Abstract

This study reports the development of fully biodegradable biocomposites based on polylactic acid (PLA) and polyhydroxybutyrate (PHB) reinforced with alkaline-treated hemp fibers and granules. The thermal, mechanical, dynamic mechanical, and rheological properties of the composites were investigated to assess the influence of reinforcement morphology and content. Differential scanning calorimetry (DSC) confirmed that hemp fibers acted as more effective nucleating agents than granules, increasing the degree of crystallinity of the PLA/PHB blend. Thermal conductivity analysis revealed that hemp incorporation does not systematically improve heat transfer: while long fibers slightly enhanced conductivity, several granule-based composites exhibited lower values than the neat blend. Tensile testing showed that all reinforced samples had lower tensile strength than the neat PLA/PHB matrix, although stiffness was increased, particularly for fiber-based composites. In contrast, flexural strength was maximized in granule-reinforced systems, notably PLA/PHB-2–10-G and PLA/PHB-0.5–10-G, while fibers preserved or improved ductility. Dynamic mechanical analysis confirmed the viscoelastic nature of all composites, with reduced tan δ compared to the neat blend. Rheological testing demonstrated that most composites exhibited lower G′ and complex viscosity than the neat PLA/PHB blend, except for PLA/PHB-2–10-G, which showed stronger matrix–filler interactions. Overall, the results highlight that the performance of PLA/PHB/hemp biocomposites is formulation-dependent, and the selection of hemp morphology and content is crucial for tailoring properties to specific applications.

1. Introduction

The development of biocomposites from renewable polymers reinforced with natural fibers has emerged as a key strategy to reduce the environmental footprint of conventional plastics. Among biodegradable polymers, polylactic acid (PLA) and polyhydroxybutyrate (PHB) stand out due to their complementary properties. PLA, produced from renewable feedstocks such as corn starch and sugarcane, offers good processability, biocompatibility, and relatively high mechanical strength [,,,]. However, its use remains limited by intrinsic brittleness, low thermal stability, and slow degradation under natural conditions. In contrast, PHB, a bacterial polyester, exhibits high crystallinity and faster biodegradability in natural environments, but its processing window is narrow and it is also brittle [,,]. To overcome these individual drawbacks, PLA and PHB are often blended in order to combine the processability and strength of PLA with the crystallinity and biodegradability of PHB. Despite their chemical similarity (Figure 1), the two polymers are generally immiscible, which induces phase separation and results in suboptimal mechanical performance in unmodified blends [,]. To improve compatibility and enhance properties, several approaches have been investigated, including the incorporation of plasticizers, chain extenders, and reinforcing fillers [,].

Figure 1.

Chemical structure of PLA (left) and PHB (right).

In recent years, natural fibers have attracted growing interest as reinforcements in polymer composites owing to their low density, biodegradability, cost-effectiveness, and relatively high mechanical performance [,,,,,]. Among them, hemp fibers stand out for their excellent stiffness and tensile strength, combined with ecological advantages such as rapid growth and minimal agricultural inputs [,,]. Their high aspect ratio and favorable mechanical properties make them promising candidates for reinforcing biodegradable matrices such as PLA and PHB. Previous research has demonstrated that incorporating natural fibers into PLA or PHB can enhance stiffness, thermal stability, and overall material performance [,]. However, limited attention has been given to PLA/PHB blends reinforced with hemp fibers, particularly regarding the influence of fiber morphology and alkaline surface treatment on the thermal, mechanical, and rheological properties of the resulting biocomposites. Addressing this gap is essential to better understand structure–property relationships and to evaluate the potential of hemp-reinforced PLA/PHB systems for sustainable industrial applications.

The objective of this study is to design fully biodegradable PLA/PHB biocomposites reinforced with hemp in two morphological forms—granules and fibers—pretreated with sodium hydroxide to improve fiber–matrix interfacial adhesion. Particular attention is given to the effect of fiber size, shape, and content on crystallization behavior, mechanical properties, and viscoelastic performance. Through a comprehensive thermal, mechanical, and rheological characterization, this work aims to establish clear structure–property relationships in PLA/PHB/hemp systems. By bridging the current knowledge gap, the study not only highlights the role of fiber morphology and surface treatment in optimizing composite performance but also assesses the potential of these biocomposites for thermoforming processes and environmentally friendly packaging applications.

To the best of our knowledge, this is one of the first systematic investigations on PLA/PHB blends reinforced with hemp in both granule and fiber forms, coupled with alkaline surface treatment. This approach provides new insights into how fiber morphology and chemical modification govern the thermal, mechanical, and rheological responses of biocomposites, thereby positioning PLA/PHB/hemp systems as promising candidates for sustainable industrial applications.

2. Materials and Methods

2.1. Materials

Polylactic acid (PLA 2003D, NatureWorks LLC, (17400 Medina Road, Suite 800, Plymouth, MN 55447, USA), CAS No. 26100-51-6) and polyhydroxybutyrate (PHB P226, Biomer, (Biomer GmbH, Hans-Losch-Strasse 1, 82152 Krailling, Germany), CAS No. 26780-50-7) were selected as the polymer matrix components. PLA 2003D is a high-purity extrusion-grade polymer, suitable for melt processing and thermoforming. PHB P226 is a biodegradable bacterial polyester known for its high crystallinity and moderate thermal stability.

Hemp reinforcements were supplied by ArtCan R&D (Québec, QC, Canada) and were used in two physical forms: (i) ground granules with average particle sizes of 0.5 mm, 1 mm, and 2 mm, and (ii) cut fibers with lengths of 2 mm and 20 mm. Before incorporation into the polymer matrix, the hemp fibers were subjected to an alkaline pretreatment to improve interfacial adhesion with the PLA/PHB blend. The fibers were immersed in a 4 wt.% NaOH aqueous solution (Sigma-Aldrich, 3050 Spruce Street, St. Louis, MO 63103, USA, 99% purity) at room temperature for 2 h under continuous stirring. This treatment removes hemicellulose, lignin, waxes, and other surface impurities, thereby increasing surface roughness and exposing more cellulose hydroxyl groups for hydrogen bonding. After treatment, the fibers were thoroughly rinsed with distilled water until neutral pH was reached, followed by oven-drying at 80 °C for 24 h.

