Abstract

This study investigates the tribological effects of nano-sized metal oxides (ZrO2, CuO, Y2O3 and TiO2) in Group III type base oil containing 0.3% pour point depressant (PPD) and 5% viscosity modifier (VM) to enhance friction and wear performance. The homogenized lubricant samples with varying concentrations of oxide nanoparticles (0.1–0.5 wt%) on a linear oscillating tribometer performed static and dynamic frictional tests. Optical and confocal microscopy surface analysis evaluated the wear of the specimen, and SEM and EDX analyses characterized the wear tracks, nanoparticle distributions, and quantification. The cooperation between PPD and nanoparticles significantly improved friction and wear values; however, the worn surface suffered extensively from fatigue wear. The collaboration between VM and nanoparticles resulted in a nanoparticle-rich tribofilm on the contact surface, providing excellent wear resistance that protects the component while also favorably impacting friction reduction. This study found CuO reduced wear volume by 85% with PPD and 43% with VM at 0.5 wt%, while ZrO2 achieved 80% and 63% reductions, respectively. Y2O3 reduced wear volume by 82% with PPD, and TiO2 reduced friction by 20% with VM. These nanoparticles enhanced tribological performance at optimal concentrations, but high concentrations caused tribofilm instability, highlighting the need for precise optimization.

1. Introduction

The development and optimization of lubricants represent a crucial research field in the machinery industry, as effective friction reduction and wear protection contribute to extending the operational lifetime of machinery and reducing maintenance costs [,]. In recent years, advances in nanotechnology have opened up new opportunities for further enhancing the performance of lubricants via nanoparticles [,,,,,].

In addition to nanoadditives due to nanotechnology, viscosity modifier (VM) and pour point depressant (PPD) additives play an essential role in the present research. Viscosity index improvers, particularly poly(methacrylate) polymers (PMA), are crucial for enhancing lubricating oil’s viscosity-temperature characteristics, ensuring low viscosity at low temperatures and adequate viscosity at high temperatures []. This research investigates the combined effect of nanoparticles and viscosity modifying or pour point depressant additives. An essential question is how these substances interact with the oil components. According to Guangwen et al., despite PMA’s benefits, their poor thermal and shear stability necessitates copolymerization with various olefin monomers to improve performance []. There have been several studies on the synthesis of PMA polymer. Lomège et al. describe the synthesis of alkyl sulfur-functionalized PMA-based viscosity index improvers derived from oleic acid for use in mineral paraffinic lubricating oils. Their tests indicated significant improvements in polymer thickening powers and viscosity index with temperature, outperforming previously reported polymers like poly(2-[methacryloyloxy]ethyl oleate) (PMAEO) []. Campbell et al. designed and synthesized linear polar and linear nonpolar PMAs for use as lubricant viscosity index improvers with enhanced shear and anti-wear resistance. These polymers, characterized by low and narrow molecular weights, exhibited higher viscosity indexes and significantly reduced wear compared to commercial benchmarks, demonstrating their suitability for fluid power applications []. Jalilian et al. have shown that lower molecular weight synthesized PMA homopolymers provide better friction control performance at low temperatures []. Cosimbescu et al. investigated polymer systems designed to improve the viscosity index and prevent wear. Examples of such polymers studied were polar poly(methacrylate)s and ionic liquid-containing PMAs. Their results show that the polymer systems tested can reduce friction and wear, except ionic liquid-containing PMA, which was somewhat unfavorable for tribological metrics [,,]. Researchers have studied the viscosity modifier olefin copolymer (OCP) under investigation. The OCP is made from ethylene and other olefins, such as propylene and butylene. It possesses high thickening efficiency and low-cost advantages. However, its disadvantages include poor shear stability and adverse effects on cold properties []. Using OCPs can result in significant changes in the viscosity parameters of base oils [].

In addition to the viscosity modifiers and pour point depressants used in the oil samples, the nanoceramics mentioned above were used, too. The enhancing effect of nanoceramics has been proven. The nanoparticles’ size positively affected friction and wear, according to Dai et al. []. Nanoparticles can fill up surface roughness grooves, resulting in notable changes in surface morphology and increased contact between surfaces and nanoparticles []. They also contribute to the transition from sliding to rolling movement and help form a protective layer. Thanks to these repairing mechanisms, the nanoadditives doped into the oil can reduce wear and friction, thus increasing the lifetime of components [,]. The present study investigated four nanoadditives: copper (II) oxide, zirconium dioxide, yttrium oxide, and titanium dioxide. First, for copper (II) oxide, researchers performed tests with copper (II) oxide nanoparticles. Studies have shown that copper (II) oxide can reduce the coefficient of friction by 14.59–42.92% compared to the reference and also creates a film layer that reduces contact area and wear rate [,]. Another studied nanoparticle, zirconia, was investigated by Tóth et al. They found that the optimum percentage by weight of zirconium dioxide additive in oil is 0.4 wt%, where the additive produced the most favorable tribological properties []. Zirconia is often mixed with rare earth elements, such as yttrium, to minimize microcracking due to thermal stress, thus creating reliable molecular stability [,].

Suri found that zirconia can be replaced by 15% yttria before any adverse effects occur []. With the application of the third studied nanoparticle, yttrium oxide, Tóth et al. found a 45% reduction in wear scar diameter and a 90% reduction in wear volume at 0.5 wt%, compared to their reference. It was observed that the yttria nanoparticles embedded in the surface roughness grooves could create a smoother contact surface []. Several studies have shown that titanium dioxide nanoparticles reduce wear and friction [,] in different tribosystems. Machine learning can be used to develop the nanoadditives’ research under investigation further and to produce various parameter impact studies []. Kamal et al. showed that physical parameters of nanoparticles, such as kinetic energy, potential atom energy, and density, have a substantial effect on the properties of nanofluids: agglomeration factors, viscosity, tribological and thermal behavior [].

While oxide nanoparticles demonstrate significant tribological potential in studies, several challenges must be addressed before practical application. Specific metallic nanoparticles, which may form through triboreduction and enter the lubricant, can accelerate its oxidative degradation. Stability issues and sedimentation problems lead to nanoparticle agglomeration and eventual precipitation from the fluid. Additionally, the health and environmental concerns associated with nanoparticle usage, such as toxicity and persistence in ecosystems, require careful consideration and regulation. However, much information is still unknown about health impact.

Summarizing the examined studies, it can be concluded that using nanoadditives can significantly reduce wear and friction, contributing to increased component lifetime and improved lubricant performance. However, the interactions between oxide nanoparticles and common additives, such as pour point depressants (OCP) and viscosity modifiers (PMA), remain unexplored from a tribological perspective.

This research aims to bridge this gap by systematically studying the synergistic effects of oxide nanoparticles (ZrO2, CuO, Y2O3, and TiO2) in combination with these additives. The main novelty of the paper lies in its quantitative evaluation of these interactions, revealing both their potential for enhancing tribological performance and the challenges posed by high nanoparticle concentrations, such as system instability and fatigue wear. The findings are expected to provide valuable insights for developing advanced lubricant formulations, significantly contributing to tribology and lubricant design.

2. Materials and Methods

In this study, copper(II) oxide, yttrium oxide, zirconium oxide, and titanium dioxide nanoparticles were added to Group III 4 cSt type base oil formulated with two different base oils containing 5% viscosity modifier (VM) and 0.3% pour point depressant (PPD). The two differently additive-treated base oils (PPD and VM) provided the reference values. During the measurement planning, the pairing of test parameters and equipment was selected to ensure that no measurement parameter approached the limits of the equipment’s range, thereby eliminating potential errors arising from measurement boundary limitations. The reference values were determined from the arithmetic mean of eight measurements, while the results of the oil samples with nanoparticle additives were averaged from four measurements. The standard deviation was also calculated from these results using Microsoft Excel 2019 software.

2.1. Nanoparticles

The common feature of all the applied nano-additives is that they are transition metal oxides with spherical morphology and diameter below 50 nm, and all were purchased from Reanal Laborvegyszer Kereskedelmi Ltd., Budapest, Hungary, in bulk APS powder form. Their properties are summarized in Table 1.

Table 1.

Material properties of the specimens used.

The nanoadditives used in this study were treated with surface activation according to the method outlined by Tóth et al. []. This approach resulted in the formation of an ethyl oleate layer on the nanoparticles’ surface, effectively reducing undesirable size growth and aggregation, thereby increasing the lifetime and stability of the oil sample.

2.2. Lubricant

This research was supported by MOL-Lub Ltd. (Almásfüzitő, Hungary) with lubricants. The base oil used for the tests was selected based on state-of-the-art, high-performance commercial lubricants intended for modern passenger vehicles. The base of the lubricating oils was a Group III base oil with a viscosity of 4 cSt, composed of C20–C50 molecules produced by hydrocracking. The manufacturer prepared two lubricant samples based on Group III base oils for the measurements. In one oil sample, the Group III base oil was supplemented with 0.3 V/V% poly(methacrylate) polymer (PMA) as a pour point depressant (PPD) additive. The Group III base oil was formulated with 5 V/V% olefin copolymer (OCP) as a viscosity modifier in the other oil sample.

