Abstract

The adoption of electric vehicles (EVs) is increasing due to governmental policies focused on curbing climate change. EV batteries are retired when they are no longer suitable for energy-intensive EV operations. A large number of EV batteries are expected to be retired in the next 5–10 years. These retired batteries have 70–80% average capacity left. Second-life use of these battery packs has the potential to address the increasing energy storage system (ESS) demand for the grid and also to create a circular economy for EV batteries. The needs of modern grids for frequency regulation, power smoothing, and peak shaving can be met using retired batteries. Moreover, these batteries can also be employed for revenue generation for energy arbitrage (EA). While there are articles reviewing the general applications of retired batteries, this paper presents a comprehensive review of the research work on applications of the second-life batteries (SLBs) specific to the power grid and SLB degradation. The power electronics interface and battery management systems for the SLB are also thoroughly reviewed.

1. Introduction

Electric vehicles (EVs) are replacing internal combustion engine (ICE) vehicles due to the calls for CO2 emissions reduction and fighting climate change. The number of EVs around the globe is set to increase from 30 million in 2022 to 240 million in 2030 [1]. Moreover, total EV sales are expected to reach 25 million in 2025 and over 40 million in 2030 [1]. The battery packs used in the EVs are retired after the loss of 20% or 30% of capacity (Ah) because they are no longer suitable for the energy-intensive EV operation. Globally, the combined capacity of these retired batteries is expected to increase to an excess of 200 GWh by 2030 [2]. On the other hand, the demand for the battery energy storage system (BESS) for the grid is expected to grow to 183 GWh by 2030 [3]. The majority of retired EV batteries are lithium-ion (Li-ion) batteries that can be either disposed of, recycled, or repurposed. Disposing of huge quantities of battery packs is harmful to the environment and also results in the loss of chemical elements. Recycling Li-ion batteries is still a developing industry facing economic, logistical, and regulatory challenges to its economic viability [4,5]. Repurposing the battery packs for second-life applications is a viable and sustainable option.

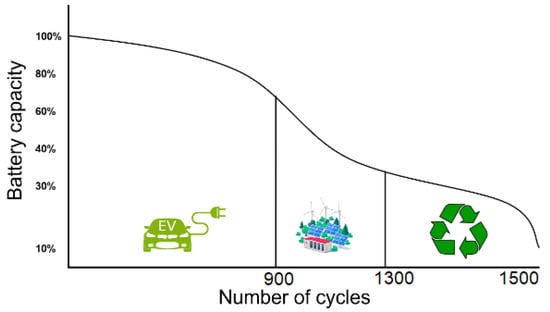

Various terms that can be used for the secondary use of retired batteries are “second-life”, “second-use”, and “reuse” [6]. We will use the term “second-life” throughout this paper for the reuse of the retired batteries. Second-life batteries (SLBs) can be used for a variety of applications. For example, the retired batteries can be used to provide charging services for an EV charging station [7,8]. However, their use as stationary battery energy storage systems (BESSs) is more common. Repurposing retired batteries for application as second-life-battery energy storage systems (SLBESSs) in the electric grid has several benefits: It creates a circular economy for EV batteries and helps integrate renewable energy sources into the electrical grid. Figure 1 shows the life cycle of a retired battery pack when used for a second life in the grid.

Figure 1.

Life cycle of an EV battery pack.

This paper provides a comprehensive review of research works conducted in (1) degradation and state-of-health (SOH) estimation techniques of SLBs, (2) applications of SLBs in the electrical grid, and (3) power electronics interfaces for SLBs in the power grid and identifying the potential research areas of SLB integration, reliability, and power processing. While there have been review papers separately written on retired battery degradation [9,10] and stationary energy storage applications of retired batteries [6,11], to the best of our knowledge, no review paper links degradation and power grid applications. Additionally, there is no review paper on the power electronics interface specific to SLBs.

The degradation pattern of retired batteries differs from that of fresh batteries in the sense that the second-life aging is heavily dependent on the first-life use. Each battery pack, therefore, follows a different trajectory of aging. The underlying mechanisms of degradation are the same as the fresh battery. The main mechanisms include solid electrolyte interface (SEI) growth, lithium plating, and particle fracture.

SLBESSs can provide a variety of ancillary services needed for a grid/microgrid. These include frequency control [12], voltage regulation [13], power smoothing [14], and peak-shaving [15]. During frequency control, SLBESSs help maintain grid stability by adjusting charge and discharge rates rapidly in response to fluctuations in supply and demand. Voltage regulation in a power grid refers to the ability of the system to maintain a stable voltage level within acceptable limits despite variations in load and other operating conditions. Maintaining proper voltage levels is crucial for the reliable and efficient operation of electrical devices and equipment connected to the grid. SLBs can play a role in voltage regulation by providing energy storage capabilities. Furthermore, SLBs prove valuable in load shifting, a strategy where excess energy generated during periods of low demand is stored in the batteries and released during peak demand hours. This not only optimizes the utilization of renewable energy sources but also reduces the need for additional conventional power plants to meet peak demands, ultimately contributing to energy efficiency and grid cost-effectiveness. The modular nature of SLBs allows for scalability, enabling the creation of large-scale energy storage facilities. These facilities can serve as grid-scale energy storage, providing backup power, grid balancing, and support for intermittent renewable energy sources, such as solar and wind. The deployment of SLBs in grid applications aligns with the global push for decarbonization and the transition to a more sustainable and resilient energy infrastructure.

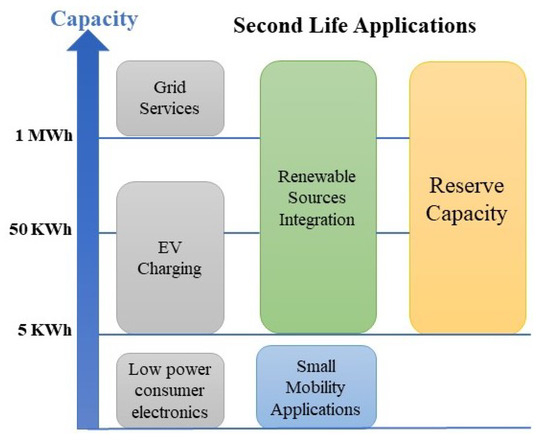

Before employing SLBESSs in the grid, there are a number of challenges that remain to be addressed on the regulatory and safety fronts [9,16]. One of the challenges is to design a power electronics interface for the heterogeneous degradation of cells within the battery modules. Moreover, different battery packs vary greatly in their degradation and first-life use, because of which their integration into a specific application is difficult. The planned power electronics interfaces must adhere to the restrictions of the individual batteries. The chemistry of various types of retired batteries from different manufacturers, the state at end of life (EoL) even for the same type of batteries, and the degradation in operation during second-life use vary greatly. All of this complicates the integration process and necessitates separate battery energy management circuitry that supports a single system or load made from numerous combinations of retired batteries. Previous research on modular BESSs employed the same sort of batteries and was mostly focused on high-power, medium-voltage grid systems (>100 kW around 3.3/6.6 kV) [17,18]. The wide range of identified applications and their distribution according to the power level is shown in Figure 2. The unavailability of high-voltage, high-frequency, efficient semiconductor components has caused modular topology research projects to focus on large-scale installations [19,20]. However, the recent advancements in the field of power electronics, such as the commercialization of gallium nitride (GaN) devices, have made very efficient, high-voltage blocking capabilities and high-frequency applications possible [21].

Figure 2.

Applications of SLBs against Wh capacity.

The integration of SLBs, characteristically different from each other due to distinct usage styles, is not explored much, especially from the perspective of power electronics. Modular power electronics converters are the preferred choice for integrating these SLBs [22,23] as this topology provides better flexibility and reliability compared with the classic two-level converter design [24]. The integration of vastly disparate kinds of batteries into a grid-tie converter has received little attention in the literature. This is regarded as a significant difficulty in the integration of used batteries into the grid or in their adoption for other applications. Furthermore, the coexistence of fresh and used batteries allows for system optimization as well as greater flexibility. To overcome this, in [25] a modular converter is discussed that uses different battery modules. There was, however, no comprehensive explanation of any further operational modes. The drawback is that issues like switching performance and efficiency, which affect the overall system reliability, were analyzed and discussed.

Old batteries are cheaper than new ones; however, dependability is a problem because individual cells could operate poorly or fail altogether. Thus, the overall system reliability is affected by the interfacing converter design. A proper converter topology is recommended for durable and dependable BESSs. The majority of recent research on the dependability of BESSs addressed only the dependability of power electronics components and power converters, where it was essential to reduce the number of semiconductor switches and optimize the components to increase reliability [26,27]. The weakest link in the power circuit was found to be the power electronics switches. Previous studies have not looked into the reliability of the storage source and how it affects the reliability of the entire system [28]. The reliability of power sources is relatively high as they have low failure rates. When determining total system reliability, the failure rate of SLBs cannot be neglected.

This review paper follows the following scheme: Section 2 briefly discusses the SLB market. Section 3 covers the works done in modeling the degradation of Li-ion batteries employed for second-life use. Section 4 reviews the research works on the application of SLBs to power grids. Section 5 reviews the research on power electronics interfaces for retired batteries followed by Section 7 which presents discussions on current and future research areas for SLB.

