Abstract

The construction sector is known to have the highest risks of occupational accidents. A rationale for this high occurrence of occupational risks can be related to legislative requirements to enforce safe construction practices within this sector. Within the context of excavation works in Turkey, this study investigates the leading risks for any compliance shortfalls and ultimately presents recommendations to mitigate occupational accidents’ occurrences during excavation works in the construction sector. Based on a quantitative methodology, a closed-ended survey consisting of 35 questions and based on legislative requirements was applied to project managers in the construction industry, such as site supervisors, occupational safety experts, auditors, and control personnel. A sample size of 277 responses was found to have stability and validity through a reliability analysis and an exploratory factor analysis, and was used for testing statistical significance via cross-tabulation analysis and chi-square tests. The findings revealed that the major deviation of safety in excavation works from legislative requirements is executing works during adverse weather conditions. Moreover, it was also noteworthy that protective curtains did not surround the excavation sites, and most of the employees encountered ground slippage during excavation work. Therefore, the findings revealed preliminary research that will contribute positively to providing incentives for a focus on and development of relevant security and technical measures. It also provided information to protect the safety and welfare of the workers involved in excavation works. Finally, though these findings may be considered context-specific, this research can be used for comparative purposes for similar studies into the safety practices of excavation works in different countries, where generalized findings can be later derived to inform academia and practice.

1. Introduction

When the statistics on occupational accidents and diseases conducted by the Social Security Institution over the years are analyzed, it is observed that most fatal occupational accidents occur in the construction sector [1]. The construction sector, which is one of the cornerstones of working life in Turkey, as in the whole world, is one of the sectors with the highest risk of encountering negative situations among all sectors for many reasons. These reasons can be listed as the fact that the workers are generally unskilled and uneducated, a wide variety of jobs are carried out together in terms of the work volume, the work area is dispersed and large, the rate of subcontracting is high, etc. [2]. Although the increase in legal regulations and inspections in Turkey in recent years has enabled concrete steps to be taken, the construction machinery, tools, and equipment used in the construction sector continue to pose a danger to both employees and the environment [3]. Especially in cases where occupational health and safety measures are not taken or are inadequate, problems arising from these machines can lead to serious negative situations. Safe Work Australia [4] reported that most of the fatal accidents caused by machinery involve events preventable by safety measures.

Excavation works are among the construction works in which machinery is used most frequently. Excavation works play a fundamental role in many construction projects. There are many types of excavation, depending on the work area and the nature of the work. Free excavations; underground excavations; dam and hydroelectric power plant excavations; road excavations; tunnel excavations; stripping, cleaning, and shaping excavations; and channel excavations are just some of these excavation types [5]. The biggest risk in excavation works is the formation of cave-ins [6]. In addition, to correct and improve the existing situation in excavation works where many occupational accidents with fatalities or injuries may occur, Turkey has made the necessary legal arrangements and ensures their implementation and inspection. The Occupational Health and Safety Law, which came into force on 1 January 2013, is the most important step taken on this issue [7]. This law, which imposes very serious responsibilities on employers and employees, has paved the way for very comprehensive legal regulations to take serious measures in the construction sector. The regulation on occupational health and safety in construction works, which was also issued within the scope of this law, imposes various responsibilities on employees and employers in many areas such as the measures to be taken before starting excavation works and the issues to be considered during the work [8]. Overall, it can be said that excavation work is one of the most challenging and dangerous activities in the sector [9]. For this reason, if precautions in the procedure are not taken during excavation works, negative situations may arise that may lead to serious dangers. These negative situations can be listed as collapses or cave-ins, workers falling into the excavation or trench area, material or equipment falling on workers in the excavation area, flooding of the excavation area, the potential for damage to or the collapse of the surrounding structures, the presence of hazardous and harmful gases, and damage to underground facilities such as water lines, cables, etc. [10,11].

As a guide to frame the health, safety, and environmental risks in excavation works, Köksal’s [10] and Rampuri’s [11] list of risky events that may occur during excavation works can be summarized into three risk categories [12]. Known risks are typically localized risks that are easily identified in the risk identification process. Known risks are actively managed as part of daily work operations and are created by the actual work package. Typical known risks in excavation works are collapses or cave-ins, the fall of workers into the excavation or trench area, the fall of materials or equipment on workers in the excavation area, and the potential for damage to or the collapse of the surrounding structures. Known unknown risks are another class of risks that can be both predicted and foreseeable, such as the presence of hazardous and harmful gases, underground service utilities, flooding, and groundwater. Unknown risks are risk events that cannot be easily predicted, such as force majeure events [12]. Classifying risks into easily identifiable categories allows the safety team to develop an effective response plan and mitigation strategy in the planning stage of the construction works. When risks are not planned for and managed carefully and with urgency, serious injuries can occur, leading to loss of life and a failed project embroiled in legal disputes.

A collapse is a sudden loosening and shifting of material in the excavation area, resulting in workers and equipment being trapped under the excavated material, causing significant loss of life and property [5]. Occupational Safety and Health Administration (OSHA) statistics have confirmed this information and also show that when compared with general construction work, excavation-related fatalities are about twice as high [13]. Plog et. al. [14] stated that 384 construction workers died from excavation-related injuries in the United States of America (USA) from 1992 to 2002. Similarly, statistics for the USA’s private construction industries from 2003 to 2011 show that 287 workers were killed due to excavation collapses [15]. In Turkey, it was shown that 285 workers lost their lives due to collapse and crushing among the sector-based causes of occupational accidents in 2019 [16,17]. These data show that a number of employees are either killed or injured every year [18]. As a result, it raises curiosity as to what extent the principles of regulation that meet certain criteria are complied with in construction areas. For this reason, this study aimed to examine occupational safety practices in excavation works during construction activities, taking into account the legislative and regulatory conditions in Turkey. This study’s findings can be presented as preliminary research to determine the current conditions and areas open to improvement. Additionally, it can serve as a comparison study in both national and international scientific research. To achieve this aim, the remainder of this study is structured into four sections. Section 2 provides a focused overview of the literature on the dominant scholarship influencing this study’s narrow scope, including occupational safety risks in the construction sector in Turkey, safety practices, and excavation works. Section 3 provides the research methodology, building upon the post-positivist lens for this study and providing a framework guiding the method adopted. In Section 4 (Findings and Discussion), the findings from the survey and the implications of contemporary construction practices are discussed in relation to the law and regulations. The final section concludes this study and provides suggestions to improve compliance with legislative requirements and reduce the accidents and loss of life associated with excavation works.

2. Literature Review

Although the scope of occupational health and safety is universal, occupational health and safety may differ in terms of the laws, regulations, and practices of countries [18]. When studies covering occupational safety in the construction sector in Turkey were examined, very few studies were encountered specifically on occupational safety in excavation works in construction. Kale and Eskişar [19] examined the report details of 92 accidents that occurred during excavation works. Afanuh et al. [20] drew attention to the prevention of worker fatalities due to cave-ins caused by trenching and excavation activities. Rees [21] mentioned that trenches and excavation works in civil engineering or building projects involve risks and investigated deaths and injuries. McCann [22] examined the Bureau of Labor Statistics Fatal Occupational Injury Census of 253 fatalities related to work machines at construction sites in excavation works between 1992 and 2002. Gürcanlı and Müngen [23] suggested a new occupational safety risk analysis method with fuzzy sets for occupational safety in construction in Turkey and the world. Başağa et al. [18] researched the effectiveness of occupational health and safety training for construction workers in Turkey. Uzun [24] conducted an occupational safety risk assessment on the use of construction machinery in construction. Aydoğan and Rüştü [25] studied occupational health and safety in the construction sector in terms of field surveillance and work equipment. Aktuna and Aktuna [26] surveyed 83 construction workers in their study examining occupational health and safety practices in the construction industry. Arslan [27] studied a sample health safety plan in hydroelectric power plant construction. She mentioned that excavation works should be carried out in a planned manner under the supervision of an expert and with all safety precautions. Korkmaz [28] mentioned excavation works, excavation slopes, and protective systems in excavation in the study “Occupational safety in 11 step-in construction works”.

