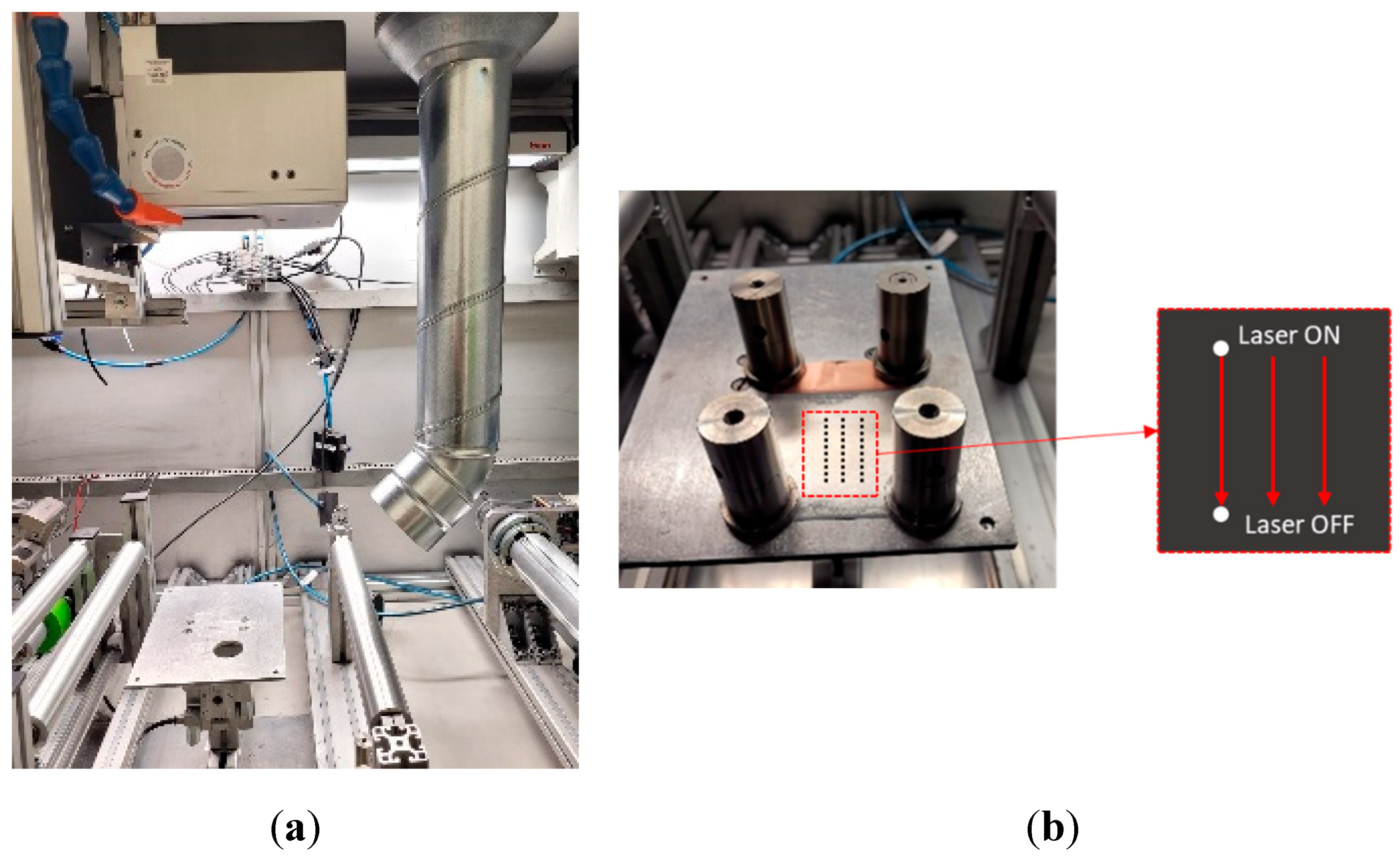

3.1. Materials, Laser System and Cutting Setup

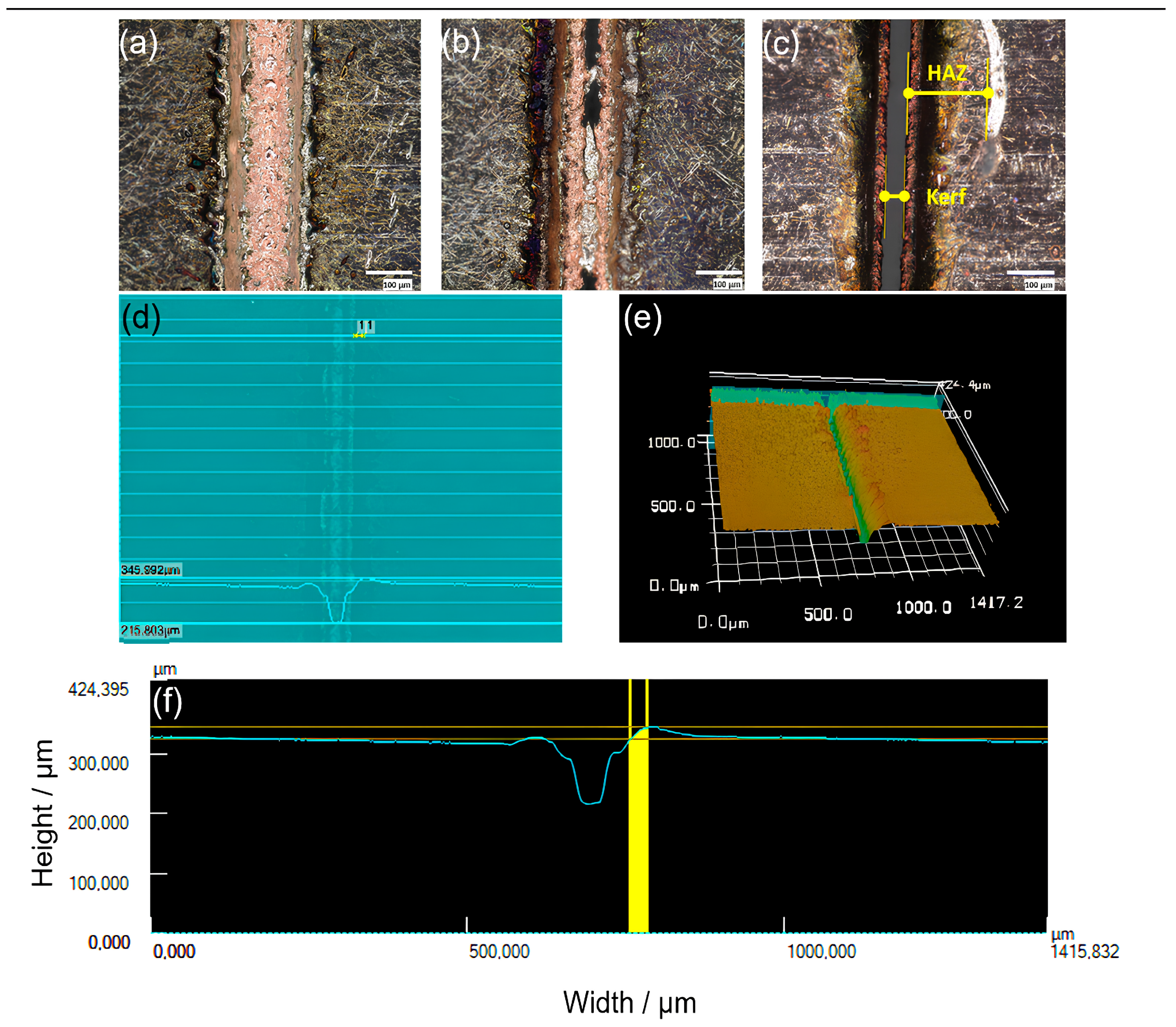