2.2. Methods

2.2.1. Elaboration of PLA/PHB/Hemp Biocomposites

The PLA/PHB matrix was prepared with a constant weight ratio of 75/25. Hemp reinforcements were added at various concentrations (5–20 wt.%), the hemp reinforcements were used in two different morphological forms: granules and fibers. For granules, the reported sizes (0.5 mm, 1 mm, and 2 mm) refer to the average particle diameter obtained after grinding and sieving of the raw hemp. For fibers, the reported sizes (2 mm and 20 mm) indicate the average fiber length measured after cutting and alkaline surface treatment. Sample labels (e.g., PLA/PHB-2–15%-G, PLA/PHB-20–10%-F) reflect the hemp morphology (G = granule, F = fiber), characteristic size (diameter for granules, length for fibers), and weight percentage of reinforcement incorporated into the PLA/PHB matrix (Table 1). The temperature profile along the barrel was set from 170 °C to 180 °C (zones: 170, 175, 180, 180, 180, 180, 177, 175, 172, and 170 °C). The screw rotation speed was maintained at 60 rpm, the compounding was carried out using a Thermo Scientific HAAKE Rheomex OS twin-screw extruder (screw diameter: 25 mm, L/D ratio: 40). The equipment provides modular screw configurations that enable efficient mixing and dispersion of natural fibers within the polymer matrix. The barrel temperature profile was set between 170 °C and 180 °C (from feed zone to die), with a screw rotation speed of 60 rpm and a throughput of approximately 4 kg/h. The extrudates were pelletized and subsequently oven-dried at 60 °C for 2 h prior to injection molding. Specimens for mechanical and thermal characterization were prepared by injection molding using a PN60 machine (Nissei, 2110 Minamijo, Sakaki-machi, Hanishina-gun, Nagano-ken 389-0693, Japan). The temperatures in the injection unit were set to 180 °C (nozzle), 185 °C (front), 180 °C (middle), and 175 °C (rear), while the mold temperature was maintained at 35 °C. All molded samples were conditioned in a desiccator for at least 48 h before testing.

Table 1.

PLA/hemp biocomposite formulations studied.

2.2.2. Characterization

Thermal Analysis

- Differential scanning calorimetry (DSC)

Differential scanning calorimetry (DSC) is a thermo-analytical technique measuring the heat flow associated with thermal transitions in a material as a function of temperature. The method relies on detecting differences in heat flow between a sample and an inert reference under identical, controlled temperature conditions. In this study, DSC analyses were carried out using a DSC 25 (TA Instruments, New Castle, DE 19720, USA) over a temperature range of 25 to 200 °C with a heating/cooling rate of 10 °C/min. Each sample underwent three consecutive cycles: first heating, cooling, and second heating to assess the thermal behavior, including glass transition and crystallinity changes induced by thermal cycling. The degree of crystallinity (Xc) was calculated from the second heating scan using the following equation:

where

- −

- ΔHm is the melting enthalpy of the sample (J/g),

- −

- ΔHcc is the cold crystallization enthalpy (J/g),

- −

- is the theoretical melting enthalpy of a 100% crystalline polymer,

- −

- ω is the weight fraction of the polymer in the blend.

For PLA, is typically taken as 93 J/g, and 146 J/g for PHB [].

- Thermal conductivity

The thermal conductivity of the PLA/PHB/hemp fiber composites was evaluated using a steady-state heat flow method based on ASTM E1225 and a home-made set-up []. The measurements were conducted at three different average temperatures (25 °C, 50 °C, and 75 °C) with a 20 °C difference to determine the effect of temperature on the thermal behavior of the biocomposites.

Square samples (50 mm × 50 mm) with a uniform thickness (about 4.5 mm) were prepared via compression molding and positioned between two parallel Peltier plates to control the imposed temperatures. The set-up ensured a stable and uniform temperature gradient across the sample thickness and the heat flux was recorded to calculate the thermal conductivity as (Fourier’s law):

where k is the thermal conductivity (W/m·K), Q is the measured heat flow (W), L is the sample thickness (m), A is the cross-sectional area (m2), and ΔT is the temperature difference across the sample (K).

Mechanical Testing

- Dynamic mechanical analysis (DMA)

Dynamic mechanical analysis (DMA) was conducted to assess the viscoelastic properties of the PLA/PHB/hemp composites as a function of temperature. The tests were performed using an RSA 3 (TA Instruments, USA) in a three-point bending geometry, from room temperature to 140 °C at a heating rate of 3 °C/min, with a fixed frequency of 1 Hz and a strain amplitude of 0.005%. This technique provides key parameters, such as the storage modulus (E′), loss modulus (E″), and damping factor (tan δ), offering insights into the stiffness, energy dissipation, and glass transition behavior.

- Tensile testing

Tensile tests were conducted according to ASTM D638 using type IV specimens on an Instron, 825 University Ave., Norwood, MA 02062-2643, USA (USA) model 5545. The tests were performed at a crosshead speed of 5 mm/min to obtain the tensile stress–strain curves, from which tensile strength, Young’s modulus, and elongation at break was determined. These parameters were used to assess the stiffness, strength, and ductility of the PLA/PHB/hemp composites, providing insight into the reinforcing efficiency of the hemp particles and the quality of hemp–matrix interfacial adhesion.

- Flexural testing

The flexural properties of the PLA/PHB/hemp composites were evaluated using a three-point bending geometry following ASTM D790 with a model 5545 universal tester from Instron (USA). The tests were performed on rectangular specimens (80 mm × 10 mm × 4 mm) with a span-to-depth ratio of 16:1 and a crosshead speed of 2 mm/min. Flexural strength, flexural modulus, and deformation at break were measured to assess the composites’ resistance to bending and their structural performance under mechanical loading.

Rheological Testing

Rheological tests were carried out to evaluate the viscoelastic behavior and processability of the PLA/PHB/hemp composites, providing essential insights into their flow characteristics and deformation response under thermal and mechanical stresses. The measurements were conducted using an ARES rheometer from TA Instruments (USA) equipped with a 25 mm parallel plate geometry and a temperature-controlled environmental chamber. A temperature sweep was performed from 140 °C to 160 °C at a constant angular frequency of 1 rad/s and within the linear viscoelastic region (2% deformation). This test allowed for the analysis of the storage modulus (G′), loss modulus (G″), and complex viscosity (η*), highlighting the effect of hemp reinforcement on the melt viscoelasticity of the PLA/PHB matrix.

