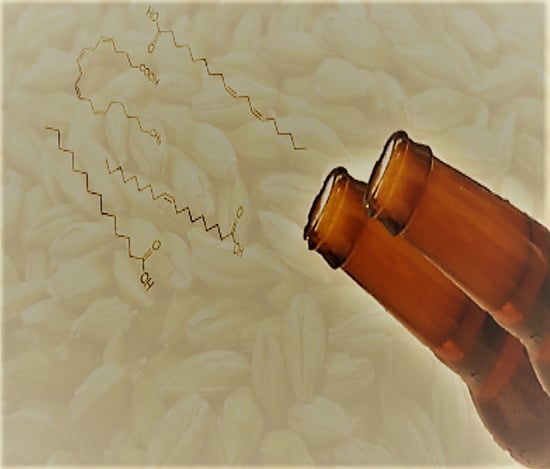

A Review on the Source of Lipids and Their Interactions during Beer Fermentation that Affect Beer Quality

Abstract

1. Introduction

2. Barley Grain

3. Effect of Climate on Grain Composition and Lipids

4. Lipids during Fermentation Affecting the Beer Flavour Profile and Quality

5. Lipids and Their Role in Beer Foam

6. Concluding Remarks

Funding

Acknowledgments

Conflicts of Interest

References

- Briggs, D.E. Malts and Malting; Springer Science & Business Media: Berlin, Germany, 1998. [Google Scholar]

- Food Agriculture Organization. Cereal Supply and Demand Brief. 2017. Available online: http://www.fao.org/worldfoodsituation/csdb/en/ (accessed on 2 October 2017).

- Awika, J.M. Major Cereal Grains Production and Use around the World. In Advances in Cereal Science: Implications to Food Processing and Health Promotion; American Chemical Society: Washington, DC, USA, 2011; pp. 1–13. [Google Scholar]

- Briggs, D.E.; Brookes, P.A.; Stevens, R.; Boulton, C.A. Brewing: Science and Practice; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Fox, G.P.; Panozzo, J.F.; Li, C.D.; Lance, R.C.; Inkerman, P.A.; Henry, R.J. Molecular basis of barley quality. Aust. J. Agric. Res. 2003, 54, 1081–1101. [Google Scholar] [CrossRef]

- Halford, N.G.; Curtis, T.Y.; Chen, Z.; Huang, J. Effects of abiotic stress and crop management on cereal grain composition: Implications for food quality and safety. J. Exp. Bot. 2015, 66, 1145–1156. [Google Scholar] [CrossRef] [PubMed]

- Porter, J.R.; Xie, L.; Challinor, A.J.; Cochrane, K.; Howden, S.M.; Iqbal, M.M.; Lobell, D.B.; Travasso, M.I.; Netra Chhetri, N.C.; Garrett, K.; et al. Food Security and Food Production Systems. In Climate Change 2014: Impacts, Adaptation, and Vulnerability. Part A: Global and Sectoral Aspects; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014; pp. 485–533. [Google Scholar]

- Hasanuzzaman, M.; Nahar, K.; Alam, M.M.; Roychowdhury, R.; Fujita, M. Physiological, biochemical, and molecular mechanisms of heat stress tolerance in plants. Int. J. Mol. Sci. 2013, 14, 9643–9684. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.-M.; Lo, S.-F.; Ho, T.-H.D. Source–sink communication: Regulated by hormone, nutrient, and stress cross-signaling. Trends Plant Sci. 2015, 20, 844–857. [Google Scholar] [CrossRef] [PubMed]

- Högy, P.; Poll, C.; Marhan, S.; Kandeler, E.; Fangmeier, A. Impacts of temperature increase and change in precipitation pattern on crop yield and yield quality of barley. Food Chem. 2013, 136, 1470–1477. [Google Scholar] [CrossRef] [PubMed]

- Bencze, S.; Veisz, O.; Bedő, Z. Effects of high atmospheric CO2 and heat stress on phytomass, yield and grain quality of winter wheat. Cereal Res. Commun. 2004, 32, 75–82. [Google Scholar]

