Abstract

To obtain enough hardness of the die-quenched products after hot stamping using direct resistance heating, the effects of the electrifying condition and initial microstructure of the quenchable steel sheet on hardness were examined in a hot bending experiment. The steel sheet was heated up to 900 °C in 3 to 10 s. The required heating time was shortened by normalising heat treatment due to the fine grain size of the sheet. The standard deviation of the hardness of the sheet heated to 900 °C in 3.2 s without temperature holding at the austenitising temperature was 12 HV, whereas the deviation reduced to 5 HV for temperature holding at the austenitising temperature of 3 s.

1. Introduction

To reduce the weight and improve the crash safety of automobiles, hot stamping of quenchable steel sheets is useful. By heating the steel sheets, the forming load is remarkably reduced, springback is prevented, and formability is improved [1]. The stamped parts are hardened by quenching with dies, and thus ultra-high strength steel parts with a tensile strength of approximately 1.5 GPa are obtained under a low forming load. In hot stamping, the quenchable steel sheets are heated to approximately 900 °C to transform the sheets to the austenite phase during heating [2]. The sheets are generally heated by a furnace in the conventional warm and hot stamping. So, the temperature decreases due to the takeout procedure of the specimen from the furnace. In addition, the oxidation of the heated sheets occurs due to the forming setup and procedure. Therefore, rapid heating of the sheet is vital to reduce the oxidation scale. By changing the layout of the electrodes, the resistance heating is applicable to heat the sheets. Utilising resistance heating is a rapid way to synchronise with a press, and has higher energy efficiency than the other heating methods such as induction heating.

Mori et al. [3] developed a hot stamping process using rapid resistance heating to improve the productivity and investment cost. The sheets are heated for only 2 s to 900 °C required for quenching. The oxide scale of the products is hardly generated by rapid heating [4]. The efficiency of resistance heating is higher than that of induction heating employed by Kolleck et al. [5] due to the direct passage of current through the sheets. Maki et al. [6] studied the feasibility of hot stamping and press quenching of ultra-high strength steel sheet of SPFC980Y using resistance heating. Ozturk et al. [7] used resistance heating in the hot stamping process of titanium alloy sheets.

Aluminium-coated sheets are mostly utilised in hot stamping process to prevent the oxide scale; however, utilising coated steel sheets are limited in hot stamping using resistance heating due to the evolution of intermetallic layer in the furnace. Lee et al. [8] examined the heating of aluminium-coated sheets using direct resistance heating and pointed out the related difficulty. Maeno et al. [9] investigated ultrasonic cleaning with a diluted hydrochloric acid solution to remove the thin oxide scale in hot stamping of non-coated 22MnB5 sheet using resistance heating. The results indicated that the ultrasonic cleaning with diluted hydrochloric acid could successfully remove the thin oxide scale and the cleaned surface had sufficient quality for welding and painting. However, the heating of the coated steel sheet using resistance heating is significantly longer than that of uncoated steel sheet and the productivity of hot stamping of coated steel sheets are low.

Roller hearth furnace is generally employed in hot stamping to heat steel sheets continuously. The heating speed, in this case, is comparatively slow, and thus the heated sheets are fully austenitised to undergo a martensitic transformation by rapid cooling. In addition, the gradual heating speed is suitable to generate an intermetallic compound having high oxidation prevention for aluminium- and zinc-coated sheets [10]. On the other hand, rapid resistance heating is too fast to austenitise the steel sheets fully. Quan et al. [11] investigated the effect of austenite’s holding time on phase transformation by finite element analysis. They showed that the final martensite volume fraction changed with an increase of the holding time in the austenite temperature range of 800–900 °C. Zhang et al. [12] studied the phase transformation in the hot stamping process of USIBOR 1500 high-strength steel based on the Kirkaldy-Venugopalan model during the pressure holding quenching process. Pedraza et al. [13] studied the effect of rapid heating and fast cooling on the transformation behaviour and mechanical properties of 22MnB5 steel. Mori et al. [14] developed smart hot stamping of ultra-high strength steel products using rapid resistance heating and mechanical servo press. Löbbe et al. [15] examined the influence of various austenitisation parameters such as rapid heating and cooling on the mechanical properties in hot stamping of ultra-high strength steel sheets.

Not only the hot stamping process but also the warm stamping process is also attractive and useful due to low heating temperature and oxidation. Mori et al. [16] investigated the warm stamping of ultra-high strength steel sheets using rapid resistance heating around a heating temperature of 300 °C. The increase in hardness in this case is related to the transformation of retained austenite into martensite at comparatively low temperatures using rapid resistance heating and cooling. Sun et al. [17] investigated the ductility and post-form strength to form a martensitic steel MS1180 into a complex-shaped component using a fast-warm stamping technique at the forming temperature range of 400–450 °C with the heating rate over 50 °C/s. Liu et al. [18] studied the characterization of thermomechanical boundary conditions of non-alloy martensitic steel for a fast forming process.

