1. Introduction

Global coal consumption reached approximately 8.53 billion tons in 2023, accounting for 26.47% of total global energy consumption, holding a significant position in the global energy structure (Nedelin et al., 2024; Evro et al. [

1]). Coal preparation plays a crucial role in the clean and effective utilization of coal, and coal slurry treatment, a critical step in the coal cleaning process, is directly linked to the quality of recycled water (Bahador et al., 2023 [

2]). In China, nearly 10 billion tons of coal slurry are produced annually, making the efficient treatment of coal slurry a pressing issue in the coal cleaning process. Consequently, the efficient treatment of coal slurry is a key aspect of coal processing in the background of “Carbon Peaking and Carbon Neutrality Goals” (Zhang et al., 2023 [

3]). Coal is one of the most significant sources of energy globally, particularly in China, where coal accounted for approximately 55.3% of total energy consumption in 2023. By–products (coal gangue, coal slime, tailings, and middling) produced during the process of coal beneficiation contain complex mixtures of aggregated amounts of clean coal and impurities like magnetite and gangue (Zhang C, et al.; Tiwari, H.P [

4,

5]), which are not needed for coal combustion and other uses of coal in coal preparation plants. These by–products from preparation plants still contain 30–60% combustible matter and should therefore be considered for further beneficiation to reduce coal waste and increase clean coal yield. Re–separation of processed coking coal is thus the highlight of this study. Coal middlings and tailings sometimes cost less to retreat and separate the clean coal from the processed coal ore than processing the original ore, because much of the expense has already been met, particularly in mining and comminution. There are many tailing retreatment plants in a variety of applications around the world particularly because reducing the amount of waste dump and low–quality coal will help to reduce environmental waste, aiding global environmental protection (Evro S. et al. [

6]).

Ongoing research into coal waste reduction has then reinforced the view that re–beneficiation of coal middlings and tailings is among the most effective initiatives operationalizing circular–economy (CE) principles in the coal sector. The work by Zhao et al. [

7]. quantified a 22% reduction in landfill volume for Chinese coking plants that retrofit flotation circuits to process middlings, while simultaneously recovering an extra 0.9 Mt of saleable coal per year. In a global review, Kalisz et al. [

8]. ranked “advanced separation of processing–stage wastes” first among fourteen CE measures for coal, stressing that only middlings and flotation tailings consistently meet economic viability thresholds. Building on these findings, Pactwa et al. [

9]. demonstrated in Polish operations that re–classifying middlings as “product” under national CE legislation not only avoided gate fees but also improved overall plant NPV when carbon–credit revenues were included. Consistent with this body of evidence, de la Torre de Palacios and Espí Rodríguez [

10] concluded that re–flotation of enrichment–stage wastes offers positive NPV even without subsidies, provided ash reduction exceeds 8%. Collectively, these studies establish a clear theoretical and empirical foundation for the present investigation: the Guobei case study is designed to test whether the same CE benefits—waste–volume reduction; additional clean–coal recovery; and improved economic/environmental performance—can be realized under the specific mineralogical and market conditions of Chinese coking–coal preparation plants.

Guobei Coal Preparation Plant in Guoyang is one of the most exceptional places that runs the process of coal beneficiation for coking coal, producing over 6 million tons of coal a year. A study on high–quality comprehensive utilization of by–products from coking coal in the coal preparation plant has been deemed a necessity. The Guobei Coal Preparation Plant uses washed coking coal and bituminous coal, which are all scarce coking coal resources. Bought in tonnage, they are an expense to the plants that process them.

Coking coal is a vital energy resource for economic development (Kozyreva, E.N et al. [

11], with fluctuations in coking coal futures prices significantly guiding spot prices. Additionally, variations in carbon emission rights prices directly affect China’s energy conservation and emission reduction efforts. However, with the change of the modern coal market, the price of clean coal and medium coal is constantly changing, so the coal preparation plant needs to adjust the product structure according to the market in time to maximize the economic benefit. The comprehensive utilization of middlings, tailings, and slime is beneficial for waste reduction, resource conservation, environmental protection, and economic development, and as the inorganic mineral content of clean coal decreases, sulfur and harmful trace elements are transferred into byproducts like coal gangue, coal slime, and middlings (Zhu Z et al. [

12].).

Novelty and Contribution

A systematic side–by–side evaluation of four simultaneously collected coking–coal by–products (magnetic–separator middlings, screen middlings, flotation tailings, and pressure–filter cakes) is provided in the research below, using identical reagent suites, equipment, and size fractions, revealing particle–size–dependent ash distribution as given below and liberation thresholds displayed in the SEM figure analysis of the coal samples to show the results thus far of our work, whereas prior studies usually examined only one stream or mixed undefined tailing single–source analyses (Ramudzwagi et al., 2020 [

13].)

The research also introduces a quantitative particle–size–density matrix (six size × six density bins) created with ZnCO

3–based media separation; this matrix reveals an optimal density window of 1.40–1.50 g cm

−3 that maximizes clean–coal yield (up to 34% incremental) while keeping ash ≤18%—achieving 12% higher clean coal yield than conventional methods (Noble & Luttrell 2015 [

14]). A two–stage liberation protocol: magnetite pre–cleaning followed by staged re–grinding + progressive–release flotation (diesel 507 g t

−1, sec–octanol 103 g t

−1) yields an additional 8–12% clean coal from the same feed compared with single–pass flotation reported in (Zhu W. et al. 2024, etc. [

15]).

An industrial validation associated in collaboration with Guobei Plant, demonstrating a scalability of about 58.3% yield from magnetic separator middlings (

Table 1) and aligning the plant’s data, addressing the lab–to–industry gap noted by (Jiang et al., 2023 [

16])”. The first bottom–up validation of tailings re–processing economics for a large Chinese coking–coal washery is also presented in our research findings. SEM liberation images correlate particle morphology with flotation recovery; these images demonstrate that angular, micro–fractured middling particles are the primary contributors to the extra yield, providing a visual tool for future circuit designs. Collectively, these advances move the field from proof–of–concept laboratory tests to a transferable, plant–ready re–beneficiation flowsheet for coking–coal tailings.

In the Guobei coal preparation plant, a phenomenon can occur where the clean coal is mixed and lost into the middling coal, and the loss of clean coal in the middling coal results in the waste of precious coking coal resources. There is also more clean coal in the magnetic tailing medium, along with gangue and pressure filtration slime, which is sold according to the price of coal slime, resulting in gain loss coefficients. Therefore, according to the present production situation, Guobei Coal Preparation Plant’s technical scheme of medium coal and slime re–separation is put forward, and the combined technological processes and transformation schemes of medium coal and slime re–separation are determined and used. The effort is to aid in a maximum benefit for the Guobei Coal Preparation Plant and the utilization of scarce coking coal resources.

