Abstract

The spirit beverages of vodka and gin are often produced from a neutral spirits base. These neutral spirits are derived from the distillation of fermented carbohydrates of agricultural origin. The fermentations in the production of these beverages are not often reported in great detail and to some extent are shrouded in mystery. The roles of fermentation and the yeast Saccharomyces cerevisiae are essential to the complete process, and without fermentation there would not be alcohol to distil. Nevertheless, it is not the yeast that is perceived to contribute to the distinctive consumer experiences, which are associated with these beverages. However, there are opportunities for the development of new strains of S. cerevisiae for the production of neutral spirits, which have a high ethanol yield, are tolerant of ethanol stress, and produce low levels of congeners.

1. Introduction

In the UK, distillers are experiencing a resurgence of consumer interest in some of the ‘white spirits’, most notably vodka and gin. This is most evident in the ‘craft distilling’ sector, where these products do not require the maturation times of other notable spirits, such as whisky and rum, and therefore offer a faster monetary return on investment. In addition to this, these spirits represent an opportunity for unleashing the creativity of the distiller and the development of a unique selling point. Although gin and vodka offer quite different consumer experiences, the early stages of their production are similar [1,2], and hence the fermentations details that lead to their production are considered here.

The origins of vodka are to be found in the distilled beverages culture of Russia in the late sixteenth century, when the term ‘vodka’ was used as a synonym for distilled grain alcohol [3]. Early vodka was not only available as a distilled product; it could be processed to be flavoured with fruits (naliviki) or herbs (nastoiki) often used to hide a poorer quality spirit [3]. Filtration of vodka to remove unwanted flavor congeners (fusel alcohols, esters, and acetaldehyde) was not commonplace until the late nineteenth century [3]. The evolution of vodka into the drink enjoyed by consumers today is complex and influenced by both Russian and, more recently, global politics and is beyond the scope of this review [3,4]. There are also specialist vodka products with roots in Eastern Europe, which were subtly flavoured with grasses (such as bison grass) or herbs [5].

Vodka is an unaged, neutral, and highly rectified spirit drink produced from fermentation-derived ethyl alcohol (ethanol) using yeast and carbohydrates from agricultural raw materials [5,6,7]. This spirit is important as both a standalone product and a base product for various alcoholic beverages. Vodka is the most popular alcoholic beverage in Poland, Russia, and other European countries and enjoys popularity in the UK and USA [1,8]. European legislation describes vodka as being made from ethyl alcohol that has been produced via the fermentation of potatoes, grains, or other agricultural products [1,2,7,9]. In both Europe and the USA, a neutral spirit is defined as having very little flavour other than that contributed by the alcohol, and it also tends to be colourless and clear [1,2,7,10]. Globally vodka is one of the most widely consumed spirits, after whisk(e)y, with an estimated value of US$50,804 million sold in 2014, equating to around a 15.6% share of the global spirits market [11].

Gin is an alcoholic beverage that has evolved greatly over the last 300 years from its origin. The inventor of gin is generally regarded as Franciscus de la Boe (1614–1672) [12], a Professor of Medicine at Leyden University, Holland. He produced the spirit for medicinal purposes [2], particularly as a remedy for military troops suffering from ‘East Indian fevers’. It contained an ethanolic extract of juniper, said to be a natural therapy for kidney function, coriander for the stomach, and calamus for colic [12]. There are historical records considering the medicinal use of juniper, which was noted as being a traditional remedy used by the Navajo Indians to control diabetes [13]. Juniper is an ancient coniferous tree, with evidence found of its presence in organic muds which were dated to around 12,400 BCE [14]. The precursor to the drink we know as ‘gin’ is named ‘Geneva’ (or Jenever) [2,15] and is still produced in Belgium and the Netherlands [15] from a distillate referred to as ‘malt wine’ [5]. From these historical roots, the drink experienced by consumers in the twenty-first century is one shaped by the history, politics, and laws of several countries [16]. The predominant flavour in gin is juniper, but the limits of this have been put to the test by creative craft distillers as they increasingly challenge these historical norms.

The most recent legislation surrounding the production of vodka, gin, and other spirit drinks, which has the benefit of being descriptive in nature is EU ruling 110/2008 (Annexe 2, item 20) [6]. In accessible terms, this piece of legislation specifies production parameters ranging from the percentage of alcohol and origin of the spirit used, methanol content, and, in the case of vodka, explicitly states that yeast must be used. The most famous line in the legislation concerning gin is that: ‘only approved natural and/or nature-identical flavouring substances or flavouring preparations shall be used for the production of gin so that the taste is predominantly that of juniper’. In the USA, the definition of gin is similar, describing ‘spirits with a main characteristic flavor derived from juniper berries…’ [10]. The flavouring of gin is normally achieved through the use of botanical materials (Table 1) [1,5,7,12,17,18], which are added to a neutral spirit base, as opposed to the spirit obtaining flavour from its source materials [12].

Table 1.

Botanicals used in the production of gin [1,5,18,19,20].

There are many publications that consider the history of gin and its association with social and political change [15,21,22], but this topic is beyond the scope of this review. In 2004, Phelan and colleagues [23] commented that, despite the resurgence of interest in gin, there was a lack of research in this field, with little peer reviewed literature. Although during the intervening years, the situation has improved, the target of most research has focussed on an understanding of the organoleptic qualities of this beverage [23,24,25,26,27,28,29,30], with fewer publications on process development [31].

