Abstract

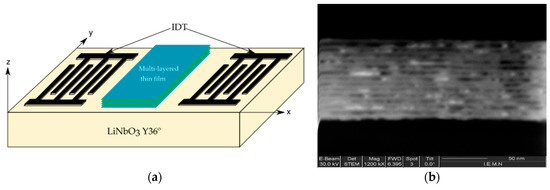

Over the last decades, the use of Surface Acoustic Waves (SAW) has emerged as a promising technology in many applications such as filters, signal processing but also sensors. We report the fabrication and the characterization of a SAW delay line magnetic field sensor using uniaxial multi-layered 14×[TbCo2(3.7nm)/FeCo(4nm)] nanostructured thin film deposited on Y36° Lithium Niobate (Figure 1a). The sensor shows an interesting dependency to a tunable bias magnetic field with different orientations relative to the easy axis. The obtained results are well explained using an equivalent piezo-magnetic model described in a previous work.

1. Introduction

SAW and magnetoelastic coupling in magnetic thin film already showed promising results to design magnetic sensors [1,2,3]. Some work is already under way in developing magnetostrictive materials used as sensing elements and improving sensor design to reach a good sensitivity in the picoTesla range at room temperature (particularly due to (Spin Reorientation Transition (SRT)) as related in [4]). Indeed, the use of suitable magnetostrictive materials and designs offers the possibility to tune such sensors in a wide range of measurement.

Therefore, it is relevant to study the behavior of Surface Acoustic Waves in magnetostrictive thin films under the bias of a tunable magnetic field. The designed SAW sensor is operated in a delay line configuration at 146 MHz on Y36° Lithium Niobate (Figure 1a). A uniaxial multi-layered 14×[TbCo2(3.7nm)/FeCo(4nm)] nanostructured thin film (see Figure 1b) is deposited by RF sputtering between the InterDigital Transducers (IDTs) as depicted Figure 2b. The fabrication process is given in Section 2. Major results are given in Section 3.

Figure 1.

(a) Scheme of a SAW delay line with a magnetoelastic thin film on the travel of the surface acoustic wave; (b) TEM picture of the multi-layered nanostructured thin film.

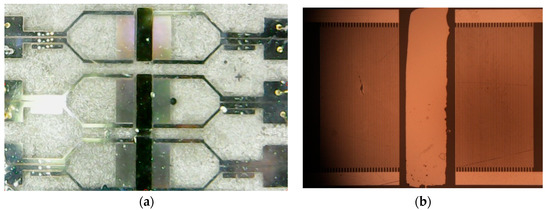

Figure 2.

(a) A photograph of the designed SAW delay line; (b) A close-up of the multilayered thin film surrounded on either side by IDTs.

2. Device Fabrication

The SAW delay line is manufactured according to a well-known process used in microelectronic technologies, photolithography. An optical mask is first designed to transfer the patterns on a resist layer deposited on the piezoelectric substrate. After exposure and development, the patterns are opened and aluminum used for IDTs is deposited by RF sputtering. A last step called lift-off is required to remove the excess resist and reveal the device as shown Figure 2b.

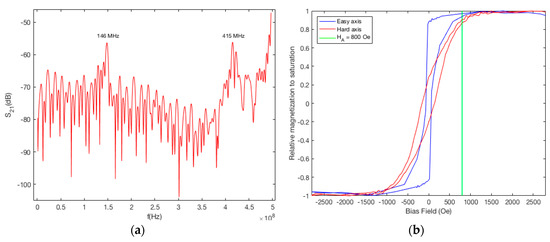

3. Characterization

The manufactured device is then characterized in terms of S parameters. As depicted Figure 3a, one can see the acoustic response at the fundamental frequency of 146 MHz corresponding to the shear wave propagating in the LiNbO3 Y36° cut. The magnetization of the multi-layered thin film is also measured using a Vibrating Sample Magnetometer (VSM) as shown on Figure 3b. It highlights the presence of the easy axis (uniaxial anisotropy) and an anisotropy field around 800 Oe.

Figure 3.

(a) Insertion Loss (S21) measured after time gating; (b) TbCo2/FeCo thin film magnetization characteristics measured using a VSM along the hard axis (red) and easy axis (blue). The anisotropy field is around 800 Oe (green).