3. Research Methodology

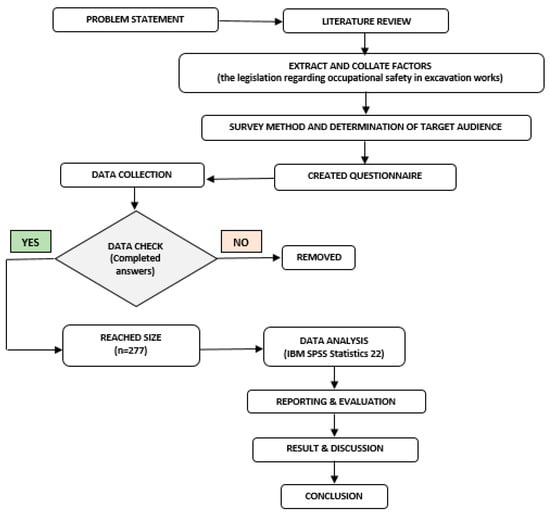

This research is quantitative in its nature and adopts a post-positivist theoretical paradigm to evaluate the causal relationships between events and perceptions [29]. This approach treats reality in a flexible way, independent of the phenomenon under investigation. To achieve this, a closed-ended questionnaire tool was used to gather primary data from primary stakeholders involved in the process of construction excavation works. The flowchart in Figure 1 summarizes the research methodology involved in this study.

Figure 1.

Research methodology flowchart.

In this study, legislation related to excavation works in Turkey was examined in detail, and, in this context, a survey form was developed by compiling the principles regarding field practices [7,8,30,31]. The survey form, consisting of a total of 35 questions, was prepared systematically via the descriptive-scan type with expert advice and provided the opportunity to see the current situation regarding the implementation of the regulation in the field. The survey form first included a general section consisting of 10 questions to obtain information about the employees’ job description, working hours, educational status, information on occupational health and safety, current field information, whether they have had a work accident, and, if so, the reasons. Afterward, it contained a second section consisting of 25 questions with two choices (yes and no), developed by examining the legislation regarding occupational safety practices in excavation works in Turkey. The reason why two-choice questions were preferred is that employees either comply with the legislation requirements or they do not. The survey form was answered by the construction site supervisor, occupational safety specialist, auditor, or control staff responsible for projects working in the Gaziantep and Kilis provinces of Turkey and the private sector. These personnel, consisting of civil engineers, architects, construction technicians, building inspection technicians, and occupational safety experts, have the authority to ensure and enforce regulations through their job descriptions [32,33].

Within the scope of this study, a survey was administered through individual distribution to project managers working on different projects. Ethical consent was first requested from employees prior to participating in the survey. All participants were informed of the aims and use of the survey, and participation was an entirely voluntary exercise. Participants were notified that there were 35 questions in the survey form and told to make a single choice or one answer per question. To improve the data’s validity, only 100% completed surveys were selected for analysis. Incomplete surveys were excluded from the evaluation to reduce unwanted variability in the results that could skew the construct validity and reliability of the findings [12]. Then the completed surveys of a total of 277 employees were collated, organized, and transferred into the SPSS Version 22© statistical data program. Both descriptive and inferential statistical tests were completed using this statistical tool. Frequency analyses were conducted to determine the frequency of observations and the percentage distribution of the data. To appreciate how the variables are correlated, cross-tabulation analysis was performed on the data to quantitatively derive the trends of one or more variables with the results of another variable. The chi-square test was also used to check whether the results of the cross-tabulation analysis were statistically significant. The researchers tested for statistical significance, traditionally understood by the use of the probability or p-value, to determine whether, in the results, there was evidence that the sample had an effect on the population. The alpha value, α, or critical value, is another statistic used to indicate the boundaries of whether the p-value is significant or not. The value of p ≤ α = 0.05 was accepted as statistical significance. In addition, reliability and exploratory factor analyses were performed to indicate the stability and validity of the measured values.

4. Findings and Discussions

This section includes the findings and evaluations of the survey study on occupational safety in excavation works obtained with the statistical data analysis program SPSS Version 22. The findings of the survey have been evaluated in two subsections, which are the findings of the frequency analysis and the findings of cross-tabulation and chi-square analyses. In this study, the Cronbach’s alpha (α) value was found to be 0.854 as a result of the reliability analysis of the two-choice evaluation series with the SPSS 22 program. In the literature, α > 0.8 is regarded as high (good) reliability [34,35]. Thus, the high consistency and reliability of the evaluated results were confirmed [36,37].

Exploratory factor analysis (EFA) was conducted to explain whether the measurement tool used reflects the characteristic to be measured. For this, principal components and direct oblique rotation methods were used. This is because principal components are the most frequently and easily used method in practice [38], and direct oblique rotation is thought to show a relationship between the questions [39]. First, the suitability of the dataset for factor analysis was assessed by the Kaiser–Meyer–Olkin (KMO) test and Bartlett’s sphericity test [40,41]. The KMO value was 0.782, which showed that the dataset was suitable for EFA. The fact that the KMO value was greater than 0.5 indicated that the dataset’s size was sufficient for factor analysis [42,43]. Moreover, if this value is between 0.7 < KMO < 0.8, it is classified as “good enough” [44,45,46]. As a result of Bartlett’s test, x2 (300) = 2702.657; p < 0.05. These findings show that the correlation between questions suits EFA [41,42].

As a result of EFA, it was determined that the part of the occupational safety survey in construction excavation works consisting of 25 questions, evaluated according to the principles of regulation, consisted of a seven-factor structure, and these seven factors constituted 63.245% of the total variance. As a result, the scale of this section could explain 63.245% of the features to be measured. In the literature, studies in which the cumulative variance does not fall below 50% are considered sufficient [44,47,48,49,50]. Therefore, the magnitude of the explained variance demonstrates the validity of the information obtained from the scale. In addition, while the first factor explains 26.888% of the features that could be measured with this scale, the second factor explains 8.804%, the third factor explains 7.098%, the fourth factor explains 6.202%, the fifth factor explains 5.786%, the sixth factor explains 4.401%, and the seventh factor explains 4.065%. Table 1 shows the distribution of the questions according to factors and their factor loadings.

Table 1.

Direct oblique rotated factor loading matrix from the exploratory factor analysis.

As seen in Table 1, Factor 1 consists of nine questions, Factor 2 consists of four questions, Factor 3 consists of five questions, Factor 4 consists of two questions, Factor 5 consists of four questions, Factor 6 consists of six questions and Factor 7 consists of five questions. Factor loadings took values between −0.920 and 0.798. Factor loadings can take values between −1 and +1 [51]. These values are coefficients that explain the relationship of the question with the factor. Loadings closer to −1 or +1 indicate that the relationship between the question and the factor is higher, while loadings closer to 0 indicate that it is weaker [52]. In the literature, factor loadings above 0.30 in absolute value are considered significant [47,53,54]. Negatively signed factors express an inverse relationship between the factor and the question or variable [52,53]. It can be seen that the questions forming Factors 1, 2, 4, 5, and 6 contributed in a positive direction, and the questions forming Factors 3 (except Q3) and 7 contributed in a negative direction.