3.2. Analysis of Cut Edge

4. Results and Discussion

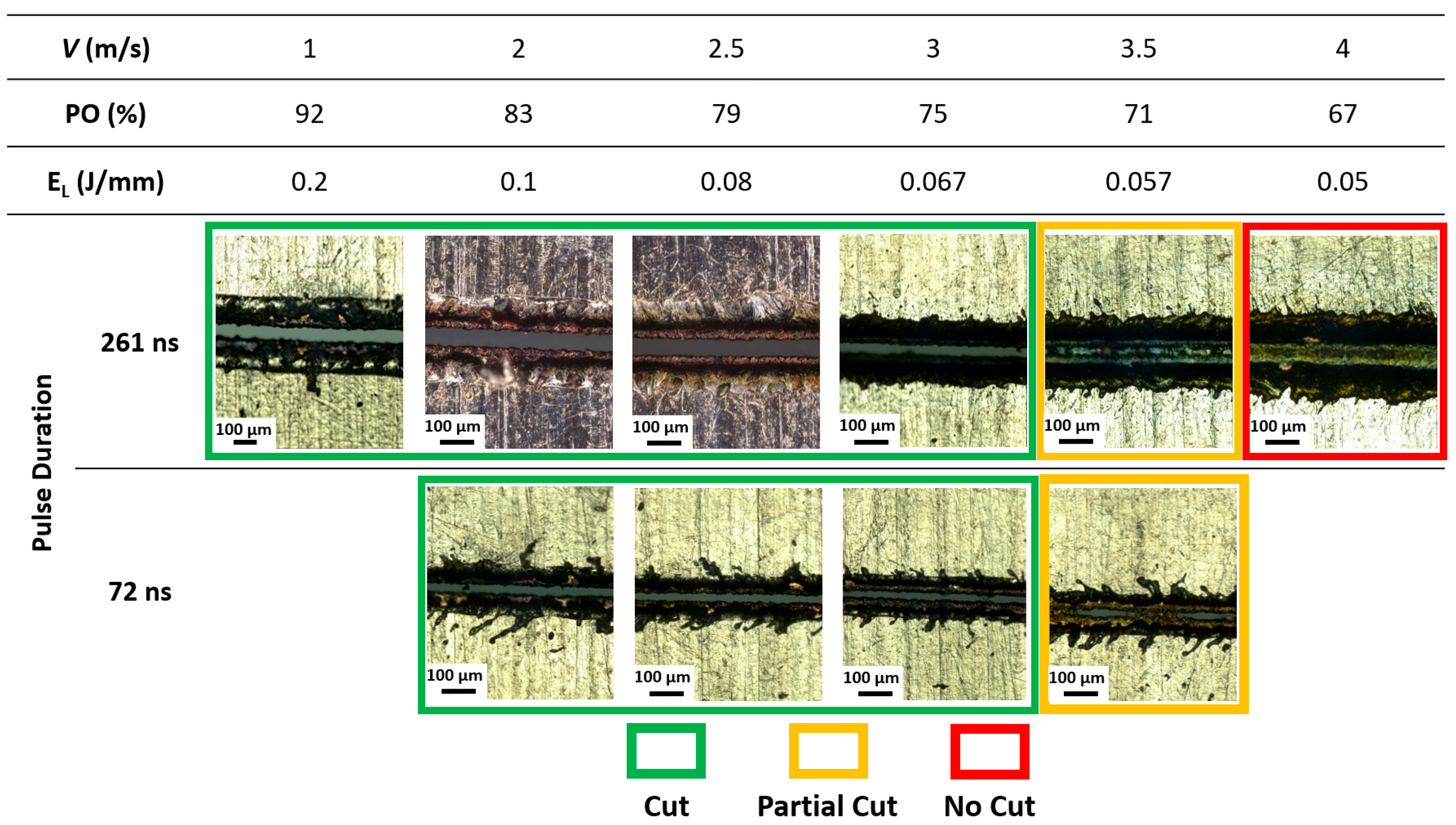

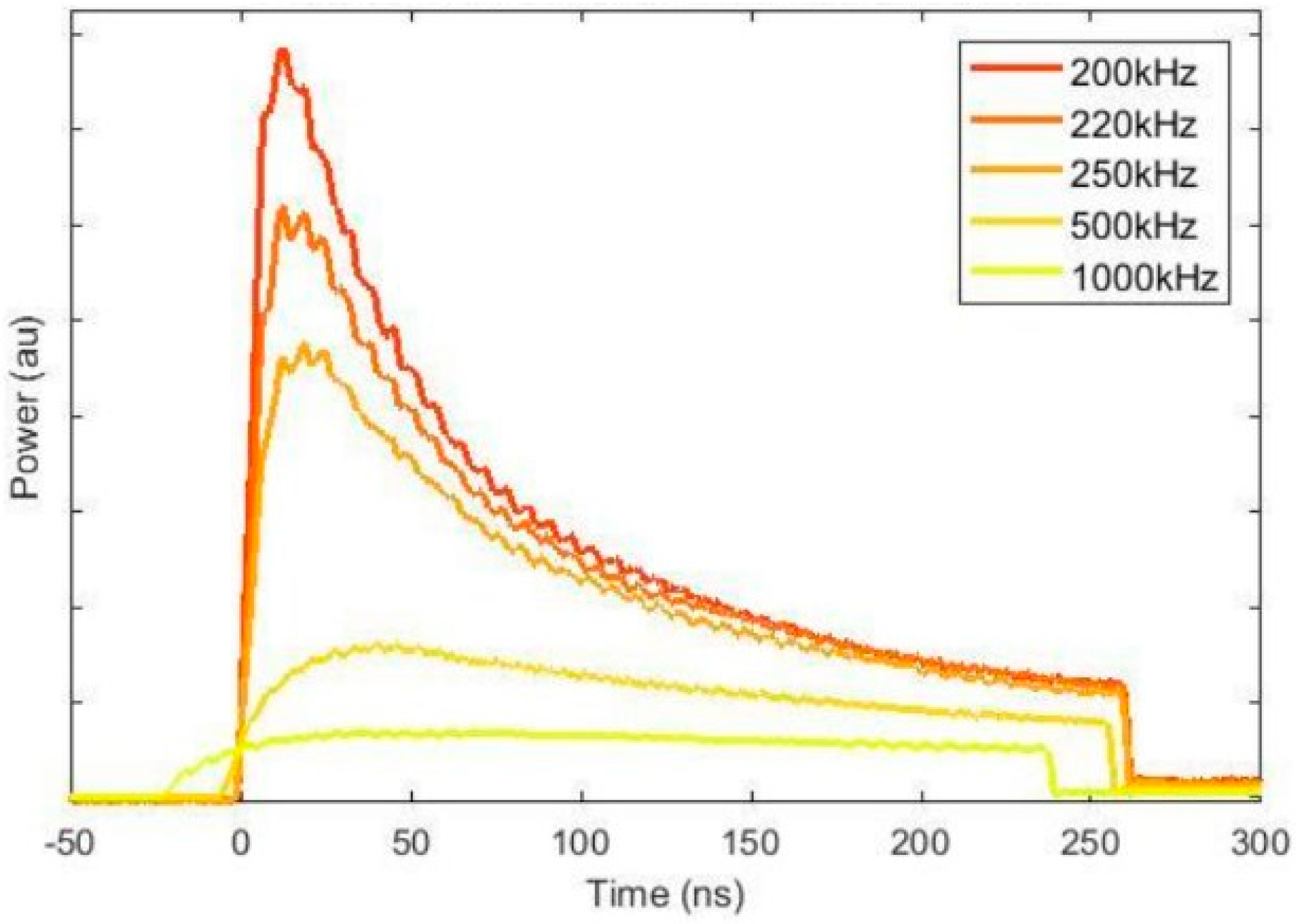

