Abstract

In this study, prospects of designing new Al–Ca–Cu–Mn (Zr) alloys for additive manufacturing (AM) were evaluated for the example of laser remelting of thin-sheet rolled products. The new as-cast alloys have a hypereutectic structure containing Al27Ca3Cu7 primary crystals and ultrafine eutectic particles of (Al,Cu)4Ca and Al27Ca3Cu7 phases in equilibrium with the aluminum solid solution. The solid solutions are additionally strengthened by alloying with Mn and micro additions of Zr, which contribute to the formation of coarsening-resistant phases without compromising the manufacturability of the alloys. Laser remelting, which simulates AM-typical solidification conditions, promotes the formation of a pseudoeutectic cellular structure without the occurrence of undesirable primary Al27Ca3Cu7. The size of the dendritic cells and eutectic particles is 10 times smaller (for solidification rates of ~200 K/s) than that of the as-cast state. This structure provides for a higher hardness of the laser-remelted alloy (96 HV) as compared to the as-cast alloy (85 HV). Data for the alloy after 350–400 °C long-term annealing for up to 100 h show that the hardness of the Al–Ca–Cu–Mn–Zr alloys declines relatively slowly by ~7.5% as compared to the Zr-free alloy, whose hardness decreases by ~22%. Thus, one can consider these alloys as a promising candidate for AM processes that require high thermal stability.

1. Introduction

A review of published activity in the field of additive manufacturing (AM) of aluminum alloy products shows that the greatest attention is paid to the optimization of printing modes and the strengthening of powder compositions of conventional casting alloys (Al12Si, AlSI10Mg, and AlSi20) [1,2,3,4,5,6,7,8,9]. These alloys are characterized by higher eutectic fraction, narrow solidification range, low hot tearing tendency, and, as a consequence, improved technological properties both for casting and AM processes. AM processes develop conditions similar to those for casting (or welding), melting, and rapid solidification processes, though in micro-volumes of material.

However, the mechanical properties of these alloys after PBF-LB (Laser Beam Powder Bed Fusion) are in the 350–400 MPa range; in a number of studies, the AlSi10Mg alloy [7,8,9] exhibited a tensile strength of about 450 MPa after printing in an optimized mode. However, even short-term heating at above 300 °C leads to a significant loss of strength due to the degradation of the ultrafine eutectic structure formed during the PBF-LB.

As an alternative to silumins (Al–Si), eutectic aluminum alloys based on new alloying systems, including REM (rare-earth metal) and Ni, can be a basis for the development of new alloy compositions for additive manufacturing in an attempt to improve strength or thermal stability [10,11,12,13,14,15,16,17,18,19,20,21,22]. Thus, Al–Ni [10,12], Al–Ce [13,14,15,16], Al–Ce–Fe [17], Al–Cu–Ce [18,19], Al–Cu–Ni [20], and Al–Ce–Ni [21,22,23] systems have been actively studied, including those additionally alloyed with Mn, Zr, and Sc, for reducing the hot tearing tendency index and improving the mechanical properties during annealing due to dispersion hardening.

In [18], the new Al–3Ce–7Cu alloy was proposed for laser powder-bed fusion. After printing, its ultimate strength, yield strength, and relative elongation are 456 MPa, 274 MPa, and 4.4%, respectively. However, annealing at temperatures above 250 °C leads to a significant decrease in the hardness. In [21], the Al–6Ce–3Ni–0.7Fe alloy having a fine eutectic structure with an about 18% volume fraction of second phases was studied. This structure delivers stability of the alloy’s structure and properties at up to 300 °C. The yield strength after annealing at 300 °C is about 170 MPa. The reduction in the hardness due to annealing at 400 °C for 144 h is within 35%. In the course of further research, the Al–7.5Ce–4.5Ni–0.4Mn–0.7Zr alloy with an about 27% volume fraction of second phases was considered [22]. Mn and Zr alloying enhances the hot cracking resistance and mechanical properties of the alloy during annealing due to dispersion hardening.

However, although one can obtain a relatively successful combination of strength, heat resistance, plasticity, and manufacturability for the alloys of the considered systems via PBF-LB, it should be noted that their widespread use in industry is hindered by the high cost of REM.

According to reports data, calcium is a more attractive alloying element. Earlier results [24,25,26] showed that aluminum–calcium eutectic-based alloys exhibit a good set of such difficultly combinable properties as strength, processability (during casting [24], deformation [24], and welding [25]), and corrosion resistance [26]. These properties are achieved due to the formation of an ultrafine (Al+Al4Ca) eutectic structure during solidification. Moreover, the magnitude of the properties can be controlled by changing the heterogeneity of the structure due to the formation of multiple calcium-containing phases with alloying elements, as reported earlier [27,28,29,30]. Furthermore, there is the possibility of obtaining a supersaturated aluminum solid solution with transition metals, e.g., Mn, Zr, and Sc, which provides hardening during heterogenization annealing due to the release of secondary metastable L12–Al3(Zr, Sc) aluminides, etc. [31].

To date, certain results have been obtained on the laser processing of Al–Ca alloys in terms of modeling the structure and properties of additive manufacturing products, including powder fusion process modes, analysis of the structure and mechanical properties in the cross section of single tracks, and single studies on the structure and properties of samples obtained by laser powder-bed fusion. For example, single tracks obtained by laser powder-bed fusion showed the possibility of defect-free laser fusion of crushed powder particles of the Al6Ca4La2Mn and Al7Ca4Ni1.5Mn hypereutectic alloys [24,32]. It was shown that processing of these alloys produces an ultrafine (quasi-eutectic) composite structure containing more than 25 vol.% intermetallic phase. This structure delivers high microhardness of the alloys, i.e., 170 and 201 HV, respectively. Moreover, the hardness of the alloys remains high, dropping by only about 20% during isothermal exposure at up to 350–400 °C, unlike the standard Al–Si alloy. In [33], 10 × 10 × 10 mm3 cubic samples of the Al–10 wt.% Ca alloy were, for the first time, obtained by laser powder-bed fusion (the powder was synthesized by gas atomization). The samples exhibited high quality and density and had no cracks. The hardness of the obtained samples was in the 178–188 HV range. The new Al3.0Ce0.9Ca1.9Mn1.2Zr alloy [34] leverages the excellent heat resistance of the Al–Ce alloys, with Ca incorporation lowering both the cost and the density, and Mn and Zr addition improving the formability and increasing the precipitation strengthening of the materials. The hardness of the samples was ~124 HV. After annealing at 425 °C for 8 h, the hardness was ~115 HV.