4.1. Frequency Analysis

Frequency analyses were conducted to present detailed information on the responses of the 277 employees who participated in the survey. Frequency distributions for the first part of the survey are given with graphics. The answers to the two-choice questions are presented in Table 2.

Table 2.

Frequency analysis results for two-choice questions prepared for the evaluation of the relevant application principles.

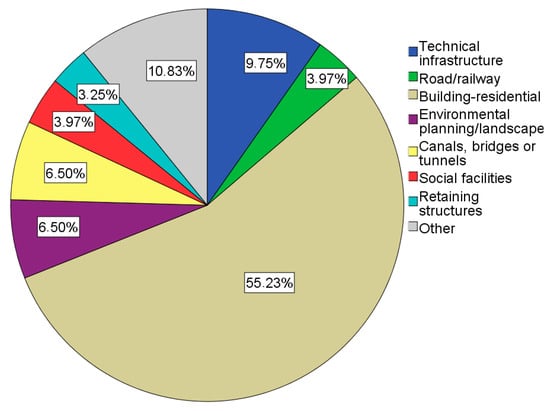

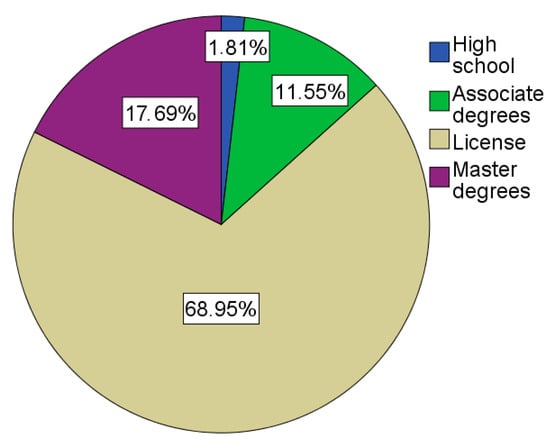

The distribution of the surveyed employees according to the types of projects in their working areas is shown in Figure 2. Accordingly, the largest percentage of the respondents are those working in building—residential projects (55.2%). It has been shown, in a study by Güllüoğlu and Güllüoğlu, that 64% of those working in the sector work in building construction [55]. This type of project is followed by others with 10.8% and technical infrastructure (sewerage, water, electricity, natural gas) with 9.7%. These project types are followed by environmental planning/landscape and canals, bridges, or tunnels (6.5%); highways/railways and social facilities (shopping malls, hotels, etc.) (4.0%); and retaining/stabilization structures (3.2%). Figure 3 shows the level of education of those working as site supervisors, occupational safety specialists, auditors, or control staff responsible for the project. Of the 277 employees who participated in the survey, 191 hold license degrees, 49 hold Masters’ degrees, 32 hold associate degrees, and 5 hold high school degrees. It can be seen that the majority of the participants are at license and Masters’ level (86.7%).

Figure 2.

Project type.

Figure 3.

Educational status.

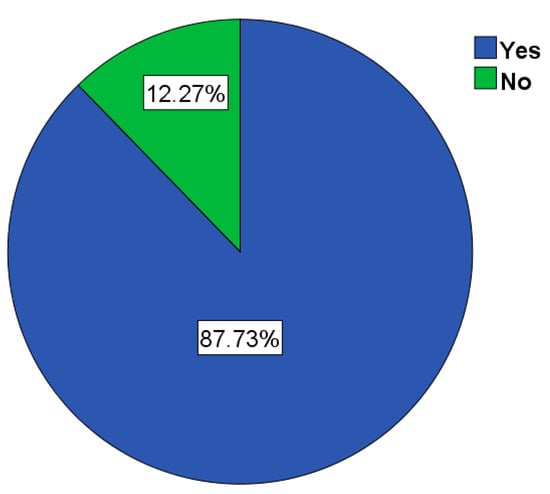

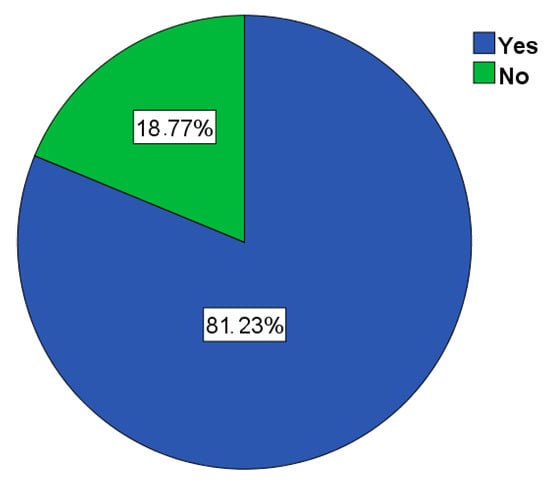

Figure 4 shows that 87.7% of the employees have knowledge related to Occupational Health and Safety Law No. 6331 [7]. Figure 5 shows that while 81.2% of the employees have previously received training on occupational health and safety, 18.8% have not received training. Construction works are classified as very hazardous. According to Law No. 6331 [7], the employer is obliged to organize training activities for employees, covering a minimum level of issues repeatedly, according to the hazard class, taking into account the nature of the job and the employees. These results may indicate that some employers have failed to fulfil their legal obligation to provide training to employees.

Figure 4.

Employees’ information about Occupational Health and Safety Law No. 6331.

Figure 5.

Training of employees on occupational health and safety.

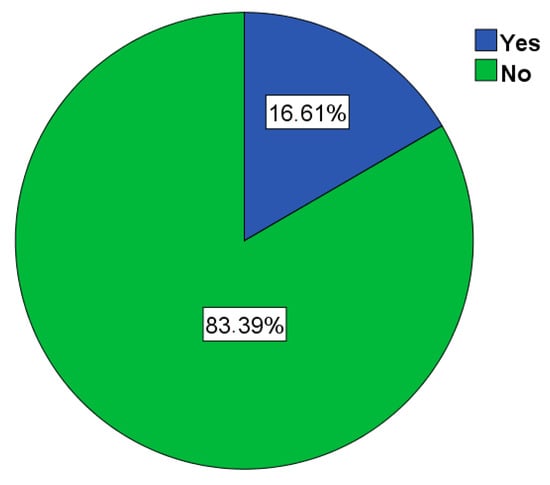

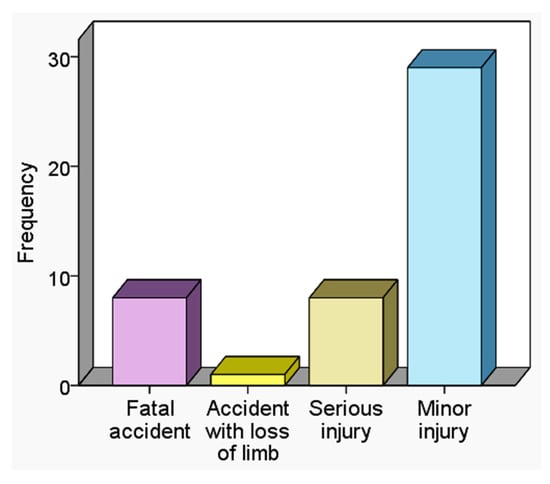

Figure 6 shows that 16.6% of the employees stated that they had encountered occupational accidents, while 83.4% stated that they had not encountered occupational accidents. Amirah et al. [56] stated that safety behavior and safety culture have a positive effect on preventing or reducing accidents in the workplace. Figure 7 shows the occupational accident results of 46 employees who had previously experienced an occupational accident (16.6%). When Figure 7 is examined, it is seen that the rate of minor injury accidents is high. Eight employees encountered serious injuries, and eight employees encountered fatal accidents. There was only one employee who encountered limb loss in an accident.

