1. Introduction

The blast furnace is the basic production unit in the hot metal production process. The main objective of iron production in the blast furnace is to minimise costs and meet customer requirements. The blast furnace process involves many complex chemical, thermal and mechanical reactions. The complexity of the process, the number of variables and the constantly changing temperature in the furnace make the creation of a process model extremely complex. Process modelling enables real-time analysis of large datasets describing a given process, providing immediate suggestions on which parameters need to be adjusted to restore equilibrium or optimise the process both quantitatively and qualitatively.

2. Process Description

The purpose of a blast furnace is to chemically reduce and physically convert iron oxides into liquid iron, called hot metal. Hot metal makes an input charge for the Basic Oxide Furnace (BOF). Hot metal is an alloy of iron, carbon and other elements, where the carbon content amounts to ca. 4%. Hot metal is breakable and not plastic, therefore, it cannot be subject to mechanical working.

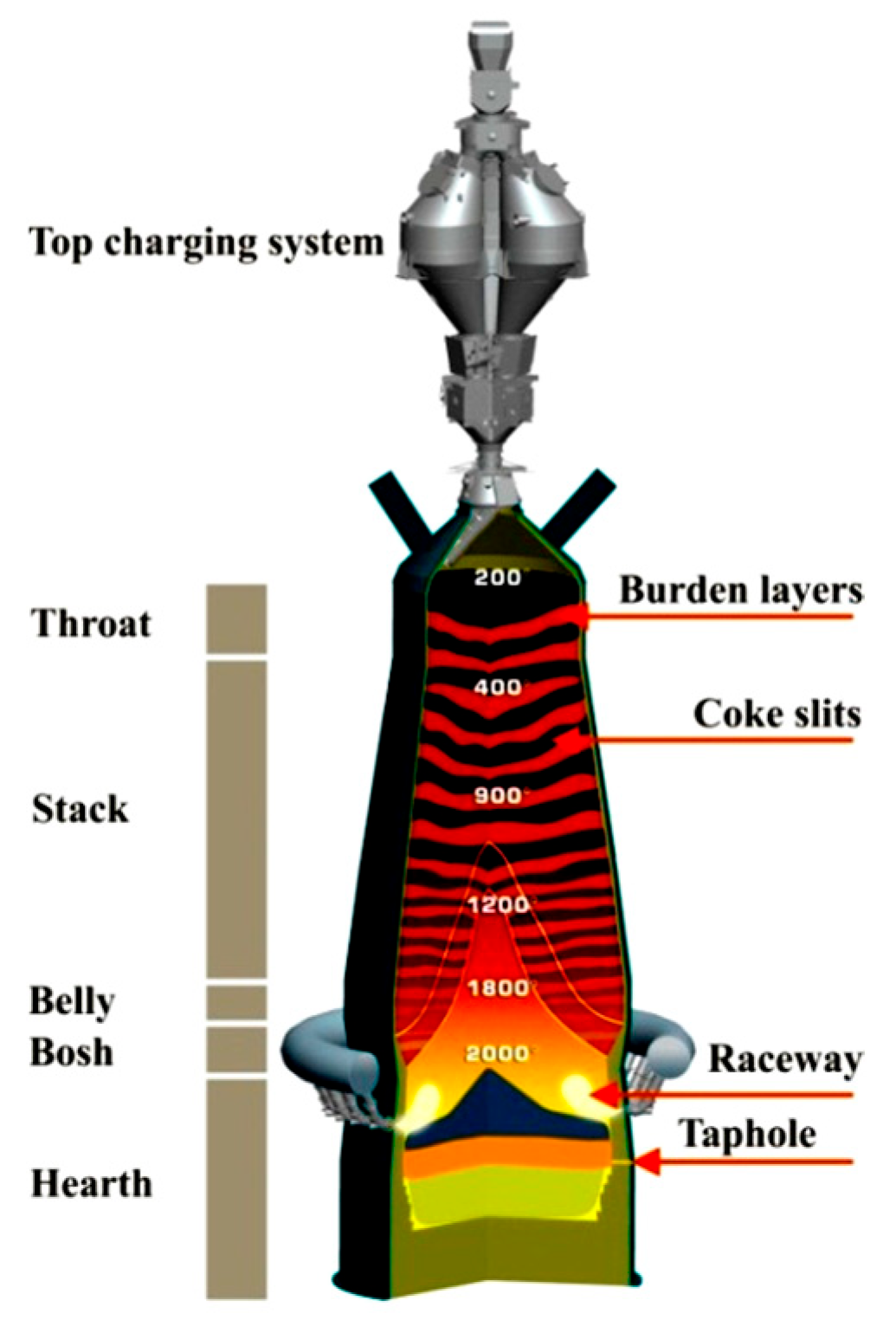

In a blast furnace charging process, batches of charge material are typically loaded in a cyclical sequence into the furnace from the top hoppers using a top charging system. A top charging system currently used in modern BFs consists of two hoppers into which coke and sinter are loaded. The blast furnace is a type of shaft furnace; each segment of the furnace—going from the top to the bottom—is characterised by its own geometry. It is connected with processes that take place inside the BF (

Figure 1) [

1].

Modern blast furnaces are the refinement of traditional furnaces but are equipped with instruments and control architecture. The most important parts of the production process are the operation and control of the blast furnace in terms of controlling the internal temperature at various segments and monitoring the impurity levels online [

2].

BF charge materials (mix of sinter, iron ore, coke and fluxes) are charged into the top of the shaft. An incorrect charge distribution disturbs a BF operation and reduces hot metal output. A blast of heated air and also, in most instances, a gaseous, liquid or powdered fuel are introduced through openings at the bottom of the shaft just above the hearth crucible. The heated air burns the injected fuel and much of the coke is charged in from the top to produce the heat required by the process and to provide reducing gas, which removes oxygen from the ore. The reduced iron melts and runs down to the bottom of the hearth. The flux combines with the impurities in the ore to produce slag, which also melts and accumulates on top of the liquid iron in the hearth [

