Abstract

General aviation (GA), comprised mainly of piston engine airplanes, has an inferior safety history compared with air carriers in the United States. Most studies addressing this safety disparity has focused on pilot deficiencies. Herein, we determined the rates/causes of equipment failure-related GA fatal accidents for type-certificated and experimental-amateur-built airplanes. Aviation accidents/injury severity were per the NTSB AccessR database. Statistical tests employed proportion/binomial tests/a Poisson distribution. The rate of fatal accidents (1990–2019) due to equipment failure was unchanged (p > 0.026), whereas the fatal mishap rate related to other causes declined (p < 0.001). A disproportionate (2× higher) count (p < 0.001) of equipment-related fatal accidents was evident for experimental-amateur-built aircraft with type-certificated references. Propulsion system (67%) and airframe (36%) failures were the most frequent causes of fatal accidents for type-certificated and experimental-amateur-built aircraft, respectively. The components “fatigue/corrosion” and “manufacturer–builder error” resulted in 60% and 55% of powerplant and airframe failures, respectively. Most (>90%) type-certificated aircraft propulsion system failures were within the manufacturer-prescribed engine time-between-overhaul (TBO) and involved components inaccessible for examination during an annual inspection. There is little evidence for a decline in equipment failure-related fatal accident rate over three decades. Considering the fact that powerplant failures mostly occur within the TBO and involve fatigue/corrosion of one or more components inaccessible for examination, GA pilots should avoid operations where a safe off-field landing within glide-range is not assured.

1. Introduction

General aviation (GA) comprises mainly single-piston engine-powered fixed-wing aircraft (≤12,500 lbs) []. In the United States, they operate under the code of federal regulations (CFRs) encapsulated in 14CFR Part 91 []. These airplanes can be classified into those which are type-certificated under 14CFR Part 23 [] and those which are experimental-amateur-built [], representing 90% and 10% of the GA fleet, respectively []. It should be noted that whilst manufacture/assembly of type-certificated GA airplanes is highly prescriptive per 14 CFR Part 23 [], these regulations do not apply to experimental-amateur-built aircraft which are defined as any in which more than 50% of the fabrication/assembly is accomplished by the builder [].

Regardless of type certification, or lack thereof, GA safety has always shown a far inferior safety record compared with the airlines manifesting a 260-fold higher fatal accident rate [], although, admittedly, there is some evidence of improvement in recent years []. Towards improving safety, much research has been undertaken over the years as to the causes of fatal GA accidents. Such studies have almost exclusively focused on the pilot documenting poor aeronautical decision-making (both pre- and in-flight []), a lack of pilot proficiency/skills [], inadequate preflight planning [], and poor training/lack of knowledge [] as causal—or contributory—to GA mishaps.

Although the aforementioned studies focused on the pilot, there is a paucity of research on fatal accidents in which the initial event (also referred to as the “defining” event) was due to equipment failure, possibly because they are causal for only a minority (8%) of GA mishaps []. While a prior study by the first author [] reported a higher fraction (relative to that herein) of GA accidents due to malfunctioning equipment, importantly, fatal and non-fatal accidents were not separated. Nevertheless, the question as to equipment failure should not be disregarded considering that the US GA fleet is aging: airplanes manufactured between 1977 and 1979 represent the greatest proportion of active aircraft in 2023 []. That is, the typical GA airplane is 45–48 years of age, with an earlier study reporting an increase in mechanical-related GA accident rates [].

On the other hand, in regard to the safety of an aging fleet, GA aircraft (both type-certificated and experimental-amateur-built) are subject to mandatory annual inspections [], the scope and details of which are described in 14CFR Part 43, Appendix D []. Equally important is that, over time, the manufacturing and airframe/powerplant maintenance sector has sought to improve aviation safety via a number of avenues. For example, improved procedures via the Maintenance Event Decision Aid (MEDA), in which practices are corrected after an event investigation, were introduced in the early 1990s []. Also, a slew of Advisory Circulars and airworthiness directives addressing new and/or updated inspection/alterations [] could also contribute to fewer equipment failure-related fatal accidents. Finally, the recognition by the aviation industry that some deviations arise from flawed procedures, simple mistakes and that such deviations can be most effectively corrected through root cause analysis and education, rather than punitive action, has culminated in the FAA “Compliance Program” [,] and Aviation Safety Reporting System [].

