In the last years, the interest to protect the integrity of historical objects has increased worldwide. Due to their composition (traces of Cu, Ag, and Fe), the risk of deterioration is present [1]. When atmospheric gases (such as CO2, SOx, NOx, and VOC) come in contact with water in the atmosphere or on the ground, they are chemically converted to acidic substances [2] that can attack the surface of historical objects. The aim of this work is to coat glass similar to ancient glass in order to prevent deterioration of surface by the acetic acid.

Model glass similar to ancient glass with oxide composition 29.23 SiO2-70 PbO- 0.5 CuO- 0.15Ag2O- 0.12 Fe2O3 was prepared by the traditional melt quenching route into an electrical oven at 1400 °C, for 1 h. The glass was cast in a carbon mold and thermally treated at 500 °C for 2 h. The covering solutions were prepared by sol-gel as reported [1,3]. The coated and uncoated glasses were subjected to chemical stability tests in acetic acid. The structure of the glass was investigated with FTIR spectroscopy and vitreous state was identified. The morphology was investigated by scanning electron microscopy (SEM) using a microscope; the Quanta FEI 200 model. The solutions were investigated by the inductively coupled plasma optical emission spectrometry (ICP-OES) method in order to determine the elements extracted during tests.

When the glass surface is in contact with an aqueous acidic medium for long time, the H+ ions can replace the metallic atoms in the glass after reaction: Si-O-M-O-Si + 2H+ → 2Si–O–H + M

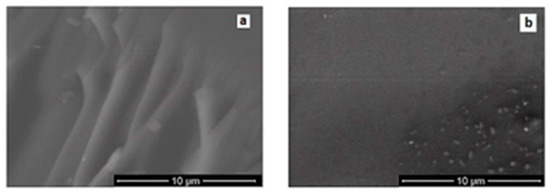

Figure 1a shows the high damage, with grooves in the surface of the uncoated glass after an acetic acid attack. In Figure 1b can be seen the smooth surface of silica-coated glass after acetic acid corrosion. The ICP-OES analysis of the solution resulting from corrosion of the uncoated glass shows extraction of 52 ppb Pb, 20 ppb Ag, 108 ppb Cu, and 40 ppb Fe.

Figure 1.

SEM images after acetic acid corrosion (a) uncoated glass and (b) silica coated glass.

The surface of model glass similar to ancient glass was damaged by acetic acid. The silica coating protected the glass against corrosion from acetic acid.

References

- Mocioiu, O.C.; Atkinson, I.; Pandele, J.; Boroica, L.; Sava, B.; Mocioiu, A.M.; Zaharescu, M. Protective coatings for the silicate glasses containing Fe2O3. Rev. Roum. Chim. 2014, 59, 267–272. [Google Scholar]

- Mehta, P. A conceptual understanding of scientific and legal perspective of acid precipitation and its impacts: A review. J. Appl. Sci. Res. 2015, 3, 54–75. [Google Scholar]

- Mocioiu, O.C.; Atkinson, I.; Cusu-Pandele, J.; Brătan, V.; Petrescu, S.; Băila, D.I.; Mocioiu, A.M. Structural and physico-chemical characterization of Zn-doped SiO2 glasses obtained by sol-gel route. Rev. Roum. Chim. 2018, 63, 419–424. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).