2. Second-Life Battery Market

The main types of SLBs in the market are lead-acid batteries, nickel metal hydride (NMH), and lithium-ion batteries, whereas the main battery sources are two-wheelers, electric buses, and EVs. The economic viability of retired batteries is an important factor in deciding their use in the grids. The SLB market is relatively new and depends on a lot of variables. The market is immature and faces steep competition from recyclers due to the huge demand for raw materials like cobalt, nickel, and lithium by battery manufacturers who are looking to cut costs. SLBs also face competition from flow batteries, which can be the preferred choice for ESSs in the grid. The gigantic global supply of retired batteries (200 GWh) by 2030 will have significant effects on the future costs of SLBs [29]. In [30], the authors considered the SLBs from three different EVs and worked up the cost to be USD 825/kWh and an additional USD 100/kWh and USD 1000 for capturing balance-of-system (BOS) costs. The uncertainties in calculating the market price were addressed in [31], where a comprehensive framework for estimating SLB cost by calculating the battery salvage value (S) on retirement while considering the cost of fresh batteries () discounted by a health factor () and a used product discount factor () and refurbishment cost () is given by (1)

where salvage value (S) is the maximum of the appreciated cost at the time of the second-life application or when sending them for recycling (C). A techno-economic model for PV plus SLBESS in California using 2017 utility prices identifies two revenue streams for the system. The first is by selling the power to the utility by storing energy in SLBESSs at the time of low prices and selling at the time of increased prices, and second, by selling the capacity credits [32]. The benefit–cost ratio is calculated by (2)

The above study demonstrates that a system incorporating state-of-charge limits within the 65–15% range significantly extends the project’s operational life beyond 16 years. This projection is based on the assumption that a battery is considered to have reached its end of life at 60% of its original capacity. In comparison to a project utilizing a new battery with state-of-charge limits set between 85 and 20%, the economic viability of a second-life project becomes more favorable, provided the second-life battery costs are less than 80% of the cost of a new battery.

2.1. SLB Players in the USA Market

Long-duration energy storage requirements in the grid are being addressed by several startups in the USA. ‘B2U Storage Solutions’, based in California, is a provider of large-scale ESSs made of retired batteries. San-Diego-based ‘Smart’ won a $10 million grant from the Department of Energy (DoE) to develop long-duration ESSs made of SLBs [33]. Another California-based startup, ‘Rejoule’, is working to repurpose used batteries. Their product BATTSCAN is a fast, reliable, and easy-to-use diagnostic tool for retired batteries. For battery repurposing, it speeds up test time from 6+ h to 10 min.

2.2. SLB Players in the Global Market

The second-life battery market is rapidly expanding outside the United States as companies around the world are recognizing the potential of this technology to reduce waste and extend the life of valuable resources. In Europe, companies like Zenobe [34], Relion, and Second Life Batteries [35] are leading the way in developing and deploying SLB solutions for a variety of applications, including grid storage, backup power, and electric vehicles. In Asia, Hitachi is making significant progress in this area. The Asia–Pacific region, including Japan, China, and Korea, has one of the highest penetrations of EVs and a greater supply of SLBs. Companies like Fortum, ION Energy Inc., and Enel X are working on the reuse of restored batteries [36]. These companies are also taking advantage of government policies that are supportive of the development of the second-life battery industry. For example, the European Union has set ambitious targets for the recycling of lithium-ion batteries, and the Chinese government has provided subsidies for the development of second-life battery projects. These policies are helping to create a favorable environment for the growth of the second-life battery industry outside the United States, and they are likely to play a key role in driving innovation and investment in this area in the years to come.

3. Degradation Mechanisms and State-of-Health (SOH) Estimation of Second-Life Batteries

3.1. Degradation Mechanisms

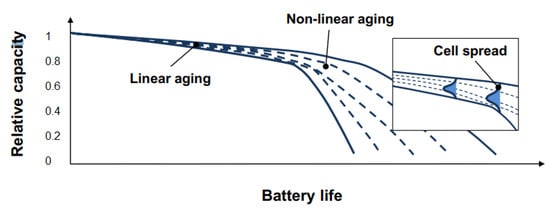

Charging and discharging cycles result in a decrease in battery capacity, which increases resistance and reduces battery performance. The primary degradation mechanisms for batteries are solid electrolyte interface (SEI) layer growth, lithium plating, and particle fracture. Other aging mechanisms also occur under distinct operation conditions. Generally, the degradation profile of a battery is nonlinear and can be broken down into two distinct phases [37]. Figure 3 shows an initial slow degradation phase for li-ion batteries followed by a rapid fading region, with a noticeable knee point marking the transition between these phases. The degradation rate goes up sharply beyond this knee point. Degradation in fresh batteries is mostly caused by the earlier linear phase, while a more detailed evaluation is necessary for SLBs. To comprehend the current degradation status of an SLB, it is essential to determine the battery’s historical charge–discharge profile from its previous usage. The primary reason for this is that distinct operation conditions, i.e., charging and discharging rates, and environmental temperatures can result in different degradation states. The governing degradation mechanisms may vary depending on the operating conditions. In addition, providing the charging and discharging profile during its second-life usage can enhance the prediction of the upcoming degradation curve.

Figure 3.

Impact of uncertainties on linear and non-linear aging in battery systems. Reprinted with permission from Ref. [38]. 2017, Elsevier.

3.1.1. Solid Electrolyte Interface (SEI) Growth

During battery operations, a passivating layer is formed at the interface between the electrode and the electrolyte, which is known as a solid electrolyte interface (SEI). To maintain a stable environment for the reaction, it is advantageous to have a stable SEI layer [39]. However, the capacity of lithium-ion batteries will deteriorate from the SEI layer’s continuous growth, which will limit their lifetime. There are four major SEI growth mechanisms, i.e., solvent diffusion, electron tunneling, electron conduction, and Li-interstitial diffusion [40]. The solvent diffusion model demonstrates that the reactive solvent components diffuse across the SEI layer [41]. An insoluble product is produced by solvent reduction, which increases the thickness of the SEI and degrades the battery performance. In [42], Pinson et al. illustrate that a single-particle model (SPM) can effectively account for the observed capacity degradation in commercial cells using graphite anodes and can forecast future degradation. Moreover, the model is expanded to encompass porous electrodes. According to the study, the SEI layer’s growth is essentially uniform throughout the electrode, even at high discharge rates [42]. The predicted SEI thickness increases linearly with the square root of time. Electron tunneling degradation in lithium-ion batteries occurs due to the progressive deterioration of electrode materials caused by repetitive charge and discharge cycles. These repetitive cycles lead to the emergence of a few defects within the electrode, which hinder the smooth flow of electrons and decrease the battery’s capacity and overall performance with time [43,44]. The electron conduction model demonstrates that the movement of electrons leads to the growth of SEI, which damages the battery’s capacity [45,46,47]. Single et al. presented a model that includes both the solvent diffusion and the electron conduction transport mechanisms [48]. The results depict the porosity of the SEI layer and also capture the dual-layer chemistry and morphology. Finally, the Li-ion interstitial diffusion model describes the gradual breakdown of the pathways that Li-ions follow within the electrode, which leads to the capacity decay of the battery [49,50].

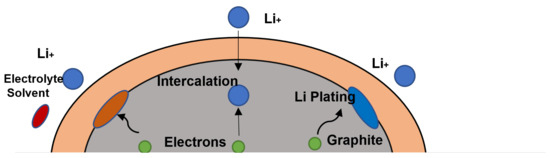

3.1.2. Lithium Plating

Another process that causes degradation in lithium-ion batteries is lithium plating, which is a side reaction on the surface of the negative electrode. Figure 4 depicts the electrochemical reactions during the charging process [51]. The intercalation of lithium into graphite is a desired process; however, the diffusion of electrolyte solvent across the surface film could cause the formation of new SEI. In addition, lithium metal could be deposited on the surface as the lithium plating occurs. There are two types of lithium plating: thermodynamic plating and kinetic plating. The thermodynamic plating takes place when the surface is fully lithiated [52]. Kinetic plating is usually caused by fast charging. Lithium plating can occur due to a number of factors, including cold temperatures, high state of charge, high charge current, high cell voltage, and insufficient negative electrode mass or electrochemically active surface area [53].

Figure 4.

A schematic illustration of the electrochemical reactions during the charging process of a Li-ion battery. Reprinted with permission from [51].

3.1.3. Particle Fracture

In addition to the growth of the SEI layer and lithium plating mentioned above, there is another notable degradation mechanism, namely, particle fracture, that occurs during the usage of batteries. The reason for particle fracture is the volume changes in electrode materials and the mechanical stress caused by electrochemical operations [54]. It may occur on both electrodes and has several consequences [53]. Disruption in the electrical connections between active particles, conductive additives, and the current collector results in a decrease in electronic and ionic conductivity. The capacity of the battery deteriorates as it continues to charge and discharge. Particles that exceed a specific critical size undergo fracturing and break into isolated islands [55].

3.1.4. Other Degradation Mechanisms

Many other degradation processes are recognized, including salt precipitation, current collector corrosion, binder decomposition, separator pore blockage, electrode–current collector delamination, and electrolyte evaporation. The specific details of these degradation processes are thoroughly covered in separate reviews [56,57,58]. However, this work focuses on providing readers with an overview of the primary degradation mechanisms encountered during typical SLB usage, enhancing the comprehension of the most crucial aspects of battery performance and reliability.

