Abstract

The drilling of carbon fiber reinforced polymer (CFRP) plate is very critical in its structural applications in aeronautical, aerospace, and automobile industries. For ensuring the good quality of drilled holes in terms of least drilling damage and prolonged tool life, suitable selection of drill geometry and material, and drilling parameters—such as cutting speed and feed rate—are imperative in the drilling of CFRP plate. This study aims to evaluate the cutting performance of conventional two-flute twist drills made of cemented tungsten carbide YG6X (WC-6 wt % Co) for the dry drilling of the multidirectional T700 CFRP plate. The effects of varying cutting speed and tool wear pattern on the drilling performance are analyzed. The drilling performance is assessed in terms of hole quality by the qualitative and quantitative analysis of drilling-induced delamination and hole diameter. Furthermore, the correlation between the tool wear progression and the drilled hole quality is established. Through this assessment, a suitable set of drilling parameters, i.e., cutting speed of 9000 rpm and feed rate of 400 mm/min, is proposed for producing the best quality holes for multidirectional T700 CFRP plate.

1. Introduction

Carbon fiber reinforced polymer (CFRP) has long been known for its low density and thermal expansion, corrosion resistance, high tensile- and fatigue-strength. Therefore, it is reliable in enduring severe working conditions under which structural assemblies operate in automobile, architecture, aerospace, and aeronautical industries. This endurance has made manufacturing of CFRP components more economical, light, and efficient over the years [1,2,3,4,5]. Given recent developments and novel practices of mass-production of CFRP components, the manufacturing industry is yet to harness its full potential in the upcoming years. For producing the near net shape of the CFRP components, machining operations are always required with few exemptions. Different machining operations are performed on CFRP workpieces—such as milling and water-jet cutting—but drilling stands out as the most frequently used approach [6]. In addition to drilling, helical milling can also be used for making holes in structural components [7,8]. However, significant cutting resistance, which is detrimental to the quality of machined parts, is generated due to the CFRP’s inhomogeneous and anisotropic characteristics, low thermal conductivity, and high tensile and fatigue strength [9]. Besides, the intrinsic abrasive nature of the CFRP fibers is responsible for quick tool wear which, in turn, also affects the machined surface or, in case of drilled holes, the hole surface quality [10].

Many research studies have been conducted on the drilling of CFRP plate using a variety of tool geometries. The principle distinction among all tool geometries lies in the varying distribution of cutting forces on the CFRP plate [11]. This distribution of cutting forces originates from the difference in point angle, cutting edge angle, and tool wear mechanism [12,13]. The conventional twist drills are often used in the CFRP industry because of their need of joining structural components and assemblies [14]. However, the effect of unconventional double point angle twist drills [15], candle stick drills [16,17], step drills [18], dagger drills [17,19], saw drills, core drills [20,21], step-core drills [22,23], and core-special drills [24] have also been studied and thoroughly analyzed in relation with the drilling of CFRP plate. Using twist drills has been confirmed to be the best choice as compared with candle stick, dagger, and special step-drills [18]. Within the context of delamination, the peel-up delamination produced by conventional twist drills is 5% lower as compared to stepped-drills [13]. Moreover, conventional twist drills are regarded as the appropriate choice for economical drilling of CFRP plate with low damages and good bearing strength [25]. Given almost all the existing evidence using various tool geometries for drilling CFRP plate, there are still uncompromising limitations offered by unconventional tool geometries and, therefore, conventional drills have maintained their reputation as the industrial standard.

Drill tool material has a significant effect on tool wear during drilling of CFRP plate. In this context, many conventional drill tool materials have been employed, notably high speed steels (HSS) and cemented tungsten carbide. It has been found that high speed steel (HSS) drills are worn severely, resulting in larger delamination areas after machining 1000 holes in CFRP plate. On the other hand, the wear for the cemented tungsten carbide drills is minor and so is the produced delamination [26]. Cemented tungsten carbide twist drills definitely outperform HSS twist drills and carbide four-flute drills, producing a lower delamination factor value [27]. Besides, carbide drills are exclusively preferred for the drilling of CFRP plate due to their lower wear progression which has considerable impact on the extent of the quality of drilled holes in terms of delamination [28,29,30]. The wear mechanism is very sensitive and intricate and is predominantly attributed to the abrasive nature of the CFRP plate along with non-homogenous structure and anisotropy [31]. Therefore, wear of cutting edge of the drill during drilling of CFRP plate cannot be avoided. The drills may experience premature and large-scale damage, or gradual harm which may come from selection of unsuitable drilling parameters. Therefore, it is essential that drilling is carried out under optimized set of drilling parameters [32]. The drilling parameters along with drilling tools can be chosen by following the testing methods described in the literature [33]. The increase in the drilling parameters such as cutting speed and feed rate enhances the tool wear progression which in turn increases the cutting forces and thus deteriorates the holes quality in terms of delamination [34,35,36].

With respect to the drilling of CFRP plate, the drilling-induced delamination may occur either on the entrance side (peel-up delamination) or the exit side (push-down delamination) of the drilled hole. The delamination in a structure may result in stiffness loss, local stress concentration in local bearing piles, and a local instability causing its further growth [37]. Due to the inter-dependency of the tool wear, cutting forces, and drilling parameters, the cutting speed and feed rate are key factors in controlling the delamination [38]. There is solid evidence that the peel-up and push-down delamination increases with increasing feed rate during the drilling of CFRP plate [39]. Contrary to the feed rate, the evidence regarding the effect of cutting speed is somehow debatable. Some studies validate the increase in drilling induced delamination with increasing cutting speed while others confirm otherwise [40]. This contradiction is possibly due to the varying drill tool geometries, tool materials, anisotropy, or strength of the CFRP laminates.

