Smart Biomechanical Adaptation Revealed by the Structure of Ostrich Limb Bones

Abstract

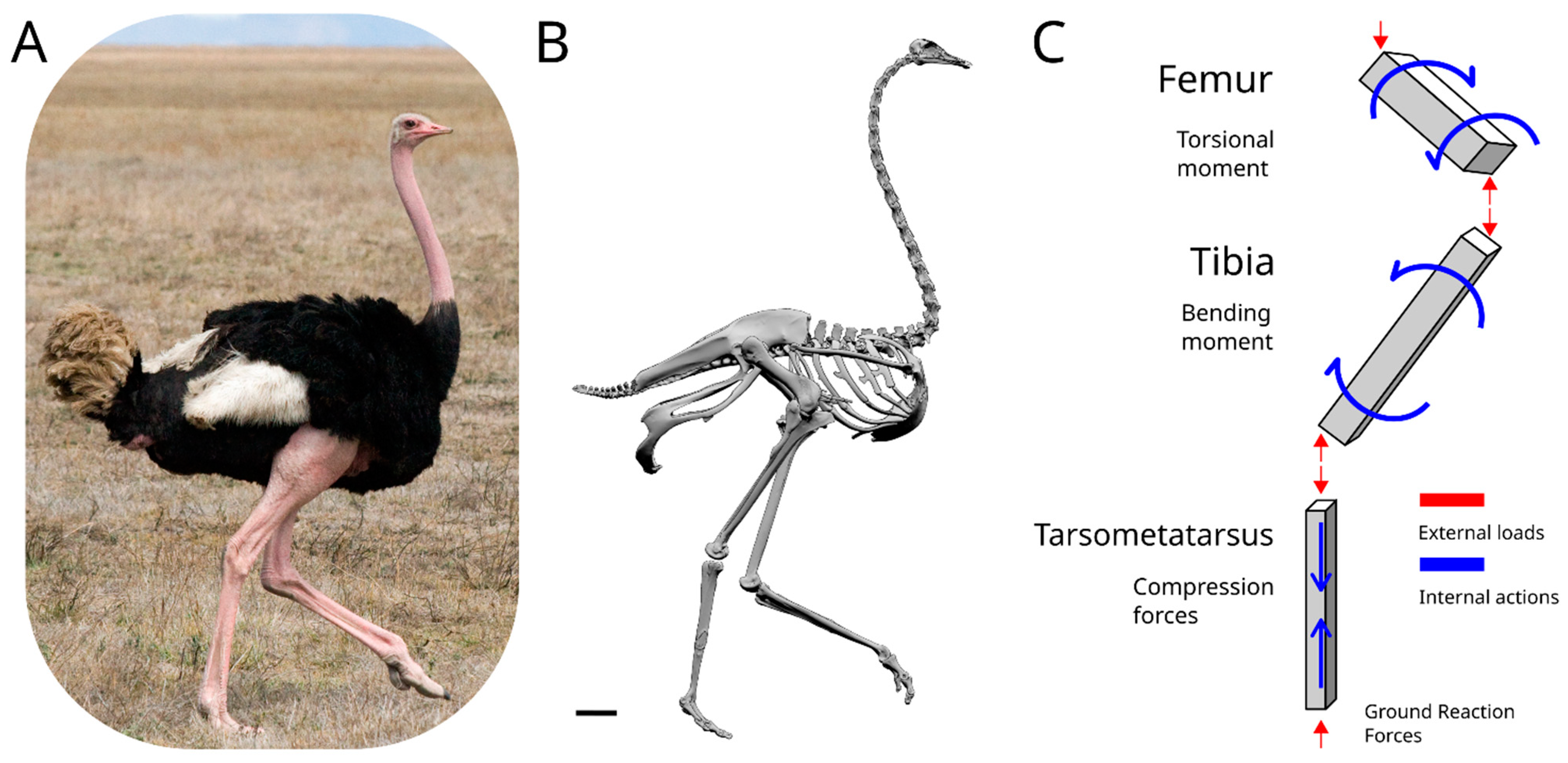

1. Introduction

1.1. Why Ostrich?

1.1.1. Bone Structure

1.1.2. Density

1.1.3. Isotropy and Orthotropy

1.2. Finite Element Method

2. Materials and Methods

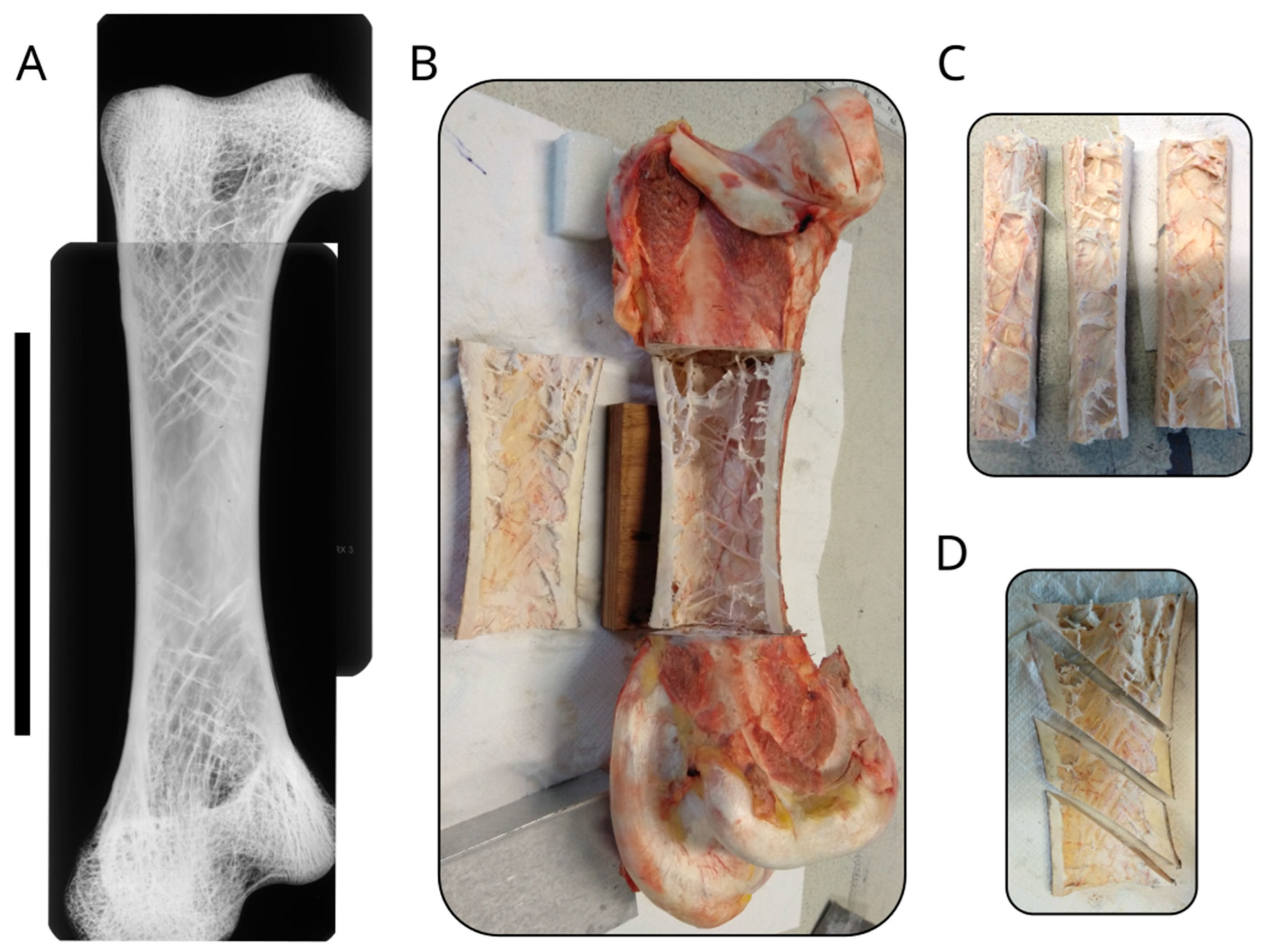

2.1. Materials

2.1.1. Origin

2.1.2. Density

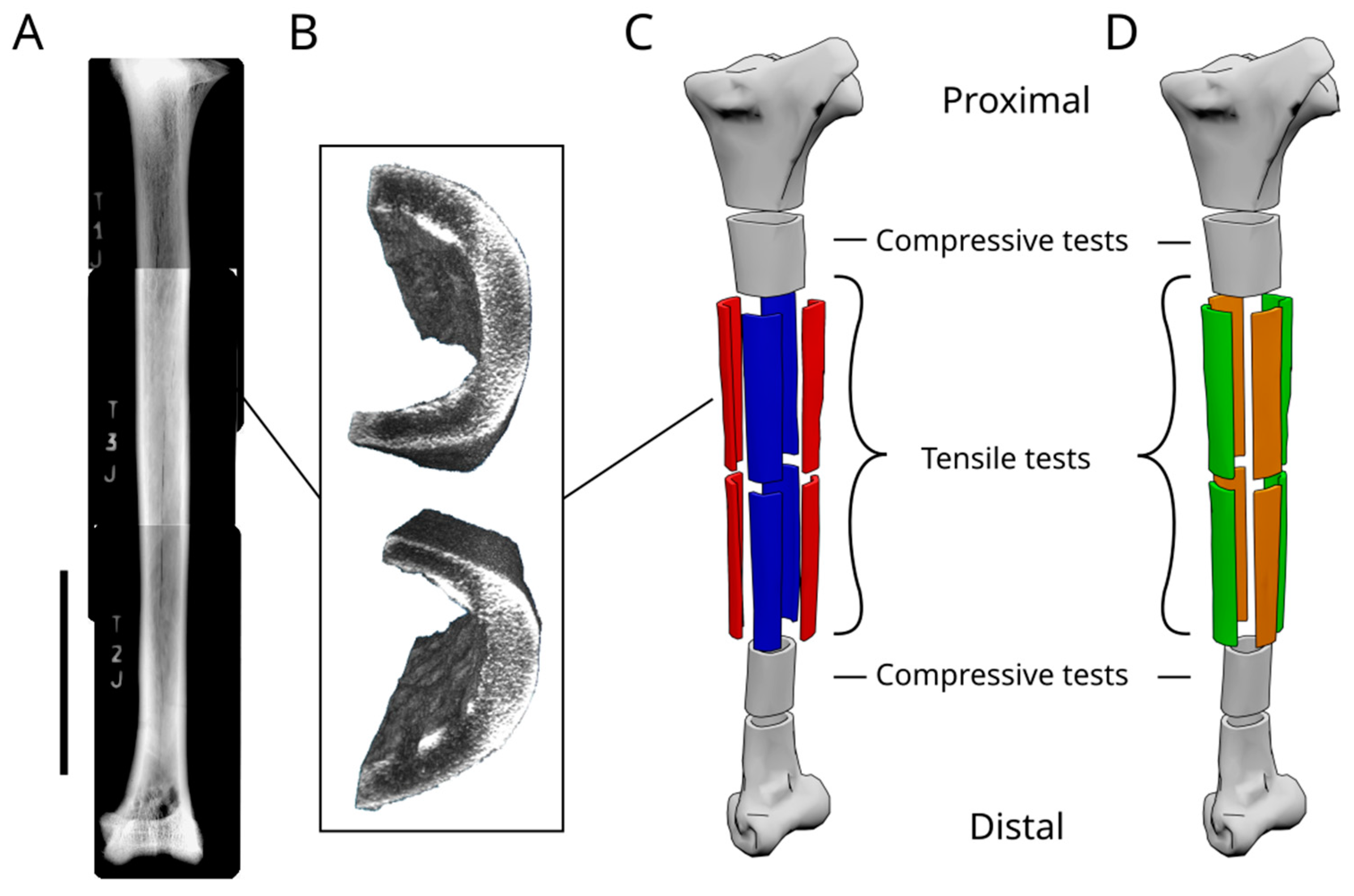

2.1.3. Mechanical Characterization

2.1.4. Water Absorption

3. Results

3.1. The Density of the Bone

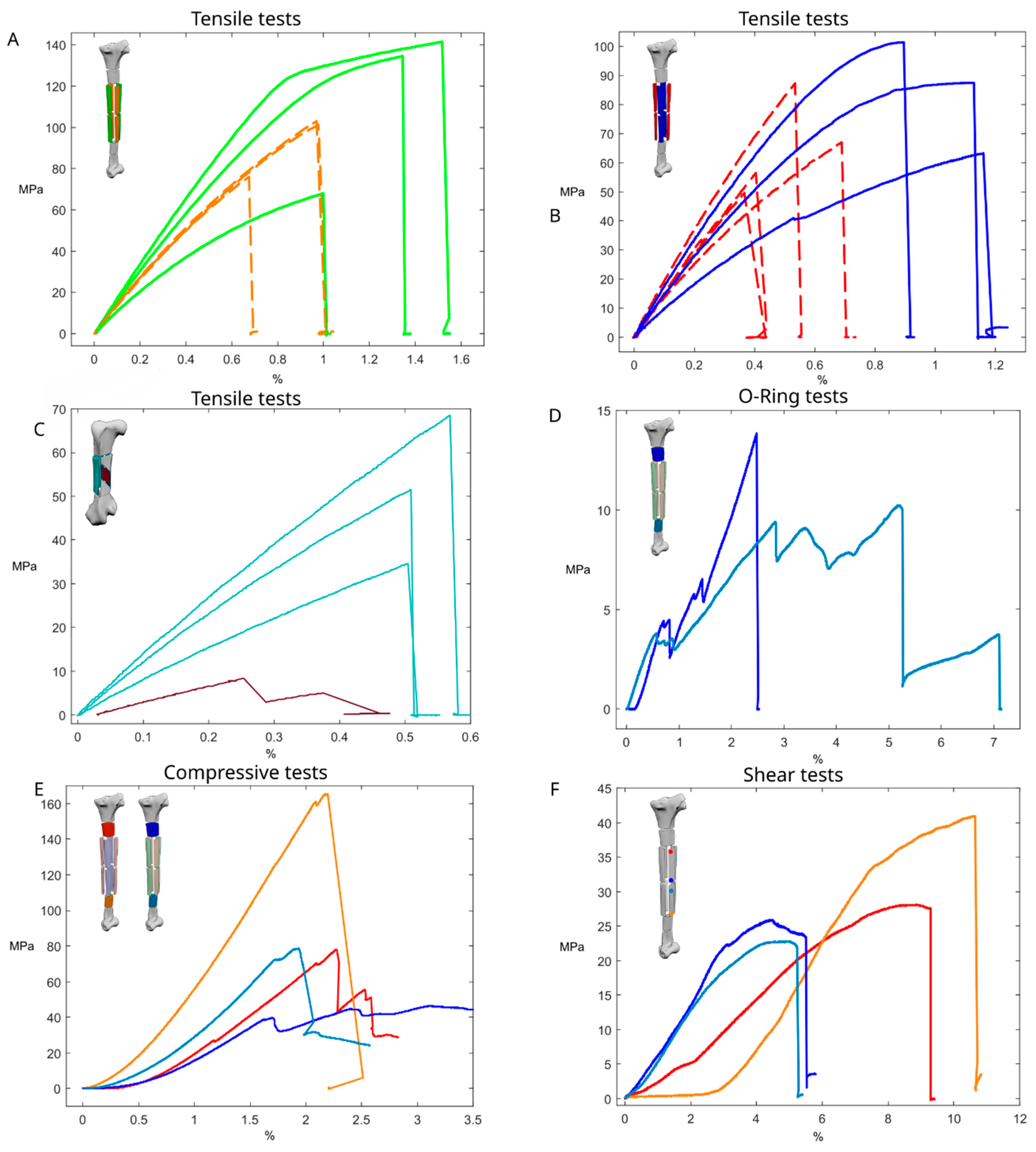

3.2. Mechanical Characterisation of Ostrich Bone

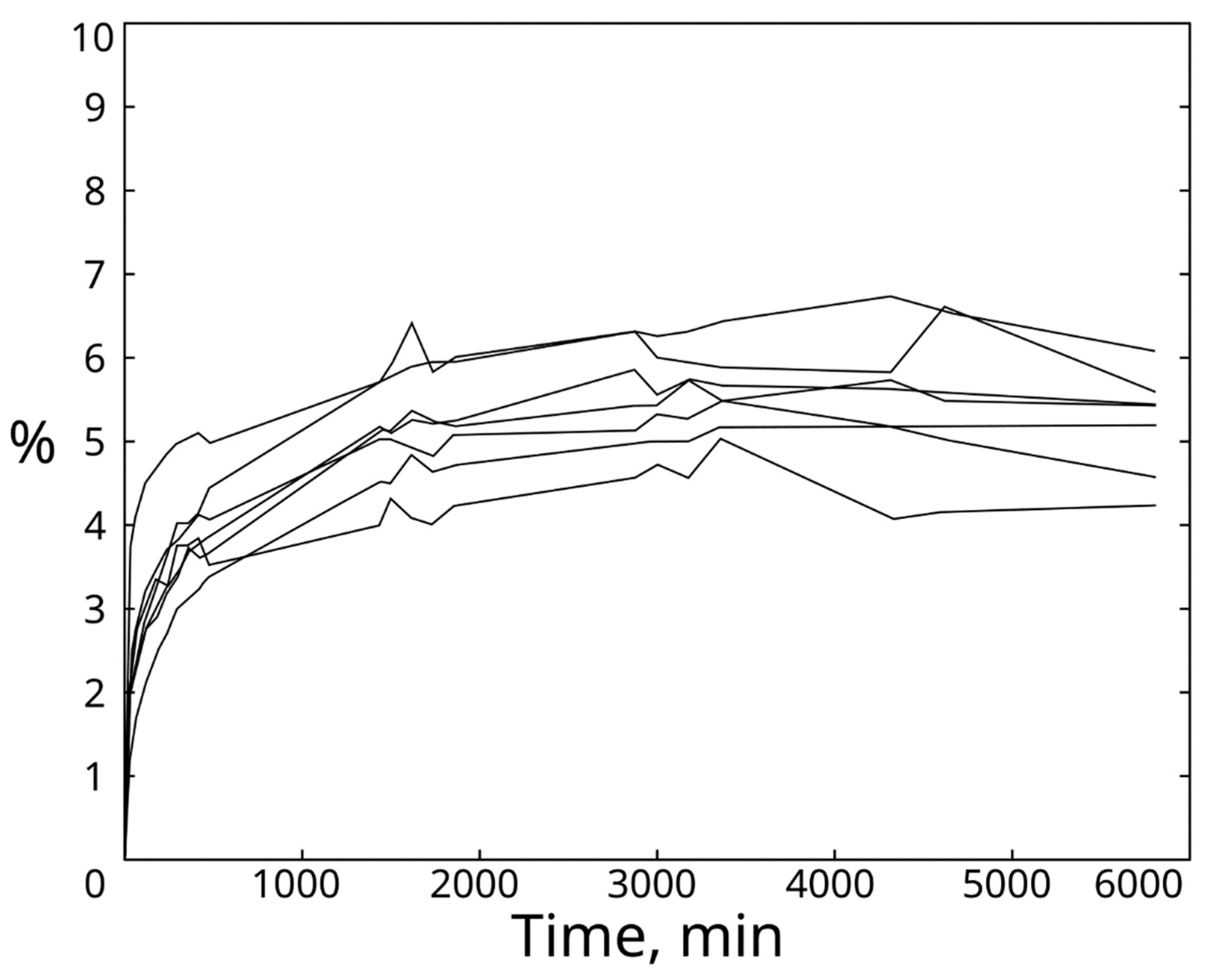