2.2.1. Pour Point Depressant

Poly(methacrylate) polymers (PMAs) are widely used as motor oil additives, particularly as pour point depressants (PPDs). The primary role of PMAs is to improve the behavior of motor oil at low temperatures by preventing the oil from crystallizing and solidifying in cold environments. The long, branched chains of PMA integrate into the paraffin crystals that form when the oil cools. These polymers alter the shape and size of these crystals, preventing them from interlocking and creating a solid structure. As a result, the oil maintains its viscosity at low temperatures (stability), ensuring easy cold-starting of the engine and efficient lubrication over a wide temperature range. In the preliminary stages of motor oil development, it is essential to investigate the interaction between PMAs and nanoparticles, as combining specific components with PMAs can negatively impact lubricants’ tribological, oxidation, and foaming properties.

2.2.2. Viscosity Modifier

Olefin copolymers (OCPs) are engine lubricants’ most commonly used viscosity modifiers. OCPs effectively enhance the viscosity index of engine lubricants, which means they help maintain optimal lubricant viscosity across a wide temperature range (cold to hot). OCPs comprise long, elastic polymer chains that respond sensitively to temperature changes. In warm conditions, the polymers expand, increasing the oil’s viscosity, which helps maintain proper lubrication properties. In cold conditions, the polymers contract, preventing the oil from becoming too thick and facilitating easier pumpability. Their application reduces component wear and increases the lubricant’s oxidative stability; however, these long molecules can break under high shear forces, leading to degradation and loss of effectiveness. Selecting OCPs poses a challenge during motor oil formulation, as they can interact with other substances and exhibit varying (either better or worse) tribological and antioxidant properties.

2.3. Lubricant Preparation

The homogenization of lubricant samples used for measurements is crucial for the success of tribological tests. Five different concentration mixtures were created based on the nanoparticles added to the tested lubricant samples: 0.1, 0.2, 0.3, 0.4, and 0.5 wt%. A magnetic stirrer was initially used to homogenize the appropriately concentrated oil sample. To aid the homogenization process during preparation, toluene (Lach-Ner Ltd., Neratovice, Czech Republic, CAS 108-88-3) was added to the lubricating oil samples, 27 times the weight of the measured nanoadditive. Toluene improves the dispersion of nanoparticles in the oil. It is also recommended by several studies [,,]. Before undertaking the requisite analysis, the lubricating oil samples were subjected to a 16-h magnetic stirring process. After 16 h of mixing, the toluene evaporates entirely from the oil sample. This was verified using the FTIR (Fourier-transform infrared spectroscopy) technique, and no toluene was detected in the measured oil samples. This was followed by an ultrasonic stirring process for a 15-min duration at 50 °C temperature, immediately preceding the commencement of the measurement phase.

2.4. Tribotests

The tribological measurements were performed in the Tribology Laboratory at the University of Győr, using an Optimol SRV®5 (Munich, Germany) tribometer with an oscillating module. These tribotests do not accurately simulate real industrial conditions, such as complex geometric contact or contamination. However, they provide controlled and repeatable conditions, making them suitable for comparative studies and fundamental tribological analysis. During the oscillating motion, two test specimens, a disc and a ball, were placed in contact using an oscillating frame and a push rod. The frame executed the motion while the push rod applied the load to the test pieces. A disc and a ball specimen were used for the tribological measurements, and their material properties are detailed in Table 2. Each disc accommodates four measurements per side, allowing for eight suitable measuring positions per disc. Bearing steel balls were paired with the disc bases, with each ball used for four measurements. Before each measurement, the test specimens were cleaned in an ultrasonic cleaner at 50 °C for 15 min.

Table 2.

Material properties of the specimens used.

Tribometer’s measurement programs were created in accordance with ISO 19291:2016 []. Each measurement lasted 2 h and 30 s, starting with a 50 N preload for 30 s, followed by applying a 100 N normal force. Measurements were performed at a stroke length of 1 mm, a frequency of 50 Hz, and an oiling rate of 225 mL/h. The tests used a cassette capable of a 200 N load. Both specimens and lubricant were conditioned at 100 °C during the tests. To ensure the reproducibility of the tribotests, 4 measurements were taken for each oil sample. The tribometer directly measured the friction absolute integral (FAI) value, where the FAI is the area under the curve of the coefficient of friction values measured over the entire stroke length at a high frequency (25 kHz) []:

where ‘s’ is the stroke and ‘μ’ is the coefficient of friction. Static friction (stiction) value (COF) is the maximum coefficient of friction per stroke. In oscillating motion, it is typically given at the dead center.

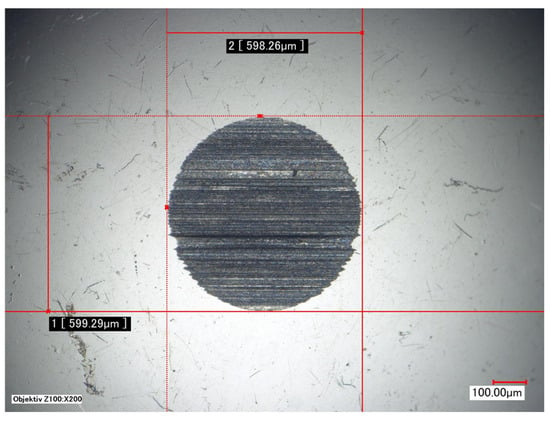

2.5. Surface Analysis

In addition to these two values, two others were examined with microscopes. These are wear parameters, which represent the wear of the test specimens. After measurements, the test specimens were soaked in naphtha and cleaned with an ultrasonic cleaner at 50 °C for 15 min to remove all contamination, wear debris, and leftover oil. The specimens were stored in a desiccator with a vapor absorber silica gel between the cleaning and microscopic measurements. Using a Keyence VHX-1000 (Osaka, Japan) digital microscope, the wear scar diameter (WSD value) on the ball specimen was determined. The diameter was measured by placing the ball specimen on an adjustable hemispherical ball holder and then on the microscope’s table. The microscope’s objective lens was zoomed in on the ball’s surface until it was focused. A magnification of 200 times was used for the measurement. The adjustment of the ball holder element has been fine-tuned until the wear scar is in the center. Subsequently, the microscope software scaled the centrally located wear scar in focus. The ISO 19291:2016 standard is used to evaluate the anti-wear properties of lubricants using a steel ball-on-flat surface wear test method, which determines the WSD. To determine the WSD value, measure the width and height of the wear scar on the ball in the direction of movement and then calculate the arithmetic mean of these two values to obtain the result (see Figure 1).

Figure 1.

Measurement of the dimensions required to determine the wear scar diameter of a worn ball according to the ISO 19291:2016 standard.

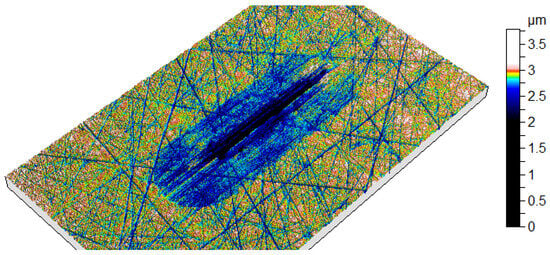

A Leica DCM 3D (Wetzlar, Germany) confocal microscope was used to determine the wear volume of the wear mark on the disc specimen. Confocal microscopes use a laser beam to scan the surfaces under examination, from which images are continuously captured by moving along three axes and then combined to create a three-dimensional image (see Figure 2). The inserted disc specimen must be leveled before measuring with a confocal microscope. A 20× magnification objective was used for the measurement. In the evaluation software of the microscope, it is possible to calculate the volume of the worn material from the microscopic image using the least squares method.

Figure 2.

3D scan of wear scar using a confocal microscope to calculate wear volume.

To investigate the events that occurred on the worn surface and the interactions of the nanoparticle additives, the worn surfaces were examined using scanning electron microscopy (SEM). SEM analysis does not accurately capture the full resolution of wear grooves or nanoparticles on the contact surface, but it provides high-resolution insights into surface features and wear mechanisms. Two characteristic points of the wear scars on the disc were analyzed: the center of the wear scar and the center of the dead point of the ball (the endpoint of the wear scar in the direction of motion). These two locations represent different tribological conditions. In the center of the wear scar, the relative speed of the ball is highest, leading to the best lubrication conditions.