Rapid cooling is one of the essential parameters to harden the formed parts in die quenching. On the other hand, the cooling rate of die quenching is lower than that of water quenching due to low heat transfer. Hoffmann et al. [19] concluded that the cooling speed of die quenching is influenced by the die pressure and a large holding force is required to increase the cooling speed during die quenching. Nürnberger et al. [20] studied the hot stamping of heat treatable steel 22MnB5 using water-air spray cooling. Ota et al. [21] improved the formability by partial air cooling of potential cracking regions of blank to harden them before forming. Zhao et al. [22] showed high hardness and minimum springback of a hot-stamped part by using rapid cooling to a forming temperature between 700 and 750 °C after ejecting from the furnace. Lee et al. [23] designed a slice die to improve the cooling rate of the blank during hot stamping and the quenching process.

The productivity of hot stamping is lower than that in cold stamping due to the requirement of holding at the bottom dead centre for die-quenching. Behrens et al. [24] decreased the holding time by spraying water cooling just after removal of the stamped-parts from the tools. Maeno et al. [25] improved and shortened the holding time for die quenching by the water and die quenching process in the hot deep drawing test. They reduced the holding time for hardening due to the high cooling speed of the water. Nakagawa et al. [26] reduced the holding time at bottom dead centre in hot stamping by water and die quenching using submerged tools.

In the present study, the hardening behaviour of an uncoated quenchable steel sheet for hot stamping using rapid resistance heating was examined in a hot bending experiment to obtain full hardening of the products. To achieve full hardening, the heating rate was decreased, and the holding at the austenitising temperature was performed in hot stamping using resistance heating.

2. Hot Stamping Using Direct Resistance Heating

2.1. Hot Stamping Having Simultaneous Heating of Next Blank with the Die Quenching

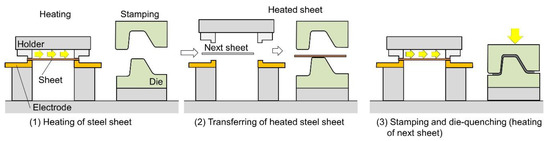

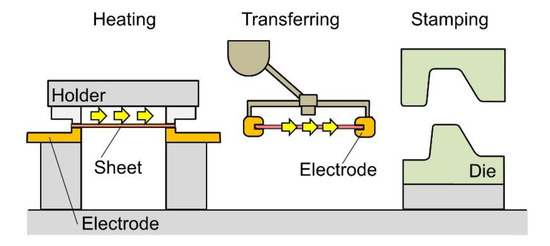

Resistance heating is attractive for downsizing the hot stamping processes. In resistance heating, steel sheets are Joule-heated by passing current between both the edge electrodes. A hot stamping process having simultaneous heating of the next blank with the die quenching and its time table are shown in Figure 1 and Figure 2, respectively. For furnace heating, the blanks are in a furnace where the temperature is kept constant. So, it is easy to match the timing of taking out the heated blank from the furnace with the finishing of the stamping of the preceded products. On the other hand, for direct resistance heating, heating must be complete just before the die quenching. The heating starts after the die quench of the preceded products, and the die lies idle until the end of heating. The synchronising of direct resistance heating and die-quenching improve the productivity of hot stamping. In addition, having the heating time shorter than the die quenching time is desirable to avoid the bottleneck.

Figure 1.

Hot stamping having simultaneous heating of next blank with the die quenching.

Figure 2.

Time table of hot stamping having simultaneous heating of next blank with the die quenching.

2.2. Experimental Procedure of Hat-Shaped Bending Using Direct Resistance Heating

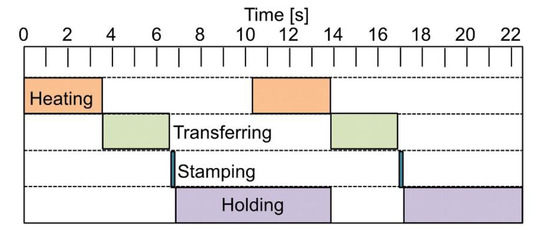

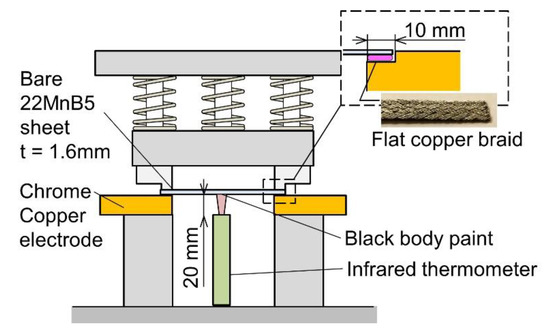

Non-coated 22MnB5 steel sheets are bent into hat-shapes in hot stamping using direct resistance heating to investigate the effects of the resistance heating conditions on hardening behaviour in hot stamping. The details of the used electrodes and dies in the experiment are shown in Figure 3 and Figure 4, respectively. The equipment for resistance heating and the bending dies were installed in a 1500 kN CNC servo press. A typical uncoated quenchable steel sheet non-coated 22MnB5 having 1.6 mm in thickness was used for the experiment. The length, width and thickness of the 22MnB5 sheet were 155, 90 and 1.6 mm, respectively, and the heating temperature was 900 °C.