3.3. Saturation Results

3.4. Change in Mechanical Properties Due to Saturation

4. Discussion

4.1. Mechanical Testing and Implications for Literature Data

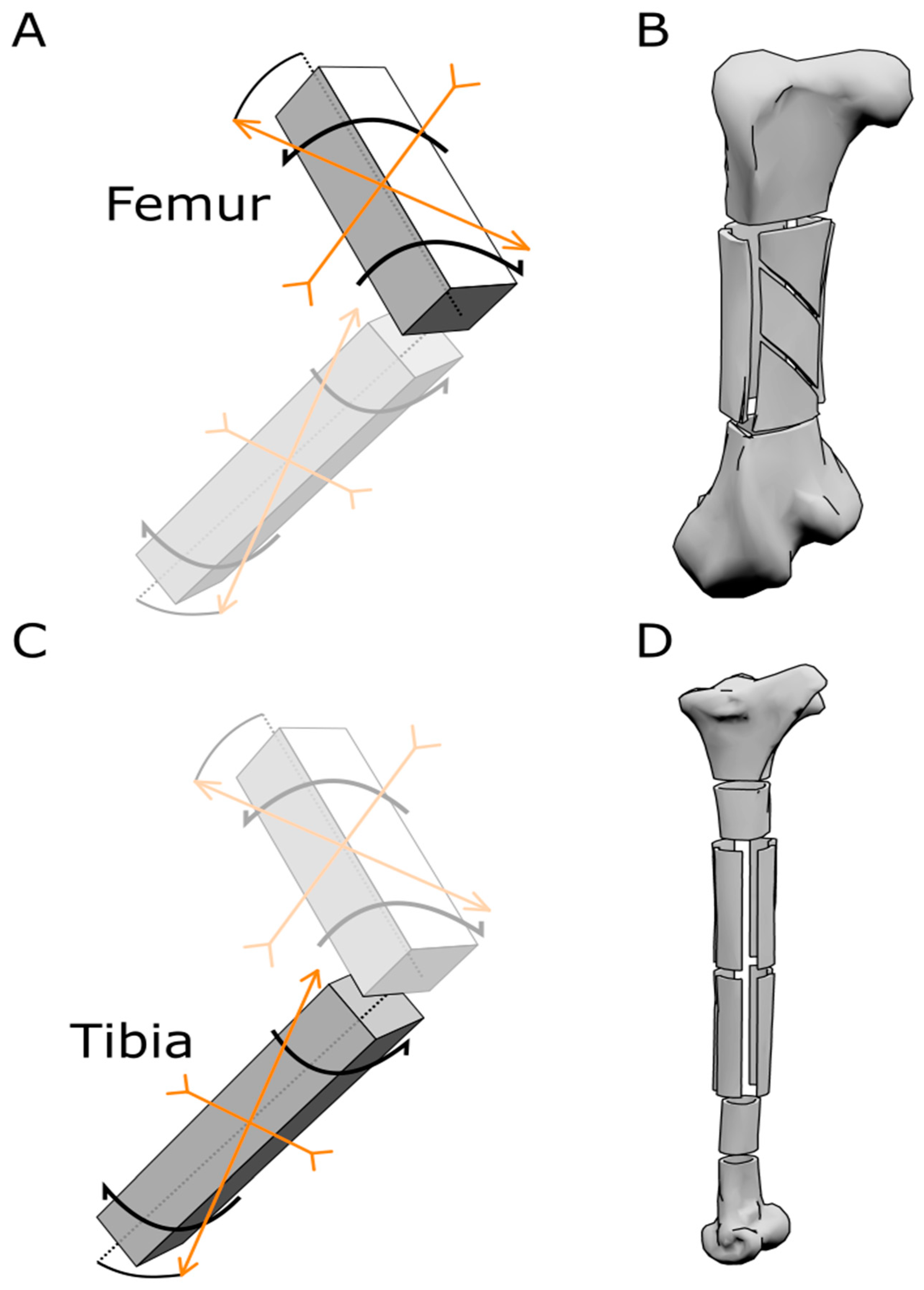

4.1.1. Femur

4.1.2. Tibia

4.1.3. Engineering and Nature

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adams, G.J.; Cook, R.B.; Hutchinson, J.R.; Zioupos, P. Bone Apparent and Material Densities Examined by Cone Beam Computed Tomography and the Archimedes Technique: Comparison of the Two Methods and Their Results. Front. Mech. Eng. 2018, 3, 23. [Google Scholar] [CrossRef]