3.2. State-of-Health (SOH) Estimation for SLBs

The mathematical methodologies of battery performance modeling and SOH estimation primarily fall into three categories: physics-based electrochemical models, electrical-equivalent circuit models, and data-driven models. These modeling and prediction approaches have been extensively reviewed [59,60], and thus they are not elaborated in this work. The degradation mechanisms mentioned above indicate that the degradation of SLBs is greatly influenced by their previous first-life usage. Particularly, the nonlinear aging region’s appearance and timing during the first utilization are essential for predicting degradation in its second utilization, as illustrated in Figure 3 [38].

It is hard to predict whether the battery can provide sufficient power in its second-life usage due to the uncertainty of the aging knee. With distinct approaches, i.e., Bacon–Watts, maximum curvature, and slope changing ratio, distinct aging knees are obtained based on a group of cells dataset [61,62,63,64]. Pozzato et al. presented an enhanced single-particle model (ESPM) that incorporates a mechanism for the loss of active material [65]. The integrated model accurately predicts the capacity degradation pattern, which is crucial for evaluating the viability of batteries intended for reuse in second-life applications. The ESPM model accurately predicts the voltage variation of the battery, including that of the fresh battery at the beginning and the voltage after 1000 and 3300 cycles of usage.

4. Applications of Second-Life Batteries in Electrical Grids

The complexity of the modern power grid has increased manyfold on the consumption side as well as the generation side. On the consumption end, the demand response and intelligent load management make the load a lot more dynamic than before [66]. With the increase in intermittent renewable power sources such as wind and solar in the generation mix, there is more uncertainty in the system. There is a need for backup power sources in cases where the supply does not meet the demand. Moreover, there is a need for a storage solution when the supply of power is in excess of the load. The provision of conventional power sources, such as thermal generation, as a backup is costly as well as contrary to global carbon reduction goals. The use of energy storage systems (ESSs) for the electrical grid, therefore, has increased lately for the integration of renewable energy storage. Large-scale battery storage is expected to reach 12,000 MW in the USA, with California Independent System Operator (CAISO) leading among the utilities, followed by the Electric Reliability Council of Texas (ERCOT) [67]. Fitzgerald et al. identified 13 different application areas and three different stakeholders for the energy storage system in an electrical grid. The three stakeholders are transmission system operators (TSOs), utility companies, and consumers [68]. Many works have reviewed the applications of fresh BESSs [69,70] and other types of ESSs [71,72,73] in the power grid. The SLB packs for stationary ESSs in the grid are a relatively new concept that is not only cheap but can also generate profit while promoting the circular economy of EV batteries. Various power grid services for SLBs are discussed below.

4.1. Power Smoothing

Renewable energy sources like wind and solar are highly intermittent in nature. They can cause a lot of uncertainty on the power generation side and need to be supported by backup generation, which can be costly. For integrating the intermittent sources in the grid, SLBESSs can provide power smoothing services. The sizing of SLBs is performed in [74] for power smoothing or variability smoothing. A mixed least-squares estimator ramp-rate-compliant (MLSERRC) algorithm smooths the plant power output, followed by an optimization algorithm that provides a charging and discharging profile for SLBs.

4.2. Peak Shaving

The electrical load of any utility or microgrid varies greatly over the time of the day and also throughout the seasons of the year. The highest amount of load is called load peak. The utility must be able to supply power to the load at all times, which means that the generation will vary throughout the day. Also, the designed capacity of generation needs to be according to the peak load, which increases cost since the generating plants are not running at their capacity throughout the day. SLBESSs can provide peak shaving service by providing the power at the peak hours and hence reducing the amount of peak load capacity. In [75], SLB packs from different EVs are tested for various grid services that include peak shaving. Standard hardware tests are performed along with a few analytical methods on various battery packs, including the 2019 Tesla Model 3 SR+, 2018 Chevrolet Bolt, 2015 BMW i3, 2012 Nissan Leaf, and 2012 Lishen EV-LVP. The study concluded that SLBs of various makes differ greatly under grid operation. Moreover, one SLB pack can be very different from another even if they both are made from the same chemistry. This is because the first-life use of two different batteries has a lot of bearing on their second-life use.

4.3. Energy Arbitrage

Exchanging power from the utility based on the electricity tariff to maximize revenue is called energy arbitrage. SLBESSs can be used to maximize revenue by using energy arbitrage. In [76], a PyBaMm (python battery mathematical modeling)-based degradation and optimization of SLB cells is performed against Michigan’s DTE utility tariff. The peak shaving against the summer’s time of use (ToU) tariff is classified as the best use case for the particular region and geography. In [32], the authors developed a techno-economic framework for a PV and SLBESS system and calculated that an SLBESS can be cheaper than a fresh ESS if the SOC window is maintained between 80 and 20%.

4.4. Frequency Containment Reserve (FCR) Service

The frequency in the power system is a sensitive parameter that must always be maintained at a particular value. There is a minimum and maximum threshold that is allowed by various system operators depending on the country or the geography. The ancillary service to maintain the frequency within this threshold is called frequency control, frequency containment reserve, or frequency regulation. SLBs are tested for FCR for a Czech Republic case, and its technical and economic feasibility framework is evaluated [77]. The return on investment (ROI) varies between 8% and 21%. Six different EV batteries of varied chemistries were experimentally tested in [76] for frequency regulation (FR) service. The authors found that energy efficiency in batteries takes precedence over energy density for frequency regulation services.

Apart from utilities, the SLBESS for local energy communities is also a viable option. A local energy community is one in which a community’s energy needs are met locally without dependence on the utility. A techno-economic framework for SLBESSs for a local energy community is discussed in [78]. Table 1 lists the summary of research papers for SLBESS operation in the electrical grid.

Table 1.

Summary of works on SLB applications in power grids.

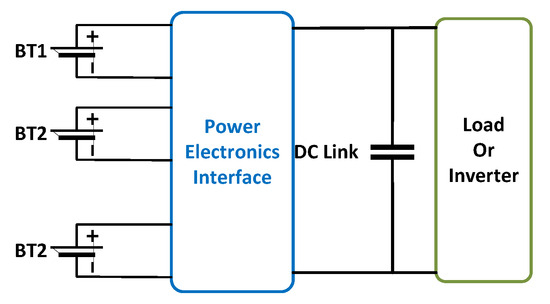

5. Power Electronics Interface for Second-Life Batteries

The difficulty in assembling and aggregating second-use batteries to function together in a system is the heterogeneity in their capacity and power limits, which might change as their health deteriorates. This section analyzes the power converters’ topologies and power processing architecture for SLBs to be used for energy storage purposes, which are individually heterogeneous. Various power processing architectures are compared along with power converter topologies to identify the optimal solution that ensures high reliability and efficient integration. Figure 5 shows the fundamental system structure for different capacities and types of SLBs. BTN refers to the Nth-connected battery. Matching between the source side and the DC link is performed through a power electronics interface, which is further sourced to the load or inverters for onward conversion.

Figure 5.

System interconnection structure.

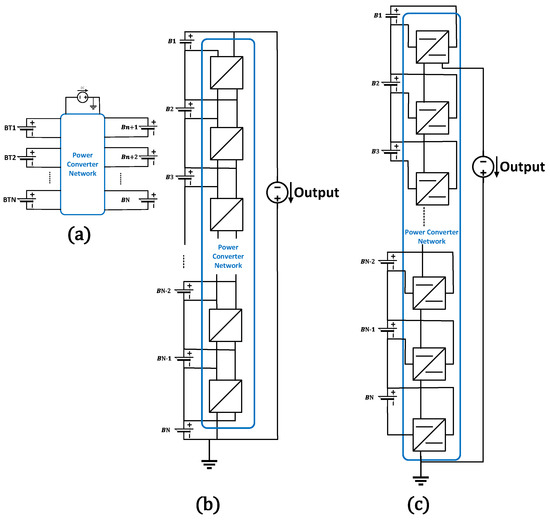

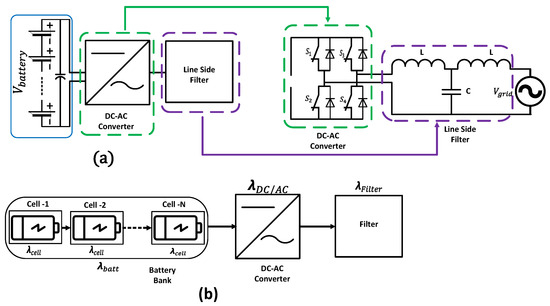

5.1. Power Processing Architectures

The traditional strategy for SLBs with heterogeneous characteristics is to process each battery’s power individually and to individualize each battery’s power trajectory [80]. A canonical network is presented in Figure 6a, which contains the interconnected network of batteries with the power converter network; for the new batteries that have high homogeneous characteristics, the conventional power processing (CPP) approach is adopted. The cost and power rating of the converter can be reduced with the partial power processing technique [81]. Moreover, reducing the power rating increases efficiency and lowers the thermal management cost [82]. The partial power processing architecture is shown in Figure 6b, from where it is evident that the mismatched power is processed instead of full power, which helps in reducing the power ratings. The conventional strategy for handling two BESSs is to individually process the power from each battery to adjust the heterogeneity issue, as shown in Figure 6c, termed the full power processing (FPP) architecture. The drawback of the FPP approach is that the power ratings of the converter must be at least equal to the battery ratings, leading to higher system costs as the cost is directly proportional to the power ratings. Moreover, the efficiency is also the least in this case as it heavily depends on the power converter’s efficiency. For instance, to gain the overall 99% system efficiency, the converter efficiency must be at least 99% too, which means higher cost.

Figure 6.

