Abstract

This work presents a simple method to extract the piezoelectric coefficient based on analytical model fitting. A theoretical circuit model is developed for a piezoelectric circular membrane actuator based on PZT thin film. The circular diaphragm consists of a 12 µm silicon layer, an 800 nm thick PZT layer, and a 200 nm Ti/Pt layer, featuring a single 50% inner top electrode coverage. The proposed model is validated by the finite element method with a 2D axisymmetric model of a PZT piezoelectric membrane. Further, piezoelectric coefficient is extracted by fitting the Laser Doppler Vibrometer (LDV) experimental result with the analytical model.

1. Introduction

MEMS devices based on piezoelectric thin films have become ubiquitous in applications such as RF filters, acoustic devices, and energy harvesters [1]. The properties of the piezoelectric film play an important role in the performance of devices, especially the piezoelectric coefficient . Several piezoelectric measurement techniques have been reported, including direct and indirect methods [2,3]. In this work, we propose a simple and easily accessible approach to measuring piezoelectric constants by fitting the Laser Doppler Vibrometer (LDV) experimental data with an analytical model.

2. Materials and Methods

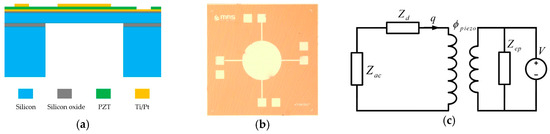

Figure 1a shows a fabrication schematic consisting of a stack of Si/SiO2/Ti/Pt/PZT/Ti/Pt layers. Figure 1b shows the optical photograph of a fabricated PZT device. An equivalent circuit model is developed to predict the behavior of the piezoelectric actuator, including the influence of residual stress. The theoretical model is validated by a finite element simulation model, and the piezoelectric constant is then extracted by fitting LDV experimental data with the theoretical model.

Figure 1.

(a) Schematic of the piezoelectric actuator; (b) Optical photograph of the fabricated PZT device. (c) The equivalent circuit model of the piezoelectric membrane actuator.

3. Discussion

The equivalent circuit model is shown in Figure 1c, where is the acoustic impedance; the diaphragm impedance; is the membrane volume velocity; and is the impedance collected from the piezoelectric film. is the transformer ratio related to volume velocity and actuation voltage . By analyzing the model, the piezoelectric constant can be extracted by Equation (1) as follows:

where is the angular frequency; is the radius of the membrane; is the Young’s modulus; is the distance from the mid-plane of the PZT layer to the neutral axis; is the flexural rigidity of the membrane; is the Poisson’s ratio of PZT; is the vibration mode-related function; and is the radial mode shape number [4].

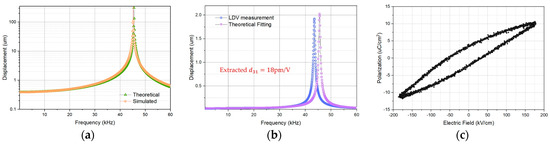

Figure 2a compares the theoretical and simulated results of the membrane displacement with a residual stress of 200 MPa, which match well. Figure 2b shows the displacement per voltage of a fabricated device measured by LDV and predicted by a theoretical model. The residual stress of the diaphragm is 200 MPa, as measured by a DektakXT stylus tool. To fit the experimental data, a measured quality factor value of 76 is substituted into the theoretical model. The theoretical and experimental results exhibit good agreement; the differences can be attributed to material parameters and fabrication tolerance. Subsequently, the piezoelectric constant is extracted as 18 pm/V. Figure 2c shows the polarization vs. electric field hysteresis loop of deposited PZT film at 1 kHz.

Figure 2.

(a) Comparison of the theoretical and simulated results of the membrane displacement. (b) Results measured by LDV and predicted by the theoretical model. (c) P−E hysteresis loop of deposited PZT film at 1 kHz.

Author Contributions

Y.G.: Conceptualization, methodology, software, validation, formal analysis, and writing—original draft preparation. M.M.T.: methodology and validation. S.V.J. and S.S.: data curation and methodology. A.Q. and C.W.: investigation. M.K.: writing—review and editing, supervision, project administration, and funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the China Scholarship Council (CSC) under Grant CSC No. 202006320040 and the Micro- and Nanosystems group headed by Prof. Michael Kraft.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Please contact the authors if you need further information.

Acknowledgments

We express our gratitude for the help provided by Michel De Cooman and Donald Raddoux.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Pillai, G.; Li, S.S. Piezoelectric MEMS resonators: A review. IEEE Sens. J. 2020, 21, 12589–12605. [Google Scholar] [CrossRef]

- Liu, J.M.; Pan, B.; Chan HL, W.; Zhu, S.N.; Zhu, Y.Y.; Liu, Z.G. Piezoelectric coefficient measurement of piezoelectric thin films: An overview. Mater. Chem. Phys. 2002, 75, 12–18. [Google Scholar] [CrossRef]

- Fialka, J.; Beneš, P. Comparison of methods of piezoelectric coefficient measurement. In Proceedings of the 2012 IEEE International Instrumentation and Measurement Technology Conference Proceedings, Graz, Austria, 13–16 May 2012; pp. 37–42. [Google Scholar]

- Sammoura, F.; Smyth, K.; Bathurst, S.; Kim, S.G. An analytical analysis of the sensitivity of circular piezoelectric micromachined ultrasonic transducers to residual stress. In Proceedings of the 2012 IEEE International Ultrasonics Symposium, Dresden, Germany, 7–10 October 2012; pp. 580–583. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).