3. Results and Discussion

3.1. Thermal Analysis

3.1.1. Differential Scanning Calorimetry (DSC)

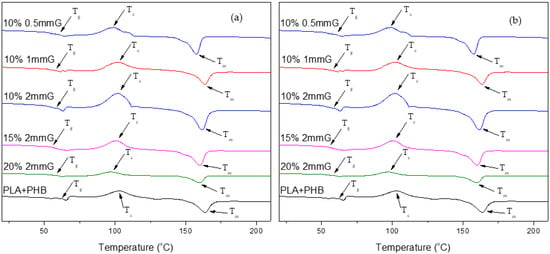

Differential scanning calorimetry (DSC) was performed to analyze the thermal transitions and crystallization behavior of the PLA/PHB composites reinforced with hemp in both granule and fiber forms. The thermograms (Figure 2) revealed three main thermal events characteristic of the polymer matrix: the glass transition temperature (Tg), the cold crystallization temperature (Tc), and the melting temperature (Tm).

Figure 2.

Differential scanning calorimetry results of the PLA/PHB biocomposites based on: (a) hemp granules and (b) hemp fibers.

Figure 2 shows the DSC thermograms of PLA/PHB biocomposites reinforced with hemp granules (a) and fibers (b). The incorporation of hemp reinforcements had a marked impact on the crystallization behavior of the matrix, as evidenced by a general increase in the degree of crystallinity (Xc). This effect confirms the nucleating role of hemp, consistent with previous studies reporting that natural fibers can serve as heterogeneous nucleation sites in biopolymer systems [].

For granule-reinforced composites, increasing the content from 10 to 20 wt.% led to a progressive reduction in the cold crystallization temperature (Tc), indicating more efficient nucleation. At the same time, a slight decrease in melting temperature (Tm) was observed at higher loadings, which may be attributed to imperfect crystalline structures caused by particle agglomeration. Granule size also played a role: smaller particles (0.5 mm) produced narrower and more intense thermal transitions, suggesting improved dispersion and more homogeneous crystallization.

Fiber-based systems exhibited an even stronger crystallization response. Both short (2 mm) and long (20 mm) fibers significantly decreased Tc and enhanced Xc, confirming their efficiency as nucleating agents. Unlike granules, Tm remained stable, while sharper melting peaks—especially in long fiber composites—revealed faster crystallization kinetics and more organized crystalline domains. The superior performance of fibers compared to granules highlights the importance of fiber morphology and the interfacial interactions promoted by the alkaline treatment [].

The calculated crystallinity values (Table 2) confirm the nucleating role of hemp reinforcements. Compared to the neat PLA/PHB blend (Xc = 12.8%), the incorporation of hemp significantly increased Xc, with the strongest effect observed for long fibers at 10 wt.% (Xc ≈ 22.0%). These results clearly demonstrate that hemp fibers promote more efficient nucleation than granules, consistent with the sharper melting peaks observed in the DSC curves.

Table 2.

Degree of crystallinity (Xc) of PLA/PHB and PLA/PHB/hemp biocomposites calculated from DSC (second heating).

Overall, these results demonstrate that hemp reinforcements, and particularly fibers, substantially improve the crystallization behavior of PLA/PHB blends without compromising the polymer network. By providing higher crystallinity and more stable thermal transitions, hemp-reinforced PLA/PHB biocomposites offer a unique balance of processability and dimensional stability. This original contribution emphasizes the potential of tailoring filler morphology—granules for improved dispersion and fibers for enhanced nucleation—to design bio-based composites suitable for thermoforming and heat-exposed applications.

3.1.2. Thermal Conductivity

The thermal conductivity values of the PLA/PHB and PLA/PHB/hemp biocomposites at 75 °C are summarized in Table 3. As expected, the addition of hemp reinforcements altered the heat transfer capability of the matrix. However, the effect strongly depended on the hemp morphology and content. While some formulations (notably long fibers at 10 wt.%) slightly increased the thermal conductivity compared to the neat PLA/PHB blend, several granule-based composites exhibited lower values than the control. This reduction may be attributed to interfacial voids and poor thermal continuity between the granules and the matrix, which limit phonon transfer. Therefore, the incorporation of hemp does not systematically enhance heat conduction, and the balance between reinforcement morphology and dispersion quality plays a decisive role in defining the thermal transport properties.

Table 3.

Thermal conductivity of the PLA/PHB/hemp biocomposites at different temperatures (25 °C, 50 °C, and 75 °C).

This improvement can be explained by the formation of continuous thermal conduction pathways within the composites. Hemp particles, which possess a relatively higher intrinsic conductivity compared to the PLA/PHB matrix, facilitate heat transfer by creating interconnected networks. Similar trends have been observed in other polymer systems reinforced with conductive fillers, such as PLA/nano-graphite composites [].

However, the effect of hemp content on thermal conductivity was not strictly linear. While a 15 wt.% loading of 2 mm granules resulted in the highest thermal conductivity at 75 °C (0.221 W/m·K), further increasing the content to 20 wt.% led to reduced values at elevated temperatures. This decline is likely due to particle agglomeration and poor dispersion at higher loadings, which increase interfacial thermal resistance and disrupt efficient heat transfer. Particle size also played a critical role: granules of 2 mm provided better conductivity than smaller 0.5 mm particles, most likely because their larger dimensions enabled stronger interconnections across the polymer matrix.

For fiber-reinforced systems, the gains in conductivity were more modest. Long fibers showed slightly higher values than short ones, but the differences were less significant than in the granule-based composites. This behavior may be attributed to less uniform fiber dispersion and weaker thermal contact at the fiber–matrix interface.

Overall, these findings emphasize the importance of controlling both filler morphology and dispersion quality to optimize thermal transport in bio-based composites. The demonstration that hemp morphology (granules vs. fibers, particle size, and content) directly governs thermal conductivity in PLA/PHB blends represents an original contribution of this study. This aspect is particularly relevant for thermoforming and packaging applications, where enhanced heat transfer ensures more homogeneous heating and improved dimensional stability during processing.