4.1. Laser Parameter Effects on Cutting Performance

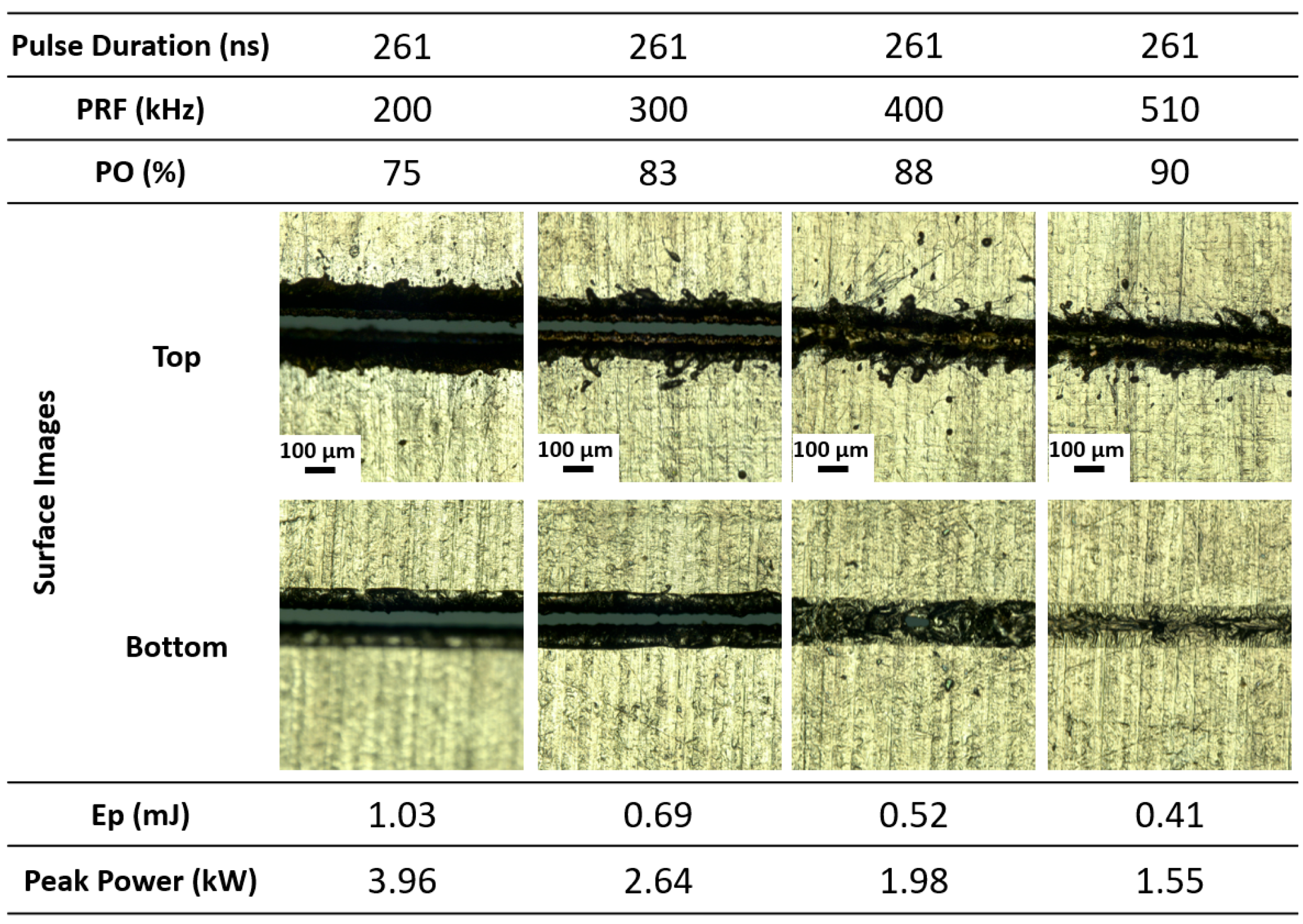

4.2. Effect of Cutting Parameters on Edge Quality

5. Conclusions

- A maximum single-pass cutting speed of 3.0 m/s was achieved at a constant line energy of 0.067 J/mm. This speed represents a practical upper limit under the tested conditions for maintaining continuous kerf formation without incomplete cuts.