In contrast, at the dead point, the ball stops, its relative speed drops to zero, and then it starts again, allowing the examination of the stop-stick-start effect, where lubrication is the most insufficient. The SEM images were taken at the Material Testing Laboratory at the University of Győr. A Hitachi S-3400N (Tokyo, Japan) device was used to capture the pictures of the wear scars at 1000× magnification. The images were supplemented with energy-dispersive X-ray spectroscopy (EDX) to examine the location and quantity of nanoparticles present on the surface. The SEM and EDX analyses were conducted under high vacuum conditions, with an accelerating voltage of 20 kV and a working distance of 8.5–10.2 mm.

3. Experimental Results

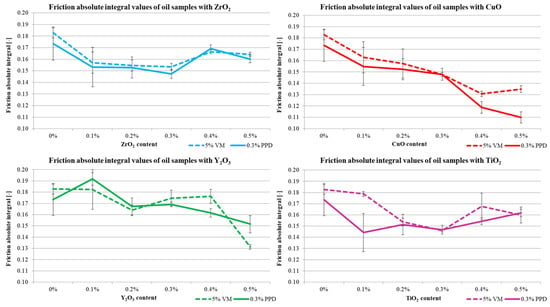

3.1. Friction Absolute Integral

The Friction Absolute Integral (FAI) is a quantitative indicator used to comprehensively evaluate friction performance over a given period or under varying conditions. This measure effectively characterizes lubricity by considering fluctuations and variations in friction behavior rather than relying on a single-point measurement. The FAI value allows for a thorough cumulative examination of friction in tribological systems where friction dynamically changes.

The FAI results obtained from the tribometer tests are shown in Figure 3. From the reference tests, it can be concluded that the dynamic friction (µ = 0.183) of the Group III base oil with 5% viscosity modifier (VM) is slightly higher than that of the base oil with 0.3% pour point depressant (PPD) (µ = 0.173). It can be established that applying both formulating additives (VM and PPD) reduces the FAI value when nanoparticles are used.

Figure 3.

The friction absolute integral results of the tested oxide nanoparticles are shown with a dashed line for the lubricant sample containing 5% viscosity modifier and a solid line for the lubricant sample containing 0.3% pour point depressant. All y-axes are truncated at 0.1.

In the zirconium dioxide nanoparticle additive case, a similar trend was observed in the FAI analysis with both VM and PPD additives, suggesting no interaction between the formulating additives and the zirconia nanoparticle additive. Although all applied concentrations reduced friction, it was found that lower concentrations (<0.4 wt%) yielded more favorable results, with a 12–16% reduction. The best results in both oil samples were achieved with 0.3 wt% zirconia content. Among the oil samples containing 0.3 wt% zirconia, the one with VM operated with 16% lower friction, and the one with PPD operated with 15% lower friction.

The FAI analysis of the CuO nanoparticle additive demonstrates a significant friction-reducing effect. Examining the relationship between friction and CuO content, it can be observed that increasing the amount of CuO resulted in progressively lower friction within the tested range. The trends of the VM and PPD-formulated base oils show very similar FAI results, suggesting that there is no interaction between the formulating additives and the CuO nanoparticle additive at low concentrations (<0.5 wt%). Exceptions to this are the oil samples containing the highest amount, 0.5 wt% CuO, where the poly(methacrylate) polymer PPD was able to enhance the friction-reducing effect further, while the olefin copolymer VM was not. Group III + 5% VM oil sample, adding 0.4 wt% CuO nanoparticles resulted in 28% lower dynamic friction compared to the reference; for the Group III + 0.3% PPD oil sample, adding 0.5 wt% CuO nanoparticles resulted in a 37% reduction in dynamic friction compared to the reference.

The FAI analysis of the yttria nanoparticle additive revealed that in the 0–0.4 wt% concentration range, friction was minimally reduced for both VM and PPD additives. Within this range, the friction trend was also very similar, suggesting no significant interaction between VM, PPD, and yttria regarding friction reduction. For both oil samples, the 0.5 wt% yttria content resulted in the lowest FAI value, with the application of VM significantly contributing to a 28% reduction in friction. In contrast, the PPD-containing oil sample showed a 13% reduction in friction.

The friction-reducing effect of the titania nanoparticle additive is similar to that of zirconia; significant friction reduction can be achieved at concentrations of 0.1–0.3 wt%, while friction starts to increase at higher concentrations. The friction trends generally move in parallel in the presence of both VM and PPD formulating additives, except for the FAI results for the 0.1% titania-containing oil samples, where the measurement results for the PPD sample showed higher than usual variability. The best dynamic friction result was achieved with 0.3 wt% titania content in the presence of VM, showing a 20% reduction. With PPD, the best result was obtained with 0.1 wt% titania content, resulting in a 17% reduction in friction.

Although the FAI results show lower friction in all cases, they can be categorized into two types. Zirconia and titania nanoparticle additives provided the lowest dynamic friction at 0.1–0.3 wt% concentrations, typically showing 12–20% improvements. The dynamic friction began to increase at higher concentrations of 0.4–0.5 wt%. The other group includes cupric oxide and yttria nanoparticle additives, where higher concentrations progressively enhanced the friction-reducing effect, with improvements ranging from 13 to 37%. There was no clear correlation regarding a cooperative effect between the VM-PPD formulators and the tested oxide nanoparticles on the dynamic friction results.

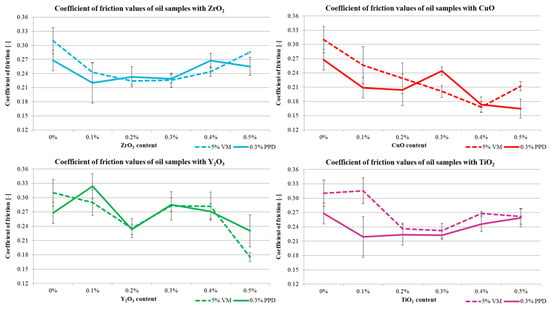

3.2. Static Friction

The coefficient of friction (COF) characterizes the system’s starting resistance in a tribological system. In the present tribological system, this occurs during the oscillating motion every time the ball stops at the dead point and restarts; this is where the maximum friction force arises, which must be overcome for the motion to commence.

When examining the COF results, correlations similar to those observed with the FAI can be noted (see Figure 4). When analyzing stiction, it is evident that there is a significant difference between the results of the Group III base oil formulated with VM and PPD. The base oil formulated with PPD shows much lower stiction (µ = 0.268) than the one formulated with VM (µ = 0.310). The PPD better supports the tribological state when lubrication is insufficient, whereas the VM additive does not perform well under these conditions.

Figure 4.

The static friction results of the tested oxide nanoparticles are shown with a dashed line for the lubricant sample containing a 5% viscosity modifier and a solid line for the lubricant sample containing 0.3% pour point depressant. All y-axes are truncated at 0.12.

The COF results for zirconia and titania nanoparticle additives are characterized by the lowest stiction achieved in the 0.1–0.3 wt% nanoparticle range, with an increasing trend observed at concentrations of 0.4–0.5 wt%. It can be concluded that the zirconia nanoparticle additive can reduce stiction more effectively than dynamic friction. The COF analysis found that adding 0.2 wt% zirconia nanoparticles, combined with 5% olefin copolymer VM, resulted in a 28% reduction in stiction. A decrease of 18% in stiction was observed with the addition of 0.1 wt% zirconia nanoparticles in the presence of 0.3% poly(methacrylate) polymer PPD.

Similarly to zirconia, the olefin copolymer VM also better supported the reduction in stiction during the application of titania nanoparticles (0.3 wt% titania resulted in a 25% reduction in COF) compared to the poly(methacrylate) polymer PPD (0.1 wt% titania resulted in an 18% reduction in COF).

The cupric oxide and yttria nanoparticle additives also produced similar COF-FAI comparative results, although there are some outliers in the COF results, such as 0.2 wt% yttria and 0.3% PPD + 0.3 wt% cupric oxide. For both nanoparticles, lower coefficients of stiction were achieved in the higher concentration range (0.4–0.5 wt%). The cupric oxide nanoparticle showed an inverse trend in reducing the COF value with increasing concentration. The minimum COF was achieved with VM at 0.4 wt% nanoparticle concentration, resulting in a 46% reduction. With PPD, the lubricant sample containing 0.5 wt% CuO reduced COF by 38% compared to the reference.

The yttria nanoparticle additive showed fluctuating COF results in the presence of both PPD and VM, with high variability in the results, indicating that the tribofilm—and consequently the tribological system—is unstable at the dead point. The lubricant sample with the highest yttria content, 0.5 wt%, reduced stiction the most: when used with VM, the COF decreased by 43%, and with PPD, it decreased by 14%. The VM + 0.5 wt% yttria combination produced tribologically stable results with low deviation.