One of the promising alloying systems for further study is Al–Ca–Cu. The new Al–Ca–Cu system is preferable for the design of aluminum matrix composites with very high contents of insoluble intermetallics, due to several quasi-binary eutectic phase transformations described earlier [30]. The alloy compositions close to the eutectic point (5.6 Ca, 4.5 Cu) have elevated contents of the (Al, Cu)4Ca and Al27Ca3Cu7 intermetallic phases in their structure and can be considered promising as a basis for the additive manufacturing of new materials. The above composition ensures the formation of a ~20% second-phase volume fraction. For comparison, the formation of a heterogeneous structure with a similar second-phase volume fraction in the Al–Ce–Cu alloys can be achieved at ~12% Cu and ~7% Ce. Thus, the new alloys offer a significant advantage and are economically profitable and lightweight.

Various methods are used to evaluate the prospects of new alloys in additive technologies. Along with direct laser-powder bed fusion, a promising method is laser remelting of cast or wrought surface aluminum alloy, providing for solidification conditions typical of additive manufacturing (AM) processes [18,35,36,37,38].

The aim of this work was to evaluate the prospects of new Al–Ca–Cu–Mn (–Zr) system alloys for additive technologies (laser powder-bed fusion) by simulating the structure and properties of laser-processed materials (laser remelting of thin-rolled sheets). Mn and Zr contribute to the saturation of (Al) and the formation of coarsening-resistant phases during high-temperature exposure.

2. Materials and Methods

Two model alloys, i.e., Al5Ca3Cu1.5Mn and Al5Ca3Cu1.5Mn0.4Zr, were prepared in a resistance furnace. Technical purity aluminum (99.9%), copper (99.9%), and Al-10% Ca, Al-20% Mn, and Al-15% Zr binary master alloys were used as the charge. After the melting of the basic components, the metal was cast into a graphite mold with a working cavity measuring 10 × 40 × 180 mm. The casting temperature was ~800 °C, the cooling rate being ~10 K/s. The actual chemical compositions (wt.%) of the alloys (Table 1) were measured using scanning electron microscopy (SEM, TESCAN VEGA 3, Brno, Czech Republic), with energy-dispersive X-ray spectroscopy (EDS, Oxford Instruments plc, Abingdon, UK) at an 20 kV accelerating voltage.

Table 1.

Chemical composition of experimental alloys.

Qualitative assessment of the hot tearing tendency (HTT) was carried out with a pencil probe [24]. HTT is defined as the maximum diameter of the cylindrical portion of the sample that still does not reveal any cracks. The higher the HTT, the worse the hot cracking performance of the test aluminum alloy.

The resulting ingot was used as an initial blank to fabricate thin-sheet rolled products for further laser remelting. The sheets were obtained by hot rolling of the initial ingot at 400 °C (without annealing) to a thickness of 1 mm (compression ratio of 90%).

The laser remelting process was carried out using a robotic laser welding machine, which included a 6-axis Fanuc M710iC-50 robot, an IPG FLW D50 welding head, and a 5 kW LS-5 ytterbium fiber laser. To identify the optimal welding parameters, the laser power was varied in the range of 1000–1600 W with a spot size of 1.5 mm on the sample surface. The laser scanning speed was 20 mm/s, resulting in energy densities varying from 33 to 53 J/mm2. The optimal welding parameters providing a complete remelting (without cracks, poor penetration, and other visual defects) of the thin-sheets workpiece were the laser power P = 1400 W and the scanning speed v = 20 mm/s. The focal length was 193 mm, the shielding gas (argon) supply flow rate to the remelting zone being 15 L/min.

The heat treatment (HT) of laser-remelted alloys was performed in SNOL furnaces with a temperature maintenance accuracy of 3 °C.

Scanning electron microscopy (SEM, TESCAN VEGA 3, Brno, Czech Republic), with energy-dispersive X-ray spectroscopy (EDS, Oxford Instruments plc, Abingdon, UK), and transmission electron microscopy (TEM, JEM−2100, Tokyo, Japan) were employed to examine the structure and elemental compositions of the alloys. The specimens were prepared by mechanical and electrolytic polishing. The thin foils for TEM were prepared by ion thinning with a Struers device (Struers, Copenhagen, Denmark) and studied at 200 kV.

X-ray diffraction (XRD) data were obtained at room temperature using a DRON-4 diffractometer in Co Kα radiation and analyzed with a software package [39]. XRD profiles were taken in a 2θ range of 10 to 130 deg with a 0.1 deg step and a 5 s exposure.

Thermo-Calc software version TCW5, database TTAL5 (Foundation for Computational Thermodynamics, Stockholm, Sweden), was used for thermodynamic calculations.

Microhardness measurements were conducted using DUROLINE MH-6 (Metkon, Bursa, Turkey). The Vickers indentation loads were 1 H, the dwell time being 5 s.