- Gilbert, M.M.; Snively, E.; Cotton, J. The Tarsometatarsus of the Ostrich Struthio camelus: Anatomy, Bone Densities, and Structural Mechanics. PLoS ONE 2016, 11, e0149708. [Google Scholar] [CrossRef] [PubMed]

- Hutchinson, J.R.; Rankin, J.W.; Rubenson, J.; Rosenbluth, K.H.; Siston, R.A.; Delp, S.L. Musculoskeletal modelling of an ostrich (Struthio camelus) pelvic limb: Influence of limb orientation on muscular capacity during locomotion. PeerJ 2015, 3, e1001. [Google Scholar] [CrossRef] [PubMed]

- Main, R.P.; Biewener, A.A. Skeletal strain patterns and growth in the emu hindlimb during ontogeny. J. Exp. Biol. 2007, 210, 2676–2690. [Google Scholar] [CrossRef] [PubMed]

- Rankin, J.W.; Rubenson, J.; Hutchinson, J.R. Inferring muscle functional roles of the ostrich pelvic limb during walking and running using computer optimization. J. R. Soc. Interface 2016, 13, 20160035. [Google Scholar] [CrossRef]

- Rayfield, E.J. Strain in the ostrich mandible during simulated pecking and validation of specimen-specific finite element models: Ostrich mandible FEA validation. J. Anat. 2011, 218, 47–58. [Google Scholar] [CrossRef]

- Reed, K.L.; Brown, T.D. Elastic modulus and strength of emu cortical bone. Iowa Orthop. J. 2001, 21, 53. [Google Scholar]

- Rubenson, J.; Lloyd, D.G.; Besier, T.F.; Heliams, D.B.; Fournier, P.A. Running in ostriches (Struthio camelus): Three-dimensional joint axes alignment and joint kinematics. J. Exp. Biol. 2007, 210, 2548–2562. [Google Scholar] [CrossRef]