Figure 3.

Resistance heating equipment for hot stamping of hat-shaped bending.

Figure 4.

Dies used for hot stamping of hat-shaped bending.

Both ends of the steel sheet in the longitudinal direction were sandwiched between the chromium copper electrode and the stainless-steel holder under a pressure of 1.4 MPa. The blank was heated by the passage of direct current for several seconds. To heat the sheet uniformly, flat copper braids were inserted at the interface between the electrode and the steel sheet to obtain the uniform distribution in electrical contact resistance as shown in Figure 3. The heated blank was released from the holder immediately after heating and was transferred to the hat-shaped bending dies with a pneumatic cylinder. The heated sheet was bent and die-quenched under the conditions of stamping shown in Table 1. Each experiment was performed three times to verify the repeatability of the experiments.

Table 1.

Conditions used for hot stamping of hat-shaped bending.

It is important to precisely measure the temperature of the blank in hot stamping. However, it is not easy to measure temperature in resistance hating because the electrical noise is significant for thermocouple, and emissivity changes with the growth of the oxide layer for infrared thermometers. In this study, the temperature was measured with a spot type infrared thermometer as shown in Figure 3. The centre portion of the lower surface of the blank was painted by a black body paint, the temperature was measured from the bottom, and feedforward-controlled current was utilised for the experiments. However, black body paint cannot be used in mass production, and it is not suitable for feedforward control. Therefore, it is desirable to measure temperature without contact even at changing emissivity. The two-colour thermometry system without emissivity calibration is suitable for hot stamping production with resistance heating [27].

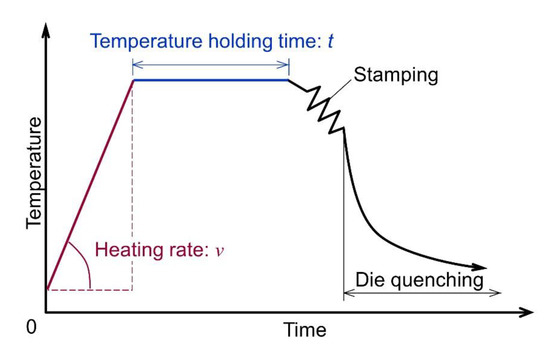

The heating path and conditions of resistance heating used for the experiment are shown in Figure 5 and Table 2, respectively. The temperature of the blank increases almost linearly with the heating time. The heating rate v during the rise in temperature was adjusted with the current density. The target temperature of 900 °C was held between 0 and 5 s by the passage of low current.

Figure 5.

Heating path used for hot stamping using direct resistance heating.

Table 2.

Conditions of resistance heating used for hot stamping.

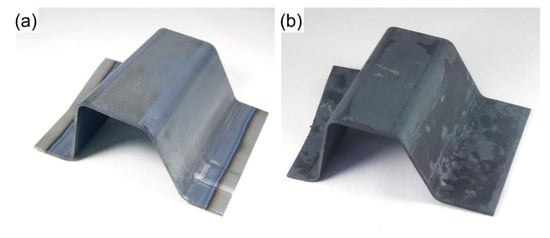

An example of a hat-shaped bent part using direct resistance heating is shown in Figure 6. The heating condition is v = 275 °C/s and t = 0 s. A result using furnace heating at 900 °C for 240 s is also shown for comparison. The oxidation of resistance-heated one is remarkably small compared with that of furnace-heated one.

Figure 6.

Hot hat-shaped bent parts using (a) direct resistance heating and (b) furnace heating.