On the basis of strength, CFRPs are classified into three types—i.e., low-strength, medium-strength, and high-strength CFRP—depending on the grade of reinforced carbon fibers [41]. Many authors have paid attention to the drilling of either high-strength (T800) or low-strength (T300) CFRP laminates [42,43]. However, the medium strength CFRP (T700) has been almost neglected in relation with the drilling operation. Silva et al. focused on the drilling of medium-strength CFRP (T700) with its scope restricted to unidirectional CFRP plate [25]. On the other hand, few studies have been conducted on the drilling of multidirectional T700 CFRP plate. Shyha et al. and Halim et al. have demonstrated that the multidirectionality of carbon fibers in CFRP plate definitely influences the drilling performance thereby making its drilling operation more difficult [44,45]. Therefore, there is obvious room for a study related to the drilling of multidirectional T700 CFRP plate.

The purpose of this study is to evaluate the drilling performance of cemented tungsten carbide drills in drilling multidirectional T700 CFRP plate using varying sets of drilling parameters. The wear progression of the cemented WC drills is quantitatively and qualitatively analyzed with varying drilling parameters. Moreover, the drilling-induced delamination factor and hole diameter error are numerically computed for evaluating the quality of drilled holes. A relation between flank wear of the cemented WC drills and variation in delamination factor and hole diameter error is developed through a rational discussion. Eventually, the optimized set of drilling parameters for drilling multidirectional T700 CFRP plate is proposed.

2. Experimental

2.1. Workpiece Material

The composite workpiece under investigation is the medium-strength T700 plate with rectangular dimensions of 400 × 500 mm2 and a total thickness of 6 mm, which is further machined into smaller plates with size of 170 × 200 mm2. The CFRP plate is fabricated by autoclave method using carbon/epoxy prepreg and 37 layers of unidirectional carbon/epoxy prepreg with stacking sequence of 0°/45°/0°/90°/0°/−45°/0°. The mechanical properties of the T700S fiber and its prepreg are shown in Table 1.

Table 1.

Mechanical properties of T700S fiber and its prepreg.

2.2. Drilling Setup and Parameters

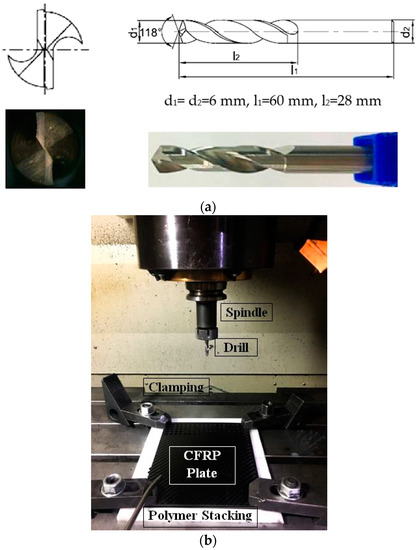

For drilling tests, the two-flute 6 mm diameter twist drills with 118° point angle, 28 mm flute length, and 60 mm total length, are used, as shown in Figure 1a. The chisel edge position angle is 129° and the half-width of the chisel edge is 0.138 mm and are measured in the same way as described in the literature [46]. The carbide grade of the employed drill is YG6X cemented tungsten carbide with 6 wt % cobalt as binding phase. The drilling operation was carried out in a five-axis Makino A-55 (Makino, Tokyo, Japan) machining center with maximum spindle speed of 20,000 rpm and maximum feed rate of 50 m/min. A support (or stacking) plate made of polymer was installed under the CFRP plate to avoid push-down delamination, as proved effective in the previous studies [47,48]. The drilling test arrangement is shown in Figure 1b. Drilling was performed under dry condition and fine chip powder was removed using a pneumatic air gun with air pressure of 0.5 MPa. For the drilling parameters, cutting speed and feed rate within wide ranges, 3000–20,000 rpm and 5–1200 mm/min, respectively, were employed for drilling multidirectional T700 CFRP plate. For the sake of convenience in this study, the feed rate was kept constant at most suitable value of 400 mm/min and cutting speed was varied in regular intervals. The overall summary of the employed drilling parameters is shown in Table 2.

Figure 1.

Experimental setup: (a) profile and geometrical parameters of two-flute twist drill; (b) CFRP plate clamping arrangement (Makino A-55).

Table 2.

Sets of drilling parameters.

2.3. Assessment Methods

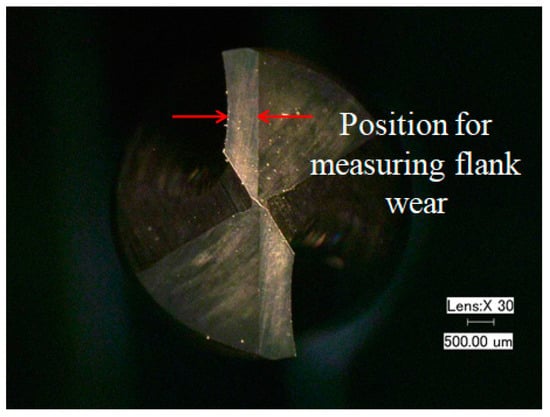

2.3.1. Tool Wear

Super-depth optical microscope (Model: VHX-600E, Keyence, Osaka, Japan), was used to take images and measure wear of cemented WC drills. The flank wear was measured according to the standard (ISO 3685:1995) along the line bisecting the cutting edge’s distance from the circumference to the center, as shown in Figure 2. In order to further analyze the extent and dominant regions of wear of cemented WC drills, scanning electron microscope (SEM, SUPRA55, Zeiss, Oberkochen, Germany) was also used.

Figure 2.

Measurement of tool flank wear.