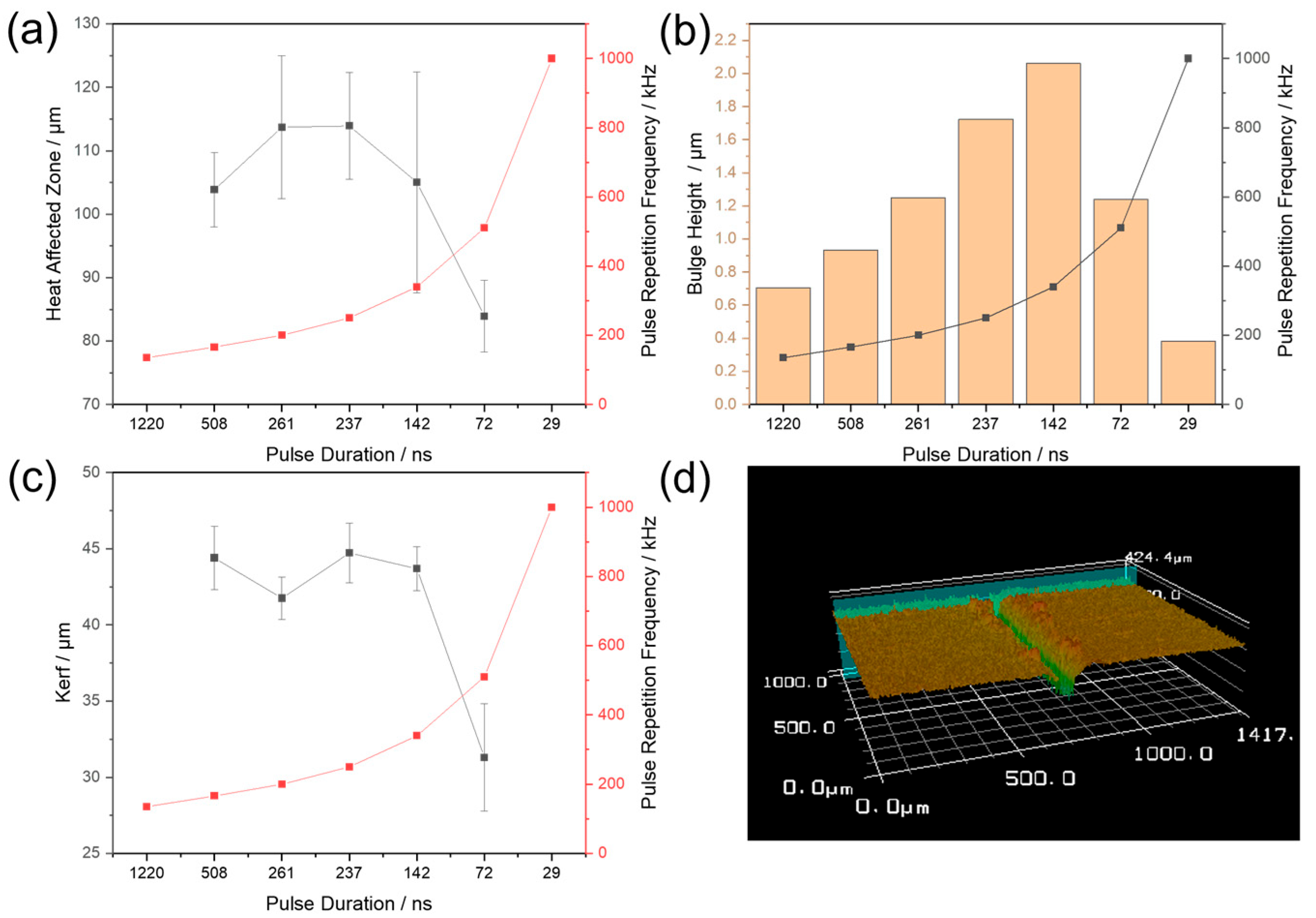

- Pulse duration and energy distribution were found to critically influence cut quality. While short pulses (e.g., 72 ns) enabled efficient ablation through high peak power, they also introduced excessive spatter due to explosive vaporization. In contrast, moderate pulse durations (261–508 ns) provided a more balanced energy delivery, resulting in clean kerfs with minimal thermal damage and melt accumulation.

- A dual-threshold condition was identified for effective cutting: both pulse energy (>~0.4 mJ) and peak power (>~2.4 kW) are required to generate sufficient recoil pressure for stable melt ejection.

- Morphological analysis revealed that shorter pulse durations markedly reduce the heat-affected zone (HAZ) width, kerf width, and melt bulge height, indicating a shift toward a vapor-dominated ablation regime. However, this regime also increases the likelihood of spatter formation due to intensified recoil pressure, highlighting a trade-off between cutting precision and surface cleanliness.

- The results emphasize the importance of temporal energy delivery and pulse overlap in optimizing laser–material interactions, particularly for reactive and low-viscosity materials like lithium.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shaffer, B.; Auffhammer, M.; Samaras, C. Make electric vehicles lighter to maximize climate and safety benefits. Nature 2021, 598, 254–256. [Google Scholar] [CrossRef]

- Xu, W.; Wang, J.; Ding, F.; Chen, X.; Nasybulin, E.; Zhang, Y.; Zhang, J.-G. Lithium metal anodes for rechargeable batteries. Energy Environ. Sci. 2014, 7, 513–537. [Google Scholar] [CrossRef]

- Winter, M.; Barnett, B.; Xu, K. Before Li Ion Batteries. Chem. Rev. 2018, 118, 11433–11456. [Google Scholar] [CrossRef] [PubMed]

- Albertus, P.; Babinec, S.; Litzelman, S.; Newman, A. Status and challenges in enabling the lithium metal electrode for high-energy and low-cost rechargeable batteries. Nat. Energy 2018, 3, 16–21. [Google Scholar] [CrossRef]

- Wang, R.; Cui, W.; Chu, F.; Wu, F. Lithium metal anodes: Present and future. J. Energy Chem. 2020, 48, 145–159. [Google Scholar] [CrossRef]

- Gao, X.; Zhou, Y.-N.; Han, D.; Zhou, J.; Zhou, D.; Tang, W.; Goodenough, J.B. Thermodynamic Understanding of Li-Dendrite Formation. Joule 2020, 4, 1864–1879. [Google Scholar] [CrossRef]