3. Results

3.1. Experimental Analysis of As-Cast and Hot-Rolled Structure

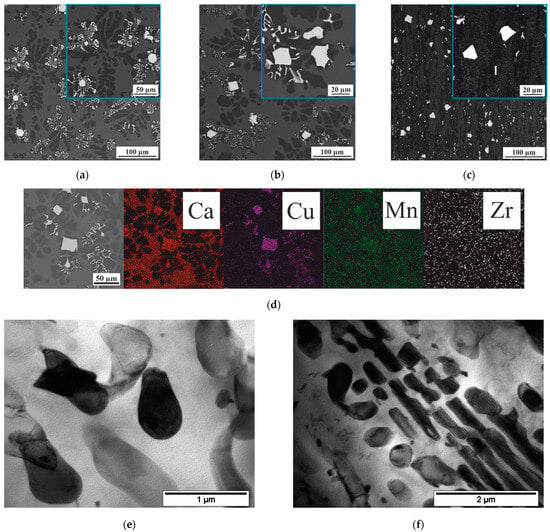

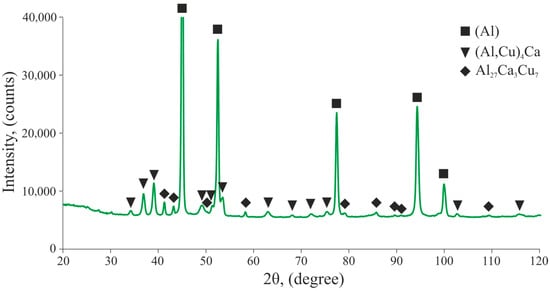

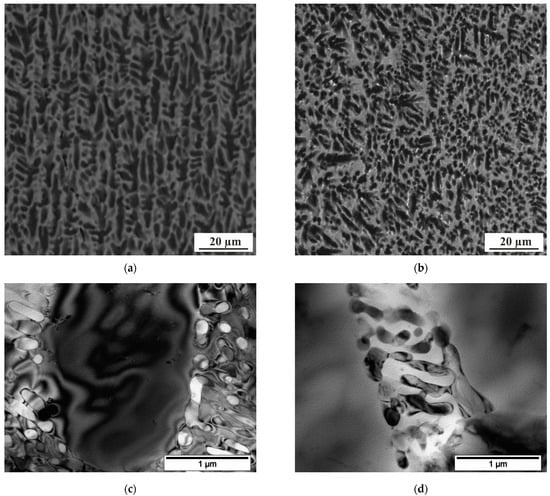

Figure 1 shows the as-cast microstructure of the Al5Ca3Cu1.5Mn(0.4Zr) (wt.%) hypereutectic alloy containing ~20 μm-sized primary Al27Ca3Cu7 particles with a faceted equiaxed morphology and ultrafine (Al,Cu)4Ca and Al27Ca3Cu7 eutectic phase particles (Figure 2 and Table 2) in equilibrium with the aluminum solid solution. According to the XRD data (Figure 2 and Table 2), the volume fraction of the (Al,Cu)4Ca phase is ~15.5%, and that of Al27Ca3Cu7 is ~4.1%. TEM microstructure imaging showed that the size of eutectic intermetallic particles is about 1–2 μm (Figure 1). Quantitative EMPA analysis showed that Mn (~1.3–1.4%) and Zr (~0.35%) are contained in the supersaturated solid solution (Al). A small fraction of manganese is dissolved in the Al27Ca3Cu7 phase. The structure of the hot-rolled sheet metal obtained at 400 °C and a relative deformation of approximately 90% is shown in Figure 1c. The primary crystals are substantially refined by deformation treatment. The structural components are elongated in the rolling direction.

Figure 1.

(a–d) SEM and (e,f) TEM microstructure of the experimental alloys: (a) Al5Ca3Cu1.5Mn, (b–f) Al5Ca3Cu1.5Mn0.4Zr. (a,b,d–f) cast, (c) wrought state, and (d) elemental mapping obtained from the selected area.

Figure 2.

XRD pattern for the Al5Ca3Cu1.5Mn(0.4Zr) alloys. The Al5Ca3Cu1.5Mn(0.4Zr) alloy was analyzed in the as-cast state (after accelerated solidification at a ~10 K/s cooling rate) using CoKα radiation.

Table 2.

XRD for the experimental alloy.

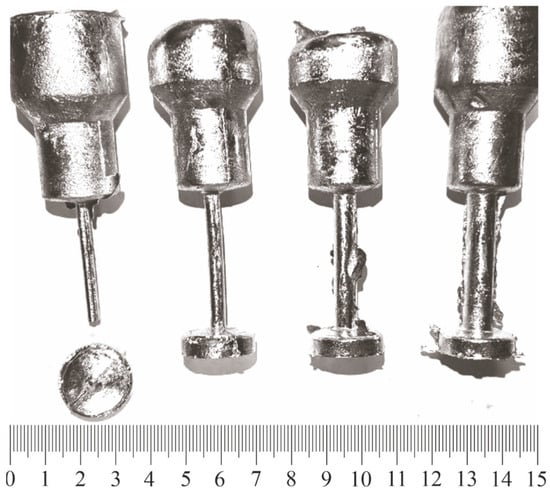

The hot tearing tendency of the Al5Ca3Cu1.5Mn0.4Zr alloys was evaluated using the pencil test samples. The experimental alloys showed lower hot cracking propensity as compared to the conventional Al-Si system alloys [24]. The hot tearing index (the minimum as-cast sample diameter, mm) is 4. The general appearance of a hot crack formed during the casting of the Al5Ca3Cu1.5Mn0.4Zr alloy is shown in Figure 3. This elevated hot cracking resistance ensures good casting properties and, as a result, presupposes high technological properties for welding and additive technologies.

Figure 3.

Cast Al5Ca3Cu1.5Mn0.4Zr alloy samples 3, 4, 6, and 8 mm in diameter, obtained using the pencil test.

Thus, in addition to the good castability, the high volume fraction of secondary phases can provide elevated strength of these alloys obtained by additive manufacturing. Laser remelting of thin-sheet products allows studying the structure and properties formed at elevated solidification rates typical of additive manufacturing.

3.2. Influence of Laser Remelting on the Microstructure

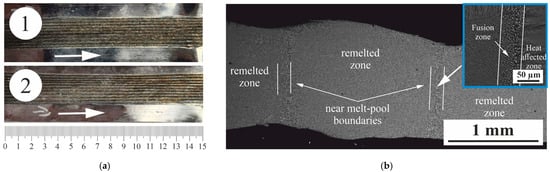

Laser remelting of thin-sheet products was carried out to further study the effect of process conditions typical of AM technologies on the structure and properties of the alloys. The appearance of the obtained 1 mm sheet samples with laser remelting field is presented in Figure 4a. SEM microstructure of track transverse view showing the possible zones formed along the molten pool and tracks quality is presented in Figure 4b. The laser treatment mode with P = 1400 W and V = 20 mm/s allowed the obtainment of a high-quality (crack-free and minimum number of pores) laser remelting field.

Figure 4.

The images of sheet samples with laser remelting field: (a) general view, (b) SEM microstructure of track transverse view showing the possible zones formed along the molten pool and tracks quality. (a) The arrow indicates a unidirectional scanning path along the rolling direction of the thin-sheet products.

The microstructure of the laser remelted zone mainly consists of Al-rich gray-colored cells surrounded by a white-colored intermetallic matrix (Figure 5a,b). The average size of the dendritic cells in the melting zone is 3–4 μm, which is 8–10 times smaller than that observed for the structure obtained at conventional cooling rates, i.e., ~8–10 K/s. Using the known relationship between dendritic cell size (d) and cooling rate V = A/d [25], A equaling 100, one can estimate the cooling rate for solidification at laser welding to be approximately 20 times higher. Also, the high cooling rates heavily refine the eutectic microstructures and eliminate the coarse primary Al27Ca3Cu7 particles. The eutectic ellipsoid particles are much finer than in the as-cast alloy, with a size of 200 nm, as measured on TEM micrographs (Figure 5c,d). This structure type is commonly considered pseudoeutectic.