Considering the aforementioned arguments, the overall goal of this research was to determine the rates and causes of equipment failure-related GA fatal accidents for type-certificated and experimental-amateur-built aircraft. To this end, we sought to answer the following questions:

- (1)

- Has the rate of GA fatal accidents related to equipment failure declined for type-certificated and experimental-amateur-built aircraft over the last three decades?

- (2)

- Are fatal accidents related to equipment failure disproportionate for experimental-amateur-built referencing type-certificated aircraft?

- (3)

- Can the most prevalent system failures resulting in fatal accidents for both type-certificated and experimental-amateur-built aircraft be identified?

- (4)

- What are the underlying cause(s) of the equipment failure?

2. Materials and Methods

2.1. Fatal Accidents Involving Equipment Failure

The NTSB aviation accident Access databases (April 2025 and 1982–2007 releases) were downloaded and queried for fatal mishaps (1989–present) involving piston engine-powered airplanes operating under 14CFR Part 91 [], and in which the text contained any of the following terms: “defect,” “fatigue,” the root stem “separat*,” “corrosion”. Whether the airplane was type-certificated or experimental-amateur-built was determined using the NTSB Access database. Records were de-duplicated and manually inspected to remove any records where the defining event was not equipment failure (e.g., pilot fatigue). Accidents in which airframe failure was due to pilot control inputs in which structural G limits were exceeded were also deleted from the study. Fatal mishaps unrelated to equipment failure were determined by a query of the databases, as described above, excluding the search terms and thereafter deleting accidents returned in the equipment-related fatal accident set.

Fatal accident rates were determined using fleet activity (flight hours) per the annual GA survey for fixed wing piston (single and multi-engine) as the denominator, or, where indicated, experimental-amateur-built (i.e., experimental-amateur-built) airplanes []. Fleet activity for 2011 was determined by interpolating the data from 2010 and 2012. It should be noted that since fleet activities for experimental-amateur-built aircraft were only available after 1993, temporal analysis for this group could only be performed thereafter.

2.2. Equipment Failure Categories

We elected to use our own self-defined taxonomy rather than that previously promulgated by the Commercial Aviation Safety Team [] due to the narrowness of non-power plant-related equipment failures, which fails to address a myriad of possible failures. Accordingly, the following system failure categories were empirically employed: (1) propulsion to include the ignition system, turbocharger, propellor and lubrication; (2) airframe inclusive of vertical/horizontal stabilizer; (3) flight control system comprising all moveable surfaces.

Causes of any of the aforementioned failed systems were per the final NTSB report.

2.3. Statistics

Changes in accident rate over time were tested for statistical significance using a Poisson distribution []. A binomial test was used to determine if the fraction of equipment-related fatal accidents for type-certificated airplanes differed significantly from those which were experimental-amateur-built. A Chi-Square test [] ([], pp. 720–759) was employed to determine which system failure(s) was/were over-represented for experimental-amateur-built and type-certificated airplanes. All statistics were performed using the IBM SPSSR program (Version 27, Armonk, NY, USA). Statistical power analysis for population size was undertaken using G*Power (v3.1.9.4) (University of Dusseldorf, Dusseldorf, Germany).

3. Results

3.1. Equipment-Related Fatal Accidents

We first sought to determine whether the rate of fatal accidents related to equipment failure has declined with the passage of time. For this part of the study, both type-certificated and experimental-amateur-built airplanes (single and multi-engine) were aggregated in the analysis. A start year of 1990 was chosen as this was the earliest year in which fleet time became available per the GA survey []—necessary for calculating accident rates. An end year of 2019 was chosen to avoid the confounding effect of the COVID-19 pandemic [].

