1. Introduction

Over the past two decades, many microfluidic systems have been designed and built for a wide range of applications. These systems are essentially formed by microchannels and chambers whose geometries have a strong influence on the flow characteristics. Improving the design of such systems requires understanding in detail the fluid flow characteristics. One of the flow characteristics that still needs to be better quantified is the microchannel entrance length, required to achieve fully developed flow, which is an important design parameter especially when it represents a significant fraction of the total microchannel length. However, entrance effects are typically ignored by researchers who usually assume the laminar flow to be fully developed [

1].

Different cross-sections (e.g., rectangular, trapezoidal, triangular, circular and elliptical) have been used by numerous researchers with the purpose of exploring the flow behavior in microchannels [

2,

3,

4,

5,

6,

7,

8,

9]. One important fact that should be highlighted is that the flow field in rectangular channels is more complex than in circular channels, because of the additional dependence on the aspect ratio (

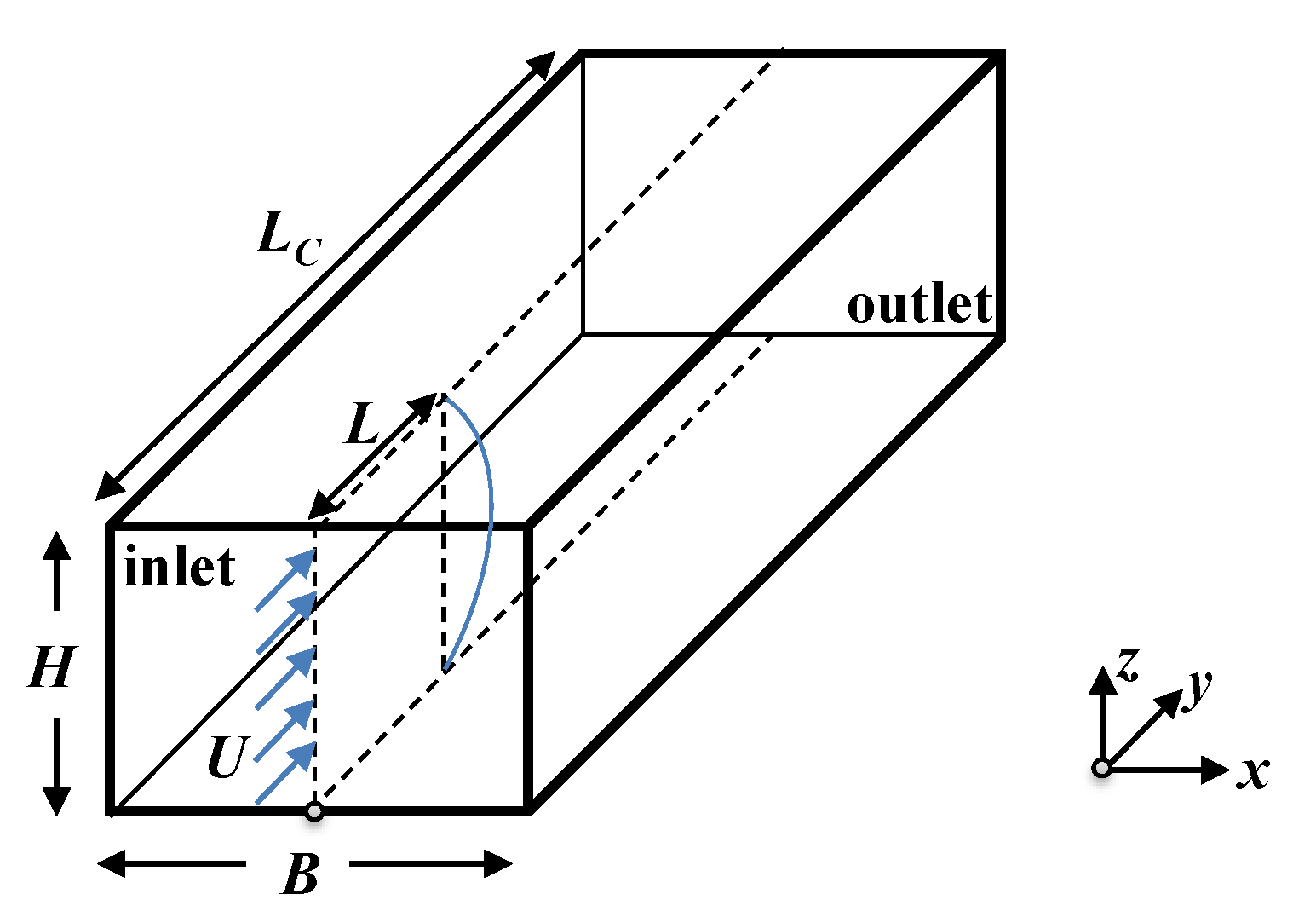

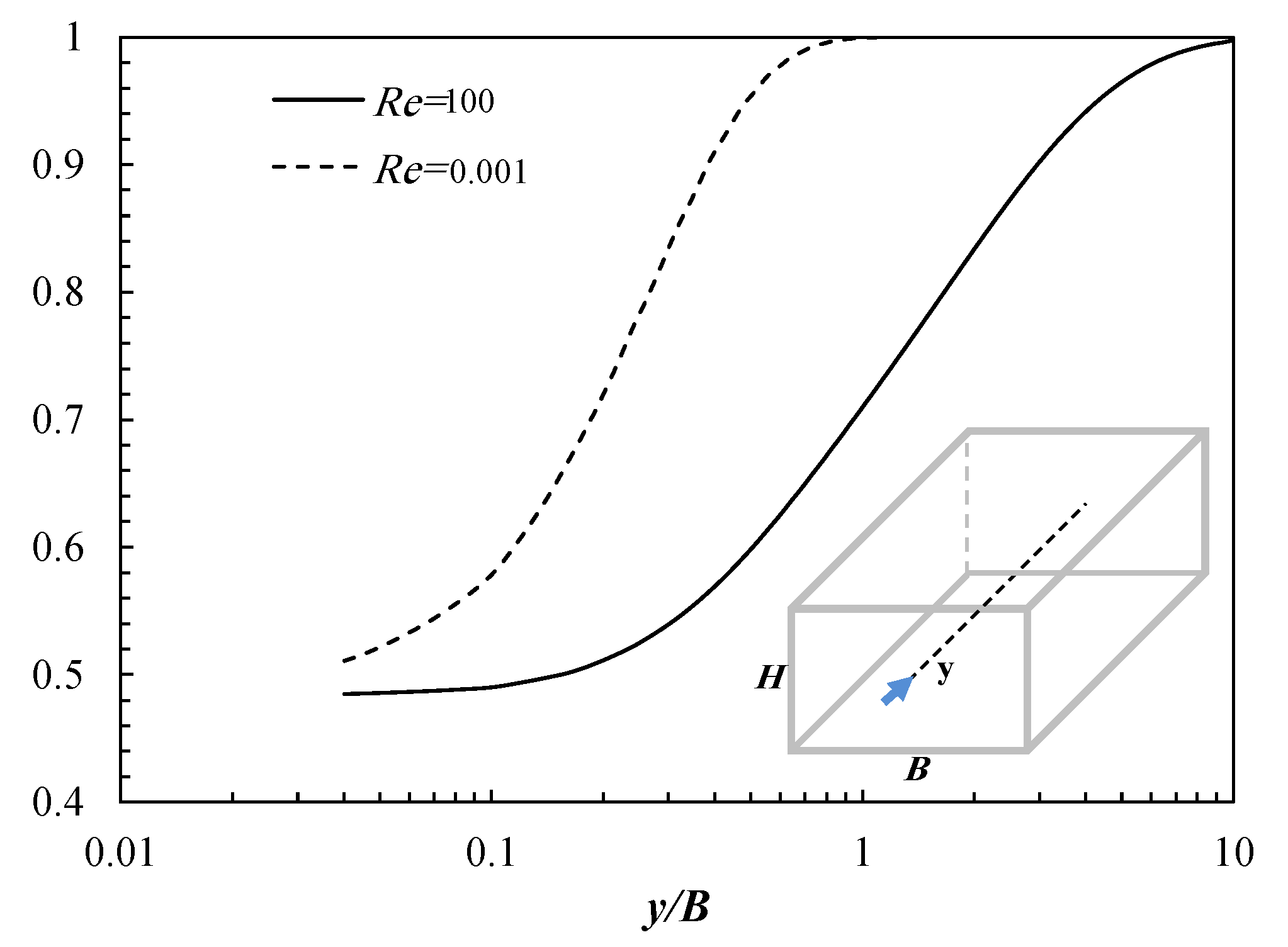

) of the cross-section, as shown in

Figure 1.