The absolute values of the measured COF results were roughly the same when examining the PPD and VM formulation additives. However, since VM provides a higher reference value, the overall results indicate that its presence supports the nanoparticles more effectively in achieving lower COF than PPD. It would be worthwhile to investigate further the potential effect of olefin copolymer VM in the future, as it may enhance the friction-reducing effect of oxide nanoparticles. Notably, the results with yttria nanoparticle additives were unstable, a unique characteristic of the nanoparticle in the dead point region, which was only stabilized by the VM + 0.5 wt% yttria lubricant sample.

3.3. Mean Wear Scar Diameter

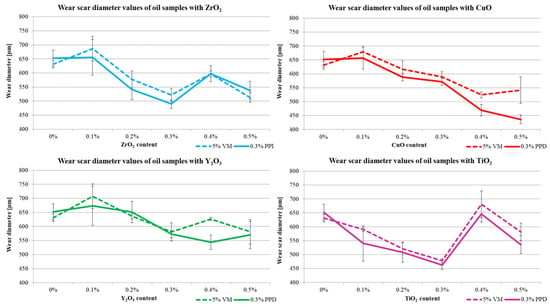

The wear scar diameter (WSD) measured on the ball indicates the lubricating ability of the system and its resistance to contact pressure. Figure 5 summarizes the WSD results of the examined tribological system.

Figure 5.

The mean wear scar diameter results of the balls tested with oxide nanoparticles are shown with a dashed line for the lubricant sample containing a 5% viscosity modifier and a solid line for the lubricant sample containing 0.3% pour point depressant. All y-axes are truncated at 400 µm.

When comparing the WSD results of the reference oil sample containing 5% VM and 0.3% PPD, it can be observed that the wear scar diameters are nearly identical, with minimal differences (WSDVM = 631 µm; WSDPPD = 652 µm), slightly favoring the VM. It is noted that all tested oxide ceramics show similar results with both formulating additive combinations, particularly in the cases of zirconia and titania. Significant differences are observed in only 0.5 wt% CuO and 0.4 wt% yttria. It can be seen that, although the PPD reference value is higher, when examined with nanoparticles, the optimum points of the oxide ceramics display lower WSD values with PPD. When used with VM at a 0.5 wt% concentration, the zirconia nanoparticle reduces the WSD by 19%, and when used with PPD at a 0.3 wt% concentration, it reduces the WSD by 25%.

A similar trend is observed for the WSD of balls tested with titania, depending on nanoparticle content. At the optimal point of 0.3 wt% titania, VM reduces the WSD by 24% and PPD by 29%. It is worth noting and examining in the future that for this pair of nanoparticle additives, the 0.4 wt% concentration typically results in high wear values.

Similar to the friction test results, the wear scar diameter analysis shows that higher CuO concentrations provide more favorable tribological properties. In the presence of the PPD formulating additive, a continuous reduction in wear can be observed with increasing CuO concentration, reaching a maximum WSD reduction of 33%. The VM additive and CuO nanoparticle display a similar trend, but the best WSD value is achieved at a 0.4 wt% CuO concentration, where the reduction is 17%. The lubricant sample containing Group III + 0.3% PPD + 0.5 wt% CuO demonstrated the highest resistance to contact pressure in the entire measurement series.

When used with VM, the yttria nanoparticle showed a minor wear-reducing effect, with an 8% reduction in wear observed at both 0.3 wt% and 0.5 wt% concentrations. In contrast, the lubricant with 0.4 wt% yttria, which appeared optimal when used with PPD, presented an average wear scar diameter that was 17% smaller compared to the reference. Based on the WSD results, it can be calculated that the contact pressure during the various tests ranged widely between approximately 240–700 MPa.

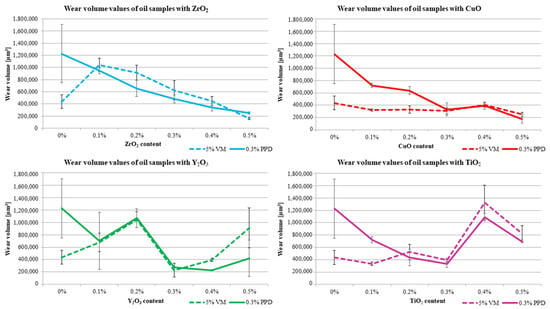

3.4. Wear Volume

Wear volume (WV) values are crucial parameters in terms of the wear resistance and lifespan of the system. Numerous factors influence the final developed WV. The wear volume of the disc specimen is based on the volume reduction expressed in µm3. The results of the reference measurements show a drastic difference in the system’s wear resistance: the wear tracks on the discs formed with the base oil containing 5% VM had an average volume of approximately ~437,000 µm3, while the samples containing 0.3% PPD additive had an average volume of ~1,229,000 µm3 with a huge deviation. The high variability in the measured values of the PPD reference suggests that the tribological system is unstable, with an insufficient protective tribofilm forming on the surface, as the material build-up and degradation processes alternate. The WV values measured during surface analytical examinations are summarized in Figure 6.

Figure 6.

The wear volume results of the disks tested with oxide nanoparticles are shown with a dashed line for the lubricant sample containing a 5% viscosity modifier and a solid line for the lubricant sample containing 0.3% pour point depressant.

The zirconia nanoparticles can improve the high reference wear of PPD in direct proportion to the increase in concentration. The wear values are roughly similar with both VM and PPD additives. A high zirconia concentration is required for the VM additive to achieve a significant wear-reducing effect. The 0.5 wt% zirconia content in both formulating additives showed the best anti-wear properties, with wear reductions of 63% for VM and 80% for PPD.

The cupric oxide nanoparticle provided favorable wear resistance properties for PPD and VM-containing lubricant samples. For the PPD additive, the gradual increase in CuO concentration led to progressively better wear values, with the best anti-wear performance observed at 0.5 wt% CuO, achieving an 85% reduction. Similarly, for the VM additive, every nanoparticle concentration improved wear resistance, though the improvement was not directly proportional to the concentration. However, the optimal result was also observed at 0.5 wt% CuO, where the wear volume reduction was 43%. The lubricant sample containing Group III + 0.3% PPD + 0.5 wt% CuO exhibited the most wear-resistant performance in the entire measurement series.

As observed in the friction results, the final wear volume (WV) of yttria nanoparticle additives is also influenced by the instability of the tribological system, especially at low yttria concentrations (0.1–0.2 wt%), evidenced by fluctuating values and high variability ranges. The 0.3–0.4 wt% yttria content is an optimal range for wear volume reduction, achieving the highest WV reduction with PPD (82% WV reduction) and VM (48% WV reduction) additives. However, at 0.5 wt% yttria, the wear volume and variability increase drastically again, likely due to the dominance of intensive three-body abrasion processes caused by the high hardness of the yttria nanoparticles.

Titania nanoparticle additives at concentrations of 0.2 wt% and higher can equalize the differences between the oil samples containing the two different formulating additives. Combining titania nanoparticles and PPD generally provides lower wear volume than with VM additive. The oil sample with 0.4 wt% titania also shows notably poor wear resistance, similar to what was observed in the WSD values. The lubricant sample containing 0.3 wt% titania with PPD achieved a 73% reduction in wear. In contrast, with VM additives, lower titania concentrations (0.1–0.3 wt%) show better wear resistance, with the best performance observed in the 0.1 wt% sample, which reduced wear by 24%.

The unstable tribofilm of the oil sample containing only PPD was stabilized by most nanoparticles at any concentration except for low and very high yttria concentrations. Its unfavorable anti-wear properties were significantly improved starting from 0.2 to 0.3 wt% nanoparticle concentration. While there are some favorable combinations, only the CuO nanoparticle consistently produced positive results in the presence of VM. However, the wear-reducing effect of zirconia at 0.4–0.5 wt% concentration is also noteworthy. For each oxide nanoparticle, there was a specific concentration beyond which parallel results could be observed with both VM and PPD additives. Above this concentration, when the nanoparticles override the tribological effects of the formulating additives, PPD typically resulted in lower wear values in most cases, as it better supported the nanoparticles in enhancing their anti-wear properties.

3.5. SEM/EDX

Scanning electron microscope (SEM) wear investigation provides insight into the surface processes occurring at the end of the measurement. The characteristic types of wear on the surface were identified at the dead points and centers of the wear marks. Identifying microstructural changes can help understand the functioning of additives and the reasons for changes in friction and allow conclusions to be drawn about the system’s lifespan. During the EDX analysis, the presence, location, and potential deposition/incorporation of nanoadditives are investigated. The analysis targets the transition metal elements of the oxide nanoparticles, specifically zirconium, copper, yttrium, and titanium. The components of the tribological system (test specimens and lubricating oils) were paired with the tested nanoadditives so that they contain these target elements either not at all or only in negligible amounts. This ensures that the EDX signals can be attributed solely to the nanoadditives.