(a) Battery energy storage system—interconnection, (b) conventional partial power processing (C-PPP) architecture, (c) full power processing (FPP) architecture.

The partial power processing approach is a good alternative to the conventional approach as it offers high efficiency, low cost, and low thermal requirements; however, accommodating the heterogeneities of the used batteries is still a challenge. Recently, a new lite-sparse hierarchical partial processing (LS-HiPPP) was proposed, demonstrating promising results and optimization [83]. With increased heterogeneity, the C-PP and FPP approaches become more inefficient and an unfeasible choice. The LS-HPPP architecture ensures that, unlike the conventional approaches, the power capability is not compromised for similar-rated power converters. Another advantage of the LS-HiPPP architecture is its lower sensitivity to the battery heterogeneity, leading to high power derating. Combined with the increased power capability, it is more cost-efficient. Table 2 presents a performance comparison among the discussed architectures [84]. The goal is to maximize the battery utilization factor, which can be achieved by minimizing the power processing. The inherited heterogeneity with the SLBs yields performance issues. Therefore, the sensitivity of output power to heterogeneity is a major research challenge. The power derating and the capture value for power capability in a second or used BESS can be obtained with the help of Monte Carlo analysis [85].

Table 2.

Comparison of power processing architectures.

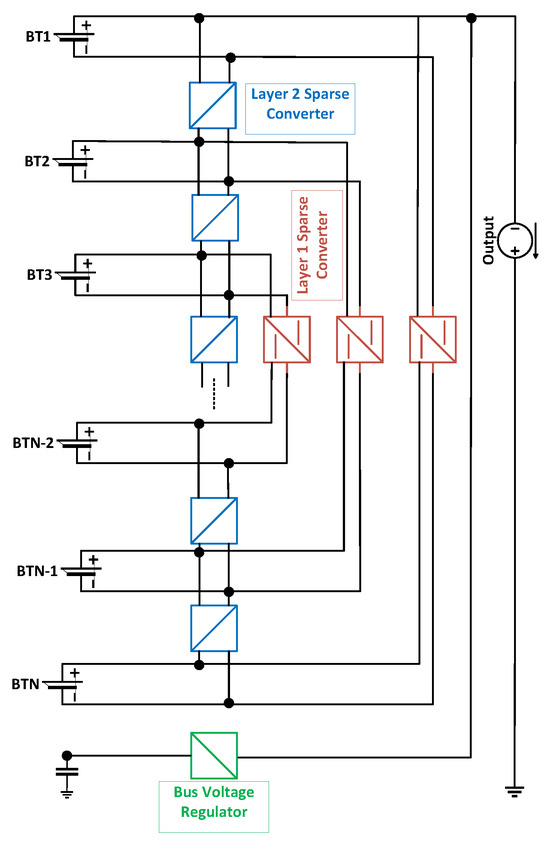

The LS-HiPPP architecture comprises low-power converters and a few high-power converters. The hierarchy in partial power processing is used to take an economic advantage by lowering the number of required converters. The up-to-date and most optimized solution for implementing the LS-HiPPP architecture is shown in Figure 7. It consists of two layers: the first layer consists of every one of the few high-power converters, whereas the second layer holds many low-power converters. It can be noted that layer 2 (lite converters) includes a bus voltage regulator to process the mismatch between the battery string and the potential required by the load. Only the mismatched power is processed by these converters, but compared with the ratings of the traditional power processing architectures, it needs lower-power-rated converters. In this way, the heterogeneity of the SLBs is adjusted, and the associated issues are resolved. A parallel approach for the LS-HiPPP is discussed in [86]. In comparison with FPP and C-PPP, LS-HiPPP delivers improved battery use and higher system efficiency by adopting a unique hierarchical power processing architecture. By including the second-use battery supply’s heterogeneity statistics, LS-HiPPP is less sensitive to individual battery variation and has higher power derating and power capture values than FPP and C-PPP. Compared with FPP, LS-HiPPP requires only one-fifth of the power converter rating at 95% battery use. The use of artificial intelligence (AI) techniques to extend and improve the strategies reviewed is a great potential research area. Moreover, improving SLB models by including more parasitic elements and prognostic techniques is also a worthy research direction.

Figure 7.

Lite sparse hierarchical partial power processing (LS-HiPPP) architecture.

5.2. Reliability

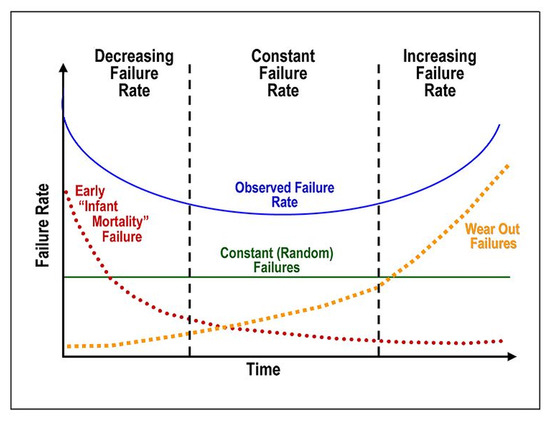

SLBs are more affordable, but reliability is crucial to take into account because the used batteries could degrade. The converter topology design can be used to increase the reliability of the entire system. This research looks into the various power electronics converter topologies to date from the reliability perspective and recommends the most suitable topology. Various topologies with variations in the power electronics and battery connections are discussed. The data from the handbook MIL-HDBK217 [87] are utilized for reliability estimation. Moreover, as the power converters consist of various active and passive electronic components, the bathtub failure-rate curve has been used to discuss electronic equipment reliability, as shown in Figure 8 [88]. The bathtub failure-rate curve (the blue curve) is the sum of infant mortality, random failure, and wear-out curves.

Figure 8.

Bathtub Failure Rate Curve for Reliability Assessment.

The reliability estimation technique presented in [28] can be used to compute the system reliability, also depicted in Equation (1).

where is the failure rate of component i and n is the total number of power stages. For the case in which the system comprises a different number of power stages, the reliability can be assessed as shown in Equation (2), where is the individual reliability of the power stage and n represents the total number of power stages.

Figure 9 presents the reliability block diagram, including the power stages. Systems are considered to have k-out-of-m redundancy if there are ‘n’ number of modules in them, and ‘k’ of those modules must work properly for the system to function properly. Equation (3) can be used to calculate a structure’s reliability.

Figure 9.

Power stages—conventional battery energy storage system.

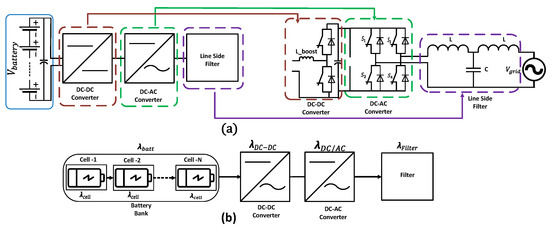

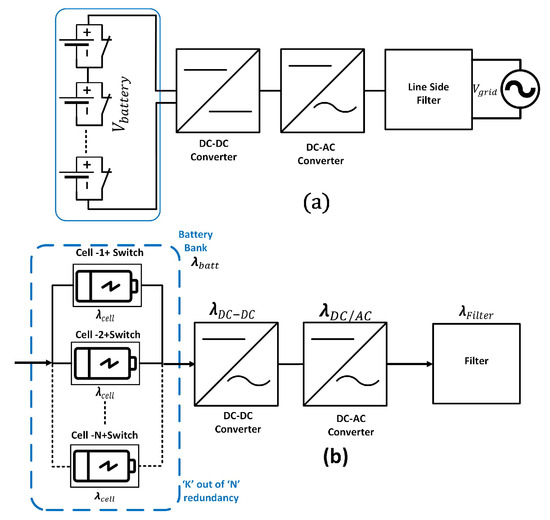

5.2.1. Single-Stage Converter

Figure 10a depicts the scenario when the number of battery cells is connected in series from a battery bank, which results in a single-stage converter topology. The reliability block diagram for the single-stage BESS is shown in Figure 10b. The reliability diagram shows that the system reliability is greatly affected by the reliability of individual cells, mathematically written as in Equation (4). This topology ensures a high efficiency of over 95%; however, the failure of a single cell can cause overall system failure. An LCL filter is utilized for the grid interconnection on the output side.

Figure 10.

(a) Single-stage converter topology and (b) reliability block diagram of single-stage converter.

5.2.2. Two-Stage Converter

In the two-stage topology, the high-voltage battery bus is no longer needed compared with the single-stage topology. In this scheme, the DC-DC converter stage ensures a stable DC-link voltage by decoupling the main inverter DC-link to the battery. This allows operation over a wide modulation range index. The topology and reliability diagram are shown in Figure 11a and Figure 11b, respectively. There is a limit when reducing the series-connected batteries due to boosting requirements because a very high boost ratio will result in poor efficiency. The failure rate of this topology is given in Equation (5).

Figure 11.

(a) Two-stage power converter topology and (b) reliability block diagram of two-stage power converter.

5.2.3. Two-Stage Topology with Redundant Cell Mechanism

In this converter topology, the reliability of the two-stage topology is enhanced by applying cell redundancy. The cell redundancy is implemented by a cell-bypassing approach through the utilization of switches as shown in Figure 12a, followed by the reliability diagram in Figure 12b. The mathematical representation is almost the same as for the simple two-stage approach, and the can be extracted from Equation (3).

Figure 12.

