Abstract

Objective This research is aimed to reduce time for the aircraft painting processes and decrease the budget for the painting activities which will not affect to the life limit of the painting and will not affect to the aerodynamic of the aircraft. method The research will be conducted by setting up the experiments to study the aircraft surface painting preparation methods, in order to find the better method of aircraft painting study the technical specification of the aircraft coating in associate with the viscosity of painting, air temperature for painting, relative humidity, drying time, lifetime period, hardness and difference, interval of time between painting and mixing solvent quality study the tools that use for painting such as air spray, airless spray, roller and brush study for error checking methods for understanding the painting defects result Reduce the errors that might occur during the aircraft painting processes which will lead to the budget decreasing and time reducing for aircraft painting conclusion To obtain the good quality of painting, it is very important to realize the specification of applied coating, working processes and painting equipment that associate with the maintenance manual of each aircraft, the effect factors that take into account of the painting and the technique of painting that is used.

1. Introduction

Painting is to protect material surface forming dry film from moisture, dielectric, anti-chemical, sound wave, air flow, etc., against corrosion also is good to see appearance. The principal of basic anticorrosion is to cut humidity, air and chemical from the surface. In addition, the process of corrosion occurrence is that the metal is exposed by surrounding, it is reacted to chemical and electrical, finally property can be changed.

Corrosion factors and progress according to environment are as follows (Table 1).

Table 1.

Corrosion factors relate with environment

2. Surface Preparation

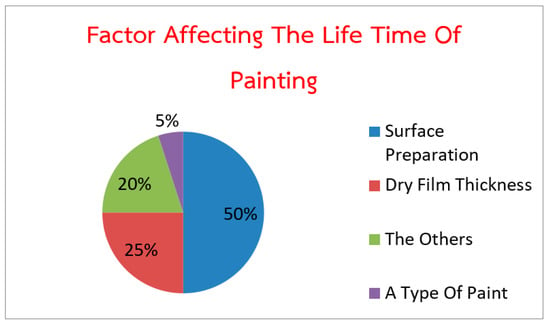

Surface preparation is the most important to determine a factor of paint life, damaged materials and contaminated things on surfaces should be totally removed and to forming “Profile” (roughness on the surface) to improve adherence for paint workability. The method are chemical (solvent, thinner, etc.) and Mechanical (sandpaper, power tool, etc.) (Figure 1).

Figure 1.

Factor affecting the life time of painting or coating.

3. Wording Explanation of Paint and Coating

There are a lot of painting wording. For example, pot life, SVR (solid volume ratio between wet film and dry film), recoating interval, viscosity, relative humidity, dry film thickness, paint specification, profile, holiday (miss spot on surface) etc. (Figure 2).

Figure 2.

comparison between surface with profile and without profile.

4. Method:

4.1. Equipment and Painting Are Used in Royal Thai Navy’s Aircraft

The type of painting method in RTN’s aircraft are brush painting, roller painting, air spray, airless spray. Environment for painting must be considered, defects can occur according temperature, humidity, dew point, wind, vent condition. The specification of painting is guidance for coating (Table 2).

Table 2.

Example of coating specification

Figure 3.

Wet film thickness guage.

Figure 4.

Dry film thickness measure.

5. Result

Understanding, how to clean up the surface and use suitability tool, decrease time for coating and painting, decrease error occur, save budget, the aircraft look beautiful (Figure 5 and Figure 6).

Figure 5.

RTN painting’s work.

Figure 6.

RTN painting’s work.

6. Conclusions

The painting or coating is very important to protect aircraft from corrosion and make she looks beautiful. Depend on right action and suitable specific coating. That can reduce time for the aircraft painting processes and decrease the budget.

Acknowledgments

1. Aircraft rework faculty center royal Thai naval air division. 2. Sahayong Mongkol Ltd. Thailand, Part.

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).