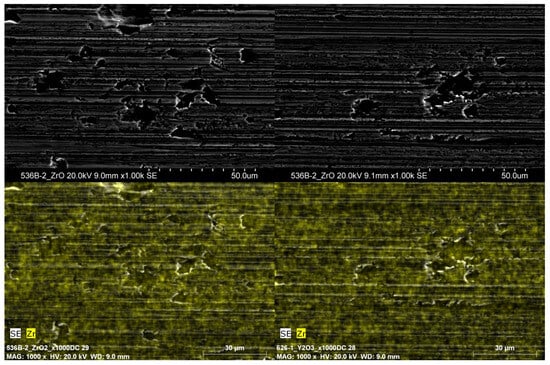

3.5.1. Wear Marks Tested with Zirconia

The characteristic wear patterns of PPD + 0.5% wt% zirconia containing lubricant are shown in the top row of Figure 7. The left image shows an SEM image taken at the dead point of the disc, revealing that the wear is predominantly influenced by two main factors: longitudinal abrasive marks parallel to the direction of motion and severe fatigue. The repetitive loading due to the ball’s repeated stopping and starting exerts significant surface stress on the disc, leading to the formation of microcracks. These cracks propagate over time, eventually causing small, and later more significant, fragments to break off from the surface due to fatigue wear. The released wear debris can further enhance the degree of three-body abrasion. In the center of the wear track (Figure 7, top right), where the ball speed is highest and the lubrication conditions are better, the tendency for fatigue is somewhat reduced. However, significant fatigue wear is still observed. The main abrasive lines are also present in the central region of the wear track.

Figure 7.

SEM and EDX images of the worn surface of the disc specimens tribotested with Group III + 0.3% pour point depressant + 0.5 wt% zirconia nanoadditive. The photos were taken from the wear track dead center (left) and stroke-middle section (right) areas with the horizontal sliding direction. In the bottom row are the results of the EDX analysis of the same images, with the location of the zirconium element highlighted in yellow.

The EDX analysis of the wear mark (Figure 7, bottom row) reveals that zirconia is distributed almost uniformly across the entire wear mark, 0.67 norm.at% zirconium can be observed in the middle point. At the dead center point, more zirconia was incorporated into the surface, with the amount of zirconium found here being 1.09 norm.at%. Only a few smaller locations show noticeable zirconia enrichment. This zirconia-enriched tribofilm endowed the disc with good wear-resistant properties but could not eliminate the significant fatigue wear.

The top row of Figure 8 shows characteristic SEM images of the wear mark created with the VM + 0.5 wt% zirconia-containing lubricating oil sample. The dead point image (top left) and the image taken at the center of the wear mark (top right) indicate minimal wear, with many of the original surface machining marks still visible. Minor, minimal fatigue marks originate from the stress concentration points of the surface machining. Along the abrasive grooves, traces of plastic deformation on the surface can be observed.

Figure 8.

SEM and EDX images of the worn surface of the disc specimens tribotested with Group III + 5% viscosity modifier + 0.5 wt% zirconia nanoadditive. The photos were taken from the wear track dead center (left) and stroke-middle section (right) areas with the horizontal sliding direction. In the bottom row are the results of the EDX analysis of the same images, with the location of the zirconium element highlighted in yellow.

The synergy between the viscosity modifier additive and zirconia is unique, providing excellent lubricating capability to the oil. This cooperation with the nanoparticles forms a highly effective surface-protecting tribofilm. The detected distribution of zirconium on the surface is uniform; however, as the zirconia nanoadditive facilitated plastic deformation, some enrichment points can be observed around those areas. The amount of zirconium at the dead center of the wear mark is 0.57 norm.at%, while an average of 0.73 norm.at% zirconium is found at the centers of the wear track.

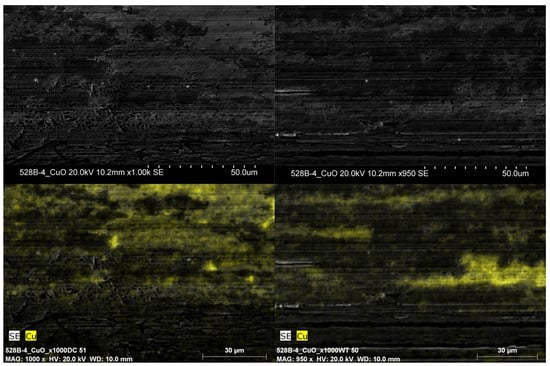

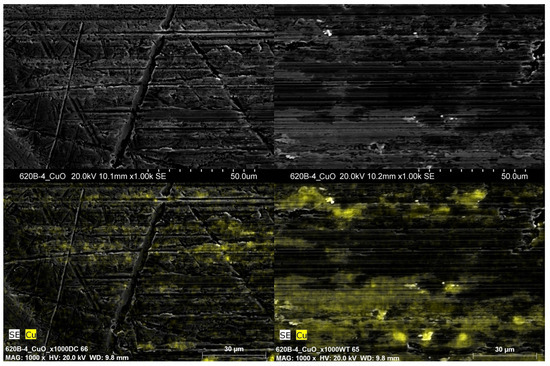

3.5.2. Wear Marks Tested with Cupric Oxide

Figure 9 shows the characteristic image of wear marks on the disc tested with the PPD + 0.5 wt% cupric oxide oil sample. The top left photo shows the wear mark at the dead point, where various wear types and processes can be identified. Few and very thin abrasive grooves are visible on the wear pattern of the surface. Small spallings from fatigue wear and adhesion marks indicating lubrication insufficiency can also be observed. The shallow extent and small volume of the wear mark are indicated by the presence of original surface roughness machining marks in certain areas. However, the most characteristic feature of the wear surface formed with the cupric oxide nanoadditive is the light gray protective layer composed of elemental copper. This layer is formed by the smearing of elemental copper onto the surface due to the triboreduction of nanometer-sized cupric oxide particles []. This elemental copper layer can repair the surface as it builds up, withstands high pressure, and provides a low coefficient of friction. The improved lubrication conditions eliminate all adhesive effects at the center of the wear track. The wear becomes deeper, and the surface exhibits a combination of minor abrasion, very mild fatigue, and copper triboreduction, which helps repair these effects. Plastic deformation shapes the disc material and the copper build-ups. The protective layer of copper formed on the surface also creates significant and extensive areas.

Figure 9.

SEM and EDX images of the worn surface of the disc specimens tribotested with Group III + 0.3% pour point depressant + 0.5 wt% cupric oxide nanoadditive. The photos were taken from the wear track dead center (left) and stroke-middle section (right) areas with the horizontal sliding direction. In the bottom row are the results of the EDX analysis of the same images, with the location of the copper element highlighted in yellow.

The extensive elemental copper coating covers the surface with a large amount of copper, with nearly identical quantities at the dead point (4.07 norm.at%) and the center of the disc (3.97 norm.at%).

The SEM images shown in Figure 10 are characteristic images of wear marks created with VM + 0.5 wt% cupric oxide. The combined effect of the viscosity modifier and the cupric oxide nanoparticles has preserved the original surface (see top left). Most of the wear consists of abrasive grooves and small fatigue spallings. Very little elemental copper was able to reduce onto the surface (0.81 norm.at%), and significant plastic deformation is also present. This combination explains the high COF results for this oil sample. Examining the center of the wear track, it can be observed that the primary type of wear is abrasive, with characteristic longitudinal grooves. A large extent of copper coating is on the surface, contributing to the favorable tribological properties. The surface at the disc’s center contains an average of 4.65 norm.at% elemental copper. However, where this layer is absent, severe fatigue wear appears (compare the images on the right), resulting in large particle-sized debris that intensifies the abrasive effect. Further investigations aim to determine whether fatigue occurs where no copper layer forms or if fatigue is observed where the copper from triboreduction has not yet repaired the surface.

Figure 10.

SEM and EDX images of the worn surface of the disc specimens tribotested with Group III + 5% viscosity modifier + 0.5 wt% cupric oxide nanoadditive. The photos were taken from the wear track dead center (left) and stroke-middle section (right) areas with the horizontal sliding direction. In the bottom row are the results of the EDX analysis of the same images, with the location of the copper element highlighted in yellow.

