Abstract

Additive manufacturing (AM) has proven in a number of demonstrators its tremendous potential for structural components. AM has gone beyond being a prototyping process and is now firmly being explored as production process in numerous domains. The objective of the paper is to provide an overview of remaining challenges in the field of AM and structural health monitoring. A symbiotic solution, a smart structure, for some of the challenges in both fields will be presented. The development progress made in these domains by the Acoustics and Vibration Research Group (AVRG) of the Vrije Universiteit Brussel will be discussed and the future outlook.

1. Introduction

Additive manufacturing (AM), also known as 3D Printing or Rapid Manufacturing is a group of technologies used for manufacturing of (near)-net shape products (functional parts, prototypes, tooling components, etc.) starting from 3D computer-aided design (CAD) data or other geometry representations. Nowadays numerous types of metal alloys, polymers and ceramics can be processed with these new technologies. The Standard Terminology for Additive Manufacturing Technologies has been defined by the ASTM F42 and ISO TC 261 committee in the EN ISO/ASTM 52900 standard to clarify the plenitude of terms used by different organizations. This terminology will also further be used here. In this paper, the focus will be on the metallic AM technologies that have a high potential to create structures with excellent material properties in the future.

Within the domain of metal AM the following two technology categories powder bed fusion (PBF) and direct energy depositions (DED) are receiving the most attention. Within these two categories laser and electron beams are being applied as energy sources.

One of these technologies, within PBF category, is Layerwise Laser Melting (LLM). Layerwise Laser Melting is often referred to as Selective Laser Melting (SLM) (MTT technologies), Laser Cusing (Concept Laser GmbH) and Direct Metal Laser Sintering (EOS).

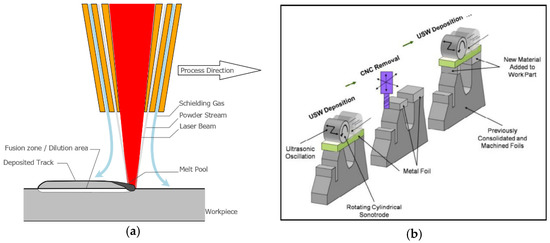

A second technology, within the DED category, is Laser Metal Deposition (LMD). Laser Metal Deposition is often referred to as Direct Metal Deposition (POM Group), Laser Engineered Net Shaping (Optomec) Laser Cladding or Construction Laser Additive Direct (BeAM), Beam Deposition (BD). A schematic representation of the nozzle of the LMD process is depicted in Figure 1. In this process a laser beam is focused on the surface of a solid metallic workpiece, locally heating the surface. The powder stream is preheated by passing through a focused laser beam. Subsequently the preheated metallic powder stream is blown into the laser-induced melt pool at the workpiece surface. The heated metallic powder is blown into this melt pool where it mixes with the molten substrate material. As the nozzle is moving, the melt pool solidifies and a track of solid material (a clad) is formed. By sequentially applying multiple clads 3D components can be produced.

Figure 1.

(a) Schematic representation of a nozzle of an LMD machine; (b) Schematic representation of the UAM process [1].

In order to integrate an intelligence or smartness within a structural component, a sensor system typically needs to be integrated within the component itself. Ultrasonic additive manufacturing (UAM) is a promising technique in the field of sensor integration due to the low temperature during manufacturing of 150 °C. It is a solid state AM process which belongs to the sheet lamination category, in this process metal foils are bonded together using ultrasonic welding (USW), besides the USW process also a computer numerical control (CNC) machine is integrated to remove material [1]. UAM has not yet established itself as an attractive manufacturing alternatives probably because of a critical operational issue known as “height-to-width ratio problem” [2]. This means that when the build height reaches the width bonding failure occurs at the top foil and additional layers cannot be bonded anymore.

Within the domain of smart structures Lehmhaus et al. provided an overview of applications of smart structures ranging from object tracking, structural health monitoring (SHM), usage monitoring, etc. [3]. In the context of internet of things (IoT) products will become smarter and smarter in the future. The potential exists that the structures of these products will participate in this evolution. As such the mechanical behavior can be monitored by SHM systems of complete populations of structures or a representative group. The impact of this data in the future on the complete value chain can be enormous. For example a “continuous” structure optimization process from design point of view and production point of view. This change will take time and according to the authors will rather be an evolution than a revolution. In order to enable this evolution to become an economical viable solution, a manufacturing process is required that supports this flexibility. In this domain AM could provide huge opportunities in the future. Lehmhaus et al. discuss the link between AM and sensor integration and provide a classification for smart components based on sensor level integration and manufacturing system configuration [3]. The technological and economic requirements of the application will drive the manufacturing configuration and sensor integration approach into the component.