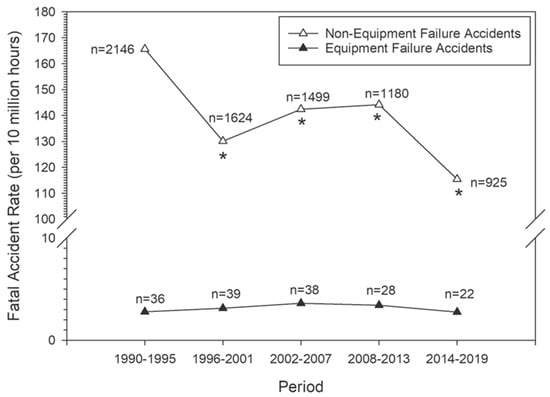

Although the equipment failure-related fatal accident rate was substantially lower than that for fatal mishaps due to causes unrelated to equipment failure (Figure 1), there was little evidence of a decline over the 30 years (1990–2019) for the piston-powered type-certificated and experimental-amateur-built aggregated aircraft fleet. Thus, a Poisson distribution indicated a fatal accident Rate Ratio of 0.988 (95% confidence intervals; 0.581, 1.679) for the 2014–2019 period, using the initial period (1990–1995) as reference (p = 0.964). In contrast, relative to the initial time frame (1990–1995), the rate of fatal accidents due to causes unrelated to failed equipment showed a statistical decline for all subsequent time frames (p < 0.001). This latter observation is consistent with the improved safety trend evident for GA as per the Joseph T Nall report [].

Figure 1.

Equipment-related/unrelated fatal GA accident rates (1990–2019). GA fatal accident rates (inclusive of type-certificated and experimental-amateur-built aircraft) related to equipment failure or other causes are shown. Rates were determined using GA fleet activity as the denominator. A Poisson distribution was employed to determine if the rate change was statistically significant using the earliest period (1990–1995) as reference. *, p < 0.001. n, Fatal accident count.

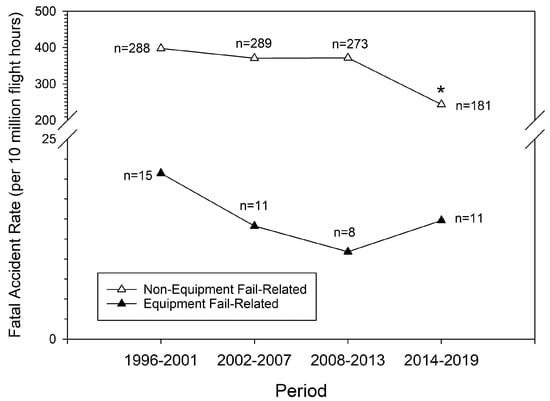

The aforementioned longitudinal analysis was then constrained to experimental-amateur-built airplanes. Note that since fleet time data (for calculating accident rates) for this group of aircraft were categorized separately in 1993 and thereafter [] and to maintain comparable time frames to the prior analysis, a reference period (1996–2001) was chosen. Again, like the combined type-certificated aircraft/experimental-amateur-built fleet, the rate of experimental-amateur-built fatal accidents related to equipment failure was substantially lower (Figure 2) than that brought about by other causes. Interestingly, referencing the 1996–2001 time frame, a downward trend in the equipment failure-related fatal accident rate was apparent for subsequent periods with a 47% reduction evident for the 2008–2013 period. However, Poisson distribution statistical testing showed these reductions to be non-significant with confidence intervals all crossing unity. It should be emphasized that this lack of statistical significance was not due to insufficient statistical power. Thus, a power analysis using an Exp(B) value of 0.526 per the 2008–2013 period indicated that the minimum total population size (n = 17) criterion had been met.

Figure 2.

Equipment-related/unrelated fatal GA accident rates for experimental-amateur-built aircraft (1996–2019). This is based on Figure 1 but restricting the analysis to experimental-amateur-built aircraft. The shorter time frame reflects a later availability of fleet time for this group of aircraft required to calculate accident rates. A Poisson distribution was employed to determine if the rate change was statistically significant using the earliest period (1996–2001) as reference. *, p < 0.001. n, Fatal accident count.

