Abstract

Various pretreatments are employed to increase the utilization of rice straw as a ruminant feed ingredient to minimize its negative environmental impact. However, an efficient alternative is still needed. The purpose of this study was to evaluate the ability of ammonia and/or white-rot fungi (Pleurotus ostreatus) to degrade lignin, increase the nutritional value, and enhance the rumen fermentability of rice straw. Rice straw was treated with ammonia and/or basidiomycete white-rot fungi (P. ostreatus) with untreated straw as control under solid-state fermentation employing a completely randomized design. The crude protein increased from 2.05% in the control to 3.47% in ammoniated rice straw, 5.24% in basidiomycete white-rot fungi (P. ostreatus), and 6.58% in ammoniated-basidiomycete white-rot fungi-treated (P. ostreatus) rice straw. The ammoniated-basidiomycete white-rot fungi-treated (P. ostreatus) rice straw had the least lignin content (3.76%). Ammoniated-basidiomycete white-rot fungi-treated (P. ostreatus) rice straw had improved in vitro dry matter digestibility (65.52%), total volatile fatty acid (76.56 mM), and total gas production (56.78 mL/g) compared to ammoniated rice straw (56.16%, 67.71 mM, 44.30 mL/g) or basidiomycete white-rot fungi-treated (P. ostreatus) rice straw (61.12%, 75.36 mM, 49.31 mL/g), respectively. The ammoniated-basidiomycete white-rot fungi (P. ostreatus) treatment improved rice straw’s nutritional value, in vitro dry matter digestibility, volatile fatty acids, and gas production.

1. Introduction

Rice straw (RS) is one of the major agro-byproducts generated worldwide, with an annual global yield of close to 731 million tons [1]. RS is predominantly fed as an energy roughage to meet ruminant maintenance requirements, particularly in drought periods [2]. In contrast to some agro-byproducts, for which there is stiffer competition between the livestock sector and industrial usage, particularly in first economies, the existing competition for RS in even the most industrialized agrarian economies is almost nonexistent, considering the enormous tonnage that is burned, causing air pollution. Moreover, RS usage in the industrialized agrarian economies is limited. This is because RS is intrinsically low in nitrogen and the hydrolyzable fiber (holocellulose) is chemically encrusted within a lignin envelope [3], which suppresses its digestibility and nutritional value. The reduced fiber digestibility also contributes to the buildup of enteric methane, representing an energy loss to ruminants [4] and major greenhouse gas [5], and so is thus undesirable. Numerous methods increase rice straw’s nutritional value and digestibility by disrupting the lignin–holocellulose linkage before feeding ruminants [6]. An adopted strategy extensively used is ammonification.

Ammonification, which involves using an ammoniating agent such as urea or aqueous ammonia, has become essential in improving the nutritional value of straw. Ammonification improves straw digestibility via the action of ammonia on the lignin-structural polysaccharide linkages. It also increases the crude protein of the straw through the fixation of applied nitrogen [7] and effectively breaks the bond between the lignin and the polysaccharides. The ammonification process occurs at high temperatures (over 100 °C) and under pressure for a short time. However, it does not necessarily change the lignin content of the substrate [8] because the lignin residue in the straw is not affected and thus impedes the action of the rumen microbial enzymes on cellulose hydrolysis [9]. This explains why ammoniated corn straw’s nutritional value and total energy were not improved [10]. There is a need for an additional technique that breaks lignin bonds and eliminates them from the straw.

White rot-fungi species are the only organisms known to completely mineralize lignin into carbon dioxide and water [11], leading to the improved digestibility and nutritional value of biodegraded straw [12]. Pleurotus ostreatus (P. ostreatus), a member of the basidiomycetes white-rot fungus, is extensively used for straw degradation because it is edible and highly ligninolytic [13]. Furthermore, the mycelium colonization of straw yields cellulose-protein-enriched biomass [14], which has the potential to lower the need for and cost of protein supplementation. It is hypothesized that “basidio-ammonification”, which is a biochemical method of treating RS with both ammonia and a basidiomycete white-rot fungus (P. ostreatus), would produce a highly delignified straw with improved nutritional value, digestibility, and in vitro fermentation indices than either ammonification or white-rot fungi treatment alone.

Extensive studies on either ammonification, physiochemical, or white-rot fungi applications have been widely explored to improve the nutritional value of various straw materials [15,16,17]. Unfortunately, there is a paucity of information on the potential of ammonification combined with basidiomycete white-rot fungi species to improve the nutritional value of straw and its impact on fermentation characteristics in vitro. The study, therefore, seeks to evaluate the effect of “basidio-ammonification” co-treatment of rice straw on the proximate composition, cell wall constituents, in vitro digestibility, volatile fatty acid (VFA) composition, and gas production.

2. Materials and Methods

2.1. Basidiomycete White-Rot Fungi

Basidiomycete white-rot fungi, P. ostreatus CGMCC 3.7292, were procured from the China Agricultural University in Beijing, China. It was developed on a malt extract agar (MEA; malt extract 20 g; agar 20 g; nutritional yeast 2 g; per L) culture medium and preserved at 4 °C. A sterilized agar plate was prepared by autoclaving MEA for 25 min at 121 °C. It was then inoculated with 0.5 cm2 of the fungi and incubated at 25 ± 1 °C until mycelium had colonized the whole surface of the MEA plate.

2.2. Grain Spawn Preparation

Millet grains were rinsed with water and parboiled for 15 min. The parboiled grains were transferred onto a mesh strainer for the water to drain. The grains were loaded into a sealable spawn mycobag (25 cm width and 37 cm height) until three-quarters full, and then autoclaved for 45 min at 121 °C. Spawn mycobag contents were allowed to cool to room temperature, and were then aseptically inoculated with six pieces of the mycelium agar (1 cm2) and sealed. The spawn mycobag was agitated manually to ensure the uniform distribution of mycelium and grains. It was then kept at 25 ± 1 °C in an incubator (RGX-350, Beijing Zhongxingweiye Instrument Co., Ltd., Beijing, China) until the fungi mycelium completely colonized all grains. The prepared spawn was kept in a cold chamber at 4 °C to halt mycelia growth and for future use.

2.3. Rice Straw Collection and Preparation

The rice straw used for the study was obtained from Yangzhou University’s rice farm in Jiangsu, China. The rice straw was physically cut into 2 to 3 cm lengths, packed into storage bags, and hermetically sealed to be used later for solid-state fermentation.

2.4. Solid-State Fermentation

Aqueous ammonia (3% w/w) was sprayed on 250 g of the rice straw in quadruplicate samples on a DM basis. Sterilized water was then added to increase the moisture content to 50%. The samples were thoroughly mixed rapidly and packed into polyethylene mycobags representing the ammoniated rice straw (ARS) group. The ARS was then autoclave sterilized for 60 min at 121 °C and allowed to cool to room temperature. The ammoniated-basidiomycete white-rot fungi-treated (P. ostreatus) rice straw group (AFTRS) was prepared the same way as the ARS group and inoculated with P. ostreatus spawn at 3% w/w of the substrate. The basidiomycete white-rot fungi-treated (P. ostreatus) rice straw group (FTRS) was prepared in the same way as the AFTRS group but for the addition of ammonia. To ensure the uniform distribution of the spawn, the FTRS and AFTRS were agitated before incubation in line with the procedure of Oei [18]. The control group, untreated rice straw (UTRS), was neither ammoniated nor inoculated with basidiomycete white-rot fungi (P. ostreatus). All the mycobags were kept in an incubator (RGX-350, Beijing Zhongxingweiye Instrument Co., Ltd., Beijing, China) at 25 ± 1 °C and 75–80% humidity for 30 d. After incubation, the mycobags were oven dried for 48 h at 64 °C and ground over a 1 mm sieve using a miller machine (CM100, Beijing Yongguangming Co., Ltd., Beijing, China) to obtain uniform samples for further chemical and in vitro analysis.