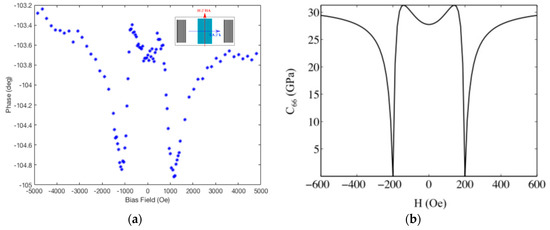

Due to magnetostrictive effect in the magnetic thin film and magnetoelastic coupling occurring in this kind of structure, the velocity of the shear waves follows the magnetoelastically-induced changes of the Young modulus according to the bias magnetic field, known as ΔE-effect, resulting in a phase shift in the transmission (S21 parameter). On the measurements reported Figure 4a, the bias magnetic field is applied along the hard axis, perpendicular to the direction of propagation.

Figure 4.

(a) S21 phase shift as a function of the bias magnetic field at 146 MHz; (b) c66 elastic constant as calculated with the piezomagnetic equivalent model described in [5].

At a first glance on Figure 4a,b, the phase shift due to elastic coupling proves to be correlated with the c66 elastic constant shown on Figure 4b. This dependency of elastic constant was calculated in the same configuration using the piezomagnetic equivalent model described in [5,6]. This result is not surprising since this elastic constant is mainly involved in shear displacement on the travel of a transverse acoustic wave. Furthermore, the relative velocity variation associated is estimated at 1.7% at 146 MHz based on the relative phase shift which is in agreement with previous work.

4. Conclusions

The use of magnetostrictive thin film as a sensing element turns out to be a really convenient way to measure magnetic field. The magnetoelastic coupling allows the use of surface acoustic waves to detect the dependence of the thin film properties towards magnetic field. Based on the measurements carried on a delay line, the transmitted SAW amplitude and phase show a variation according to the bias magnetic field allowing measurement of positive and negative field without the need of any kind of polarization. The behavior of SAW towards magnetostrictive thin film under a bias magnetic field is rather well explained by taking into account the coupling between the elastic system and the magnetic state of the system.

Author Contributions

All the authors contributed equally to this work.

Acknowledgments

The authors would like to thank the support of the Agence Nationale de la Recherche through grant 2010 BLAN 923 0, RENATECH NETWORK and Centrale Lille through PhD fellowship.

Conflicts of Interest

The authors declare no conflict of interest. The founding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Zabel, S.; Reermann, J.; Fichtner, S.; Kirchhof, C.; Quandt, E.; Wagner, B.; Schmidt, G.; Faupel, F. Multimode delta-E effect magnetic field sensors with adapted electrodes. Appl. Phys. Lett. 2016, 108, 222401. [Google Scholar] [CrossRef]

- Kittmann, A.; Durdaut, P.; Zabel, S.; Reermann, J.; Schmalz, J.; Spetzler, B.; Meyners, D.; Sun, N.X.; McCord, J.; Gerken, M.; et al. Wide Band Low Noise Love Wave Magnetic Field Sensor System. Sci. Rep. 2018, 8, 278. [Google Scholar] [CrossRef] [PubMed]

- Tiercelin, N.; Talbi, A.; Preobrazhensky, V.; Pernod, P.; Mortet, V.; Haenen, K.; Soltani, A. Magnetoelectric effect near spin reorientation transition in giant magnetostrictive-aluminum nitride thin film structure. Appl. Phys. Lett. 2008, 93, 162902. [Google Scholar] [CrossRef]

- Zhou, H.; Talbi, A.; Tiercelin, N.; Matar, O.B. Multilayer magnetostrictive structure based surface acoustic wave devices Appl. Phys. Lett. 2014, 104, 114101. [Google Scholar]

- Matar, O.B.; Gasmi, N.; Zhou, H.; Goueygou, M.; Talbi, A. Legendre and Laguerre polynomial approach for modeling of wave propagation in layered magneto-electro-elastic media. J. Acoust. Soc. Am. 2013, 133, 1415–1424. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Talbi, A.; Tiercelin, N.; Matar, O.B. Theoretical and Experimental Study of Multilayer Piezo-magnetic Structure based Surface Acoustic Wave Devices for High Sensitivity Magnetic Sensor. In Proceedings of the 2013 Joint UFFC, EFTF and PFM Symposium, Prague, Czech Republic, 21–25 July 2013. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).