2. Process Overview

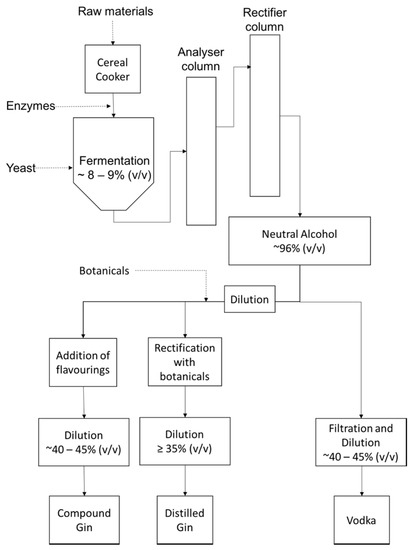

Around the world, both families of drinks are commonly produced using neutral alcohol (ethanol) from a range of agricultural raw materials [5]. The majority are produced from wheat, maize, and molasses. A smaller volume is made from other materials such as barley, rice, fruits including grapes, potatoes, and, more unusually, cheese whey [1,2,22]. The use of good quality fermentation feedstock material is essential, an important aspect of which is to have low levels of microbial contamination [5]. Contaminants will influence the efficiency of fermentation to the detriment of the final ethanol concentration achieved [32]. All of these raw materials provide the essential carbohydrates for fermentation [1]. These raw materials are processed (Figure 1) to result in the production of a nutrient and carbohydrate rich liquid, in distilling often referred to as ‘wort’. Yeast is added to this wort, and, after a short lag period, fermentation will begin. When fermentation is complete, the fermented wort is now known as wash and is distilled in a continuous system running between two and five columns, each of which removes different undesirable volatile components [1]. The exact number of columns varies between distilleries. Column distillation produces a distillate of around 96% alcohol by volume (abv) (alternatively expressed as 96% (v/v)) with very low to undetectable concentrations of volatile congeners [1,33,34]. Methanol is removed by the use of a demethylising column [1], and it should be noted that different raw materials are associated with the formation of differing levels of methanol. In many ways, the production of neutral alcohol is similar to the distillation process to produce grain whisky and other spirits [5], the subject of which is discussed elsewhere in this Special Issue and the details of distillation are reviewed in depth by Murtagh [5].

Figure 1.

Simplified process diagram for the production of gin and vodka.

If the neutral alcohol (ethanol) from fermentation is to be used for the production of vodka, emphasis is then placed on the treatment of the spirit (Figure 1) to remove as many volatile congeners as possible, which produces a nearly flavourless odourless spirit [35]. If the neutral alcohol is to be used to produce gin, botanicals (Table 1) must be used to give flavour, aroma, and occasionally colour to the final product (Figure 1). After processing is complete, the spirit is diluted with high purity, demineralised, sterile, deaerated water [1] to achieve a target alcoholic strength and packaged for sale to consumers. For example, vodka must be bottled at a final alcohol concentration of at least 37.5% (v/v). In some countries, the addition of authenticity indicators (glycerol, sweeteners, propylene glycol) is required as a means of identification in the marketplace [1,36].

There are two types of gin manufactured, distilled and compound, both of which involve the imparting of botanically sourced flavor; however only one is produced by a distillation (or rectification) step (Figure 1). Copper pot stills are used to produce distilled gin (Figure 1), and there are variations in the method of inclusion of the botanicals. The selection of botanicals (Table 1) will be specific to the brand of gin being produced [2]. They can either be added directly to the still with the spirit and distilled together (steep method), or, during distillation the spirit vapours pass through a botanicals basket which is integrated into the head or the lyne arm of the still (vapour infusion). The middle portion of the distillate is collected as potable spirit, which usually has an alcoholic strength of approximately 80% abv (80% (v/v)) [1].

In an often crowded marketplace, manufacturers of gin and vodka have attempted to create differentiation by introducing innovative aspects to their new products [37]. This includes the use of novel sources of fermentable carbohydrates. The most commonly used sources of carbohydrate are cereals such as maize (corn) and wheat. These cereals require heat treatment (starch gelatinisation) before they can be processed to produce the carbohydrate rich liquid required for fermentation. The use of exogenous enzymes (alpha amylases, amylo-glucosidases, proteases, cellulases, glucanases, and xylanases) for the production of neutral alcohol is permitted by the legislation that controls its production [33,38,39]. The processing steps to which the raw materials are subjected convert long chain polymers (starch) into smaller monomers, which can later be utilised by the yeast during fermentation for the production of ethanol, carbon dioxide, other metabolites, and some yeast biomass. The enzymes which can be utilised for this function are derived from fungi or bacteria and must be non-toxic and produced according to international quality standards [39].

The most efficient processing choice for fermentation when producing a neutral spirit is the use of continuous or cascade fermentation systems, offering the opportunity to maximise vessel utilisation and production [8]. The challenge presented by these systems for distillers is to maintain good microbiological control, as wild yeast and lactic acid bacteria contamination can cause significant problems [32]. These microorganisms can outcompete the pitched strain of yeast, rapidly consume the carbohydrates present, demonstrate shorter lag phases and cellular division times, and display a greater tolerance of stress inducing conditions [40]. The advantage of using a cascade fermentation system is that it allows the yeast to combat osmotic stress more effectively, which overall increases the ethanol levels that can be produced from the available sugar [8].