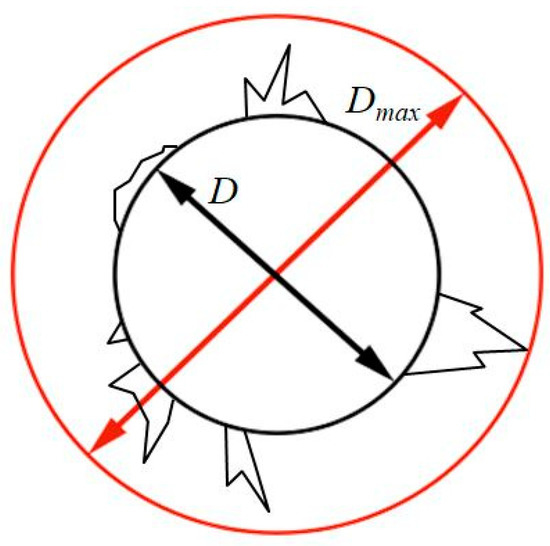

2.3.2. Delamination Factor (Fd)

Super-depth optical microscope (VHX-600E) was also used for qualitative and quantitative examination of drilling induced delamination in CFRP plate. For the quantitative analysis, one-dimensional conventional delamination factor (Fd) was computed by using Equation (1), as originally proposed by Chen et al. [29].

In Equation (1), Dmax is the maximum delaminate diameter (see Figure 3) and D is the hole nominal diameter.

Figure 3.

Schematic diagram for determining delamination factor (Fd).

2.3.3. Hole Diameter Error (Eh)

To measure the hole diameter of the drilled holes produced by cemented WC drills, a coordinate measuring machine (CMM) (PRISMO Navigator, Zeiss, Oberkochen, Germany) employing variable accuracy and speed probing technology (VAST) was used. Four points were taken along the hole inner wall 0.5 mm below the entrance surface of the CFRP plate and the results were recorded and comparison was done after the computation of hole diameter error, Eh (%). The Eh (%) is defined and computed by using Equation (2), as described in the literature [34,49].

In above equation, Da is the actual diameter of the drilled hole which was measured by the CMM and Dn is the nominal diameter of the hole which is 6 mm in this study.

3. Results and Discussion

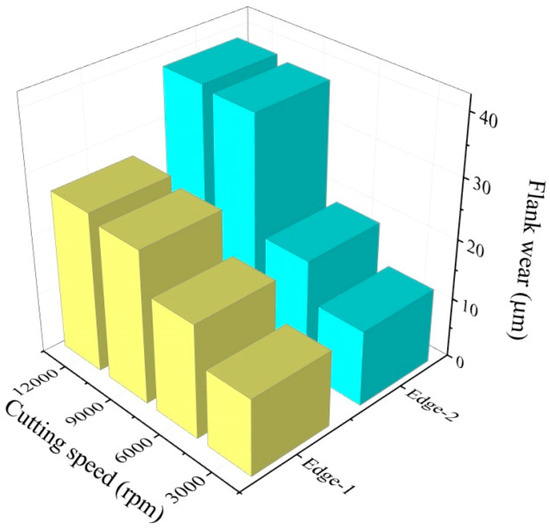

3.1. Tool Wear

Flank wear of cemented WC drills, which is recorded after drilling of 30 holes with each set of drilling parameters (Table 2), is shown in Figure 4. It is evident in Figure 4 that the flank-wear along the cutting edges increases with increasing cutting speed (revolutions per minute). Similar results regarding the effect of cutting speed on wear are found in the literature [28,43,50]. However, this increment in the wear progression is slight at higher cutting speed of 12,000 rpm as compared to 9000 rpm. The tool wear is caused due to the cutting forces that are distributed along the main flank of the primary cutting edges of the drill. The magnitude of these cutting forces increases with increasing cutting speed, thus leading to increased wear progression.

Figure 4.

Flank wear variation with cutting speed after drilling 30 holes.

It can be seen from the Figure 4 that edge-2 is worn up to 50% more than edge-1 for 9000 rpm and 12,000 rpm as compared to 3000 rpm and 6000 rpm. The possible cause of significant increase in edge-2 wear is attributed to the topology of the machined surface coupled with the fact that the flank wear is in the first zone of its evolution curve. Another possible reason of this increased wear of edge-2 is the localized change in the macro geometry of the cutting edge due to the variation in cutting forces arising from increased cutting speeds (9000 rpm and 12,000 rpm). This explanation of localized geometric change is found in similar study by Cadorin et al. [51].