Figure 6.

Cases of encountering work accidents.

Figure 7.

Results of occupational accidents.

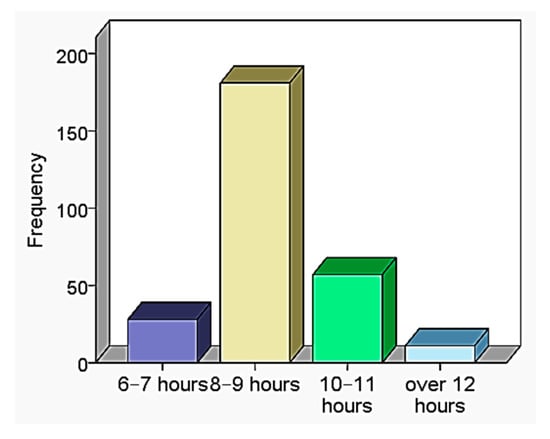

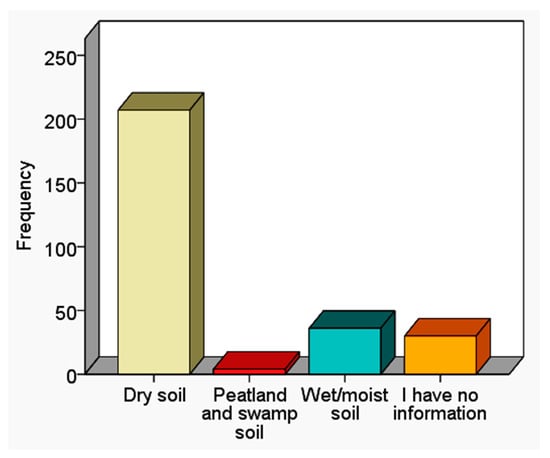

Figure 8 shows the results for the daily working hours of the employees. In total, 65.3% of the employees surveyed worked 8–9 h a day. It is observed that 20.6% of the employees worked 10–11 h, 10.1% worked 6–7 h, and 4.0% worked 12 h or more. In the Labor Act of Turkey Law No. 4857 [57], normal weekly working hours are defined as a maximum of 45 h. If an evaluation is made for those who worked at least 5 days a week and 10–11 h, it can be calculated that the employees worked a minimum of 50 h. In light of this information, it can be said that 34.7% of employees worked overtime beyond the maximum 45 h limitation of the law. Workers working overtime in construction sites and who lack adequate training and precautions regarding occupational health and safety can trigger occupational accidents [58]. Figure 9 shows the results of the responses of the employees regarding the water content of the soil in the excavation areas. While 74.7% of the employees stated that they worked on dry soil, regarding the water content of the soil, 10.8% (30 employees) stated that they had no information, 13.0% of the employees worked on wet/moist soil, and 1.4% on peatland and swamp soil.

Figure 8.

Average daily working hours.

Figure 9.

Water content of the soil in the excavation area.

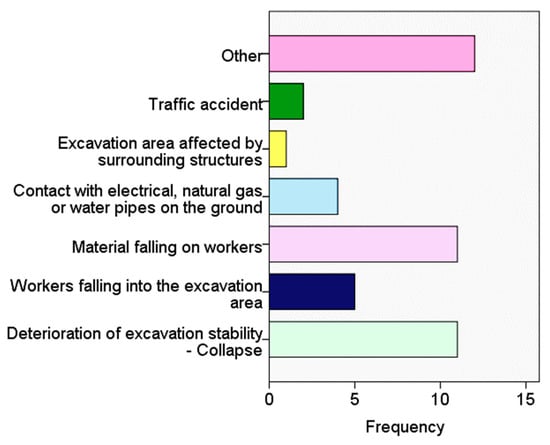

Figure 10 shows the causes of the accidents of the employees who encountered accidents. The highest cause was given as “other” by 12 employees. Subsequently, 11 employees stated that they encountered accidents such as deterioration of excavation stability and collapse, and another 11 employees encountered accidents such as material falling on the worker. Occupational accidents caused by workers falling into the excavation area were reported by five employees, and accidents caused by contact with electricity, natural gas, or water pipes in the ground were reported by four employees. One employee encountered an accident that occurred when the excavation area was affected by the surrounding structures. It can be said that 45.65% of the total 46 employees who encountered an accident encountered an occupational accident due to excavation work. Metinsoy and Müngen [59] determined that excavation works were weak in terms of occupational safety, with 69.4%. They stated that most of the injuries were the result of soil collapse. Socias-Morales et al. [60] showed that ground irregularities, uneven ground cracks, ditches, and holes contribute to the causes of slips, trips, or falls of workers.

Figure 10.

Causation of accidents.

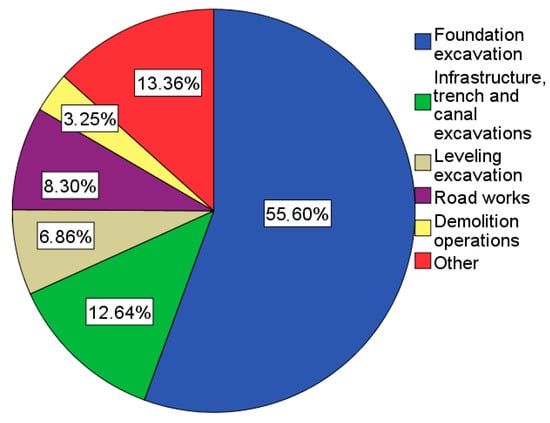

Figure 11 shows the responses of the employees regarding the type of excavation work they perform. In total, 55.6% of the employees are engaged in foundation excavation; 13.4% in other types of excavation; 12.6% in infrastructure, trench, and canal excavation; 8.3% in road works; 6.9% in leveling excavation; and 3.2% in demolition operations.

Figure 11.

Types of excavation.

When Table 2 is examined, it can be seen that there are some noteworthy frequency and percentage values. In total, 74.0% of the employees answered “yes” to situations where the capacity of the work machines was strained during excavation works. Work machines should be selected with the best features and engine power depending on the ground and land conditions. At the same time, they should operate with high efficiency [61]. In such cases, the excavation height, slope, and land details can be reviewed and updated with the appropriate work machine. While 87.4% of the surveyed employees stated that ground surveys had been carried out according to the most unfavorable ground conditions, 45.8% of the employees stated that they encountered dangers such as ground slipping, soft pocket areas forming, etc. during excavation works. If ground surveys have been carried out in the excavation area, the behavior of the ground during the excavation should be known. In cases where the ground properties are soft, loose rock or are likely to collapse, appropriate interventions should be developed in advance. It is necessary to create protective systems in the excavation area and thus reduce potential dangers [9]. Another question asked whether there were protective systems such as shoring, shields, etc. against the risk of collapse in the excavation. While 71.5% of the employees stated that there is a protective system, 28.5% stated that there is no protective system. The regulation refers to the determination of ground surveys in excavations with the qualities and quantities that best represent the field area, and the calculation and implementation of slopes, supports, or sets to ensure the stability of the excavations [8,31].