Much of the research surrounding specific spirits such as vodka has focussed on maximising the potential of the raw materials [41,42], the use of alternative raw materials [43], and the development of new processes to remove any congeners which might otherwise influence the aroma and flavour of the final product [44,45].

3. Microbiological Aspects

It is generally accepted that the important parameters when considering vodka quality are the source of raw materials [46] and the filtration of the distilled spirit [44,45], usually through activated charcoal [47]. Yeast selection is not a principal consideration in the production of most vodkas and gins. This is due to the fact that the fermented wash will be subject to several rounds of distillation (Figure 1), during which many of the flavour and aroma compounds contributed by the yeast will not be collected as part of the spirit fractions. Many small gin producers, for instance, will purchase (grain) neutral spirits from large scale commercial producers. Consequently, the fermentation stage is not a consideration for many producers of these beverages. For those that do produce neutral alcohol for gin and vodka, the concerns for fermentation will ultimately focus on fermentation efficiency and avoiding microbiological contamination, both of which will influence the final yield of alcohol [18].

However, this does not mean that the yeast, usually Saccharomyces cerevisiae (S. cerevisiae), is not an essential part of the production of these spirits, especially when considering fermentation conditions. The fermentations involved take place at high or very high wort gravities which contribute positively to the environmental sustainability of the industry through reduced energy and water requirements [39]. Yeasts that are ethanol tolerant and produce low levels of flavour congeners are usually recommended for the production of vodka and grain neutral spirit (Table 2). When using grain (typically wheat or maize) as a source of carbohydrate for the subsequent fermentation, the yeast strain of choice for grain distillers is often S. cerevisiae strain ‘M’ [48]. In fact, the fermentation processes for the production of a neutral spirit for vodka or gin will be similar and often identical to those employed in the production of Scotch grain whisky [33]. Many other strains of yeast are available both commercially and for research purposes from yeast supply companies and culture collections. Details of some the main commercial yeast strains for distilled spirits are presented in Table 2.

Table 2.

Commonly available commercial yeast strains for the production of spirits to be further processed into gin or vodka.

4. Role of Yeast

Yeast is available to the distiller in several formats, the most popular being cream yeast (around 15%–20% dry matter), pressed cake (around 28%–35% dry matter), and active dried yeast (around 95% dry matter) [49,50]. The format chosen by the distiller will be influenced by the size and capabilities of the distillery. However, large-scale industrial producers are more likely to choose creamed yeast, despite a short shelf life (of around 28 days), compared to active dried yeast (1 year). These distilleries have the production turnover to select cream yeast to be their format of choice [49,50]. Smaller (e.g., craft) distillers generally prefer dried yeast for convenience and longer shelf-life. A newer product available on the market is stabilized liquid yeast (23%–26% w/v), which is produced by Lallemand; the use of food stabilizers extends the shelf life of the yeast to 3 months [51].

The metabolic reactions taking place within the yeast cell during fermentation are not limited to the production of ethanol and carbon dioxide. At the same time, other biosynthetic pathways within the cell produce by-products of its metabolism, including compounds contributing to overall spirit flavour and aroma. There are thought to be over 200 different volatile compounds in raw spirit, the largest groups of which are esters (fatty acid ethyl esters and acetate esters) and higher alcohols [52]. Plutowska, et al. [52] also identified furans, sulphur compounds, benzene derivatives, and terpenoids in the raw spirits investigated. It is the development of sensitive analytical detection methods in recent years that has allowed this number of compounds to be identified in raw spirits. For example, in 1970, Harrison and Graham [53] reported identifying just ten chemical components in vodka.

Several researchers have suggested that the raw material providing carbohydrate for fermentation will influence the different levels of by-products formed [54,55]. Ng, et al. [56] determined that 18 different vodkas could be differentiated according to the raw materials used and the method of production. In this work, ethyl ester levels (fermentation by-products from yeast) were one of the markers used to identify the different spirits [56]. These results were not confirmed by Cai, et al. [45] who found that, when examining 12 commercially available vodkas, the levels of volatile congeners could not be correlated to the raw material for fermentation or the geographical origin of the spirit.

It should be noted that there is no consensus of opinion on the importance of the contribution of the choice of yeast strain to the levels of metabolic by-products produced, although the authors of this review are of the opinion that common sense would suggest that both strain selection and raw material choice would have an influence on yeast growth, fermentation efficiency, and the production of flavour active by-products such as esters, aldehydes, and higher alcohols. Klosowski, et al. [57] found that the levels of aldehydes and higher alcohols were influenced by yeast strain selection. Subsequent to this, Klosowski and Czuprynski [55] suggested that no statistical differences could be determined between the two strains of the yeast examined and that the differences in fermentation by-products in the final spirit were narrowed down to the raw material used. Pietruszka and St Szopa [58] took this further and demonstrated that differences in the concentration of spirit volatile congeners could be detected between different varieties of rye used as a raw material. The preconditioning of distillers’ yeast (M strain) has been proven to have a negative impact on the production of volatile esters [59]. This suggests that there could be the opportunity to reduce the levels of some volatile congeners by adapting the environmental conditions that the yeast has been subjected to prior to fermentation. However, given the efficacy of filtering treatments already employed for the removal of congeners especially for vodka, this development is more likely to be of use in the production of other distilled spirits such as whisk(e)y, brandy, and rum.