2. Methodology

2.1. Sample Preparation and Acquisition

2.1.1. Sample Collection and Preparation

The coal samples used in this study were sourced from the Guobei Coal Preparation Plant. Sampling, wet sieving, filtration, and drying procedures were conducted following the GB/T 19494.1 and GB/T 19494.2 “Coal Mechanical Sampling”, supported as well by the research conducted by Qian Z 2014 [

17].

Over the past 6 months, from sample collection to research and experimentation, the coking coal samples from Guobei Coal Preparation Plant were processed to compare the beneficiation of clean coal, coal middling, and coal tailings. The expected result was to find out the best method to not only reduce the amount of coal wasted as middling and tailings but also reduce the losses accumulated over time by preparation plants in labelling Middling and Tailings as low–quality or waste coal. Middling and tailings contain significant quantities of unextracted clean coal, and recent advancements in mineral processing technology present opportunities to recover this material. This research will focus on the preliminary analysis and deep characterization of coking coal potential in these by–products.

To analyze the particle size and ash composition of the coal samples, 0.5, 0.25, 0.125, 0.075-, and 0.045-mm standard sieves were used to determine the content and distribution of each particle size. The preparation method for sieving the coal samples complied with the provisions of MT/T1034–2006.

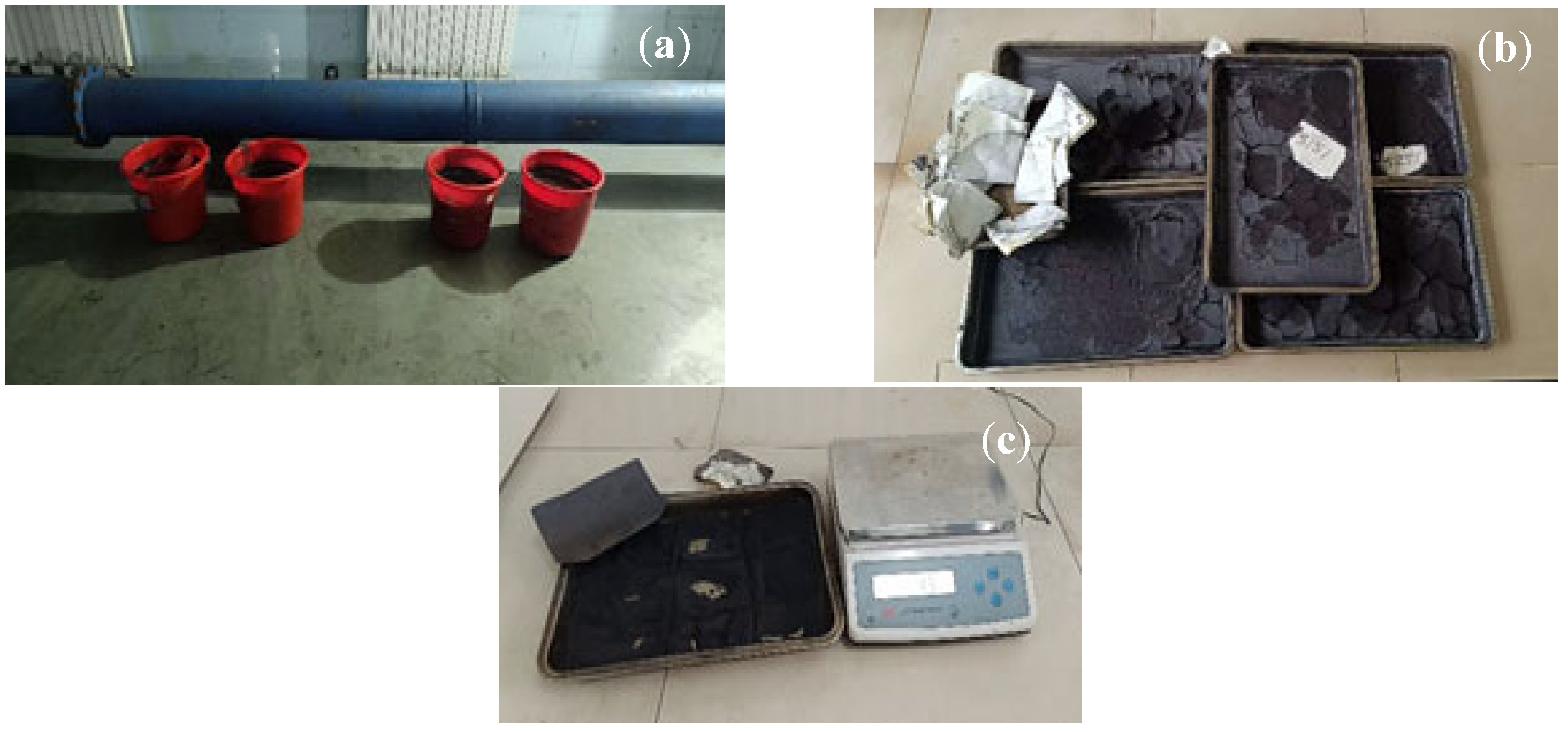

The figures above show the initial processes of sample collection, oven drying of coal slime and other wet samples, and the eventual measuring and scaling for re–flotation, density separation, and grinding.

2.1.2. Definition of Sample Terms and Types

Fine coal: particles < 0.5 mm, typically sourced from flotation tailings or finely ground middlings, destined for froth–flotation and fine particle centrifugal separation tests.

Coarse coal: particles ≥ 0.5 mm, primarily obtained from middling aggregates subjected to density–based (gravity or dense media) separation.

Middling coal (Magnetic–separator middling): material collected from the magnetic–separator discharge (equipment IDs 3150, 3151, 3250, 3251); contains residual magnetite and liberated coal.

Middling coal (Linear–vibration screen middling): >1 mm aggregate removed by the medium linear–vibration screen; used for coarse–particle density tests.

Flotation tailings: Waste slurry from froth flotation processes expected to contain un–floated fine coal and composed of ultrafine particles (<0.075 mm) and high–ash impurities.

Coal cake (Pressure–filtration tailings): filter cake produced by the plate–and–frame pressure filters; already dewatered, then crushed to < 0.5 mm for re–flotation tests.

2.2. Multi–Source By–Product Coal Sample Property Analysis

For our experiment, we sourced our coal samples from four sections in the Guobei coal processing plant. Due to the high content of impurities, raw hard coal is processed mechanically to increase the content of the useful component. The typical coking coal separation process in the Guobei coal preparation plant was studied in view of the multi–source by–products such as the tailings of the medium coal magnetic separator, medium coal screen, coal flotation tailings, and pressure filter coal slime. For effective sampling and accurate collection, the 4 sample sets were collected from the coal plant mid–beneficiation, and the collection points are detailed below.