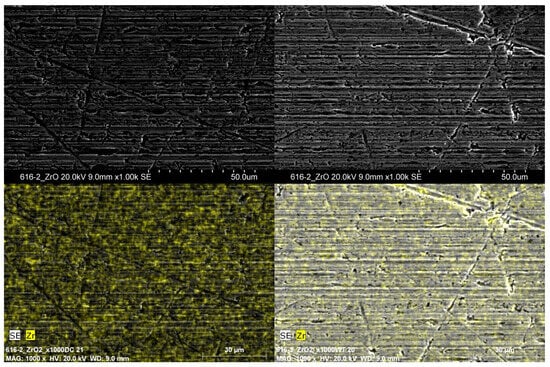

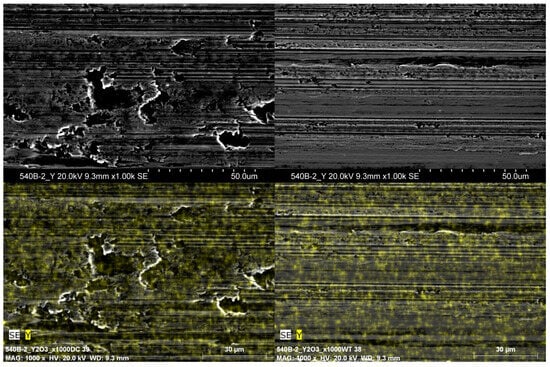

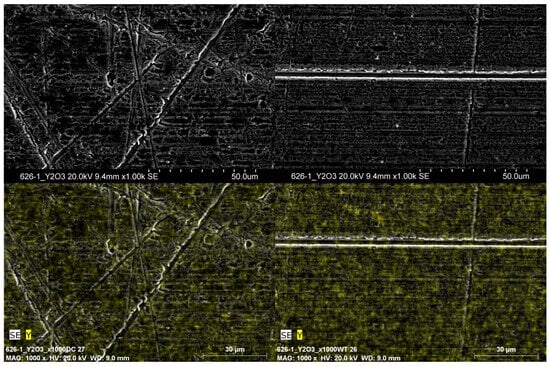

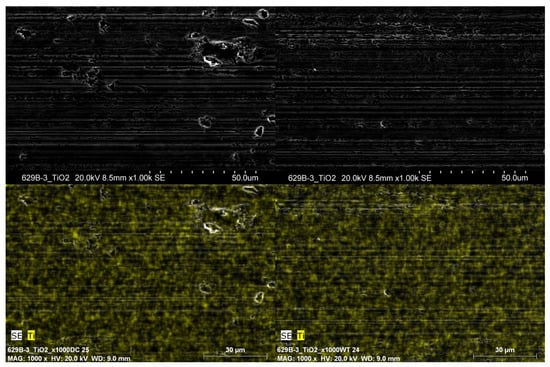

3.5.3. Wear Marks Tested with Yttria

The wear marks on the disc tested with PPD + 0.5 wt% yttria lubricating oil show extreme fatigue at the dead points, with many cracks on the surface, suggesting that this could further intensify (see Figure 11). In addition to the fatigue, parallel abrasive grooves are visible on the surface. At the center of the disc, due to improved lubrication and movement conditions that differ significantly from the dead points, the extent of fatigue is reduced dramatically. Still, it remains high, with numerous smaller spallings. The surface of the center of the wear mark is predominantly characterized by abrasion, along with additional plastic deformation. The amount of yttrium found on the surfaces is relatively low and uniformly distributed, with 0.55 norm.at% at the dead points and an average of only 0.16 norm.at% in the center of the wear mark.

Figure 11.

SEM and EDX images of the worn surface of the disc specimens tribotested with Group III + 0.3% pour point depressant + 0.5 wt% yttria nanoadditive. The photos were taken from the wear track dead center (left) and stroke-middle section (right) areas with the horizontal sliding direction. In the bottom row are the results of the EDX analysis of the same images, with the location of the yttrium element highlighted in yellow.

The SEM images of the wear track on the disc tested with VM + 0.3 wt% yttria-containing lubricating oil reveal unique surface formations (see Figure 12). During the testing of this oil sample, stable results were obtained with shallow wear. The SEM images in the top row show that a peculiar surface formation can be observed across the entire surface of the disc. The original surface roughness marks are still significantly present at the dead point (top left) and, to a lesser extent, at the center of the disc (top right). The surface exhibits a few thin abrasive lines and one intense groove. Around the dead point, mild fatigue initiates from the deepest surface machining marks. The synergy between the VM and yttria nanoparticles results in the entire surface being covered with a unique patterned tribofilm composed of small and large pits, which possess excellent oil retention capabilities. Furthermore, EDX analyses show that this surface structure contains yttrium-rich areas predominantly found at the higher points of the surface roughness (significantly less yttrium is found in the grooves). The WV results indicate that the combination of VM and yttria forms this tribofilm, providing excellent anti-wear properties.

Figure 12.

SEM and EDX images of the worn surface of the disc specimens tribotested with Group III + 5% viscosity modifier + 0.3 wt% yttria nanoadditive. The photos were taken from the wear track dead center (left) and stroke-middle section (right) areas with the horizontal sliding direction. In the bottom row are the results of the EDX analysis of the same images, with the location of the yttrium element highlighted in yellow.

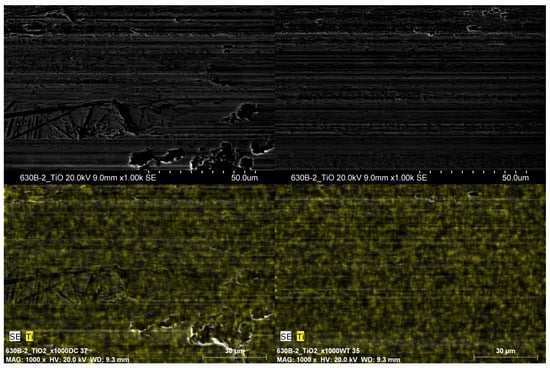

3.5.4. Wear Marks Tested with Titania

Figure 13 shows SEM images of the disc worn with the PPD + 0.3 wt% titania-containing lubricating oil sample. The top left image taken at the dead point shows similar results as those of zirconia and yttria. Harder nanoparticles such as titania, yttria, and zirconia, combined with PPD, resulted in significant surface fatigue at the dead point. A common feature of these nanoparticles is that they cause abrasive and fatigue wear. The image clearly shows that the wear depth is caused by debris breaking out from the fatigue craters, which enhances three-body abrasion. Even the original surface roughness can be observed where this did not occur. For the PPD + titania SEM analysis, similar results are seen with zirconia and yttria: fatigue is reduced at the center of the wear mark, abrasion is the dominant wear type, and there are plastically deformed areas. Approximately similar amounts of these nanoparticles are incorporated into the surfaces with uniform distribution; an average of 0.66 norm is at the dead points.at% titanium is found, while at the center, an average of 0.35 norm.at% titanium is present.

Figure 13.

SEM and EDX images of the worn surface of the disc specimens tribotested with Group III + 0.3% pour point depressant + 0.3 wt% titania nanoadditive. The photos were taken from the wear track dead center (left) and stroke-middle section (right) areas with the horizontal sliding direction. In the bottom row are the results of the EDX analysis of the same images, with the location of the titanium element highlighted in yellow.

Figure 14 shows the SEM images of the wear marks on the disc tested with VM + 0.3 wt% titania-containing lubricating oil. The main wear types, in this case, are severe fatigue wear, characterized by craters, piles of detached debris, and primary abrasive lines. Unlike the other additives tested, it was found that the VM did not help preserve the original surface when using titania nanoparticles. Although the wear was not deep, it extended across the entire disc. It is visible that fatigue is reduced at the center of the wear mark (top right). In the center of the wear track, a porous surface structure is observed, building up on the previously abraded surface. This surface structure covers a large part of the surface, predominantly appearing in more significant amounts in the central areas of the wear track. Its porosity provides excellent oil retention, which may have contributed to a 20% reduction in FAI in the tribological system. EDX results indicate that the higher surface areas (peaks and elevated contact regions) contain more titanium incorporated into the tribofilm. The embedded nanoparticles enhanced the wear resistance of the test specimens. Titanium was uniformly distributed across the entire wear mark, with concentrations of 0.5 norm.at% near the dead points and an average of 0.45 norm.at% in the center of the disc.

Figure 14.

SEM and EDX images of the worn surface of the disc specimens tribotested with Group III + 5% viscosity modifier + 0.3 wt% titania nanoadditive. The photos were taken from the wear track dead center (left) and stroke-middle section (right) areas with the horizontal sliding direction. In the bottom row are the results of the EDX analysis of the same images, with the location of the titanium element highlighted in yellow.

Table 3 summarizes the EDX quantification results from the wear marks produced during the tribotests with different oil samples. The results indicate that due to the triboreduction processes, a significant amount of elemental copper was deposited on the worn surfaces in all tests conducted with cupric oxide additives. Furthermore, it can be concluded that zirconia was incorporated into the tribofilm at a slightly higher ratio during the tests than titania, with yttria showing the lowest incorporation rate. It was also observed that neither the PPD nor the VM combinations led to significantly higher or lower incorporation of the oxide nanoparticles into the tribofilm.

Table 3.

EDX results of the tested oil samples are expressed as the atomic % of the investigated nanoparticle.