During fermentation, yeast is subjected to a myriad of environmental stresses, and, despite being well documented and subject to a great deal of research, the mechanisms for the tolerance of yeast to stress are still not well understood [60]. In the production of ethanol, the starting gravity is being progressively raised by many companies, from a specific gravity (being a measure of soluble carbohydrate) of 1060–1080 up to 1085–1097, which commensurately increases the amount of stress (osmotic and ethanol) to which the yeast cells are subjected [48]. To date, it can be said that the response of S. cerevisiae to stress involves the regulation gene expression, protein expression, and post-translational modification, amongst others. Interestingly, research has demonstrated that, under fermentation conditions, there was complete repression of heat shock proteins [61]. Ethanol stress has been extensively reviewed [60,62,63], and therefore the implications will not be discussed further here. However, the ethanol stress tolerance of strains of distilling yeast (both potable and fuel alcohol) have been determined to demonstrate strain specific responses when fermenting at very high gravities and are also influenced by the format in which the yeast is supplied [48].

With the wide range of varieties and strains of yeast used for the production of ethanol of agricultural origin, it is inevitable that there will also be variation in the mechanisms of sugar uptake by these yeasts. For example, it has been suggested that ‘M’ yeast does not exhibit glucose repression over the uptake of maltose from wash in grain fermentations [64]. Another study [42] examined the impact of adding sucrose to potato starch fermentations. These experiments determined that this increased the levels of methanol present in the raw spirit, which requires removal (using a demethylising column) before the final product is ready for packaging.

It is interesting to note that Hansen, et al. [65] determined that changes in the morphology of distillers’ ‘M yeast could be observed in both industrial and laboratory fermentations. However, these changes could not be fully visualised and interpreted; it was thought that reduction in membrane potential and low adenosine triphosphate (ATP )levels could have been the reason. What could be seen was a reduction in cell size and the development of a granular appearance in the cells during alcohol fermentations.

5. Yeast Strain Selection and Improvement

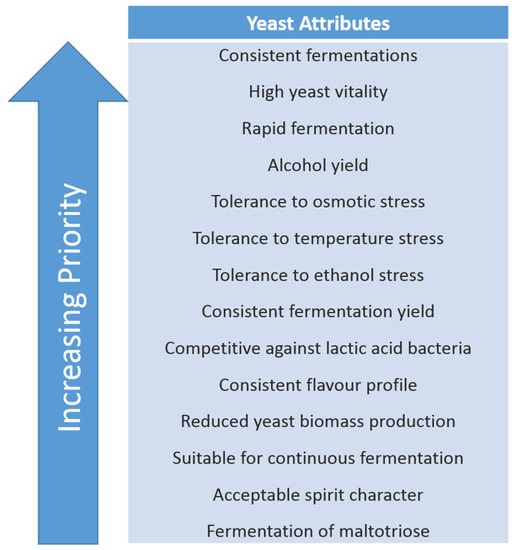

It is often listed that the desired characteristics of yeast for efficient fermentation include carbohydrate utilisation, rapid fermentation rates, tolerance to alcohol, and the culture’s stability [66]. This list has more recently been expanded by Walker, et al. [33] to include traits such as improved overall stress tolerance, which will ultimately contribute a reduction in water and energy demands. It is still desirable that these yeast strains should produce low levels of the volatile congeners previously discussed but also that the levels of undesirable flavour compounds are minimised [33]. A series of qualitative targets were recommended by Walker, et al. [33], and these are summarised in Figure 2 in the order of priority suggested by the authors. It is considered that the essential targets of research and development should be around the consistency of fermentation (yield and vitality of the yeast) and that the final yeast should be available in a cream or liquid format [33]. In addition to these targets, the yeast discussion panel at the 2012 Worldwide Distilled Spirits Conference [67] suggested the following additional desirable characteristics; antibacterial properties, carbon dioxide tolerance, genetic stability, resistance to mechanical sheer and hydrostatic pressure, and acid tolerance, as well as resistance to the stresses involved in dehydration and rehydration.

Figure 2.

Summary of the desired attributes of distilling yeast for neutral spirit fermentations. The more desirable attributes are located at the top, and this decreases down the table (after Walker, et al. [33]).

Genetically modified strains of S. cerevisiae, which may possess many of these idealised characteristics, could already exist in research laboratories around the globe. It is consumer perception that rests between these strains and their commercial utilisation. In addition, there are groups now developing synthetic yeast in the laboratory [68], where, eventually, the potable alcohol industry could utilise S. cerevisiae strains constructed to meet industry specific demands and the creation of a ‘perfect’ distilling yeast. However, even if this were a reality, the barriers surrounding consumer perception would still need to be eliminated [69,70]. Indeed, to convince consumers that spirits produced by genetically modified yeast were a desirable commodity, may require the consumer to perceive a direct benefit to their experience of a product. All the targets listed as desirable targets for the ideal distilling yeast strain are based around the needs of the distiller rather than the consumer. Therefore, more persuasion will be required to achieve general consumer acceptance.