2.5. Experimental Design

A completely randomized design was used to assign treatments to the experimental units. The experiment was performed in quadruplicate.

2.6. Proximate and Cell Wall Composition Analysis

The samples were dried in an oven drier (DHG-9123A, Zhengzhou Wollen Instrument Equipment Co., Ltd., Shanghai, China) at 105 °C for 3 h to determine their dry matter content. The nitrogen (N) content and ether extract (EE) were determined using the Kjeldahl and Soxhlet method according to the Association of Official Analytical Chemists [19]. The crude protein (CP) was estimated by multiplying the nitrogen (N) by 6.25. Neutral detergent fiber (NDF), acid detergent fiber (ADF), cellulose, hemicellulose, and acid detergent lignin (ADL) analyses were carried out as recommended by Van Soest et al. [20] with an Ankom 2000 automated fiber analyzer (ANKOM Technology, Macedon, New York, NY, USA). Samples (0.5–1 g) of the rice straw were weighed into polyester mesh bags (Ankom F57, ANKOM Technology, Macedon, New York, NY, USA) and heat-sealed using an FS-300 impulse heat sealer (Zhejiang Tianyu Industry Co. Ltd., Yongkang, China). The sealed bags and 2000 mL of neutral detergent were placed in an automatic fiber analyzer for 60 min at 100 °C. The bags were then rinsed to neutral with distilled water, dried, and weighed. The dried residue constituted the NDF. 2000 mL of acid detergent was added to the remaining dried sample, and the same NDF approach was used to determine ADF. Hemicellulose (H) was estimated as NDF minus ADF. The dried residue was soaked in 72% (v/v) H2SO4 and kept for 2 h at 25 °C. The bags were rinsed to neutral with distilled water, dried, and weighed. The remaining samples were kept for 3 h at 550 °C in a tared crucible and reweighed to calculate the loss as ADL. Cellulose (C) was estimated as ADF less ADL. Carbonization of the samples for 3 h at 550 °C in a muffle furnace (1200 Kiln, Jinan Cyeeyo Instruments Co., Ltd., Jinan, China) was used to evaluate ash content. Organic matter (OM) was estimated as the difference between dry matter (DM) and ash. All calculations were done on a percentage dry matter basis.

2.7. In Vitro Fermentation

The Institutional Animal Care Committee of Yangzhou University (Yangzhou, China) approved protocols for the care of rumen-fistulated Holstein cows and rumen fluid collection techniques. Fresh rumen fluid was obtained from three rumen-fistulated Holstein cows maintained on corn silage and an oat straw-based diet. The rumen fluid was then filtered through four layers of cheesecloth and mixed in a 1:2 (v/v) buffer solution (Buffer A: 13.2 g CaCl2·2H2O, 10.0 g MnCl2·4H2O, 1.0 g CoCl2·6H2O and 8.0 g FeCl3·6H2O per 100 mL; Buffer B: 35.0 g NaHCO3 and 4.0 g NH4HCO3 per 1000 mL; Buffer C: 5.7 g Na2HPO4 and 0.6 g MgSO4·7H2O and 6.2 g KH2PO4 per 1000 mL) under constant flushing with CO2 as prescribed by Menke et al. [21]. 0.2 g of oven-dried control and experimental group samples were weighed into 100 mL glass vials. Each glass vial was filled with 30 mL of the buffered rumen fluid, sealed with a rubber stopper, and kept in an incubator shaker (Model THZ-320, Jinghong Devices, Shanghai, China) for 48 h at 39 °C along with blanks (vials containing rumen fluid and buffer but no samples). All the groups (control, treatments, and blank) had four replications.

2.8. In Vitro Gas, Volatile Fatty Acids, and Dry Matter Digestibility

The gas pressure (headspace) at 0, 3, 6, 12, 24, 36, and 48 h in each glass vial was measured using a digital pressure transducer gauge (Model DPG1000B15PSIG-5, Cecomp Electronics, Libertyville, IL, USA) fitted with a 22-gauge hypodermic needle following the guidelines of Theodorou et al. [22]. After correcting the gas production values for blanks (gas of sample − the gas of blank), the gas pressure was converted to gas volume using the mathematical formula: Vgas = Vj × Ppsi × 0.068004084, where Vgas is the gas volume at 39 °C, mL, Vj is the vial volume headspace of liquid, mL, and Ppsi is the pressure of the vial, psi.

The glass vials were removed from the incubator and placed in an ice bath to terminate fermentation after 48 h. The rubber stopper sealant of each glass vial was then removed, and the pH of the content (fermentation mixture) was recorded using a pH meter (Model PHS-3C, Puchun Co., Ltd., Shanghai, China). The contents were drained into 50 mL conical sterile polypropylene centrifuge tubes and then centrifuged for 15 min at 8000× g and 4 °C in an Eppendorf centrifuge 5810R (Fisher Scientific Co., Ltd., Waltham, MA, USA) to yield a supernatant and precipitate (nonfermented solid residue). The supernatant from each sample was placed into 1.5 mL conical sterile polypropylene centrifuge tubes, and 1 mL of the supernatant was combined with 0.2 mL of 20% metaphosphoric acid and refrigerated overnight at 4 °C for VFA measurement.

A gas chromatography-mass spectrometer (GC-MS 9800, Shanghai Kechuang Chromatographic Instrument Co., Ltd., Shanghai, China) with a thermal conductivity detector Agilent capillary column (30 m × 0.32 mm × 0.25 μm, DB-FFAP: TDX-01, Agilent Technologies, Shanghai, China) was used to estimate the VFA concentration. The injector, column, and detector were heated to 200 °C, 110 °C, and 200 °C, respectively. The carrier gas was nitrogen, with a 50 mL/min flow rate and a volume injection of 1 µL. Each sample’s residue was dried overnight at 65 °C and weighed. The in vitro dry matter digestibility (IVDMD) was calculated as the weight of the residue less the initial weight of the 50 mL conical sterile polypropylene centrifuge tubes. IVDMD was adjusted for blank corrections.

2.9. Statistical Analysis

The effects of the treatments on proximate composition, cell wall content, in vitro pH, VFA, and gas were evaluated using a completely randomized research design. Generated data were statistically analyzed as One-Way Analysis of Variance (ANOVA) using SPSS version 21.0 (IBM Corp., Armonk, NY, USA). A posthoc multiple comparison with Duncan’s significant test at a significance level of 0.05 was used to establish the significance between experimental groups. Prior to conducting the ANOVA, Levene’s test was used to ensure that the assumption of homogeneity of variances was met (p > 0.05).