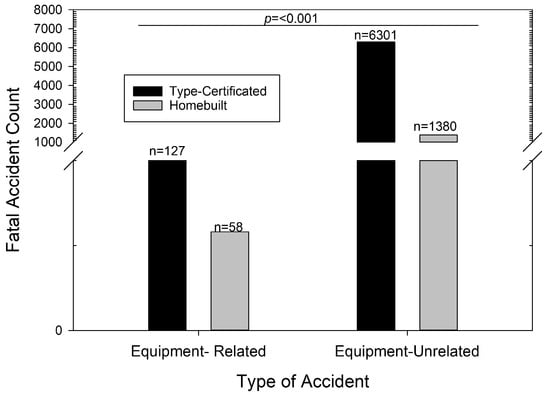

Considering the non-regulatory nature of manufacture/approval of experimental-amateur-built airplanes in comparison with type-certificated aircraft (14CFR Part 23) [], we were curious as to whether there was a disproportionate count of equipment failure-related fatal accidents for the former. Indeed, equipment failure-related fatal accidents involving experimental-amateur-built aircraft were over-represented (p < 0.001) with respect to those which were type-certificated (Figure 3). That is, there were 100% more fatal accidents related to equipment failure for experimental-amateur-built aircraft than would be expected based on the corresponding fraction for type-certificated aircraft. These data clearly indicate a demarcation of equipment-related fatal accident risk for these two categories of GA aircraft.

Figure 3.

Disproportionate count of equipment failure-related fatal accidents for experimental-amateur-built aircraft. A comparison of fatal accidents (1989–2023) involving type-certificated and experimental-amateur-built aircraft caused by either equipment failure or unrelated to an equipment malfunction. A binomial test was used to determine if fatal accidents related to equipment failure was over-represented for experimental-amateur-built airplanes. n, Fatal accident count.

3.2. System Failures for Experimental-Amateur-Built and Type-Certificated Airplanes

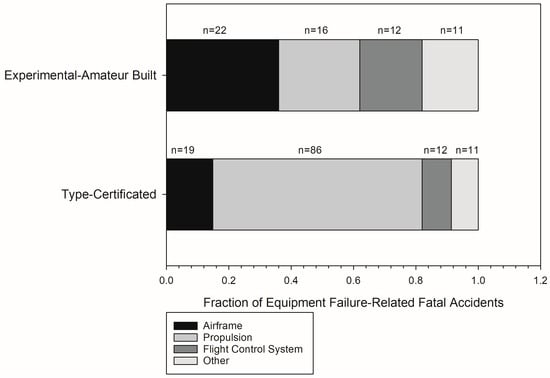

We then sought to determine the type of equipment failure most prevalent for both categories of aircraft (Figure 4). A 2 × 2 Chi-Square analysis indicated an overall difference (p < 0.001) in the fraction of fatal accidents across the types of system failures between these two aircraft categories (1989–2023). To identify the cells responsible for the overall change in proportion, we used adjusted residuals (Z-scores) as described previously ([], pp. 32–34). Importantly, a failed propulsion system accounted for the majority (67%) of fatal accidents involving type-certificated aircraft. This count was disproportionate as determined with adjusted residuals (p < 0.001). Conversely, airframe failures represented the largest system failure category (36%) leading to experimental-amateur-built aircraft fatal accidents. Again, statistically, the count of airframe failures culminating in a lethal mishap was over-represented (p = 0.001) for experimental-amateur-built airplanes. These data serve to illustrate a difference between experimental-amateur-built and type-certificated aircraft in terms of the most common system failure culminating in fatal accidents.

Figure 4.

Categorization of equipment failure for fatal accidents involving type-certificated and experimental-amateur-built aircraft. System failures (1989–2023) leading to fatal accidents for type-certificated and experimental-amateur-built aircraft are shown. A Chi-Square test was employed to determine if there was a difference in proportions across the categories of system failures between type-certificated and experimental-amateur-built aircraft. The “Other” group comprises malfunctions of a window, throttle quadrant, fuel or exhaust system, the landing gear, canopy separation, and alternate air. The summed fraction for the various system failures for each aircraft group (type-certificated and experimental-amateur-built) = 1. n, Count of fatal accidents.