6. Conclusions

The successful production of neutral alcohol (ethanol) and its impact on the overall efficiency of this process is important. Whilst flavours derived from the yeast metabolism are important to many other spirit drinks such as whisk(e)y, rum and brandy, these are not wanted at levels that can be detected by the consumer. The markers that researchers use to differentiate between the raw materials used for the production of raw spirit are those compounds that are produced by the yeast during fermentation. Therefore, it can be said that, from the point of view of identification and even possibly authenticity, these differences can be utilised. Given these factors, it can be said that the yeast may be an overlooked component by some in the production of gin and vodka. Without yeast activity during fermentation, there would be no alcohol to distil into the raw spirit, which will be made into gin or vodka. The contributions of individual S. cerevisiae strains are, to date, an area that has not been investigated fully. There are opportunities for further research in this area, especially if it could play a role in confirming brand authenticity. There may also be opportunities for the development of new strains in the production of neutral spirits, which have a high ethanol yield, are tolerant of ethanol, and display other fermentation parameter associated stresses and that produce low levels of flavour congeners.

Opportunities may also be based around the development of yeast assessment technology to provide researchers and distillers with a greater understanding of the yeast strains currently available. This will permit more informed selection to choose the correct strain for the purpose. In order to achieve these objectives and those of the ‘ideal distilling yeast’ distillers, yeast suppliers and the scientific research community must collaborate to fulfil these goals.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Aylott, R.I. Gin and Vodka. In Production, Technology and Innovation, Proceedings of the Worldwide Distilled Spirits Conference, Edinburgh, UK, 18–22 September 2005; Bryce, J.H., Piggott, J.R., Stewart, G.G., Eds.; Nottingham University Press: Nottingham, UK, 2008; pp. 299–303. [Google Scholar]

- Buglass, A.J.; McKay, M.; Lee, C.G. Chapter 3.4: Other cereal based spirits. In Handbook of Alcoholic Beverages: Technical, Analytical and Nutritional Aspects, 1st ed.; Buglass, A.J., Ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2011; pp. 535–553. [Google Scholar]

- Christian, D. ‘Living Water’: Vodka and Russian Society on the Eve of Emancipation, 1st ed.; Oxford University Press: Oxford, UK, 1990. [Google Scholar]

- Benjamins, A.N. Vodka. Russia’s Gigantic Monopoly in Drink. How it is made; How it is sold and what is done with the money. The Idler; An Illustrated Monthly Magazine 1902, 159–165. [Google Scholar]

- Murghagh, J.E. Chapter 13: Production of neutral spirits and preparation of gin and vodka. In The Alcohol Textbook: A Reference for the Beverage, Fuel and Industrial Alcohol Industries, 3rd ed.; Jacques, K.A., Lyons, T.P., Kelsall, D.R., Eds.; Nottingham University Press: Nottingham, UK, 1999; pp. 195–210. [Google Scholar]

- European Union (EU). Regulation (EC) No. 110/2008 of the European Parliament and of the Council of 15 January 2008 on the Definition, Description, Presentation, Labelling and the Protection of Spirit Drinks, 2008. Available online: http://www.wipo.int/wipolex/en/details.jsp?id=5422 (accessed 4 February 2017).

- Aylott, R.I. Flavoured Spirits. In Fermented Beverage Production, 1st ed.; Lea, A.G.H., Piggott, J., Eds.; Blackie Academic and Professional: Glasgow, UK, 1995; pp. 275–300. [Google Scholar]

- Korhola, M. Developments in vodka production. In New Horizons: Energy, Environment and Enlightenment, Proceedings of the Worldwide Distilled Spirits Conference, Edinburgh, 7–10 September 2008; Walker, G.M., Hughes, P.S., Eds.; EnergyNottingham University Press: Nottingham, UK, 2010; pp. 53–61. [Google Scholar]

- Wiśniewska, P.; Śliwińska, M.; Dymerski, T.; Wardencki, W.; Namieśnik, J. Differentiation between spirits according to their botanical origin. Food Anal. Methods 2016, 9, 1029–1035. [Google Scholar] [CrossRef]

- Alcohol and Tobacco Tax and Trade Bureau. Electronic Code of Federal Regulations: Title 27, Chapter 1, Subchapter A, Part 5. US Government Publishing Office. 2017–01–04. Available online: http://www.ecfr.gov/cgi-bin/text-idx?SID=eddaa2648775eb9b2423247641bf5758&mc=true&node=pt27.1.5&rgn=div5#se27.1.5_121 (accessed on 4 January 2017).

- MarketLine. Industry Profile: Global Spirits; Datamonitor: London, UK, 2015. [Google Scholar]

- Hughes, N. Gin. Nutr. Food Sci. 1992, 92, 14–146. Available online: http://dx.doi.org/10.1108/EUM0000000000962 (accessed on 1 September 2016). [Google Scholar]

- McCabe, M.; Gohdes, D.; Morgan, F.; Eakin, J.; Sanders, M.; Schmitt, C. Herbal Therapies and Diabetes Among Navajo Indians. Diabetes Care 2005, 28, 1534–1535. [Google Scholar] [CrossRef] [PubMed]

- Pennington, W.; Tutin, T.G. Vegetation History in the North West of England: A Regional Synthesis. In Studies in the Vegetation History of the British Isles: Essays in Honour of Harry Godwin; Walker, D., West, R.G., Eds.; Cambridge University Press: London, UK, 1970; p. 43. [Google Scholar]

- Van Acker–Beittel, V. Genever: 500 Years of History in A Bottle, 1st ed.; Flemish Lion LLC: Richmond, VA, USA, 2014. [Google Scholar]

- Abel, E.L. The gin epidemic: much ado about what? Alcohol Alcohol. 2001, 36, 401–405. [Google Scholar] [CrossRef] [PubMed]