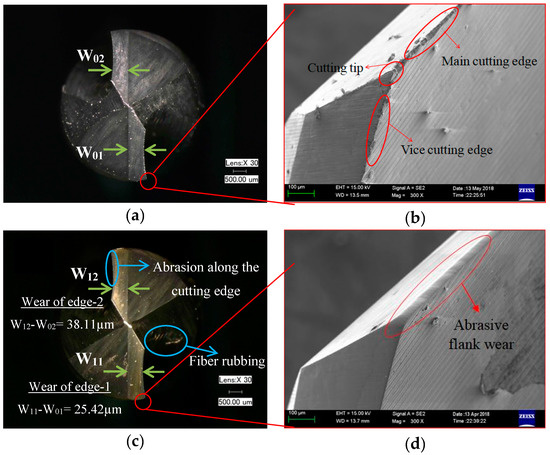

In order to further analyze the wear of cemented WC drills, the microscopic and SEM images of the WC drill are taken before and after drilling of 30 holes with cutting speed 9000 rpm and feed rate 400 mm/min (see Figure 5). It can be seen that before the drilling, as shown in Figure 5a,b, the cutting edge and the cutting tip of the WC drill are sharp. With start of the drilling operation, the high rate of flank wear of the WC drill begins with the breakage (chipping) of the sharp corners and weak areas on the cutting edge because of the their lack of ability to bear high stresses. This chipping corresponds to the first zone of the typical wear evolution curve of the WC drills as can be found in literatures [32,51]. The abrupt breakage of sharp corners and weak areas is followed by the abrasion which is associated with gradual and steady wear progression of the cutting edge and the cutting tip. The abrasive wear of the cutting edge and cutting tip is shown in Figure 5c,d. It is clear that the abrasive wear is dominant on the main cutting edge and the cutting tip. The vice cutting edge, however, is less susceptible to abrasive wear. The reason behind dominant abrasive wear on main cutting edge and cutting tip is attributed to the distribution of the cutting forces on these areas. The magnitude of these cutting forces is the most at the cutting tip and, hence, the wear at the cutting tip is large, as shown in Figure 5d. With subsequent number of holes and ongoing flank wear during drilling, the magnitude of these cutting forces is augmented, which in turn most likely becomes the potential cause of detrimental hole quality. It is the gradient of the cutting speed (cutting force) along the cutting edge that is responsible for its smooth wear, as shown in Figure 5d.

Figure 5.

Microscopic and SEM images showing cutting tip and main cutting edge: (a,b) before; (c,d) after drilling 30 holes with cutting speed of 9000 rpm and feed rate of 400 mm/min.

The abrasive modes of wear for cemented WC drills can be explained in either of two ways: hard abrasion and soft abrasion. Hard abrasion corresponds to the dynamic stresses experienced by WC grains owing to integrated effect of CFRP plate chip powder, broken fibers, and the reinforcement. These stresses lead to crack initiation and then propagation inside WC grains eventually causing them to undergo brittle fracture and to fall away. Soft abrasion, on the other hand, relates to the abrasive damage of the soft Co binder by carbon fibers, which has low hardness as compared to WC grains. With deepening wear of Co binder, the WC grains become more exposed and are then fractured by fatigue acceleration. These interpretations about wear modes are also found in studies on drilling of CFRP plate [52,53].

3.2. Delamination Factor (Fd)

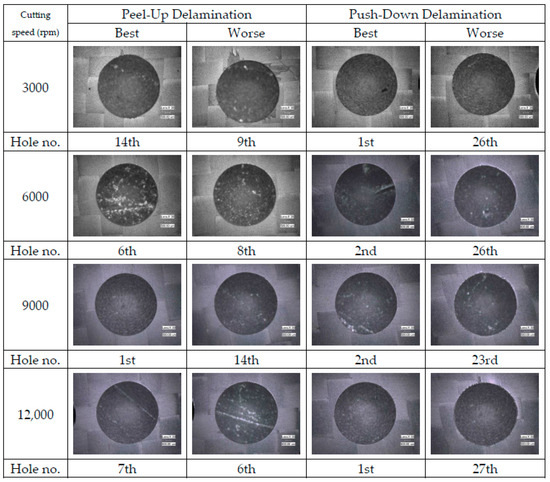

Drilling induced delamination is observed by the microscopic examination of every drilled hole. Figure 6 shows the qualitative delamination of drilled holes in terms of peel-up and push-down delamination for each cutting speed adopted for the drilling of T700 CFRP plate. It is clear that the peel-up delamination decreases with increasing cutting speed. Figure 6 shows that the maximum and minimum delamination on the entrance side are for 3000 rpm and 9000 rpm, respectively. The peeling force in the upward direction, which breaks either the single layer of fibers or the entire upper ply, is responsible for the peel-up delamination [54]. However, at a cutting speed of 12,000 rpm, as shown in Figure 6, the entrance side delamination tends to augment slightly as compared to 9000 rpm.

Figure 6.

Drilling induced peel-up and push-down delamination with varying cutting speed at feed rate of 400 mm/min.

Push-down delamination, unlike peel-up delamination, increases with increasing cutting speed, as shown in Figure 6. The holes corresponding to cutting speeds of 3000 rpm and 6000 rpm have the least and comparable push-down delamination damage. The quality of holes, on the exit side, corresponding to 9000 rpm and 12,000 rpm is exceptional in the start but with increasing the number of holes, it starts to deteriorate slightly not only in terms of delamination but also minor circumferential deformation. The slight decline in the exit quality of holes with subsequent number of holes is well explained in the context of thrust force. With increasing number of holes, the thrust force increases and overreaches the interlaminar bonding strength of the fiber layers so as to eventually cause the separation of plies by pushing them down. In other words, the continuous increase in the thrust force from its critical thrust force value, as presented by Ho-Cheng and Dharan [55], with subsequent number of holes, is responsible for increase in the extent of push-down delamination. It is also equally important to point out that feed rate is normally the major contributor in thrust force escalation, whereas the effect of the varying cutting speed is negligible [51,56]. Since the feed rate is constant, i.e., 400 mm/min in this study, the thrust force increment with increasing the number of holes originates from the steady wear of the cutting edges. This explanation is also found in the similar literature [28]. This visual analysis of delamination is further supported by delamination factor (Fd), calculated as per Equation (1), as shown in Figure 7.

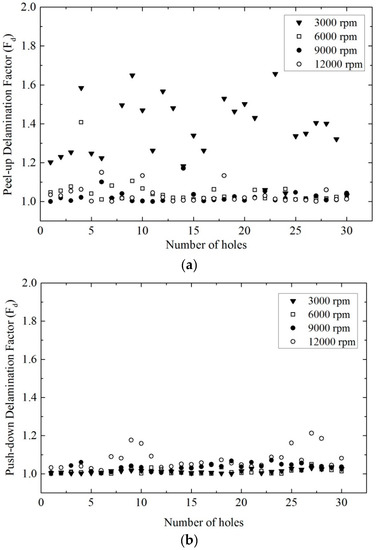

Figure 7.