3. Effect of Heat Microstructure of Blank Sheet on Quenchability in Die Quenching

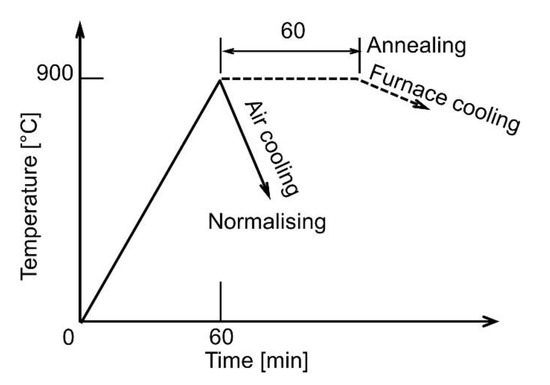

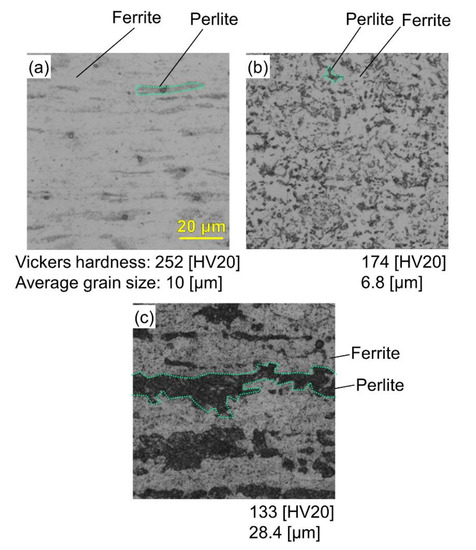

To investigate the effect of the microstructure of the blank sheet on the die-quenchability for v = 275 °C/s and t = 0 s as comparatively short heating time, normalise and anneal heat treatment were performed before hot stamping. Then, the heat-treated sheets were resistance-heated, stamped, and quenched for the experiments. The heating path used for the heat treatment and the microstructures of the as-received, normalised and annealed sheets before hot stamping are shown in Figure 7 and Figure 8, respectively. At first, the cut section was polished with emery paper to get a smooth mirror-like surface, and then it was lapped with alumina powder. The polished surface was etched with Nital solution. The optical microscope was utilised for observation. As illustrated in Figure 8, the dark areas show perlite and the light-grey areas show ferrite. All of the sheets in these experiments contain ferrite and perlite structures. The as-received sheet reveals the band structure due to cold rolling; however, the granular perlite with the precipitated ferrite is obtained from normalised sheet. The annealed sheet shows the band structure, because the manganese forms the band structure by rolling and carbon is also segregated according to the segregation of manganese. The grain size of the normalised sheet is considerably small, whereas that for the annealed sheet is large.

Figure 7.

Heating path used for the heat treatment.

Figure 8.

Microstructures of (a) as-received sheet, (b) normalised and (c) annealed 22MnB5 sheets.

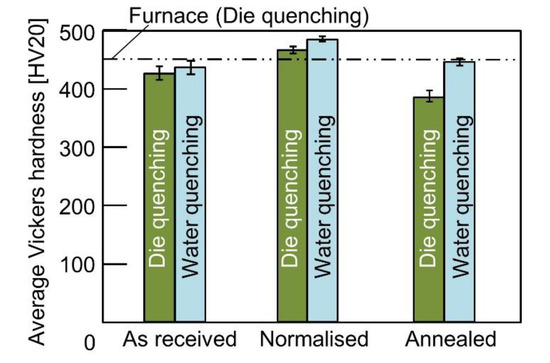

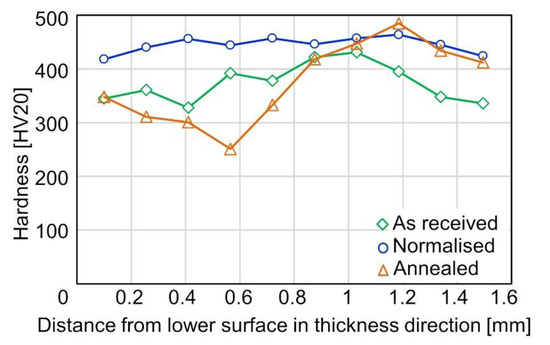

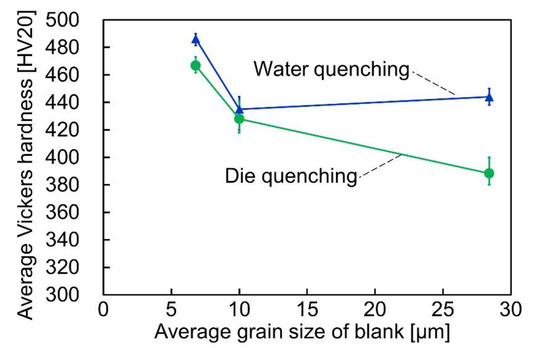

An effect of the heat treatment of the blank before hot stamping on Vickers hardness after die- and water-quenching using direct resistance heating for v = 275 °C/s and t = 0 s is shown in Figure 9. The die-quenched hardness of the as-received sheet using furnace heating of 240 s reaches 450 HV, whereas the die-quenched hardness of the as-received and annealed sheets using direct resistance heating reduce. Figure 10 illustrates the effect of heat treatment of blank on the distributions of Vickers hardness in thickness direction after die-quenching using direct resistance heating for v = 275 °C/s and t = 0 s. The hardness scatter of the normalised sheet becomes approximately steady in thickness direction, whereas it increases for the annealed sheet and decreases for the as-received one. The result of Figure 9 was arranged based on the grain size of the microstructure of the blank and is shown in Figure 11.

Figure 9.