- Coates, G. Classic Gin, 1st ed.; Prion Press: London, UK, 2000; pp. 77–84. [Google Scholar]

- Simpson, A.C. Gin Manufacture. Process Biochem. 1966, 1, 355–358, 365. [Google Scholar]

- Simpson, A.C. Gin and Vodka. In Alcoholic Beverages; Rose, A.H., Ed.; Academic Press: London, UK, 1977; pp. 537–594. [Google Scholar]

- Clutton, D.W. The production of Gin and Vodka. Brew. Guard. 1979, 108, 25–30. [Google Scholar]

- Barnett, R. The Book of Gin; Grove Press: New York, NY, USA, 2011. [Google Scholar]

- Knoll, A.J.; Smith, D.T. The Craft of Gin; White Mule Press: Hayward, CA, USA, 2013. [Google Scholar]

- Phelan, A.D.; Jack, F.R.; Conner, J.M.; Reid, K.J.G.; Priest, F.G. Sensory assessment of gin flavour. In Tradition and Innovation, Proceedings of the Worldwide Distilled Spirits Conference, Edinburgh, UK, 8–11 September, 2002; Bryce, J.H., Stewart, G.G., Eds.; Nottingham University Press: Nottingham, UK, 2004; pp. 53–58. [Google Scholar]

- Vichi, S.; Riu-Aumatell, M.; Mora-Pons, M.; Buxaderas, S.; López-Tamames, E. Characterization of volatiles in different dry gins. J. Agric. Food Chem. 2005, 53, 10154–10160. [Google Scholar] [CrossRef] [PubMed]

- MacNamara, K.; Howell, J.; Huang, Y.; Albert, R. Analysis of gin essential oil mixtures by multidimensional and one-dimensional gas chromatography/mass spectrometry with spectral deconvolution. J. Chromat. A 2007, 1164, 281–290. [Google Scholar]

- El-Ghorab, A.; Shaaban, H.A.; El-Massry, K.F.; Shibamoto, T. Chemical composition of volatile extract and biological activities of volatile and less-volatile extracts of juniper berry (Juniperus drupacea L.) fruit. J. Agric. Food Chem. 2008, 56, 5021–5025. [Google Scholar] [CrossRef] [PubMed]

- Vichi, S.; Riu-Aumatell, M.; Buxaderas, S.; López-Tamames, E. Assessment of some diterpenoids in commercial distilled gin. Anal. Chim. Acta 2008, 628, 222–229. [Google Scholar] [CrossRef] [PubMed]

- Albert, R.; Kowalsick, A.; Howell, J. Tracking juniper berry content in oils and distillates by spectral deconvolution of gas chromatography/mass spectrometry data. J. Chromatog. A 2011, 1218, 5531–5541. [Google Scholar]

- Dussort, P.; Deprêtre, N.; Bou-Maroun, E.; Fant, C.; Guichard, E.; Bruinerie, P.; Le Fur, Y.; Le Quéré, J.-L. An original approach for gas chromatography-olfactometry detection frequency analysis: Applications to gin. Food Res. Int. 2012, 49, 253–262. [Google Scholar] [CrossRef]

- Sádecká, J.; Uríčková, V.; Hrobońová, K.; Májek, P. Classification of juniper-flavoured spirit drinks by multivariate analysis of spectroscopic and chromatographic data. Food Anal. Methods 2015, 8, 58–69. [Google Scholar] [CrossRef]

- Greer, D.; Pfahl, L.; Rieck, J.; Daniels, T.; Garza, O. Comparison of a novel distillation method in a model gin system using liquid/liquid extraction. J. Agric. Food Chem. 2008, 56, 9030–9036. [Google Scholar] [CrossRef] [PubMed]

- Wilson, N.R. Contamination: Bacteria and wild yeasts in a whisky fermentation. In Whisky: Technology, Production and Marketing, 2nd ed.; Russell, I., Stewart, G., Eds.; Academic Press: Oxford, UK, 2014; pp. 147–154. [Google Scholar]

- Walker, G.M.; Brosnan, J.; Bringhurst, T.; Jack, F. Selecting new distilling yeast for improved fermentation and for sustainability. In Science and Sustainability, Proceedings of the Worldwide Distilled Spirits Conference, Glasgow, UK, 12–15 September 2011; Walker, G.M., Goodall, I., Fotheringham, R., Murray, D., Eds.; Nottingham University Press: Nottingham, UK, 2012; pp. 127–136. [Google Scholar]

- Richards, C. Diversity of yeast supply for distilled spirit fermentation. In Future Challenges, New Solutions, Proceedings of the Worldwide Distilled Spirits Conference, Glasgow, UK, 8–11 September 2014; Goodall, I., Fotheringham, R., Murray, D., Speers, R.A., Walker, G.M., Eds.; Context Products Ltd.: Packington, UK, 2015; pp. 37–41. [Google Scholar]

- Simpkins, W.A. Congener profiles in the detection of illicit spirits. J. Sci. Food Agric. 1985, 36, 367–376. [Google Scholar] [CrossRef]

- Gregori, M.; Motta, P.; Caldarelli, G. Chemistry supports marketing: Characterisation of vodkas. In Future Challenges, New Solutions, Proceedings of the Worldwide Distilled Spirits Conference, Glasgow, UK, 8–11 September 2014; Goodall, I., Fotheringham, R., Murray, D., Speers, R.A., Walker, G.M., Eds.; Context Products Ltd.: Packington, UK, 2015; pp. 221–223. [Google Scholar]