- Guo, F.; Wu, C.; Chen, H.; Zhong, F.; Ai, X.; Yang, H.; Qian, J. Dendrite-free lithium deposition by coating a lithiophilic heterogeneous metal layer on lithium metal anode. Energy Storage Mater. 2020, 24, 635–643. [Google Scholar] [CrossRef]

- Park, S.K.; Copic, D.; Zhao, T.Z.; Rutkowska, A.; Wen, B.; Sanders, K.; He, R.; Kim, H.-K.; De Volder, M. 3D Porous Cu-Composites for Stable Li-Metal Battery Anodes. ACS Nano 2023, 17, 14658–14666. [Google Scholar] [CrossRef]

- Cui, Y.; Liu, S.; Liu, B.; Wang, D.; Zhong, Y.; Zhang, X.; Wang, X.; Xia, X.; Gu, C.; Tu, J. Bi-containing Electrolyte Enables Robust and Li Ion Conductive Solid Electrolyte Interphase for Advanced Lithium Metal Anodes. Front. Chem. 2020, 7. [Google Scholar] [CrossRef]

- Jansen, T.; Hartwig, S.; Blass, D.; Dilger, K. Laser cutting of pure lithium metal anodes—Effects of atmospheric conditions. In Proceedings of the ICALEO 2017: 36th International Congress on Applications of Lasers & Electro-Optics, Atlanta, GA, USA, 22–26 October 2017. [Google Scholar]

- Jansen, T.; Kandula, M.W.; Hartwig, S.; Hoffmann, L.; Haselrieder, W.; Dilger, K. Influence of Laser-Generated Cutting Edges on the Electrical Performance of Large Lithium-Ion Pouch Cells. Batteries 2019, 5, 73. [Google Scholar] [CrossRef]

- Kriegler, J.; Binzer, M.; Zaeh, M.F. Process strategies for laser cutting of electrodes in lithium-ion battery production. J. Laser Appl. 2020, 33. [Google Scholar] [CrossRef]

- Marc, S.; Adam, R.; Jack, G.; Axel, F.; Lin, L.; Daniel Huerta, M. High-throughput battery foil cutting: A comparison of different pulsed laser approaches. In Proceedings of the Laser-based Micro- and Nanoprocessing XVII, San Francisco, CA, USA, 31 January–2 February 2023; SPIE: Bellingham, WA, USA; Volume 12409, p. 124090M. [Google Scholar]

- Zhang, Y.; Li, J.; Yang, R.; Liu, T.; Yan, Y. Analysis of kerf quality on ultrafast laser cutting of anode material for lithium-ion battery. Opt. Lasers Eng. 2019, 118, 14–21. [Google Scholar] [CrossRef]

- Lee, D.; Patwa, R.; Herfurth, H.; Mazumder, J. High speed remote laser cutting of electrodes for lithium-ion batteries: Anode. J. Power Sources 2013, 240, 368–380. [Google Scholar] [CrossRef]

- Luetke, M.; Franke, V.; Techel, A.; Himmer, T.; Klotzbach, U.; Wetzig, A.; Beyer, E. A Comparative Study on Cutting Electrodes for Batteries with Lasers. Phys. Procedia 2011, 12, 286–291. [Google Scholar] [CrossRef]

- Jansen, T.; Blass, D.; Hartwig, S.; Dilger, K. Processing of Advanced Battery Materials—Laser Cutting of Pure Lithium Metal Foils. Batteries 2018, 4, 37. [Google Scholar] [CrossRef]

- Eckl, M.J.; Mäder, G.; Roch, J.; Thümmler, P.; Abendroth, T. Method and Device for Cutting a Metal-Containing Foil, and Laser-Cut Metal-Containing Foil. U.S. Patent 18/551,774, 30 May 2024. [Google Scholar]

- Kriegler, J.; Duy Nguyen, T.M.; Tomcic, L.; Hille, L.; Grabmann, S.; Jaimez-Farnham, E.I.; Zaeh, M.F. Processing of lithium metal for the production of post-lithium-ion batteries using a pulsed nanosecond fiber laser. Results Mater. 2022, 15, 100305. [Google Scholar] [CrossRef]

- Heidari Orojloo, P.; Dib, S.A.; Kriegler, J.; Ballmes, H.; Zaeh, M.F.; Demir, A.G. Nanosecond- and picosecond-pulsed laser cutting of lithium metal anodes with copper current collector. Int. J. Adv. Manuf. Technol. 2025, 139, 657–671. [Google Scholar] [CrossRef]

