Non-Isothermal Process of Liquid Transfer Molding: Transient 3D Simulations of Fluid Flow Through a Porous Preform Including a Sink Term

Abstract

1. Introduction

2. Methodology

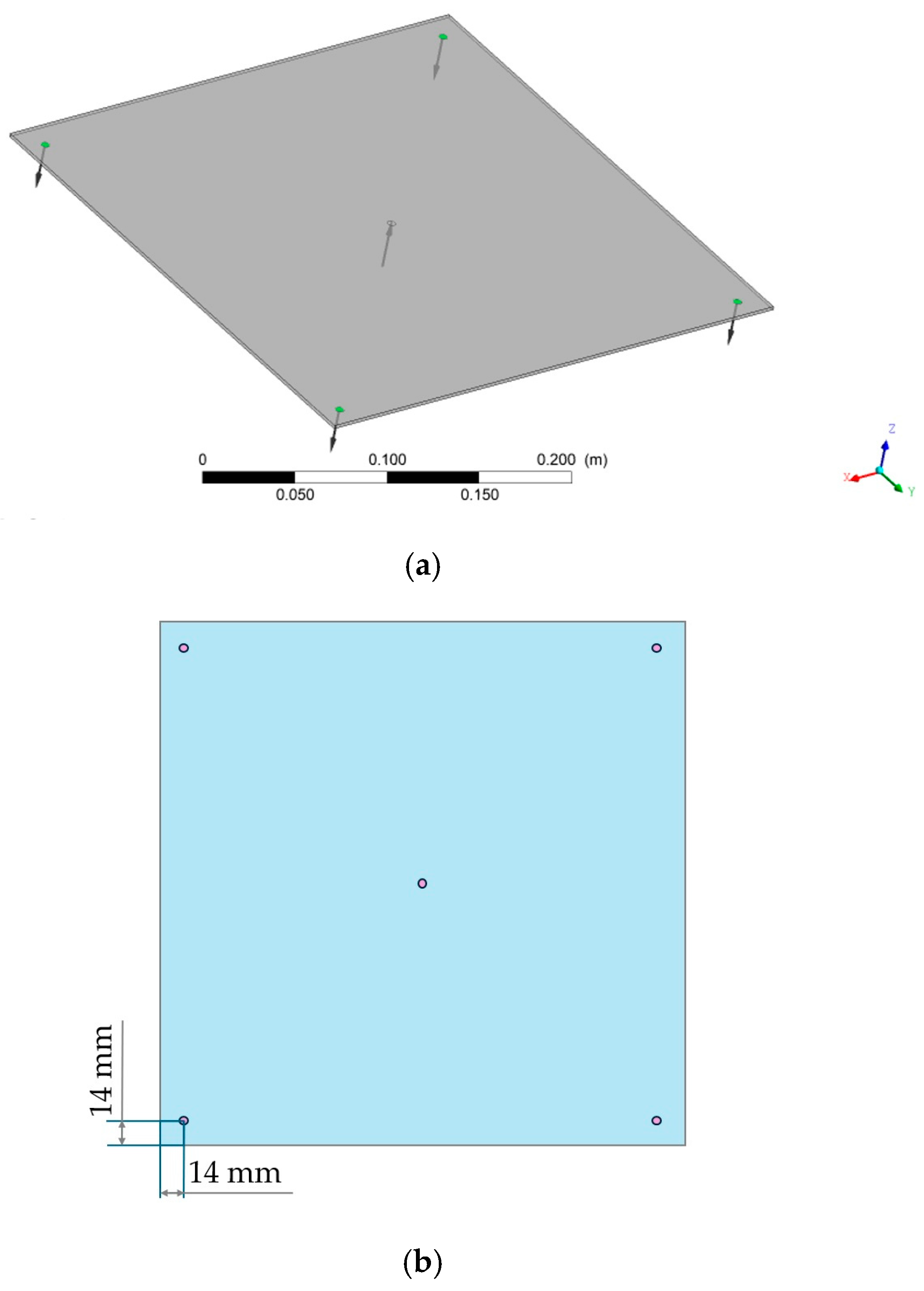

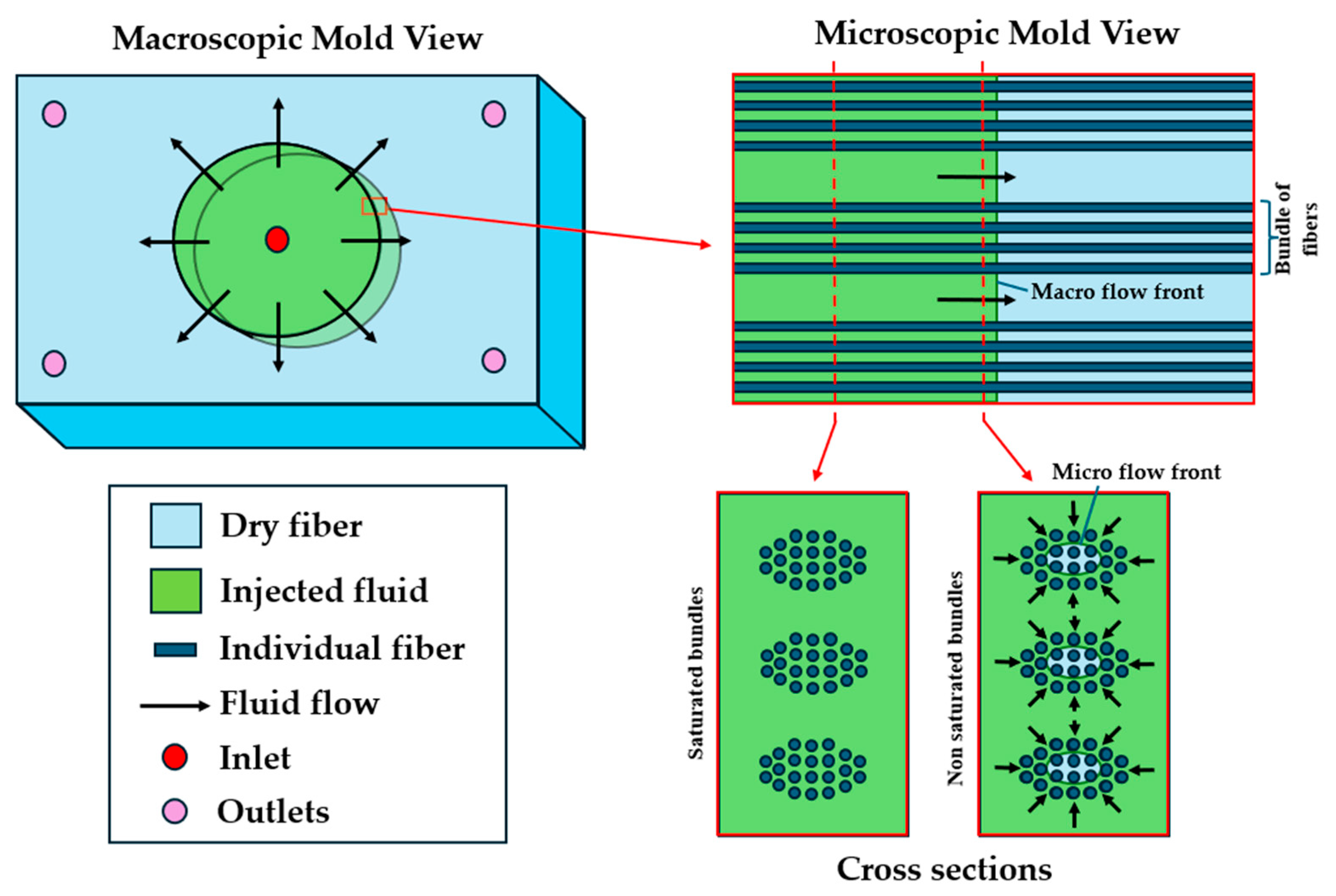

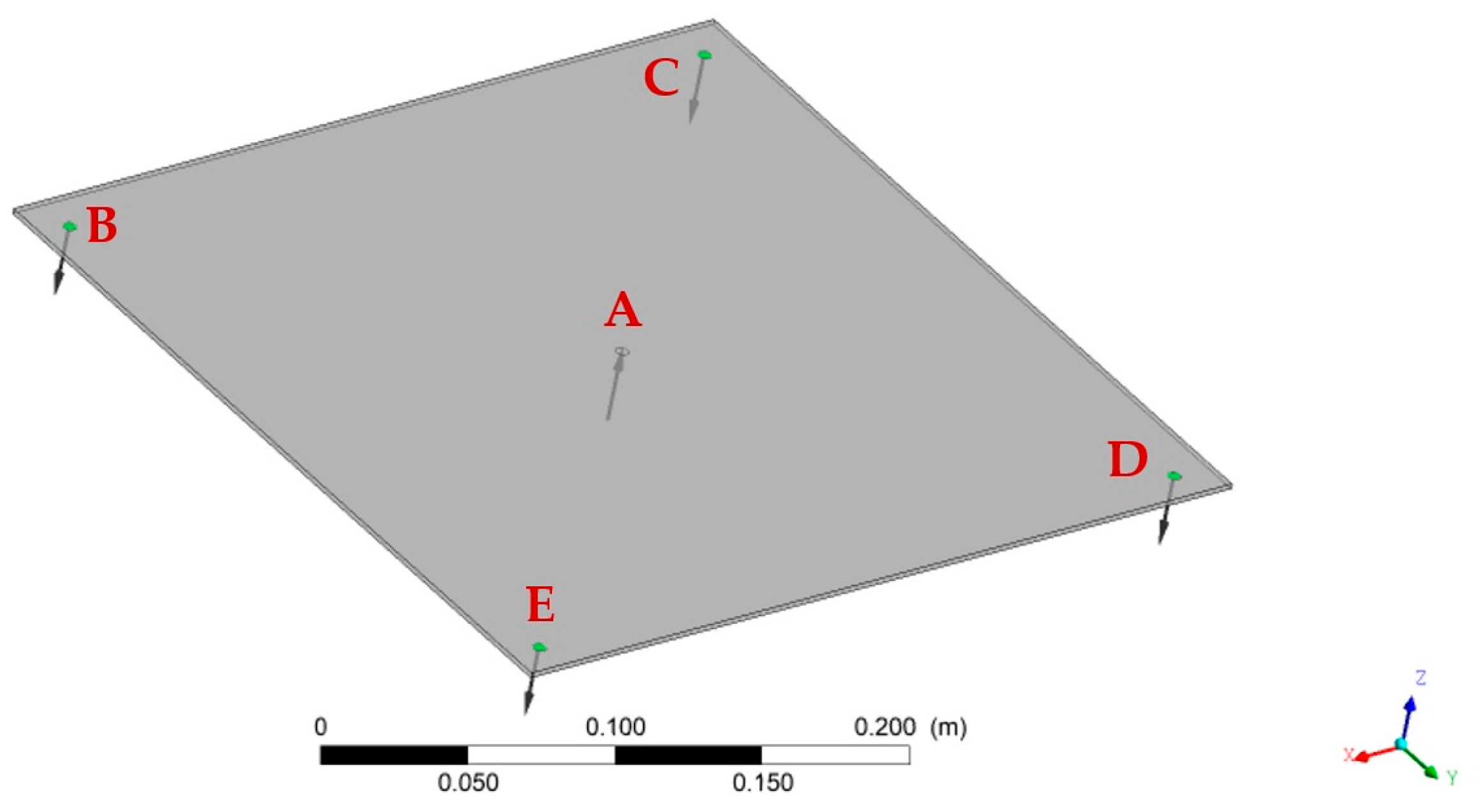

2.1. The Physical Problem and Mold Geometry

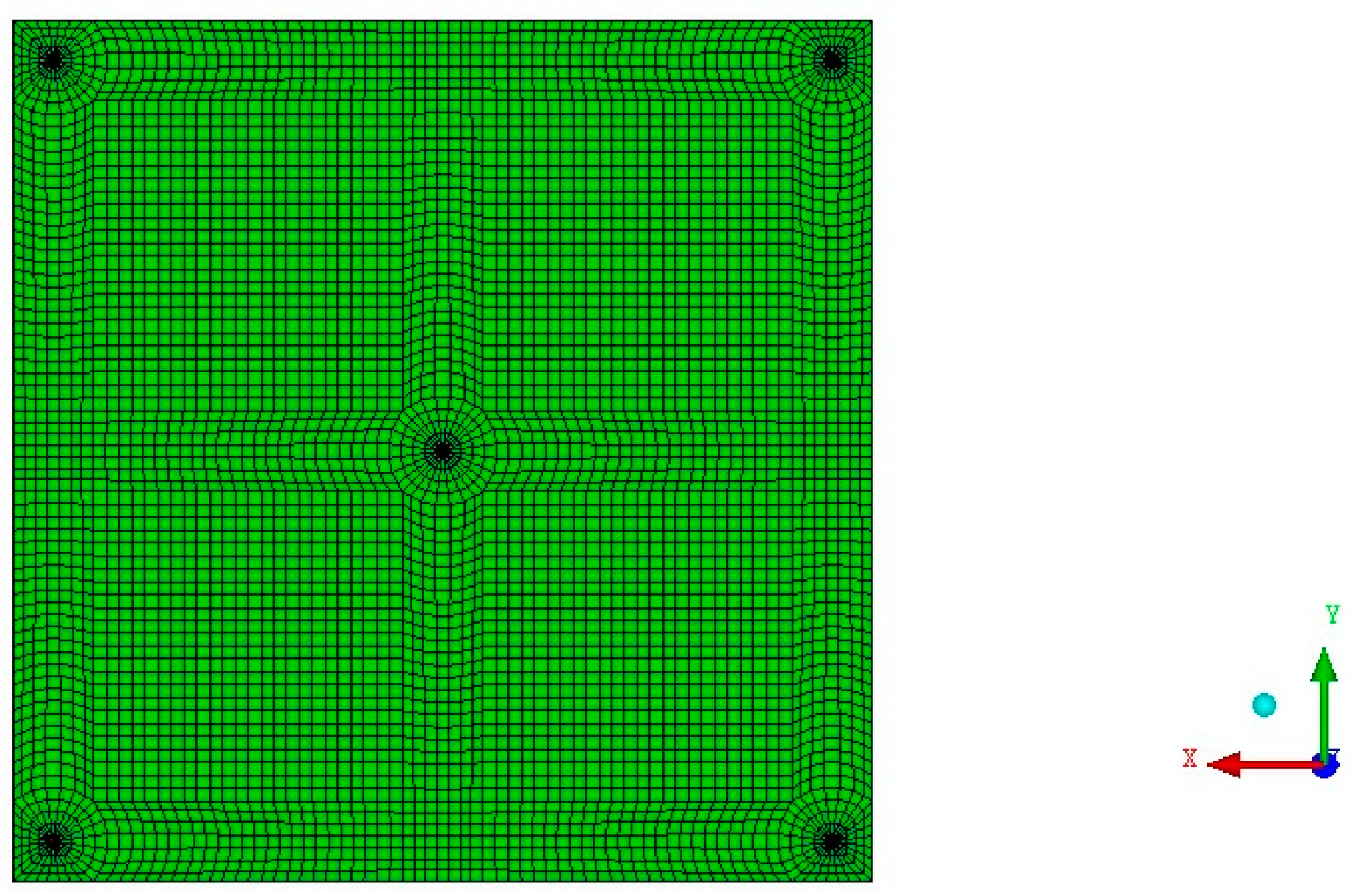

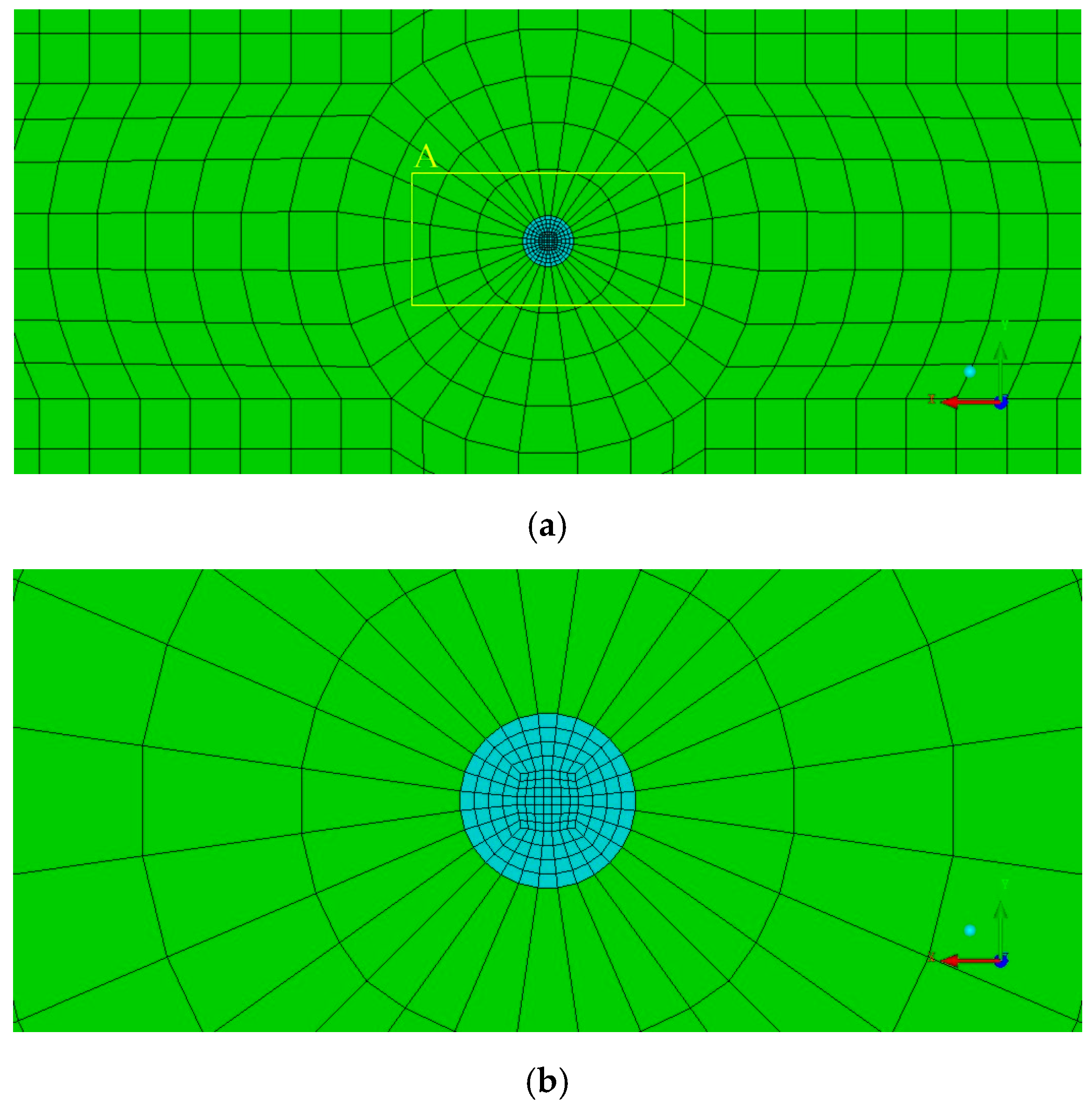