Effect of heat treatment of blank before hot stamping on Vickers hardness after die- and water-quenching using direct resistance heating for v = 275 °C/s and t = 0 s.

Figure 10.

Effect of heat treatment of blank on distributions of Vickers hardness after die-quenching using direct resistance heating for v = 275 °C/s and t = 0 s.

Figure 11.

Effect of average grain size of blank on Vickers hardness after die- and water-quenching using direct resistance heating for v = 275 °C/s and t = 0 s.

All heat-treated sheets have enough hardness in case of water quenching. Therefore, the quenchability of the sheet is a reason for insufficient hardness. The manganese and boron have a large effect on the quenchability. However, since the band structure was formed for as-received and annealed sheets as shown in Figure 8, it expects the segregation of manganese and boron near perlite and grain boundary. So, it is difficult to diffuse those to ferrite for short heating time, hence the low quenchability portion partially appears.

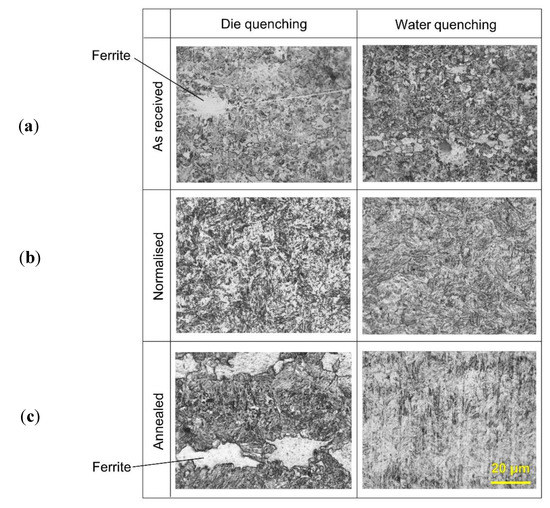

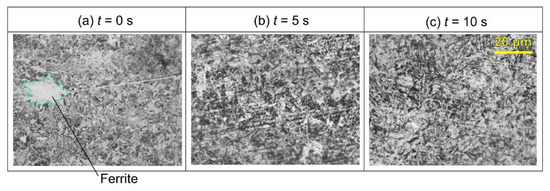

The microstructures of the die- and water-quenched sheets from as-received, normalised and annealed sheets for v = 275 °C/s and t = 0 s are shown in Figure 12. On the results of die quenching, ferrite is observed for as-received and annealed sheets. In particular, ferrite forms a thick layer in the result of the annealed sheet, corresponding to the microstructure shown in Figure 8c. As a result of water quenching, a small ferrite layer was observed for both the as-received and the annealed sheets. A full martensitic transformation occurred for the result from the normalised sheet even for the comparatively short heating time of direct resistance heating.

Figure 12.

Microstructures of die- and water-quenched sheet from (a) as-received, (b) normalised and (c) annealed sheets for v = 275 °C/s and t = 0 s.

4. Full Hardening of Products by a Decrease in Heating Rate and by Temperature Holding in Hot Stamping Using Direct Resistance Heating

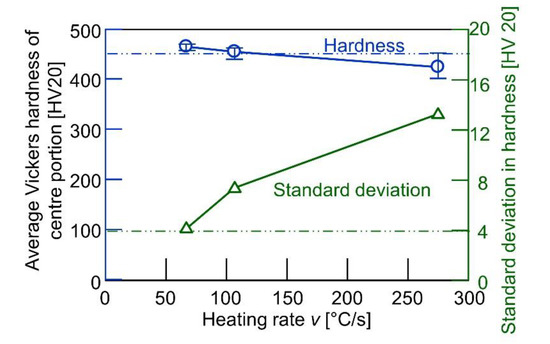

The effect of the heating rate on the Vickers hardness and the standard deviation of the as-received sheet without pre-heating treatment for t = 0 s is shown in Figure 13. As the heating rate decreases, the standard deviation of the hardness improves and the hardness slightly increases. The heating rate is required below a certain value for full hardening.

Figure 13.

Effect of heating rate on Vickers hardness and standard deviation for t = 0 s.

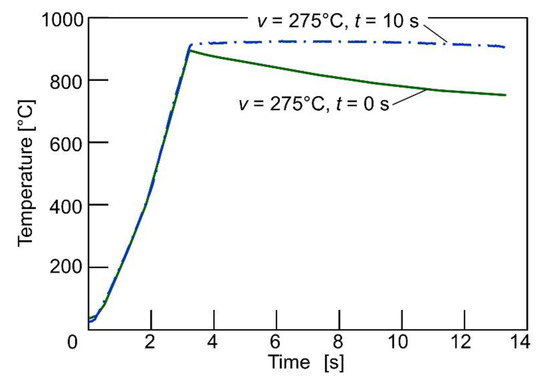

The heating temperature was held at the target temperature for several seconds to obtain full hardening even for a short heating time in direct resistance heating. The variations in temperature in resistance heating with and without holding at 900 °C above the austenitising temperature for v = 275 °C/s are shown in Figure 14. After reaching 900 °C, the temperature was kept almost constant by resistant-heating under low current.