3. Results

3.1. Subjective Observations

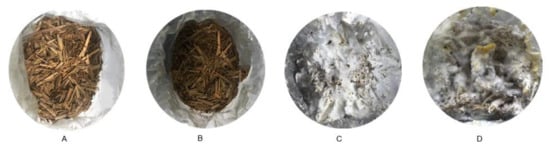

No mold growth was detected in treatment groups after the incubation period, as shown in Figure 1. Ammonia odor was apparent from ammoniated rice straw (Figure 1B) and ammoniated-basidiomycete white-rot P. ostreatus (Figure 1D) after opening, and the straw had become more brownish (Figure 1B). Basidiomycete white-rot P. ostreatus successfully colonized both the unammoniated rice straw (Figure 1C) and the ammoniated rice straw (Figure 1D).

Figure 1.

Thirty-day incubation of rice straw: (A) untreated, (B) ammoniated, (C) basidiomycete white-rot P. ostreatus, and (D) ammoniated-basidiomycete white-rot P. ostreatus.

3.2. Proximate Composition

Significant differences were recorded between all the treatments for the various parameters (DM, OM, ash, CP, and EE) that were considered, as shown in Table 1. The UTRS recorded significantly higher OM and DM contents than the other treatments. This was followed by the ARS, FTRS, and AFTRS in that order. The AFTRS, on the other hand, recorded significantly higher ash, CP, and EE. The FTRS was second to the AFTRS with respect to the parameters mentioned above (Ash, CP, and EE), while the ARS recorded the least fractions of these parameters save the CP, for which the UTRS recorded the least proportion.

Table 1.

Proximate composition (% DM basis) of ammonia and/or basidiomycete white-rot P. ostreatus-treated rice straw.

3.3. Cell Wall Content

Significant differences were recorded between all the treatments for all the parameters (NDF, ADF, ADL, C, and H) presented in Table 2. The AFTRS recorded significantly the lowest percentages for all the parameters, followed by FTRS, ARS, and UTRS in succession.

Table 2.

Cell wall contents (% DM basis) of ammonia and/or basidiomycete white-rot P. ostreatus-treated rice straw.

3.4. In Vitro Fermentation Characteristics

Except for the pH, significant differences were recorded among all the treatments with respect to the IVDMD, total VFA, and the individual volatile fatty acids (VFAs) produced, as shown in Table 3. The AFTRS had significantly higher IVDMD and total VFA compared to the other treatments. This was followed by FTRS and ARS treatments for both parameters. The UTRS produced the least IVDMD and total VFA. Similarly, the UTRS produced the least propionic acid, isobutyric, and isovaleric acid, while the AFTRS produced the highest amount of these acids. There was no significant difference in the valeric produced by the UTRS and the ARS. There was neither any significant difference between the FTRS and AFTRS. The UTRS, however, had the highest acetic acid, A/P, and butyric acid, while the AFTRS produced the least concentration of the VFAs. The FTRS had a significantly lower acetic acid, A/P, and butyric acid than the ARS.

Table 3.

pH, IVDMD, and VFA of ammonia and/or basidiomycete white-rot P. ostreatus-treated straw.

3.5. In Vitro Gas Volume

Significant differences were recorded between the treatments in the volume of gas produced at all periods, as presented in Table 4. The UTRS had the lowest volume of gas among the treatments, irrespective of the period. This was followed by the ARS and FTRS. The AFTRS had significantly the highest volume of gas at all periods. Even though the volume of gas increased exponentially at the initial stages, the rate of increase was comparatively marked in the last stage for all treatments.

Table 4.

In vitro gas volume of ammonia and/or basidiomycete white-rot P. ostreatus-treated rice straw.

4. Discussion

The most noticeable transformation in rice straw treated with ammonia was the color of the straw. During the ammoniation process, browning of the rice straw ensued, and the ammoniated rice straw was more pliable than the untreated rice straw.

The observed decline in the DM and OM content of the ammoniated rice straw (ARS) in the present study is similar to the findings of Moreira Filho et al. [23] and Hassan et al. [24] in their treatment of barley and corn straw, respectively. Similarly, Fazaeli [25] and Khonkhaeng and Cherdthong [15] recorded a decline in their treatment of wheat straw and purple field corn residue, respectively, with P. ostreatus, which is consistent with the reduction in the DM and OM observed in FTRS in the current study. The general decline in the DM and OM of the treated material has been identified as unavoidable losses characteristic of the ammoniation reaction [23] and white-rot fungi degradation of straw constituents [26] because of the ability of ammonia to alter the cell wall fraction and the dependence of basidiomycete white-rot P. ostreatus fungi on the straw for their energy requirements. This substantiates the comparatively higher decline in the AFTRS due to their synergetic effect on the biomass.

Kutlu et al. [27] reported an increase in CP when wheat straw was either ammoniated or treated with Pleurotus florida fungi, which is comparable to the noticeable rise in CP in this study. The observed increase in the CP of the ARS results from ammonia absorption and subsequent fixation of inorganic N into the cell wall [28]. The increased CP of FTRS could originate from either colonization and proliferation of the straw [29,30] by the fungi mycelia, the capture of accessible N via aerobic fermentation by fungus [31] and extracellular proteinaceous enzymes secreted by fungi [32], or a combination of all or some of these factors.

The CP content of FTRS compared to the ARS was higher in the current study. According to Ragunathan et al. [33], the protein content of fungi mycelia is relatively high, which explains the comparatively higher CP in the FTRS compared to the ARS. Admittedly, the mycelia of the fungi, according to Chang and Miles [34], is predominantly nitrogen (60–70% of N occurring in the fungal cell is protein), which contributes to the protein content of the substrate.

In the case of AFTRS, the fungi converted both the accessible inorganic N initially within the straw and that contributed by the ammonification agent into proteinic N, which is a richer form of protein nutrient [35]. There were two sources of inorganic N and, consequently, a relatively higher CP in the AFTRS. The OM and CP of AFTRS, being markedly the least and highest, respectively, in the present study, are consistent with the findings of Rouzbehan et al. [36]. The latter reported a similar trend using ammoniated Pleurotus of Iranian tissue-treated (TS2) wheat straw.

The ash content of ARS was markedly the least of all the treatments, and it is coherent with the report of Ma et al. [7]. The comparable decline in ash content after ammonification compared to untreated straw is indicative of the loss of soluble mineral elements [37]. The increase in ash content of FTRS was consistent with the report of Fazaeli [25] and Velázquez-De Lucio et al. [38]. This is due to fungus breaking down the straw to release minerals and inorganic matter [39]. The AFTRS yielded the highest amount of ash because it degraded the most organic matter. This is attributable to the synergetic or combining effects of basidio-ammonification.

The EE of ARS, which is markedly the least among the treatments, is similar to the report of Suksombat [40]. Yalchi [41] reported a numerical decline in the EE of ammoniated triticale compared to untreated triticale. However, the decline was not significant. This variation could be due to differences in straw types used. Treating straw with fungi (FTRS) led to increased EE, and this aligns with the findings of Akinfemi et al. [42] and Tuyena et al. [43]. The increase in EE of FTRS and AFTRS originates from fungi biomass. Fungi derive nutrients by decomposing and transforming OM into substances, including lipids [44,45]. Lipid compounds play vital functions in the fungal life cycle, occurring predominantly in the stationary growth phase [46]. Sancholle and Lösel [47] stated that during the colonization and growth of fungi on biomass, there is a rapid surge in the synthesis and accumulation of lipids within the fungi mycelium. The lipids remain in the substrate after the completion of the fungal life cycle. The increased EE of AFTRS in the present study contradicts the report of Kutlu et al. [27]. This was due to the inability of the fungi to successfully colonize the ammoniated wheat straw employed in this study.