Figure 5.

(a,b) SEM and (c,d) TEM images of laser remelting field structure in melting zone: (a,c) Al5Ca3Cu1.5Mn and (b,d) Al5Ca3Cu1.5Mn0.4Zr.

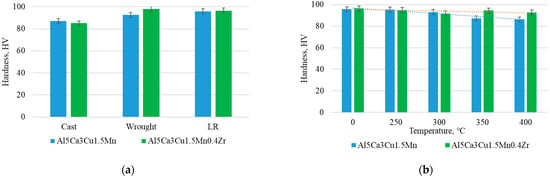

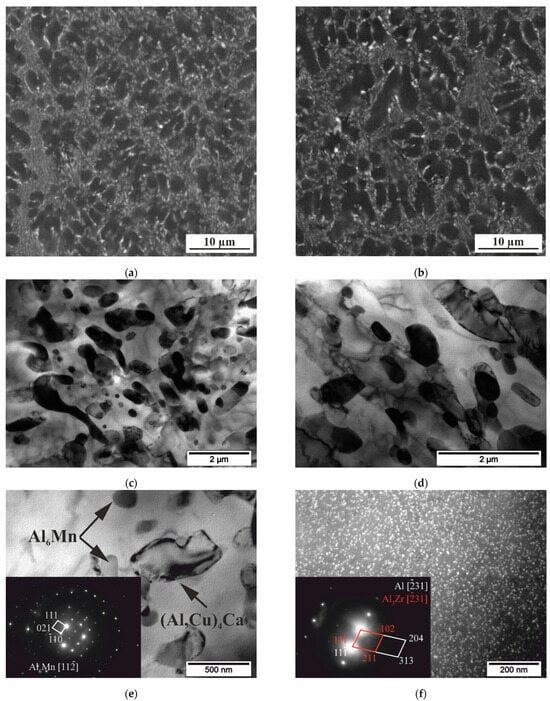

Thus, the structures formed during rapid solidification contribute to a higher hardness (~96 HV) as compared to the as-cast alloy, the hardness of which is 85 HV (Figure 6a).

Figure 6.

(a) Hardness as a function of technological state, (b) laser-remelted (LR) zone hardness as a function of step annealing temperature (3 h), and LR zone hardness as a function of annealing time at (c) 350 °C and (d) 400 °C for the laser-remelted zone structure (melting zone) (point “0” denotes as-remelted state). The number of hardness indentations was 20 for each condition.

Another notable feature of the laser-remelted zone is a change in the chemical composition of base alloys within that zone. During laser remelting, the interaction of the high-intensity laser beam with the molten metal produces a vapor-gas channel due to the evaporation of the weld material [40,41]. The difference in the partial pressures of the elements in the alloys results in the deposition of elements on the channel walls. Some of the elements are subsequently returned to the weld pool, while other elements evaporate irreversibly. Table 3 presents the EMPA data on the chemical composition of the as-cast and laser-remelted aluminum–calcium alloy for the optimal laser treatment mode with P = 1400 W and V = 20 mm/s. It can be seen that the calcium evaporation rate in the laser-remelted field is approximately 4.1–6.1%.

Table 3.

Chemical composition of basic and laser-remelted (LR) alloys.

3.3. Influence of Annealing on the Hardness and Microstructure

To evaluate the prospect of these alloys for high thermal stability applications, we studied the effect of heat treatment of the laser-remelted zone on hardness. As can be seen from Figure 6b (stepwise annealing), 250 °C exposure for 3 h is insufficient for changing the hardness. A negligible reduction in the hardness to 94 ± 2 may be associated with the elimination of dislocations and thermal stress relief. Further stepwise annealing at 300–400 °C caused softening of the basic laser-remelted Al5Ca3Cu1.5Mn alloy to 86 HV (~10%). However, the hardness of the laser-remelted Al5Ca3Cu1.5Mn0.4Zr alloy decreased to 92 HV (~4%).

Figure 6c,d shows the hardness evolution as a function of annealing time at 350 °C and 400 °C for the laser-remelted Al5Ca3Cu1.5Mn and Al5Ca3Cu1.5Mn0.4Zr (wt.%) alloys. It can be seen that 350 °C annealing leads to a smooth decrease in the hardness of the Al5Ca3Cu1.5Mn alloy from 96 HV to 75 HV (i.e., by ~22%) in 100 h of exposure (i.e., for the longest time used). A different annealing behavior was observed for the Al5Ca3Cu1.5Mn0.4Zr alloy: a substantially higher annealing temperature was required for a similar sharp decrease in the microhardness. The most intense hardness reduction to 91 HV (~5%) occurred during the first 10 h of exposure. Annealing for more than 40 h increased the hardness to the initial level, i.e., ~96 HV. After that, a transition to the steady stage occurred, characterized by an almost unchanged microhardness of 96 ± 2 for up to 100 h of exposure.

Annealing at 400 °C for 100 h led to the same result for the base Al5Ca3Cu1.5Mn alloy (Figure 6d). The alloy exhibited a gradual decrease in the hardness to 74 HV. However, the hardness of the Al5Ca3Cu1.5Mn0.4Zr alloy during exposure for up to 100 h demonstrated high thermal stability toward softening. The minimum hardness of 89 HV was reached after 100 h of exposure.

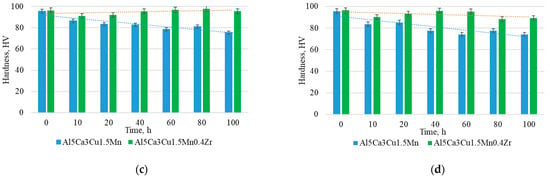

Analysis of the SEM and TEM micrographs (Figure 7) explains the above-identified behavior and the heat resistance of the laser-remelted Al5Ca3Cu1.5Mn0.4Zr alloy after long-term 350–400 °C exposure. Annealing causes a significant coarsening of the initial eutectic laser-remelted structure. Figure 7a–c show a growth of the intermetallic particle size to ~700–900 nm as compared to the initial laser-remelted state, for which the size of the eutectic particles was ~200 nm (Figure 5).

Figure 7.

(a,b) SEM and (c–f) TEM images of laser remelting field structure for melting zone after annealing at 400 °C for 100 h: (a,c,e) Al5Ca3Cu1.5Mn and (b,d,f) Al5Ca3Cu1.5Mn0.4Zr.