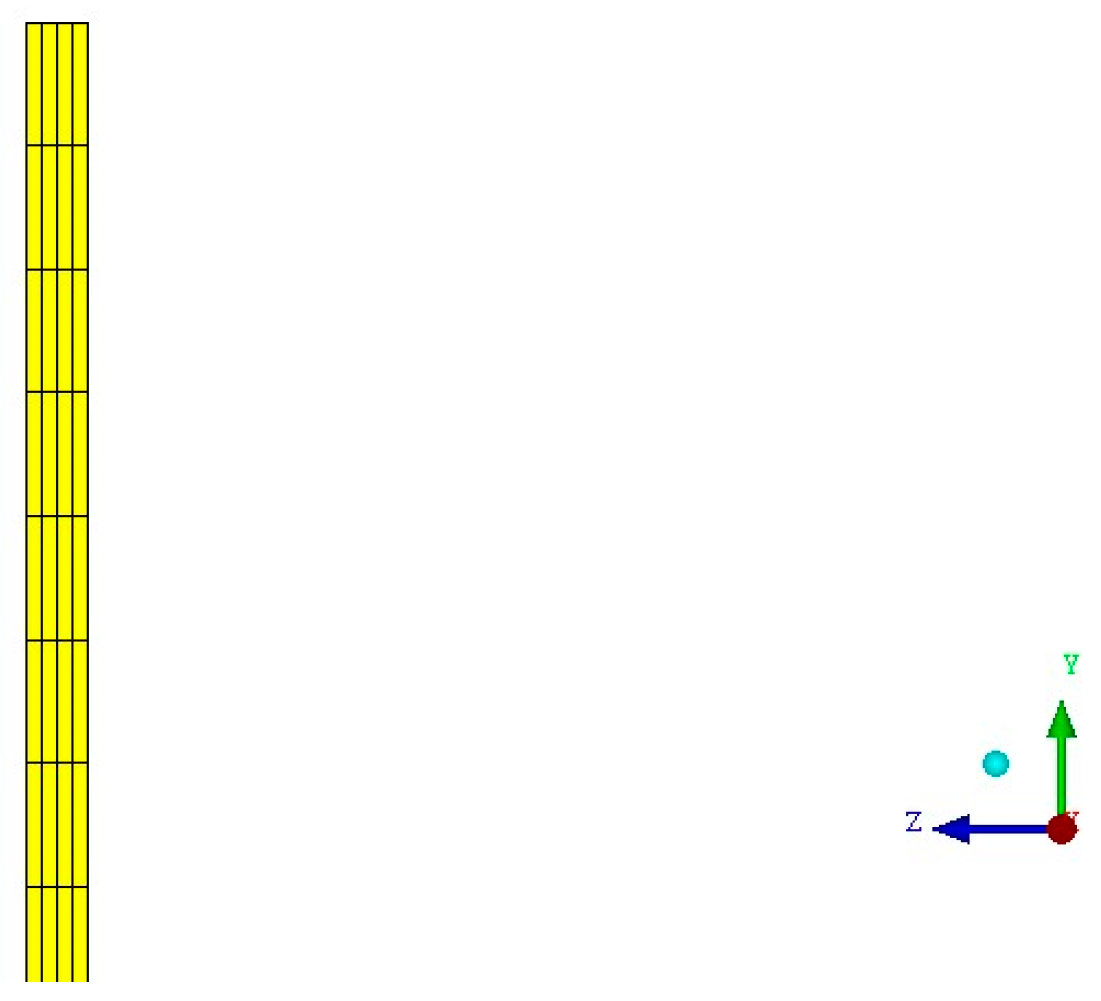

2.2. Numerical Mesh

2.3. Mathematical Modeling

2.3.1. The Conservation Equations

- (a)

- Three-dimensional, transient, non-isothermal, and laminar flow;

- (b)

- Incompressible fluid;

- (c)

- Isotropic porous medium;

- (d)

- No internal heat generation;

- (e)

- The injection pressure and viscosity of the injected fluid are variables;

- (f)