Treating rice straw with ammonia and/or basidiomycete white-rot P. ostreatus fungi resulted in a general decline in all cell wall constituents. Yalchi [41] reported a decline in NDF and ADF using ammoniated triticale straw, which is coherent with the observations in the current study. According to Sarnklong et al. [6], ammonia triggers a collapse in the structure of lignocellulose due to its absorption into the cell walls of the straw, leading to the disruption of linkages between lignin and cellulose or hemicellulose.

Ammoniated rice straw (ARS) recorded a decline in lignin, cellulose, and hemicellulose. Several authors have equally reported a decrease in lignin [10,48], cellulose [24,49], and hemicellulose [50,51] in various ammoniated straws. According to Chundawat et al. [52], the decline in hemicellulose results from its depolymerization into oligosaccharides due to the cleavage of lignin–carbohydrate complex ester bonds and subsequent partial solubilization during the ammonia pretreatment process. Kumar et al. [53] specified that ammonia effectively degrades hemicellulose acetyl and uronic ester groups leading to its solubilization. According to Kim et al. [54], the decline in lignin is due to the increase in lignin solubility originating from the splitting of ether bonds in lignin or the disruption of ether/ester bonds within the lignin-hemicellulose-cellulose polysaccharide complex. Furthermore, ammonia acts selectively on lignin bonds, especially C-O-C bonds, and ester and ether bonds [54,55], which reduces lignin in the lignocellulose matrix. Cellulose loss results from the breakdown of ester and glycosidic side chains, which initiates cellulose structural alteration leading to its partial decrystallization and partial solvation [56]. A positive effect of a reduction in cellulose content is the enhanced access of cellulolytic microorganisms to the content of the cell wall [49], thus promoting fiber fermentation.

The decline in the cell wall constituents (NDF, ADF, ADL, C, and H) of FTRS in the present study is similar to reports by various authors [57,58,59]. The losses in the NDF and ADF from the straw suggest that the fungi could solubilize and utilize the contents of the cell wall as a carbon source and thus modify the soluble to insoluble carbohydrates fraction in the straw [60]. The decline in ADL, cellulose, and hemicellulose resulted from the basidiomycete white-rot fungi secretion of various ligninolytic enzymes (laccase, manganese peroxidase, ligninase) [61] and hydrolytic enzymes (cellulases) [62]. These enzymes are engaged in selective lignin degradation over cellulose and hemicellulose utilization as energy. Lignin biopolymer is converted to water and carbon dioxide [11]. This increases cellulose and the bioavailability of other substrate polymers for microbial/enzyme fermentation [63,64].

Ammoniated rice straw fermented with basidiomycete white-rot P. ostreatus (AFTRS) having the least cell wall constituents was expected. The combination in AFTRS achieving the most considerable loss in lignin and holocellulose implies that integration of ammonification and basidiomycete white-rot P. ostreatus treatment of straw resulted in a synergic effect evident in higher lignin removal/breakdown alongside the efficient utilization of holocellulose. The changes in the rice straw lignocellulose by ammonification provided better conditions for cell wall constituent degradation and, thus, helped the basidiomycete white-rot fungi obtain energy for growth. In addition, the rise in the CP of the substrate associated with the ammonia treatment could be sufficient to meet fungal nutritional and growth requirements for free amino nitrogen [65].

The pH is an essential indicator that reflects the rumen microenvironment. The pH values of the treatment groups in this study were not significantly different, which agrees with the findings of Vorlaphim et al. [66]. This shows that the effect of ammonia and/or basidiomycete white-rot P. ostreatus fungi treatment of rice straw on rumen pH was not evident in this study. The values in the current study, however, were all within the normal limit (>6.3) for ideal rumen metabolism [67].

In the present study, the treatments increased the IVDMD of rice straw. This observation is not surprising because lignin is responsible for the recalcitrant nature of straw [68] and hence its delignification would yield substrates with a high rumen digestibility depending on the extent of degradation/loss [69]. Liu et al. [10] reported an increase in IVDMD after ammonia treatment of corn straw, similar to the increased IVDMD of the ammoniated rice straw in this study. According to Chenost and Kayouli [37], ammonia treatment physically makes the structural fibers swollen and chemically breaks the ester bonds between the lignin and hemicellulose, and cellulose. These effects enable the rumen microbes to attack the structural carbohydrates more easily and thus increase digestibility. Other reasons associated with the improvements noted after the ammonification of cereal residues, including rice straw, are the collapse of vascular bundle sheath cells [70], rupture of inner cuticular surfaces and separation from adjacent ground parenchyma [71], modification in the friability of the stiff coating casing the inner surface of cell walls [72], the capability of ammonia to form ammonia–cellulose complex which aids in reducing the cellulose crystallinity [73] among others. Any decrease in the crystallinity of the cellulose that forms the cell wall’s microfibrils contributes to the fragility of the cell wall and consequently makes them more vulnerable to the action of cellulolytic bacteria [73].

The improvement in IVDMD of the FTRS in the present study is consistent with the report by Wen et al. [74]. In general, basidiomycetes white-rot fungi are the only fungi group capable of degrading lignin and its moiety (guaiacyl-, syringyl-, and p-hydroxyphenyl units) completely from the substrate [75]. P. ostreatus, a member of the basidiomycete white-rot fungi, degraded lignin most effectively due to its ability to produce extracellular ligninolytic oxidative enzymes [76]. The lignin is removed from the substrate as it is converted to water and carbon dioxide [11]. During lignin degradation, cellulose and hemicellulose are released and then attacked by fungal glycoside hydroxylases [77], thereby yielding substrate for microbes and potentially improving the IVDMD value of lignocellulosic biomass.

Ammoniated rice straw treated with basidiomycete white-rot P. ostreatus (AFTRS), compared to the other treatment groups, achieved markedly the highest IVDMD. Similarly, Rouzbehan et al. [36] reported a considerably higher IVDMD using ammoniated wheat straw treated with Pleurotus of Iranian tissue (TS2). The noticeable improvement in the IVDMD of the AFTRS is due to the ability of the fungi to degrade the lignin efficiently and, in the process, make the contents of the cell wall of the rice straw easily accessible and consequently increase the CP. Thus, ammonia combined with basidiomycete white-rot P. ostreatus fungi treatment of rice straw worked synergistically to achieve a protein-rich and highly delignified material whose structural polysaccharide can be easily hydrolyzed by rumen microbes.

The energy reserve for ruminants is VFA, which is the last product following carbohydrate fermentation and reflects the digestibility of feed. Feeds with a high digestibility produce high VFA [78]. The varying amounts of total VFA in different treatment groups correspond to the observed IVDMD and gas production. The increase in the total VFA of the ammonia and/or basidiomycete P. ostreatus fungi fermented rice straw in the present study is similar to the reports of Fariani et al. [79], Tampoebolon et al. [80], and Wen et al. [74], respectively. The increase in VFA production is mainly due to an increase in substrate digestibility. The total VFA of the AFTRS being markedly higher compared to the other treatment groups was expected. This is because rumen microbes have more access to fermentable carbohydrates when a substrate has a high digestibility value. This leads to a higher total VFA than when a substrate has a low digestibility.