4. Discussion

The article investigates the tribological effects of nano-sized transition metal oxides on base oils containing pour point depressants and viscosity modifiers. It offers a novel approach by studying the combined impact of formulating additives and oxide nanoadditives on their tribological properties. This study demonstrates that oxide nanoparticles (ZrO2, CuO, Y2O3, and TiO2) can exhibit their hypothesized friction- and wear-reducing effects even in the presence of poly(methacrylate) polymer pour point depressant and olefin copolymer viscosity modifier.

Based on the summarized results (see Table 4), it can be concluded that applying zirconia nanoparticles favors friction reduction at concentrations below 0.3 wt%, while concentrations above 0.3 wt% are more effective in reducing wear. Cupric oxide and yttria typically exhibit significant wear-reducing effects at concentrations above 0.4 wt%; however, the drastic friction-reducing effect of CuO is particularly noteworthy. Titania nanoparticles were found to reduce friction and wear optimally at concentrations below 0.3 wt%.

Table 4.

Summary of the tribological performance of various oxide nanoparticles with VM and PPD additives added to Group III base oil, compared to the reference, neat Group III oil.

The synergy between PPD and nanoparticles generates a drastic 73–85% wear reduction, highlighting that poly(methacrylate) effectively enhances the anti-wear properties of oxide nanoparticles in the present tribological system. It was found that PPD has a slightly better impact on reducing friction and wear compared to VM, but it cannot protect the wearing surfaces from fatigue even when combined with the nanoparticles. The cooperation between VM and oxide nanoparticles gave the tribological system promising tribological properties and excellent wear resistance.

The results are difficult to compare directly with previous research because formulating additives and nanoparticles has not been studied in simplified model environments. However, the findings support the literature’s hypotheses regarding nanoparticles’ excellent tribological effects. Zirconia and titania facilitated the relative movement between contacting surfaces [], and their incorporation into the tribofilm resulted in a more robust tribological boundary layer. The triboreduction-formed copper layer increased copper content in the wear marks, which helped reduce the coefficient of friction, enhanced surface protection, and prevented fatigue []. According to SEM images, yttria nanoparticle behavior in the tribological system was similar to that observed in Tóth’s research, showing uniform distribution on the surface and promoting plastic deformation [].

The main limitation of this study is that the tests were conducted under laboratory conditions, with simplified specimen pairing, which do not fully reflect industrial applications. Further research is needed to validate these findings under real operating conditions, such as in engines or industrial systems, where variables like temperature fluctuations, pressure changes, and contamination play a significant role. Additionally, scaling the application of these oxide nanoparticles to industrial production poses challenges, including ensuring long-term stability and avoiding agglomeration.

The economic implications of using these additives are also noteworthy. The final cost factor largely depends on the material, rarity, purity, particle size, applied concentration, required treatments, and availability of the chosen nanoparticles. However, the potential for energy saving due to lower friction and enhanced component lifetimes could counterbalance higher initial costs, contributing to long-term cost efficiency.

The results are promising and encouraging for continuing research on using oxide nanoparticles as sustainable lubricant additives. The findings could serve as a basis for integrating these additives into chemical engineering processes in motor oil development. Overall, this study provides new insights into the tribological efficiency of various oxide nanoparticles, highlighting their potential benefits and challenges, and contributes to the design of lubricants for modern systems with high wear resistance requirements.

5. Conclusions

Each transition metal oxide nanoparticle exhibits distinct tribological behavior when used alongside pour point depressants (PPD) and viscosity modifiers (VM). The combined effects of these nanoadditives with formulating agents are complex and cannot be easily predicted, necessitating experimental evaluation to determine their actual impact. Understanding the interactions between nanoparticles and formulating additives is crucial for developing advanced, high-performance lubricants. This study successfully investigated these interactions through detailed tribological testing. The key conclusions derived from the results of this research are:

- Zirconia (ZrO2): Demonstrates effective friction at lower concentrations (<0.4 wt%) and wear reduction at higher concentrations (>0.4 wt%), with optimal performance at 0.3–0.5 wt%. Zirconia is more effective in lowering stiction than dynamic friction. Zirconia-enriched tribofilms provide significant anti-wear properties but struggle to prevent fatigue wear under high stress.

- Cupric oxide (CuO): Shows strong excellent friction (28–46%) and wear volume reduction (43–85%), particularly at higher concentrations (0.4–0.5 wt%). The formation of an elemental copper-containing tribofilm contributes to the beneficial tribological properties. Fatigue wear remains an issue in areas without sufficient copper coverage.

- Yttria (Y2O3): Provides moderate friction reduction but strong wear reduction at specific concentrations (0.3–0.4 wt%). The unique patterned tribofilm formed by VM and yttria, with pits enhancing oil retention, contributed to favorable friction and wear characteristics. Tribofilm instability and wear debris-induced abrasion highlight the need for optimized yttria content.

- Titania (TiO2): Offers significant friction (−17–25%) and wear reduction (−24–73%) at lower concentrations (0.1–0.3 wt%), but higher levels lead to increased wear and system instability. Titania tribofilms enhance oil retention, improving overall performance at optimal concentrations. The abrasive wear was primarily driven by debris from fatigue craters, enhancing three-body abrasion.

- Combining VM with oxide nanoparticles generally enhances friction and wear reduction, particularly at 0.1–0.3 wt% nanoparticle concentrations. Moreover, VM consistently helps form stable nanoparticle (zirconia, yttria, titania) reinforced tribofilms. However, high nanoparticle concentrations can lead to increased wear and system instability in some cases, underscoring the need for precise concentration control.

- PPD combined with oxide nanoparticles effectively reduces friction and wear and provides superior tribological performance at higher nanoparticle concentrations (0.3–0.5 wt%). It massively enhances the anti-wear properties of cupric oxide and yttria, showing strong wear resistance and lower wear volumes. However, PPD’s efficiency varies significantly depending on the nanoparticle type and concentration.

Author Contributions

Conceptualization, Á.I.S.; methodology, Á.I.S.; formal analysis, Á.I.S.; resources, H.H.; data curation, Á.I.S.; writing—original draft preparation, Á.I.S. and K.S.; writing—review and editing, Á.I.S. and K.S.; visualization, K.S.; supervision, H.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available because they were generated within the framework of the industrial project: “Synthetic fuels production and validation in cooperation between industry and university”, project number “ÉZFF/956/2022-ITM_SZERZ”.

Acknowledgments

This article is published in the framework of the project “Synthetic fuels production and validation in cooperation between industry and university”, project number “ÉZFF/956/2022-ITM_SZERZ”. The authors would like to thank Álmos Dávid Tóth, Péter Bence Pápai and Márk Marsicki for their general support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Deng, G.; Zhu, H.; Tieu, A.K. Advances in Friction, Lubrication, Wear and Oxidation in Metals Manufacturing. Metals 2023, 13, 505. [Google Scholar] [CrossRef]

- Ali, M.K.; Fuming, P.; Younus, H.A.; Abdelkareem, M.A.; Essa, F.A.; Elagouz, A.; Xianjun, H. Fuel economy in gasoline engines using Al2O3/TiO2 nanomaterials as nanolubricant additives. Appl. Energy 2018, 211, 461–478. [Google Scholar] [CrossRef]

- Htwe, Y.Z.N.; Al-Janabi, A.S.; Wadzer, Y.; Mamat, H. Review of tribological properties of nanoparticle-based lubricants and their hybrids and composites. Friction 2024, 12, 569–590. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Hou, X. Role of bis(2-ethylhexyl) phosphate and Al2O3/TiO2 hybrid nanomaterials in improving the dispersion stability of nanolubricants. Tribol. Int. 2021, 155, 106767. [Google Scholar] [CrossRef]

- Baijing, R.; Liang, G.; Botao, X.; Mengjun, L.; Shangda, Z.; Guoqing, Z.; Xu, R. Tribological properties and anti-wear mechanism of ZnO@graphene core-shell nanoparticles as lubricant additives. Tribol. Int. 2020, 144, 106114. [Google Scholar] [CrossRef]

- Hong, F.T.; Schneider, A.; Sarathy, S.M. Enhanced lubrication by core-shell TiO2 nanoparticles modified with gallic acid ester. Tribol. Int. 2020, 146, 106263. [Google Scholar] [CrossRef]

- Tang, Z.; Li, S. A review of recent developments of friction modifiers for liquid lubricants (2007–present). Curr. Opin. Solid State Mater. Sci. 2014, 18, 119–139. [Google Scholar] [CrossRef]

- Bakunin, V.N.; Suslov, A.Y.; Kuzmina, G.N.; Parenago, O.P.; Topchiev, A.V. Synthesis and Application of Inorganic Nanoparticles as Lubricant Components—A Review. J. Nanoparticle Res. 2004, 6, 273–284. [Google Scholar] [CrossRef]