To the question of whether the excavation area and its surroundings have been surrounded by curtains at least 2 m high to prevent unauthorized people from entering, 70% answered “yes” and 30% answered “no”. If the area is surrounded by curtains, 78.3% answered “yes” and 21.7% answered “no” to the question of whether there are the necessary occupational safety warning signs. It can be inferred from this result that although there are certain occupational safety warnings and signs around the excavation, the excavation area is not surrounded to prevent unauthorized access. Excavation areas should be surrounded by barriers, curtains, or guardrails to prevent workers from slipping and falling. Unauthorized persons should be prevented from entering the excavation areas, and no unauthorized entries and exits should be made. Furthermore, necessary warning, caution, and prohibition signs should be placed in the excavation area [5,8]. While the 254 employees who participated in the survey stated that they take the weather and environmental conditions into consideration before and during the excavation, 111 employees indicated that they had carried out excavation work in cases of heavy rain, frost, and snow. Adverse weather conditions can cause an unexpected deterioration in the excavation’s stability [62]. When heavy rainfall occurs, the process of infiltration and seepage in low-permeability cohesive soils can be facilitated and increase the risk of the excavation’s failure [63]. In another related question, 23.5% of the employees stated that no work was carried out to prevent water accumulation in the excavation area.

4.2. Cross Tables and Chi-Square Analyses

Cross-tabulation analysis was used to compare the results of one variable with the results of another variable from the data obtained from the survey. Whether there was a statistically significant relationship between the two compared variables was determined by the chi-square test. Table 3, Table 4, Table 5, Table 6, Table 7, Table 8, Table 9 and Table 10 present the cross-tabulation and chi-square results.

Table 3.

Cross-tabulation of the education level of employees on occupational health and safety issues and occupational accidents.

Table 4.

Cross-tabulation of questions related to whether the capacity of the work machine is stressed or not, and weather and environmental conditions.

Table 5.

Cross-tabulation of project types and accidents’ causes.

Table 6.

Cross-tabulation of movement areas within the excavation area, with distance from the excavation edge and safe exits in case of danger.

Table 7.

Cross-tabulation of protective systems and occupational safety of workers in excavation works deeper than 1.5 m.

Table 8.

Cross-tabulation of soil water content status with soil conditions and ground surveys.

Table 9.

Cross-tabulation of the formation of soft pocket zones by examining the soil conditions and structure, and ground surveys of the excavation area and its surroundings.

Table 10.

Cross-tabulation of questions based on occupational health and safety instructions and practices.

Table 3 shows the results of the cross-tabulation analysis for the questions “Have you received training in occupational health and safety before?” and “Have you ever encountered an occupational accident before?” concerning the educational level of the employees. When Table 3 is examined, it is seen that 68.9% of those who have previously received training on occupational health and safety are at the license level. The 49 employees who participated in the survey have received Masters’ degree education. Of those who received Masters’ degree education, 85.7% stated that they had previously received training in occupational health and safety. However, it is seen that the highest percentage of employees who encounter accidents are Masters’ degree graduates, with 30.61%. Başağa et al. [18] have shown the opposite of this. It can be stated that the results are related to the frequencies of the education levels of the employees. While there is no significant correlation between the level of education and receiving training on occupational health and safety before (0.101 > 0.05), there is a significant correlation between those who have/have not had occupational accidents before (0.021 < 0.05).

Table 4 explains the situations where the capacity of the construction equipment is strained or not strained in adverse weather and environmental conditions. In case of heavy rain, frost, and snow, 88.3% of employees who carried out excavation work had difficulty in excavation work, while 11.7% did not. In heavy rain, frost, and snow, 64.5% of employees who do not do excavation work have encountered situations where the work machine was forced. However, 72.8% of employees who took the weather and environmental conditions into account before and during the excavation encountered a situation where the capacity of the work machine was strained. According to these relationships, it can be concluded that the work machine should be selected by foreseeing difficult working conditions and land characteristics in excavation works. While there is a significant relationship between the capacity of the work machine in excavation works and excavation works in cases of heavy rain, frost, and snow (0.000 < 0.05), there is no significant relationship between consideration of the weather and environmental conditions in excavation (0.139 > 0.05).

Table 5 provides a cross-tabulation of the accident causes of those who encountered occupational accidents by project type. In total, 100% of the employees who stated “other” as the highest cause of occupational accidents worked in the building – residential project type. Zengin [64] stated that in the construction sector, most occupational accidents occur in building construction. Occupational accidents in the case of deterioration of excavation stability and collapse have been observed in different project types. Occupational accidents caused by workers falling into the excavation area occurred in 60% of building – residential projects and 40% in “other” projects. In building – residential projects, occupational accidents occurred from all accident causes except traffic accidents. There is a statistically significant relationship between the cause of the accident and the type of project worked on (0.002 < 0.05).

Table 6 presents a cross-tabulation of the questions on workers’ access to a safe place in case of danger and the distance from the earthwork and the edge of the excavation to the maneuvering, parking, and movement areas of machinery and vehicles within the excavation area. In total, 95.7% of those who have taken measures for employees to reach a safe place stated that machines and vehicles have movement areas. Similarly, 94.0% of those who stated that there is sufficient distance at the edge of the excavation so that the earthwork does not slide into the excavation area also stated that there is space for movement for machinery and vehicles. On the other hand, 15 employees stated that there is sufficient distance at the edge of the excavation to prevent the earthwork from sliding into the excavation area but they stated that there is no movement space for work machines. When Table 5 is examined, it is seen that the pairwise cross-tabulation analyses are related in terms of chi-square values (0.000 < 0.05).

Table 7 presents a cross-tabulation of the questions related to ensuring excavation and occupational safety for excavation works deeper than 1.5 m. While 93.9% of the employees who stated that there is a protective system in the excavation stated that measures are taken to prevent the side walls from collapsing in excavation works deeper than 1.5 m, 6.1% stated that no measures are taken. The 56 employees who responded that there is no protective system in the excavation stated that measures are taken to prevent the side walls from collapsing during deep excavation works. Twelve employees stated that there is a protective system against the risk of collapse in the excavation, but no precautions are taken to prevent the side walls from collapsing in excavations deeper than 1.5 m. Twenty-four employees stated that there are no safe ways for employees to get to and from the excavation site in excavations deeper than 1.5 m and that no precautions are taken to prevent the side walls from collapsing during deep excavations. For excavations deeper than 1.5 m, measures should be taken to prevent the risk of the ground collapsing by using protective systems such as slopes or supports and sets [8,65]. An adequate number of stairs and safe methods must be provided for employees to ascend and descend in the excavation area. Otherwise, it may be difficult for the employees to reach the work area, and the possibility of occupational accidents may increase. Dėjus and Antuchevičienė [66] stated in their study that protective system applications that are not compatible with the projected/standard values may cause injury or death to workers. In the results of the chi-square analysis, the relationship between two different variables was found to be statistically significant (0.000 < 0.05).

