Abstract

There is an evolution and progress that has been taking place in recent years in science and technology and in the evolution of polymers that have created new plastic materials with excellent physical properties and durability. However, the plastic products that are made, generally have several applications, but for a single use, especially if it is in the part of food packaging, or for the pharmaceutical industry, in medical applications. Since these materials are not biodegradable, they remain on the surface of the earth for hundreds of years without considerable changes in their structure, causing pollution and damage to wildlife and the environment. With this research we intend to eliminate these plastics from petroleum derivatives, by biodegradable plastics. At the same time, the use of the generated by-products is sought, giving them an energy, thermal or fertilizer value.

1. Introduction

The use of fossil fuels has led us to seek new solutions in energy matters and the use of renewable energy sources such as sun, wind, water has already generated great advances. Currently, a circular economy is sought [1].

The consumption of these non-degradable plastics represents a very large negative impact on the environment. In addition to the time for their decomposition, the fauna around the spills, of this type of materials, can be affected in various ways, affecting their habitat or food. Even being able to cause the death of certain specimens. A study documents, real cases and the characterization of sludge, allows us to identify the properties to produce bioplastics (PHA) from the fermentation of volatile fatty acids (VFA).

Waste since the beginning of time, is a problem, regardless of the raw material from which they come. The waste from the treatment of wastewater with high carbon content produces bioplastics and a fertilizer with high organic content. In the production of biofuels such as biodiesel or bioethanol, we pro-duce waste that we will value as glycerin and fertilizer [2,3].

The water to be treated has been characterized, conducting an experimental study to produce VFA from industrial wastewater from sewage treatment plants, using membrane reactors technology. These waters had the following characteristics: ph: 7; a COD 8000 mg/L, the reactor with a capacity of 2 L and an organic load of 15 g/L/day. Wastewater is characterized by its high concentration of suspended solids and its high organic matter content [4].

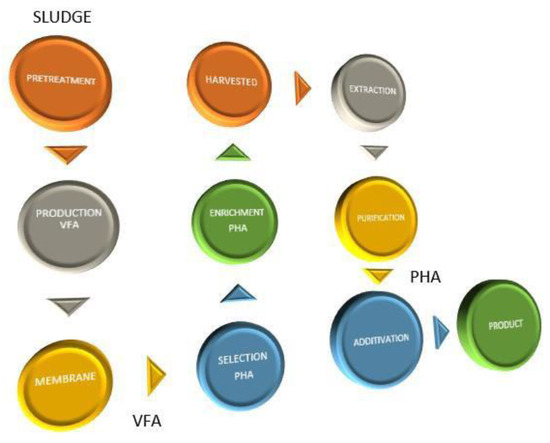

Once the water and sludge characterization phase were carried out, all the information collected was carried out an investigation of the bioreactor to produce VFA according to the different types of water. By means of anaerobic technologies with membrane and without membrane, measurements were made to produce VFA. We have completed the experimental development by studying the reactor conditions (Temperature, pH, hydraulic retention time, organic loading speed, sludge pretreatment and flushing). The resulting PHA solution is purified by two methods: Filtering and Washing or Centrifugation, to remove cell debris, then it is concentrated and the PHA is precipitated in methanol or ethanol and the polymer is recovered by vacuum drying and solvent evaporation (see Figure 1) [5].

Figure 1.

Bioplastic Production from Sludge.

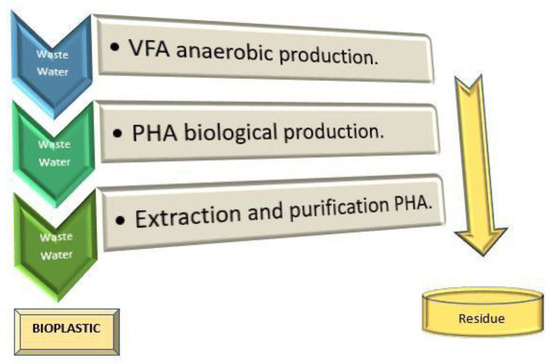

With a previous pretreatment, the greatest accumulation of PHA has been achieved in a low concentration of nutrients; Two possibilities of reduction were studied: Obtaining 91% phosphate and 60% ammonium by means of an alkaline fermentation of sludge, drying out the high quantity PHA biomass sample. Depending on their origin or if they are biodegradable or not, it can be seen in Figure 2. In the production of biofuels or VFA from wastewater they are routes to produce usable products such as bioplastics, biofuels, organic derivatives or fertilizers. The approach of this investigation of mixture of residues is to obtain a raw material with better properties.