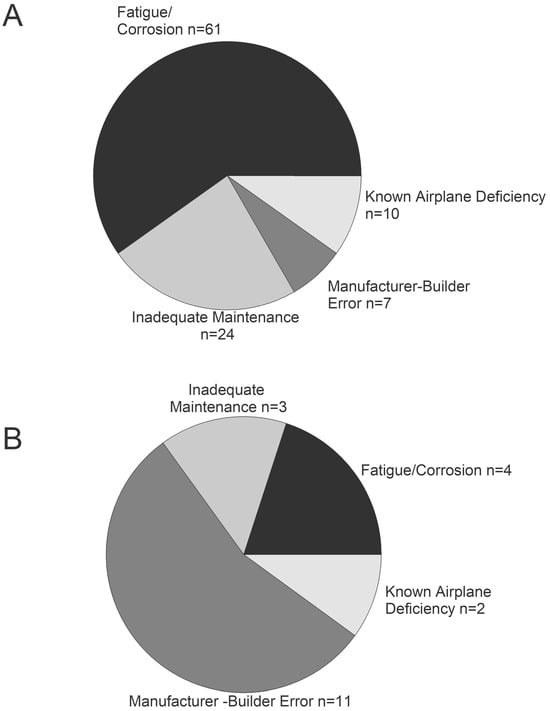

We then posed the question as to the cause(s) of the most common system failure leading to fatal accidents (1989–2023) for both type-certificated and experimental-amateur-built airplanes (propulsion system and airframe respectively). Causes of system failures were categorized and defined (Table 1) empirically per the present study. For type-certificated airplanes, failure of the propulsion system was, for 60% of the fatal mishaps, caused by component fatigue or corrosion (Figure 5A). Conversely, inadequate maintenance accounted for only 23% of propulsion system failures leading to a fatal outcome (Figure 5A). In contrast, the majority of fatal accidents related to airframe failure for experimental-amateur-built aircraft fell under the “Manufacture-Builder Error” category (Figure 5B). Unlike type-certificated aircraft where fatigue/corrosion accounted for the majority of the propulsion system failure, only 20% of lethal mishaps attributed to a failed airframe for fatal experimental-amateur-built airplane accidents could be grouped in this category. It should be noted that the sum of accidents across the indicated categories varied from that in Figure 4 for two reasons: (i) each mishap could have multiple categories and (ii) a lack of information in some NTSB reports.

Table 1.

Causes of propulsion/airframe systems failure and corresponding definitions.

Figure 5.

Causes of propulsion and airframe system failure for type-certificated and experimental-amateur-built aircraft, respectively. The cause(s) of a failed propulsion or airframe, as described in Table 1, is illustrated for type-certificated (Panel (A)) and experimental-amateur-built aircraft (Panel (B)), respectively. Note that one accident may involve multiple causes. n, Fatal accident count.

While our broad categories of failed aircraft systems were deliberate for increased statistical power, it obfuscated which component most commonly failed. This represented the next line of inquiry as to the propulsion system failure for type-certificated aircraft. A similar analysis was not conducted for experimental-amateur-built airframe failures due to an insufficient fatal accident count. Interestingly, a third (34%) of fatal accidents involving type-certificated airplanes for which the propulsion system malfunctioned was attributed to failure of the crankshaft or connecting rod or piston (Table 2). Failure of a component in the cylinder (inclusive of the head and barrel) and camshaft groups (inclusive of the inlet–exhaust valves and rocker arm) were causal for 20% and 15% of propulsion-related fatal accidents in type-certificated aircraft. It should be emphasized that none of these components are amenable to examination in an annual inspection per 14CFR Part 43, Appendix D []. Moreover, it is noteworthy that for 92% of fatal accidents caused by a failed powerplant, the engine time was less than that prescribed by the manufacturer (TBO) at the time of the mishap.

Table 2.

Failed propulsion component for type-certificated aircraft involved in fatal accidents. Reciprocating engine components are illustrated on the following website: https://aerotoolbox.com/engine-intro/ (Accessed on 1 May 2025).

4. Discussion and Conclusions

We report that the rate of fatal GA accidents caused by equipment failure has not changed over the past three decades. The finding of a static equipment-related fatal accident rate was somewhat surprising considering improved maintenance practices [] and a new FAA compliance philosophy [,], which encourages error reporting without the fear of punitive action. Nevertheless, it should be emphasized that despite a static rate of equipment-related lethal accidents, such mishaps only represent a small proportion of all GA fatal mishaps occurring over the thirty-year study period.