Table 8 presents the cross-tabulation of the examination of the excavation site and its surroundings in terms of soil conditions, properties, and ground surveys with the water content of the soil in the excavation area. When Table 8 is examined, it is observed that 26 employees stated that the soil conditions and structure of the excavation area and its surroundings were examined before the excavation works started, while they had no information about the water content of the soil in the excavation area. Similarly, the 19 employees who stated that ground surveys were carried out at the excavation area had no information on the water content of the soil at the excavation area. Moreover, 71.4% of the employees who stated that the soil conditions and structure of the excavation area and its surroundings had not been examined before the excavation works started had information about the water content of the soil in the excavation area. It is observed that 68.5% of the employees who stated that ground surveys had not been carried out in the excavation area had information about the water content of the soil. While the relationship between ground surveys based on the most unfavorable situation in the excavation area and the water content of the soil in the excavation area is statistically significant (0.000 < 0.05), examination of the soil conditions and structure of the excavation area and its surroundings is statistically insignificant (0.092 > 0.05).

When the results of the frequency analysis in Table 2 are analyzed, it is observed that there are 127 employees (45.8%) who stated that they encountered dangers such as slipping of the ground, formation of soft pocket areas, etc. during excavation works. For this reason, a cross-tabulation of the examination of the excavation area and its surroundings in terms of the soil conditions, structure, and ground surveys has been prepared for the formation of soft pocket zones. Table 9 presents the relationship of the relevant variables. When Table 9 is examined, 54.8% of the employees who stated that the excavation area and its surroundings were examined in terms of soil conditions and structure did not encounter soft pocket formation, while 45.2% have encountered soft pocket formation. Of the 127 employees who experienced risks such as slipping of the ground in the excavation area and the formation of soft pocket areas, only 8 employees stated that the excavation area was not examined in terms of soil conditions and structure. In addition, 14 of 127 employees stated that ground surveys were not carried out in the excavation area. Examining the excavation area and its surroundings in terms of soil conditions, structure, and ground surveys has no significant relationship with the formation of soft pocket areas (0.384 > 0.05 and 0.458 > 0.05).

Table 10 provides a cross-tabulation of questions regarding occupational health and safety regulations and practices. When Table 9 is analyzed, 98.4% of the employees stated that safe routes have been provided for entering and exiting the excavation site. There are 97.9% of employees who stated that individual protection has been used, and 99.1% of employees stated that there is a pointer trained in the excavation area. These employees also stated that the project has occupational health and safety instructions. It is observed that the 17 employees who stated that the project does not have occupational health and safety instructions answered “no” to the questions on safe routes for entering and exits, individual protection, and trained pointers at rates of 76.47%, 70.6%, and 88.2%, respectively. There is a statistically significant relationship between the variables (0.000 < 0.05). Emphasizing the importance of the use of personal protective equipment to workers on construction sites and periodically providing practical training and supervision can increase the frequency of their use [7,64]. Additionally, because excavator operators have a visually and physically challenging working environment, continuous alertness and concentration are needed for safe navigation [67].

5. Conclusions and Suggestions

In this study, a survey consisting of 35 questions was applied to 277 employees to evaluate occupational safety practices in construction excavation works according to the relevant regulations in Turkey. The employees who filled out the survey included construction site supervisors, occupational safety specialists, auditors, or control staff responsible for projects in the Gaziantep and Kilis provinces of Turkey, because they have the authority to ensure and enforce the relevant regulations, according to their job descriptions. Based on the responses, some deficiencies in the implementation of the issues included in the relevant regulations in the field were found.

It can be stated that the employees responsible for the project are carrying out excavation works that do not comply with the provisions of the relevant regulation and its annexes. Because when Table 2 is examined, it is seen that there is a deviation of 5.1% or more between each legislative requirement and the related question (except Q5). This result shows that there is a minimum of 5.1% negligence. Although it is clearly stated in the relevant legislation, the greatest deviation of 40% was found for the execution of excavation works during adverse weather conditions. In addition, it can be concluded that some notification or control issues that are the responsibility of the employer are not provided effectively and for the purpose. These results may indicate that the occupational safety system in excavation works is not yet fully established. It is therefore clear that there is a need for proactive and high-quality improvement of occupational safety in excavation works. This study makes positive contributions to encouraging relevant security and technical measures that can be focused on and improved. It is also recommended that training on technical infrastructure knowledge and occupational health and safety be increased, and that authorities develop improvements based on safety and control measures. Future studies are also recommended to compare legal requirements in different locations and reveal if the adequacy of the measurement tool can be correlated with the confirmatory factor analysis.

Author Contributions

Conceptualization, N.Y. and N.B.; methodology, A.A.C., N.B. and N.Y.; software, N.B. and N.Y.; validation, A.A.C. and H.M.A.; formal analysis, N.B. and N.Y.; investigation, N.B. and N.Y.; resources, A.A.C. and H.M.A.; data curation, A.A.C., N.B. and N.Y.; writing—original draft preparation, N.B. and N.Y.; writing—review and editing, A.A.C. and N.B.; visualization, N.B.; supervision, H.M.A. and N.B.; project administration, A.A.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

This study was conducted by the Declaration of Helsinki and approved by the Institutional Ethics Committee of Kilis 7 Aralık University (Decision No. 04.09.2023-E.32899).

Informed Consent Statement

Informed consent was obtained from all participants involved in this study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors acknowledge that this research is one phase of a series of investigations into construction safety practices in Turkey and extend their appreciation to the project managers who have contributed to building knowledge in this research area.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Social Security Institution of Turkey (SSI). Annual Statistics Information, Official Website. Available online: https://www.sgk.gov.tr/Istatistik/Yillik/fcd5e59b-6af9-4d90-a451-ee7500eb1cb4/ (accessed on 1 April 2024).

- Zorluer, İ.; Eleren, A. Determination of risks on occupational safety and health in the construction industry and an exemplary application. In Proceedings of the 3rd Occupational Health and Safety Symposium, Çanakkale, Turkey, 21–23 October 2011; pp. 185–193, ISBN 978-605-01-0168-3. [Google Scholar]

- İkinci, S.S. Occupational risks in health care workers and employee safety concept. J. Int. Health Sci. Manag. 2015, 1, 1–13. [Google Scholar]

- Safe Work Australia. Work-Related Fatalities Associated with Unsafe Design of Machinery, Plant, and Powered Tools, 2006–2011; Department of Education, Skills and Employment: Canberra, Australia, 2014; ISBN 978-1-74361-936-0.

- Kekeç, B.; Bilim, N.; Bilim, A. Occupational health and safety in excavation works. In Proceedings of the 3rd International Civil Engineering and Architecture Congress, Trabzon, Turkey, 12–14 October 2023; pp. 105–119, ISBN 978-605-81854-7-0. [Google Scholar]

- Gurley, E.; Prevent Excavation Cave-In Fatalities. NPCA Blog: Workforce Development, 9 November 2012. Available online: https://precast.org/blog/prevent-excavation-cave-in-fatalities/ (accessed on 19 April 2024).