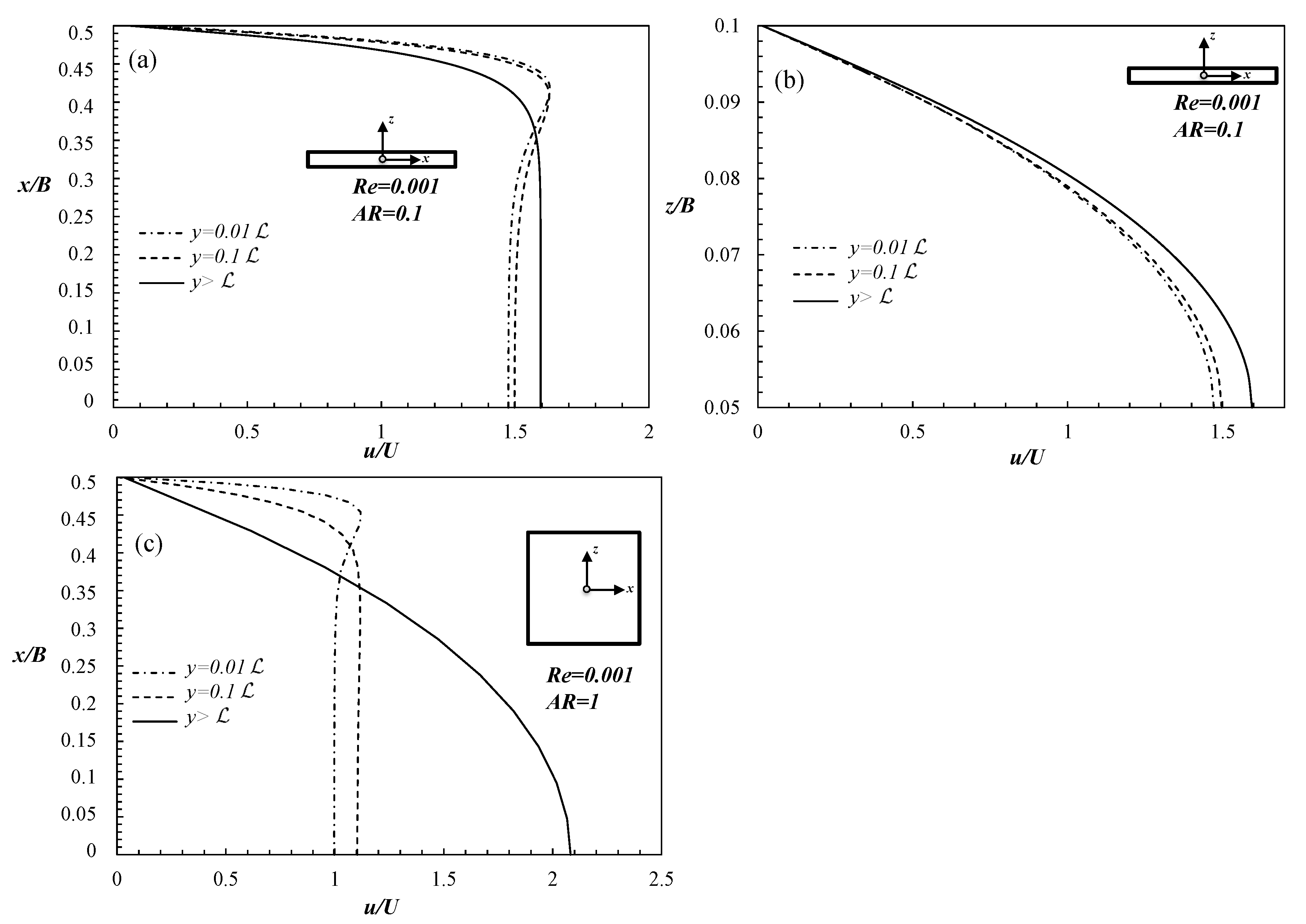

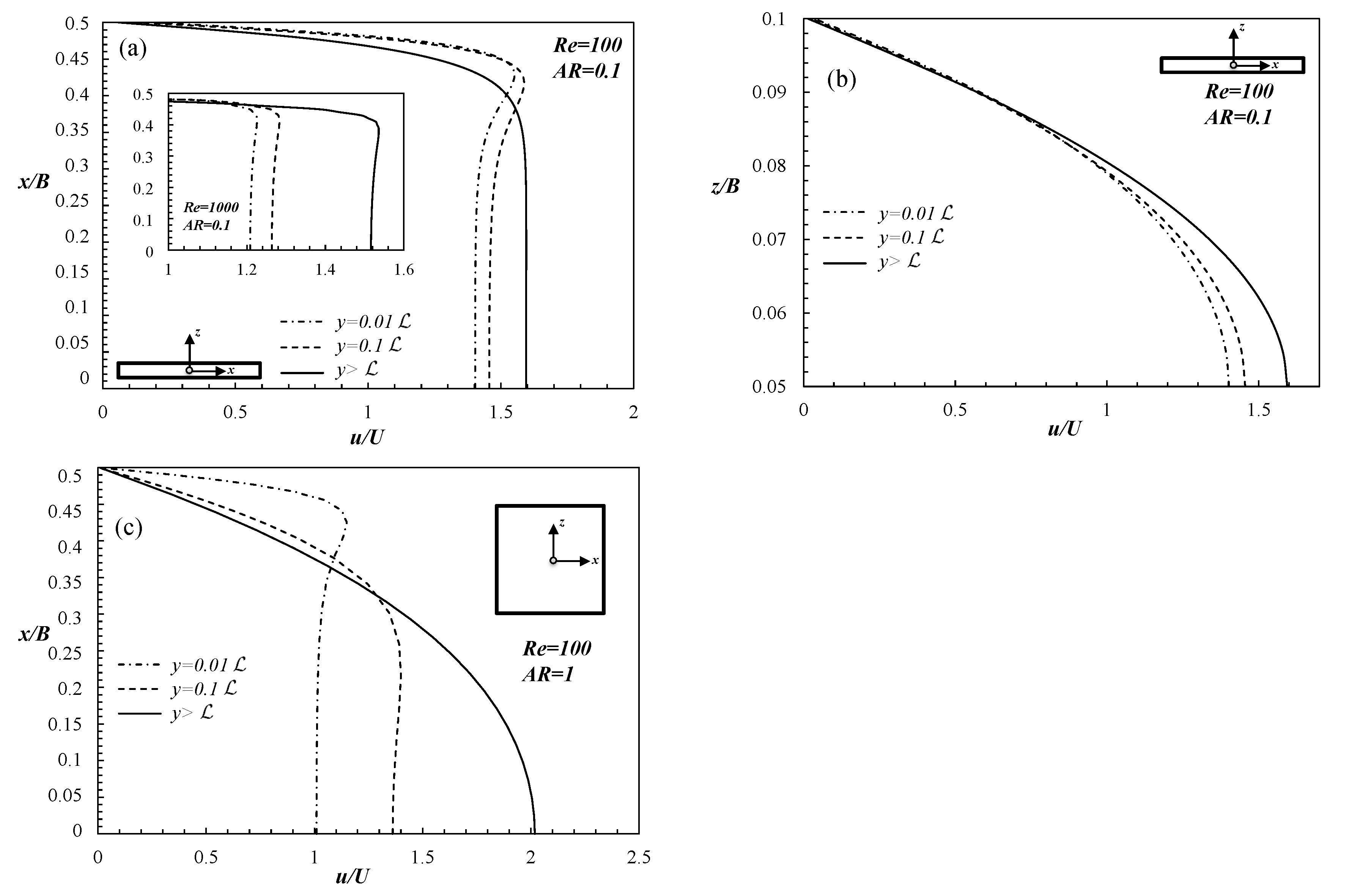

When a fluid enters a rectangular channel, the initial uniform velocity profile is gradually redistributed, accelerating around the centerplane(s) and de-accelerating near the walls. The fluid will reach a location after which the velocity profile no longer changes in all directions, and under such conditions the flow is considered to be fully developed.

Estimating this

entrance length, also called

development length, is one of the classical problems in fluid mechanics with practical use in microsystems design and studies of transition to turbulence [

10]. Here, following the criteria proposed by Shah and London [

11], the normalized development length,

, is defined as the non-dimensional distance measured from the entrance of the microchannel, where the velocity profile is uniform, up to the axial location where the flow reaches 99% of the corresponding fully developed velocity profile. Many analytical, experimental and numerical works on the

development length problem have been published over the years [

11,

12,

13,

14].