- The phenomenon of absorption of the injected fluid by the fibrous reinforcement is considered.

- (a)

- Mass conservation equation:

- (b)

- Linear Momentum Conservation Equation:

- (c)

- Energy Conservation Equation:

- For the injected fluid, it was calculated as follows:

- For the air, it was calculated as follows:

- For the porous medium (fibrous preform), it was calculated as follows:

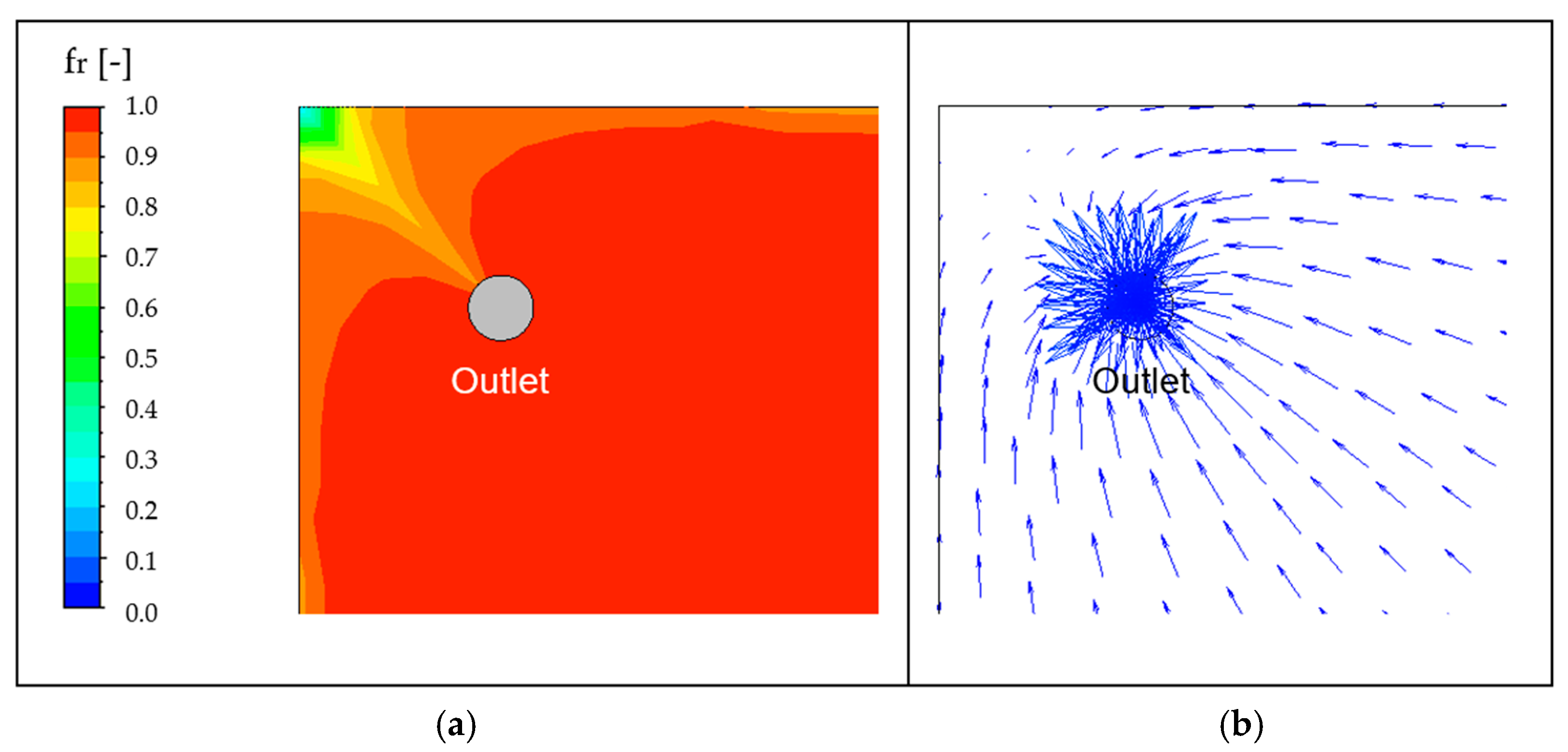

2.3.2. Boundary Conditions

- (a)