The TEM micrographs (Figure 7e,f) show dispersoids formed upon long-term annealing at 400 °C of the laser-remelted Al5Ca3Cu1.5Mn and Al5Ca3Cu1.5Mn0.4Zr alloys due to the decomposition of the supersaturated Mn- and Zr-containing aluminum solid solution (Al). The TEM micrographs of the as-annealed Al5Ca3Cu1.5Mn alloy reveal ~100–200 nm sized round-shaped Al6Mn particles (Figure 7e). In the primary α-Al region of the Al5Ca3Cu1.5Mn0.4Zr alloy, there are 15 nm sized dispersoids identified as the Al3Zr–L12 phase (Figure 7f).

Thus, the laser-remelted Al5Ca3Cu1.5Mn0.4Zr alloy demonstrates excellent thermal stability at 350–400 °C over the whole annealing time range (0–100 h), due to joint Mn and Zr alloying of the aluminum matrix.

It is reasonable to assume that the decrease in the hardness of the Al5Ca3Cu1.5Mn0.4Zr alloy during the first 10 h of annealing is caused by coarsening of the eutectic particles. A further increase in the hardness leads to the decomposition of the aluminum solid solution and the formation of multiple Al6Mn and Al3Zr–L12 phase dispersoids. The coarsening of eutectic particles and the decomposition of the aluminum solid solution occur simultaneously; however, the effect of the formation of precipitates allows one to offset the decrease in the hardness due to the coarsening of the eutectic particles.

4. Discussion

We finally discuss the hardening mechanism of Al5Ca3Cu1.5Mn(0.4Zr). The initial sample, laser-remelted and annealed at 400 °C, is suitable for comparative analysis for the evolution of the structure and properties. We assume that the structure of the laser-remelted Al5Ca3Cu1.5Mn0.4Zr alloy consists of 15.5 vol.% (Al,Cu)4Ca eutectic, 4.1 vol.% Al27Ca3Cu7 (according to XRD analysis) in the form of 100–200 nm ellipsoid particles (TEM), and Mn (1.4 wt.%) and Zr (0.35 wt.%) saturated (Al). To calculate the resulting strength of the alloy, we can use the basic additivity principle for composite properties. Based on it, the yield strength of the alloy can be calculated using a simple equation:

where σ0 is the yield strength of pure aluminum (~30 MPa) [21,32], σeut is the contribution of eutectic particles, and σSS is the contribution of Mn and Zr solute atoms. The strengthening effect caused by the eutectic particles can be assessed using the following Orowan equation [31]:

where M is the Taylor factor (3.06), G is the shear modulus (25.4 GPa), b is Burger’s vector (0.286 nm), ν is Poisson’s ratio (0.345), Pe is the ellipse perimeter, r0 = 1.5b, and λ is the interparticle spacing. The interparticle spacing λ is proportional to the particle size d and inversely proportional to the particle volume fraction fv; it can be calculated using the following equation [42]:

σYS = σ0 + σeut + σSS,

Although Equation (3) applies to spherical precipitates, the application of the effective radius R of the eutectic ellipsoid particles for calculations using this equation is believed to be an acceptable approximation, provided fv and λ are known, because the resulting approximate R values are used in Equation (2), which has a low logarithmic sensitivity to R. The same approach was previously used for the laser-processed Al–Ce alloy [13,35].

The main numerical parameters used for the calculation strength increments produced by the Orowan looping mechanism for as-laser-remelted (LR) and as-annealed (400 °C/100 h) states are resented in Table 4.

Table 4.

The main numerical parameters used for the calculation strength increments produced by the Orowan looping mechanism for as-laser-remelted (LR) and as-annealed (400 °C/100 h) states.

The solid solution contribution can be calculated as follows:

where Ci is the concentration of the i-th element in the solid solution and ki is the corresponding scaling factor (for Mn k = 80 MPa/wt.%2/3 [43], for Zr k = 9 MPa/wt.%2/3 [44,45]). In the as-solidified state, Zr acts in α-Al as a solute whose contribution to solid-solution strengthening is expected to be negligible due to its small concentration.

The alloy structure changes significantly during annealing. Initially, the eutectic particles are significantly coarsened. The average size of the intermetallic particles is 800 nm. Furthermore, the new alloys can be strengthened by Mn- and Zr-containing precipitates. A simple thermodynamic calculation (ThermoCalc) shows that the dissolution of 1.4 wt.% Mn in (Al) should lead to the formation of about 5.2 vol.% Al6Mn phase at 400 °C (average spherical precipitate diameter ~150 nm). Similarly, the dissolution of 0.35 wt.% Zr in (Al) should lead to the formation of about 0.6 vol.% L12-type phase (average precipitate diameter ~15 nm). The resulting strength of the alloy after annealing can be calculated as follows:

σYS = σ0 + σEUT + σAl6Mn+ σAl3Zr,

The modified Orowan model for spherical precipitates [31] can be used for analyzing the nanoparticle-related increase in the yield strength. According to this model,

where R is the average radius of the circular cross section.

According to the calculations (Table 5), the yield strength of the new Al5Ca3Cu1.5Mn(0.4Zr) alloy in laser-remelted state is 244 MPa. This predicted strength increment is lower than the observed hardness, since hardness (~96 HV) can be roughly related to yield strength as HV = YS/3. However, taking into account the measurement error, the correlation coefficient is still close to the known one: ~2.3–2.9. Meanwhile, calculations show the contribution of each structural element to the hardening. Thus, the eutectic particles make the greatest contribution to the strength of the alloy after laser remelting (~56%), the second contribution (~18%) pertaining to atoms (Mn) dissolved in aluminum. In the as-annealed state, the contribution of the eutectic particles to hardening is almost two times smaller (~25–30%), while the contribution of Al6Mn (~25–30%) and Al3Zr (~35%) dispersoids to strengthening is the greatest. Moreover, the presence of zirconium in the alloy is crucial for high-temperature processing.

Table 5.

Strength increments (MPa) produced by various strengthening mechanisms for as-laser-remelted (LR) and as-annealed (400 °C/100 h) states.

In comparison with another prospect, Al8Ce0.2Sc0.1Zr [35] aluminum alloy considered for PBF-LB, the new Al5Ca3Cu1.5Mn0.4Zr is preferable due to the use of cheaper and lighter calcium instead of cerium. This combination of cheaper and lighter elements makes it possible to increase the fraction of secondary phases (8.8 vol.% vs. 19.6 vol.%). Such a structure provides a comparable level of strength properties and hardening for as-laser-remelted and as-annealed alloy at higher temperatures (325 °C vs. 400 °C/100 h). There is also no expensive scandium additive in the new alloy.