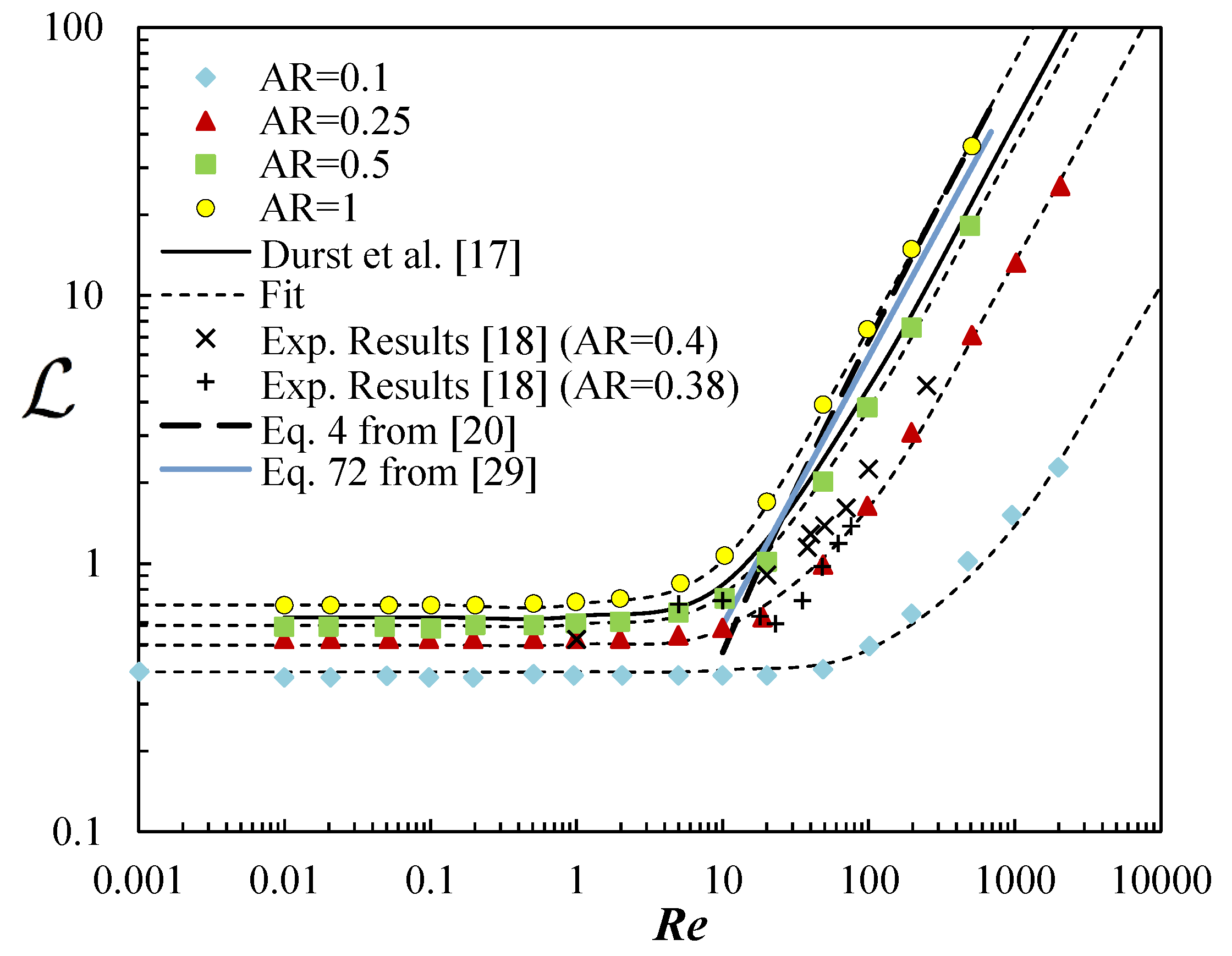

Most of the previous works proposed a linear functional relation between the development length and Reynolds number,

, in which

represents the asymptotic limit in the creeping flow regime,

. The proposed values for

in the literature are scattered, with the linear correlation hardly predicting the development length accurately for low Reynolds number flows (see

Table 1).

The Reynolds number is defined in this work as

and the aspect ratio is

, where

B is chosen as the larger side and

H as the smaller side of the rectangular channel (see

Figure 1), thus in all cases

.

Remark 1. It should be noted that, to present a correlation where the results for the different can be comparable, the dimension B was used as the characteristic length scale in all dimensionless development lengths. This means that this correlation cannot be compared with the one from Durst et al. [17], for planar channels, . We define and , thus . Note also that the Reynolds based on the hydraulic diameter () is given by , with . Therefore, we have . For a square duct, and . The nonlinear behaviors of the entrance length with respect to the Reynolds number for pipe and parallel plate flows were first investigated by Atkinson et al. [

15], using a linear combination of creeping flow with boundary-layer type solutions, and Chen [

16], using the integral momentum method to derive approximate solutions for the development length. The resulting functional relations for

in planar channel flows are listed in

Table 1, along with the appropriate fitting constants. These nonlinear correlations indicate that the development length has a rational relationship with the Reynolds number when the Reynolds number is small, with

approaching a constant value as

.

When the Reynolds number increases, the constant and rational portions become less dominant and the entrance length variation with becomes linear.