1,

2].

The blast furnace process starts when a hot blast is blown into the blast furnace via tuyeres at a temperature of up to 1200 °C. Hot blast burns the fuel, which is accumulated in front of the tuyeres. That burning generates a very hot flame and is visible through the peepholes as the raceway [

3,

4].

3. Results and Discussion

The aim of this work was to develop a system to support the technology of operating countercurrent shaft furnaces based on mathematical models describing the bi-level evolution of thermo-chemical processes. This system is based on the assumption that the plant has a traditional measurement base (a measurement of the temperature in the furnace hearth and along the furnace shaft, a measurement of pressure along the furnace shaft, and a measurement of the chemical composition of the gas). Ideally, the furnace should have a profilometer and two key instruments for analysing the gas composition and temperature, one near the surface of the charge and the other 4 to 5 m below. This arrangement of measuring devices will allow a significant improvement in the identification of the state of the processes in the working space through the construction of mathematical models that take into account the states in all rings around the furnace axis, based on the theory of A. Rist. The implementation of the work objectives will allow:

An improvement in the distribution of feed materials in the furnace throat through the continuous monitoring of distribution accuracy and ongoing adjustments;

Improve the efficiency of the indirect reduction of ferrous materials by making better use of the process gases in the upper part of the furnace throat;

Stabilisation of the thermo-chemical parameters of the products.

In order to develop the model, work began with the development and verification of a basic system of balance equations, together with auxiliary equations, to provide the data to carry out the balance calculations. It was decided to adopt a system of four balance equations for the work: nitrogen, hydrogen, carbon and oxygen balances. The complete material and heat balance of the blast furnace was used to develop mathematical models to optimise the fuel consumption in the production of hot metal in the blast furnace and to predict the silicon content of the hot metal. In calculating the silicon content of the next tap, it was assumed that the position of the cohesive zone and its geometry should not change between taps so that the amount of heat loss from the producing zone is the same.