- Datamonitor. Skyy Vodka Case Study: Creating Differentiation in the Premium Vodka Market; Informa PLC: London, UK, 2009. [Google Scholar]

- Kotarska, K.; Klosowski, G.; Czupryński, B. Characterization of technological features of dry yeast (strain I-7–43) preparation, production of electrofusion between Saccharomyces cerevisiae and Saccharomyces diastaticus, in industrial application. Enzym. Microb. Technol. 2011, 49, 38–43. [Google Scholar] [CrossRef] [PubMed]

- Janser, E.; Andersen, E.A. Advanced enzymatic pre-treatment for High Gravity fermentation. In New Horizons: Energy, Environment and Enlightenment, Proceedings of the Worldwide Distilled Spirits Conference, Edinburgh, 7–10 September 2008; Walker, G.M., Hughes, P.S., Eds.; Nottingham University Press: Nottingham, UK, 2010; pp. 20–26. [Google Scholar]

- Butcher, S.; Koistinen, T.; Väisänen, E. The growth of contaminating Lactobacilli and alcohol or baker’s yeast production organisms under inhibitory conditions. In Proceedings of the COMETT Course on Microbial Contaminants, Helsinki, Finland, 9–10 June 1992; Korhola, M., Backström, V., Eds.; Foundation for Biotechnological and Industrial Fermentation Research: Helsinki, Finland, 1992; Volume 7, pp. 99–130. [Google Scholar]

- Lim, Y.; Jang, Y.; Kim, K. Production of a high concentration of ethanol from potato tuber by high gravity fermentation. Food Sci. Biotechnol. 2013, 22, 441–448. [Google Scholar] [CrossRef]

- Menezes, A.G.T.; Menezes, E.G.T.; Alves, J.G.L.F.; Rodrigues, L.F.; das Graças Cardoso, M. Vodka production from potato (Solanum tuberosum L.) using three Saccharomyces cerevisiae isolates. J. Inst. Brew. 2016, 122, 76–83. [Google Scholar]

- Tomaszewska, M.; Białończyk, L. Ethanol production from whey in a bioreactor coupled with direct contact membrane distillation. Catal. Today 2016, 268, 156–163. [Google Scholar] [CrossRef]

- Perederii, M.; Tsodikov, M.; Uvarov, V. Purification of aqueous alcohol solutions in two-bed adsorber filters. Solid Fuel Chem. 2011, 45, 34–38. [Google Scholar] [CrossRef]

- Cai, L.; Rice, S.M.; Koziel, J.A.; Jenks, W.S.; van Leeuwen, J.H. Further purification of food-grade alcohol to make a congener-free product. J. Inst. Brew. 2016, 122, 84–92. [Google Scholar] [CrossRef]

- Wiśniewska, P.; Śliwińska, M.; Dymerski, T.; Wardencki, W.; Namieśnik, J. Qualitative characteristics and comparison of volatile fraction of vodkas made from different botanical materials by comprehensive two-dimensional gas chromatography and the electronic nose based on the technology of ultra-fast gas chromatography. J. Sci. Food Agric. 2016. Available online: http//dx.doi.org/10.1002/jsfa.7868 (accessed on 10 August 2016). [Google Scholar]

- Siříšťová, L.; Přinosilová, S.; Riddellová, K.; Hajšlová, J.; Melzoch, K. Changes in quality parameters of vodka filtered through activated charcoal. Czech J. Food Sci. 2012, 30, 474–482. [Google Scholar]

- Cheung, A.W.Y.; Brosnan, J.M.; Smart, K.A. The tolerance of Saccharomyces cerevisiae distilling and bioethanol strains to ethanol. In Science and Sustainability, Proceedings of the Worldwide Distilled Spirits Conference, Glasgow, UK, 12–15 September 2011; Walker, G.M., Goodall, I., Fotheringham, R., Murray, D., Eds.; Nottingham University Press: Nottingham, UK, 2012; pp. 117–125. [Google Scholar]

- Walker, G.; Bringhurst, T.; Brosnan, J. The ideal distillers yeast. Brew. Distill. Int. 2011, 7, 30–32. [Google Scholar]

- Cheung, A.W.Y.; Brosnan, J.M.; Phister, T.; Smart, K.A. Impact of dried, creamed and cake supply formats on the genetic variation and ethanol tolerance of three Saccharomyces cerevisiae distilling strains. J. Inst. Brew. 2012, 118, 152–162. [Google Scholar]

- Lallemand Biofuels and Distilled Spirits. Stabilized Liquid Yeast. 2017–01–04. Available online: http://www.lallemandbds.com/wp-content/uploads/2012/12/2013_LBDS_Data-Sheet_SLY_10090_Data_Rev.00.01.01.2013.pdf (accessed on 4 January 2017).

