Abstract

Ideally, for non-invasive sensor integration in fiber reinforced composites, sensors should be made of resin or fibers. For the first time, the curing degree of RTM6 resin in Glass Fiber Reinforced Polymer (GFRP) is measured with a sensor made of the identical resin that reinforces the fibers. Resin Transfer Molding type RTM6 is mixed with a plasticizer to get a thin and flexible substrate. Interdigital Capacitive (IDC) sensor is screen-printed using silver filled epoxy on the flexible RTM6 substrate. The sensor is integrated into GFRP and the curing of the RTM6 resin in glass fiber reinforced polymer composite is measured successfully.

1. Introduction

The desired mechanical properties of fiber reinforced composite materials depend highly on the completeness of resin cure. Thus, in-situ monitoring of the resin cure is necessary. Interdigital capacitive sensors are the most common sensors for in-situ cure monitoring of resins [1,2,3,4,5]. They are available in a microscale dimensions with a perforated substrate [4] for minimizing the so-called wound effect [6]. Microscale interdigital capacitive sensors can remain in the composite; however, there is a mismatch of thermal stresses between these small sensors with polyimide substrate and the host material. Ideally, the sensors for production monitoring of fiber reinforced materials should be made out of identical resin or fibers in the composite. The sensor made of different material that fibers and resin in composite behaves as a wound and impose foreign body effect to the host material. Flexible RTM6 substrate is developed for the first time [7]. In this paper, the interdigital capacitive structure is screen-printed on a flexible RTM6 substrate for GFRP production monitoring by means of a sensor made of identical resin that reinforces the fibers.

2. Materials and Methods

RTM6 (Hexcel) is a mono-component thermoset resin, which is precisely designed to afford the needs of aerospace industry. Similar to other thermoset resins, RTM6 solidifies after curing which makes it brittle if it is thin. This brittleness of the substrate prevents using a pure RTM6 as a substrate for thin sensors. To make a flexible RTM6, it is mixed with a plasticizer called Dibutyl sebacate with the weight ratio of 1:0.75.

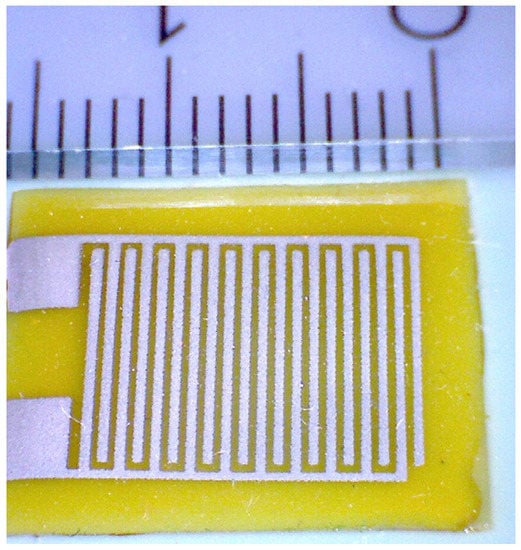

A silicone (smoothinoc) mold with a cavity of W × L × T = 1.5 × 1.5 × 0.045 mm3 is filed with the resin mixture. The mixture of RTM6 and plasticizer is cured in an convection oven at 155 °C for 8 h. After curing of the mixture, an interdigital structure is screen-printed on the substrate using a manual screen-printing machine with plastic screen hollow mask (SEFAR, PCF-FC180-27-Y-PW). The electrically conducting silver paste KA801 (Du Pont) is chosen for interdigitated combs. After screen-printing, the silver paste is cured at 135 °C, for 15 min. A photograph of this sensor is given in Figure 1. The electrodes have width and spacing of 500 µm.

Figure 1.

A photograph of a screen-printed interdigital capacitive structure on flexible RTM6 substrate (the small scale is in mm).

To wire the sensor, single copper core wire 36AWG (MWs Wire Industries) with polyimide coating is used. After wiring, the sensor is embedded in glass fabric in a mold, which is filled with RTM6 and isothermal curing process is run at 150 °C for 2.5 h.

3. Results

3.1. Monitoring Curing of RTM6 Resin in GFRP

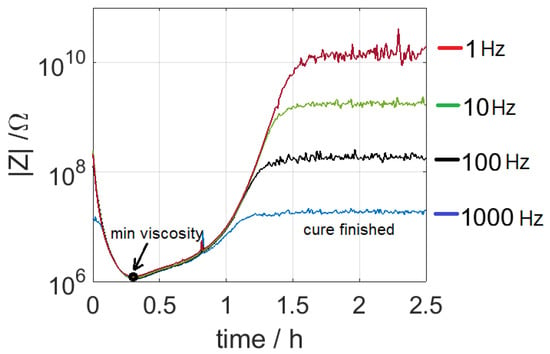

The sensor is placed in glass fabric laminate in a mold, which is filled with RTM6 (Hexcel) and isothermally cured at 150 °C for 2.5 h. Impedance analyzer (IVIUM CompactStat) is used to apply AC voltage with peak-to-peak 0.5 V. The measured impedance from the contact pads of interdigital capacitive sensor is shown in Figure 2.

Figure 2.