The results show that the Al5Ca3Cu1.5Mn0.4Zr model alloy is quite promising as a basis for the design of additive manufacturing alloys with high thermal stability toward softening at heating up to 400 °C.

5. Conclusions

In this study, thin sheet products of hypereutectic alloy based on the Al–Ca–Cu–Mn (Zr) system were laser-remelted to simulate the solidification conditions typical of SLM processes. The structure and properties of the material (as-cast, wrought, and laser-remelted in the as-solidified state, and annealed at 250–400 °C for 3 to 100 h) were characterized. The results are as follows:

- (1)

- The as-cast alloy microstructure consists of the primary Al27Ca3Cu7 phase and (Al) + (Al,Cu)4Ca + Al27Ca3Cu7 ternary eutectic regions. The total intermetallic volume fraction is about 19.6%. Mn and Zr are contained in the supersaturated solid solution (Al). Laser remelting induces a much higher cooling rate (estimated as ~200 K/s) and suppresses the formation of primary Al27Ca3Cu7 phase crystals during solidification. Laser remelting also produces a much finer α-Al dendritic structure and eutectic (Al,Cu)4Ca and Al27Ca3Cu7 particles. Laser-induced microstructural refinement in the Al5Ca3Cu1.5Mn(0.4Zr) alloy produces dendritic cells and eutectic particles, which are approximately 10 times finer than those typical of the as-cast structure.

- (2)

- During casting, the alloys demonstrate elevated resistance to the formation of hot tears. The hot tearing tendency of the Al5Ca3Cu1.5Mn0.4Zr alloy is close to that of the conventional aluminum alloys (Al–Si).

- (3)

- Laser processing changes the chemical composition of the aluminum–calcium alloys in the melting zone. Under optimal laser processing conditions, calcium evaporation in the melting zone can reach ~6%.

- (4)

- Key approaches to the design of the Al–Ca–Cu–Mn (–Zr)-based alloys for achieving enhanced mechanical properties during laser processing and subsequent annealing were demonstrated. Manganese and zirconium addition lead to hardening during exposure at 350–400 °C due to the decomposition of the (Al) solid solution and the formation of Al6Mn particles and L12–Al3(Zr) phase nanoparticles. The Al5Ca3Cu1.5Mn0.4Zr alloy demonstrates higher thermal stability of hardness during long-term (100 h) isothermal annealing (hardness drops by ~7% during annealing at 350–400 °C). For comparison, the zirconium-free quaternary alloy shows a hardness drop of up to 22%. This suggests that the test Al5Ca3Cu1.5Mn0.4Zr alloy is a promising candidate for high-temperature applications (350–400 °C).

Thus, the prospects of the new Al5Ca3Cu1.5Mn0.4Zr alloy for additive technology applications were demonstrated by simulating typical solidification conditions of laser-induced microstructural refinement. Key alloying approaches to improving the mechanical properties of alloys via laser remelting and subsequent heat exposure were demonstrated. It can be concluded that the Al–Ca–Cu–Mn–Zr alloys have prospects for AM processes which require high thermal stability. Future work based on the data obtained will include laser processing of metal-powder Al5Ca3Cu1.5Mn0.4Zr alloy compositions by laser powder-bed fusion, printing mode testing, and studying the properties of synthesized samples.

Author Contributions

Conceptualization, N.V.L. and T.K.A.; data curation, S.O.C., P.A.P., N.V.L.; investigation, A.S.F., S.O.C., P.A.P., R.Y.B.; methodology, N.V.L., T.K.A., A.B.L.; writing—original draft, N.V.L.; writing—review and editing, T.K.A.; visualization, N.V.L.; project administration, N.V.L.; funding acquisition, N.V.L. All authors have read and agreed to the published version of the manuscript.

Funding

The study was carried out with the financial support of the Russian Science Foundation (Grant No. 24-79-00259) (alloys preparation, SEM, laser remelting) and Moscow Polytechnic University within the framework of the Grant named after Pyotr Kapitsa (TEM, hardness analysis).

Data Availability Statement

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhu, Z.; Hu, Z.; Seet, H.; Liu, T.; Liao, W.; Ramamurty, U.; Nai, S. Recent progress on the additive manufacturing of aluminum alloys and aluminum matrix composites: Microstructure, properties, and applications. Int. J. Mach. Tools Manuf. 2023, 190, 10404. [Google Scholar] [CrossRef]

- Cui, L.; Peng, Z.; Chang, Y.; He, D.; Cab, Q.; Guo, X.; Zeng, Y. Porosity, microstructure and mechanical property of welded joints produced by different laser welding processes in selective laser melting AlSi10Mg alloys. Opt. Laser Technol. 2022, 150, 107952. [Google Scholar] [CrossRef]

- Ma, P.; Prashanth, K.G.; Scudino, S.; Jia, Y.; Wang, H.; Zou, C.; Wei, Z.; Eckert, J. Influence of Annealing on Mechanical Properties of Al–20Si Processed by Selective Laser Melting. Metals 2014, 4, 28–36. [Google Scholar] [CrossRef]

- Pozdniakov, A.V.; Churyumov, A.Y.; Loginova, I.S.; Daubarayte, D.K.; Ryabov, D.K.; Korolev, V.A. Microstructure and properties of novel AlSi11CuMn alloy manufactured by selective laser melting. Mater. Lett. 2018, 225, 33–36. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, P.; Jia, Y.; Yu, Z.; Sokkalingam, R.; Shi, X.; Ji, P.; Eckert, J.; Prashanth, K.G. Microstructure and Mechanical Properties of Al–(12–20)Si Bi-Material Fabricated by Selective Laser Melting. Materials 2019, 12, 2126. [Google Scholar] [CrossRef] [PubMed]

- Manca, D.R.; Churyumov, A.Y.; Pozdniakov, A.V.; Ryabov, D.K.; Korolev, V.A.; Daubarayte, D.K. Novel heat-resistant Al-Si-Ni-Fe alloy manufactured by selective laser melting. Mater. Lett. 2019, 236, 676–679. [Google Scholar] [CrossRef]

- Salandari-Rabori, A.; Wang, P.; Dong, Q.; Fallah, V. Enhancing as-built microstructural integrity and tensile properties in laser powder bed fusion of AlSi10Mg alloy using a comprehensive parameter optimization procedure. Mater. Sci. Eng. A 2021, 805, 140620. [Google Scholar] [CrossRef]