Treatment of the rice straw with ammonia or basidiomycete white-rot P. ostreatus fungi resulted in a decline in the acetic acid with a concomitant increase in propionic acid. This is due to the decrease in cell wall constituents due to the treatment imposed. Wen et al. [74] reported a similar trend using wheat straw treated with P. ostreatus fungi. On the contrary, ammonia treatment of rice straw did not affect the acetic acid and propionic acid [81]. The nonsignificance was due to the high variation among the replicates [81]. The worth of a feed is not limited to its total VFA but its molar proportion, principally the A:P ratio. A lower A:P ratio is associated with a rise in feed efficiency in the rumen. Compared to the untreated straw, ammonification or treatment of rice straw with basidiomycete white-rot P. ostreatus fungi resulted in a decline in the A:P ratio. Griffith et al. [82] and Zuo et al. [83] reported a similar observation with ammoniated barley and corn stover treated with P. ostreatus, respectively. The AFTRS having considerably the least A:P ratio was expected because it achieved the least acetic acid and highest propionic acid values than the other treatments.

Branched-chain volatile fatty acids (BCVFA), isobutyrate, 2-methylbutyrate, and isovalerate, and the straight-chain valerate acid, which are collectively referred to as isoacids [84], are a by-product of amino acid deamination in the rumen [85]. These are essential for the growth of ruminal cellulolytic bacteria and, thus, their proliferation and action. The BCVFA of the AFTRS being markedly the highest compared to the other treatment groups is consistent with the report that diets with high crude protein yields increased BCVFA levels [86]. However, the higher proportion of BCVFA could be due to the higher amount of protein and not necessarily be related to the NH3 depending on the amino acid profile of the substrate tested in vitro [87]. Furthermore, since fungi protein is a rich source of amino acids, including Val, Ile, and Leu [88], it met the amino acid requirements of the cellulolytic bacteria, which in turn increased the BCVFA product yield. This establishes the BCVFA in FTRS and AFTRS being superior to that of the ATRS and UTRS.

In the rumen, in vitro gas production (IVGP) appears to be related to the chemical composition of the fiber, the lignin content of roughage feed [89] and its digestibility [90]. All the treatment groups recorded a progressive increase in the volume of gas produced. The rise in IVGP of ARS and FTRS in the present study is similar to the reports of Eun et al. [91] and Sufyan et al. [92], respectively. This is due to the decline in lignin content caused by the ammonia or basidiomycete white-rot P. ostreatus fungi treatment of rice straw leading to increased IVDMD. Lignin reduction decreases cell wall recalcitrance and allows the rumen microbes and/or their enzymes free access to cellulose and other polysaccharides for fermentation. The volume of gas produced was comparatively higher in the AFTRS than in the other treatment groups. This can be ascribed to the synergetic effect between the ammonification agent and basidiomycete white-rot fungi. This, to a much greater extent, achieved a considerably higher degree of lignin degradation and reduced cell wall constituents, as evident in a superior IVDMD compared to the other treatment groups.

Further research should be directed towards in vivo feeding trials at the farm level to ascertain animal performance and possible commercialization.

5. Conclusions

The ammoniated rice straw treated with basidiomycete white-rot P. ostreatus enhanced the digestibility of rice straw and its nutritive value compared to the other treatments. This is evident in the comparative increase in the CP, IVDMD, VFA, and in vitro gas production.

Author Contributions

Conceptualization, O.D., K.W. and S.M.; Data curation, O.D.; Formal analysis, O.D.; Methodology, O.D., Q.Y., K.W. and S.M.; Supervision, G.Z. and L.M.; Validation, O.D., Q.Y., K.W. and L.M.; Writing—original draft, O.D.; Writing—review and editing, O.D. and L.O.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the China Agriculture Research System of MOF and MARA.

Institutional Review Board Statement

The animal study protocol was approved by the Institutional Review Board (Animal Care and Use Committee) of Yangzhou University (Jiangsu, China).

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on reasonable request from the corresponding authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Karimi, K.; Emtiazi, G.; Taherzadeh, M. Ethanol production from dilute-acid pretreated rice straw by simultaneous saccharification and fermentation with Mucor indicus, Rhizopus oryzae, and Saccharomyces cerevisiae. Enzyme Microb. Technol. 2006, 40, 138–144. [Google Scholar] [CrossRef]

- Quayle, W.C. Alternative Management of Rice Straw. 2016. Available online: http://www.agrifutures.com.au/related-projects/alternative-management-of-rice-straw/ (accessed on 2 March 2020).

- Van Soest, P. Rice straw, the role of silica and treatments to improve quality. Anim. Feed Sci. Technol. 2006, 130, 137–171. [Google Scholar] [CrossRef]

- Subepang, S.; Suzuki, T.; Phonbumrung, T.; Sommart, K. Enteric methane emissions, energy partitioning, and energetic efficiency of zebu beef cattle fed total mixed ration silage. Asian-Australas. J. Anim. Sci. 2019, 32, 548. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Lu, C.; Ciais, P.; Michalak, A.M.; Canadell, J.G.; Saikawa, E.; Huntzinger, D.N.; Gurney, K.R.; Sitch, S.; Zhang, B. The terrestrial biosphere as a net source of greenhouse gases to the atmosphere. Nature 2016, 531, 225–228. [Google Scholar] [CrossRef]

- Sarnklong, C.; Cone, J.; Pellikaan, W.; Hendriks, W. Utilization of rice straw and different treatments to improve its feed value for ruminants. Asian-Australas. J. Anim. Sci. 2010, 23, 680–692. [Google Scholar] [CrossRef]

- Ma, Y.; Chen, X.; Khan, M.Z.; Xiao, J.; Liu, S.; Wang, J.; He, Z.; Li, C.; Cao, Z. The Impact of Ammoniation Treatment on the Chemical Composition and In Vitro Digestibility of Rice Straw in Chinese Holsteins. Animals 2020, 10, 1854. [Google Scholar] [CrossRef]

- Yamashita, D.; Kimura, S.; Wada, M.; Samejima, M.; Takabe, K. Effect of ammonia treatment on white birch wood. Holzforschung 2018, 72, 31–36. [Google Scholar] [CrossRef]

- Brodeur, G.; Yau, E.; Badal, K.; Collier, J.; Ramachandran, K.; Ramakrishnan, S. Chemical and physicochemical pretreatment of lignocellulosic biomass: A review. Enzyme Res. 2011, 2011, 787532. [Google Scholar] [CrossRef]

- Liu, J.; Liu, B.; Zhan, L.; Wang, P.; Ju, M.; Wu, W. Solid-state fermentation of ammoniated corn straw to animal feed by Pleurotus ostreatus Pl-5. BioResources 2017, 12, 1723–1736. [Google Scholar] [CrossRef]

- Hou, L.; Ji, D.; Dong, W.; Yuan, L.; Zhang, F.; Li, Y.; Zang, L. The Synergistic Action of Electro-Fenton and White-Rot Fungi in the Degradation of Lignin. Front. Bioeng. Biotechnol. 2020, 8, 99. [Google Scholar] [CrossRef]

- Nayan, N.; Sonnenberg, A.; Hendriks, W.; Cone, J. Screening of white-rot fungi for bioprocessing of wheat straw into ruminant feed. J. Appl. Microbiol. 2018, 125, 468–479. [Google Scholar] [CrossRef]