(a) Two-stage converter with cell redundancy and (b) reliability diagram of two-stage bess with cell redunancy.

5.2.4. Three-Stage Converter

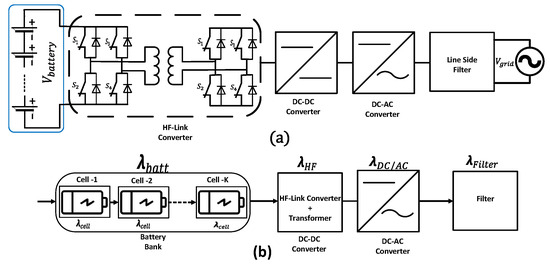

The three-stage converter topology is one of the most commonly used and found in the literature. In this configuration, a high-frequency transformer is utilized for boosting purposes from the battery voltage as depicted in Figure 13a and followed by its reliability block diagram in Figure 13b.

Figure 13.

(a) Three-stage high-frequency (HF)-link converter topology and (b) reliability block diagram of the three-stage hf-link converter topology.

The battery-side DC voltage is converted into high-frequency AC and then again to DC before passing it on to the grid through an inverter. This topology offers isolation due to the use of a transformer. However, the component count is also increased compared with the two-stage approach. The unit failure rate for N number of cells can be represented as

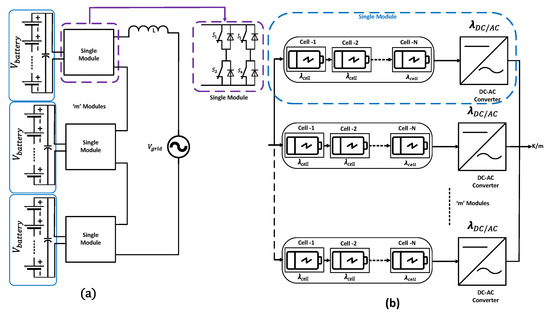

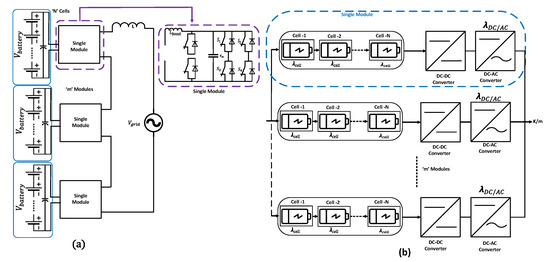

5.2.5. Cascaded Multilevel Converter

This topology’s modular design provides increased reliability. Reliability is increased as a result of fewer series-connected batteries, as evident in Figure 14a. Multiple sets of ‘m’ modules with a lower number of series-connected batteries can be formulated and connected in the cascade configuration. The overall cost of this topology will be high due to the high component count required for improved reliability. The reliability block diagram is presented in Figure 14b. The failure rate is presented in Equation (7). From the block diagram, it can be seen that for modular topologies, the reliability calculation is performed in two steps: the reliability of individual units and then the addition of the redundancy step.

Figure 14.

(a) Cascaded multi-level converter topology and (b) reliability block diagram of cascaded multi-level topology.

5.2.6. DC-DC Converter Integrated Cascaded Multilevel Converter

Compared to the previously discussed cascaded multilevel converter, a DC-DC converter is present with each module in this topology, providing the functionality to charge each module at distinct currents. It needs a lower number of modules to be connected to the grid while maintaining the same number of series-connected batteries. The topology structure and the related reliability diagram are presented in Figure 15a and Figure 15b, respectively.

Figure 15.

(a) Cascaded multilevel converter with integrated DC-DC converter and (b) reliability block diagram of cascaded multilevel converter with integrated DC-DC converter topology.

The failure rate can be presented as

It is clear that this topology ensures high reliability and redundancy with fewer battery cells than the simple cascaded multilevel topology.

6. Battery Management System (BMS) for Second Life Batteries (SLBs)

A battery management system (BMS) plays a crucial role in the optimal performance and safety of SLBs. A robust BMS is essential to ensure efficient and safe utilization of these batteries. SLBs often consist of multiple cells, each with its own unique characteristics due to the varying usage patterns in their first life [89]. The BMS monitors individual cells’ voltage and state of charge and performs cell balancing to equalize their energy levels. This ensures that no single cell is overcharged or over-discharged, which can lead to reduced capacity and safety hazards. Managing temperature is critical for the longevity and safety of batteries [90]. The BMS monitors the temperature of each cell and the overall battery pack. If temperatures rise beyond safe limits, the BMS can initiate cooling systems or, in extreme cases, disconnect the battery to prevent thermal runaway. Accurate estimation of the SOC and SOH is vital for understanding the battery’s available energy and predicting its lifespan [91]. The BMS uses algorithms and sensors to continuously assess these parameters, allowing users to make informed decisions about the battery’s usage and replacement timing. Second-life batteries may have internal or external faults due to wear and tear. The BMS continuously monitors for abnormalities like voltage spikes, current imbalances, or abnormal temperature fluctuations. If a fault is detected, the BMS can isolate the problematic section or, in some cases, the entire battery to prevent further damage. BMS systems in second-life batteries are often equipped with communication interfaces that allow for remote monitoring and control. This feature enables integration with energy management systems and facilitates data logging for performance analysis and predictive maintenance. The BMS regulates the charging and discharging processes to prevent overcharging, over-discharging, and excessive current flows. This ensures the safe and efficient use of the second-life battery in various applications, such as stationary energy storage for homes, businesses, or renewable energy installations. SLBs may have huge differences in the SOH level of individual cells. The worst cell in that case may affect the performance of the battery pack. An active balancing approach for a BMS in [92] balances the SOH of each cell in an SLB, which results in decreased degradation of the pack over time.

Research in battery management systems (BMS) for SLBs faces several intriguing challenges and opportunities. Optimization algorithms tailored to the unique characteristics of second-life batteries could enhance economic and environmental benefits by identifying optimal charging and discharging strategies. Considering factors like aging and previous usage, predictive modeling for battery performance remains an essential research gap to improve state-of-charge and health estimations. Advanced diagnostic techniques are needed for non-intrusive fault detection and characterization, addressing the complexity of internal defects and assessing the impact of prior usage on battery health. Integrating second-life batteries into renewable energy systems requires exploration, focusing on the effective management of intermittent energy sources and developing control strategies [93,94]. Lifecycle analysis and environmental impact assessments are crucial for understanding the overall sustainability of repurposed batteries. Standardization and interoperability gaps must be addressed to create common protocols and communication interfaces. Understanding user behavior, acceptance, and preferences is pivotal for designing user-friendly interfaces and educational materials [95]. Evaluating economic viability and establishing business models, along with defining reliability and safety standards, are essential for the widespread adoption of repurposed batteries. Grid integration challenges, such as bidirectional power flow and grid stability, present additional areas for investigation. Addressing these research gaps will contribute to the advancement of SLB technology, making it a more reliable, cost-effective, and sustainable solution for energy storage applications.

7. Discussion

The primary degradation mechanisms affecting the lifespan of lithium-ion batteries include SEI growth, lithium plating, and particle fracture. SLBs have similar degradation mechanisms compared with fresh cells, but these mechanisms differ in their dominance over the lifecycle of batteries. Consequently, this divergence produces distinct patterns in the state-of-health curve for secondary batteries compared with fresh cells. Moreover, the precise prediction of secondary battery aging is highly dependent on their initial operating conditions during their initial use. That is, distinct operating conditions can affect the timing of knee point appearance, resulting in different rates of degradation in their second-life applications. This field will keep progressing with numerous potential extensions and generalizations. In addition to acquiring charge–discharge profiles during first-life usage, assessing various statuses at the beginning of second-life usage, i.e., the lithium plating level and SEI layer thickness, is also beneficial for accurate SOH estimation. Therefore, the study of developing new techniques to detect these statuses can certainly bring additional opportunities. As the models for SLB usage become more refined and the accuracy of SOH prediction increases, system-level simulations and cost-effective analysis, i.e., a renewable system that includes photovoltaics, wind turbines, electrical grids, and batteries, will provide more useful guidance in practical applications.The development of solid-state batteries is attractive in recent studies. The modeling of its performance is challenging due to the complexity of its structure configuration and “complex chemo-mechanics at both electrodes and interfaces that cannot be any longer buffered as by liquid electrolytes” [96]. Meanwhile, a good understanding of its degradation mechanisms is crucial to estimating the lifespan of its second-life applications.

The use of SLBESSs in the power grid may look promising, but there is a need to look into the optimized operation of SLBESSs in the grid. Moreover, EV packs from different EVs and manufacturers are suitable for various grid services. Correctly assembling the used battery packs is essential for increased efficiency and safety.

The power-electronics-based power processing architectures for integration with the SLBs were covered, and their advantages and disadvantages were analyzed after an in-depth comparison. The important aspects of system efficiency, battery utilization, and converter ratings were analyzed. This paved the way for understanding and resolving the challenge of the heterogeneous characteristics of used batteries. From the power electronics reliability perspective, the single-stage converter reliability becomes drastically reduced after around five years, which identifies that the series-connected batteries are the weak link in the reliability analysis. The conventional single-, two-, and three-stage topologies cannot meet the reliability requirements. Thus, the addition of redundancy enhances reliability. A wide research potential is available in the area of redundancy addition to the fundamental topologies. Moreover, improved and intelligent mathematical models can be formulated and translated into power electronics topologies with better reliability.