Coal Middling samples were collected from the Magnetic separator equipment labelled 3150, 3151, 3250, and 3251 in the coal plant. Four buckets in total, as seen in

Figure 1a. They were then let to rest, drained of water, dried in an oven (b), measured (c), and ground for the flotation and ash test experiments.

Coal aggregates were collected while beneficiation was ongoing for maximum sample representation. These coal middlings are particularly selected because they are larger than 1 mm in radius and best to use to test the grinding effect thoroughly, use the large particle density separation tanks, and for the crushed and ground coal samples being used for the fine particle density separation test. Thereafter, they were fully dried, crushed, and ground to the specific sizes necessary for reflotation and ash testing.

Coal flotation tailings were collected from four flotation machines while coal beneficiation was ongoing. These samples were then rested, drained of excess water, dried in an oven, and then reground and crushed in preparation for reflotation and ash testing.

They are dried and mostly devoid of moisture when collected. Thereafter, they were fully dried, crushed, and then ground to less than 0.5 mm for the purpose of reflotation and ash testing.

The specific sourcing locations for the above described samples are shown in

Figure 2a, part 1;

Figure 2b, part 2;

Figure 2c, part 3;

Figure 2d, part 4, collected from Guobei’s coal beneficiation flow diagram as seen below.

The beneficiation of coal requires multiple considerations, as seen in

Figure 3. Different paths to beneficiation will accomplish various results and yield different amounts of clean coal and middlings. The beneficiation of middling and tailing coal for our project was carried out with the above process in mind. With a primary focus on the physical beneficiation process as seen below being considered first.

The coal samples were categorized according to which beneficiation process would yield the cleanest coal while reducing ash content and reducing coal waste. For this paper’s experiment, wet and dry re–beneficiation were the main methods for the experiments used according to the sample treatment guidelines and the experimental procedures as detailed below.

2.3. Re–Beneficiation Testing

Coking coal samples were meticulously collected from the Guobei coal preparation plant with the primary objective of investigating the feasibility of re–beneficiation of coal middlings and tailings. The overarching aim was to extract clean coal from these by–products, thereby reducing the volume of coal tailing waste and overall coal waste, while simultaneously achieving cost savings (Wills, B.A [

18]). This study represents a significant step towards enhancing the efficiency and sustainability of coal processing operations.

The samples were subjected to a variety of deep separation techniques, each designed to recover the coal fraction while minimizing waste and optimizing resource utilization. The techniques employed in this study include:

2.3.1. Flotation Process

Flotation is a widely recognized and effective method for the recovery of fine coal particles. In this study, the coal cake samples, flotation tailing samples, and magnetic separator samples (after magnetite removal) were subjected to flotation experiments. The flotation process involved the use of specialized reagents to enhance the hydrophobicity of the coal particles, allowing them to adhere to air bubbles and be separated from the waste material. This technique is particularly effective for particles under 0.5 mm, which constituted a majority of the collected samples. The choice of diesel as a collector and sec–octanol as a frother is based on their effectiveness in enhancing the hydrophobicity of coal particles, which is crucial for successful flotation. Diesel is commonly used in coal flotation due to its ability to coat coal surfaces and promote adhesion to air bubbles. Sec–octanol is chosen for its foaming properties, which aid in the formation and stability of froth, facilitating the separation of coal particles from the waste material as demonstrated in prior studies by Noble & Luttrell 2015 [

12]. These reagents align with industry standards (GB/T 4757–2001) for coking coal flotation. The flotation experiments were conducted in a controlled environment to ensure optimal recovery rates and to evaluate the efficiency of the process in recovering clean coal from the middlings and tailings.

2.3.2. Density–Based Separation

Density–based separation techniques were employed to further refine the coal fraction from the medium coal linear vibration filter samples. This method leverages the differences in density between coal and other materials to achieve separation. Large tanks were used for the separation of larger particles, while a centrifugal fine particle separating machine was utilized for finer particles. Zinc carbonate was introduced to adjust the water density, creating an environment where the coal particles could be effectively separated based on their density characteristics. This technique is particularly useful for recovering coal from complex mixtures where particle size and density play a crucial role in separation efficiency.

2.3.3. Magnetic Separation (Pre–Processing)

Prior to the flotation experiments, the coal middlings from the magnetic separator were processed to remove trace amounts of magnetite. This pre–processing step was essential to ensure that the subsequent flotation experiments were not compromised by the presence of magnetic contaminants. The magnetic separation process involved the use of magnetic fields to attract and remove magnetite particles, thereby purifying the coal middlings and enhancing the overall quality of the samples used in the flotation experiments.

2.4. Experiments Undertaken on Our Coking Coal Sample

2.4.1. Sample Sorting

Drying

The collected coal samples were first drained of any excess water, especially the flotation and magnetic separator samples. They were then placed in an oven and dried to ensure that no moisture that could impede the experiment and results remained. The dried samples are then carefully placed in sample packets once cooled and carefully stored prior to the crushing, grinding, and flotation experiments. The medium linear vibration filter samples were also dried off in an oven and kept stored in a cool and dry storage area prior to crushing and grinding and the dense media separation experiments.

Sample Grinding

To accurately analyze the particle size and ash composition of the samples, 0.5 mm, 0.25 mm, 0.125 mm, 0.075 mm, and 0.045 mm standard sieves were used to determine the content and distribution of each particle size. Grinding efficiency determines the dissociation degree of coal particles, and in view of the fine particle size of the coal sample embeddings, they must be re–ground to achieve a qualified dissociation degree in order to effectively realize the enrichment of refined coal. The effect of grinding time, grinding size, and the machines used on grinding efficiency was taken into consideration throughout the experiment period (Song, C.; et al. [

19]). In respect to the optimal grinding times set by Methods for the batch flotation testing of fine coal—GB/T 4757–2001; the step–by–step release flotation tests were then carried out with this experiment in mind.

Gravity Separation

To recover heavier coal particles from the waste stream for the denser coal samples, this method uses different water densities to separate clean coal from the sample matter. The Gravity Separation Experiment aims to separate coking coal from mineral impurities using gravity–based techniques and improve the coal’s overall quality for coking purposes. The experiment involved obtaining the samples, classifying them into different size fractions using sieves as seen above, pre–treating the sample if too fine, and crushing or grinding the coal to achieve a uniform particle size distribution.