- Injection channel (point A):

- (b)

- Output channels (points B–E):

- (c)

- Mold walls:

- (d)

- Porous medium:

2.4. Properties of Materials

| Property | Value (for s = 0.0 × 10−4 s−1) | Value (for s = 0.5 × 10−4 s−1) |

|---|---|---|

| Porosity (-) 1 | 0.5783 | |

| Permeability (m2) | 4.50 × 10−11 | 4.25 × 10−11 |

| Density (kg/m3) 2 | 2575 | |

| Specific heat (kJ/kg.K) 2 | 0.8025 | |

| Thermal conductivity (W/m.K) 2 | 1.275 | |

| Property | Value |

|---|---|

| Dynamic viscosity (cP) | Equation (14) |

| Density (kg/m3) 1 | 913.9 |

| Specific heat (kJ/kg.K) 2 | 1.9348 |

| Thermal conductivity (W/m.K) 2 | 0.1533 |

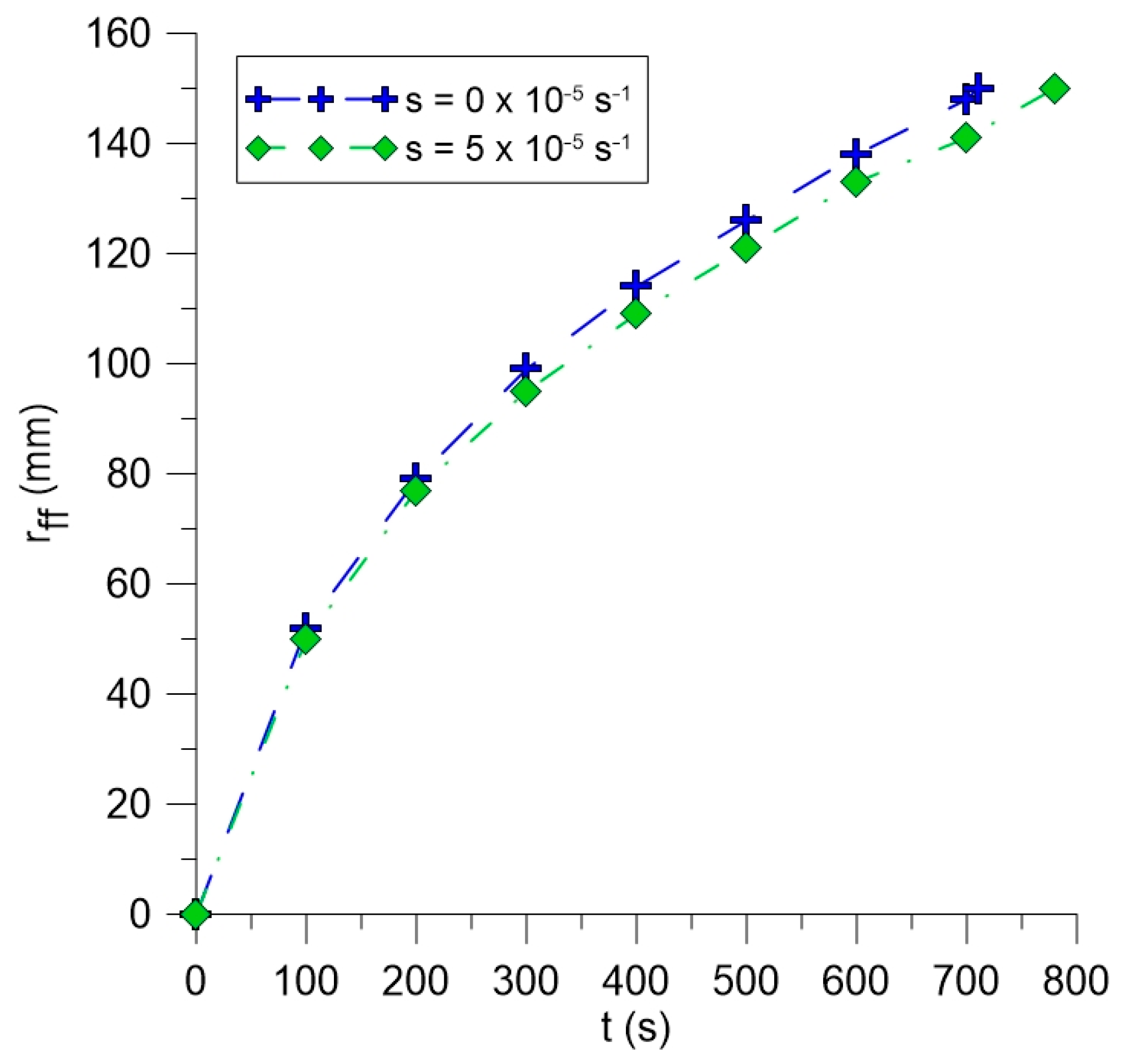

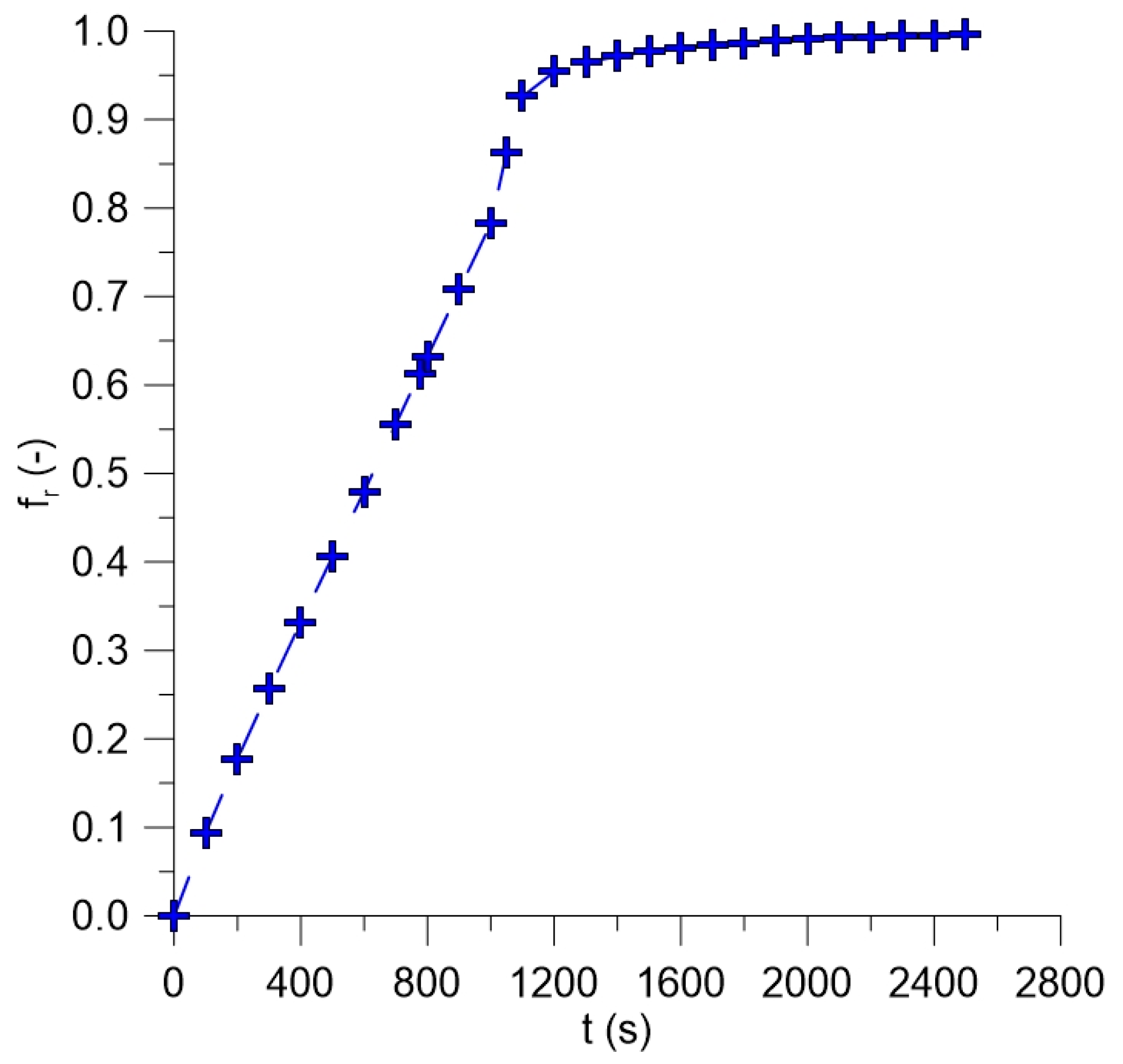