8. Conclusions

This paper presents a comprehensive review of the degradation of SLBs and their use in the power grid. The SLB market is growing and a glimpse of active startups is presented. The degradation of these SLB packs differs from the degradation of fresh batteries due to these packs’ heavy dependence on first-life battery use. The degradation modeling of SLBESSs is an active research area. Moreover, for the integration of SLBs, the power-electronics-based power processing architectures were analyzed, and the LS-HiPPP architecture was identified as the most suitable one in terms of incorporating the heterogeneity of the used batteries and optimizing the overall system cost and efficiency. Another important parameter, namely, the power rating of the converter, was discussed, and strategies were identified to lower the power rating of individual converters, which leads to overall high efficiency and low system cost. Adjusting the heterogeneity of used batteries through modified power processing architectures and modern control techniques is a good potential research avenue. Various power-electronics interfacing topologies for SLBs were discussed and compared from the reliability point of view, and the integrated DC-DC converter for the cascaded multilevel converter was identified as the most optimal topology. Moreover, the advantages and drawbacks of all existing topologies were covered, and the shortcomings and potential research areas for improvements were identified. Future research work should be focused on increasing the redundancy level for existing converter topologies and proposing new topologies. Though sustainable, second-life use of EV batteries faces challenges on the regulation, safety, and technical fronts.

Author Contributions

A.H.: investigation, methodology, writing (Applications of second-life batteries in electrical grid)—original draft preparation and editing; S.A.K.: investigation, methodology, writing (Power electronics for second-life batteries)—original draft preparation; R.L.: investigation, methodology, writing (Degradation of second-life batteries and SOH estimation techniques)—original draft preparation; X.Z.: supervision—review; W.S.: project administration, funding acquisition, review. M.W.: supervision—review—Power electronics expert insights; B.W.: Investigation, writing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| battery energy storage system | |

| battery management system | |

| conventional power processing | |

| energy arbitrage | |

| end of life | |

| enhanced single-particle model | |

| full power processing | |

| frequency regulation | |

| internal combustion engine | |

| LS-HiPP | lite-sparse hierarchical partial processing |

| mixed least-squares estimator ramp-rate compliant | |

| solid electrolyte interface | |

| SLB | second-life battery |

| second-life battery energy storage system | |

| state of health | |

| single-particle model | |

| time of use | |

| individual cell reliability | |

| reliability of DC-AC converter | |

| reliability of filter stage | |

| total reliability | |

| reliability function of a system considered to have k-out-of-m redundancy if there are ‘n’ number of modules in them | |

| individual reliability of the power stage | |

| reliability of the overall module |

References

- IEA. Global EV Outlook 2023; Technical Report; IEA: Paris, France, 2023; Available online: https://www.iea.org/reports/global-ev-outlook-2023 (accessed on 3 October 2023).

- Engel, H.; Hertzke, P.; Siccardo, G. Second-Life EV Batteries: The Newest Value Pool in Energy Storage; McKinsey & Company: Chicago, IL, USA, 2019. [Google Scholar]

- Zhu, J.; Mathews, I.; Ren, D.; Li, W.; Cogswell, D.; Xing, B.; Sedlatschek, T.; Kantareddy, S.N.R.; Yi, M.; Gao, T.; et al. End-of-life or second-life options for retired electric vehicle batteries. Cell Rep. Phys. Sci. 2021, 2, 100537. [Google Scholar] [CrossRef]

- IEA. The Role of Critical Minerals in Clean Energy Transitions; IEA: Paris, France, 2021. [Google Scholar]

- Chen, M.; Ma, X.; Chen, B.; Arsenault, R.; Karlson, P.; Simon, N.; Wang, Y. Recycling end-of-life electric vehicle lithium-ion batteries. Joule 2019, 3, 2622–2646. [Google Scholar] [CrossRef]

- Faessler, B. Stationary, second use battery energy storage systems and their applications: A research review. Energies 2021, 14, 2335. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, Y.; Luo, F.; Mu, Y. Operational Planning of Centralized Charging Stations Utilizing Second-Life Battery Energy Storage Systems. IEEE Trans. Sustain. Energy 2021, 12, 387–399. [Google Scholar] [CrossRef]

- Salek, F.; Morrey, D.; Henshall, P.; Resalati, S. Techno-Economic Assessment of Utilising Second-Life Batteries in Electric Vehicle Charging Stations; Technical Report, SAE Technical Paper; SAE International: Warren, PA, USA, 2023. [Google Scholar]

- Shahjalal, M.; Roy, P.K.; Shams, T.; Fly, A.; Chowdhury, J.I.; Ahmed, M.R.; Liu, K. A review on second-life of Li-ion batteries: Prospects, challenges, and issues. Energy 2022, 241, 122881. [Google Scholar] [CrossRef]

- Khan, S.A.; Wang, M.; Su, W.; Liu, G.; Chaturvedi, S. Grid-Forming Converters for Stability Issues in Future Power Grids. Energies 2022, 15, 4937. [Google Scholar] [CrossRef]

- Hu, X.; Deng, X.; Wang, F.; Deng, Z.; Lin, X.; Teodorescu, R.; Pecht, M.G. A review of second-life lithium-ion batteries for stationary energy storage applications. Proc. IEEE 2022, 110, 735–753. [Google Scholar] [CrossRef]

- Hassan, A.; Altin, M.; Bingöl, F. Inertia and droop controller for a modern variable speed wind turbine to provide frequency control in a microgrid. Politek. Derg. 2020, 23, 771–777. [Google Scholar] [CrossRef]

- Zhang, D.; Li, J.; Hui, D. Coordinated control for voltage regulation of distribution network voltage regulation by distributed energy storage systems. Prot. Control Mod. Power Syst. 2018, 3, 1–8. [Google Scholar] [CrossRef]

- Wang, G.; Ciobotaru, M.; Agelidis, V.G. Power smoothing of large solar PV plant using hybrid energy storage. IEEE Trans. Sustain. Energy 2014, 5, 834–842. [Google Scholar] [CrossRef]

- Chua, K.H.; Lim, Y.S.; Morris, S. Energy storage system for peak shaving. Int. J. Energy Sect. Manag. 2016, 10, 3–18. [Google Scholar] [CrossRef]

- Khan, S.A. Unified voltage droop control strategy for VSC-MTDC in HVDC system. In Proceedings of the 16th IET International Conference on AC and DC Power Transmission (ACDC 2020), Online, 2–3 July 2020; IET Conference Proceedings; pp. 846–851. [Google Scholar]

- Hagiwara, M.; Akagi, H. Experiment and Simulation of a Modular Push–Pull PWM Converter for a Battery Energy Storage System. IEEE Trans. Ind. Appl. 2014, 50, 1131–1140. [Google Scholar] [CrossRef]

- Soong, T.; Lehn, P. Evaluation of Emerging Modular Multilevel Converters for BESS Applications. IEEE Trans. Power Deliv. 2014, 29, 2086–2094. [Google Scholar] [CrossRef]

- Vasiladiotis, M.; Rufer, A. Analysis and Control of Modular Multilevel Converters With Integrated Battery Energy Storage. IEEE Trans. Power Electron. 2015, 30, 163–175. [Google Scholar] [CrossRef]

- Chaturvedi, S.; Wang, M.; Fan, Y.; Fulwani, D.; Hollweg, G.V.; Khan, S.A.; Su, W. Control Methodologies to Mitigate and Regulate Second-Order Ripples in DC–AC Conversions and Microgrids: A Brief Review. Energies 2023, 16, 817. [Google Scholar] [CrossRef]

- Hollweg, G.V.; Khan, S.A.; Chaturvedi, S.; Fan, Y.; Wang, M.; Su, W. Grid-Connected Converters: A Brief Survey of Topologies, Output Filters, Current Control, and Weak Grids Operation. Energies 2023, 16, 3611. [Google Scholar] [CrossRef]

- Mukherjee, N.; Strickland, D. Second life battery energy storage systems: Converter topology and redundancy selection. In Proceedings of the 7th IET International Conference on Power Electronics, Machines and Drives (PEMD 2014), Manchester, UK, 8–10 April 2014; IET: Stevenage, UK, 2014; pp. 1–6. [Google Scholar]

- Birkl, C.R.; Frost, D.F.; Bizeray, A.M.; Richardson, R.R.; Howey, D.A. Modular converter system for low-cost off-grid energy storage using second life li-ion batteries. In Proceedings of the IEEE Global Humanitarian Technology Conference (GHTC 2014), San Jose, CA, USA, 10–13 October 2014; pp. 192–199. [Google Scholar] [CrossRef]

- Mukherjee, N.; Strickland, D.; Varnosfaderani, M.A. Adaptive Control of Hybrid Battery Energy Storage Systems under Capacity Fade. EPE J. 2015, 25, 25–33. [Google Scholar] [CrossRef][Green Version]

- Mukherjee, N.; Strickland, D. Control of second-life hybrid battery energy storage system based on modular boost-multilevel buck converter. IEEE Trans. Ind. Electron. 2014, 62, 1034–1046. [Google Scholar] [CrossRef]

- Chen, G.; Burgos, R.; Liang, Z.; Lacaux, F.; Wang, F.; Van Wyk, J.; Odendaal, W.; Boroyevich, D. Reliability-oriented design considerations for high-power converter modules. In Proceedings of the 2004 IEEE 35th Annual Power Electronics Specialists Conference (IEEE Cat. No. 04CH37551), Aachen, Germany, 20–25 June 2004; IEEE: Piscataway, NJ, USA, 2004; Volume 1, pp. 419–425. [Google Scholar]