- Olesen, J.E.; Trnka, M.; Kersebaum, K.C.; Skjelvåg, A.O.; Seguin, B.; Peltonen-Sainio, P.; Rossi, F.; Kozyra, J.; Micale, F. Impacts and adaptation of European crop production systems to climate change. Eur. J. Agron. 2011, 34, 96–112. [Google Scholar] [CrossRef]

- Zhang, B.; Li, X.; Liu, J.; Xie, F.; Chen, L. Supramolecular structure of A- and B-type granules of wheat starch. Food Hydrocoll. 2013, 31, 68–73. [Google Scholar] [CrossRef]

- Koehler, P.; Wieser, H. Chemistry of Cereal Grains. In Handbook on Sourdough Biotechnology; Gobbetti, M., Gänzle, M., Eds.; Springer: Boston, MA, USA, 2013; pp. 11–45. [Google Scholar]

- Buléon, A.; Colonna, P.; Planchot, V.; Ball, S. Starch granules: Structure and biosynthesis. Int. J. Biol. Macromol. 1998, 23, 85–112. [Google Scholar] [CrossRef]

- Herb, D.; Filichkin, T.; Fisk, S.; Helgerson, L.; Hayes, P.; Meints, B.; Jennings, R.; Monsour, R.; Tynan, S.; Vinkemeier, K.; et al. Effects of barley (Hordeum vulgare L.) variety and growing environment on beer flavor. J. Am. Soc. Brew. Chem. 2017, 75, 345–353. [Google Scholar] [CrossRef]

- Yangcheng, H.; Gong, L.; Zhang, Y.; Jane, J.L. Pysicochemical properties of Tibetan hull-less barley starch. Carbohydr. Polym. 2016, 137, 525–531. [Google Scholar] [CrossRef] [PubMed]

- Bravi, E.; Marconi, O.; Perretti, G.; Fantozzi, P. Influence of barley variety and malting process on lipid content of malt. Food Chem. 2012, 135, 1112–1117. [Google Scholar] [CrossRef] [PubMed]

- Evans, D.E.; Goldsmith, M.; Redd, K.S.; Nischwitz, R.; Lentini, A. Impact of mashing conditions on extract, its fermentability, and the levels of wort free amino nitrogen (fan), beta-glucan, and lipids. J. Am. Soc. Brew. Chem. 2012, 70, 39–49. [Google Scholar]

- Yano, M.; Morikawa, M.; Yasui, T.; Ogawa, Y.; Ohkochi, M. Influence of wort oiling and wort clarification conditions on cardboard flavor in beer. Master Brew. Assoc. Am. Tech. Q. 2004, 41, 317–320. [Google Scholar]

- Brennan, C.S.; Harris, N.; Smith, D.; Shewry, P.R. Structural differences in the mature endosperms of good and poor malting barley cultivars. J. Cereal Sci. 1996, 24, 171–177. [Google Scholar] [CrossRef]

- DeVries, K. Determination of free fatty acids in wort and beer. J. Am. Soc. Brew. Chem. 1990, 48, 13–17. [Google Scholar] [CrossRef]

- Vanderhaegen, B.; Neven, H.; Verachtert, H.; Derdelinckx, G. The chemistry of beer aging—A critical review. Food Chem. 2006, 95, 357–381. [Google Scholar] [CrossRef]

- Gallardo, E.; De Shutter, D.P.; Zamora, R.; Derdelinckx, G.; Delvaux, F.R.; Hidalgo, F.J. Influence of lipids in the generation of phenylacetaldehyde in wort-related model systems. J. Agric. Food Chem. 2008, 56, 3155–3159. [Google Scholar] [CrossRef] [PubMed]

- Cozzolino, D.; Roumeliotis, S.; Eglinton, J.K. The role of total lipids and fatty acids profile on the water uptake of barley grain during steeping. Food Chem. 2014, 151, 231–235. [Google Scholar] [CrossRef] [PubMed]