- Paul, M.J.; Liu, Q.; Best, J.P.; Li, X.; Kruzic, J.J.; Ramamurty, U.; Gludovatz, B. Fracture resistance of AlSi10Mg fabricated by laser powder bed fusion. Acta Mater. 2021, 211, 116869. [Google Scholar] [CrossRef]

- Gao, T.; Gao, J.; Zhang, J.; Song, B.; Zhang, L. Development of an accurate “composition-process-properties” dataset for SLMed Al–Si– (Mg) alloys and its application in alloy design. J. Mater. Inform. 2023, 3, 6. [Google Scholar] [CrossRef]

- Pandey, P.; Makineni, S.K.; Gault, B.; Chattopadhyay, K. On the origin of a remarkable increase in the strength and stability of an Al rich Al–Ni eutectic alloy by Zr addition. Acta Mater. 2019, 170, 205–217. [Google Scholar] [CrossRef]

- Oeser, S.; Preußner, J.; Rödler, G.; Pirch, N.; Weisheit, A. Laser Metal Deposition of a Near-Eutectic Al–Ni Alloy. Adv. Eng. Mater. 2022, 24, 2200696. [Google Scholar] [CrossRef]

- Rödler, G.; Fischer, F.G.; Preußner, J.; Friedmann, V.; Fischer, C.; Weisheit, A.; Schleifenbaum, J.H. Additive manufacturing of high-strength eutectic aluminium-nickel alloys—Processing and mechanical properties. J. Mater. Process. Technol. 2021, 298, 117315. [Google Scholar] [CrossRef]

- Zhou, L.; Huynh, T.; Park, S.; Hyer, H.; Mehta, A.; Song, S.; Bai, Y.; McWilliams, B.; Cho, K.; Sohn, Y. Laser powder bed fusion of Al–10 wt% Ce alloys: Microstructure and tensile property. J. Mater. Sci. 2020, 55, 14611–14625. [Google Scholar] [CrossRef]

- Plotkowski, A.; Rios, O.; Sridharan, N.; Sims, Z.; Unocic, K.; Ott, R.T.; Dehoff, R.R.; Babu, S.S. Evaluation of an Al–Ce alloy for laser additive manufacturing. Acta Mater. 2017, 126, 507–519. [Google Scholar] [CrossRef]

- Henderson, H.B.; Hammons, J.A.; Baker, A.A.; McCall, S.K.; Li, T.T.; Perron, A.; Sim, Z.C.; Ott, R.T.; Meng, F.; Thompson, M.J.; et al. Enhanced thermal coarsening resistance in a nanostructured aluminum-cerium alloy produced by additive manufacturing. Mater. Des. 2021, 209, 109988. [Google Scholar] [CrossRef]

- Ekaputra, C.N.; Rachmonov, J.U.; Leinenbach, C.; Dunand, D.C. Hypereutectic Al–Ce–X (X=Mn, Cr, V, Mo, W) alloys fabricated by laser powder-bed fusion. Addit. Manuf. 2024, 93, 104442. [Google Scholar] [CrossRef]

- Chernyshikhin, S.V.; Dzidziguri, E.L.; Fedorenko, L.V.; Gromov, A.A.; Larionov, K.B.; Lyange, M.V.; Kharitonova, N.A.; Naumova, E.A.; Ozherelkov, D.Y.; Pelevin, I.A.; et al. Structure and Mechanical Properties of Al–Ce–Fe Alloy Synthesized by LPBF Method. Met. Mater. Int. 2024, 30, 3184–3201. [Google Scholar] [CrossRef]

- Manca, D.R.; Churyumov, A.Y.; Pozdniakov, V.; Prosviryakov, A.S.; Ryabov, D.K.; Krokhin, A.Y.; Korolev, V.A.; Daubarayte, D.K. Microstructure and Properties of Novel Heat Resistant Al–Ce–Cu Alloy for Additive Manufacturing. Met. Mater. Int. 2021, 25, 633–640. [Google Scholar] [CrossRef]

- Rojas-Arias, N.; Coury, F.G.; Amancio-Filho, S.T.; Gargarella, P. A novel approach for tailoring aluminum alloys for additive manufacturing. Sci. Eng. A 2025, 931, 148179. [Google Scholar] [CrossRef]

- Schon, A.F.; Gouveia, G.L.; Sobral, B.S.; Spinelli, J.E.; Riva, R.; Capella, A.G.; Silva, B.L. Microstructure and hardness of laser remelted surfaces of Al–5%Cu and Al–4%Cu–1%Ni alloys. J. Alloys Compd. 2023, 954, 170189. [Google Scholar] [CrossRef]

- Wu, T.; Poplawsky, J.D.; Allard, L.F.; Plotkowski, A.; Shyam, A.; Dunand, D.C. Microstructure and strengthening of Al-6Ce-3Ni-0.7Fe (wt.%) alloy manufactured by laser powder-bed fusion. Addit. Manuf. 2023, 78, 103858. [Google Scholar] [CrossRef]

- Bahl, S.; Wu, T.; Michi, R.A.; An, K.; Yu, D.; Allard, L.F.; Rakhmonov, J.U.; Poplawsky, J.D.; Fancher, C.M.; Dunand, D.C.; et al. An additively manufactured near-eutectic Al–Ce–Ni–Mn–Zr alloy with high creep resistance. Acta Mater. 2024, 268, 119787. [Google Scholar] [CrossRef]

- Grejtak, T.; Shyam, A.; Blau, P.J.; Qu, J. Additively manufactured and cast high-temperature aluminum alloys for electric vehicle brake rotor application. Wear 2025, 1, 205961. [Google Scholar] [CrossRef]

- Akopyan, T.K.; Letyagin, N.V.; Avxentieva, N.N. High-tech alloys based on Al–Ca–La(–Mn) eutectic system for casting, metal forming and selective laser melting. NFM 2020, 1, 52–59. [Google Scholar] [CrossRef]

- Letyagin, N.V.; Akopyan, T.K.; Palkin, P.A.; Cherkasov, S.O.; Lyukhter, A.B.; Pechnikov, I.S. Laser welding of aluminum-calcium alloys based on ((Al) + Al4(Ca, La)) eutectic. Metallurgist 2024, 68, 692–701. [Google Scholar] [CrossRef]