- Kuraimid, Z.K.; Ammouri, Q.M.; Ahmed, T.A.; Husain, H.A. Synthesis of viscosity index improver for motor lubricating oil. Eurasian Chem. Commun. 2021, 3, 477–483. [Google Scholar]

- Li, G.; Hua, Q.; Huang, Z.; Da, Z. Progress on polymethacrylate as viscosity index improvers for lube oil. Chem. Ind. Eng. Prog. 2023, 42, 1562–1571. [Google Scholar] [CrossRef]

- Lomège, J.; Negrell, C.; Robin, J.-J.; Lapinte, V.; Caillol, S. Synthesis of Alkyl Sulfur-Functionalized Oleic Acid-Based Polymethacrylates and Their Application as Viscosity Index Improvers in a Mineral Paraffinic Lube Oil. J. Am. Oil Chem. Soc. 2019, 97, 309–318. [Google Scholar] [CrossRef]

- Campbell, K.B.; Erck, R.; Swita, M.; Cosimbescu, L. Multifunctional Tunable Polymethacrylates for Enhanced Shear Stability and Wear Prevention. ACS Appl. Polym. Mater. 2020, 2, 2839–2848. [Google Scholar] [CrossRef]

- Jalilian, S.M.; Jozaghkar, M.; Ziaee, F. Novel insight into low-temperature performance of various poly(alkyl methacrylate) homopolymers in lube oil. Polyolefins J. 2023, 10, 169–175. [Google Scholar] [CrossRef]

- Cosimbescu, L.; Robinson, J.W.; Yan, Z.; Jun, Q. Dual functional star polymers for lubricants. RSC Adv. 2016, 6, 86259–86268. [Google Scholar] [CrossRef]

- Bapat, A.P.; Erck, R.; Seymour, B.T.; Zhao, B.; Cosimbescu, L. Lipophilic polymethacrylate ionic liquids as lubricant additives. Eur. Polym. J. 2018, 108, 38–47. [Google Scholar] [CrossRef]

- Bapat, A.P.; Erck, R.; Seymour, B.T.; Zhao, B.; Cosimbescu, L. What is the effect of lipophilic polymeric ionic liquids on friction and wear? React. Funct. Polym. 2018, 131, 150–155. [Google Scholar] [CrossRef]

- Khalafvandi, S.A.; Pazokian, M.A.; Fathollahi, E. The Investigation of Viscometric Properties of the Most Reputable Types of Viscosity Index Improvers in Different Lubricant Base Oils: API Groups I, II, and III. Lubricants 2022, 10, 6. [Google Scholar] [CrossRef]

- Negi, M.S.; Kumar, N.K.; Bhardwaj, A.; Kapur, G.S.; Ramakumar, S.S.V. Prediction of thickening efficiency of olefin copolymers and kinematic viscosities of the blended base oils by determining intrinsic viscosities of the copolymers in cyclohexane. Egypt. J. Pet. 2022, 31, 7–14. [Google Scholar] [CrossRef]

- Dai, W.; Kheireddin, B.; Gao, H.; Liang, H. Roles of nanoparticles in oil lubrication. Tribol. Int. 2016, 102, 88–98. [Google Scholar] [CrossRef]

- Zheng, X.; Su, L.; Deng, G. Influence of Nanoparticles in Lubricant on Sliding Contact of Atomic Rough Surfaces—A Molecular Dynamics Study. Lubricants 2024, 12, 160. [Google Scholar] [CrossRef]

- Bukvić, M.; Gajević, S.; Skulić, A.; Savić, S.; Ašonja, A.; Stojanović, B. Tribological Application of Nanocomposite Additives in Industrial Oils. Lubricants 2024, 12, 6. [Google Scholar] [CrossRef]

- Ahmed Ali, M.K.; Abdelkareem, M.A.A.; Elagouz, A.; Xianjun, H. Nanolubricant additives. In Nanotechnology in the Automotive Industry; Song, H., Nguyen, T.A., Yasin, G., Singh, N.B., Gupta, R.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 675–711. [Google Scholar] [CrossRef]

- Abdel-Rehim, A.A.; Akl, S.; Elsoudy, S. Investigation of the Tribological Behavior of Mineral Lubricant Using Copper Oxide Nano Additives. Lubricants 2021, 9, 16. [Google Scholar] [CrossRef]

- Asnida, M.; Awang, N.W.; Amirruddin, A.K.; Noor, M.M.; Kadirgama, K.; Ramasamy, D.; Najafi, G.; Tarlochan, F. Copper (II) oxide nanoparticles as additve in engine oil to increase the durability of piston-liner contact. Fuel 2018, 212, 656–667. [Google Scholar] [CrossRef]

- Tóth, Á.D.; Szabó, Á.I.; Kuti, R. Tribological properties of nano-sized ZrO2 ceramic particles in automotive lubricants. FME Trans. 2021, 49, 36–43. [Google Scholar] [CrossRef]

- Piconi, C.; Maccauro, G. Zirconia as a ceramic biomaterial. Biomaterials 1999, 20, 1–25. [Google Scholar] [CrossRef]

- Manicone, P.F.; Iommetti, P.R.; Raffaelli, L. An overview of zirconia ceramics: Basic properties and clinical applications. J. Dent. 2007, 35, 819–826. [Google Scholar] [CrossRef] [PubMed]

- Suri, G.S. Synthesis and Structural Characterisation of Yttrium-Doped α-Zirconium Phosphate. ChemEngineering 2021, 5, 83. [Google Scholar] [CrossRef]

- Tóth, Á.D.; Szabó, Á.I.; Leskó, M.Z.; Rohde-Brandenburger, J.; Kuti, R. Tribological Properties of the Nanoscale Spherical Y2O3 Particles as Lubricant Additives in Automotive Application. Lubricants 2022, 10, 28. [Google Scholar] [CrossRef]

- Nabhan, A.; Rashed, A. Effects of TiO2 and SiO2 Nano Additive to Engine Lubricant Oils on Tribological Properties at Different Temperatures. In Proceedings of the 20th International Conference on Aerospace, Mechanical, Automotive and Materials Engineering (ICAMAME 2018), Rome, Italy, 30–31 October 2018; Volume 20, pp. 2463–2472. [Google Scholar]

- Gulzar, M.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Zulkifli, N.W.M.; Mufit, R.A.; Zahid, R.; Yunus, R. Dispersion Stability and Tribological Characteristics of TiO2/SiO2 Nanocomposite-Enriched Biobased Lubricant. Tribol. Trans. 2017, 60, 670–680. [Google Scholar] [CrossRef]

- Jogesh, K.S. Machine Learning Framework for Predicting Friction and Wear Behavior of Nano-Lubricants in High-Temperature. IRE J. 2023, 7, 591–599. [Google Scholar]

- Dehkordi, K.G.; Karimipour, A.; Afrand, M.; Toghraie, D.; Isfahani, A.H.M. Molecular dynamics simulation concerning nanofluid boiling phenomenon affected by the external electric field: Effects of number of nanoparticles through Pt, Fe, and Au microchannels. J. Mol. Liq. 2021, 324, 114775. [Google Scholar] [CrossRef]

- Tóth, Á.D.; Mike-Kaszás, N.; Bartus, G.; Hargitai, H.; Szabó, Á.I. Surface Modification of Silica Nanoparticles with Ethyl Oleate for the Purpose of Stabilizing Nanolubricants Used for Tribological Tests. Ceramics 2023, 6, 980–993. [Google Scholar] [CrossRef]

- Alves, S.M.; Mello, V.S.; Faria, E.A.; Camarago, A.P.P. Nanolubricants developed from tiny CuO nanoparticles. Tribol. Int. 2016, 100, 263–271. [Google Scholar] [CrossRef]

- Laurent, S.S.; Forge, D.; Port, M.; Roch, A.; Robic, C.; Elst, L.V.; Muller, R.N. Magnetic Iron Oxide Nanoparticles: Synthesis, Stabilization, Vectorization, Physicochemical Characterizations, and Biological Applications. Chem. Rev. 2008, 108, 2064–2110. [Google Scholar] [CrossRef]

- Uflyand, I.E.; Zhinzhilo, V.A.; Burlakova, V.E. Metal-containing nanomaterials as lubricant additives: State-of-the-art and future development. Friction 2019, 7, 93–116. [Google Scholar] [CrossRef]

- ISO 19291:2016(E); Lubricants—Determination of Tribological Quantities for Oils and Greases—Tribological Test in the Translator Oscillation Apparatus. International Organization for Standardization: Geneva, Switzerland, 2016.

- Tóth, Á.D.; Szabó, Á.I.; Kuti, R.; Rohde-Brandenburger, J. Tribological Investigation of Applicability of Nano-Sized Cupric Oxide (CuO) Ceramic Material in Automotive Vehicles. FME Trans. 2020, 49, 335–343. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).