3. Results and Discussion

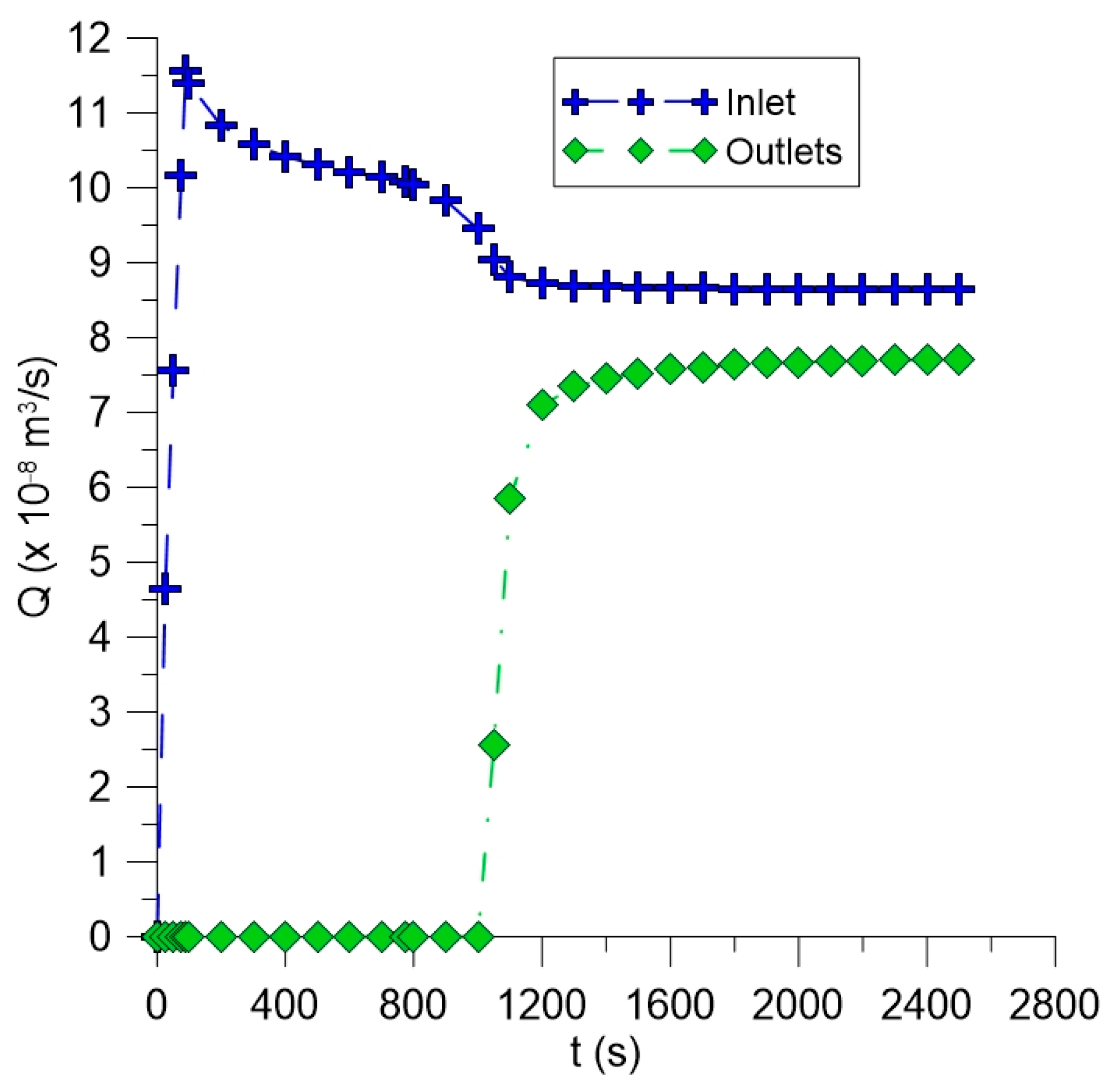

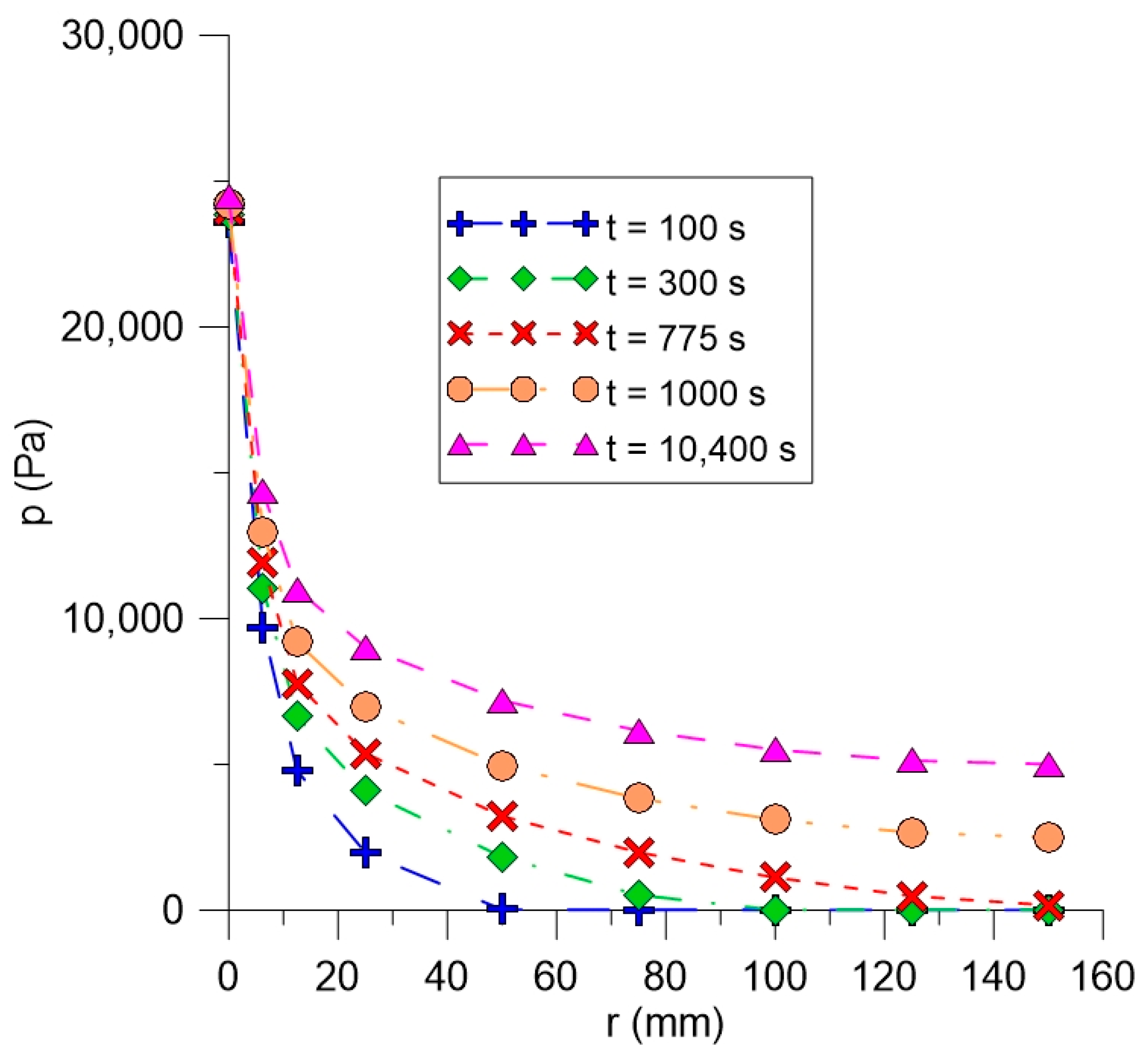

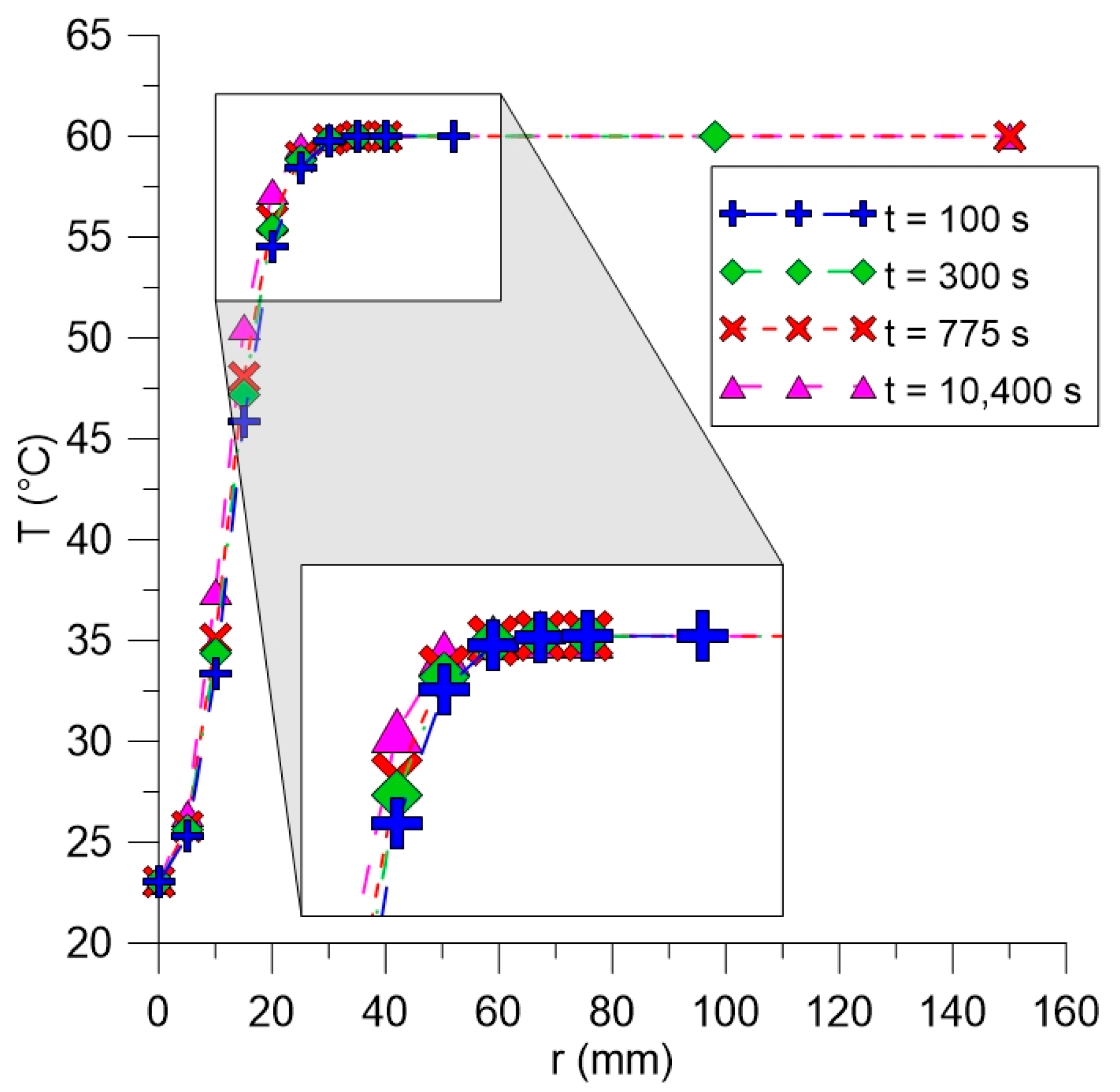

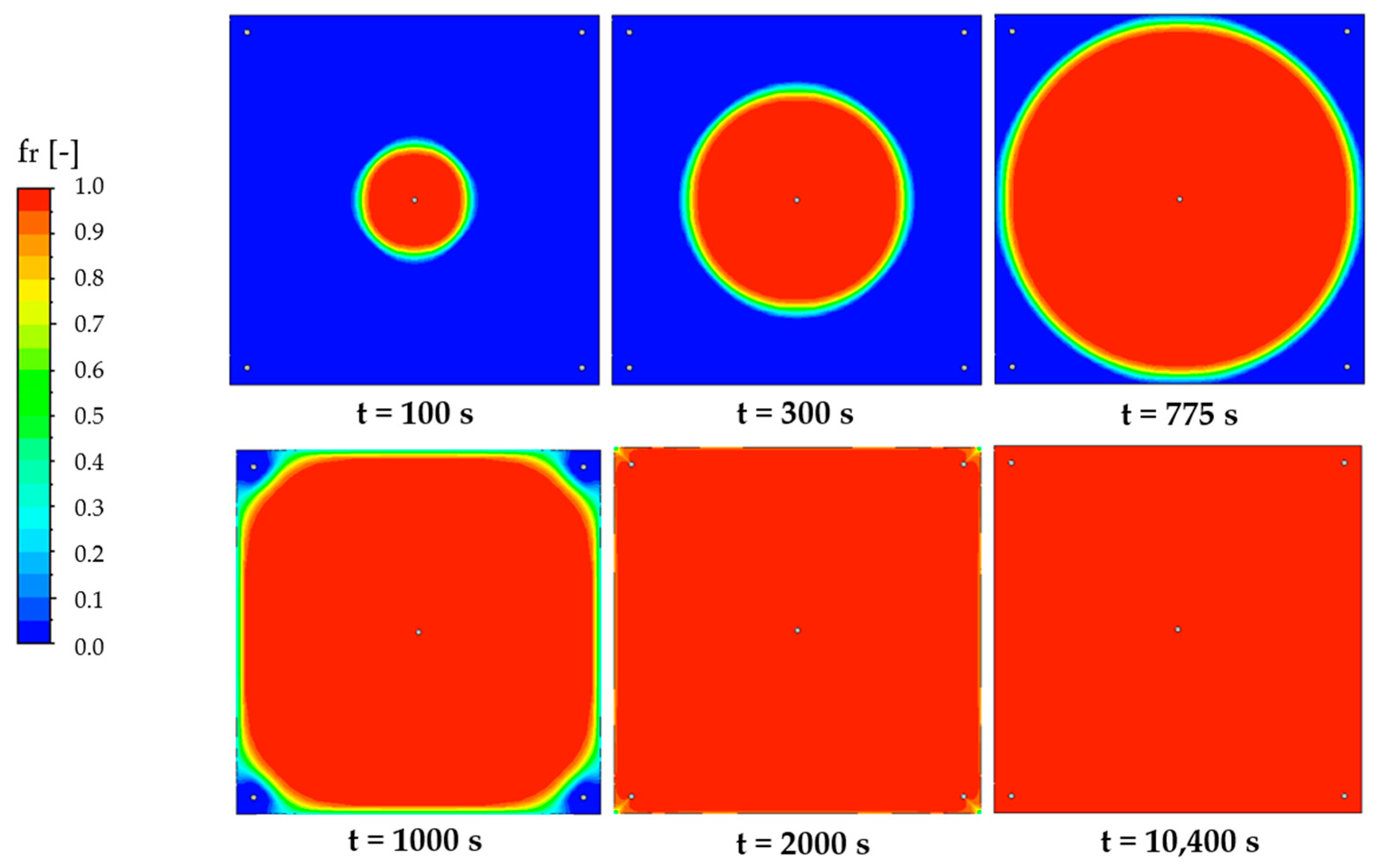

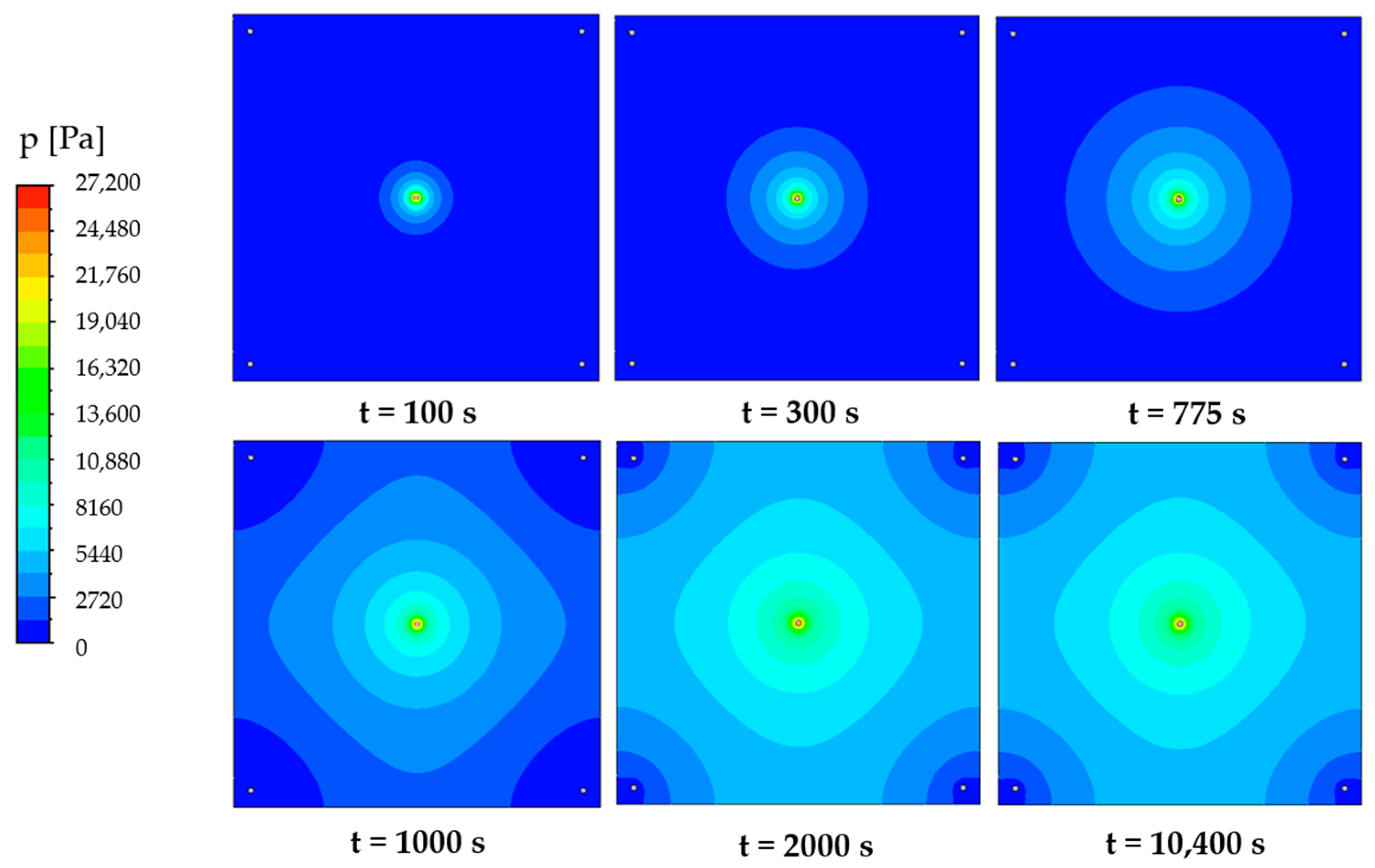

3.1. Thermo-Fluid Dynamic Analysis of Flow

3.2. Robustness and Limitations of the Proposed Model

- (a)