- Schachner, E.R.; Hedrick, B.P.; Richbourg, H.A.; Hutchinson, J.R.; Farmer, C.G. Anatomy, ontogeny, and evolution of the archosaurian respiratory system: A case study on Alligator mississippiensis and Struthio camelus. J. Anat. 2021, 238, 845–873. [Google Scholar] [CrossRef]

- Schaller, N.U.; Herkner, B.; Villa, R.; Aerts, P. The intertarsal joint of the ostrich (Struthio camelus): Anatomical examination and function of passive structures in locomotion. J. Anat. 2009, 214, 830–847. [Google Scholar] [CrossRef]

- Rubenson, J.; Lloyd, D.G.; Heliams, D.B.; Besier, T.F.; Fournier, P.A. Adaptations for economical bipedal running: The effect of limb structure on three-dimensional joint mechanics. J. R. Soc. Interface 2010, 8, 740–755. [Google Scholar] [CrossRef] [PubMed]

- Spatz, H.-C.; O’Leary, E.J.; Vincent, J.F.V. Young’s moduli and shear moduli in cortical bone. Proc. R. Soc. Ser. B Boil. Sci. 1996, 263, 287–294. [Google Scholar] [CrossRef]

- Tatara, M.R.; Krupski, W.; Charuta, A.; Brodzki, A.; Jóźwik, A.; Strzałkowska, N.; Poławska, E.; Chmielowiec, K.; Horbańczuk, J.O. Morphological, densitometric and mechanical properties of pelvic limb bones in 14-month-old female ostriches (Struthio camelus). Poult. Sci. 2016, 95, 2421–2426. [Google Scholar] [CrossRef]

