1. Introduction

An increase in the use of composite materials, owing to improved design and fabrication processes, has led to cost reductions in many industries. Resistance to corrosion, high specific strength, and stiffness are just a few of their many attractive properties. However, damage tolerance remains a major concern in the implementation of composites, while uncertainty regarding the lifetimes of components can lead to the over-design and under-use of such materials.

Non-destructive evaluation (NDE) techniques are often adopted for the periodic inspection of composite structures while they are in service. Inspecting structures in this way can reduce the life cycle cost of a component by preventing premature replacements, while also improving safety and reducing the likelihood of catastrophic failure. Common methods of NDE include the use of X-rays, ultrasonic waves [1], eddy currents [2], shearography [3,4,5], and infrared thermography [6,7,8,9,10,11,12,13,14,15,16,17]. Though non-destructive techniques (NDTs) offer an insight into the performance of composite materials and the environments in which they operate, their implementation can represent significant downtime and labour costs. The use of structural health monitoring (SHM) systems has sparked interest in recent years as they can be integrated directly into a composite structure during manufacture [18,19]. Sensors and embedded networks can be used to monitor various parameters such as local stress, strain, temperature, impact, delamination, and crack propagation both in situ and in real time [20,21,22,23]. Where the use of SHM and NDE is combined, it becomes possible to carry out “focused” inspections using non-destructive techniques, saving both time and money.

2. Experimental Methodology

In this work, infrared thermography (IRT) was employed for the NDE of tubular composite specimens before and after impact. Four samples were impacted with energies of 5 J, 7.5 J, and 10 J by an un-instrumented falling weight set-up. Acoustic emissions (AE) were monitored using bonded piezoelectric sensors during one of the four impact tests. IRT data is used to generate diffusivity and thermal depth mappings of each sample using the thermographic signal reconstruction (TSR) red, green, blue (RGB) projection technique.

3. Results

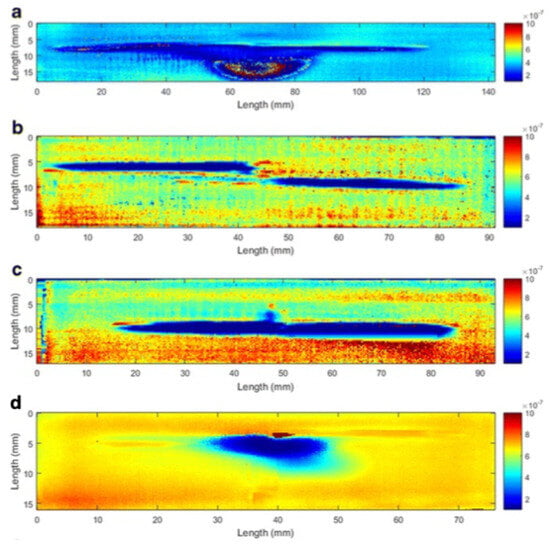

The diffusivity mapping was obtained for each sample by calculating the diffusivity of each individual pixel in the raw image. This is performed by calculating t*, which requires the fitting of two tangents. A minimum correlation coefficient of 0.99 is used to fit the tangent to the curve. Figure 1 shows the thermal diffusivity mapping of the four samples after impact. The coloured scale indicates the value of thermal diffusivity for each pixel in the image. The measurement of the width of each sample here allows for a comparison between each of the defects.

Figure 1.

Thermal diffusivity mapping focused on the impact locations on (a) Sample 1–10 J, (b) Sample 2–7.5 J, (c) Sample 3–5 J, and (d) Sample 4–10 J. The scale bar shows the thermal diffusivity, α (m2/s).

Analysis of AE data alone for a 10 J impact suggests significant damage to the fibres and matrix; this is in good agreement with the generated thermal depth mappings for each sample, which indicate damage through multiple fibre layers. IRT and AE data are correlated and validated by optical micrographs taken along the cross-section of damage.

Author Contributions

Conceptualization, H.L., N.C., and M.G.; methodology, H.L.; software, H.L.; validation, H.L. and N.C.; formal analysis, H.L.; investigation, H.L. and N.C.; resources, M.G.; data curation, H.L.; writing—original draft preparation, H.L. and N.C.; writing—review and editing, N.C. and M.G.; visualization, H.L.; supervision, N.C. and M.G.; project administration, M.G.; funding acquisition, M.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the UK’s Engineering and Physical Sciences Research Council (EPSRC) through the Materials for Demanding Environments Centre for Doctoral Training, grant number EP/L01680X.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors would like to acknowledge the funding and technical support received from BP through the BP International Centre for Advanced Materials (BP-ICAM) which made this research possible. The authors are also grateful for the use of facilities at the Aerospace Research Institute and the Northwest Composites Centre at the University of Manchester. Moreover, I would like to acknowledge Xiaoming Li for providing the raw data of the acoustic emissions used in this paper.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Rose, J.L. Ultrasonic Guided Waves in Structural Health Monitoring. Key Eng. Mater. 2004, 270–273, 14–21. [Google Scholar] [CrossRef]

- Cheng, L.; Tian, G.Y. Surface crack detection for carbon fiber reinforced plastic (CFRP) materials using pulsed eddy current thermography. IEEE Sens. J. 2011, 11, 3261–3268. [Google Scholar] [CrossRef]