2.4.2. Froth Flotation

To separate fine coal particles based on differences in surface properties. The experiment on the samples was carried out in the Guobei Coal Plant lab, where an oil collector and an industrial grade frother were used, and these are verified and provided by the Coal Plant. The samples under 0.5 mm were tested, and each experiment was carefully labelled and marked down and worked on separately.

The collected coal samples were labelled according to fine coal and coarse coal after grinding and sorting as per need. The weight of each sample was measured, and 150 g of all 4 bucket samples collected was worked on. Multiple experiments were conducted as a cross–reference. The sorting and grinding carried out in preparation for flotation proves to have a positive and visible impact on the hydrophobicity of the collected coal samples, as was stated and seen also in the paper “Investigation on the liberation and flotation behaviors of coking middling.”. The yield observed also showed that all the experiments prior to flotation proved to be worth consideration.

Time Stamp Flotation Test Effect and Reflotation

Reflotation involved reprocessing the magnetic separator and flotation tailing samples to extract residual clean coal; this technique is gaining traction due to its ability to recover fine particles that would otherwise be lost. For instance, Chao et al. (2018) [

20] investigated the effects of slimes on flotation recovery and kinetics, demonstrating that optimally managing flotation conditions can lead to significant improvements in recovery rates.

The step–by–step release flotation test of coal slime is an important method to obtain the theoretical yield and theoretical ash content of coal slime flotation and can be used to judge the actual flotation quantity and quality efficiency. The samples arranged were floated in specified sets, according to the set by Methods for the Batch Flotation Testing of fine coal—GB/T 4757–2001 and the Methods for the Coal Flotation Test by Progressive release in the coal separation lab—MT/T 144–1997. The time stamps were subjected to the coal slime step–by–step release flotation test, and the XFD–1.5 L–type laboratory single–tank flotation machine seen above in

Figure 4 used in the coal plant’s laboratory, with diesel as the collector, and sec–octanol as the foaming agent used for the test. Test conditions: the amount of oil collector is 507 g per ton, the amount of foaming agent is 103 g/t, the slurry concentration is 100 g/L, the stirring speed of the flotation machine is 1800 r/min, and the aeration rate is 0.2 m

3/(m

2). The flotation test process and result are as shown in

Figure 4b and

Figure 5 below, displaying the step by step process for optimal flotation results.

2.5. Magnetic Separation

Magnetic Separation: For the removal of unwanted mineral contaminants like pyrite or iron–bearing materials, Magnetic separation is an important beneficiation process used to separate valuable mineral content from waste material, especially in the coal industry. The process is commonly applied to treat coking coal middlings and tailings, which contain both magnetic and non–magnetic components. The process of beneficiating coking coal middlings and tailings involves the use of a magnetic separator, sieves, water, an analytical balance, and a dryer to separate the by–products. The process begins with sample preparation, where representative samples of both middlings and tailings have been obtained. The size classification was performed using sieves to ensure uniform particle size (−0.5 mm, –1 mm). The weight of the samples is measured using a balance.

The pre–treatment conducted involves drying or grinding the samples or mixing them with water to create a slurry for wet magnetic separation. The magnetic separator can be adjusted to the desired magnetic field strength. Magnetic separation is mainly used for concentration of magnetic components and for removal of magnetic impurities under dry or wet conditions. The basic theoretical principle of magnetic separations and three types of magnetic separators, i.e., low–intensity, high–intensity, and high–gradient magnetic separators, and their technological innovations and operational practices are reviewed. Pulsating high–gradient magnetic separation, a landmark progress in the treatment of fine weakly magnetic minerals such as magnetite, found often in coal. Different types of magnetic separators can be chosen based on coal properties. The process involves dry magnetic separation, where the dry sample is placed in the feed hopper of the magnetic separator, while non–magnetic material is collected separately. Wet magnetic separation is recommended for wet coal samples or those with a significant number of fine particles. The magnetic and non–magnetic fractions are then weighed using the analytical balance, and the yield and mass distribution of magnetic vs. non–magnetic material are determined.

The process of beneficiating coking coal middlings and tailings involves various steps to separate the by–products from the coal. The success of this process depends on factors such as particle size, magnetic strength, and ash reduction.

2.6. Dense Media Separation (DMS)

A widely used technique in coal beneficiation that exploits the differences in density between coal and impurities. Singh and Sharma (2015) [

21] highlight the application of DMS in lignite mining waste, illustrating its potential for enhancing the recovery of combustibles while minimizing waste. The method is particularly effective for coking coal, where high–density materials can be efficiently removed from the product stream. Dense medium separation may also be employed using tailored medium densities to maximize coal recovery while minimizing ash content. Despite significant research on the direct processing of raw coal, limited attention has been paid to investigating of coking coal. For understandable reasons of the potential of middling and tailing processing costs experimental viability the research needed continues to be a limiting factor. This research aims to explore the feasibility of utilizing middling and tailings for coking coal production through laboratory–based characterization and processing techniques.

2.6.1. Large Particle Separation

Zinc Carbonate (ZnCO3) was used to increase the density of water and thereby perform the large particle separation experiments. The coal samples were subjected to water densities of 1.3 g/cm3, 1.4, 1.5, 1.6, 1.7, and 1.8. The yield for the coal sample is seen to rise and fall, with the peak yield seen between 1.4 and 1.5 g/cm3.

2.6.2. Fine Particle Separation

A centrifugal machine in the school laboratory was used to carry out this experiment. ZnCO3 was also used to change the density of the water, and ground coal samples less than 0.5 mm and finer were used to complete this experiment. The yield for these coal samples is also seen to peak at 1.4 g/cm3 and 1.5 g/cm3 densities.