- Yoav, S.; Salame, T.M.; Feldman, D.; Levinson, D.; Ioelovich, M.; Morag, E.; Yarden, O.; Bayer, E.A.; Hadar, Y. Effects of cre1 modification in the white-rot fungus Pleurotus ostreatus PC9: Altering substrate preference during biological pretreatment. Biotechnol. Biofuels 2018, 11, 212. [Google Scholar] [CrossRef]

- Khonkhaeng, B.; Cherdthong, A. Pleurotus Ostreatus and Volvariella Volvacea Can Enhance the Quality of Purple Field Corn stover and Modulate Ruminal Fermentation and Feed Utilization in Tropical Beef cattle. Animals 2019, 9, 1084. [Google Scholar] [CrossRef]

- Khonkhaeng, B.; Cherdthong, A. Improving Nutritive Value of Purple Field Corn Residue and Rice Straw by Culturing with White-Rot Fungi. J. Fungi 2020, 6, 69. [Google Scholar] [CrossRef]

- Buthane, T.F.; Motsei, L.E.; Mnisi, C.M.; Ravhuhali, K.E. Effect of anhydrous ammonia gas treatment of low-quality cereal straws on chemical composition and in vitro ruminal fermentation. Range Manag. Agrofor. 2021, 42, 150–156. [Google Scholar]

- Muthia, D.; Laconi, E.; Ridla, M.; Jayanegara, A.; Ridwan, R.; Fidriyanto, R.; Abdelbagi, M.; Ramdani, H. Effect of combining autoclave and ammoniation on nutritional value and in vitro digestibility of rice straw. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Makassar, Indonesia, 3–4 November 2020; p. 012052. [Google Scholar]

- Oei, P. Mushroom Cultivation with Special Emphasis on Appropriate Techniques for Developing Countries; Tool Publications: Leiden, The Netherlands, 1996; pp. 3–5. [Google Scholar]

- Association of Official Analytical Chemists. Official Methods of Analysis of the Association of Official Analytical Chemists, 16th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1995. [Google Scholar]

- Van Soest, P.; Robertson, J.; Lewis, B. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Menke, K.; Raab, L.; Salewski, A.; Steingass, H.; Fritz, D.; Schneider, W. The estimation of the digestibility and metabolizable energy content of ruminant feedingstuffs from the gas production when they are incubated with rumen liquor in vitro. J. Agric. Sci. 1979, 93, 217–222. [Google Scholar] [CrossRef]

- Theodorou, M.K.; Williams, B.A.; Dhanoa, M.S.; McAllan, A.B.; France, J. A simple gas production method using a pressure transducer to determine the fermentation kinetics of ruminant feeds. Anim. Feed Sci. Technol. 1994, 48, 185–197. [Google Scholar] [CrossRef]

- Filho, M.A.M.; Alves, A.A.; Vale, G.E.S.d.; Moreira, A.L.; Rogério, M.C.P. Nutritional value of hay from maize-crop stubble ammoniated with urea. Rev. Cienc. Agron. 2013, 44, 893–901. [Google Scholar] [CrossRef][Green Version]

- Hassan, S.A.; Sadq, S.M.; Hassan, K.M. Evaluation of Fungal or Chemical Treatments for Barley Straw in Ruminants Feeding 1-Chemical composition, in vitro, in vivo digestibility and voluntary intake. JJAS 2012, 8, 232–241. [Google Scholar]

- Fazaeli, H. Nutritive value index of treated wheat straw with Pleurotus fungi. Biotechnol. Anim. Husb. 2007, 23, 169–180. [Google Scholar] [CrossRef]

- Isroi, I.; Millati, R.; Niklasson, C.; Cayanto, C.; Taherzadeh, M.J.; Lundquist, K. Biological treatment of Lignocelluloses with white-rot fungi and its applications. BioResources 2011, 6, 5224–5259. [Google Scholar] [CrossRef]

- Kutlu, H.R.; Görgülü, M.; Baykal, L.; Özcan, N.; Büyükalaca, S. Effects of Pleurotus florida inoculation or urea treatment on feeding value of wheat straw. Turk. J. Vet. Anim. Sci. 2000, 24, 169–176. [Google Scholar]

- Dean, D.; Adesogan, A.; Krueger, N.; Littell, R. Effects of treatment with ammonia or fibrolytic enzymes on chemical composition and ruminal degradability of hays produced from tropical grasses. Anim. Feed Sci. Technol. 2008, 145, 68–83. [Google Scholar] [CrossRef]

- Belewu, M.; Belewu, K. Cultivation of mushroom (Volvariella volvacea) on banana leaves. Afr. J. Biotechnol. 2005, 4, 1401–1403. [Google Scholar] [CrossRef]

- Akinfemi, A.; Ogunwole, O. Chemical composition and in vitro digestibility of rice straw treated with Pleurotus ostreatus, Pleurotus pulmonarius and Pleurotus tuber-regium. Slovak J. Anim. Sci. 2012, 45, 14–20. [Google Scholar]

- Akinfemi, A. Bioconversion of peanut husk with white rot fungi: Pleurotus ostreatus and Pleurotus pulmonarius. Livest. Res. Rural. Dev. 2010, 22, 1–11. [Google Scholar]

- Siddhant, C.; Singh, S. Recycling of spent oyster mushroom substrate to recover additional value. KUSET 2009, 5, 66–71. [Google Scholar]

- Ragunathan, R.; Gurusamy, R.; Palaniswamy, M.; Swaminathan, K. Cultivation of Pleurotus spp. on various agro-residues. Food Chem. 1996, 55, 139–144. [Google Scholar] [CrossRef]

- Chang, S.T.; Miles, P.G. Mushrooms: Cultivation, Nutritional Value, Medicinal Effect, and Environmental Impact, 2nd ed.; CRC press: Boca Raton, FL, USA, 2004; p. 480. [Google Scholar]

- Wan, C.; Li, Y. Microbial delignification of corn stover by Ceriporiopsis subvermispora for improving cellulose digestibility. Enzyme Microb. Technol. 2010, 47, 31–36. [Google Scholar] [CrossRef]

- Rouzbehan, Y.; Fazaeli, H.; Kiani, A. The chemical composition and digestibility of wheat straw treated with urea and white rot fungi. Proc. Br. Soc. Anim. Sci. 2001, 2001, 123. [Google Scholar] [CrossRef]

- Chenost, M.; Kayouli, C. Roughage Utilization in Warm Climates; FAO: Rome, Italy, 1997. [Google Scholar]

- Velázquez-De Lucio, B.S.; Hernandez-Dominguez, E.M.; Tellez-Jurado, A.; Ayala-Martinez, M.; Soto-Simental, S.; Cervantes, J.Á. Protein fraction, mineral profile, and chemical compositions of various fiber-based substrates degraded by Pleurotus ostreatus. BioResources 2020, 15, 8849–8861. [Google Scholar] [CrossRef]

- Ruggeri, B.; Sassi, G. Experimental sensitivity analysis of a trickle bed bioreactor for lignin peroxidases production by P. chrysosporium. Process Biochem. 2003, 38, 1669–1676. [Google Scholar] [CrossRef]

- Suksombat, W. Comparison of Different Alkali Treatment of Bagasse and Rice Straw. Asian-Australas. J. Anim. Sci. 2004, 17, 1430–1433. [Google Scholar] [CrossRef]

- Yalchi, T. Effects of urea and aqueous ammonia treatment on the nutritive value of triticale straw. J. Food Agric. Environ. 2010, 8, 69–72. [Google Scholar]