- Cawley, P. The rapid non-destructive inspection of large composite structures. Composites 1994, 25, 351–357. [Google Scholar] [CrossRef]

- Hung, Y. Shearography for non-destructive evaluation of composite structures. Opt. Lasers Eng. 1996, 24, 161–182. [Google Scholar] [CrossRef]

- Hung, Y.; Chen, Y.; Ng, S.; Liu, L.; Huang, Y.; Luk, B.; Ip, R.; Wu, C.; Chung, P. Review and comparison of shearography and active thermography for nondestructive evaluation. Mater. Sci. Eng. R Rep. 2009, 64, 73–112. [Google Scholar] [CrossRef]

- Meola, C.; Carlomagno, G.M. Recent advances in the use of infrared thermography. Meas. Sci. Technol. 2004, 15, R27–R58. [Google Scholar] [CrossRef]

- Meola, C.; Carlomagno, G.M.; Giorleo, L. Geometrical limitations to detection of defects in composites by means of infrared thermography. J. Nondestruct. Eval. 2004, 23, 125–132. [Google Scholar] [CrossRef]

- Mayr, G.; Hendorfer, G. Porosity Determination by Pulsed Thermography in Reflection Mode. In Proceedings of the 10th International Conference on Quantitative InfraRed Thermography (QIRT 2010), Quebec City, QC, Canada, 24–29 June 2010. [Google Scholar] [CrossRef]

- Mayr, G.; Plank, B.; Sekelja, J.; Hendorfer, G. Active thermography as a quantitative method for non-destructive evaluation of porous carbon fiber reinforced polymers. NDT E Int. 2011, 44, 537–543. [Google Scholar] [CrossRef]

- Kordatos, E.Z.; Aggelis, D.G.; Matikas, T.E. Monitoring mechanical damage in structural materials using complimentary NDE techniques based on thermography and acoustic emission. Compos. B Eng. 2012, 43, 2676–2686. [Google Scholar] [CrossRef]

- Maldague, X.P.V. Introduction to NDT by active infrared thermography. Mater Eval. 2002, 60, 1060–1073. Available online: https://www.scribd.com/document/359584380/Introduction-To-Ndt-By-Active-Infrared-Thermography-pdf (accessed on 1 January 2015).

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; López, I. Feature extraction and analysis for automatic characterization of impact damage in carbon fiber composites using active thermography. NDT E Int. 2013, 54, 123–132. [Google Scholar] [CrossRef]

- Ley, O.; Godinez, V. Non-destructive evaluation (NDE) of aerospace composites: Application of infrared (IR) thermography. In Non-Destructive Evaluation (NDE) of Polymer Matrix Composites; Karbhari, V.M., Ed.; Woodhead Publishing Ltd.: Cambridge, UK, 2013; pp. 309–336e. [Google Scholar] [CrossRef]

- Bagavathiappan, S.; Lahiri, B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared thermography for condition monitoring—A review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Avdelidis, N.P.; Gan, T.-H. Non-destructive evaluation (NDE) of Composites: Infrared (IR) thermography of wind turbine blades. In Non-Destructive Evaluation (NDE) of Polymer Matrix Composites; Karbhari, V.M., Ed.; Woodhead Publishing Ltd.: Cambridge, UK, 2013; pp. 634–650e. [Google Scholar] [CrossRef]

- Munoz, V.; Valès, B.; Perrin, M.; Pastor, M.L.; Welemane, H.; Cantarel, A.; Karama, M. Damage detection in CFRP by coupling acoustic emission and infrared thermography. Compos. Part B Eng. 2016, 85, 68–75. [Google Scholar] [CrossRef]

- Montesano, J.; Fawaz, Z.; Bougherara, H. Use of infrared thermography to investigate the fatigue behavior of a carbon fiber reinforced polymer composite. Compos. Struct. 2013, 97, 76–83. [Google Scholar] [CrossRef]

- Gresil, M.; Giurgiutiu, V. Guided wave propagation in composite laminates using piezoelectric wafer active sensor. Aeronaut. J. 2013, 117, 971–995. [Google Scholar] [CrossRef]

- Sánchez, D.M.; Gresil, M.; Soutis, C. Distributed internal strain measurement during composite manufacturing using optical fibre sensors. Compos. Sci. Technol. 2015, 120, 49–57. [Google Scholar] [CrossRef]

- Gresil, M.; Saleh, M.N.; Soutis, C. Transverse crack detection in 3d angle interlock glass fibre composites using acoustic emission. Materials 2016, 9, 699. [Google Scholar] [CrossRef] [PubMed]

- Güemes, A.; Fernández-López, A.; Fernandez, P. Damage Detection in Composite Structures from Fibre Optic Distributed Strain Measurements. In Proceedings of the 7th European Workshop on Structural Health Monitoring, Nantes, France, 8–11 July 2014; pp. 528–535. [Google Scholar]

- Fu, T.; Liu, Y.; Lau, K.-T.; Leng, J. Impact source identification in a carbon fiber reinforced polymer plate by using embedded fiber optic acoustic emission sensors. Compos. Part B Eng. 2014, 66, 420–429. [Google Scholar] [CrossRef]

- Di Sante, R. Fibre Optic Sensors for Structural Health Monitoring of Aircraft Composite Structures: Recent Advances and Applications. Sensors 2015, 15, 18666–18713. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).