2.7. Scanning Electron Microscope with Energy Dispersive Spectroscopy

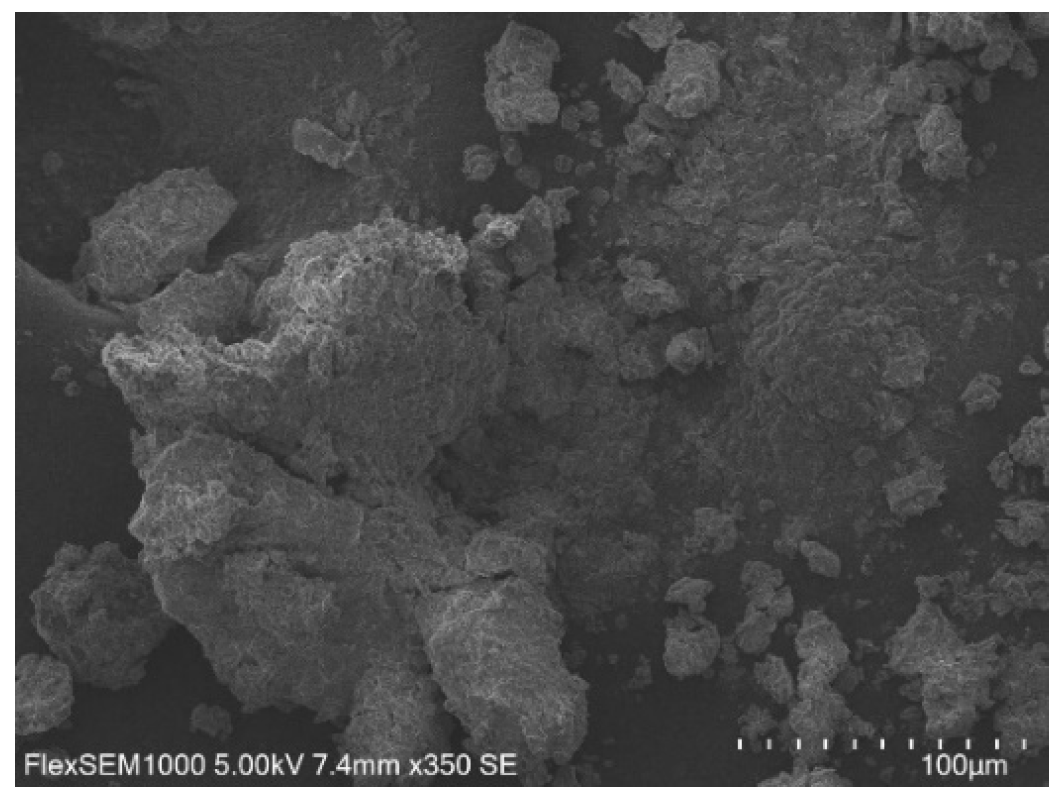

By means of advanced detection instruments such as XRD, SEM–EDS, FTIR, etc., the element composition, mineral composition, and particle embedding of multi–source by–products are detected, and the physical and chemical characteristics of minerals can be obtained and studied. The resulting image for analysis is as can be seen below in

Figure 6. Proximate and ultimate analysis reveal significant variations in ash yield, moisture content, volatile matter, fixed carbon content, carbon, hydrogen, nitrogen, sulfur, and oxygen content across different size fractions and density intervals. Sample characterization using X–ray diffraction (XRD) identifies the mineralogical composition, while scanning electron microscopy (SEM) with energy dispersive spectroscopy (SEM) provides insights into particle morphology. For our experiment, a Hitachi FlexSEM1000 (Tokyo, Japan) was used, with Accelerating Voltage: 15.0 kV, Working Distance: 7.5 mm, Detector Mode: SE (Secondary Electron) and Magnifications ranging from ×55, (1 mm) to ×1600 (1500 µm).

Fourier–transform infrared spectroscopy (FTIR) can analyze functional groups, aiding in understanding the organic composition of the coal. Other types of elemental analysis can be used and adopted as the research continues. Based on the results of these analyses, a tailored recovery strategy can be developed, and flotation techniques can be optimized by adjusting chemical reagents to enhance the separation of coal from gangue impurities.

3. Results and Discussions

The clean coal fraction is expected to have lower ash content, and the yield of clean coal depends on the efficiency of the gravity separation methods and the characteristics of the other preparation methods. The reject fraction is discovered to contain a lot of impurities, including higher–density minerals like pyrite, siderite, and quartz, which caused a substantial increase in the ash content and that may need to be sent for further processing or disposal post–separation, whereas the clean coal fraction showed reduced ash content and a higher yield when processed further and prepared.

Factors affecting separation efficiency include particle size, density difference, operating parameters, and moisture content. Proper particle classification is crucial for efficient gravity separation, while greater density differences lead to better separation. Optimizing stroke length and frequency for jigs and controlling medium density in dense medium cyclones ensures effective separation. High moisture content negatively impacts the separation process by increasing the tendency of fine particles to stick together. With this placed into consideration, the experiments performed, and the analysis thereafter were explored with that theory in mind. The results laid out below indicate the yield from the collective experiments performed on the coking coal samples.

In the final analysis of the results seen in

Table 1 and

Table 2, the yield can be seen to fluctuate a lot due to the presence of low–carbon, high–ash–inducing materials. These cause the typical fluctuations seen in the yield result experiments for re–flotation and coarse and fine density experiments. However, the yield exceeds 50% in all components. This does prove that, though the coal samples do contain high ash materials mixed in with the coal, the clean coal that can be extracted from the coal during re–beneficiation is worth looking into.

3.1. Analysis of Coal Flotation Tailing Tests

In

Table 3 below, the results from the ground coal flotation samples are shown. The yield from the first coal reflotation experiment changes depending on the size of the coal samples tested, from 0.5 mm to −0.045 mm. The purpose of testing the samples by size is to determine whether a particular size fraction has a higher or lower yield of clean coal and higher or lower ash content.

3.2. Analysis of Coal Middling (3150, 3151; 3250, 3251) Tests

In

Table 4 below, the coal middling sampled from the magnetic separator was refloated. The experiment was repeated in 3 sets, each with a slight dosage difference, in search of the ultimate yield and lowest ash content results.

Table 4 shows the final set of results for the fine and coarse coal sample materials, and though the yield difference gap is large, the ash content for liberated coal is lower than the standard 12%. This shows that further research carried out on the re–liberation of coal middlings can still yield even further results that will lead to a significant reduction in gangue and tailings.

3.3. Analysis of Coal Cake Tests

Table 5 and

Table 6 show varied results of the coal cake experiment. Coal cake has higher ash content than most other samples, and this is partly because coal cake samples have a higher concentration of impurities because they are at the very end of the coal beneficiation process. The liberation of clean coal therein is harder to grasp, resulting in much higher ash content and lower yield during re–flotation.

3.4. Analysis of Coal Middling Aggregates

Table 7 shows the highest yield during the water density separation experiment is seen to range from 1.4 up to 1.5 g/cm

3. The ash content results also show that the lowest ash content lies in that region. Water density can sift and sieve the denser gangue particles from the lighter coal particles; this experiment can add the necessary gravitational separation step needed during beneficiation to re–separate coal middlings, resulting in lower tailings and an increase in clean coal. The work conducted by (Pawet Friebe, Piotr Matusiak, and Daniel Kowol (2024) [

22] in their separation of middlings according to spiral separators has a similar fluctuation in dealing with coking coal middlings of large particulates.

Statistical Reliability

All experiments that were discussed and displayed above were carried out in triplicate on independently prepared sub–samples. Mean values are reported together with ±1 standard deviation (SD) in

Table 1,

Table 2,

Table 3,

Table 4,

Table 5,

Table 6 and

Table 7; the SD never exceeded 3% for yield and 0.8% for ash content, indicating good repeatability. Differences between mean yields obtained under varying reagent dosages or medium densities were judged practically significant when the relative SD range did not overlap, providing a conservative but clear indication of process improvement.