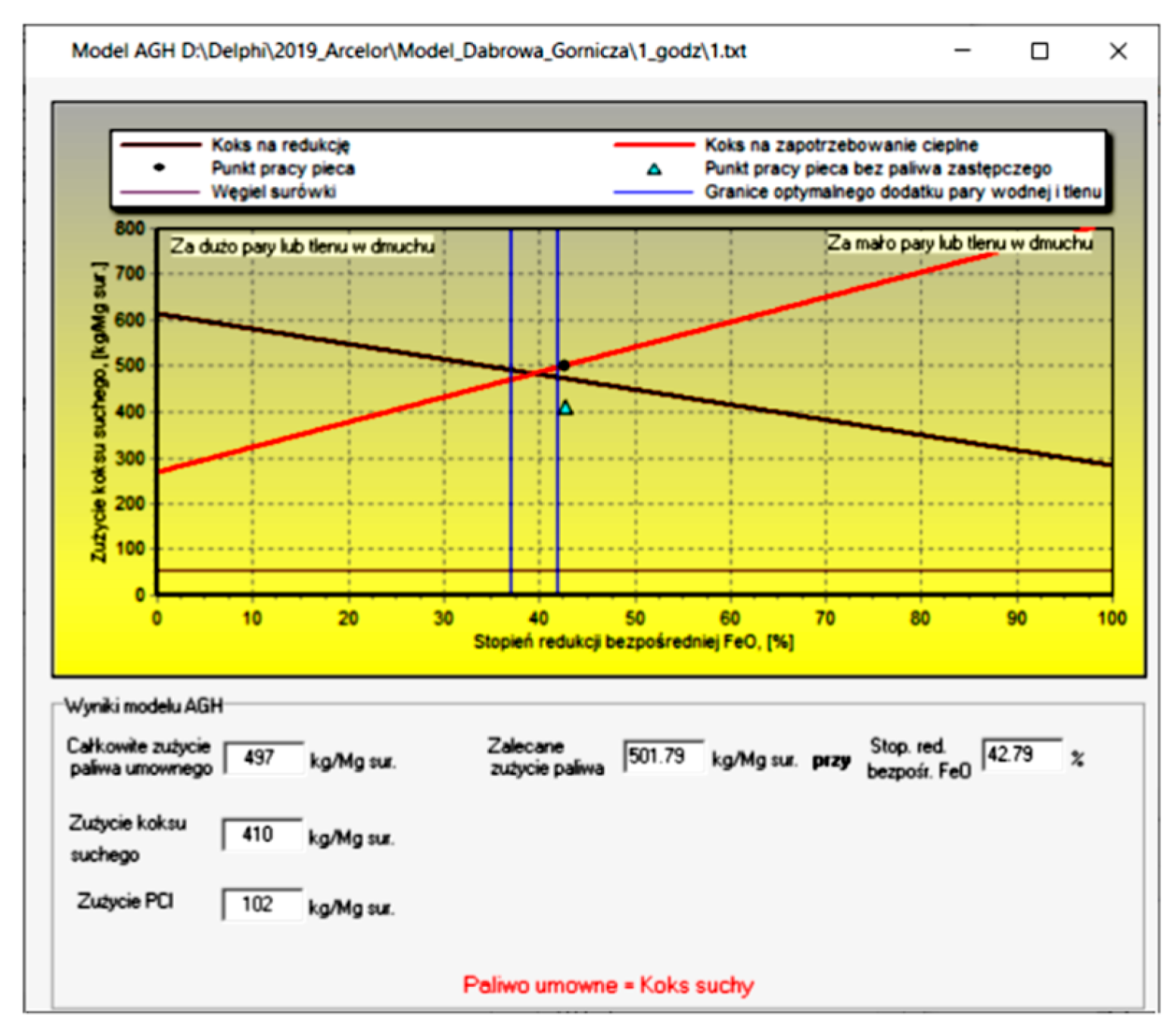

The model for minimising the fuel consumption (

Figure 2) in the production of hot metal in a blast furnace is based on the material and heat balance of the reactor, and its design is based on the theory of A.N. Ramm, who proposed the construction of a diagram showing the dependence of the thermo-chemical demand for carbon in the process on the degree of reduction partitioning.