- Plutowska, B.; Biernacka, P.; Wardencki, W. Identification of volatile compounds in raw spirits of different organoleptic quality. J. Inst. Brew. 2010, 116, 433–439. [Google Scholar] [CrossRef]

- Harrison, J.S.; Graham, J.C.J. Yeasts in distillery practice. In The Yeasts, Volume 3; Rose, A.H., Harrison, J.S., Eds.; Academic Press: London, UK, 1970; pp. 283–348. [Google Scholar]

- Biernacka, P.; Wardencki, W. Volatile composition of raw spirits of different botanical origin. J. Inst. Brew. 2012, 118, 393–400. [Google Scholar] [CrossRef]

- Klosowski, G.; Czupryński, B. Kinetics of acetals and esters formation during alcoholic fermentation of various starchy raw materials with application of yeasts Saccharomyces cerevisiae. J. Food. Eng. 2006, 72, 242–246. [Google Scholar] [CrossRef]

- Ng, L.-K.; Hupé, J.; Harnois, J.; Moccia, D. Characterisation of commercial vodkas by solid-phase microextraction and gas chromatography/mass spectrometry analysis. J. Sci. Food Agric. 1996, 71, 380–388. [Google Scholar] [CrossRef]

- Klosowski, G.; Czupryński, B.; Wolska, M. Characteristics of alcoholic fermentation with the application of Saccharomyces cerevisiae yeasts: As-4 strain and I-7–43 fusant with amylolytic properties. J. Food Eng. 2006, 76, 500–505. [Google Scholar] [CrossRef]

- Pietruszka, M.; St. Szopa, J. Agricultural distillates from Polish varieties of rye. Czech. J. Food Sci. 2014, 32, 406–411. [Google Scholar]

- De Nicola, R.; Hall, N.; Melville, S.G.; Walker, G.M. Influence of zinc on distiller’s yeast: Cellular accumulation of zinc and impact on spirit congeners. J. Inst. Brew. 2009, 115, 265–271. [Google Scholar] [CrossRef]

- Gibson, B.R.; Lawrence, S.J.; Leclaire, J.P.R.; Powell, C.D.; Smart, K.A. Yeast responses to stresses associated with industrial brewery handling. FEMS Microbiol. 2007, 31, 535–569. [Google Scholar] [CrossRef] [PubMed]

- James, T.C.; Campbell, S.; Donnelly, D.; Bond, U. Transcription profile of brewery yeast under fermentation conditions. J. Appl. Microbiol. 2003, 94, 432–448. [Google Scholar] [CrossRef] [PubMed]

- Ding, J.M.; Huang, X.W.; Zhang, L.M.; Zhao, N.; Yang, D.M.; Zhang, K.Q. Tolerance and stress response to ethanol in the yeast Saccharomyces cerevisiae. Appl. Microbiol. Biotechnol. 2009, 85, 253–263. [Google Scholar] [CrossRef] [PubMed]

- Stanley, D.; Bandara, A.; Fraser, S.; Chambers, P.J.; Stanley, G.A. The ethanol stress response and ethanol tolerance of Saccharomyces cerevisiae. J. Appl. Microbiol. 2010, 109, 13–24. [Google Scholar] [CrossRef] [PubMed]

- Hansen, R.; Moffat, F.; Jamieson, D.J. Analysis of a distiller’s yeast during industrial grain fermentation. In Science and Sustainability, Proceedings of the Worldwide Distilled Spirits Conference, Glasgow, UK, 12–15 September 2011; Walker, G.M., Goodall, I., Fotheringham, R., Murray, D., Eds.; Nottingham University Press: Nottingham, UK, 2012; pp. 109–116. [Google Scholar]

- Hansen, R.; Ferguson, A.M.; Pearson, S.Y.; Brosnan, J.M.; Meaden, J.M.; Jamieson, D.J. Proteomic analysis of distillers’ yeast. In Production, Technology and Innovation. Proceedings of the Worldwide Distilled Spirits Conference, Edinburgh, UK, 18–22 September 2005; Bryce, J.H., Piggott, J.R., Stewart, G.G., Eds.; Nottingham University Press: Nottingham, UK, 2008; pp. 93–107. [Google Scholar]

- Watson, D.C. Distilling Yeasts. Dev. Ind. Microbiol. 1984, 25, 213–220. [Google Scholar]

- Walker, G.M. Current challenges and future opportunities for distillers yeast: Discussion forum. In Science and Sustainability, Proceedings of the Worldwide Distilled Spirits Conference, Glasgow, UK, 12–15 September 2011; Walker, G.M., Goodall, I., Fotheringham, R., Murray, D., Eds.; Nottingham University Press: Nottingham, UK, 2012. [Google Scholar]

- Enquist-Newman, M.; Faust, A.M.E.; Bravo, D.D.; Santos, C.N.S.; Raisner, R.M.; Hanel, A.; Sarvabhowman, P.; Le, C.; Regitsky, D.D.; Cooper, S.R.; et al. Efficient ethanol production from brown macroalgae sugars by a synthetic yeast platform. Nature 2013, 505, 239. [Google Scholar] [CrossRef] [PubMed]

- Grunert, K.G.; Bredahl, L.; Scholderer, J. Four questions on European consumers’ attitudes toward the use of genetic modification in food production. Inn. Food Sci. Emerg. Technol. 2003, 4, 435–445. [Google Scholar] [CrossRef]

- Frewer, L.J.; van der Lans, I.A.; Fischer, A.R.H.; Reinders, M.J.; Menozzi, D.; Zhang, X.; van den Berg, I.; Zimmerman, K.L. Public perception of agri-food applications of genetic modification―A systematic review and meta-analysis. Trends Food Sci. Technol. 2013, 30, 142–152. [Google Scholar] [CrossRef]

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).