- Turkish Occupational Health and Safety Law No. 6331. Official Gazette, Legislation Information System, 2012, RG: 30.06.2012/28339. Available online: https://www.resmigazete.gov.tr/eskiler/2012/06/20120630-1.htm (accessed on 1 February 2024). (In Turkish)

- Turkish Occupational Health and Safety Regulations in Construction Works. Official Gazette, Legislation Information System. 2013. Legislation No: 18928, RG: 05.10.2013/28786. Available online: https://www.resmigazete.gov.tr/eskiler/2013/10/20131005-2.htm (accessed on 1 February 2024). (In Turkish)

- Wang, J.; Zhang, S.; Teizer, J. Geotechnical and safety protective equipment planning using range point cloud data and rule checking in building information modeling. Autom. Constr. 2015, 49, 250–261. [Google Scholar] [CrossRef]

- Köksal, K.N. Occupational Safety Requirements and the Effect of Education on Risk Perception in Excavation Works. Master’s Thesis, Department of Civil Engineering, Adana Alparslan Türkeş Science and Technology University, Adana, Turkey, 2019. [Google Scholar]

- Rampuri, S. Excavation & trenching work safety: A review. Int. J. Inst. Saf. 2019, 2, 6–9. [Google Scholar]

- Chadee, A.A.; Martin, H.H.; Gallage, S.; Banerjee, K.S.; Roopan, R.; Rathnayake, U.; Ray, I. Risk evaluation of cost overruns (COs) in public sector construction projects: A fuzzy synthetic evaluation. Buildings 2023, 13, 1116. [Google Scholar] [CrossRef]

- Occupational Safety and Health Administration. Trenching and Excavation Safety; U.S. Department of Labor: Washington, DC, USA, 2018. Available online: https://www.osha.gov/Publications/trench_excavation_fs.html, (accessed on 1 April 2024).

- Plog, B.A.; Materna, B.L.; Gillen, M.; Vannoy, J. Strategies to Prevent Trenching-Related Injuries and Deaths; Center to Protect Workers’ Rights: Silver Spring, MD, USA, 2006. [Google Scholar]

- Bureau of Labor Statistics (BLS). Census of Fatal Occupational Injuries Current and Revised Data; Bureau of Labor Statistics: Washington, DC, USA, 2017. Available online: https://www.bls.gov/iif/oshcfoi1.html/ (accessed on 1 April 2024).

- İSİG. Health and Safety Labour Watch, Turkey. 2020. Available online: https://isigmeclisi.org (accessed on 1 April 2024). (In Turkish).

- Bayrak, E.; Karan, T.Y.; Karakaş, İ.; Rüştü, U.Ç.A.N.; Bingöl, N.; Karahan, M. Analysis of the reflection of the training methods applied to occupational health and safety on employee behaviors. OHS Acad. 2021, 3, 25–45. [Google Scholar]

- Başağa, H.B.; Temel, B.A.; Atasoy, M.; Yıldırım, İ. A study on the effectiveness of occupational health and safety trainings of construction workers in Turkey. Saf. Sci. 2018, 110, 344–354. [Google Scholar] [CrossRef]

- Kale, Ö.A.; Eskişar, T. Occupational accidents occured in excavation works in construction industry. BAUN Sci. Inst. J. 2018, 20, 265–277. [Google Scholar]

- Afanuh, S.; Gillen, M.; Lentz, T. Preventing Worker Deaths from Trench Cave-Ins; DHHS Publication, No. 2011–208; Department of Health and Human Services: Washington, DC, USA, 2011.

- Rees, B.I. Excavation injuries in wales. Occup. Med. 1977, 27, 105–106. [Google Scholar] [CrossRef]

- McCann, M. Heavy equipment and truck-related deaths on excavation work sites. J. Saf. Res. 2006, 37, 511–517. [Google Scholar] [CrossRef]

- Gürcanlı, G.E.; Müngen, U. A New Occupational Safety Risk Analysis Method Using Fuzzy Sets; İtüdergisi/d; Istanbul Technical University: İstanbul, Turkey, 2010; Volume 5, pp. 83–94. [Google Scholar]

- Uzun, İ.M. The Risk Assessment of Work Safety in the Use of Construction Equipments in Construction Sites. Master’s Thesis, Department of Civil Engineering, Istanbul Technical University, İstanbul, Turkey, 2012. (In Turkish). [Google Scholar]

- Aydoğan, S.Ö.; Rüştü, U.Ç.A.N. Investigation of occupational health and safety in terms of site supervision and work equipment: Building sector. Resilience 2022, 6, 111–125. [Google Scholar]

- Aktuna, A.; Aktuna, A. Occupational health and safety in the construction industry: Example of Suleymanpasa. In Proceedings of the III. IBANESS Congress Series, Edirne, Turkey, 4–5 March 2017; pp. 1394–1406. [Google Scholar]

- Arslan, M. An Example Health Safety Plan in Hydroelectric Power Plants Construction. Master’s Thesis, Department of Civil Engineering, Kahramanmaras Sutcu Imam University, Kahramanmaraş, Turkey, 2018. (In Turkish). [Google Scholar]

- Korkmaz, A.V. Occupational safety in 11 step in construction works. J. Eng. Earth Sci. 2019, 4, 1–12. [Google Scholar]

- Chadee, A.A.; Gallage, S.; Martin, H.H.; Rathnayake, U.; Ray, I.; Kumar, B.; Sihag, P. Minimizing liability of the COVID-19 pandemic on construction contracts—A structural equation model for risk mitigation of force majeure impacts. Buildings 2022, 13, 70. [Google Scholar] [CrossRef]

- Turkish Zoning Law, No. 3194. Official Gazette, Legislation Information System. 1985. RG:09.05.1985/18749. Available online: https://www.mevzuat.gov.tr/mevzuat?MevzuatNo=3194&MevzuatTur=1&MevzuatTertip=5 (accessed on 20 July 2024). (In Turkish)

- Republic of Türkiye, Ministry of Environment, Urbanization and Climate Change, Directorate General of Construction Works, Circular No. 2018/10, 31 August 2018, (“Circular”). Available online: https://eski.imo.org.tr/resimler/dosya_ekler/8d1f82275049691_ek.pdf?tipi=2&turu=X&sube=0 (accessed on 20 July 2024). (In Turkish).

- Turkish Regulation on Construction Site Supervisor. Official Gazette, Legislation Information System. 2019. RG: 02.03.2019/30702. Available online: https://www.resmigazete.gov.tr/eskiler/2019/03/20190302-2.htm (accessed on 20 July 2024). (In Turkish)

- Turkish Regulation on Duties, Authorities, Responsibilities, and Training of Occupational Safety Experts. Official Gazette, Legislation Information System. 2012. RG: 29.12.2012/28512. Available online: https://www.mevzuat.gov.tr/mevzuat?MevzuatNo=16923&MevzuatTur=7&MevzuatTertip=5 (accessed on 20 July 2024). (In Turkish)

- Tan, Ş. Misuses of KR-20 and Cronbach’s alpha reliability coefficients. Educ. Sci. 2009, 34, 101–112. [Google Scholar]

- Ekolu, S.O.; Quainoo, H. Reliability of assessments in engineering education using Cronbach’s alpha, KR, and split-half methods. Glob. J. Eng. Educ. 2019, 21, 24–29. [Google Scholar]

- Chang, C.W.; Nagata, T.; Anthony, L.E.; Lin, R.T. Evolution of occupational safety and health disclosure practices: Insights from 8 years in Taiwan’s construction industry. Safety 2024, 10, 46. [Google Scholar] [CrossRef]

- Zaira, M.M.; Hadikusumo, B.H. Structural equation model of integrated safety intervention practices affecting the safety behaviour of workers in the construction industry. Saf. Sci. 2017, 98, 124–135. [Google Scholar] [CrossRef]

- Abdi, H.; Williams, L.J. Principal component analysis. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 433–459. [Google Scholar] [CrossRef]

- Corner, S. Choosing the right type of rotation in PCA and EFA. JALT Test. Eval. SIG Newsl. 2009, 13, 20–25. [Google Scholar]