- Cozzolino, D.; Roumeliotis, S.; Eglinton, J. A novel approach to monitor the hydrolysis of barley (Hordeum vulgare L) malt: A chemometrics approach. J. Agric. Food Chem. 2014, 62, 11730–11736. [Google Scholar] [CrossRef] [PubMed]

- Debet, M.R.; Gidley, M.J. Three classes of starch granule swelling: Influence of surface proteins and lipids. Carbohydr. Polym. 2006, 64, 452–465. [Google Scholar] [CrossRef]

- Bravi, E.; Perretti, G.; Buzzini, P.; Della Sera, R.; Fantozzi, P. Technological steps and yeast biomass as factors affecting the lipid content of beer during the brewing process. J. Agric. Food Chem. 2009, 57, 6279–6284. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, N.; Kaneda, H.; Kano, Y.; Koshino, S. Determination of fatty acid hydroperoxides produced during the production of wort. J. Inst. Brew. 1993, 99, 143–146. [Google Scholar] [CrossRef]

- Evans, D.E.; Redd, K.; Haraysmow, S.E.; Elvig, N.; Metz, N.; Koutoulis, A. The influence of malt quality on malt brewing and barley quality on barley brewing with Ondea Pro, compared by small-scale analysis. J. Am. Soc. Brew. Chem. 2014, 72, 192–207. [Google Scholar] [CrossRef]

- Yu, W.; Tan, X.; Zou, W.; Hu, Z.; Fox, G.P.; Gidley, M.J.; Gilbert, R.G. Relationships between protein content, starch molecular structure and grain size in barley. Carbohydr. Polym. 2017, 155, 271–279. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Christensen, D.A.; McKinnon, J.J.; Beattie, A.D.; Yu, P. Predicted truly absorbed protein supply to dairy cattle from hulless barley (Hordeum vulgare L.) with altered carbohydrate traits with multi-year samples. J. Cereal Sci. 2013, 58, 372–379. [Google Scholar] [CrossRef]

- Yan, X.; Shi, H.; Zhang, F.; Ying, Y.; Zhang, W.; Yu, P. Effect of durations of microwave irradiation (3 and 5 min) on truly absorbable nutrient supply of newly developed hulless barley varieties (Hordeum vulgare L.) in comparison with conventional hulled barley variety. J. Cereal Sci. 2018, 79, 424–430. [Google Scholar] [CrossRef]

- Yang, L.; McKinnon, J.J.; Christensen, D.A.; Beattie, A.D.; Yu, P. Characterizing the molecular structure features of newly developed hulless barley cultivars with altered carbohydrate traits (Hordeum vulgare L.) by globar-sourced infrared spectroscopy in relation to nutrient utilization and availability. J. Cereal Sci. 2014, 60, 48–59. [Google Scholar] [CrossRef]

- Cozzolino, D.; Roumeliotis, S.; Eglinton, J. Relationships between fatty acid contents of barley grain, malt, and wort with malt quality measurements. Cereal Chem. 2015, 92, 93–97. [Google Scholar] [CrossRef]

- Briggs, D.E.; Hough, J.S.; Stevens, R.; Young, T.W. Malting and Brewing Science, 2nd ed.; Malt and Sweet Wort; Chapman & Hall: London, UK, 1995. [Google Scholar]

- Muller, M.P.; Schmid, F.; Becker, T.; Gastl, M. Impact of different hop compounds on the over foaming volume of beer caused by primary gushing. J. Inst. Brew. 2010, 116, 459–463. [Google Scholar] [CrossRef]

- Evans, D.E.; Bamforth, C.W. Beer foam: Achieving a suitable head. In Handbook of Alcoholic Beverages: Beer, a Quality Perspective; Bamforth, C.W., Russel, I., Stewart, G.G., Eds.; Elsevier: Burlington, MA, USA, 2009; pp. 1–60. [Google Scholar]