Figure 14.

Variations in temperature in resistance heating for v = 275 °C/s and t = 0, 10 s.

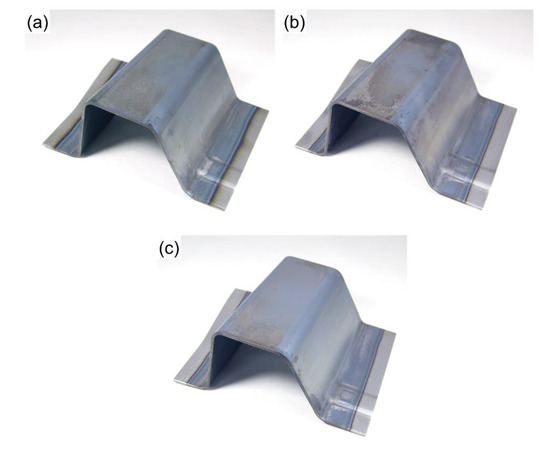

The hot hat-shaped bent parts for v = 275 °C/s and t = 0, 5, and 10 s are shown in Figure 15. The appearances about oxidation of the formed products are similar to the parts without temperature holding due to the short temperature holding time.

Figure 15.

Hot hat-shaped bent parts for v = 275 °C/s and (a) t = 0 s, (b) 5 s, and (c) 10 s.

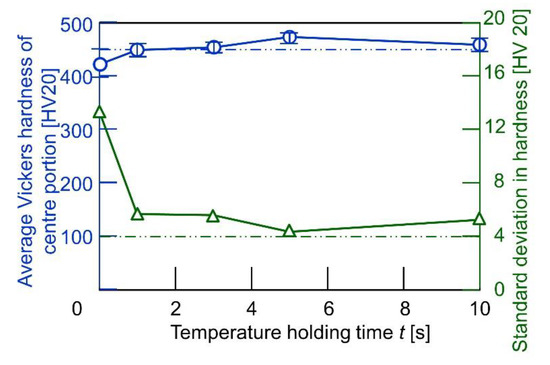

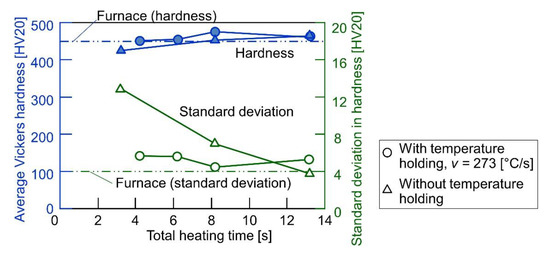

The effect of temperature holding during austenitising on the Vickers hardness and standard deviation of that for v = 275 °C/s is shown in Figure 16. As the holding time during austenitising increases, the hardness slightly increases up to t = 5 s. The standard deviation of the hardness is remarkably reduced by temperature holding above 1 s and is similar to the result of furnace heating.

Figure 16.

Effect of temperature holding during austenitising on Vickers hardness and standard deviation in hardness for v = 275 °C/s.

The microstructures of hot hat-shaped bent parts with and without temperature holding during austenitising for v = 275 °C/s are shown in Figure 17. By temperature holding, formation of the ferrite is prevented, and the fully martensitic structures are obtained for t = 5 and 10 s.

Figure 17.

Microstructures of hot hat-shaped bent parts with and without holding at austenitising temperature for v = 275 °C/s and t = (a) 0 s, (b) 5 s and (c) 10 s.

The decrease in heating rate and temperature holding during austenitising are effective for full hardening of products in hot stamping using direct resistance heating. The total heating times with and without temperature holding during austenitising were compared. The relationships between the Vickers hardness and total heating time with and without temperature holding during austenitising are shown in Figure 18. For resistance heating with temperature holding, the sufficient hardness was obtained above 4 s, whereas 8 s is required without temperature holding. The minimum heating time for full hardening is decided to 4 s based on the hardness in this quenchable steel sheet in hot stamping using direct resistance heating. The rapid heating rate with temperature holding during austenitising is effective to minimise the heating time for full hardening.

Figure 18.

Relationships between Vickers hardness and total heating time with and without holding at 900 °C.