- Due to the implementation of a constant sorption source term in the model, there is no identification of the saturation limit of the micropores of the fibers;

- (b)

- The phenomenon of thermal expansion of the mold (mechanical and thermal) is not taken into account;

- (c)

- The effect of the infiltration of the injected fluid into the individual fibers, such as swelling of the fibers, is not taken into account;

- (d)

- Different microscopic effects (trapped microvoids, void migration, void compression, and resin microflow) during fiber filling were neglected;

- (e)

- The dimension, shape, orientation, movement, and accommodation of the fibers, interaction between individual fibers, and deformation of the preform were neglected;

- (f)

- Curing effects were neglected;

- (g)

- Modifications in the thickness and deformation of the mold due to the action of pressure inside the closed cavity (mold) and temperature were neglected.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFD | Computational Fluid Dynamic |

| GCI | Global Convergence Index |

| RTM | Resin Transfer Molding |

References

- Mallick, P.K. Fiber-Reinforced Composites: Materials Manufacturing and Design, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2007; pp. 24–41. [Google Scholar]

- Trzepieciński, T.; Najm, S.M.; Sbayti, M.; Belhadjsalah, H.; Szpunar, M.; Lemu, H.G. New Advances and Future Possibilities in Forming Technology of Hybrid Metal-Polymer Composites Used in Aerospace Applications. J. Compos. Sci. 2021, 5, 217. [Google Scholar] [CrossRef]

- Precedence Research. Composites Market. Available online: https://www.precedenceresearch.com/composites-market (accessed on 16 February 2024).

- Oliveira, I.R. Infiltration of Charged Fluids in Porous Media via RTM Process: Theoretical and Experimental Analysis. Ph.D. Thesis, Federal University of Campina Grande, Paraíba, Brazil, 2014. [Google Scholar]

- Greve, L.; Pickett, A.K. Delamination Testing and Modelling for Composite Crash Simulation. Compos. Sci. Technol. 2006, 66, 26–816. [Google Scholar] [CrossRef]

- Ferreira, R. Special Composite Transformation Processes, 1st ed.; Federal Institute of Education, Science and Technology Sul-Rio-Grandense: Sapucaia do Sul, Brazil, 2017; pp. 30–32. [Google Scholar]

- Osborne Industries. How the Resin Transfer Molding Process Works. Available online: https://www.osborneindustries.com/news/resin-transfer-molding-process-works/ (accessed on 29 September 2023).

- Delgado, J.M.P.Q.; Lima, A.G.B.; Santos, M.J.N. Transport Phenomena in Liquid Composite Molding Processes, 1st ed.; Springer: Cham, Switzerland, 2019; pp. 1–86. [Google Scholar]

- Hiremath, P.; Ambiger, K.D.; Jayashree, P.K.; Heckadka, S.S.; Deepak, G.D.; Murthy, B.R.N.; Kowshik, S.; Naik, N. Computational Approach for Optimizing Resin Flow Behavior in Resin Transfer Molding with Variations in Injection Pressure, Fiber Permeability, and Resin Sorption. J. Compos. Sci. 2025, 9, 129. [Google Scholar] [CrossRef]

- Rudd, C.D.; Long, A.C.; Kendall, K.N.; Mangin, C. Liquid Moulding Technologies: Resin Transfer Moulding, Structural Reaction Injection Moulding and Related Processing Techniques, 1st ed.; Woodhead Publishing: Cambridge, UK, 1997; pp. 294–319. [Google Scholar]

- Achim, V.; Ruiz, E. Guiding Selection for Reduced Process Development Time in RTM. Int. J. Mater. Form. 2010, 24, 1277–1286. [Google Scholar] [CrossRef]

- Ruiz, E.; Achim, V.; Soukane, S.; Trochu, F.; Bréard, J. Optimization of Injection Flow Rate to Minimize Micro/Macro-Voids Formation in Resin Transfer Molded Composites. Compos. Sci. Technol. 2006, 66, 475–486. [Google Scholar] [CrossRef]

- Santos, A.C.M.Q.S.; Monticeli, F.M.; Ornaghi, H.; Santos, L.F.P.; Cioffi, M.O.H. Porosity characterization and respective influence on short-beam strength of advanced composite processed by resin transfer molding and compression molding. Polym. Polym. Compos. 2020, 29, 1353–1362. [Google Scholar] [CrossRef]

- bin Sulaiman, A.F.F.; binti Abdullah, F.; bin Osman, E.; Rashidi, S.A.; bin Mohd Jais, G. Feasibility Study on a Fabrication Resin Transfer Molding Machine for Aircraft Part (Hinge) Application. In Proceedings of the 7th International Conference and Exhibition on Sustainable Energy and Advanced Materials (ICE-SEAM 2021), Melaka, Malaysia, 23 November 2021. [Google Scholar] [CrossRef]

- Chen, Z.; Peng, L.; Xiao, Z. Experimental Characterization and Numerical Simulation of Voids in CFRP Components Processed by HP-RTM. Materials 2022, 15, 5249. [Google Scholar] [CrossRef] [PubMed]

- Martins, F.P.; Santos, L.; Torcato, R.; Lima, P.S.; Oliveira, J.M. Reproducibility Study of the Thermoplastic Resin Transfer Molding Process for Glass Fiber Reinforced Polyamide 6 Composites. Materials 2023, 16, 4652. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; Wei, J.; Zhu, Y.; Xu, H.; Liu, D.; Chen, G.; Liu, X.; Dai, J.; Lv, D. Preparation and properties of carbon fiber reinforced bio-based degradable acetal-linkage-containing epoxy resin composites by RTM process. Polym. Compos. 2023, 44, 4081–4094. [Google Scholar] [CrossRef]

- Zhang, C.; Sun, T.; Xu, J.; Shi, X.; Zhang, G. Effect of Mold on Curing Deformation of Resin Transfer Molding-Made Textile Composites. Polym. Compos. 2023, 44, 7599–7610. [Google Scholar] [CrossRef]

- Aldhahri, K.S.; Klosterman, D.A. Additively Manufactured Resin Transfer Molding (RTM) Plastic Tooling for Producing Composite T-joint Structures. Prog. Addit. Manuf. 2025, 10, 2283–2301. [Google Scholar] [CrossRef]

- Wang, X.; Xue, F.; Gu, X.; Xia, X. Simulation of Frost-Heave Failure of Air-Entrained Concrete Based on Thermal–Hydraulic Mechanical Coupling Model. Materials 2024, 17, 3727. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Liu, X.; Zhao, J.; Feng, T.; Guo, W. Plant fiber-reinforced composites based on injection molding process: Manufacturing, service life, and remanufacturing. Polym. Compos. 2024, 45, 4876–4899. [Google Scholar] [CrossRef]

- Song, X.; Grimsley, B.W.; Hubert, P.; Cano, R.J.; Loos, A.C. VARTM Process Modeling of Aerospace Composite Structures. In Proceedings of the American Society for Composites, 17th Technical Conference, West Lafayette, IN, USA, 21–23 October 2002. [Google Scholar]

- Isoldi, L.A.; Oliveira, C.P.; Rocha, L.A.O.; Souza, J.A.; Amico, S.C. Three-Dimensional Numerical Modeling of RTM and LRTM Processes. J. Braz. Soc. Mech. Sci. Eng. 2012, 34, 105–111. [Google Scholar] [CrossRef]

- Oliveira, I.R.; Amico, S.C.; Souza, J.A.; Lima, A.G.B. Resin Transfer Molding Process: A Numerical and Experimental Investigation. Int. J. Multiphysics 2013, 7, 125–135. [Google Scholar] [CrossRef]

- Moumen, A.E.; Saouab, A.; Imad, A.; Kanit, T. Towards a Numerical Modeling of the Coupling Between RTM Process and Induced Mechanical Properties for Rigid Particle-Filled Composites. J. Adv. Manuf. Technol. 2023, 125, 1251–1270. [Google Scholar] [CrossRef]