- Mills, E.N.C.; Gao, C.; Wilde, P.J.; Rigby, N.M.; Wijesinha-Bettoni, R.; Johnson, V.E.; Smith, L.J.; Mackie, A.R. Partially folded forms of barley lipid transfer protein are more surface active. Biochemistry 2009, 48, 12081–12088. [Google Scholar] [CrossRef] [PubMed]

- Garbe, L.A.; Barbosa De Almeida, R.; Nagel, R.; Wackerbauer, K.; Tressl, R. Dual positional and stereospecificity of lipoxygenase isoenzymes from germinating barley (green malt): Biotransformation of free and esterified linoleic acid. J. Agric. Food Chem. 2006, 54, 946–955. [Google Scholar] [CrossRef] [PubMed]

- Segawa, S.; Yamashita, S.; Mitani, Y.; Masachika, T. Analysis of detrimental effect on head retention by low molecular weight surface-active substances using surface excess. J. Am. Soc. Brew. Chem. 2002, 60, 31–36. [Google Scholar] [CrossRef]

- Cooper, D.J.; Husband, F.A.; Mills, E.N.C.; Wilde, P.J. Role of beer lipid-binding proteins in preventing lipid destabilization of foam. J. Agric. Food Chem. 2002, 50, 7645–7650. [Google Scholar] [CrossRef] [PubMed]

- Bamforth, C.W. The foaming properties of beer. J. Inst. Brew. 1985, 91, 370–383. [Google Scholar] [CrossRef]

- Roberts, R.T.; Keeney, P.J.; Wainwright, T. The effects of lipids and related materials on beer foam. J. Inst. Brew. 1978, 8, 9–12. [Google Scholar] [CrossRef]

- Dickie, K.H.; Cann, C.; Norman, E.C.; Bamforth, C.W.; Muller, R.E. Foam negative materials. J. Am. Soc. Brew. Chem. 2001, 59, 17–23. [Google Scholar] [CrossRef]

- Nieuwoudt, M.; Lombard, N.; Rautenbach, M. Optimised purification and characterisation of lipid transfer protein 1 (LTP1) and its lipid-bound isoform LTP1b from barley malt. Food Chem. 2014, 157, 559–567. [Google Scholar] [CrossRef] [PubMed]

- Lindorff-Larsen, K.; Lerche, M.H.; Poulsen, F.M.; Roepstorff, P.; Winther, J.R. Barley lipid transfer protein, LTP1, contains a new type of lipid-like post-translational modification. J. Biol. Chem. 2001, 276, 33547–33553. [Google Scholar] [CrossRef] [PubMed]

- Lindorff-Larsen, K.; Winther, J.R. Surprisingly high stability of barley lipid transfer protein, LTP1, towards denaturant, heat and proteases. FEBS Lett. 2001, 488, 145–148. [Google Scholar] [CrossRef]

- Jegou, S.; Douliez, J.P.; Molle, D.; Boivin, P.; Marion, D. Purification and structural characterization of LTP1 polypeptides from beer. J. Agric. Food Chem. 2000, 48, 5023–5029. [Google Scholar] [CrossRef] [PubMed]

- Stanislava, G. Barley grain non-specific lipid-transfer proteins (ns-LTPs) in beer production and quality. J. Inst. Brew. 2007, 113, 310–324. [Google Scholar] [CrossRef]

- Perrocheau, L.; Bakan, B.; Boivin, P.; Marion, D. Stability of barley and malt lipid transfer protein 1 (LTP1) towards heating and reducing agents: Relationships with the brewing process. J. Agric. Food Chem. 2006, 54, 3108–3113. [Google Scholar] [CrossRef] [PubMed]

- Sorensen, S.; Bech, L.; Muldbjerg, M.; Beenfeldt, T.; Breddam, K. Barley lipid transfer protein 1 is involved in beer foam formation. Masters Brew. Assoc. Am. Tech. Q. 1993, 30, 136–145. [Google Scholar]