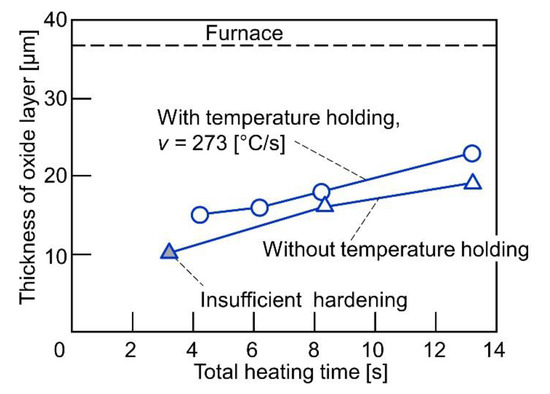

The effect of the total heating time on the thickness of the oxide layer of hat-shaped bent parts in hot stamping using direct resistance heating is shown in Figure 19. The oxide layer was removed by the soaking into the 3% hydrochloric acid with ultrasonic vibration. Then, the thickness was measured after removing the oxide layer. The thickness of the oxide layer is half of the difference in thickness of between that before and after oxide removing. The thicknesses of the oxide layer of both heating paths increase with the increase of the total heating time. For the result using temperature holding, the thicknesses of the oxide layer are slightly thicker than that without temperature holding owing to the fact that the time at the high temperature was slightly long.

Figure 19.

Effect of total heating time on thickness of oxide layer of hat-shaped bent parts in hot stamping using direct resistance heating.

From the aforementioned results, it was found that the increase in the heating time due to holding at the austenitising temperature and decrease in heating rate is small, and this time is included in the time for transferring the heated sheet to dies. For example, it is conceivable to maintain the temperature by installing an electrode on the transfer manipulator as shown in Figure 20.

Figure 20.

Maintaining temperature by installing electrodes on transfer manipulator.

5. Conclusions

Hot stamping using direct resistance heating is attractive due to high and flexible productivity and low investment. Sufficient austenitisation is important even in a short heating time with rapid resistance heating to obtain the full hardening. Since the initial microstructure of the steel sheet affects the quenchability of the sheets, it is important to care for the microstructure of the blank such as band structures by rolling. The development of normalised steel sheets is suitable for rapid resistance heating. Since it is not difficult to normalise a steel sheet at material production, the use of that can be effective to reduce the heating time for austenitisation and to obtain high productivity. Full hardening was obtained, and the standard deviation of the hardness was reduced by holding at the austenitising temperature and the decrease in heating rate.

Author Contributions

Investigation, T.M., K.-i.M., M.S., Y.N. and A.T.-A.; data curation, T.M., M.S., Y.N. and A.T.-A.; writing—original draft preparation, T.M.; writing—review and editing, T.M., K.-i.M. and A.T.-A.; visualization, T.M., M.S., Y.N. and A.T.-A.; supervision, T.M. and K.-i.M.; project administration, T.M.; funding acquisition, K.-i.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by JSPS KAKENHI Grant Number 18H01749.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Karbasian, H.; Tekkaya, A.E. A Review on Hot Stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Mori, K.; Bariani, P.F.; Behrens, B.A.; Brosius, A.; Bruschi, S.; Maeno, T.; Merklein, M.; Yanagimoto, J. Hot stamping of ultra-high strength steel parts. CIRP Ann. 2017, 66, 755–777. [Google Scholar] [CrossRef]

- Mori, K.; Maki, S.; Tanaka, Y. Warm and Hot Stamping of Ultra High Tensile strength Steel Sheets Using Resistance Heating. CIRP Ann. 2005, 54, 209–212. [Google Scholar] [CrossRef]

- Mori, K.; Okuda, Y. Tailor Die Quenching in Hot Stamping for Producing Ultra-High Strength Steel Formed Parts Having Strength Distribution. CIRP Ann. 2010, 59, 291–294. [Google Scholar] [CrossRef]

- Kolleck, R.; Veit, R.; Merklein, M.; Lechler, J.; Geiger, M. Investigation on Induction Heating For Hot Stamping of Boron Alloyed Steels. CIRP Ann. 2009, 58, 275–278. [Google Scholar] [CrossRef]

- Maki, S.; Hamamoto, A.; Saito, S.; Mori, K. Hot Stamping and Press Quenching of Ultrahigh Strength Steel Sheet using Resistance Heating. Key Eng. Mater. 2007, 344, 309–316. [Google Scholar] [CrossRef]

- Ozturk, F.; Ece, R.E.; Polat, N.; Koksal, A.; Evis, Z.; Polat, A. Mechanical and microstructural evaluations of hot formed titanium sheets by electrical resistance heating process. Mater. Sci. Eng. A 2013, 578, 207–214. [Google Scholar] [CrossRef]

- Lee, C.W.; Choi, W.S.; Cho, Y.R.; De Cooman, B.C. Direct resistance joule heating of Al-10 pct Si-coated press hardening steel. Metall. Mater. Trans. A 2016, 47, 2875–2884. [Google Scholar] [CrossRef]

- Maeno, T.; Mori, K.I.; Ogihara, T.; Fujita, T. Removal of thin oxide scale by ultrasonic cleaning with diluted hydrochloric acid in hot stamping of bare 22MnB5 sheet using resistance heating. Procedia Manufact. 2019, 29, 225–231. [Google Scholar] [CrossRef]

