1. Introduction

Physical models that are somewhat representative of the actual components are used to study transient areas. By applying the developed methods and calculations to these physical models, it is possible to identify transition areas that are important because they determine the quality of the final product and the economic efficiency of the entire process. Physical modeling allows for the simulation of these transient zones, which is challenging and costly in industrial practice.

2. Subject of Research and Research Methodology

The aim of this study was to examine the length of transient areas formed in a three-stream tundish when one stream of molten steel is shut off. Two measurements were conducted on the model, where each measurement involved shutting down a different strand.

The research was conducted at the SimConT laboratory, Institute of Metallurgy, Technical University of Košice, focusing on the physical modeling of continuous casting processes. For the experiment, a ”T”-shaped three-stream tundish model was used to observe the impact of shutting off each outlet stream on the flow characteristics [1,2,3].

Measurements were conducted over ten minutes, monitoring the electrical conductivity of water, which was used as a substitute for molten steel due to their similar kinematic properties. The regime of the tundish was set to a nominal level of 300 mm, which represents 0.182 m3 of water.

Electrical conductivity in siemens [S] was measured using sensors located at the outlet nodes of the tundish, with one sensor per strand. Electrical conductivity on the strands was measured at 0.1 s intervals to achieve the most accurate results. Potassium permanganate (KMnO4) was added to the water for the visualization of the process, and potassium chloride (KCl) was used as a tracer to increase the water’s electrical conductivity.

As water with the tracer (KCl), which has higher electrical conductivity, drained from the bottom of the model through the outlets, clean water flowed in at the top, causing the conductivity at the sensors to decrease, forming a so-called F-curve with a downward trend [4,5].

The data, converted to dimensionless quantities, were analyzed using Pareto’s 80/20 rule and the derived 90/10 rule.

3. Preliminary Results and Discussion

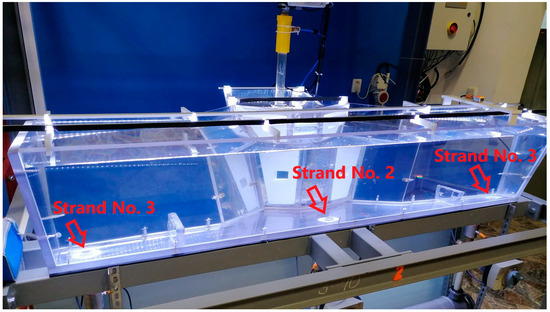

Figure 1 shows the individual streams. The results showed that the best predictions of transient areas were achieved when the middle stream was shut off, where the transient areas were symmetrical and easily predictable. Conversely, shutting off an outer stream resulted in significant differences in flow between the streams. Calculations demonstrated that, according to the 80/20 and 90/10 rules, the differences in the lengths of transient areas between the streams were minimal, which increases the accuracy of predictions.

Figure 1.

Three-stream tundish model with labeled pouring strands.

This study concludes that shutting off the middle stream is the most effective for predicting transient areas and optimizing the overall process. This finding has practical applications for improving the quality of continuously cast products and reducing steel production costs.

Author Contributions

Conceptualization, B.B. and L.F.; methodology, P.D. and J.D.; software, S.H.; validation, P.Š., J.D. and D.D.; formal analysis, S.H.; investigation, D.D.; resources, P.Š.; data curation, P.Š.; writing—original draft preparation, P.Š. and D.D.; writing—review and editing, L.F.; visualization, P.Š. and P.D.; supervision, L.F.; project administration, P.D.; funding acquisition, B.B. All authors have read and agreed to the published version of the manuscript.

Funding

The presented research was conducted thanks to the grant project 1/0199/24, and it was financially supported by the VEGA agency of the Ministry of Education, Science, Research and Sport of the Slovak Republic and the Slovak Academy of Sciences.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available from the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest regarding the publication of this paper. I, the corresponding author, on behalf of all contributing authors, hereby declare that the information given in this disclosure is true and complete to the best of my knowledge and beliefs.

References

- Bul’ko, B.; Molnár, M.; Demeter, P.; Baricová, D.; Pribulová, A.; Futáš, P. Study of the Influence of intermix conditions on steel cleanliness. Metals 2018, 8, 852. [Google Scholar] [CrossRef]

- Bul’ko, B.; Demeter, P. Laboratory of Simulation of Flow Processes; Technical University of Košice, Institute of Metallurgy, Department of Metallurgy and Foundry: Košice, Slovakia, 2017; Available online: https://ohaz.umet.fmmr.tuke.sk/lspp/index_en.html (accessed on 8 May 2023).

- Fogaraš, L.; Šmigura, P.; Buľko, B.; Demeter, P.; Hubatka, S.; Demeter, J.; Šmigura, P. Investigation of optimal transient conditions in t-shape tundish during steel intermixing. In Proceedings of the 30th International Conference on Metallurgy and Materials, Brno, Czech Republic, 17–19 May 2023. [Google Scholar]

- Warzecha, P.; Hutny, A.M.; Warzecha, M.; Merder, T. Hydrodinamic conditions of flow in the tundish depending on selected technological parameters for different steel group. Arch. Metall. Mater. 2019, 64, 65–70. [Google Scholar] [CrossRef]

- Warzecha, P.; Hutny, A.M.; Warzecha, M.; Merder, T. Optimization of steel flow in the tundish by modifying its working area. Arch. Metall. Mater. 2016, 61, 2071–2078. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).