- Letyagin, N.V.; Akopyan, T.K.; Sokorev, A.A.; Sviridova, T.A.; Cherkasov, S.O.; Mansurov, Y.N. The Characterization of Coatings Formed on As-Cast Al, Al–Si, and Al–Ca Aluminum Substrates by Plasma Electrolytic Oxidation. Metals 2023, 13, 1509. [Google Scholar] [CrossRef]

- Belov, N.A.; Naumova, E.A.; Doroshenko, V.V.; Korotkova, N.O.; Avxentieva, N.N. Determination of the Parameters of a Peritectic Reaction that Occurred in the Al-Rich Region of the Al–Ca–Mn System. Phys. Met. Metallogr. 2022, 123, 759–767. [Google Scholar] [CrossRef]

- Belov, N.A.; Naumova, E.A.; Bazlova, T.A.; Doroshenko, V.V. Phase Composition and Hardening of Castable Al–Ca–Ni–Sc Alloys Containing 0.3% Sc. Met. Sci. Heat Treat. 2017, 59, 76–81. [Google Scholar] [CrossRef]

- Akopyan, T.K.; Belov, N.A.; Letyagin, N.V.; Cherkasov, S.O.; Nguen, X.D. Description of the New Eutectic Al-Ca-Cu System in the Aluminum Corner. Metals 2023, 13, 802. [Google Scholar] [CrossRef]

- Shen, T.; Zhang, S.; Liu, Z.; Yu, S.; Jiang, J.; Tao, X.; Akopyan, T.; Belov, N.; Yao, Z. Convert Harm into Benefit: The Role of the Al10CaFe2 Phase in Al–Ca Wrought Aluminum Alloys Having High Compatibility with Fe. Materials 2023, 16, 7488. [Google Scholar] [CrossRef] [PubMed]

- Akopyan, T.K.; Belov, N.A.; Naumova, E.A.; Letyagin, N.V.; Sviridova, T.A. Al-matrix composite based on Al−Ca−Ni−La system additionally reinforced by L12 type nanoparticles. Trans. Nonferrous Met. Soc. China 2022, 30, 850–862. [Google Scholar] [CrossRef]

- Shurkin, P.K.; Letyagin, N.V.; Yakushkova, A.I.; Samoshina, M.E.; Ozherelkov, D.Y.; Akopyan, T.K. Remarkable thermal stability of the Al–Ca–Ni–Mn alloy manufactured by laser-powder bed fusion. Mater. Lett. 2021, 285, 129074. [Google Scholar] [CrossRef]

- Preußner, J.; Rödler, G.; Fischer, F.G.; Hintz, K.; Friedmann, V.; Weisheit, A. Additive manufacturing of a lightweight Al–Ca alloy by direct energy deposition and laser powder bed fusion. Pract. Metallogr. 2023, 60, 704–715. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, M.; Yu, X.; Zhang, Z.; Cai, D.; Shen, B.; Long, J.; Sun, Y. Microstructure and Mechanical Properties of a Novel Lightweight and Heat-Resistant Al–3.0Ce–0.9Ca–1.9Mn–1.2Zr Alloy Fabricated by Selective Laser Melting. Coatings 2025, 15, 247. [Google Scholar] [CrossRef]

- Rakhmonov, J.U.; Weiss, D.; Dunand, D.C. Comparing evolution of precipitates and strength upon aging of cast and la-ser-remelted Al–8Ce–0.2Scv0.1Zr (wt.%). Mater. Sci. Eng. A 2022, 840, 142990. [Google Scholar] [CrossRef] [PubMed]

- Rogachev, S.O.; Naumova, E.A.; Komissarov, A.A.; Vasina, M.A.; Pavlov, M.D.; Tokar, A.A. Effect of laser surface modification on the structure and mechanical properties of Al–8%Ca, Al–10%La, Al–10%Ce, and Al–6%Ni eutectic aluminum alloys. Izv. Vuzov Tsvetnaya Metall. 2022, 28, 58–70. [Google Scholar] [CrossRef]

- Nunes, A.T.; Gouveia, G.L.; Riva, R.; Capella, A.G.; Garcia, A.; Spinelli, J.E. Laser resolidification of Al–5Mg–0.1Sc alloy: Growth of cells and banded structures. J. Alloys Compd. 2024, 973, 172889. [Google Scholar] [CrossRef]

- Zhang, C.; Chai, L.; Liu, Y.; Li, Z.; Zhang, F.; Li, X.; Fu, Z. Correlating microstructural features with improved wear and corrosion resistance of laser surface remelted A356 alloy at different scanning speeds. Mater. Charact. 2023, 202, 113021. [Google Scholar] [CrossRef]

- Shelekhov, E.V.; Sviridova, T.A. Programs for X-ray analysis of polycrystals. Met. Sci. Heat Treat. 2000, 42, 309–313. [Google Scholar] [CrossRef]

- Huber, S.; Glasschroeder, J.; Zaeh, M.F. Analysis of the Metal Vapour during Laser Beam Welding. Phys. Procedia 2011, 12, 712–719. [Google Scholar] [CrossRef][Green Version]

- Huang, Y.; Shen, C.; Ji, X.; Li, F.; Zhang, Y.; Hua, X. Correlation between gas-dynamic behaviour of a vapour plume and oscillation of keyhole size during laser welding of 5083 Al alloy. J. Mater. Process. Technol. 2020, 283, 116721. [Google Scholar] [CrossRef]

- Knipling, K.E.; Dunand, D.C.; Seidman, D.N. Precipitation evolution in Al–Zr and Al–Zr–Ti alloys during aging at 450–600 °C. Acta Mat. 2008, 56, 1182–1195. [Google Scholar] [CrossRef]

- Cinkilic, E.; Yan, X.; Luo, A.A. Modeling Precipitation Hardening and Yield Strength in Cast Al–Si–Mg–Mn Alloys. Metals 2020, 10, 1356. [Google Scholar] [CrossRef]

- Orlova, T.S.; Latynina, T.A.; Mavlyutov, A.M.; Murashkin, M.Y.; Valiev, R.Z. Effect of annealing on microstructure, strength and electrical conductivity of the pre-aged and HPT-processed Al–0.4Zr alloy. J. Alloys Compd. 2019, 784, 41–48. [Google Scholar] [CrossRef]

- Mohammadi, A.; Enikeev, N.A.; Murashkin, M.Y.; Arita, M.; Edalati, K. Developing age-hardenable Al–Zr alloy by ultra-severe plastic deformation: Significance of supersaturation, segregation and precipitation on hardening and electrical conductivity. Acta Mater. 2021, 203, 116503. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).