The developed algorithm identifies the position and shape of the cohesion zone (

Figure 3). The cohesion zone is defined as the area between the position of the isotherm at the beginning of the softening of ferroelectric materials and the position of the isotherm at the end of the softening of these materials. It consists of two distinct parts. The first relates to the furnace preparation zone and is based on the mass and heat exchange under the intermediate reduction conditions prevailing there. Equations for this exchange have been developed for an algorithm whose task is to determine the location and shape of the thermo-chemical reserve zone in the furnace working space. The determination of this zone serves as the boundary condition for the algorithm to locate the positions of the isotherms, marking the beginning and end of the softening of the iron charge [

2,

5,

6].

The charge design model is responsible for the proper distribution of the individual feed materials in the furnace throat. The composition of the blast furnace charge consists of the correct selection of ferrous materials, fluxes, blast furnace coke and substitute fuels, taking into account their chemical compositions. All components of the chemical analysis of the plastics whose values affect the calculated composition of the charge according to the defined objective function are included in the database. To obtain predictions of the expected composition of the blast furnace hot metal and slag and their quantities, it is necessary to take into account the mass and chemical composition of the dust escaping with the throat gas. In addition, the values of the achievable partition coefficients of certain elements, expressed as percentage conversion rates to hot metal, must be assumed.

4. Conclusions

This work describes mathematical models that provide a wealth of previously unavailable information on heat and mass transfer and the associated reactions in the working space. It contributes to the optimisation of furnace operation, ensuring that the chemical composition and temperature of the products are stabilised at the desired level and that the production volume is set at an optimised fuel consumption.

Author Contributions

Conceptualization, M.B. and A.G.; methodology, M.B. and A.G.; software, M.B.; validation, M.B. and A.G.; formal analysis, A.G.; investigation, M.B. and A.G.; resources, A.G.; data curation, M.B.; writing—original draft preparation, M.B.; writing—review and editing, M.B.; visualization, M.B.; supervision, A.G.; project administration, A.G.; funding acquisition, A.G. All authors have read and agreed to the published version of the manuscript.

Funding

The project was co-financed under the grant agreement number: “POIR.01.01.01-00-0118/18 signed with the National Centre for Research and Development under the Operational Programme Intelligent Development, sub-measure "Industrial research and development work carried out by enterprises”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The dataset is available on request from the authors.

Conflicts of Interest

Author Marek Berlinski and Agata Grzybowska were employed by the company ArcelorMittal Poland S.A. The funding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Dobrzański, L.A.; Gawron, M.; Berliński, M. The use of artificial neural networks for the prediction of a chemical composition of hot metal produced in blast furnace. J. Achiev. Mater. Manuf. Eng. 2014, 67, 32–38. [Google Scholar]

- Burgo, J.A. The Manufacture of Pig Iron in the Blast Furnace. In The Making, Shaping and Treating of Steel, 11th ed.; Wakelin, D.H., Ed.; AIST: Warrendale, PA, USA, 1999; pp. 699–740. [Google Scholar]

- Geerdes, M.; Toxopeus, H.; van der Vliet, C. Modern Blast Furnace Ironmaking; IOS Press: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Król, L. Blast Furnace, Onstruction and Equipment; Silesian University of Technology Press: Gliwice, Poland, 1989. [Google Scholar]

- Bernasowski, M.; Stachura, R.; Klimczyk, A.; Łędzki, A. Defined thermochemically reduction ranges in blast furnace. Hut. Wiadomości. Hut. 2015, 82, 701–706. [Google Scholar]

- Bernasowski, M. Theoretical study of the hydrogen influence on iron oxides reduction at the blast furnace process. Steel Res. Int. 2014, 85, 670–678. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).