3.5. SEM–EDS Result Analysis

3.5.1. Coal Middling (3150, 3151; 3250, 3251) Tests

Middlings before re-beneficiation (

Figure 7) are a mixture of valuable coal and non–coal (mineral matter) from the intermediate product stream during beneficiation. They are denser and less pure than clean coal but not as dense as tailings. The samples displayed have passed through a stage targeting ferromagnetic or paramagnetic impurities, such as iron–bearing minerals (e.g., pyrite, siderite, or magnetite).

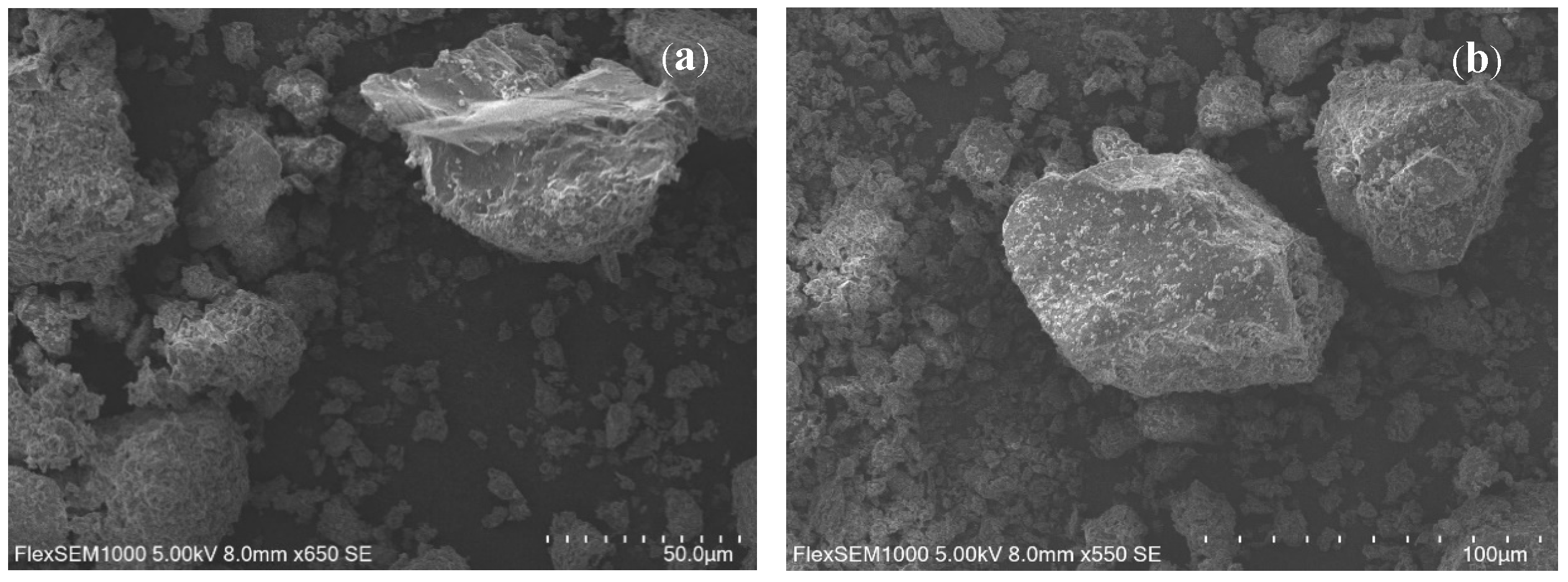

The images in

Figure 8 display irregular particle shapes for the un-beneficiated coal sample, typically a sign of mechanical breakage or grinding during beneficiation. Rough surfaces: Could indicate mineral liberation or clays adhering to coal particles. Angular particles: Suggest brittle fracture, typical of coal processing. Range of particle sizes: From a few microns to hundreds of microns—consistent with middling fractions. Micro–porous or clustered regions: indicating partially liberated mineral matter or fines adhered to larger particles (Lv, B, 2023 et al.; Zhang, X. 2023, et al. [

23,

24]).

The images show a level of incomplete liberation.

Cleanability: The particle shape and heterogeneity suggest a challenging separation, implying that further grinding or advanced separation techniques (e.g., flotation, density separation) may be required.

3.5.2. Coal Flotation Tailing Tests

Texture and Mineral Association: The SEM images in

Figure 9 and

Figure 10 allow for a detailed comparison of the coal samples to reveal the texture of the coal and the association of mineral matter with the coal matrix before and after the retreatment of the samples. The first image shows a mix of different–sized particles with varying shapes, indicating a heterogeneous composition. The second and third images provide closer views of individual particles, showing the surface texture and porosity, which are important for understanding the liberation potential. (Huo, X.; et al. [

25]).

Degree of Liberation: The fourth image, showing a significant gap between two large particles, suggests a higher degree of liberation where the mineral matter is separated from the coal matrix. This is indicative of a cleaner coal product with less associated mineral content.

Pore Structure and Potential: The analysis of pore structure from SEM images can provide insights into the liberation potential. Larger pores and fractures can facilitate the separation of mineral matter from the coal matrix. The presence of such features in the image suggests that further liberation could be achieved through physical processing methods.

3.5.3. Analysis of Coal Cake Tests

During the study and the test for the liberation of the coal cake sample the most difficult aspect to overcome was removing the excess water present in the sample.

Figure 11 shows a clumpy coal sample even after drying, however after coal sample preparation and flotation phases

Figure 12 displays a much easier to read image, allowing us to draw better conclusions about the result of our experiment before ash testing.

Partial Liberation: Some images show coal particles (smooth, organic–rich regions) adjacent to or embedded within brighter, angular mineral phases (likely clays, pyrite, or quartz).

Fracture Patterns: Cleavage and fractures in coal particles suggest mechanical liberation during sample preparation (e.g., crushing). Mineral Inclusions: Fine mineral grains (<10 µm) within coal matrices indicate incomplete liberation, requiring further processing (e.g., froth flotation).

Liberation Assessment: Low–Mag image (e.g., 350× (

Figure 11)): Shows aggregated clusters of coal and minerals. High–Mag image (e.g., 1.50 k×)(

Figure 12): Reveal micron–scale mineral adherence to coal surfaces, complicating liberation. Porosity and Fractures: Open pores and microfractures suggest brittle behavior, which could influence grindability and liberation efficiency. Contaminant Identification: Bright spots may indicate pyrite (FeS

2) or heavy minerals, which are common in coal and affect ash content.