- Yamada, M.; Watanabe, T.; Gunji, T.; Wu, J.; Matsumoto, F. Review of the Design of Current Collectors for Improving the Battery Performance in Lithium-Ion and Post-Lithium-Ion Batteries. Electrochem 2020, 1, 124–159. [Google Scholar] [CrossRef]

- Leitz, K.-H.; Redlingshöfer, B.; Reg, Y.; Otto, A.; Schmidt, M. Metal Ablation with Short and Ultrashort Laser Pulses. Phys. Procedia 2011, 12, 230–238. [Google Scholar] [CrossRef]

- Schmidt, L.O.; Wehbe, H.; Hartwig, S.; Kandula, M.W. Investigation of the Laser Material Interaction of Lithium Copper Foils Under Different Process Gases for All-Solid-State Batteries. Batteries 2025, 11, 195. [Google Scholar] [CrossRef]

- Aota, L.S.; Jung, C.; Zhang, S.; Büyükuslu, Ö.K.; Saksena, A.; Hatipoglu, E.; Yadav, P.; Singh, M.P.; Chen, X.; Woods, E.; et al. Grain Boundaries Control Lithiation of Solid Solution Substrates in Lithium Metal Batteries. Adv. Sci. 2025, 12, 2409275. [Google Scholar] [CrossRef]

- Leung, K.; Soto, F.; Hankins, K.; Balbuena, P.B.; Harrison, K.L. Stability of Solid Electrolyte Interphase Components on Lithium Metal and Reactive Anode Material Surfaces. J. Phys. Chem. C 2016, 120, 6302–6313. [Google Scholar] [CrossRef]

- Azib, T.; Thaury, C.; Cuevas, F.; Leroy, E.; Jordy, C.; Marx, N.; Latroche, M. Impact of Surface Chemistry of Silicon Nanoparticles on the Structural and Electrochemical Properties of Si/Ni3.4Sn4 Composite Anode for Li-Ion Batteries. Nanomaterials 2021, 11, 18. [Google Scholar] [CrossRef]

- Li, X.; Guan, Y. Theoretical fundamentals of short pulse laser–metal interaction: A review. Nanotechnol. Precis. Eng. 2020, 3, 105–125. [Google Scholar] [CrossRef]

| Primary Laser Parameters | Secondary Laser Parameters |

|---|---|

| Velocity/ms−1 | Pulse energy/J |

| Pulse repetition frequency/Hz | Pulse overlap |

| Spot diameter/µm | Intensity/Wmm−2 |

| Laser power/W | Line energy/Jmm−1 |

| Pulse duration/ms | Pulse shape |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pour, M.M.; Schmidt, L.O.; Carlson, B.E.; Gruhn, H.; Ambrosy, G.; Bocksrocker, O.; Salvarrajan, V.; Kandula, M.W. Nanosecond Laser Cutting of Double-Coated Lithium Metal Anodes: Toward Scalable Electrode Manufacturing. J. Manuf. Mater. Process. 2025, 9, 275. https://doi.org/10.3390/jmmp9080275

Pour MM, Schmidt LO, Carlson BE, Gruhn H, Ambrosy G, Bocksrocker O, Salvarrajan V, Kandula MW. Nanosecond Laser Cutting of Double-Coated Lithium Metal Anodes: Toward Scalable Electrode Manufacturing. Journal of Manufacturing and Materials Processing. 2025; 9(8):275. https://doi.org/10.3390/jmmp9080275

Chicago/Turabian StylePour, Masoud M., Lars O. Schmidt, Blair E. Carlson, Hakon Gruhn, Günter Ambrosy, Oliver Bocksrocker, Vinayakraj Salvarrajan, and Maja W. Kandula. 2025. "Nanosecond Laser Cutting of Double-Coated Lithium Metal Anodes: Toward Scalable Electrode Manufacturing" Journal of Manufacturing and Materials Processing 9, no. 8: 275. https://doi.org/10.3390/jmmp9080275

APA StylePour, M. M., Schmidt, L. O., Carlson, B. E., Gruhn, H., Ambrosy, G., Bocksrocker, O., Salvarrajan, V., & Kandula, M. W. (2025). Nanosecond Laser Cutting of Double-Coated Lithium Metal Anodes: Toward Scalable Electrode Manufacturing. Journal of Manufacturing and Materials Processing, 9(8), 275. https://doi.org/10.3390/jmmp9080275