- Julian, A.L.; Oriti, G. A Comparison of Redundant Inverter Topologies to Improve Voltage Source Inverter Reliability. IEEE Trans. Ind. Appl. 2007, 43, 1371–1378. [Google Scholar] [CrossRef]

- Ding, Y.; Loh, P.C.; Tan, K.K.; Wang, P.; Gao, F. Reliability evaluation of three-level inverters. In Proceedings of the 2010 Twenty-Fifth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Palm Springs, CA, USA, 21–25 February 2010; pp. 1555–1560. [Google Scholar] [CrossRef]

- Beg, O.A.; Khan, A.A.; Rehman, W.U.; Hassan, A. A Review of AI-Based Cyber-Attack Detection and Mitigation in Microgrids. Energies 2023, 16, 7644. [Google Scholar] [CrossRef]

- Williams, B.; Lipman, T. Analysis of the Combined Vehicle-Use Value of Lithium-Ion Plug-In-Vehicle Propulsion Batteries. Task 3, Second Life Applications and Value of ‘Traction’Lithium Batteries; Transportation Sustainability Research Center, University of California: Berkeley, CA, USA, 2011. [Google Scholar]

- Neubauer, J.; Pesaran, A. The ability of battery second use strategies to impact plug-in electric vehicle prices and serve utility energy storage applications. J. Power Sources 2011, 196, 10351–10358. [Google Scholar] [CrossRef]

- Mathews, I.; Xu, B.; He, W.; Barreto, V.; Buonassisi, T.; Peters, I.M. Technoeconomic model of second-life batteries for utility-scale solar considering calendar and cycle aging. Appl. Energy 2020, 269, 115127. [Google Scholar] [CrossRef]

- Bipartisan Infrastructure Law Electric Drive Vehicle Battery Recycling and Second Life Applications Funding Opportunity Announcement; Department of Energy: Washington, DC, USA, 2023.

- Hadjipaschalis, I.; Poullikkas, A.; Efthymiou, V. The role of second-life batteries in the energy storage revolution. Energy Sci. Eng. 2017, 5, 363–388. [Google Scholar]

- van Nieuwenhuijsen, W.A.; Heijman, H.J. Second-life batteries for electric vehicles: A review of commercialization and research trends. Appl. Energy 2022, 301, 1175–1189. [Google Scholar]

- NMSC. Second-Life EV Battery Market by Battery Type (Lead Acid Battery, Nickel Metal Hydride Battery, and Lithium Ion Battery) by Battery Source (Two Wheelers, Electric Buses, Electric Cars, and Others) and by Application (Residential, on-Grid, off-Grid, and Mobile)—Global Opportunity Analysis and Industry Forecast 2021–2030; 2023. Available online: https://www.nextmsc.com/report/second-life-ev-battery-market (accessed on 3 October 2023).

- Hassan, A. Frequency Control in an Isolated Power System with High Penetration of Wind Power. Available online: https://www.proquest.com/openview/d838d0ba176bc4c8fa823461ab64f2ea/1?pq-origsite=gscholar&cbl=2026366&diss=y (accessed on 3 October 2023).

- Rohr, S.; Müller, S.; Baumann, M.; Kerler, M.; Ebert, F.; Kaden, D.; Lienkamp, M. Quantifying Uncertainties in Reusing Lithium-Ion Batteries from Electric Vehicles. Procedia Manuf. 2017, 8, 603–610. [Google Scholar] [CrossRef]

- Wang, Z.; Al Alwan, B.; Ng, K.S. Multi-functions of amino thiophenol additives for shielding lithium metal anode in advanced Li-S battery. Mater. Sci. Eng. B 2023, 297, 116727. [Google Scholar] [CrossRef]

- Single, F.; Latz, A.; Horstmann, B. Identifying the Mechanism of Continued Growth of the Solid–Electrolyte Interphase. ChemSusChem 2018, 11, 1950–1955. [Google Scholar] [CrossRef]

- Ploehn, H.J.; Ramadass, P.; White, R.E. Solvent Diffusion Model for Aging of Lithium-Ion Battery Cells. J. Electrochem. Soc. 2004, 151, A456. [Google Scholar] [CrossRef]

- Pinson, M.B.; Bazant, M.Z. Theory of SEI Formation in Rechargeable Batteries: Capacity Fade, Accelerated Aging and Lifetime Prediction. J. Electrochem. Soc. 2013, 160, A243–A250. [Google Scholar] [CrossRef]

- Li, D.; Danilov, D.; Zhang, Z.; Chen, H.; Yang, Y.; Notten, P.H.L. Modeling the SEI-Formation on Graphite Electrodes in LiFePO 4 Batteries. J. Electrochem. Soc. 2015, 162, A858–A869. [Google Scholar] [CrossRef]

- Tang, M.; Lu, S.; Newman, J. Experimental and Theoretical Investigation of Solid-Electrolyte-Interphase Formation Mechanisms on Glassy Carbon. J. Electrochem. Soc. 2012, 159, A1775–A1785. [Google Scholar] [CrossRef]

- Broussely, M.; Herreyre, S.; Biensan, P.; Kasztejna, P.; Nechev, K.; Staniewicz, R.J. Aging mechanism in Li ion cells and calendar life predictions. J. Power Sources 2001, 97, 13–21. [Google Scholar] [CrossRef]

- Röder, F.; Braatz, R.D.; Krewer, U. Multi-Scale Simulation of Heterogeneous Surface Film Growth Mechanisms in Lithium-Ion Batteries. J. Electrochem. Soc. 2017, 164, E3335–E3344. [Google Scholar] [CrossRef]

- Single, F.; Horstmann, B.; Latz, A. Revealing SEI Morphology: In-Depth Analysis of a Modeling Approach. J. Electrochem. Soc. 2017, 164, E3132–E3145. [Google Scholar] [CrossRef]

- Single, F.; Horstmann, B.; Latz, A. Dynamics and morphology of solid electrolyte interphase (SEI). Phys. Chem. Chem. Phys. 2016, 18, 17810–17814. [Google Scholar] [CrossRef]

- Shi, S.; Lu, P.; Liu, Z.; Qi, Y.; Hector Jr, L.G.; Li, H.; Harris, S.J. Direct calculation of Li-ion transport in the solid electrolyte interphase. J. Am. Chem. Soc. 2012, 134, 15476–15487. [Google Scholar] [CrossRef]

- Soto, F.A.; Ma, Y.; Hoz, J.M.M.D.L.; Seminario, J.M.; Balbuena, P.B. Formation and Growth Mechanisms of Solid-Electrolyte Interphase Layers in Rechargeable Batteries. Chem. Mater. 2015, 27, 7990–8000. [Google Scholar] [CrossRef]

- Yang, X.G.; Leng, Y.; Zhang, G.; Ge, S.; Wang, C.Y. Modeling of lithium plating induced aging of lithium-ion batteries: Transition from linear to nonlinear aging. J. Power Sources 2017, 360, 28–40. [Google Scholar] [CrossRef]

- Dubarry, M.; Beck, D. Big data training data for artificial intelligence-based Li-ion diagnosis and prognosis. J. Power Sources 2020, 479. [Google Scholar] [CrossRef]

- Yang, X.G.; Ge, S.; Liu, T.; Leng, Y.; Wang, C.Y. A look into the voltage plateau signal for detection and quantification of lithium plating in lithium-ion cells. J. Power Sources 2018, 395, 251–261. [Google Scholar] [CrossRef]

- Ebner, M.; Marone, F.; Stampanoni, M.; Wood, V. Visualization and quantification of electrochemical and mechanical degradation in Li ion batteries. Science 2013, 342, 716–720. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.H.; Zhong, L.; Huang, S.; Mao, S.X.; Zhu, T.; Huang, J.Y. Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano 2012, 6, 1522–1531. [Google Scholar] [CrossRef]

- Hendricks, C.; Williard, N.; Mathew, S.; Pecht, M. A failure modes, mechanisms, and effects analysis (FMMEA) of lithium-ion batteries. J. Power Sources 2015, 297, 113–120. [Google Scholar] [CrossRef]

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A review on the key issues of the lithium ion battery degradation among the whole life cycle. ETransportation 2019, 1, 100005. [Google Scholar] [CrossRef]

- Vetter, J.; Novák, P.; Wagner, M.R.; Veit, C.; Möller, K.C.; Besenhard, J.O.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Sources 2005, 147, 269–281. [Google Scholar] [CrossRef]

- How, D.N.; Hannan, M.; Lipu, M.H.; Ker, P.J. State of charge estimation for lithium-ion batteries using model-based and data-driven methods: A review. IEEE Access 2019, 7, 136116–136136. [Google Scholar] [CrossRef]

- Guo, W.; Sun, Z.; Vilsen, S.B.; Meng, J.; Stroe, D.I. Review of “grey box” lifetime modeling for lithium-ion battery: Combining physics and data-driven methods. J. Energy Storage 2022, 56, 105992. [Google Scholar] [CrossRef]

- Li, J.; He, S.; Yang, Q.; Wei, Z.; Li, Y.; He, H. A Comprehensive Review of Second Life Batteries Towards Sustainable Mechanisms: Potential, Challenges, and Future Prospects. IEEE Trans. Transp. Electrif. 2022. [Google Scholar] [CrossRef]