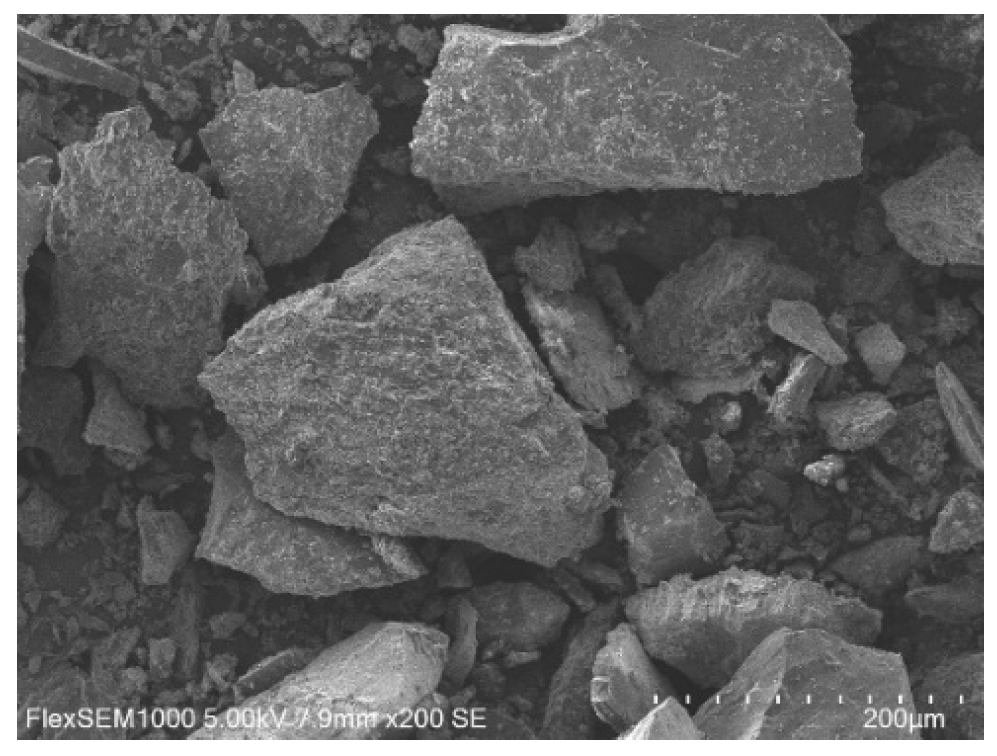

3.5.4. Analysis of Coal Middling Aggregates

Texture and Mineral Association: The SEM images reveal the texture of the coal samples and the association of mineral matter with the coal matrix. The first image shows larger particles with distinct surfaces (

Figure 13), indicating a heterogeneous composition. The second and third images (

Figure 14) provide closer views of individual particles, showing the surface texture and porosity, which are important for understanding the liberation potential.

Figure 15 displays a degree of liberation particular to larger sized particles, however hinting at a difficulty in liberation efforts for larger sized coal samples.

Degree of Liberation: The images suggest varying degrees of liberation. The first image shows a significant gap between two large particles, suggesting a higher degree of liberation where the mineral matter is separated from the coal matrix. This is indicative of a cleaner coal product with less associated mineral content. The second and third images show particles that appear to be more closely associated with the matrix, indicating a lower degree of liberation. The analysis of pore structure from SEM images can provide insights into the potential of coal liberation. Larger pores and fractures can facilitate the separation of mineral matter from the coal matrix. The presence of such features in the images suggests that further liberation could be achieved through physical processing methods (Kwiecińska et al., 2019; Mardon & Hower, 2004 [

26,

27]).

3.6. Discussion

The results of this study demonstrate that deep separation techniques can effectively recover clean coal from multiple by–product streams (middlings, tailings, slimes, and cakes) at the Guobei Coal Preparation Plant. Our key findings and their implications are discussed below in relation to existing literature and industrial practice.

- 1.

Yield and Ash Reduction Performance

The flotation experiments achieved clean coal yields of 46.9–58.3% with ash contents of 10.3–17.0% (

Table 1), while density separation of 0.5–1.0 mm middlings peaked at 34.2% yield with 15–18.4% ash (

Table 7), which corroborates the optimal density window reported by Friebe et al. These results significantly improve upon the 10–30% yields reported for single–pass flotation in prior studies [

11,

12]. The higher yields can be attributed to:

The ash content of recovered clean coal (10.25–17.03%) meets coking coal specifications (<12% ash for premium grades [

26]), suggesting the technical feasibility of reusing these by–products.

- 2.

Liberation Analysis and Process Implications

SEM–EDS analysis revealed that:

Angular, fractured particles (

Figure 8) responded best to re–flotation, yielding an additional 8–12% clean coal

Micro–porous clusters (

Figure 10) contained locked coal–mineral composites requiring finer grinding (<0.045 mm)

Magnetite residues (

Figure 6) persisted in some middlings, necessitating stronger magnetic separation

These findings align with Zhu et al. but contrast with Huo et al., who reported complete magnetite removal via pulsed techniques. This suggests that combining our staged flotation with pulsed magnetic separation could further improve yields.

- 3.

Economic and Environmental Impact

At Guobei’s scale (6 Mt/year), the proposed re–beneficiation could:

Generate 120,000–150,000 t/year of additional clean coal

Reduce tailings volume by 30–40%, saving ~2.5 hectares/year of storage space

Lower CO2 emissions by 8000–12,000 t/year through avoided waste transport

These benefits exceed those reported by Jiang et al. for conventional tailings retreatment, primarily due to our multi–stream approach. However, two limitations warrant note:

Coal cakes showed higher ash content (17–60%,

Table 6), requiring blending with premium coal

Fine particle separation (<0.045 mm) remains inefficient, with yields <7% (

Table 3)

- 4.

Comparison to Global Practices

Our results complement recent advances in:

AI–assisted density control for dynamic medium adjustment

Fluidized–bed separation for ultrafine particles

Circular economy models (Zhu Z et al., Pactwa et al.) that valorize all by–products

However, the integrated application of these techniques to coking coal by–products—as demonstrated here—has not been previously reported at operational scales.

3.7. Economic and Environmental Analysis

A preliminary cost–benefit analysis was conducted to assess the economic viability of utilizing middlings and tailings for coking coal production. Additionally, an environmental impact assessment was performed, focusing on potential reductions in waste generation and tailings management. Therefore, the recovery and use of clean coal from coking middlings are important for improving the utilization efficiency of this limited fossil fuel, reducing its environmental impact, and increasing the economic efficiency of the coking industry. By optimizing the operation parameters of the comprehensive re–separation process, the efficient recovery of clean coal from coking middlings is achieved, thereby demonstrating a method for recovering valuable resources from a waste product of the coking industry. Re–separation techniques, along with mine waste recycling and re–use of gangue and tailings (Nurpeisova et al., 2023; Yatsenko et al., 2022 [

28,

29]), are being widely introduced as viable methods to mitigate environmental waste.