Drilling induced delamination with varying cutting speed at feed rate of 400 mm/min: (a) peel-up delamination factor; (b) push-down delamination factor.

The conventional delamination factor (Fd), both for entrance and exit side, of each of the 30 holes is calculated and summarized in Figure 7. It is clear that the peel-up delamination decreases and, on the other hand, push-down delamination increases with increasing cutting speed, as shown in Figure 7a,b, respectively. It indicates that the increase in cutting speed has contradictory effect on the entrance and the exit side of the drilled hole in terms of delamination. Moreover, the effect of increase in cutting speed is more significant on the peel-up delamination than the push-down delamination, as shown in Figure 7. This quantitative interpretation of peel-up and push-down delamination with varying cutting speed is equivalent to the microscopic analysis (see Figure 6) and is also found in strong agreement in similar studies [11,12,13,27,39,57]. In Figure 7, the least peel-up and push-down delamination are recorded for 9000 rpm and 6000 rpm, respectively. The maximum delamination on the entrance and exit side of the holes is within ~0.04 mm for both 9000 rpm and 6000 rpm. It can be seen that, in Figure 7a, with increasing the number of holes, the Fd tends to become more stable with least scattering of Fd values.

Overall, for both peel-up and push-down delamination, the range of varying Fd values is narrower for 9000 rpm than that for rest of the cutting speeds, justifying its overall least influence on both peel up and push-down delamination. Therefore, 9000 rpm is proved to be the most optimum cutting speed for producing consistent good quality of holes in terms of least delamination when feed rate is kept constant at 400 mm/min.

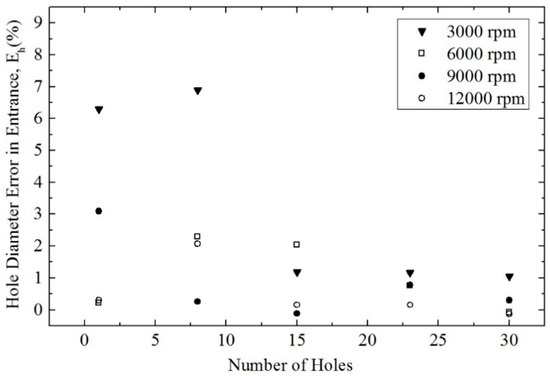

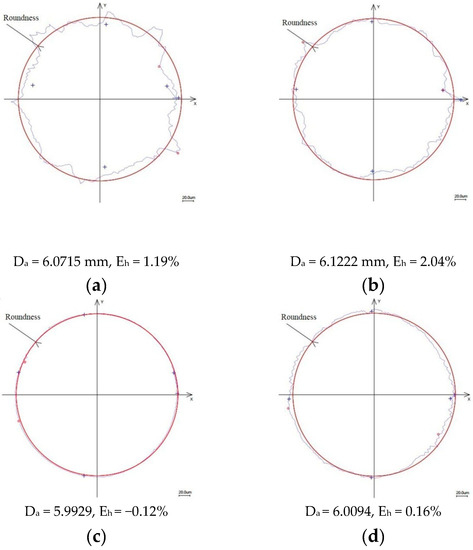

3.3. Hole Diameter Assessment

The hole diameter error Eh (%) is computed from the entrance side of the holes in CFRP plate by using Equation (2). Among 30 holes drilled for each cutting speed, the actual diameters of hole numbers 1, 8, 15, 23, and 30 are recorded and Eh (%) is computed. The scatter plot of calculated Eh (%) is shown in Figure 8. Comparing overall magnitude of Eh (%) values at different cutting speeds, it can be seen that the Eh (%) of the holes decreases with increasing cutting speed. The maximum Eh (%) is recorded for 3000 rpm producing Eh (%) error up to 7% exhibiting considerable hole oversize. However, with the increasing number of holes, the Eh (%) tends to lower down with the exception of eighth hole for which Eh (%) is higher than that of first hole, in cases of 3000, 6000, and 12,000 rpm, as is evident in Figure 8. Similarly, for 9000 rpm the Eh (%) of 23rd hole is higher than that of 15th hole. The general behavior of decreasing Eh (%) with increasing the number of holes is explained in terms of flank wear. With sharp edges of the cemented WC drill in the beginning, the produced holes tend to be oversized but with increasing the number of holes, the degree of hole oversize reduces which results from the significant progression in flank wear corresponding to the initial phase of the wear cycle. It is obvious that for all cutting speeds, the difference of Eh (%) values becomes narrower with increasing number of holes which points out towards the fact that the sharp cutting edges of the drill are becoming stable after abrupt chipping and are not subjected to steady abrasion. Therefore, the actual diameter of the holes exhibits stable shifts towards the nominal diameter with increasing the number of holes. This explanation is in agreement with Eh (%) assessment in the preceding work on drilling of CFRP plate [28].

Figure 8.

Variation of hole diameter error Eh (%) with number of holes on entrance side at feed rate of 400 mm/min.

Furthermore, the profile along with actual diameter (Da) of the 15th hole is measured by using CMM, as an account for all the holes drilled for each cutting speed and the results are shown in Figure 9.

Figure 9.

Comparison of circumferential profile and diameter error (Eh) of 15th hole drilled at feed rate of 400 mm/min with varying cutting speeds: (a) 3000 rpm; (b) 6000 rpm; (c) 9000 rpm; (d) 12,000 rpm.

As it is evident that, the hole drilled at 3000 rpm and 6000 rpm, Figure 9a,b, has higher Eh (%) as compared to 9000 rpm and 12,000 rpm. The Eh (%) value at 12,000 rpm, as shown in Figure 9d, is lower than those corresponding to 3000 rpm and 6000 rpm. The Eh (%) of hole drilled at 9000 rpm is the least with −0.12% showing minute hole undersize and its actual circumferential profile closely coincides with the nominal circumference, as shown in Figure 9c. The least Eh (%) for 9000 rpm approves that 9000 rpm is the most suitable cutting speed for drilling holes in CFRP plate because not only does it produce the least delamination, but also the least Eh (%) with suitable hole profile.