- Akinfemi, A.; Adu, O.; Adebiyi, O. Use of white rot-fungi in upgrading maize straw and, the resulting impact on chemical composition and in vitro digestibility. Livest. Res. Rural. Dev. 2009, 21, 162. [Google Scholar]

- Tuyena, V.; Phuong, H.; Cone, J.; Baars, J.; Sonnenberg, A.; Hendriks, W. Effect of fungal treatments of fibrous agricultural by-products on chemical composition and in vitro rumen fermentation and methane production. Bioresour. Technol. 2013, 129, 256–263. [Google Scholar] [CrossRef]

- Beccaccioli, M.; Reverberi, M.; Scala, V. Fungal lipids: Biosynthesis and signalling during plant-pathogen interaction. Front. Biosci. 2019, 24, 172–185. [Google Scholar] [CrossRef]

- Gutiérrez, A.; Del Rio, J.C.; Martínez-Íñigo, M.J.; Martínez, M.J.; Martínez, Á.T. Production of new unsaturated lipids during wood decay by ligninolytic basidiomycetes. Appl. Environ. Microbiol. 2002, 68, 1344–1350. [Google Scholar] [CrossRef]

- Fagone, P.; Jackowski, S. Membrane phospholipid synthesis and endoplasmic reticulum function. J. Lipid Res. 2009, 50, S311–S316. [Google Scholar] [CrossRef]

- Sancholle, M.; Lösel, D. Lipids in fungal biotechnology. In The Mycota II Genetics and Biotechnology; Kück, U., Ed.; Springer: Berlin/Heidelberg, Germany, 1995; pp. 339–367. [Google Scholar]

- Sipponen, M.H.; Österberg, M. Aqueous Ammonia pre-treatment of wheat straw: Process optimization and broad spectrum dye adsorption on nitrogen-containing lignin. Front. Chem. 2019, 7, 545. [Google Scholar] [CrossRef]

- Oji, U.; Etim, H.; Okoye, F. Effects of urea and aqueous ammonia treatment on the composition and nutritive value of maize residues. Small Rumin. Res. 2007, 69, 232–236. [Google Scholar] [CrossRef]

- Zhao, C.; Shao, Q.; Chundawat, S.P. Recent advances on ammonia-based pretreatments of lignocellulosic biomass. Bioresour. Technol. 2020, 298, 122446. [Google Scholar] [CrossRef]

- Yuan, H.; Li, R.; Zhang, Y.; Li, X.; Liu, C.; Meng, Y.; Lin, M.; Yang, Z. Anaerobic digestion of ammonia-pretreated corn stover. Biosyst. Eng. 2015, 129, 142–148. [Google Scholar] [CrossRef]

- Chundawat, S.P.; Donohoe, B.S.; da Costa Sousa, L.; Elder, T.; Agarwal, U.P.; Lu, F.; Ralph, J.; Himmel, M.E.; Balan, V.; Dale, B.E. Multi-scale visualization and characterization of lignocellulosic plant cell wall deconstruction during thermochemical pretreatment. Energy Environ. Sci. 2011, 4, 973–984. [Google Scholar] [CrossRef]

- Kumar, R.; Mago, G.; Balan, V.; Wyman, C.E. Physical and chemical characterizations of corn stover and poplar solids resulting from leading pretreatment technologies. Bioresour. Technol. 2009, 100, 3948–3962. [Google Scholar] [CrossRef]

- Kim, T.H.; Kim, J.S.; Sunwoo, C.; Lee, Y. Pretreatment of corn stover by aqueous ammonia. Bioresour. Technol. 2003, 90, 39–47. [Google Scholar] [CrossRef]

- Gao, A.H.; Bule, M.V.; Laskar, D.D.; Chen, S. Structural and thermal characterization of wheat straw pretreated with aqueous ammonia soaking. J. Agric. Food Chem. 2012, 60, 8632–8639. [Google Scholar] [CrossRef]

- Ibrahim, M.M.; El-Zawawy, W.K.; Abdel-Fattah, Y.R.; Soliman, N.A.; Agblevor, F.A. Comparison of alkaline pulping with steam explosion for glucose production from rice straw. Carbohydr. Polym. 2011, 83, 720–726. [Google Scholar] [CrossRef]

- Niu, D.; Zuo, S.; Jiang, D.; Tian, P.; Zheng, M.; Xu, C. Treatment using white rot fungi changed the chemical composition of wheat straw and enhanced digestion by rumen microbiota in vitro. Anim. Feed Sci. Technol. 2018, 237, 46–54. [Google Scholar] [CrossRef]

- Sharma, R.K.; Arora, D.S. Fungal degradation of lignocellulosic residues: An aspect of improved nutritive quality. Crit. Rev. Microbiol. 2015, 41, 52–60. [Google Scholar] [CrossRef]

- Zheng, M.; Zuo, S.; Niu, D.; Jiang, D.; Tao, Y.; Xu, C. Effect of Four Species of White Rot Fungi on the Chemical Composition and In Vitro Rumen Degradability of Naked Oat Straw. Waste Biomass Valorization 2021, 12, 435–443. [Google Scholar] [CrossRef]

- Taniguchi, M.; Suzuki, H.; Watanabe, D.; Sakai, K.; Hoshino, K.; Tanaka, T. Evaluation of pretreatment with Pleurotus ostreatus for enzymatic hydrolysis of rice straw. J. Biosci. Bioeng. 2005, 100, 637–643. [Google Scholar] [CrossRef]

- Cui, T.; Yuan, B.; Guo, H.; Tian, H.; Wang, W.; Ma, Y.; Li, C.; Fei, Q. Enhanced lignin biodegradation by consortium of white rot fungi: Microbial synergistic effects and product mapping. Biotechnol. Biofuels 2021, 14, 162. [Google Scholar] [CrossRef]

- Okal, E.J.; Aslam, M.M.; Karanja, J.K.; Nyimbo, W. Mini review: Advances in understanding regulation of cellulase enzyme in white-rot basidiomycetes. Microb. Pathog. 2020, 147, 104410. [Google Scholar] [CrossRef]

- Sharma, R.K.; Arora, D.S. Production of lignocellulolytic enzymes and enhancement of in vitro digestibility during solid state fermentation of wheat straw by Phlebia floridensis. Bioresour. Technol. 2010, 101, 9248–9253. [Google Scholar] [CrossRef]

- Ding, C.; Wang, X.; Li, M. Evaluation of six white-rot fungal pretreatments on corn stover for the production of cellulolytic and ligninolytic enzymes, reducing sugars, and ethanol. Appl. Microbiol. Biotechnol. 2019, 103, 5641–5652. [Google Scholar] [CrossRef]

- Taylor, F.; Kim, T.H.; Abbas, C.A.; Hicks, K.B. Liquefaction, saccharification, and fermentation of ammoniated corn to ethanol. Biotechnol. Prog. 2008, 24, 1267–1271. [Google Scholar] [CrossRef]

- Vorlaphim, T.; Paengkoum, P.; Purba, R.A.P.; Yuangklang, C.; Paengkoum, S.; Schonewille, J.T. Treatment of rice stubble with Pleurotus ostreatus and urea improves the growth performance in slow-growing goats. Animals 2021, 11, 1053. [Google Scholar] [CrossRef]