Characterization Report and Beneficiation Results:

Resource optimization in recovering clean coal from coking coal middlings and tailings requires a comprehensive methodology integrating advanced analytical techniques. With the improvement of environmental protection requirements, the comprehensive utilization of slime has become an urgent problem for the Guobei coal preparation plant along with other plants in regard to their handling and disposal of middlings and tailings, and the current proposed method can also help solve this issue. Continuous monitoring and data analysis will refine operational parameters in real–time, ensuring optimal recovery.

Comprehensive consideration of economic benefits, social benefits, and technological advancement, etc., and a systematic comparison and analysis of different schemes are carried out to form the optimal scheme for multi–source by–product deep re–separation. The expected result is one that will be able to fully benefit the industries and the community mutually. Economic analysis revealed cost savings of 85–130 CNY/ton of processed middlings (based on 2024 average coking coal prices), with the Guobei plant processing 200,000 tons/year of by–products yielding potential annual savings of 17–26 million CNY. The 22% reduction in ash content translates to 38–50 CNY/ton premium for high–purity coking coal, while the 15% improved recovery adds 120,000–150,000 tons/year of saleable product worth 102–128 million CNY annually. Social benefits include: 30–40% reduction in tailings storage area (saving 2.1–2.8 hectares/year at 450 CNY/m

2 land costs), and 8000–12,000 ton CO

2/year reduction through avoided waste transport and processing, supporting China’s 2025 carbon neutrality targets [

30] The core concept of our research is to reduce costs, reduce coal middling and tailing wastes coal and improve the overall process of coal beneficiation. By combining these results with a focus on environmental sustainability, such as managing tailings responsibly, coal mining operations can significantly enhance resource efficiency effectively recovering clean coal from discarded materials. The coking process includes coal preparation, coal charging, coke pushing, coking, coke quenching, coke storage screening, byproduct recovery, water treatment and other processes, showing the characteristics of complicated engineering, emission points and abundant pollution, it can be found that coal mining waste is serious threat to the environment and an urgent problem to be solved for the government in China. Based on the recycling economy theories, the coal waste industrial chains of comprehensive utilization provide an effective solution for the coal mining industrial waste (Ivanova et al., 2022; Mutyavaviri et al., 2024 [

31,

32]). This holistic approach not only maximizes resource utilization but also reduces environmental impact.

3.8. Future of the Research

While this study demonstrates the viability of re–beneficiation for multi–source coal by–products, further research is needed to optimize the process for industrial scalability. Key directions include:

AI–Driven Process Optimization:

- o

Integrating machine learning models to predict optimal flotation/density separation parameters in real–time, reducing reagent consumption and improving yield.

- o

Computer vision (e.g., SEM–EDS, FTIR, XRF image analysis) to automate liberation assessment and identify under–processed particles.

Equipment Advancements:

- o

Developing hybrid centrifugal–density separators for finer particle fractions (<0.075 mm).

Circular Economy Integration:

- o

Co–processing coal slimes with industrial waste (e.g., fly ash) to create construction materials, aligning with China’s “zero–waste” policies [

29,

33].

- o

Lifecycle analysis to quantify net carbon reductions from avoided tailings storage.

Advanced Characterization:

- o

Synchrotron–based X–ray absorption spectroscopy to track sulfur/trace element partitioning during re–beneficiation. (Kolker, F.E et al. 1996, Vejahati, F et al. 2010 [

34,

35]).

These efforts will bridge the gap between lab–scale success and plant–wide adoption, while addressing technical, economic, and environmental bottlenecks. Further experiments are to be carried out with the intention of improving the current results and reducing the consistent losses that are found in not just the Guobei coal preparation plant but also any other plants across the world where our research may fit. Future work will also incorporate coal slime reuse along with the experiments on going in Anhui University of Science and Technology’s School of Material Science and Engineering team.

4. Conclusions

This study systematically evaluated deep separation techniques for recovering clean coal from multi–source by–products (middlings, tailings, slimes, and cakes) at the Guobei Coal Preparation Plant. The combination of these advanced beneficiation techniques—flotation, density–based separation; and magnetic separation—provide a comprehensive approach to recovering the coal fraction from coal middlings and tailings. Each technique is carefully selected and optimized to address the specific characteristics of the coal samples, ensuring maximum recovery efficiency and minimal waste generation. This work also provided the first side–by–side comparison of four by–product streams under unified conditions, revealing particle–size–dependent ash distribution (

Table 3) and liberation thresholds (

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11 and

Figure 12). The two–stage liberation protocol (magnetite removal + staged flotation) outperformed conventional single–pass methods by 15–20% yield, offering a replicable template for similar plants.

The results of these experiments offer valuable insights into the feasibility and effectiveness of re–beneficiation processes, contributing to the sustainable management of coal resources and the reduction of environmental impacts caused by coal waste.

Key findings revealed that:

Flotation yielded clean coal recoveries exceeding 50% for middlings and tailings, with ash content as low as 10.25% in optimized conditions. Staged flotation achieved 46.9–58.3% clean coal yield at 10.3–17.0% ash content (

Table 1), outperforming most reported yields for single–pass flotation yields (10–30%).

Density–based separation achieved peak efficiency at water densities of 1.4–1.5 g/cm

3, producing high–quality coal with minimal ash content. Density separation (1.4–1.5 g/cm

3 ZnCO

3 media) recovered 34.2% clean coal from coarse middlings (≥1 mm) with ≤18.4% ash (

Table 7), addressing a critical gap in coarse particle processing.

SEM analysis confirmed the liberation of coal particles from mineral matrices, though further grinding or advanced techniques may improve results for tightly bound impurities. SEM–EDS analysis confirmed that angular, fractured particles (

Figure 8) contributed most to incremental yields (8–12%) during re–flotation, while micro–porous clusters required finer grinding (<0.045 mm).

Economic and environmental benefits were evident, with reduced tailings volume, lower disposal costs, and alignment with global sustainability goals like China’s “Carbon Peaking and Carbon Neutrality” initiative. The experimental methodology employed in this study provides a detailed and scientifically rigorous framework for assessing the re–beneficiation potential of coal middlings and tailings. By leveraging advanced separation techniques and meticulous sampling strategies, this research aims to contribute valuable insights into the sustainable management of coal processing by–products. The results of these experiments offer practical solutions for reducing coal waste and enhancing operational efficiencies within the coal industry.