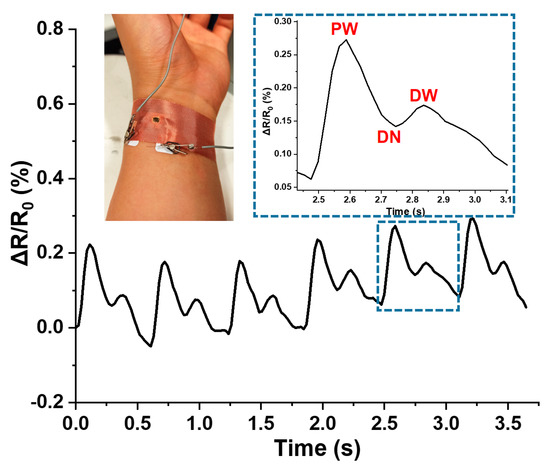

Green electronics is an emerging environment-friendly process of the design and manufacture of electronic goods for a sustainable future. A biocompatible and biodegradable sensor is a type of green electronics, which is designed to degrade after its term of use, avoiding environmental pollution. Furthermore, when used temporarily as an implanted sensor for medical monitoring, a biodegradable sensor does not require secondary surgical intervention for its removal [1,2]. Biodegradable polyurethane (PU), with high flexibility and biocompatibility, is well-suited for medical applications [3]. Its mechanical properties and biodegradation rates can be controlled by fine-tuning the molecular structure and the molar ratio of oligodiols to match the requirements of specific applications, e.g., when used as the substrate for medical strain sensors. In this regard, thin films of gold nanoparticles (GNPs) have been proposed for the fabrication of resistive strain sensors, enabling the high sensitivity, fast and reversible responses, biocompatibility, cost-efficient fabrication, and tunability of the underlying electrical properties [4]. Here, we prepared dithiol-cross-linked GNP films via layer-by-layer spin-coating on rigid substrates and transferred them onto biodegradable PU films by contact printing without the need for toxic chemicals or solvents. The strain-resistance performance of the obtained biocompatible GNP/PU sensors was tested by fatigue tests (10.000 cycles), revealing very good electro-mechanical durability. Four-point bending tests exhibited nearly linear resistive response characteristics with high gauge factors, ranging between 10 and 100. Due to their high sensitivity and the low elastic modulus of the PU substrates, our biocompatible GNP/PU strain sensors are well suited to monitoring human pulse waves, as shown in Figure 1. Furthermore, in order to exploring the potential of these sensors for in vivo application as implants, we conducted a first proof-of-concept study demonstrating the use of such strain sensors in liquid biological environments.

Figure 1.

Biocompatible gold nanoparticle/polyurethane (GNP/PU) strain sensor taped onto the position of the radial artery for pulse wave monitoring. A sequence of six pulse waves is presented as the relative change in the sensor’s resistance. Inset: Pulse wave with well-resolved details: percussion wave (PW), dicrotic notch (DN), and dicrotic wave (DW).

References

- Yu, X.; Shou, W.; Mahajan, B.K.; Huang, X.; Pan, H. Materials, Processes, and Facile Manufacturing for Bioresorbable Electronics: A Review. Adv. Mater. 2018, 30, 1707624. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Uhrich, K.E. Biodegradable and biocompatible polymers for electronic applications: A review. J. Bioact. Compat. Polym. 2019, 34, 3–15. [Google Scholar] [CrossRef]

- Hsu, S.H.; Hung, K.C.; Lin, Y.Y.; Su, C.H.; Yeh, H.Y.; Jeng, U.S.; Lu, C.Y.; Dai, S.A.; Fu, W.E.; Lin, J.C. Water-based synthesis and processing of novel biodegradable elastomers for medical applications. J. Mater. Chem. B 2014, 2, 5083. [Google Scholar] [CrossRef] [PubMed]

- Ketelsen, B.; Yesilmen, M.; Schlicke, H.; Noei, H.; Su, C.H.; Liao, Y.C.; Vossmeyer, T. Fabrication of Strain Gauges via Contact Printing: A Simple Route to Healthcare Sensors Based on Cross-Linked Gold Nanoparticles. ACS Appl. Mater. Interfaces 2018, 10, 37374–37385. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).