Abstract

The objective of this study was to investigate the influence of solid particles of talc in water contaminated wheel-rail contact. The main aim was to identify situations where low adhesion can occur and define properties that impact the drop of adhesion. For the purpose of this study a laboratory ball-on-disc device was used.

1. Introduction

Efficiency and safety of rail transportation is among other key properties mostly influenced by adhesion between wheel and rail. The layer that forms between these contact surfaces has great effect on the adhesion behavior. To manage this behavior, friction modification is widely used nowadays by train operators. Specifically water based friction modifiers (FMs) are one of the products used for this purpose. In these substances, water is used as a carrying medium and solid particles provide the friction modifying effect. However, the water itself is supposed to dry out before passage of a train. This does not have to occur every time and different amount of residual water can be present on the rail, which can significantly affect the resulting adhesion. The aim of this study was to investigate the influence of solid particles with water on resulting adhesion, thus the rest of constituents of FM were neglected.

2. Materials and Methods

The frictional behavior of water and solid particles was studied using commercial ball-on-disc apparatus (Mini traction machine, PCS Instruments). The used specimens are ball of 19.05 mm diameter and 46 mm diameter disc. Both specimens were made from bearing steel AISI 52 100. Hardness of the ball and disc were 800–920 HV and 720–780 HV respectively. The initial roughness of the ball and disc was Ra 0.01 µm and Ra 0.02 µm respectively. The parameters of used specimen do not correspond to wheel and rail, but the increased resistance to wear allow to determine more precisely the frictional properties of the applied layer. The solid particles used were chosen to be mineral particles of talc in three different sizes (D90: S—5 µm, M—9 µm, L—12 µm). Experiments were carries out under load of 16 N ± 0.01 N, which resulted in contact pressure of approximately 750 MPa. The rolling speed was set to 0.3 m/s with slide-to-roll ratio of 5%.

3. Results

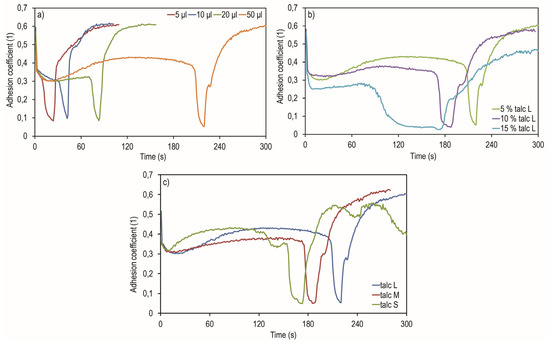

Results of laboratory experiments [1] are shown in Figure 1. Figure 1a shows results of different applied amounts of composition with water and 5 wt % of talc L. With increasing the applied amount, it is clear that the effective time is prolonged. Before reaching the dry levels of adhesion a significant drop in adhesion occurs. This phenomenon is most likely linked with the decrease of water content and increase in viscosity that leads to separating contact surfaces. The duration of this drop and the level of adhesion is not significantly affected by the increase in applied amount. However, increasing the amount of talc in composition leads to longer low adhesion zone as shown in Figure 1b. The higher concentration of solid particles allows to prolong the high viscosity regime of drying out. The value of low adhesion is only slightly lowered by increasing the talc concentration in composition. The effect of particle size is shown in Figure 1c. Increasing the size of the particles increases the effective duration of composition. However, neither the duration of low adhesion nor the value of adhesion coefficient was substantially affected by change in particle size.

Figure 1.

Friction curves for 5 wt % talc L under different applied amounts (a), 50 µL applied water and talc L (b) and 50 µL applied water and 5 wt % of solid particles (c).

4. Conclusions and Discussion

This study showed solid mineral particles of talc in water contaminated contact can lead to significant drop of adhesion level before drying out of the composition. The duration and level of adhesion was not affected by increasing the applied amount or changing the particle size. Most substantial difference has been found with increasing the particle content. Because the running surface of the disc is much wider than the contact area, the excess composition can be forced outside the contact. Thus only increasing the amount of talc content leads to change in low adhesion behavior. These results suggest that reducing low adhesion problems of water based friction modifiers should be done by finding the correct amount of solid particles in FM.

Acknowledgments

The authors are sincerely grateful to European Commission for the financial sponsorship of the H2020-MSCA-RISE Project No. 691135 “RISEN: Rail Infrastructure Systems Engineering Network,” which enables a global research network that tackles the grand challenge in railway infrastructure resilience and advanced.

Reference

- Galas, R.; Kvarda, D.; Omasta, M.; Krupka, I.; Hartl, M. The role of constituents contained in water-based friction modifiers for top-of-rail application. Tribol. Int. 2018, 117, 87–97. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).