- Vaissiere, L.; Laurent, J.P.; Reinhardt, A. Development of Pre-Coated Boron Steel for Applications on PSA Peugeot Citroen and RENAULT Bodies in White. SAE Trans. J. Mater. Manuf. 2002, 111, 909–917. [Google Scholar]

- Quan, G.Z.; Wang, T.; Zhang, L. Research on the influence of hot stamping process parameters on phase field evolution by thermal-mechanical phase coupling finite element. Int. J. Adv. Manuf. Technol. 2016, 89, 1–17. [Google Scholar] [CrossRef]

- Zhang, P.; Zhu, L.; Xi, C.; Luo, J. Study on Phase Transformation in Hot Stamping Process of USIBOR® 1500 High-Strength Steel. Metals 2019, 9, 1119. [Google Scholar] [CrossRef]

- Pedraza, J.P.; Landa-Mejia, R.; García-Rincon, O.; Isaac Garcia, C. The effect of rapid heating and fast cooling on the transformation behavior and mechanical properties of an advanced high strength steel (AHSS). Metals 2019, 9, 545. [Google Scholar] [CrossRef]

- Mori, K. Smart Hot Stamping of Ultra-High Strength Steel Parts. Trans. Nonferrous Met. Soc. China 2012, 22, s496–s503. [Google Scholar] [CrossRef]

- Löbbe, C.; Hering, O.; Hiegemann, L.; Tekkaya, A.E. Setting Mechanical Properties of High Strength Steels for Rapid Hot Forming Processes. Materials 2016, 9, 229. [Google Scholar] [CrossRef] [PubMed]

- Mori, K.; Abe, Y.; Miyazawa, S. Warm stamping of ultra-high strength steel sheets at comparatively low temperatures using rapid resistance heating. Int. J. Adv. Manuf. Technol. 2020, 108, 3885–3891. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, K.; Politis, D.J.; Chen, G.; Wang, L. An experimental investigation on the ductility and post-form strength of a martensitic steel in a novel warm stamping process. J. Mater. Process. Technol. 2020, 275, 116387. [Google Scholar] [CrossRef]

- Liu, X.; Yang, X.; Sun, Y.; Politis, D.J.; Mori, K.-I.; Wang, L. Characterization of Thermomechanical Boundary Conditions of a Martensitic Steel for a FAST Forming Process. J. Manuf. Mater. Process. 2020, 4, 57. [Google Scholar]

- Hoffmann, H.; So, H.; Steinbeiss, H. Design of hot Stamping tools with cooling system. CIRP Ann. 2007, 56, 269–272. [Google Scholar] [CrossRef]

- Nürnberger, F.; Diekamp, M.; Moritz, J.; Wolf, L.; Hübner, S.; Behrens, B.A. Spray Cooling of Early Extracted Hot Stamped Parts. In TMS 2014 Supplemental Proceedings; The Minerals, Metals & Materials Society; Springer: Berlin/Heidelberg, Germany, 2014; pp. 983–990. [Google Scholar]

- Ota, E.; Yogo, Y.; Iwata, T.; Iwata, N.; Ishida, K.; Takeda, K. Formability improvement technique for heated sheet metal forming by partial cooling. Key Eng. Mater. 2014, 622–623, 279–283. [Google Scholar] [CrossRef]

- Zhao, K.; Chang, Y.; Hu, P.; Wu, Y. Influence of rapid cooling pretreatment on microstructure and mechanical property of hot stamped AHSS Part. J. Mater. Process. Technol. 2016, 228, 68–75. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, J.; Park, K.; Kweon, D.K.; Lee, H.; Yang, D.; Park, H.; Kim, J. A study on the cooling performance of newly developed slice die in the hot press forming process. Metals 2018, 8, 947. [Google Scholar] [CrossRef]

- Behrens, B.A.; Bouguecha, A.; Gaebel, C.M.; Moritz, J.; Schrödter, J. Hot Stamping of Load Adjusted Structural Parts. Procedia Eng. 2014, 81, 1756–1761. [Google Scholar] [CrossRef]

- Maeno, T.; Mori, K.; Fujimoto, M. Improvements in productivity and formability by water and die quenching in hot stamping of ultra-high strength steel parts. CIRP Ann. 2015, 64, 281–284. [Google Scholar] [CrossRef]

- Nakagawa, Y.; Mori, K.; Maeno, T.; Nakao, Y. Reduction in holding time at bottom dead centre in hot stamping by water and die quenching. Procedia Manuf. 2018, 15, 1111–1118. [Google Scholar] [CrossRef]

- Usui, H.; Mitsui, K. Study of ratio temperature radiometry using a multi-spectrum camera. In Proceedings of the International Conference on High-Speed Imaging and Photonics, Enschede, The Netherlands, 8–12 October 2018. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).