As stated by Speckmann et al., SHM is an alternative approach of NDI for the inspection of the structural integrity of aircrafts and can be a major part of the prospective intelligent structures [4].

The paper starts by presenting key challenges that exist in the development of AM domain and fundamental challenges for Structural Health Monitoring (SHM) systems for industrial applications. The SHM challenges formed the basis toward the effectiveness of the new SHM methodology that will be described in Section 4. In this section it’s the intrinsic positive characteristics of the SHM system will be discussed and fatigue test results. Final remarks, conclusions and future vision with respect to hybrid AM and SHM are given in the last Section.

2. Key Challenges for AM

The key challenges for AM have been discussed in the literature in a number of papers, roadmaps and reports [5,6,7]. These documents have been analyzed and summarized in a non-exhaustive list of challenges from a research perspective, but with a high importance for future implementation of AM in the industry. In order to provide a framework the challenges are subdivided in four specific categories. This should allow the reader to retrieve easier the source information in the referred manuscripts.

2.1. Design

- New foundation for CAD systems, to enable an efficient representation and sharing of complex geometries and as such exploiting the design freedom offered by AM.

- Integrate variability within component design methods. This variability can be originating from the following domains: shape, materials applied, material properties, process parameters, etc.

- Enable multiscale modelling and assistance in the definition of process parameter material property relationships. The user of the design tools should be able to start the design by specifying the required properties of the components and the tools should provide support in the definition of the required geometry, material and process parameters.

2.2. Materials

- Underlying science of AM needs to be developed. Physics based models are needed relating microstructure, processing parameters and performance of AM fabricated parts.

- Understanding multiple interacting physical phenomena and how to control fatigue properties.

- Better understanding of residual stress, anisotropic material behavior and porosities.

- A shared 3rd party database with design allowables and performance capability database.

- Explore the functional graded material potential.

2.3. Process Modelling and Control

- Robust in situ process monitoring techniques including sensors for measuring and monitoring the AM process.

- Feedforward and feedback closed loop controlling systems in order to avoid machine to machine variability and enabling process certification and not part by part certification.

- Reduction of surface roughness and residual stresses within the AM process.

- Improve geometrical precision and build volume rate.

2.4. Standardization, Qualification and Certification

In 2017 the Standardization Roadmap for Additive Manufacturing, Version 1.0 was presented by America Makes & the American National Standard Institute (ANSI). The roadmap was the result of a year of work within Additive Manufacturing Standardization Collaborative (AMSC), a group specifically established to coordinate and accelerate the development of industry-wide AM standards and specifications. The roadmap identified 89 missing links or standards from an industrial point of view. Besides the previously mentioned institutes also the ASTM International Technical Committee F42 is active in the area of additive manufacturing standardization in partnership with ISO Technical Committee 263.

3. Fundamental Challenges for SHM

SHM is defined as “the process of acquiring and analyzing data from on-board sensors to evaluate the health of a structure”, in the ARP 6461 standard issued by The Aerospace Industry Steering Committee on SHM and Management (AISC-SHM) which operates as a Technical Committee with SAE Aerospace within the Aerospace Division (G-11 SHM). Health is defined as the ability to function/perform and maintain the structural integrity throughout the entire lifetime of the structure [8].

As stated by Prof. C.R. Farrar one of the most fundamental challenges is the fact that damage is typically a local phenomenon and may not significantly influence the lower-frequency global response of structures that is normally measured during system operation [9]. A self-test functionality should also be present within the SHM system that allows the user to verify the proper functioning of the system to eliminate the false detection potential.

According to the authors, another fundamental challenge exists within the definition of the lowest amount of parameters to be measured to reach the required system performance. It is a clear benefit with respect to the maintainability of the SHM system to have a small number of sensors. Also the SHM system reliability will be directly impacted by the required number of sensors. The effort to make the SHM more redundant and ‘fail-safe’ by equipping the structure with a backup sensor has a smaller economical consequence as well. Finally the minimization of the required number of sensors will lead to a reduction of the data volume that needs to be transmitted, processed and stored. It can be concluded that the required number of sensors is a challenge with a high multiplication factor with respect to the acceptance potential of the SHM methodology.

The academic community has proposed numerous Structural Health Monitoring (SHM) techniques in the last decade [10]. Many of these approaches work well in laboratory conditions but are not effective and robust enough to be applied in practice.

One aspect that is often overlooked is the lifetime of the monitoring system itself and its robustness with respect to the operational environmental conditions [11]. The importance of this robustness cannot be underestimated typically for the aeronautical industry. It can be concluded that the durability, reliability and longevity in practice of SHM is a key challenge for the successful implementation of a SHM system in real life applications. According to the authors this robustness request should also be translated in another core challenge for SHM systems namely the integration within the structure itself. In this manner it can’t be damaged by accidental mechanical loads that are not problematic for the structure itself.