4. Conclusions

This study investigated the tool wear and the holes quality in terms of drilling-induced delamination and hole diameter error Eh (%) during drilling multidirectional T700 CFRP plate. The following conclusions are evidently drawn:

- The flank wear of the cemented WC drills increases with increasing cutting speeds during drilling of multi-directional T700 CFRP plate. At higher cutting speeds such as 12,000 rpm, there is only slight increase (~2%–4%) in flank wear of the cemented WC drill as compared to its preceding increments for cutting speeds 3000, 6000, and 9000 rpm. Abrasion is the principle cause of wear for cemented WC drills and is dominant on the flank of the primary cutting edge.

- Peel-up delamination decreases with increasing cutting speeds and it is least at 9000 rpm. At higher cutting speed of 12,000 rpm, the delamination on the entrance side tends to deteriorate slightly. Push-down delamination increases with increasing cutting speed. On the exit side, the delamination for 3000 rpm and 6000 rpm is the least.

- Cutting speed has opposite effect on delamination on the entrance and the exit side of the drilled hole in multidirectional T700 CFRP plate. Moreover, the effect of increase in cutting speed on peel-up delamination is more significant than that on push-down delamination.

- The hole diameter error Eh (%) decreases with increasing cutting speeds and so does the hole oversize. Moreover, the Eh (%) or the hole oversize decreases with increasing number of holes during drilling of multidirectional T700 CFRP plate. The holes corresponding to cutting speed of 9000 rpm show good circumferential profile with the least hole undersize of Eh (%) −0.12% and the actual diametric profile almost coinciding with nominal diameter.

- The microscopic delamination examination, narrower range of low Fd values, and least Eh (%) for 9000 rpm show that 9000 rpm is the most optimum cutting speed along with 400 mm/min feed rate for drilling multidirectional T700 CFRP plate with conventional cemented WC twist drills.

Author Contributions

M.A., D.Y. and G.L. designed and executed series of drilling experiments. M.A. wrote the manuscript. L.X. supervised the experiments, helped in interpretation of results, and reviewed the manuscript.

Funding

This research is funded by the Science and Technology Project of Dalian under the grant number: 2012A13GX028.

Acknowledgments

The authors express their gratitude towards Wuxi WESN Composite Materials Co., Ltd. for supplying T700 CFRP plate for this study. They also highly appreciate Laboratory Engineer Likun Si from the School of Mechanical Engineering and Ph.D. Scholar Faizan Ali from School of Materials Science and Engineering, in Dalian University of Technology for their immense assistance.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chin, S.C.; Yahaya, F.M.; Ing, D.S.; Kusbiantoro, A.; Chong, W.K. Experimental study on shear strengthening of rc deep beams with large openings using CFRP. In Proceedings of the International Conference on Architecture, Structure and Civil Engineering, Antalya, Turkey, 7–8 September 2015. [Google Scholar]

- Ishikawa, T. Trend in carbon fiber reinforced plastic (CFRP) technology and recent applications of CFRP to aerospace structures. SEIKEI KAKOU 2005, 17, 294. [Google Scholar]

- Shanygin, A.; Fomin, V.; Kondakov, I. Designing pro-composite aircraft concepts and layouts to maximize potential benefits of high specific strength of CFRP. In Proceedings of the 28th Congress of the International Council of the Aeronautical Sciences, Brisbane, Australia, 23–28 September 2012. [Google Scholar]

- M’Saoubi, R.; Axinte, D.; Soo, S.L.; Nobel, C.; Attia, H.; Kappmeyer, G.; Engin, S.; Sim, W.M. High performance cutting of advanced aerospace alloys and composite materials. CIRP Ann. 2015, 64, 557–580. [Google Scholar] [CrossRef]

- Mays, G. Products and systems for the protection and repair of concrete structures: The current position of European standards. In Repair, Rejuvenation and Enhancement of Concrete; Thomas Telford: London, UK, 2002. [Google Scholar]

- Isbilir, O.; Ghassemieh, E. Comparative study of tool life and hole quality in drilling of CFRP/titanium stack using coated carbide drill. Mach. Sci. Technol. 2013, 17, 380–409. [Google Scholar] [CrossRef]

- Sakamoto, S.; Iwasa, H. Effect of cutting revolution speed on cutting temperature in helical milling of CFRP composite laminates. Key Eng. Mater. 2012, 523, 58–63. [Google Scholar] [CrossRef]

- Olvera, D.; Lopez de Lacalle, L.N.L.; Urbikain, G.; Lamikiz, A.; Rodal, P.; Zamakona, I. Hole making using ball helical milling on titanium alloys. Mach. Sci. Technol. 2012, 16, 173–188. [Google Scholar] [CrossRef]

- Karpat, Y.; Değer, B.; Bahtiyar, O. Drilling thick fabric woven CFRP laminates with double point angle drills. J. Mater. Process. Technol. 2012, 212, 2117–2127. [Google Scholar] [CrossRef]

- Ramirez, C.; Poulachon, G.; Rossi, F.; M’Saoubi, R. Tool wear monitoring and hole surface quality during CFRP drilling. Procedia CIRP 2014, 13, 163–168. [Google Scholar] [CrossRef]

- Melentiev, R.; Priarone, P.C.; Robiglio, M.; Settineri, L. Effects of tool geometry and process parameters on delamination in CFRP drilling: An overview. Procedia CIRP 2016, 45, 31–34. [Google Scholar] [CrossRef]