- Matejkova, M.; Zidkova, J.; Zidek, L.; Wimmerova, M.; Chmelik, J.; Sklenar, V. Investigation of thermal denaturation of barley nonspecific lipid transfer protein 1 (ns-LTP1b) by nuclear magnetic resonance and differential scanning calorimetry. J. Agric. Food Chem. 2009, 57, 8444–8452. [Google Scholar] [CrossRef] [PubMed]

- Kader, J.C. Lipid-transfer proteins in plants. Annu. Rev. Plant Physiol. Plant Mol. Biol. 1996, 47, 627–654. [Google Scholar] [CrossRef] [PubMed]

- Van Nierop, S.N.E.; Evans, D.E.; Axcell, B.C.; Cantrell, I.C.; Rautenbach, M. Impact of different wort boiling temperatures on the beer foam stabilizing properties of lipid transfer protein 1. J. Agric. Food Chem. 2004, 52, 3120–3129. [Google Scholar] [CrossRef] [PubMed]

- Gorjanovic, S.; Suznjevic, D.; Beljanski, M.; Ostojic, S.; Gorjanovic, R.; Vrvic, M. Effects of lipid-transfer protein from malting barley grain on brewers yeast fermentation. J. Inst. Brew. 2004, 110, 297–302. [Google Scholar] [CrossRef]

- Gorjanovic, S.; Spillner, E.; Beljanski, M.V.; Gorjanovic, R.; Pavlovic, M.; Gojg Cvijanovic, G. Malting barley grain non-specific lipid-transfer protein (ns-LTP): Importance for grain protection. J. Inst. Brew. 2005, 111, 99–104. [Google Scholar] [CrossRef]

- Schwarz, P.; Stanley, P.; Solberg, S. Activity of lipase during mashing. J. Am. Soc. Brew. Chem. 2002, 60, 107–109. [Google Scholar] [CrossRef]

- Jegou, S.; Douliez, J.P.; Molle, D.; Boivin, P.; Marion, D. Evidence of the glycation and denaturation of LTP1 during the malting and brewing process. J. Agric. Food Chem. 2001, 49, 4942–4949. [Google Scholar] [CrossRef] [PubMed]

- Kuroda, H.; Kobayashi, N.; Kaneda, H.; Takashio, M.; Shinotsuka, K. Trihydroxyoctadecenoic acids having negative effects on beer foam are produced by enzymatic factors present in malt. In Proceedings of the 28th European Brewery Convention, Budapest, Hungary, 1 January 2001; Volume 70, pp. 657–662. [Google Scholar]

- Lusk, L.T.; Goldstein, H.; Ryder, D. Independent role of beer proteins, melanoidins and polysaccharides in foam formation. J. Am. Soc. Brew. Chem. 1995, 53, 93–103. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gordon, R.; Power, A.; Chapman, J.; Chandra, S.; Cozzolino, D. A Review on the Source of Lipids and Their Interactions during Beer Fermentation that Affect Beer Quality. Fermentation 2018, 4, 89. https://doi.org/10.3390/fermentation4040089

Gordon R, Power A, Chapman J, Chandra S, Cozzolino D. A Review on the Source of Lipids and Their Interactions during Beer Fermentation that Affect Beer Quality. Fermentation. 2018; 4(4):89. https://doi.org/10.3390/fermentation4040089

Chicago/Turabian StyleGordon, Russell, Aoife Power, James Chapman, Shaneel Chandra, and Daniel Cozzolino. 2018. "A Review on the Source of Lipids and Their Interactions during Beer Fermentation that Affect Beer Quality" Fermentation 4, no. 4: 89. https://doi.org/10.3390/fermentation4040089

APA StyleGordon, R., Power, A., Chapman, J., Chandra, S., & Cozzolino, D. (2018). A Review on the Source of Lipids and Their Interactions during Beer Fermentation that Affect Beer Quality. Fermentation, 4(4), 89. https://doi.org/10.3390/fermentation4040089