Sadri and Floryan [

21] presented a linear correlation for the relation of

ranging from

to 2200. They relied on a numerical method based on the use of the stream function and vorticity in the flow governing equations, with a compact fourth-order finite-difference scheme. The values of their correlation overpredict the entry length at low

due to the omission of the upstream flow development and at high values of

due to the omission of flow separation effects (they decoupled the upstream and downstream regions of channel entry). Sadri and Floryan also compared different definitions of the entry length and studied their influence on the obtained development lengths of the flow.

More recently, Durst et al. [

17] improved the linear functional prediction accuracy by superimposing diffusion and convection together in their model while suggesting a method to determine the normalized entrance length in laminar pipe and planar channel flows. It should be noted that, in the works previously cited, 3D effects were neglected.

Recent experimental fluid flow analysis, focused in microchannels with rectangular and square cross-sections [

18,

19], also present nonlinear correlations for

as a function of

. Their conclusion is that the development lengths were found to be shorter than classical correlations found in [

17]. The explanation for this difference is based on the effect of the aspect ratio, the different off-center velocity maxima of the inlet profiles and due to the pre-development of the axial velocity. Recently, Lobo and Chatterjee [

20] presented a numerical study on the development of flow in a square mini-channel, taking into account the effect of flow oscillations. They also performed a steady-state study and proposed a correlation for the development length for a square microchannel.