The thermal analyses confirmed that hemp reinforcements, particularly in fiber form, significantly enhanced the crystallization behavior and contributed to improved heat transfer within the PLA/PHB matrix. These modifications are expected to influence the mechanical response of the composites, since higher crystallinity and better thermal conductivity generally translate into improved stiffness, strength, and dimensional stability under load. In addition, the clear differences observed between granules and fibers in terms of dispersion and interfacial contact suggest that morphology will also play a critical role in governing stress transfer mechanisms. To further elucidate these structure–property relationships, the mechanical performance of the composites was evaluated through dynamic mechanical analysis (DMA), tensile, and flexural testing.

3.2. Mechanical Testing

3.2.1. Dynamic Mechanical Analysis (DMA)

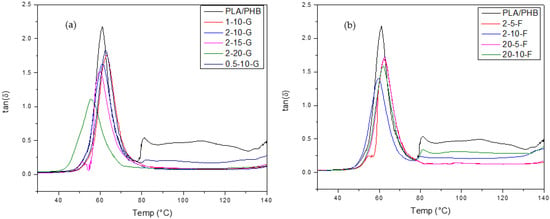

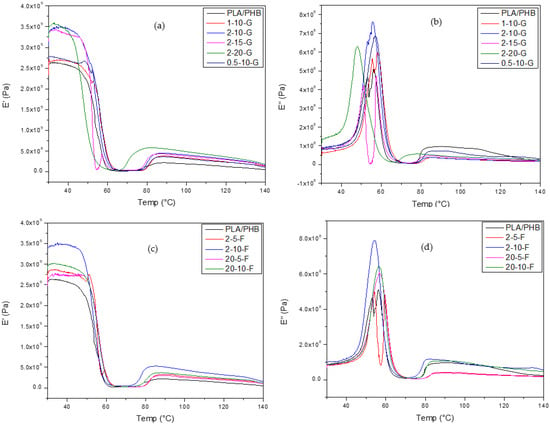

Figure 3 presents the storage modulus (E′) and damping factor (tan δ) of PLA/PHB composites reinforced with hemp granules and fibers. The incorporation of hemp reinforcements, irrespective of their form, led to a marked increase in E′ across the entire temperature range studied (25–120 °C). This increase reflects a significant gain in stiffness, which can be attributed to the rigid nature of lignocellulosic fillers and the consequent restriction of polymer chain mobility within the PLA/PHB matrix. The improvement observed here is particularly relevant, as it demonstrates that both hemp granules and fibers act as effective reinforcements in biodegradable polymer blends that are otherwise limited by low rigidity. By quantifying these effects in PLA/PHB systems, this study provides original evidence of how filler morphology contributes to the viscoelastic stiffening of bio-based composites, thereby enhancing their potential for load-bearing and thermoforming applications.

Figure 3.

Dynamic mechanical analysis (DMA) results (tan δ) of the PLA/PHB biocomposites based on: (a) hemp granules and (b) hemp fibers.

The storage modulus (E′) curves presented in Figure 4 show that the addition of hemp reinforcements modifies the stiffness of the PLA/PHB matrix. Among the granule-based composites, the formulation containing 2 mm granules exhibited the highest E′, outperforming the 0.5 mm and 1 mm granules. For fiber-reinforced samples, the PLA/PHB-2–10-F composite displayed the largest E′, confirming that fiber dispersion and interfacial bonding play a crucial role in stiffness enhancement. The loss modulus (E″) curves (Figure 4) followed similar tendencies, reflecting the higher energy dissipation ability of the reinforced systems compared to the neat blend.

Figure 4.

Storage modulus (E′) as a function of temperature for: (a) PLA/PHB and PLA/PHB/hemp granules composites, (c) PLA/PHB and PLA/PHB/hemp fibers composites, and Loss modulus (E″) as a function of temperature for: (b) PLA/PHB and PLA/PHB/hemp granules composites, and (d) PLA/PHB and PLA/PHB/hemp fibers composites.

The damping factor (tan δ, Figure 3) decreased for all reinforced composites compared to the neat PLA/PHB blend, indicating a reduction in chain mobility due to the presence of hemp particles. This decrease was observed for both fiber and granule reinforcements, contrary to the neat blend which showed a higher damping peak. In addition, the glass transition temperature (Tg) remained relatively unchanged for all composites, without any significant broadening of the transition, which confirms that hemp incorporation did not notably affect the relaxation dynamics of the PLA/PHB matrix [,]. These results underscore the critical role of filler size and morphology: while smaller granules enhance stiffness through homogeneous dispersion, long fibers provide superior interfacial bonding and reinforcement. This dual comparison represents an original contribution of the present study, as it demonstrates how tuning hemp morphology can be used to tailor viscoelastic behavior in PLA/PHB biocomposites for specific structural and thermoforming applications.

The loss modulus (E″) curves displayed relaxation peaks close to the glass transition temperature (Tg), with more pronounced intensities in composites containing 10–15 wt.% hemp. This behavior suggests enhanced energy dissipation and stronger polymer-filler interactions []. A comparison between morphologies revealed that fiber-reinforced systems exhibited smoother transitions and greater damping stability than granule-based composites, reflecting a more efficient stress transfer across the fiber–matrix interface.

The combined analysis of storage modulus (E′), loss modulus (E″), and damping factor (tan δ) indicates that the composites display viscoelastic behavior typical of thermoplastic polymer systems. The coexistence of elastic and viscous contributions, together with the observed transitions, demonstrates the ability of the materials to both store and dissipate energy under dynamic loading.

Overall, the DMA results confirm that hemp morphology has a decisive influence on the viscoelastic response of PLA/PHB biocomposites. Granules primarily act as dispersed fillers, slightly disturbing the polymer phase and leading to a broadening of the Tg. In contrast, fibers—particularly long ones—reinforce the matrix more effectively, reduce damping, and shift Tg to higher values. These effects indicate stronger interfacial adhesion and a more constrained molecular network, which enhance the structural integrity of the composites. The clear differentiation between the roles of granules and fibers represents an original contribution of this work, providing valuable insights into how filler morphology can be strategically selected to tailor the thermomechanical performance of bio-based composites for specific engineering and thermoforming applications.