There is scant published research on equipment failure-related fatal GA accidents. A prior study by the first author [] reported a higher fraction (relative to that herein) of GA accidents due to malfunctioning equipment but, importantly, fatal and non-fatal accidents were not differentiated. In that report, the propulsion category represented the most common system failure causal for GA accidents consistent with the current findings. Additionally, while addressing the role of inadequate maintenance in the cause(s) of engine failure, the earlier study [] did not determine the contribution of fatigue/corrosion to the powerplant malfunction.

Per our study, fatigue/corrosion represented the most prevalent cause of engine failure in type-certificated aircraft. Another pertinent study was that of Lv and co-workers [] who, in a meta-analysis examining 173 aircraft accidents, determined that a failed engine system represented the majority (59%) of events. Of such mishaps, component fatigue cracking constituted the largest number of occurrences. However, the reader should be cautioned in comparing this [] and our study in three respects. Firstly, the study of Lv and co-authors focused on turbine rather than piston engine failures. Second, it was unclear whether the 173 accidents analyzed were restricted to only mishaps with a fatal outcome. Finally, unlike our study, the authors categorized powerplant component fatigue and corrosion separately.

Our findings that inadequate maintenance was causal for the minority of equipment failures (23 and 15% for type-certificated propulsion and experimental-amateur-built airframes, respectively) was similar to an earlier human factor classification study (HFACS) [], which reported that 21% of GA accidents in 1994 could be attributed to deficiencies in maintenance. Importantly, and consistent with our findings, the rate of such mishaps was unchanged over the 1990–2000 period. However, as before, this earlier research [] failed to distinguish between fatal and non-fatal accidents.

One of the seminal findings of the current study is that powerplant failure is most commonly due to component fatigue/corrosion (per Figure 5) and that over 90% of such failures occur well within the TBO as prescribed by the manufacturer. Moreover, it should also be emphasized that the failed component is most commonly beyond the scope of an annual inspection as described in 14CFR Part 43, Appendix D []. Consequently, considering that single-engine piston-powered airplanes represent by far the majority of the GA fleet [], pilots should exercise extreme caution in undertaking operations at night and/or where terrain is unsuitable for off-field landings (e.g., mountainous terrain, bodies of water). Additionally, pilots should be cognizant of ambient conditions (e.g., coastal areas) accelerative for corrosion. In this regard, a previous study [] determined that the majority of GA pilots operating in such challenging environments fail to plan accordingly in terms of being within glide-range of suitable terrain or an airport after an engine failure.

An earlier report [] addressing experimental-amateur-built safety documented that a greater fraction of such accidents could be attributed to powerplant failures when compared with airframe failures. These earlier findings were divergent with ours, demonstrating the latter to be a more frequent occurrence. What might explain this dichotomy? There are several plausible reasons. First, there were the different time frames of studies, i.e., 2000–2010 for the earlier study vs. 1989–2023 for the current study. Second, different taxonomies were employed in both studies. For example, in the prior study, the “airframe” category (as employed in the current research) was aggregated with other failures into the “system component failure–non-powerplant” as per the Commercial Aviation Safety Team/International Civil Aviation Organization nomenclature []. Lastly, the number of accidents involving experimental-amateur-built aircraft was relatively small in both studies.

Limitations of the current study need to be stated. First, we cannot exclude the possibility that some equipment-related accidents were not captured based on our search strategy, in which the narrative cause was queried for the presence of specific text strings. Second, as mentioned above, the count of equipment-related accidents involving experimental-amateur-built aircraft was small. Third, we acknowledge that our accident rate analysis does not address external confounding factors, e.g., economy and technology, which may vary over time and deserve future research, for instance, logistic regression models. Fourth, one question worthy of future research is whether aviators with minimal aviator certification (e.g., private, sports, recreational pilots) are more likely to incur a fatal accident, subsequent to equipment failure, relative to those with advanced certificates (e.g., commercial, airline transport pilot).