In this work, we present a detailed numerical investigation on the development length () in rectangular microchannels by considering the laminar regime (including the limit of creeping flow conditions) and the dependence on the aspect ratio, .

It should be remarked that, although some works dedicate particular attention to the effects of surface roughness, wettability and the presence of gaseous layers (thus multiphase flows) leading to interfacial slip typical of some specific fluids and particular conditions [

22], here we assume a single phase fluid and that the quality of manufacturing is sufficiently good to ensure smooth surfaces (as in channels made of PDMS through soft lithography [

23] or made from fused-silica glass [

24] so that the no-slip boundary condition remains valid).

The remainder of this work is organized as follows. In the next section, we present the governing equations, the numerical method and computational meshes used in the simulations. In

Section 3, we present the results and discussion. The paper ends with the main conclusions.

2. Governing Equations, Numerical Method and Computational Meshes

To predict the developing flow field within the microchannel, we assume that the flow is three-dimensional, laminar, isothermal, incompressible and steady. The governing equations for such conditions are those expressing conservation of mass,

and the momentum equation,

where

is the velocity vector,

p is the pressure,

t is the time,

is the fluid density and

is the Newtonian extra stress tensor, defined as:

with

representing the symmetric rate of strain tensor and

the dynamic viscosity. An in-house finite-volume method code (FVM) was used in this numerical study (for more details, see [

25,

26]). In this code, all diffusive terms are discretized using second-order central differences, and the advective term in the momentum equation is discretized with the CUBISTA high-resolution scheme [

25], which is formally of third-order accuracy. The term

in Equation (

2) is usually represented as

in Newtonian fluid flows, but our numerical method is also applicable for more complex fluids and uses the stress tensor notation.

The channel geometry is represented in

Figure 1. A uniform velocity,

U, is imposed at the inlet (

) of the microchannel, where all other velocity components and deviatoric stresses are set to zero. Vanishing streamwise gradients are applied to all variables at the outlet plane, except for the pressure, which is linearly extrapolated to the outlet from the two nearest upstream cells. The classical no-slip condition is imposed at the channel walls.

The iterative time stepping procedure was stopped whenever the of the residuals vector of the system of equations was less than a tolerance of , which corresponds to steady-state flow. The calculations for the creeping flow limiting case, , were carried out by dropping out the convective term of the momentum equation.

In order to achieve mesh-independent results, the full physical domain depicted in

Figure 1 was discretized into eight different sets of computational domains, with consecutively refined meshes. A detailed summary of those meshes is presented in

Table 2. To avoid an effect of the computational domain on the calculated development length, the microchannel was made significantly longer than the value of

, so that, at the end, the length of the microchannel domain varied between four and twenty times the calculated development length. In turn, this depended also on the Reynolds number. The number of cells (

) in the axial direction increased with the length of the computational domain, and a non-uniform distribution of the cells sizes was used, with the ratio of the geometric progression of the cell spacing equal to 1.04040 for meshes M1, M2, M3, M4, M9, M10, M11 and M12 and 1.02 in meshes M5, M6, M7, M8, M13, M14, M15 and M16.

For the

x direction, the cells were uniformly distributed with the total number of cells, NC, shown in

Table 2. The present mesh refinement strategy was designed in order to provide a consistent estimate of uncertainty of our simulations using Richardson’s extrapolation technique [

27]. This method allows us to estimate the mesh independent extrapolated development length (

) as

based on our numerical simulations in meshes M3 and M4, for the sake of example, where

p is the order of accuracy of the computations. Assuming a second-order accuracy,

,

can be estimated as

.

This technique also allows us to estimate the accuracy of a specific calculation, defined as

where

is the length computed numerically in mesh

. In addition to the mesh-dependency study, another parameter used for estimating the accuracy in this work is the velocity relative error (

) for mesh

, defined as,

where

is the predicted maximum velocity at the outlet plane and

is the corresponding fully developed theoretical maximum velocity value computed using the analytical solution [

28].

It should be remarked that preliminary tests with different meshes where conducted initially, in order to select the most appropriate meshes, without compromising the convergence accuracy and the computational time needed to perform the simulations.