3.2.2. Tensile Testing

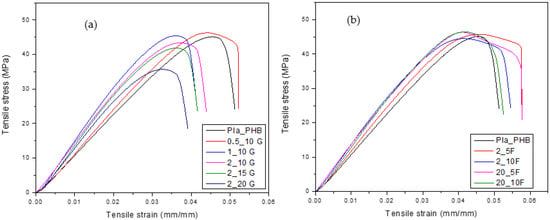

The tensile properties of the neat PLA/PHB blend and the reinforced composites are presented in Table 4 and Figure 5. The results show that the incorporation of hemp, either as granules or fibers, generally reduced the tensile strength compared to the neat PLA/PHB matrix. This decrease can be attributed to stress concentration effects at the fiber/matrix interface and possible poor load transfer due to insufficient adhesion. Among the reinforced samples, the PLA/PHB-2–10-F formulation exhibited the highest tensile strength, although still lower than that of the neat blend.

Table 4.

Young’s modulus, tensile strength, and strain at break of PLA/PHB/hemp biocomposites.

Figure 5.

Typical tensile stress–strain curves of the PLA/PHB biocomposites based on: (a) hemp granules and (b) hemp fibers.

Regarding the tensile modulus, the addition of hemp led to an improvement in stiffness, with the highest modulus observed for fiber-reinforced composites. These results indicate that while hemp reinforcement does not enhance the ultimate tensile strength of the PLA/PHB matrix, it contributes to increased rigidity of the biocomposites.

Fiber reinforcement produced even more substantial improvements compared to granules. In particular, long fibers (20 mm) at 15 wt.% provided the most significant enhancement, with tensile modulus and strength increasing by 55% and 48%, respectively, relative to the neat PLA/PHB matrix. These results confirm the strong reinforcing efficiency of long hemp fibers, which stems from their high aspect ratio and their ability to transfer stresses more effectively across the fiber–matrix interface. However, the elongation at break decreased in all fiber-reinforced systems, and this reduction became more pronounced at higher filler loadings. This behavior reflects the well-known stiffening–embrittlement trade-off commonly reported in natural fiber composites [], where increased rigidity comes at the expense of ductility.

Overall, the integration of hemp fibers significantly enhances both stiffness and strength of PLA/PHB blends, with the degree of improvement strongly dependent on fiber length, content, and dispersion quality. The originality of this work lies in the systematic demonstration that long hemp fibers, when combined with alkaline surface treatment, maximize stress transfer while still maintaining processability. This provides valuable insights into how fiber morphology and interfacial optimization can be tailored to balance stiffness and toughness in fully biodegradable composites designed for structural and thermoforming applications.

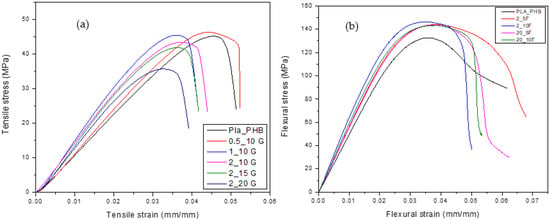

3.2.3. Flexural Testing

The flexural properties of the PLA/PHB and PLA/PHB/hemp composites are summarized in Figure 6 and Table 5. The results show that the highest flexural strength values were obtained for granule-reinforced composites, particularly PLA/PHB-2–10-G and PLA/PHB-0.5–10-G, which outperformed both the neat blend and the fiber-based samples. This enhancement can be attributed to a more homogeneous stress distribution and better packing of the granules within the matrix.

Figure 6.

Typical flexural stress–strain curves for the PLA/PHB biocomposites based on: (a) hemp granules and (b) hemp fibers.

Table 5.

Flexural modulus, flexural strength, and deflection at break of PLA/PHB/hemp composites.

For fiber-reinforced composites, the flexural strength values were slightly lower than those of the granule-based samples but still comparable to the neat PLA/PHB blend. In terms of elongation at break, the fiber-based composites exhibited values that were equal to or higher than the neat blend, indicating that fiber morphology contributed to maintaining or even improving the ductility of the system under bending.

Overall, these results confirm that granules are more efficient than fibers in enhancing flexural strength, while fibers help preserve flexibility.

For comparison, Behera et al. [] demonstrated that coating hemp fibers with PLA in epoxy-based composites enhanced flexural strength by 29%, mainly through improved fiber–matrix interfacial adhesion. Similarly, increasing the fiber volume fraction in hemp fabric–reinforced polypropylene composites was shown to improve flexural performance, attributed to more efficient stress transfer and stronger interfacial bonding []. These results are in line with the present findings, which highlight the decisive role of fiber–matrix interactions in governing flexural properties.

In this study, fiber morphology and dispersion quality proved critical to maximizing reinforcement efficiency. Long fibers provided the highest gains in flexural modulus and strength due to their superior load transfer capability and high aspect ratio. However, granule-filled composites, while less mechanically efficient, offered more uniform dispersion and dimensional stability, which may be advantageous for applications prioritizing processability over maximum strength. The originality of this work lies in directly comparing hemp granules and fibers within a PLA/PHB matrix, thereby demonstrating that the optimal reinforcement strategy depends on the targeted application: fibers for structural performance, and granules for enhanced processability and dimensional uniformity.

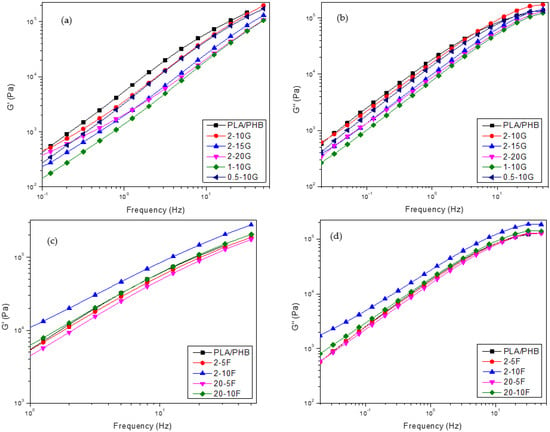

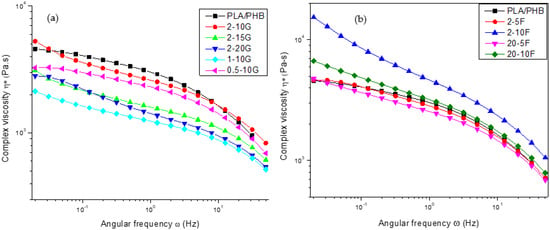

3.3. Rheological Testing

The viscoelastic behavior of PLA/PHB composites reinforced with hemp granules and fibers was investigated using small-amplitude oscillatory shear (SAOS) measurements. This technique provides key information on the balance between the solid-like and liquid-like responses of the material. The storage modulus (G′) represents the elastic component, reflecting the material’s ability to store and recover energy during deformation, whereas the loss modulus (G″) corresponds to the viscous component, associated with energy dissipation as heat. Together, these parameters describe the viscoelastic nature of the composites and their suitability for melt processing. The resulting curves are shown in Figure 7.