Measuring the changes of impedance by a screen-printed IDC sensor.

The measured impedance is correlated to the resin viscosity and correspondingly curing degree of resin [8]. For all thermoset resins, the viscosity drops by increase of temperature, until the resin reaches the point of minimum viscosity. Then, polymerization starts, which results in an increase of cross-linking in the polymeric 3D network and consequently increase of resin viscosity. The increase of viscosity consequences in the rise of the measured impedance from sensor’s contact pads.

In fact, the resistance towards the ion movement and dipole alignment in the existing electrical field in a highly viscous liquid is more than a low viscous liquid. Ultimately, the resin will turn to be solid and at this time, the constant impedance is measured at the contact pads of the sensor.

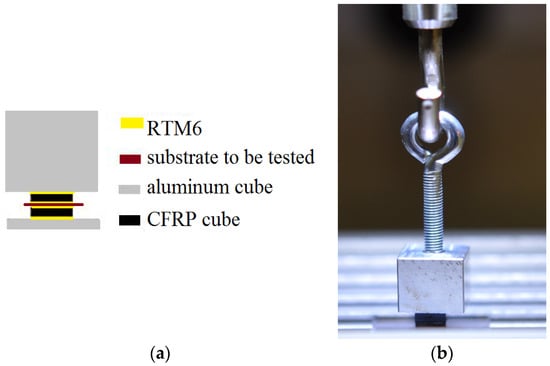

3.2. Mechanical Pulling off Test

Pulling off test is done to check whether the newly developed polymer made by mixing RTM6 and a plasticizer have a better adhesion to fibre reinforced polymer composite. To prepare the specimens for test, a thin layer of RTM6 is used to glue CFRP cubes to polyimide or Flexible RTM6 substrates or to each other as a reference specimen without inlay. The CFRP cube has a dimension of W × L × T = 5 × 5 × 2 mm3. The specimens are cured at 180 °C for 2 h at 50 mbar pressure.

The adhesion test for 10 specimens of polyimide, flexible RTM6 to CFRP and reference specimens without embedded inlays demonstrate the required average breaking forces of 49.7, 103.1 and 182.7 N respectively. This shows that the specimens of flexible RTM6 has better adhesion to the CFRP blocks made by RTM6 than polyimide substrate. However, the reference specimens, consisting of two cubes of CFRP without any substrate still show a higher breaking force. This means that adding plasticizer has reduced a covalent bonding between flexible RTM6 and CFRP.

4. Discussion

In this paper, the sensor is made out of the resin that the curing of that needs to be monitored in production of fibre reinforced polymer composite. A low cost and fast printing of interdigital structure makes the sensors cheap and easy to produce. The newly developed flexible RTM6 shows a better adhesion to fibre reinforced polymer composite compared with polyimide substrate.

The resin cure is measured with the screen-printed interdigital structure on flexible RTM6 substrate. These attributes together makes this sensor a unique option for minimally invasive in-situ cure monitoring of RTM6 in GFRP manufacturing.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Vassilikou-Dova, A.; Kalogeras, I. Dielectric Analysis. In Thermal Analysis of Polymers: Fundamentals and Applications; Menczel, J.D., Prime, R.B., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; Chapter 6. [Google Scholar]

- Kim, H.; Lee, D. Dielectric cure monitoring for glass/polyester prepreg composites. Compos. Struct. 2002, 57, 91–99. [Google Scholar] [CrossRef]

- Yang, Y.; Chiesura, G.; Luyckx, G.; Vervust, T.; Bossuyt, F.; Kaufmann, M.; Degrieck, J.; Vanfleteren, J. Development of a dielectric sensor system for the on-line cure monitoring of composites. Procedia Technol. 2014, 15, 631–637. [Google Scholar] [CrossRef]

- Kahali Moghaddam, M.; Breede, A.; Chaloupka, A.; Bödecker, A.; Habben, C.; Meyer, E.M.; Brauner, C.; Lang, W. Design, fabrication and embedding of microscale interdigital sensors for real-time cure monitoring during composite manufacturing. Sens. Actuators A 2016, 243, 123–133. [Google Scholar] [CrossRef]

- Boll, D.; Schubert, K.; Brauner, C.; Lang, W. Miniaturized Flexible Interdigital Sensor for In-Situ Dielectric Cure Monitoring of Composite Materials. IEEE Sens. J. 2014, 14, 2193–2197. [Google Scholar] [CrossRef]

- Dumstorff, G.; Lang, W. Investigations on the Impact of Material-Integrated Sensors with the Help of FEM-Based Modelling. Sensors 2015, 15, 2336–2353. [Google Scholar] [CrossRef] [PubMed]

- Kahali Moghaddam, M.; Hellmann, J.; Lang, W. Plasticisation of epoxy resin transfer molding substrate for fabrication of interdigital capacitive sensors. Procedia Eng. 2016, 168, 1110–1113. [Google Scholar] [CrossRef]

- Han, Y.; Wang, J.; Zhang, H.; Zhao, S.; Ma, Q.; Wang, Z. Electrochemical impedance spectroscopy (EIS): An efficiency method to monitor resin curing processes. Sens. Actuators A Phys. 2016, 250, 78–86. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).