- Jadidoleslami, S.; Saghatforoush, E.; Zare Ravasan, A. Constructability obstacles: An exploratory factor analysis approach. Int. J. Constr. Manag. 2021, 21, 312–325. [Google Scholar] [CrossRef]

- Genc, O. Identifying principal risk factors in Turkish construction sector according to their probability of occurrences: A relative importance index (RII) and exploratory factor analysis (EFA) approach. Int. J. Constr. Manag. 2023, 23, 979–987. [Google Scholar] [CrossRef]

- Upadhyaya, D.; Malek, M. An exploratory factor analysis approach to investigate health and safety factors in Indian construction sector. Constr. Econ. Build. 2024, 24, 29–49. [Google Scholar]

- Patil, V.B.B.; Pinto, S.M.; Govindaraju, T.; Hebbalu, V.S.; Bhat, V.; Kannanur, L.N. Multivariate statistics and water quality index (WQI) approach for geochemical assessment of groundwater quality—A case study of Kanavi Halla Sub-Basin, Belagavi, India. Environ. Geochem. Health 2020, 42, 2667–2684. [Google Scholar] [CrossRef] [PubMed]

- Yalçın, M.; Ereş, F. A study of validity and reliability on the instructional capacity scale. Univers. J. Educ. Res. 2018, 6, 57–67. [Google Scholar] [CrossRef]

- Nasiru, M.A.; Md Dahlan, N.H. Exploratory factor analysis in establishing dimensions of intervention programmes among obstetric vesicovaginal fistula victims in Northern Nigeria. J. Crit. Rev. 2020, 7, 1554–1560. [Google Scholar]

- Mostafaeipour, A.; Zarezade, M.; Goudarzi, H.; Rezaei-Shouroki, M.; Qolipour, M. Investigating the factors on using the solar water heaters for dry arid regions: A case study. Renew. Sustain. Energy Rev. 2017, 78, 157–166. [Google Scholar] [CrossRef]

- Aktan, D.Ç.; İnan, K. Investigation of validity and reliability of the Turkish language exposure scale. Cukurova Univ. Fac. Educ. J. 2020, 49, 225–256. [Google Scholar]

- Chai, Y. An empirical study on the communication effect of Xiaogang short video: Taking Xiaogang Village Red Brigade short video as an example. Int. J. Glob. Econ. Manag. 2024, 2, 419–426. [Google Scholar] [CrossRef]

- Oner, M.İ.; Erden, A.M. Academic Buoyancy: A scale development and validation study. Int. J. Turk. Educ. Sci. 2024, 12, 298–336. [Google Scholar]

- Makrakis, V.; Biasutti, M.; Kostoulas-Makrakis, N.; Ghazali, M.; Othman, W.; Ali, M.; Fitriyanto, N.A.; Mavrantonaki, K. ICT-Enabled Education for Sustainability Justice in South East Asian Universities. Sustainability 2024, 16, 4049. [Google Scholar] [CrossRef]

- De Winter, J.C.F. EFA, and PCA: Remarkable Phenomena and Practical Advice. 2024. Available online: https://www.researchgate.net/publication/378496882_EFA_and_PCA_Remarkable_Phenomena_and_Practical_Advice (accessed on 20 July 2024).

- Lugu, B.K. Exploratory Factor Analysis in R; Online Course Book: Tuscaloosa, AL, USA; Available online: https://bookdown.org/luguben/EFA_in_R/ (accessed on 20 July 2024).

- Karaman, H.; Atar, B.; Aktan, D.Ç. The comparison of factor extraction methods used in exploratory factor analysis. Gazi Univ. J. Educ. Fac. 2017, 37, 1173–1193. [Google Scholar]

- Hirschfeld, G.; von Brachel, R.; Thielsch, M. Selecting items for big five questionnaires: At what sample size do factor loadings stabilize? J. Res. Personal. 2014, 53, 54–63. [Google Scholar] [CrossRef]

- Güllüoğlu, E.N.; Güllüoğlu, A.N. Analysis of employment and work accidents in Turkish construction sector. Karaelmas J. Occup. Health Saf. 2019, 3, 65–81. [Google Scholar]

- Amirah, N.A.; Him, N.F.N.; Rashid, A.; Rasheed, R.; Zaliha, T.N.; Afthanorhan, A. Fostering a safety culture in manufacturing through safety behavior: A structural equation modelling approach. J. Saf. Sustain. 2024, 1, 108–116. [Google Scholar] [CrossRef]

- Turkish Labor Act of Turkey Law No: 4857. Date of Enactment: 22.5.2003, Official Gazette: 10.6.2003-25134. Available online: https://www.mevzuat.gov.tr/mevzuatmetin/1.5.4857.pdf (accessed on 1 April 2024). (In Turkish)

- Uzdil, O.; Güllüoğlu, A. Statistical comparison of the work accidents in Turkish construction sector in years of 2016 and 2017. Int. J. Adv. Eng. Pure Sci. 2020, 32, 137–144. [Google Scholar]

- Metinsoy, T.; Müngen, U. Method of evaluating the relationship between occupational safety management and general occupational safety performance in the construction industry. In Proceedings of the 3rd Occupational Health and Safety Symposium, Çanakkale, Turkey, 21–23 October 2011; pp. 143–156, ISBN 978-605-01-0168-3. [Google Scholar]

- Socias-Morales, C.; Konda, S.; Bell, J.L.; Wurzelbacher, S.J.; Naber, S.J.; Earnest, G.S.; Garza, E.P.; Meyers, A.R.; Scharf, T. Construction industry workers’ compensation injury claims due to slips, trips, and falls–Ohio, 2010–2017. J. Saf. Res. 2023, 86, 80–91. [Google Scholar] [CrossRef]

- Yıldırım, A. Design and Development of Autonomous Grader and Algorithm. Master’s Thesis, Department of Civil Engineering, Inonu University, Malatya, Turkey, 2019. (In Turkish). [Google Scholar]

- Wang, J.J.; Zhao, T.L.; Chai, H.J.; Tang, S.C. Failure of a rock slope 16.5 years after excavation in repeated strata of sandstone and mudstone. Environ. Earth Sci. 2016, 75, 1458. [Google Scholar] [CrossRef]

- Jiang, W.; Tan, Y. Heavy rainfall-related excavation failures in China during 1994 to 2018: An overview. Eng. Fail. Anal. 2021, 129, 105695. [Google Scholar] [CrossRef]

- Zengin, M.A. Statistical analysis of occupational accidents in the Turkish construction industry, 2011–2020. Int. J. Eng. Res. Dev. 2022, 14, 492–501. [Google Scholar] [CrossRef]

- Cui, Q.L.; Shen, S.L.; Xu, Y.S.; Wu, H.N.; Yin, Z.Y. Mitigation of geohazards during deep excavations in karst regions with caverns: A case study. Eng. Geol. 2015, 195, 16–27. [Google Scholar] [CrossRef]

- Dėjus, T.; Antuchevičienė, J. Assessment of health and safety solutions at a construction site. J. Civ. Eng. Manag. 2013, 19, 728–737. [Google Scholar] [CrossRef]

- Mehmood, I.; Li, H.; Umer, W.; Ma, J.; Shakeel, M.S.; Anwer, S.; Antwi-Afari, M.F.; Tariq, S.; Wu, H. Non-invasive detection of mental fatigue in construction equipment operators through geometric measurements of facial features. J. Saf. Res. 2024, 89, 234–250. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).