- Abrao, A.M.; Rubio, J.C.; Faria, P.E.; Davim, J.P. The effect of cutting tool geometry on thrust force and delamination when drilling glass fibre reinforced plastic composite. Mater. Des. 2008, 29, 508–513. [Google Scholar] [CrossRef]

- Shyha, I.S.; Aspinwall, D.K.; Soo, S.L.; Bradley, S. Drill geometry and operating effects when cutting small diameter holes in CFRP. Int. J. Mach. Tools Manuf. 2009, 49, 1008–1014. [Google Scholar] [CrossRef]

- Tsao, C.; Hocheng, H. Effect of tool wear on delamination in drilling composite materials. Int. J. Mech. Sci. 2007, 49, 983–988. [Google Scholar] [CrossRef]

- Lazar, M.-B.; Xirouchakis, P. Experimental analysis of drilling fiber reinforced composites. Int. J. Mach. Tools Manuf. 2011, 51, 937–946. [Google Scholar] [CrossRef]

- Tsao, C.; Hocheng, H. Computerized tomography and C-Scan for measuring delamination in the drilling of composite materials using various drills. Int. J. Mach. Tools Manuf. 2005, 45, 1282–1287. [Google Scholar] [CrossRef]

- Durão, L.M.P.; Gonçalves, D.J.; Tavares, J.M.R.; de Albuquerque, V.H.C.; Vieira, A.A.; Marques, A.T. Drilling tool geometry evaluation for reinforced composite laminates. Compos. Struct. 2010, 92, 1545–1550. [Google Scholar] [CrossRef]

- Marques, A.T.; Durão, L.M.; Magalhães, A.G.; Silva, J.F.; Tavares, J.M.R. Delamination analysis of carbon fibre reinforced laminates: evaluation of a special step drill. Compos. Sci. Technol. 2009, 69, 2376–2382. [Google Scholar] [CrossRef]

- Durão, L.M.P.; Magalhães, A.G.; Tavares, J.M.R.; Marques, A.T. Delamination Analysis after Carbon/Epoxy Plate Drilling. Repository of the University of Porto. 2005. Available online: https://web.fe.up.pt/~tavares/downloads/publications/artigos/ENVC2005_artigo__LD_JT.pdf (accessed on 21 May 2018).

- Tsao, C.; Hocheng, H. Parametric study on thrust force of core drill. J. Mater. Process. Technol. 2007, 192, 37–40. [Google Scholar] [CrossRef]

- Tsao, C. Taguchi analysis of drilling quality associated with core drill in drilling of composite material. Int. J. Adv. Manuf. Technol. 2007, 32, 877–884. [Google Scholar] [CrossRef]

- Tsao, C. Investigation into the effects of drilling parameters on delamination by various step-core drills. J. Mater. Process. Technol. 2008, 206, 405–411. [Google Scholar] [CrossRef]

- Tsao, C. Experimental study of drilling composite materials with step-core drill. Mater. Des. 2008, 29, 1740–1744. [Google Scholar] [CrossRef]

- Tsao, C.; Chiu, Y. Evaluation of drilling parameters on thrust force in drilling carbon fiber reinforced plastic (CFRP) composite laminates using compound core-special drills. Int. J. Mach. Tools Manuf. 2011, 51, 740–744. [Google Scholar] [CrossRef]

- Silva, J.M.; Ferreira, F.; Abreu, S.M.; Matos, J.E.; Durão, L.M.P. Correlation of drilling damage with mechanical strength: A geometrical approach. Compos. Struct. 2017, 181, 306–314. [Google Scholar] [CrossRef]

- Faria, P.E.; Rubio, J.C.; Abrao, A.M.; Davim, J.P. The influence of tool wear on delamination when drilling glass fibre reinforced epoxy composite with high speed steel and cemented carbide tools. Int. J. Mater. Prod. Technol. 2009, 37, 129–139. [Google Scholar] [CrossRef]

- Davim, J.P.; Reis, P. Study of delamination in drilling carbon fiber reinforced plastics (CFRP) using design experiments. Compos. Struct. 2003, 59, 481–487. [Google Scholar] [CrossRef]

- Rawat, S.; Attia, H. Wear mechanisms and tool life management of WC–Co drills during dry high speed drilling of woven carbon fibre composites. Wear 2009, 267, 1022–1030. [Google Scholar] [CrossRef]

- Chen, W.-C. Some experimental investigations in the drilling of carbon fiber-reinforced plastic (CFRP) composite laminates. Int. J. Mach. Tools Manuf. 1997, 37, 1097–1108. [Google Scholar] [CrossRef]

- Faraz, A.; Biermann, D.; Weinert, K. Cutting edge rounding: An innovative tool wear criterion in drilling CFRP composite laminates. Int. J. Mach. Tools Manuf. 2009, 49, 1185–1196. [Google Scholar] [CrossRef]

- Gordon, S.; Hillery, M. A review of the cutting of composite materials. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2003, 217, 35–45. [Google Scholar] [CrossRef]

- Sheikh-Ahmad, J.; Davim, J. Tool wear in machining processes for composites. In Machining Technology for Composite Materials; Woodhead Publishing: Cambridge, UK, 2012; pp. 116–153. [Google Scholar] [CrossRef]

- Fernández-Valdivielso, A.; Lopez de Lacalle, L.N.L.; Urbikain, G.; Rodriguez, A. Detecting the key geometrical features and grades of carbide inserts for the turning of nickel-based alloys concerning surface integrity. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 230, 3725–3742. [Google Scholar] [CrossRef]