- Alotaibi, H.; Abeykoon, C.; Soutis, C.; Jabbari, M. Numerical Simulation of Two-Phase Flow in Liquid Composite Moulding Using VOF-Based Implicit Time-Stepping Scheme. J. Compos. Sci. 2022, 6, 330. [Google Scholar] [CrossRef]

- Landi, D.; Vita, A.; Germani, M. Interactive Optimization of the Resin Transfer Molding Using a General-Purpose Tool: A Case Study. Int. J. Interact. Des. Manuf. 2020, 14, 295–308. [Google Scholar] [CrossRef]

- Goh, K.W.; Algot, K.K.; Laxmaiah, G.; Babu, P.R.; Vodnala, V.P.; Zainul, R. Experimental analysis, simulation, and evaluation of process parameters of GFRP composites produced through resin transfer molding. Adv. Manuf. Polym. Compos. Sci. 2025, 11, 2441629. [Google Scholar] [CrossRef]

- Yang, W.; Lu, S.; Xiang, L.; Liu, W. Simulation of Non-Isothermal Resin Transfer Molding Process Cycle and Optimization of Temperature System. J. Reinf. Plast. Compos. 2019, 38, 3–14. [Google Scholar] [CrossRef]

- Pazdzior, P.; Szczepanik, M. Resin Flow Simulation During the RTM Method of Composites Production. Int. J. Mod. Manuf. Technol. 2021, 13, 125–133. [Google Scholar] [CrossRef]

- Seuffert, J.; Rosenberg, R.; Kärger, L.; Henning, F.; Kothmann, M.H.; Deinzer, G. Experimental and Numerical Investigations of Pressure-Controlled Resin Transfer Molding (PC-RTM). Adv. Manuf. Polym. Compos. Sci. 2020, 6, 154–163. [Google Scholar] [CrossRef]

- Shi, F.; Zhao, Z.; Dong, X. An Improved Method of Numerical Simulation of Resin Transfer Molding for Resin-Based Composite Materials Based on Unstructured Grid. Adv. Intell. Syst. Res. 2018, 159, 280–287. [Google Scholar]

- Soares, L.L. Numerical Simulation of the RTM Process for the Infiltration of Thick Reinforcements Considering the Variation of Resin Viscosity as a Function of Temperature and Time. Master’s Dissertation, Federal University of Rio Grande, Rio Grande, Brazil, 2017. [Google Scholar]

- Yang, H.; Hsu, C.C.; Hsu, C.H. Three Dimensional Numerical Simulations for Wet-RTM Process. In Proceedings of the 35th International Conference of the Polymer Processing Society (PPS-35), Cesme-Izmir, Turkey, 26–30 May 2019. [Google Scholar] [CrossRef]

- Shahnazari, M.R.; Abassi, A. Numerical Modeling of Mold Filling and Curing in Non-Isothermal RTM Process. Int. J. Eng. Trans. A Basics 2004, 17, 395–404. [Google Scholar]

- Oliveira, J.S.; Carvalho, L.H.; Delgado, J.M.P.Q.; Lima, A.G.B.; Pereira, A.S.; Franco, C.M.R.; Chaves, F.S. Applying Resin Radial Injection for Manufacturing Fiber-Reinforced Polymer Composite: Advanced Mathematical Modeling and Simulation. Polymers 2024, 16, 3525. [Google Scholar] [CrossRef] [PubMed]

- Santos, P.H.J.; Santos, G.O.; Andrade, M.C.; Santana, P.L.; Pagano, R.L. Mesh Convergence Study for Gas-Liquid Flow Analysis Using the GCI Method. Braz. J. Dev. 2022, 8, 32586–32599. [Google Scholar] [CrossRef]

- Gomez, R.S.; Porto, T.R.N.; Magalhães, H.L.F.; Moreira, G.; André, A.M.M.C.N.; Melo, R.B.F.; Lima, A.G.B. Natural Gas Intermittent Kiln for the Ceramic Industry: A Transient Thermal Analysis. Energies 2019, 12, 1568. [Google Scholar] [CrossRef]

- Celik, I.B.; Ghia, U.; Roache, P.; Freitas, C.J.; Coleman, H.; Raad, P.E. Procedure for Estimation and Reporting of Uncertainty Due to Discretization in CFD Applications. J. Fluids Eng. 2008, 130. [Google Scholar] [CrossRef]

- Ward, J.C. Turbulent Flow in Porous Media. J. Hydraul. Div. 1964, 90, 1–12. [Google Scholar] [CrossRef]

- Luz, F.F. Comparative Analysis of Fluid Flow in RTM Experiments Using Commercial Applications. Master’s Dissertation, Federal University of Rio Grande do Sul, Porto Alegre, Brazil, 2011. Available online: https://lume.ufrgs.br/handle/10183/62075?locale-attribute=en&show=full (accessed on 28 March 2024).

- Azo Materials. E-Glass Fibre. ArticleID = 764. 2024. Available online: https://www.azom.com/properties.aspx? (accessed on 15 April 2024).

- Zhou, Z.; Jiang, B.; Chen, X.; Jiang, F.; Jiang, Y. Rheological Behavior and Process Prediction of Low Viscosity Epoxy Resin for RTM. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2014, 29, 1078–1082. [Google Scholar] [CrossRef]

- Rojas, E.E.G.; Coimbra, J.S.R.; Telis-Romero, J. Thermophysical Properties of Cotton, Canola, Sunflower and Soybean Oils as a Function of Temperature. Int. J. Food Prop. 2013, 16, 1620–1629. [Google Scholar] [CrossRef]

- Microelectronics Heat Transfer Laboratory. Fluid Properties Calculator. 2024. Available online: http://www.mhtl.uwaterloo.ca/old/onlinetools/airprop/airprop.html (accessed on 15 April 2024).

- Luz, F.F.; Amico, S.C.; Cunha, A.L.; Barbosa, E.S.; Lima, A.G.B. Applying Computational Analysis in Studies of Resin Transfer Moulding. Def. Diff. Forum 2012, 326, 158–163. [Google Scholar] [CrossRef]

- Luz, F.F.; Amico, S.C.; Souza, J.A.; Barbosa, E.S.; Lima, A.G.B. Resin Transfer Molding Process: Fundamentals, Numerical Computation and Experiments. In Numerical Analysis of Heat and Mass Transfer in Porous Media. Series: Advanced Structured Materials, 1st ed.; Delgado, J.M.P.Q., Barbosa de Lima, A.G., Vázquez da Silva, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; Volume 27, pp. 121–151. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Dynamic viscosity (kg/m.s) | 2.0061 × 10−5 |

| Density (kg/m3) | 1.0597 |

| Specific heat (kJ/kg.K) | 1.0081 |

| Thermal conductivity (W/m.K) | 0.028517 |

| s (×10−4 s−1) | texp (s) 1 | tnum (s) | Error (%) |

|---|---|---|---|

| 0.0 | 780 | 708 | −9.23 |

| 0.5 | 780 | 775 | −0.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sousa, J.V.N.; Delgado, J.M.P.Q.; Gomez, R.S.; Magalhães, H.L.F.; Lima, F.S.; Brito, G.R.F.; Alves, R.M.N.; Vieira, F.F.; Luiz, M.R.; Santos, I.B.; et al. Non-Isothermal Process of Liquid Transfer Molding: Transient 3D Simulations of Fluid Flow Through a Porous Preform Including a Sink Term. J. Manuf. Mater. Process. 2025, 9, 243. https://doi.org/10.3390/jmmp9070243

Sousa JVN, Delgado JMPQ, Gomez RS, Magalhães HLF, Lima FS, Brito GRF, Alves RMN, Vieira FF, Luiz MR, Santos IB, et al. Non-Isothermal Process of Liquid Transfer Molding: Transient 3D Simulations of Fluid Flow Through a Porous Preform Including a Sink Term. Journal of Manufacturing and Materials Processing. 2025; 9(7):243. https://doi.org/10.3390/jmmp9070243

Chicago/Turabian StyleSousa, João V. N., João M. P. Q. Delgado, Ricardo S. Gomez, Hortência L. F. Magalhães, Felipe S. Lima, Glauco R. F. Brito, Railson M. N. Alves, Fernando F. Vieira, Márcia R. Luiz, Ivonete B. Santos, and et al. 2025. "Non-Isothermal Process of Liquid Transfer Molding: Transient 3D Simulations of Fluid Flow Through a Porous Preform Including a Sink Term" Journal of Manufacturing and Materials Processing 9, no. 7: 243. https://doi.org/10.3390/jmmp9070243

APA StyleSousa, J. V. N., Delgado, J. M. P. Q., Gomez, R. S., Magalhães, H. L. F., Lima, F. S., Brito, G. R. F., Alves, R. M. N., Vieira, F. F., Luiz, M. R., Santos, I. B., Silva, S. K. B. M., & Lima, A. G. B. (2025). Non-Isothermal Process of Liquid Transfer Molding: Transient 3D Simulations of Fluid Flow Through a Porous Preform Including a Sink Term. Journal of Manufacturing and Materials Processing, 9(7), 243. https://doi.org/10.3390/jmmp9070243