Figure 7.

Frequency dependence of the storage modulus (G′) and loss modulus (G″) for PLA/PHB-based biocomposites based on: (a,b) hemp granules and (c,d) hemp fibers.

This rheological approach is particularly relevant for PLA/PHB-based systems, as it allows the effect of hemp morphology (granules vs. fibers) on melt elasticity and flow behavior to be directly quantified—an aspect that remains scarcely addressed in the literature and represents a key original contribution of the present study.

From the frequency sweep results shown in Figure 7, both the storage modulus (G′) and the loss modulus (G″) increased with frequency, reflecting the typical viscoelastic response of polymeric materials within the tested range. The incorporation of hemp reinforcements, particularly at higher contents, further modified these behaviors. Composites reinforced with hemp granules (2-15G and 2-20G) displayed significantly higher G′ values compared to the neat PLA/PHB blend, indicating that granules effectively restricted polymer chain mobility and strengthened the elastic network within the matrix. The loss modulus (G″) followed a similar trend, although differences between formulations were less pronounced, suggesting that the energy dissipation capacity was less sensitive to filler content and morphology. Interestingly, the use of smaller granules (0.5 mm) did not yield higher G′ compared to 2 mm particles, suggesting that filler morphology and loading are more critical than particle size alone in governing rheological performance.

For fiber-reinforced composites, G′ values were generally lower than those of granule-based systems at equivalent filler loadings, particularly at lower fiber contents. This effect is likely due to the less homogeneous dispersion of fibers and weaker interfacial contact compared to granules, which hinder the formation of a continuous elastic network. These observations align with previous reports demonstrating that lignocellulosic fillers can enhance the stiffness and elasticity of PLA-based composites []. and that improved dispersion and surface treatment are key to maximizing reinforcement efficiency [,]. In this study, the marked increase in G′ observed at 10–15 wt.% granule content confirms the reinforcing effect of hemp fillers and underlines the importance of morphology in tailoring rheological performance. The combination of stable G″ values and increasing G′ with frequency further indicates improved structural integrity, making these composites particularly suitable for thermoforming and other melt-processing applications that require dimensional stability.

The complex viscosity (η*) results, measured at 160 °C, revealed shear-thinning behavior typical of viscoelastic polymer systems []. Hemp granules significantly increased η*, especially at low frequencies, with the 2-10G and 2-15G formulations showing the strongest reinforcement. By contrast, the 1-10G sample exhibited lower viscosity, likely due to less rigid particle characteristics. Fiber-reinforced systems displayed an even greater increase in η*, particularly in the 2-10F and 20-10F composites, which can be attributed to the higher aspect ratio of fibers and the enhanced interfacial interactions generated by alkaline surface treatment. These findings are consistent with previous studies linking higher complex viscosity to improved mechanical interlocking and more efficient stress transfer [].

Taken together, these rheological results provide original evidence that hemp morphology plays a decisive role in controlling the melt behavior of PLA/PHB composites. While granules promote structural elasticity and stability, fibers enhance viscosity and interfacial interactions, suggesting that filler design can be strategically tuned to optimize processing behavior for industrial applications.

The increase in both storage modulus (G′) and loss modulus (G″) with frequency clearly demonstrates that the PLA/PHB/hemp composites exhibit a viscoelastic response typical of thermoplastic polymer systems. This dual contribution of elastic (G′) and viscous (G″) components highlights the ability of the materials to simultaneously store and dissipate energy during deformation, which is a key feature for processing and end-use performance. The observed behavior confirms that the prepared samples are indeed viscoelastic, in agreement with the general characteristics reported for polymer blends reinforced with natural fibers. Similar findings have been described in the literature, where the balance between G′ and G″ is used to evaluate the viscoelastic nature of polymeric systems [].

The rheological properties of the neat PLA/PHB blend and the reinforced composites are presented in Figure 7 and Figure 8. The storage modulus (G′) and loss modulus (G″) decreased for most reinforced formulations compared to the neat PLA/PHB blend, indicating reduced elastic and viscous contributions. This reduction can be associated with the introduction of rigid fillers that disrupt the continuity of the polymer matrix and create localized stress relaxation sites.

Figure 8.

Complex viscosity (η*) at 160 °C as a function of angular frequency (ω) for PLA/PHB biocomposites based on: (a) hemp granules and (b) hemp fibers.

Regarding the complex viscosity (η*), the majority of hemp-reinforced composites exhibited lower values than the neat blend, suggesting improved flowability during processing. The only exception was the PLA/PHB-2–10-G composite, which showed a significant increase in η*, indicating stronger interactions and restricted chain mobility in this formulation.

These results highlight that the incorporation of hemp does not systematically increase rheological performance; instead, the effect strongly depends on the reinforcement morphology and its dispersion within the matrix. To improve comparison, the frequency sweep data were replotted with harmonized axis scales, and the missing 0.5 mm granule sample was added in the legend of Figure 8.

Overall, this study provides original insights by directly comparing the effects of hemp granules and fibers within PLA/PHB blends, an approach rarely addressed in the literature. The findings demonstrate that the choice of hemp morphology enables fine-tuning of the balance between crystallization behavior, mechanical reinforcement, and rheological performance. This work therefore establishes PLA/PHB/hemp composites as promising candidates for sustainable thermoforming and packaging applications, where both structural integrity and processing efficiency are required.

4. Limitations of the Study

Although the results of this work demonstrate the strong reinforcing potential of hemp granules and fibers in PLA/PHB biocomposites, several limitations should be acknowledged. At higher filler loadings (≥20 wt.%), particle agglomeration and incomplete dispersion were observed, which may reduce mechanical efficiency and thermal stability. The composites are also sensitive to ambient humidity, which can affect both processing and long-term performance due to the hydrophilic nature of hemp. Furthermore, while laboratory-scale experiments confirmed promising thermoforming potential, additional studies are needed to validate the reproducibility of results at an industrial scale. Finally, biodegradation tests under real environmental conditions were not performed in this study and should be considered in future work to fully assess the ecological relevance of these materials.