- Identification and machine learning prediction of knee-point and knee-onset in capacity degradation curves of lithium-ion cells. Energy AI 2020, 1, 100006. [CrossRef]

- Diao, W.; Saxena, S.; Han, B.; Pecht, M. Algorithm to determine the knee point on capacity fade curves of lithium-ion cells. Energies 2019, 12, 2910. [Google Scholar] [CrossRef]

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; et al. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef]

- Pozzato, G.; Lee, S.B.; Onori, S. Modeling Degradation of Lithium-Ion Batteries for Second-Life Applications: Preliminary Results; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2021; pp. 826–831. [Google Scholar]

- Murthy Balijepalli, V.S.K.; Pradhan, V.; Khaparde, S.A.; Shereef, R.M. Review of demand response under smart grid paradigm. In Proceedings of the ISGT2011-India, Kollam, India, 1–3 December 2011; pp. 236–243. [Google Scholar] [CrossRef]

- EIA. Battery Storage in the United States: An Update on Market Trends; US Energy Information Administration (EIA): Washington, DC, USA, 2020. [Google Scholar]

- Fitzgerald, G.; Mandel, J.; Morris, J.; Touati, H. The Economics of Battery Energy Storage: How Multi-Use, Customer-Sited Batteries Deliver the Most Services and Value to Customers and the Grid; Rocky Mountain Institute: Basalt, CO, USA, 2015; Volume 6. [Google Scholar]

- Farivar, G.G.; Manalastas, W.; Tafti, H.D.; Ceballos, S.; Sanchez-Ruiz, A.; Lovell, E.C.; Konstantinou, G.; Townsend, C.D.; Srinivasan, M.; Pou, J. Grid-connected energy storage systems: State-of-the-art and emerging technologies. Proc. IEEE 2022, 111, 397–420. [Google Scholar] [CrossRef]

- Faisal, M.; Hannan, M.A.; Ker, P.J.; Hussain, A.; Mansor, M.B.; Blaabjerg, F. Review of energy storage system technologies in microgrid applications: Issues and challenges. IEEE Access 2018, 6, 35143–35164. [Google Scholar] [CrossRef]

- Nadeem, F.; Hussain, S.S.; Tiwari, P.K.; Goswami, A.K.; Ustun, T.S. Comparative review of energy storage systems, their roles, and impacts on future power systems. IEEE Access 2018, 7, 4555–4585. [Google Scholar] [CrossRef]

- Berrueta, A.; Ursúa, A.; Martín, I.S.; Eftekhari, A.; Sanchis, P. Supercapacitors: Electrical Characteristics, Modeling, Applications, and Future Trends. IEEE Access 2019, 7, 50869–50896. [Google Scholar] [CrossRef]

- Soman, R.; Ravindra, H.; Huang, X.; Schoder, K.; Steurer, M.; Yuan, W.; Zhang, M.; Venuturumilli, S.; Chen, X. Preliminary investigation on economic aspects of superconducting magnetic energy storage (SMES) systems and high-temperature superconducting (HTS) transformers. IEEE Trans. Appl. Supercond. 2018, 28, 1–5. [Google Scholar] [CrossRef]

- Saez-de Ibarra, A.; Martinez-Laserna, E.; Stroe, D.I.; Swierczynski, M.; Rodriguez, P. Sizing study of second life Li-ion batteries for enhancing renewable energy grid integration. IEEE Trans. Ind. Appl. 2016, 52, 4999–5008. [Google Scholar] [CrossRef]

- White, C.; Swan, L.G. Pack-level performance of electric vehicle batteries in second-life electricity grid energy services. J. Energy Storage 2023, 57, 106265. [Google Scholar] [CrossRef]

- Li, R.; Hassan, A.; Gupte, N.; Su, W.; Zhou, X. Degradation Prediction and Cost Optimization of Second-Life Battery Used for Energy Arbitrage and Peak-Shaving in an Electric Grid. Energies 2023, 16, 6200. [Google Scholar] [CrossRef]

- Janota, L.; Králík, T.; Knápek, J. Second life batteries used in energy storage for frequency containment reserve service. Energies 2020, 13, 6396. [Google Scholar] [CrossRef]

- Colarullo, L.; Thakur, J. Second-life EV batteries for stationary storage applications in Local Energy Communities. Renew. Sustain. Energy Rev. 2022, 169, 112913. [Google Scholar] [CrossRef]

- White, C.; Thompson, B.; Swan, L.G. Repurposed electric vehicle battery performance in second-life electricity grid frequency regulation service. J. Energy Storage 2020, 28, 101278. [Google Scholar] [CrossRef]

- Zhang, D.; Anwar, J.; Rizvi, S.A.A.; Wei, Y. Deep Learning for Continuous-Time Leader Synchronization in Graphical Games Using Sampling and Deep Neural Networks. Lett. Dyn. Sys. Control. 2023, 3, 031004. [Google Scholar] [CrossRef]

- Shenoy, P.; Kim, K.; Johnson, B.; Krein, P. Differential Power Processing for Increased Energy Production and Reliability of Photovoltaic Systems. IEEE Trans. Power Electron. 2013, 28, 2968–2979. [Google Scholar] [CrossRef]

- McClurg, J.; Pilawa-Podgurski, R.; Shenoy, P. A series-stacked architecture for high-efficiency data center power delivery. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition, ECCE 2014, Pittsburgh, PA, USA, 14–18 September 2014; pp. 170–177. [Google Scholar] [CrossRef]

- Cui, X.; Ramyar, A.; Contreras, V.; Judge, G.; Siegel, J.; Stefanopoulou, A.; Avestruz, A.T. Lite-Sparse Hierarchical Partial Power Processing for Parallel Batteries in Heterogeneous Energy Storage Systems. In Proceedings of the 2021 IEEE 22nd Workshop on Control and Modelling of Power Electronics (COMPEL), Cartagena, Colombia, 2–5 November 2021; pp. 1–8. [Google Scholar] [CrossRef]

- Ansari, J.A.; Liu, C.; Khan, S.A. MMC Based MTDC Grids: A Detailed Review on Issues and Challenges for Operation, Control and Protection Schemes. IEEE Access 2020, 8, 168154–168165. [Google Scholar] [CrossRef]

- Cui, X.; Ramyar, A.; Siegel, J.; Mohtat, P.; Stefanopoulou, A.; Avestruz, A.T. Comparing power processing system approaches in second-use battery energy buffering for electric vehicle charging. J. Energy Storage 2022, 49, 104017. [Google Scholar] [CrossRef]

- Moo, C.S.; Ng, K.; Hsieh, Y.C. Parallel Operation of Battery Power Modules. IEEE Trans. Energy Convers. 2008, 23, 701–707. [Google Scholar] [CrossRef]

- Reliability Prediction of Electronic Equipment, Military Handbook 217-F; Department of Defense: Arlington, VA, USA, 1991.

- Bathtub Curve. 21 June 2023. Available online: https://en.wikipedia.org/wiki/Bathtubcurve (accessed on 3 October 2023).

- Baumann, M.; Rohr, S.; Lienkamp, M. Cloud-connected battery management for decision making on second-life of electric vehicle batteries. In Proceedings of the 2018 Thirteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 10–12 April 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–6. [Google Scholar]

- Abdel-Monem, M.; Hegazy, O.; Omar, N.; Trad, K.; Van den Bossche, P.; Van Mierlo, J. Lithium-ion batteries: Comprehensive technical analysis of second-life batteries for smart grid applications. In Proceedings of the 2017 19th European Conference on Power Electronics and Applications (EPE’17 ECCE Europe), Warsaw, Poland, 11–14 September 2017; IEEE: Piscataway, NJ, USA, 2017; pp. P-1–P-16. [Google Scholar]

- Lacap, J.; Park, J.W.; Beslow, L. Development and demonstration of microgrid system utilizing second-life electric vehicle batteries. J. Energy Storage 2021, 41, 102837. [Google Scholar] [CrossRef]

- Rasheed, M.; Hassan, R.; Kamel, M.; Wang, H.; Zane, R.; Tong, S.; Smith, K. Active Reconditioning of Retired Lithium-ion Battery Packs from Electric Vehicles for Second Life Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2023. [Google Scholar] [CrossRef]

- Castillo-Martínez, D.H.; Rodríguez-Rodríguez, A.J.; Soto, A.; Berrueta, A.; Vargas-Requena, D.T.; Matias, I.R.; Sanchis, P.; Ursúa, A.; Rodríguez-Rodríguez, W.E. Design and on-field validation of an embedded system for monitoring second-life electric vehicle lithium-ion batteries. Sensors 2022, 22, 6376. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Wang, M.; Khan, S.A.; Xi, L.; Xiao, K. Degradation Analysis of The Metallized Film Capacitance under Various Conditions in EV Applications. In Proceedings of the 2022 IEEE Transportation Electrification Conference & Expo (ITEC), Anaheim, CA, USA, 15–17 June 2022; pp. 512–516. [Google Scholar] [CrossRef]

- Hossain, E.; Murtaugh, D.; Mody, J.; Faruque, H.M.R.; Sunny, M.S.H.; Mohammad, N. A comprehensive review on second-life batteries: Current state, manufacturing considerations, applications, impacts, barriers & potential solutions, business strategies, and policies. IEEE Access 2019, 7, 73215–73252. [Google Scholar]

- Optical sensors for operando stress monitoring in lithium-based batteries containing solid-state or liquid electrolytes. Nat. Commun. 2022, 13, 1153. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).