In conclusion, while fatal accidents related to equipment failure are rare, there is little evidence for a decline in the rate of such mishaps over the last three decades. Importantly, GA pilots should be cognizant of the fact that powerplant failures, for the most part, occur within the prescribed TBO and involve fatigue/corrosion of a component which is inaccessible for examination in an annual inspection. As for experimental-amateur-built aircraft, airframe failure—the most frequent cause of fatal mishaps—begs the question as to whether the building/assembly process should be subject to either greater oversight or regulations to assure continued structural integrity.

Author Contributions

Conceptualization—D.D.B.; Methodology, D.D.B. and L.J.; Formal Analysis, D.D.B.; Investigation, D.D.B.; Data Curation, D.D.B.; Writing—Original Draft Preparation, D.D.B. and L.J.; Writing—Review/Editing, D.D.B. and L.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Ethical review and approval were waived for this study by virtue of all the data being publicly available via the NTSB aviation accident database.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available from the National Transportation Safety Board Aviation Access Database (http://app.ntsb.gov/avdata/Access/), which is in the public domain. Accessed on 1 May 2025.

Acknowledgments

We would like to express our appreciation to Jesse Sanchez (Aviation Safety Inspector, FAASTem Program Manager-Flight Safety District Office, Houston) for his guidance on annual inspections of piston engines.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Electronic Code of Federal Regulation. General Definitions. 2023. Available online: https://www.ecfr.gov/current/title-14/chapter-I/subchapter-A/part-1/section-1 (accessed on 1 May 2025).

- Electronic Code of Federal Regulation. General Operating and Flight Rules. 2015. Available online: https://www.ecfr.gov/current/title-14/part-91 (accessed on 1 May 2025).

- Electronic Code of Federal Regulation. Airworthiness Standards: Normal, Utility, Acrobatic and Commuter Category Airplanes. 2017. Available online: http://www.ecfr.gov/cgi-bin/text-idx?SID=5ffea7e4489b0113fefc117f1b9fc96a&mc=true&node=pt14.1.23&rgn=div5#se14.1.23_11 (accessed on 1 May 2025).

- National Transportation Safety Board. The Safety of Experimental Amateur-Built Aircraft. SS-12/01. 2012. Available online: https://www.ntsb.gov/safety/safety-studies/Pages/SS1201.aspx (accessed on 16 June 2025).

- AOPA Air Safety Institute. 31st Joseph T. Nall Report; General Aviation Accidents in 2019. 2021. Available online: https://www.aopa.org/training-and-safety/air-safety-institute/accident-analysis/joseph-t-nall-report/nall-report-figure-view?category=all&year=2019&condition=all&report=true (accessed on 1 May 2025).

- Boyd, D.D.; Scharf, M.T. Deficient Aeronautical Decison-Making Contributions to Fatal General Aviation Accidents. Aerosp. Med. Hum. Perform. 2023, 94, 807–814. [Google Scholar] [CrossRef] [PubMed]

- Boyd, D.D. Causes and risk factors for fatal accidents in non-commercial twin engine piston general aviation aircraft. Accid. Anal. Prev. 2015, 77, 113–119. [Google Scholar] [CrossRef] [PubMed]

- Kalagher, H. Fuel Planning Errors in General Aviation from 2015 to 2020. Aerosp. Med. Hum. Perform. 2022, 92, 970–974. [Google Scholar] [CrossRef] [PubMed]

- Major, W.L.; Carney, T.; Keller, J.; Xie, A.; Price, M.; Duncan, J.; Brown, L.; Whitehurst, G.R.; Rantz, W.G.; Nicolai, D.; et al. VFR-into-IMC Accident Trends: Perceptions of Deficiency in Training. J. Aviat. Technol. Eng. 2017, 7, 50–57. [Google Scholar] [CrossRef]

- AOPA Air Safety Institute. 27th Joseph T. Nall Report. General Aviation Accidents in 2015. 2019. pp. 1–43. Available online: https://www.aopa.org/-/media/files/aopa/home/training-and-safety/nall-report/27thnallreport2018.pdf (accessed on 16 June 2025).