Finally another fundamental challenge is the cost of the SHM system itself and the installation cost. A large scale implementation of a SHM system would be inhibited if the cost is not acceptable in a large number of applications. This would form a serious limitation for the introduction of SHM systems. The cost should be as low as possible; to achieve this goal an automated production process and installation will definitely form a crucial factor together with the required number of sensors. This automation request will probably require new production technologies such as AM.

4. Lesson Learned from Fatigue Tests of eSHM System

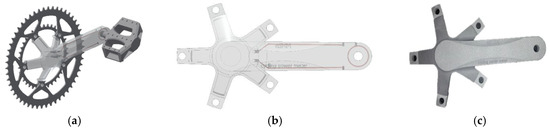

AVRG, from the Vrije Universiteit Brussel (VUB), has developed a novel Structural Health Monitoring (SHM) system, in which we here will further refer to as “eSHM” (or effective Structural Health Monitoring). It typically consists of a 3D network of capillaries or cavities (as depicted in Figure 2 in red) within the structural component. The capillaries are usually filled with a pressurized medium. As soon as a crack penetrates the capillary, a leak flow will occur and this affects the internal absolute pressure, which can be sensed by the attached pressure sensors. An example structure can be retrieved in Figure 2.

Figure 2.

Bicycle crank with integrated eSHM power meter and crack detection system (a) Isometric view; (b) front view (c) picture printed bicycle crank.

In previously presented papers the results of four point bending tests with SLM test specimens were discussed. It was shown with fracture analysis that crack nucleation sites typically developed at near-surface defects such as concentrated pores or lack-of-fusion regions in as build samples. It was proven that the SHM system did not influence the crack initiation behavior during fatigue test if correctly designed [12]. In a subsequent test campaign the porosity defects in the SLM test specimens were eliminated by applying a hot isostatic pressure (HIP) procedure. This increased the fatigue strength values (at 500,000 cycles) to significantly above the yield value of the conventional material. A further improvement of the system was reached by reducing the internal roughness of the capillary system by a chemical etching procedure [13].

Also four point bending tests were conducted for LMD specimens; these specimens demonstrated higher fatigue strength results for as build samples compared to SLM. Therefore LMD specimens were selected to test different capillary locations within the specimen. In these tests with LMD samples capillaries with the shortest edge to edge distance, the capillary became the crack initiation site under high-stress levels but lower than expected from simulations. Stress relief did not improve the fatigue response. In case of specimens of conventional material with similar dimensions, which represent ideal conditions, namely no internal defects, no residual stresses are present and fine surface finishing of the capillary. For these specimens the crack nucleated from the side of the specimens and not from the capillary region. Also FEM simulations confirmed that severe stress concentrations on the capillary are present when the roughness is taken into account in the simulations. The fatigue performance was greatly reduced when considering a printed capillary. It is concluded that the surface quality of the integrated capillary is of primary importance in order not to influence the structural integrity of the component to be monitored [14,15].

5. Outlook and Future Work with Hybrid Approach

As explained in the previous sections, the surface roughness on the inside of the cylindrical wall of the capillary has a significant effect on the fatigue performance. A controllable impact is also expected from the diameter size of the capillary. Nevertheless the smaller the diameter becomes the higher number of application that will be able to integrate the eSHM system into their structure. A major improvement can only be achieved by revisiting the production process. This has led to the idea of adding a laser-based subtractive process to an additive manufacturing process. It allows removing material in the micrometer-range. Yet, there are still some clear fundamental challenges that need to be tackled before uncovering the full potential of this innovative approach.

In consequence of the high importance for the further development of AM and the eSHM system, a symbiotic consortium between Vrije Universiteit Brussel (AVRG, MeMC, Surf, R&MM) and KU Leuven (PMA) are building a next-generation hybrid manufacturing research platform.

This research platform consists of two different machines. Each machine integrates a different additive manufacturing technology processing, namely Laser Metal Deposition (LMD) or Selective Laser Melting (SLM), with Laser Beam Micro Machining (LBMM) as a subtractive technique. LBMM is a collective term for drilling, cutting, welding, ablation and surface texturing in a contact and wear-less manner typically employing a pulsed laser with an average power below 1 kW. With this new platform we have the objective to manufacture capillaries with a diameter of 100 µm in diameter with perfect surface roughness values.

Author Contributions

Z.J., M.M. & M.L. conducted literature review in collaboration with D.D.B., M.S. & M.H. performed tests, D.D.B. wrote the paper. Future work defined by discussion between D.D.B. & P.G.