- Yamada, H.; Evans, F.G. Strength of Biological Materials; Williams & Wilkins Company: Ambler, PA, USA, 1970. [Google Scholar]

- La Barbera, V.; Pardo, F.; Tassa, Y.; Daley, M.; Richards, C.; Kormushev, P.; Hutchinson, J. OstrichRL: A Musculoskeletal Ostrich Simulation to Study Bio-mechanical Locomotion. arXiv 2021, arXiv:2112.06061. [Google Scholar]

- Bertozzo, F.; Bolotsky, I.; Bolotsky, Y.L.; Poberezhskiy, A.; Ruffell, A.; Godefroit, P.; Murphy, E. A pathological ulna of Amurosaurus riabinini from the Upper Cretaceous of Far Eastern Russia. Hist. Biol. 2022, 35, 268–275. [Google Scholar] [CrossRef]

- Goodship, A.E.; Lanyon, L.E.; McFie, H. Functional adaptation of bone to increased stress. An experimental study. J. Bone Jt. Surg. 1979, 61, 539–546. [Google Scholar] [CrossRef]

- Sheen, J.R.; Garla, V.V. Fracture Healing Overview. In StatPearls; StatPearls Publishing: Tampa, FL, USA, 2022. [Google Scholar]

- Morgan, E.F.; Unnikrisnan, G.U.; Hussein, A.I. Bone Mechanical Properties in Healthy and Diseased States. Annu. Rev. Biomed. Eng. 2018, 20, 119–143. [Google Scholar] [CrossRef]

- Cowin, S. Bone Mechanics Handbook; CRC Press: Boca Raton, FL, USA, 2001. [Google Scholar]

- Currey, J.D. Bones: Structure and Mechanics; Princeton University Press: Princeton, NJ, USA, 2002. [Google Scholar]

- Evans, F.G. Factors affecting the mechanical properties of bone. Bull. N. Y. Acad. Med. 1973, 49, 751–764. [Google Scholar]

- Feng, L.; Chittenden, M.; Schirer, J.; Dickinson, M.; Jasiuk, I. Mechanical properties of porcine femoral cortical bone measured by nanoindentation. J. Biomech. 2012, 45, 1775–1782. [Google Scholar] [CrossRef]

- Fung, Y.C. Biomechanics; Springer: New York, NY, USA, 1981. [Google Scholar] [CrossRef]

- Hengsberger, S.; Kulik, A.; Zysset, P. Nanoindentation discriminates the elastic properties of individual human bone lamellae under dry and physiological conditions. Bone 2002, 30, 178–184. [Google Scholar] [CrossRef]

- Luo, C.; Liao, J.; Zhu, Z.; Wang, X.; Lin, X.; Huang, W. Analysis of Mechanical Properties and Mechanical Anisotropy in Canine Bone Tissues of Various Ages. BioMed Res. Int. 2019, 2019, 1–7. [Google Scholar] [CrossRef]

- Baldacci, R. Scienza Delle Costruzioni; UTET: Torino, Italy, 1984. [Google Scholar]

- Ashby, M.F. Materials Selection in Mechanical Design; Butterworth-Heinemann: Oxford, UK, 2005. [Google Scholar]

- Martin, R.B.; Burr, D.B.; Sharkey, N.A.; Fyhrie, D.P. Skeletal Tissue Mechanics; Springer: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Mc Donnell, P.; Mc Hugh, P.E.; Mahoney, D.O. Vertebral Osteoporosis and Trabecular Bone Quality. Ann. Biomed. Eng. 2006, 35, 170–189. [Google Scholar] [CrossRef]

- Castanet, J.; Curry Rogers, K.; Cubo, J.; Jacques-Boisard, J. Periosteal bone growth rates in extant ratites (ostriche and emu). Implications for assessing growth in dinosaurs. Comptes Rendus L’académie Sci.—Ser. III—Sci. Vie 2000, 323, 543–550. [Google Scholar] [CrossRef] [PubMed]

- Dumont, E.R. Bone density and the lightweight skeletons of birds. Proc. R. Soc. B Boil. Sci. 2010, 277, 2193–2198. [Google Scholar] [CrossRef] [PubMed]

- Rho, J.Y.; Hobatho, M.C.; Ashman, R.B. Relations of mechanical properties to density and CT numbers in human bone. Med Eng. Phys. 1995, 17, 347–355. [Google Scholar] [CrossRef] [PubMed]