- Boyd, D.D.; Hinkelbein, J. A Comparison of Malfunction-Related Accidents for General Aviation Aircraft Manufactured in 1970–1984 and 2000–2014. J. Aviat. Technol. Eng. 2017, 6, 26–32. [Google Scholar] [CrossRef]

- Federal Aviation Administration. General Aviation and Part 135 Activity Surveys. 2021. Available online: http://www.faa.gov/data_research/aviation_data_statistics/general_aviation (accessed on 1 May 2025).

- Nelson, R.A.; Drews, J.N. Strict Product Liability and Safety: Evidence from the General Aviation Market. Econ. Inq. 2008, 46, 425–437. [Google Scholar] [CrossRef]

- Code of Federal Regulations: 14CFR Part 43. Maintenance, Preventive Maintenance, Rebuilding and Alterations. 2015. Available online: http://www.ecfr.gov (accessed on 1 May 2025).

- Boeing. Maintenace Event Decision Aid (MEDA) User’s Guide. 2018. Available online: https://www.faa.gov/about/initiatives/maintenance_hf/procedural_non-compliance/MEDA_Users_Guide_rev_February_2022.pdf (accessed on 1 May 2025).

- Federal Aviation Administration. Acceptable Methods, Techniques, and Practices-Aircraft Alterations. AC 43.13-2B. 2008. Available online: https://www.faa.gov/regulations_policies/advisory_circulars/index.cfm/go/document.information/documentid/74417 (accessed on 16 June 2025).

- Federal Aviation Administration. Federal Aviation Administration Compliance Philosophy. 2015. Available online: https://www.faa.gov/documentLibrary/media/Order/FAA_Order_8000.373.pdf (accessed on 1 May 2025).

- Federal Aviation Administration. Compliance Program. 2018. Available online: https://www.faa.gov/about/initiatives/cp (accessed on 1 May 2025).

- National Aeronautics and Space Administration (NASA). Aviation Safety Reporting System. 2015. Available online: http://asrs.arc.nasa.gov/search/database.html (accessed on 1 May 2025).

- Commercial Aviation Safety Team/International Civil Aviation Organization. Aviation Occurrence Categories. Definition and Usage Notes. 2004. Available online: https://www.cast-safety.org/pdf/cictt_occurrence-category0804.pdf (accessed on 1 May 2025).

- Dobson, A.J.; Barnett, A.G. An Introduction to Generalized Linear Models, 3rd ed.; Chapman and Hall/CRC: Boca Raton, FL, USA, 2008; pp. 165–171. [Google Scholar]

- Agresti, A. Categorical Data Analysis, 3rd ed.; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Field, A. Discovering Statistics Using IBM SPSS Statistics; SAGE Publications: Thousand Oaks, CA, USA, 2009; pp. 32–759. [Google Scholar]

- Centers for Disease Control and Prevention. Coronavirus Disease 2019 (COVID-19). 2021. Available online: https://covid.cdc.gov/covid-data-tracker/#cases_casesper100klast7days (accessed on 1 May 2025).

- Electronic Code of Federal Regulation. Appendix D to Part 43—Scope and Detail of Items (as Applicable to the Particular Aircraft) to Be Included in Annual and 100-Hour Inspections. 2025. Available online: https://www.ecfr.gov/current/title-14/chapter-I/subchapter-C/part-43/appendix-Appendix%20D%20to%20Part%2043 (accessed on 1 May 2025).

- Lv, J.H.; Wang, W.Z.; Tu, S.T.; Liu, S.W. Failure Cases Analysis in Aerospace Field. Mater. Sci. Forum 2020, 993, 1277–1285. [Google Scholar] [CrossRef]

- Boquet, A.; Detwiler, C.; Robberts, C.; Jack, D.; Schappell, S.; Wiegmann, D.A. General Aviation Maintenance Accidents: An Analysis Using HFACS and FOCUS Groups. 2002. pp. 1–5. Available online: https://www.semanticscholar.org/paper/GENERAL-AVIATION-MAINTENANCE-ACCIDENTS%3A-AN-ANALYSIS-Boquet-Detwiler/d34719c437532d29b5c650790f757ca8fe9cc57c (accessed on 16 June 2025).

- Boyd, D.D. Use of Flight Tracking Data to Inform Safety Deficiencies for General Aviation Cross-Country Operations in Challenging Flying Environments. J. Saf. Res. 2023, 84, 99–107. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).