Acknowledgments

Research funded by an SBO Project grant 110070: eSHM with AM of the Agency for Innovation by Science and Technology (IWT), and Project grant for Hybrid Laser-based additive—subtractive research platform (HyLaForm) of EWI department from the Flemish Government

Conflicts of Interest

The authors declare no conflict of interest.

References

- Friel, R.J.; Harris, R.A. Ultrasonic Additive Manufacturing—A Hybrid Production Process for Novel Functional Products. Procedia CIRP 2013, 6, 35–40, ISSN 2212-8271. [Google Scholar] [CrossRef]

- Robinson, C.J.; Zhang, C.; Ram, G.J.; Siggard, E.J.; Stucker, B.; Li, L. Maximum height to width ratio of freestanding structures built using ultrasonic consolidation. In Proceedings of the 17th Solid Freeform Fabrication Symposium, Austin, TX, USA, 14–16 August 2006. [Google Scholar]

- Lehmhus, D.; Aumund-Kopp, C.; Petzoldt, F.; Godlinski, D.; Haberkorn, A.; Zöllmer, V.; Busse, M. Customized Smartness: A Survey on Links between Additive Manufacturing and Sensor Integration. Procedia Technol. 2016, 26, 284–301, ISSN 2212-0173. [Google Scholar] [CrossRef]

- Speckmann, H.; Roesner, H. Structural Health Monitoring: A Contribution to the Intelligent Aircraft Structure. In Proceedings of the 9th European Conference on NDT (ECNDT), Berlin, Germany, 25–29 September 2006; pp. 1–7. [Google Scholar]

- Bourell, D.L.; Leu, M.C.; Rosen, D.W. Roadmap for Additive Manufacturing; University of Texas: Austin, TX, USA, 2009. [Google Scholar]

- Frazier, W.E.J. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- NIST. Measurement Science Roadmap for Metal-Based Additive Manufacturing; US Department of Commerce, National Institute of Standards and Technology, Prepared by Energetics Incorporated: Gaithersburg, MD, USA, 2013. [Google Scholar]

- Staszewski, W.J.; Boller, C.; Tomlinson, G.R. Health Monitoring of Aerospace Structures Smart Sensor Technologies and Signal Processing; John Wiley & Sons: Hoboken, NJ, USA, 2004; ISBN 0-470-84340-3. [Google Scholar]

- Farrar, C.R.; Worden, K. An introduction to structural health monitoring. Philos. Trans. R. Soc. Lond. A 2007, 365, 303–315. [Google Scholar] [CrossRef] [PubMed]

- Boller, C.; Meyendorf, N. State-of-the-Art in Structural Health Monitoring for Aeronautics. In Proceedings of the International Symposium on NDT in Aerospace, Fürth/Bavaria, Germany, 3–5 December 2008. [Google Scholar]

- Kessler, S.S.; Amaratung, K.; Wardle, B.L. An assessment of Durability Requirements for Aircraft Structural Health Monitoring Sensors. In Proceedings of the 5th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 12–14 September 2005; FU-Kuo Chang; pp. 812–819, ISBN 1-932078-51-7. [Google Scholar]

- Strantza, M.; Vafadari, R.; De Baere, D.; Vrancken, B.; Van Paepeghem, W.; Vandendael, I.; Terryn, H.; Guillaume, P.; Van Hemelrijck, D. Fatigue of Ti6Al4V Structural Health Monitoring Systems Produced by Selective Laser Melting. Materials 2016, 9, 106. [Google Scholar] [CrossRef] [PubMed]

- Hinderdael, M.; De Baere, D.; Guillaume, P. Fatigue performance of powder bed fused Ti-6Al-4V component with integrated chemically etched capillary for structural health monitoring application. In Proceedings of the 18th International Conference on Experimental Mechanics, Brussels, Belgium, 1–5 July 2018; Volume 494, pp. 1–6. [Google Scholar]

- Strantza, M.; Hinderdael, M.; De Baere, D.; Vandendael, I.; Terryn, H.; Van Hemelrijck, D.; Guillaume, P. Additive manufacturing for novel structural health monitoring systems. In Proceedings of the 8th European Workshop on Structural Health Monitoring, Bilbao, Spain, 5–8 July 2016; Volume 58, pp. 1–19. [Google Scholar]

- Hinderdael, M.; Strantza, M.; De Baere, D.; Devesse, W.; De Graeve, I.; Terryn, H.; Guillaume, P. Fatigue performance of Ti-6Al-4V additively manufactured specimens with integrated capillaries of an embedded structural health monitoring system. Materials 2017, 10, 993. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).