Figure 2.

Bioplastic Production.

In the production of PHA a comparative analysis of environmental operations has been carried out and the operating conditions in its production have been varied. A membrane reactor has been carried out, on a laboratory scale. The results obtained are better with the incorporation of membranes reducing COD by 90%, producing 15 mg/L of VFA, average. With a filtration time of 4 min at a pH of 7, at 25 °C. Obtaining H2 by-products and a possible fertilizer. The first one can make an energy use and with the second an investigation will be carried out to improve the production of plantations in the production of biodiesel.

For the quantification of PHA, the gravimetric method was used by drying and weighing. Crystallinity determined by Energy required for fusion taking as reference data 132 J/g for 100% crystallinity.

2. Conclusions

The implementation of a prototype for the sustainable recovery of liquid effluents from the agri-food industry has been carried out, based on a combination of technologies (aerobic and anaerobic) to achieve maximum conversion efficiency in bioplastics. This has been achieved through a bioreactor. We have carried out the evaluation of the costs of the process for extrapolation at a pilot scale and to demonstrate the technical-economic feasibility of the project.

The evaluation of the effectiveness of the proposed recovery system on the final effluent quality, the productive yield and the quantity of by-products generated, and products used has been optimized. In the future, we will seek to give value to some of these by-products for their use as fertilizer in curved land to produce biofuels such as biodiesel [6,7].

Through this investigation we have been able to have a better knowledge of the state of the art of VFA/PHA production from sewage sludge by being able to design and develop an AnMBR bioreactor with optimized parameters on a laboratory scale, determining the operating points suitable for the pro-duction of VFA in the anaerobic membrane bioreactor. We have also been able to establish the bases to produce new alternatives to conventional plastics with high contaminating power: Optimized synthesis of PHAs and we have developed a protocol for extraction, purification and characterization of the PHAs obtained [8].

References

- Rhu, D.; Lee, W.; Kim, J.; Choi, E. Polyhydroxyalkanoate (PHA) production from waste. Water Sci. Technol. 2003, 48, 221–228. [Google Scholar] [CrossRef] [PubMed]

- Labuzek, S.; Radecka, I. Biosynthesis of PHB tercopolymer by Bacilllus cereus UW85. J. Appl. Microbiol. 2001, 90, 353–357. [Google Scholar] [CrossRef] [PubMed]

- Anes Garcia, N.; Blanco, F.; Marques Sierra, A.L. Circular Economy in the Manufacture of Bioplastics: From Sewage Sludge to Plastic Bottle. Proceedings 2018, 2, 1425. [Google Scholar] [CrossRef]

- Wu, Q.; Huang, H.; Hu, G.; Chen, J.; Ho, K.; Chen, G. Production of poly-3-hydroxybutyrate by Bacillus sp. JMa5 cultivated in molasses media. Antonie van Leeuwenhoek 2001, 80, 111–118. [Google Scholar] [CrossRef] [PubMed]

- Borah, B.; Thakur, P.; Nigam, J. The influence of nutritional and environmental conditions on the accu-mulation of poly-E-hydroxybutyrate in Bacillus mycoides RLJ B-017. J. Appl. Microbiol. 2002, 92, 776–783. [Google Scholar] [CrossRef] [PubMed]

- Katircioglu, H.; Aslim, B.; Yüksekdað, Z.; Mercan, N.; Beyatli, Y. Production of poly E-hydroxybutyrate (PHB) and differentiation of putative Bacillus mutant strains by SDS-PAGE of total cell protein. Afr. J. Biotechnol. 2003, 2, 147–149. [Google Scholar]

- Yilmaz, M.; Soran, H.; Beyatli, Y. Determination of poly-E-hydroxybutyrate (PHB) production by some Bacillus sp. World J. Microbiol. Biotechnol. 2005, 21, 565–566. [Google Scholar] [CrossRef]

- Almeida, A.; Ruiz, J.A.; López, N.I.; Pettinari, M.J. Bioplásticos: Una alternativa ecológica. Revista Química Viva 2004, 3, 122–133. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).