- Valente, T.N.P.; da Silva Lima, E.; dos Santos, W.B.R.; Cesario, A.S.; Tavares, C.J.; Italo, L.F.; de Freitas, M.A.M. Ruminal microorganism consideration and protein used in the metabolism of the ruminants: A review. Afr. J. Microbiol. Res. 2016, 10, 456–464. [Google Scholar] [CrossRef]

- Zoghlami, A.; Paës, G. Lignocellulosic biomass: Understanding recalcitrance and predicting hydrolysis. Front. Chem. 2019, 7, 874. [Google Scholar] [CrossRef] [PubMed]

- Hakkila, P. Utilization of Residual Forest Biomass, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Itoh, H.; Terashima, Y.; Hayashizaki, A.J. Ammoniated rice straw and rice hulls and rumen microbial degradation investigated by scanning electron microscopy. Jpn. J. Zootech. Sci. 1981, 52, 671–679. [Google Scholar]

- Harbers, L.; Kreitner, G.; Davis Jr, G.; Rasmussen, M.; Corah, L. Ruminal digestion of ammonium hydroxide-treated wheat straw observed by scanning electron microscopy. J. Anim. Sci. 1982, 54, 1309–1319. [Google Scholar] [CrossRef]

- Goto, M.; Yokoe, Y.; Takabe, K.; Nisikawa, S.; Morita, O. Effects of gaseous ammonia on chemical and structural features of cell walls in spring barley straw. Anim. Feed Sci. Technol. 1993, 40, 207–221. [Google Scholar] [CrossRef]

- Isogai, A.; Usuda, M. X-ray-diffraction and solid-state C-13-NMR analyses of celluloses treated with ammonia. J. Japan Wood Soc. 1992, 38, 562–569. [Google Scholar]

- Wen, J.; Zhang, X.; Wang, M.; Wang, R.; Long, D.; Deng, J.; Tan, Z. Effects of pleurotus ostreatus treatment of wheat and rice straw on fiber composition and in vitro rumen fermentation characteristics. Chin. J. Anim. Nutr. 2019, 31, 892–899. [Google Scholar]

- Dashtban, M.; Schraft, H.; Syed, T.A.; Qin, W. Fungal biodegradation and enzymatic modification of lignin. Int. J. Biochem. Mol. 2010, 1, 36–50. [Google Scholar]

- Xiao, Q.; Ma, F.; Li, Y.; Yu, H.; Li, C.; Zhang, X. Differential proteomic profiles of Pleurotus ostreatus in response to lignocellulosic components provide insights into divergent adaptive mechanisms. Front. Microbiol. 2017, 8, 480. [Google Scholar] [CrossRef]

- Kubicek, C.P. Fungi and Lignocellulosic Biomass, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Tillman, A.; Hartadi, H.; Reksohadiprodjo, S.; Prawirokusumo, S.; Lebdosoekojo, S. Ilmu Makanan Ternak Dasar, 2nd ed.; Gadjah Mada University Press: Yogyakarta, Indonesia, 1998. [Google Scholar]

- Fariani, A.; Pratama, A.N.T.; Muslim, G. The multi-level ammoniation on the digestibility of palm press fiber. J. Adv. Vet. Anim. Res. 2021, 8, 230. [Google Scholar] [CrossRef]

- Tampoebolon, B.; Prasetiyono, B.; Mukodiningsih, S. The effect of fermentation with different times of corn husk which has obtained ammoniation treatment in the production of VFA-NH3 by in vitro digestibility. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Makassar, Indonesia, 6–7 November 2019; p. 012073. [Google Scholar]

- Jayanegara, A.; Krisnawan, N.; Widyawati, Y.; Sudarman, A. Ammoniation of rice straw and supplementation of Paraserianthes falcataria and Sapindus rarak on in vitro rumen fermentation and methane production. Bul. Peternak. 2017, 41, 420–430. [Google Scholar] [CrossRef][Green Version]

- Griffith, C.; Ribeiro, G., Jr.; Oba, M.; McAllister, T.; Beauchemin, K. Fermentation of ammonia fiber expansion treated and untreated barley straw in a rumen simulation technique using rumen inoculum from cattle with slow versus fast rate of fiber disappearance. Front. Microbiol. 2016, 7, 1839. [Google Scholar] [CrossRef]

- Zuo, S.; Niu, D.; Zheng, M.; Jiang, D.; Tian, P.; Li, R.; Xu, C. Effect of Irpex lacteus, Pleurotus ostreatus and Pleurotus cystidiosus pretreatment of corn stover on its improvement of the in vitro rumen fermentation. J. Sci. Food Agric. 2018, 98, 4287–4295. [Google Scholar] [CrossRef]

- Andries, J.; Buysse, F.; De Brabander, D.; Cottyn, B. Isoacids in ruminant nutrition: Their role in ruminal and intermediary metabolism and possible influences on performances—A review. Anim. Feed Sci. Technol. 1987, 18, 169–180. [Google Scholar] [CrossRef]

- Tedeschi, L.; Fox, D.; Russell, J. Accounting for the effects of a ruminal nitrogen deficiency within the structure of the Cornell Net Carbohydrate and Protein System. J. Anim. Sci. 2000, 78, 1648–1658. [Google Scholar] [CrossRef]

- Yang, C.-M. Response of forage fiber degradation by ruminal microorganisms to branched-chain volatile fatty acids, amino acids, and dipeptides. J. Dairy Sci. 2002, 85, 1183–1190. [Google Scholar] [CrossRef]

- Vastolo, A.; Calabrò, S.; Pacifico, S.; Koura, B.I.; Cutrignelli, M.I. Chemical and nutritional characteristics of Cannabis sativa L. co-products. J. Anim. Physiol. Anim. Nutr. 2021, 105, 1–9. [Google Scholar] [CrossRef]

- Khattab, H.; Gado, H.; Salem, A.; Camacho, L.; El-Sayed, M.; Kholif, A.; El-Shewy, A.; Kholif, A. Chemical composition and in vitro digestibility of Pleurotus ostreatus spent rice straw. Anim. Nutr. Feed Technol. 2013, 13, 507–516. [Google Scholar]

- Elghandour, M.M.; Chagoyán, J.C.V.; Salem, A.Z.; Kholif, A.E.; Castañeda, J.S.M.; Camacho, L.M.; Cerrillo-Soto, M.A. Effects of Saccharomyces cerevisiae at direct addition or pre-incubation on in vitro gas production kinetics and degradability of four fibrous feeds. Ital. J. Anim. Sci. 2014, 13, 3075. [Google Scholar] [CrossRef]

- Cone, J.W.; van Gelder, A.H. Influence of protein fermentation on gas production profiles. Anim. Feed Sci. Technol. 1999, 76, 251–264. [Google Scholar] [CrossRef]

- Eun, J.-S.; Beauchemin, K.; Hong, S.-H.; Bauer, M. Exogenous enzymes added to untreated or ammoniated rice straw: Effects on in vitro fermentation characteristics and degradability. Anim. Feed Sci. Technol. 2006, 131, 87–102. [Google Scholar] [CrossRef]

- Sufyan, A.; Ahmad, N.; Shahzad, F.; Embaby, M.G.; AbuGhazaleh, A.; Khan, N.A. Improving the nutritional value and digestibility of wheat straw, rice straw, and corn cob through solid state fermentation using different Pleurotus species. J. Sci. Food Agric. 2021, 102, 2445–2453. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).