5. Conclusions

This study investigated the thermal, mechanical, dynamic mechanical, and rheological properties of PLA/PHB biocomposites reinforced with hemp fibers and granules. The results confirmed that hemp morphology and content have a strong influence on the performance of the composites. In terms of tensile properties, all reinforced samples exhibited lower tensile strength than the neat PLA/PHB blend, although fiber incorporation contributed to increased stiffness. For flexural testing, granule-based composites, particularly PLA/PHB-2–10-G and PLA/PHB-0.5–10-G, achieved the highest flexural strength values, while fiber-reinforced systems maintained higher ductility. DMA confirmed the viscoelastic behavior of all composites, with reduced tan δ compared to the neat blend. Rheological measurements showed that most composites exhibited lower G′ and η* than the neat blend, with the exception of PLA/PHB-2–10-G, which displayed a higher viscosity due to stronger filler–matrix interactions. Finally, thermal conductivity analysis demonstrated that hemp does not systematically enhance heat transfer: while long fibers slightly increased conductivity, several granule-based composites showed lower values than the control.

Overall, the findings demonstrate that hemp can tailor the balance between stiffness, ductility, and thermal/rheological response of PLA/PHB blends, but the improvements are formulation-dependent. These results highlight the importance of carefully selecting hemp morphology and content to optimize composite performance for targeted applications.

Author Contributions

Conceptualization, Z.R. and H.K.; methodology, Z.R. and D.R.; formal analysis, Z.R. and D.R.; investigation, Z.R.; validation, F.E. and H.K.; resources, F.E. and D.R.; data curation, Z.R.; writing—original draft preparation, Z.R.; writing—review and editing, Z.R., F.E., D.R. and H.K.; supervision, F.E. and D.R.; project administration, F.E.; funding acquisition, F.E., Z.R. conducted the experimental work, data analysis, and manuscript drafting. D.R. contributed to the formal analysis, methodological guidance, and revision of the manuscript. F.E. supervised the project, provided scientific guidance, validation of results, and corrections to the manuscript. H.K. contributed to the manuscript revision and provided constructive feedback on the final version. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by the Centre de recherche sur les matériaux avancés du Québec (CREPEC) and the Université du Québec en Abitibi-Témiscamingue (UQAT). Additional technical and laboratory support was provided by the Centre de recherche sur les matériaux avancés (CERMA) at Université Laval.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

The authors wish to thank the Biomaterials Laboratory at UQAT and CERMA at Université Laval for providing the facilities and equipment required for the experimental work. Appreciation is also extended to the technical staff for their assistance during the sample preparation and characterization. The authors gratefully acknowledge CREPEC for its financial support. Special thanks are extended to Fouad Erchiqui, Denis Rodrigue and Hamid Kaddami for their valuable scientific discussions, guidance, and supervision throughout this research.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

| PLA | Polylactic acid |

| PHB | Polyhydroxybutyrate |

| DSC | Differential Scanning Calorimetry |

| DMA | Dynamic Mechanical Analysis |

| DTG | Derivative Thermogravimetry |

| Tg | Glass transition temperature |

| Tc | Cold crystallization temperature |

| Tm | Melting temperature |

| Xc | Degree of crystallinity |

| G′ | Storage modulus |

| G″ | Loss modulus |

| η* | Complex viscosity |

| wt.% | Weight percentage |

References

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Wuisman, P.; Smit, T. Bioresorbable polymers: Heading for a new generation of spinal cages. Eur. Spine J. 2006, 15, 133–148. [Google Scholar] [CrossRef]

- Ashothaman, A.; Sudha, J.; Senthilkumar, N. A comprehensive review on biodegradable polylactic acid polymer matrix composite material reinforced with synthetic and natural fibers. Mater. Today Proc. 2023, 80, 2829–2839. [Google Scholar] [CrossRef]

- Middleton, J.C.; Tipton, A.J. Synthetic biodegradable polymers as orthopedic devices. Biomaterials 2000, 21, 2335–2346. [Google Scholar] [CrossRef]

- Vahabi, H.; Rad, E.R.; Parpaite, T.; Langlois, V.; Saeb, M.R. Biodegradable polyester thin films and coatings in the line of fire: The time of polyhydroxyalkanoate (PHA)? Prog. Org. Coat. 2019, 133, 85–89. [Google Scholar] [CrossRef]

- Bugnicourt, E.; Cinelli, P.; Lazzeri, A.; Alvarez, V.A. Polyhydroxyalkanoate (PHA): Review of synthesis, characteristics, processing and potential applications in packaging. Express Polym. Lett. 2014, 8, 791–808. [Google Scholar] [CrossRef]

- Braunegg, G.; Lefebvre, G.; Genser, K.F. Polyhydroxyalkanoates, biopolyesters from renewable resources: Physiological and engineering aspects. J. Biotechnol. 1998, 65, 127–161. [Google Scholar] [CrossRef]

- dos Santos, A.J.; Oliveira Dalla Valentina, L.V.; Hidalgo Schulz, A.A.; Tomaz Duarte, M.A. From obtaining to degradation of PHB: Material properties. Part I. Ing. Cienc. 2017, 13, 269–298. [Google Scholar] [CrossRef]

- Ansari, S.; Fatma, T. Cyanobacterial polyhydroxybutyrate (PHB): Screening, optimization and characterization. PLoS ONE 2016, 11, e0158168. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; Hernández, A.; Rayón, E. Ternary PLA–PHB–Limonene blends intended for biodegradable food packaging applications. Eur. Polym. J. 2014, 50, 255–270. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; López, J.; Jiménez, A. Combined effect of poly (hydroxybutyrate) and plasticizers on polylactic acid properties for film intended for food packaging. J. Polym. Environ. 2014, 22, 460–470. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Castro-López, M.d.M.; Rayón, E.; Barral-Losada, L.F.; López-Vilariño, J.M.; López, J.; González-Rodríguez, M.V. Plasticized poly (lactic acid)–poly (hydroxybutyrate)(PLA–PHB) blends incorporated with catechin intended for active food-packaging applications. J. Agric. Food Chem. 2014, 62, 10170–10180. [Google Scholar] [CrossRef]

- Frone, A.N.; Panaitescu, D.M.; Chiulan, I.; Gabor, A.R.; Nicolae, C.A.; Oprea, M.; Ghiurea, M.; Gavrilescu, D.; Puitel, A.C. Thermal and mechanical behavior of biodegradable polyester films containing cellulose nanofibers. J. Therm. Anal. Calorim. 2019, 138, 2387–2398. [Google Scholar] [CrossRef]