- Rawat, S.; Attia, H. Characterization of the dry high speed drilling process of woven composites using Machinability Maps approach. CIRP Ann. 2009, 58, 105–108. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Fangmann, S.; Rentsch, R. Drilling of composites and resulting surface integrity. CIRP Ann. 2011, 60, 57–60. [Google Scholar] [CrossRef]

- Murphy, C.; Byrne, G.; Gilchrist, M. The performance of coated tungsten carbide drills when machining carbon fibre-reinforced epoxy composite materials. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2002, 216, 143–152. [Google Scholar] [CrossRef]

- Garg, A.C. Delamination—A damage mode in composite structures. Eng. Fract. Mech. 1988, 29, 557–584. [Google Scholar] [CrossRef]

- Gaugel, S.; Sripathy, P.; Haeger, A.; Meinhard, D.; Bernthaler, T.; Lissek, F.; Kaufeld, M.; Knoblauch, V.; Schneider, G. A comparative study on tool wear and laminate damage in drilling of carbon-fiber reinforced polymers (CFRP). Compos. Struct. 2016, 155, 173–183. [Google Scholar] [CrossRef]

- Krishnaraj, V.; Prabukarthi, A.; Ramanathan, A.; Elanghovan, N.; Kumar, M.S.; Zitoune, R.; Davim, J.P. Optimization of machining parameters at high speed drilling of carbon fiber reinforced plastic (CFRP) laminates. Compos. Part B Eng. 2012, 43, 1791–1799. [Google Scholar] [CrossRef]

- Davim, J.P.; Reis, P. Drilling carbon fiber reinforced plastics manufactured by autoclave—Experimental and statistical study. Mater. Des. 2003, 24, 315–324. [Google Scholar] [CrossRef]

- Xu, J.; An, Q.; Cai, X.; Chen, M. Drilling machinability evaluation on new developed high-strength T800S/250F CFRP laminates. Int. J. Precis. Eng. Manuf. 2013, 14, 1687–1696. [Google Scholar] [CrossRef]

- Zhang, J.G.; Wang, B.; Sun, F.H.; Gao, H. Improvement on the Cutting Performance of CVD Diamond Coated Drills in Drilling CFRP. Key Eng. Mater. 2012, 499, 366–371. [Google Scholar] [CrossRef]

- Xu, J.; An, Q.; Chen, M. A comparative evaluation of polycrystalline diamond drills in drilling high-strength T800S/250F CFRP. Compos. Struct. 2014, 117, 71–82. [Google Scholar] [CrossRef]

- Shyha, I.; Soo, S.L.; Aspinwall, D.; Bradley, S. Effect of laminate configuration and feed rate on cutting performance when drilling holes in carbon fibre reinforced plastic composites. J. Mater. Process. Technol. 2010, 210, 1023–1034. [Google Scholar] [CrossRef]

- Halim, A.; Huda, N.F.; Aminanda, Y. Experimental Study of Cutting Parameter for Drilling on Fabric Carbon/Epoxy Laminates. Adv. Mater. Res. 2011, 311, 240–243. [Google Scholar] [CrossRef]

- Lopez de Lacalle, L.N.L.; Rivero, A.; Lamikiz, A. Mechanistic model for drills with double point-angle edges. Int. J. Adv. Manuf. Technol. 2009, 40, 447–457. [Google Scholar] [CrossRef]

- Hocheng, H.; Tsao, C. The path towards delamination-free drilling of composite materials. J. Mater. Process. Technol. 2005, 167, 251–264. [Google Scholar] [CrossRef]

- Capello, E. Workpiece damping and its effect on delamination damage in drilling thin composite laminates. J. Mater. Process. Technol. 2004, 148, 186–195. [Google Scholar] [CrossRef]

- Harris, M.; Qureshi, M.A.M.; Saleem, M.Q.; Khan, S.A.; Bhutta, M.M.A. Carbon fiber-reinforced polymer composite drilling via aluminum chromium nitride-coated tools: Hole quality and tool wear assessment. J. Reinf. Plast. Compos. 2017, 36, 1403–1420. [Google Scholar] [CrossRef]

- Zimmermann, M.; Heberger, L.; Schneider, F.; Effgen, C.; Aurich, J.C. Investigation of chip formation and workpiece load when machining carbon-fiber-reinforced-polymer (CFRP). Procedia Manuf. 2016, 6, 124–131. [Google Scholar] [CrossRef]

- Cadorin, N.; Zitoune, R. Wear signature on hole defects as a function of cutting tool material for drilling 3D interlock composite. Wear 2015, 332, 742–751. [Google Scholar] [CrossRef]

- Masuda, M.; Kuroshima, Y.; Chujo, Y. Failure of tungsten carbide-cobalt alloy tools in machining of carbon materials. Wear 1993, 169, 135–140. [Google Scholar] [CrossRef]

- Teti, R. Machining of composite materials. CIRP Ann. 2002, 51, 611–634. [Google Scholar] [CrossRef]

- Haeger, A.; Schoen, G.; Lissek, F.; Meinhard, D.; Kaufeld, M.; Schneider, G.; Schuhmacher, S.; Knoblauch, V. Non-destructive Detection of Drilling-induced Delamination in CFRP and its Effect on Mechanical Properties. Procedia Eng. 2016, 149, 130–142. [Google Scholar] [CrossRef]

- Ho-Cheng, H.; Dharan, C. Delamination during drilling in composite laminates. J. Eng. Ind. 1990, 112, 236–239. [Google Scholar] [CrossRef]

- Raj, D.S.; Karunamoorthy, L. Study of the effect of tool wear on hole quality in drilling CFRP to select a suitable drill for multi-criteria hole quality. Mater. Manuf. Process. 2016, 31, 587–592. [Google Scholar] [CrossRef]

- Palanikumar, K. Experimental investigation and optimisation in drilling of GFRP composites. Measurement 2011, 44, 2138–2148. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).