- Surowiec, R.K.; Allen, M.R.; Wallace, J.M. Bone hydration: How we can evaluate it, what can it tell us, and is it an effective therapeutic target? Bone Rep. 2022, 16, 101161. [Google Scholar] [CrossRef]

- Boskey, A.L.; Robey, P.G. The Composition of Bone. In Primer on the Metabolic Bone Diseases and Disorders of Mineral Metabolism; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 49–58. [Google Scholar] [CrossRef]

- Zhou, J.; Cui, Z.; Sevostianov, I. Effect of saturation on the elastic properties and anisotropy of cortical bone. Int. J. Eng. Sci. 2020, 155, 103362. [Google Scholar] [CrossRef]

- Lautenschlager, S. Multibody dynamics analysis (MDA) as a numerical modelling tool to reconstruct the function and palaeobiology of extinct organisms. Palaeontology 2020, 63, 703–715. [Google Scholar] [CrossRef]

- Cunningham, J.A.; Rahman, I.A.; Lautenschlager, S.; Rayfield, E.J.; Donoghue, P.C.J. A virtual world of paleontology. Trends Ecol. Evol. 2014, 29, 347–357. [Google Scholar] [CrossRef]

- Ballell, A.; Moon, B.C.; Porro, L.B.; Benton, M.J.; Rayfield, E.J. Convergence and functional evolution of longirostry in crocodylomorphs. Palaeontology 2019, 62, 867–887. [Google Scholar] [CrossRef]

- Button, D.J.; Barrett, P.M.; Rayfield, E.J. Comparative cranial myology and biomechanics of Plateosaurus and Camarasaurus and evolution of the sauropod feeding apparatus. Palaeontology 2016, 59, 887–913. [Google Scholar] [CrossRef]

- Rayfield, E.J.; Norman, D.B.; Horner, C.C.; Horner, J.R.; Smith, P.M.; Thomason, J.J.; Upchurch, P. Cranial design and function in a large theropod dinosaur. Nature 2001, 409, 1033–1037. [Google Scholar] [CrossRef]

- Rayfield, E.J.; Milner, A.C. Establishing a framework for archosaur cranial mechanics. Paleobiology 2008, 34, 494–515. [Google Scholar] [CrossRef]

- Porro, L.B.; Holliday, C.M.; Anapol, F.; Ontiveros, L.C.; Ontiveros, L.T.; Ross, C.F. Free body analysis, beam mechanics, and finite element modeling of the mandible of Alligator mississippiensis. J. Morphol. 2011, 272, 910–937. [Google Scholar] [CrossRef] [PubMed]

- Buccino, F.; Martinoia, G.; Vergani, L.M. Torsion—Resistant Structures: A Nature Addressed Solution. Materials 2021, 14, 5368. [Google Scholar] [CrossRef] [PubMed]

- Pfafrod, G.O.; Saulgozis, Y.Z.; Knet-S, I.V.; Yanson, K.A. Experimental determination of the shear modulus of compact bone tissue. Polym. Mech. 1974, 8, 601–608. [Google Scholar] [CrossRef]

| Ex GPa | σu MPa | Ey GPa | σu MPa | G GPa | Τu MPa | |||

|---|---|---|---|---|---|---|---|---|

| Tibial Shaft Proximal Portion | 15.3 | 134.55 | 0.7 | 13.85 | 0.8 | 27.54 | ||

| Tibial Shaft Distal Portion | 17.3 | 141.49 | 0.11 | 9.37 | 0.4 | 40.92 | ||

| E along main axis bone GPa | σu along main axis bone MPa | E parallel to ridges orientation GPa | σu parallel to ridges orientation MPa | |||||

| Femur | 13.2 | 68.56 | 3.75 | 8.25 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Conti, S.; Sala, G.; Mateus, O. Smart Biomechanical Adaptation Revealed by the Structure of Ostrich Limb Bones. Biomimetics 2023, 8, 98. https://doi.org/10.3390/biomimetics8010098

Conti S, Sala G, Mateus O. Smart Biomechanical Adaptation Revealed by the Structure of Ostrich Limb Bones. Biomimetics. 2023; 8(1):98. https://doi.org/10.3390/biomimetics8010098

Chicago/Turabian StyleConti, Simone, Giuseppe Sala, and Octavio Mateus. 2023. "Smart Biomechanical Adaptation Revealed by the Structure of Ostrich Limb Bones" Biomimetics 8, no. 1: 98. https://doi.org/10.3390/biomimetics8010098

APA StyleConti, S., Sala, G., & Mateus, O. (2023). Smart Biomechanical Adaptation Revealed by the Structure of Ostrich Limb Bones. Biomimetics, 8(1), 98. https://doi.org/10.3390/biomimetics8010098