- Frone, A.N.; Batalu, D.; Chiulan, I.; Oprea, M.; Gabor, A.R.; Nicolae, C.-A.; Raditoiu, V.; Trusca, R.; Panaitescu, D.M. Morpho-structural, thermal and mechanical properties of PLA/PHB/cellulose biodegradable nanocomposites obtained by compression molding, extrusion, and 3D printing. Nanomaterials 2019, 10, 51. [Google Scholar] [CrossRef]

- Dong, W.; Ma, P.; Wang, S.; Chen, M.; Cai, X.; Zhang, Y. Effect of partial crosslinking on morphology and properties of the poly (β-hydroxybutyrate)/poly (d, l-lactic acid) blends. Polym. Degrad. Stab. 2013, 98, 1549–1555. [Google Scholar] [CrossRef]

- Mosnáčková, K.; Šišková, A.; Janigová, I.; Kollár, J.; Šlosár, M.; Chmela, Š.; Alexy, P.; Chodák, I.; Bočkaj, J.; Mosnáček, J. Ageing of plasticized poly (lactic acid)/poly (β-hydroxybutyrate) blend films under artificial UV irradiation and under real agricultural conditions during their application as mulches. Chem. Pap. 2016, 70, 1268–1278. [Google Scholar] [CrossRef]

- Mosnáčková, K.; Šlosár, M.; Kollár, J.; Janigová, I.; Šišková, A.; Chmela, Š.; Sikorska, W.; Perďochová, D.; Gálisová, I.; Alexy, P. Ageing of plasticized poly (lactic acid)/poly (3-hydroxybutyrate)/carbon black mulching films during one season of sweet pepper production. Eur. Polym. J. 2019, 114, 81–89. [Google Scholar] [CrossRef]

- Mosnáčková, K.; Opálková Šišková, A.; Kleinová, A.; Danko, M.; Mosnáček, J. Properties and degradation of novel fully biodegradable PLA/PHB blends filled with keratin. Int. J. Mol. Sci. 2020, 21, 9678. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Mansor, M.; Mastura, M.; Sapuan, S.; Zainudin, A. The environmental impact of natural fiber composites through life cycle assessment analysis. In Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 257–285. [Google Scholar]

- Garlotta, D. A literature review of poly (lactic acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Dou, Y.; Rodrigue, D. Morphological, thermal and mechanical properties of polypropylene foams via rotational molding. Cell. Polym. 2021, 40, 198–211. [Google Scholar] [CrossRef]

- Xia, K.; Liu, X.; Wang, W.; Yang, X.; Zhang, X. Synthesis of modified starch/polyvinyl alcohol composite for treating textile wastewater. Polymers 2020, 12, 289. [Google Scholar] [CrossRef]

- Righetti, M.C.; Cinelli, P.; Mallegni, N.; Massa, C.A.; Bronco, S.; Stäbler, A.; Lazzeri, A. Thermal, mechanical, and rheological properties of biocomposites made of poly (lactic acid) and potato pulp powder. Int. J. Mol. Sci. 2019, 20, 675. [Google Scholar] [CrossRef]

- Guo, R.; Ren, Z.; Bi, H.; Xu, M.; Cai, L. Electrical and thermal conductivity of polylactic acid (PLA)-based biocomposites by incorporation of nano-graphite fabricated with fused deposition modeling. Polymers 2019, 11, 549. [Google Scholar] [CrossRef] [PubMed]

- Lin, K.; Wang, Z. Multiscale mechanics and molecular dynamics simulations of the durability of fiber-reinforced polymer composites. Commun. Mater. 2023, 4, 66. [Google Scholar] [CrossRef]

- Ferreira, F.; Dufresne, A.; Pinheiro, I.; Souza, D.; Gouveia, R.; Mei, L.; Lona, L. How do cellulose nanocrystals affect the overall properties of biodegradable polymer nanocomposites: A comprehensive review. Eur. Polym. J. 2018, 108, 274–285. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; Ferrándiz, S.; Peltzer, M.A. Characterization of PLA-limonene blends for food packaging applications. Polym. Test. 2013, 32, 760–768. [Google Scholar] [CrossRef]

- Magagula, S.; Sefadi, J.; Mochane, M.; Mokhothu, T.; Mokhena, T.; Lenetha, G. The effect of alkaline treatment on natural fibers/biopolymer composites. In Surface Treatment Methods of Natural Fibres and Their Effects on Biocomposites; Elsevier: Amsterdam, The Netherlands, 2022; pp. 19–45. [Google Scholar]

- Behera, S.; Gautam, R.K.; Mohan, S. Polylactic acid and polyhydroxybutyrate coating on hemp fiber: Its effect on hemp fiber reinforced epoxy composites performance. J. Compos. Mater. 2022, 56, 929–939. [Google Scholar] [CrossRef]

- Sahbaz Karaduman, N. Experimental investigation of the effect of weave type on the mechanical properties of woven hemp fabric/epoxy composites. J. Compos. Mater. 2022, 56, 1255–1265. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A. Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym. Degrad. Stab. 2012, 97, 1898–1914. [Google Scholar] [CrossRef]

- Mazzanti, V.; de Luna, M.S.; Pariante, R.; Mollica, F.; Filippone, G. Natural fiber-induced degradation in PLA-hemp biocomposites in the molten state. Compos. Part A Appl. Sci. Manuf. 2020, 137, 105990. [Google Scholar] [CrossRef]

- Nazrin, A.; Sapuan, S.; Zuhri, M.; Ilyas, R.; Syafiq, R.; Sherwani, S. Nanocellulose reinforced thermoplastic starch (TPS), polylactic acid (PLA), and polybutylene succinate (PBS) for food packaging applications. Front. Chem. 2020, 8, 213. [Google Scholar] [CrossRef] [PubMed]

- Ferry, J.D. Viscoelastic Properties of Polymers; John Wiley & Sons: Hoboken, NJ, USA, 1980. [Google Scholar]

- Sodeifian, G.; Nikooamal, H.R.; Yousefi, A.A. Molecular dynamics study of epoxy/clay nanocomposites: Rheology and molecular confinement. J. Polym. Res. 2012, 19, 9897. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).