Abstract

Background: Jute, recognized as the ‘golden fiber’ of Bangladesh, produces a substantial amount of stick left over (waste), a byproduct of the fiber. Usually, unused jute sticks (JS) are thrown away or burned, since they are treated as landfill or unusable waste. Noteworthy research gaps exist in the farming process, infrastructure, [supply chains], unfavorable policies, government interference, and insufficient farmers’ knowledge of the export market. This research examines the potential of jute stick charcoal (JSC) as a sustainable and value-added product within the circular economy framework. Methods: This study employs a system dynamics (SD) modeling approach to examine how various factors, including agricultural output, supply chain process efficiency, trade flows, and relevant variables, influence JSC supply chain performance. Considering technologies, logistics, and policy variables, this study constructed a simulation model with three scenarios: current, worst-case, and improved, using Vensim DSS to identify system behavior under changing conditions. Results: The simulation indicates that optimizing idle jute resources, enhancing supply chain processes, and expanding markets can increase economic returns, reduce waste, and create more rural jobs, particularly for women. Conclusions: Enhanced coordination, technologies, and logistics can reduce carbon emissions, benefit farmers, support rural industries, and contribute to SDGs 8, 12, and 13.

Keywords:

jute; supply chain; jute stick; charcoal; circular economy; production; system dynamics; agro-waste; simulation; modeling; sustainability; Bangladesh 1. Introduction

Jute sticks are produced after extracting jute fiber from a jute tree, also known as Patkhari in the local language, a lightweight byproduct of jute fiber extraction and processing []. Jute stick charcoal is derived from jute sticks, a lightweight black carbon residue created by intensely heating wood in the absence of oxygen [], and is considered a low-cost source of charcoal and activated carbon. Its purity and lightweight properties surpass those of other sources. In Bangladesh, the yearly output of jute sticks is approximately 3.0 million tons [], and they are mostly unused or used for non-economic purposes, such as fuelwood or fencing in rural areas. Traditionally, jute sticks, which are left over after extracting the valuable bast fiber from jute, have been used as fuel for earthen stoves or to build fences in betel leaf plantations. The ash produced by burning jute sticks has practical applications, such as cleaning kitchen utensils []. Despite the availability of alternative charcoal and activated carbon sources, the jute stick remains the most cost-effective option for producing charcoal. Furthermore, charcoal made from jute sticks is purer and lighter than charcoal made from other materials. This is consistent with the increasing demand for jute stick-derived carbon in the international market. In addition, open burning and under-utilization of agro-residues generate avoidable emissions and forego rural value addition in many emerging economies. Converting jute sticks into charcoal can displace unsustainably harvested fuelwood, lower particulate and GHG emissions, and create rural incomes. JSC also offers environmental benefits and significant economic potential for various applications. Jute stick charcoal, derived from jute sticks, effectively removes toxic substances from water, thereby significantly reducing ecological pollution []. It is used in water purification, food processing, avalanche control, municipal water treatment, industrial pollution control, radio wave capture, odor removal, metal purification, and sewage treatment [,].

The market for Jute Stick Carbon and its derivative products is growing gradually due to increasing environmental awareness, the need for pollution control, the recycling of carbon-based products, and the demand for a sustainable, eco-friendly carbon source. Bangladesh began exporting JSC in 2012 [] and has realized substantial economic opportunities, earning between $3.00 and $3.50 billion in foreign currency annually []. Yet, there is a dearth of information to determine the full potential of this product, and no notable studies have been conducted on JSC’s supply chain process, despite its significant potential to contribute to achieving a sustainable economy in Bangladesh. The existing literature has extensively explored the value chains of raw jute, jute fiber, and diversified jute products [,,,], with a focus on production efficiency, stakeholder engagement, and export performance. However, JSC, as a byproduct that has gradually been recognized for its economic and environmental value, remains mainly ignored in academic research. There is little evidence of studies examining the logistics, actor interactions, or market constraints that shape the supply chain of JSC. This study addresses that gap by offering a structured analysis of the JSC supply chain in Bangladesh, from production to export. Drawing on field-based insights and stakeholder input, it identifies key operational bottlenecks and traces the movement of materials, information, and value. The research contributes original knowledge to an underrepresented area, with practical implications for policymakers, supply chain actors, and industries aiming to develop bio-based exports more sustainably and effectively.

Due to the lack of intensive research on the supply chain process of this product, the JSC industry has received very little attention. There are bottlenecks in the JSC supply chain, for example, a syndicate formed by a few businessmen prohibiting exports by all manufacturers []. Additionally, farmers are among the most negligible stakeholders in the jute supply chain and its diverse products. Due to their limited access to support services, tertiary farmers, often the least privileged participants in the value chain, are less able to participate in higher-value segments. Additionally, they employ minimal input and get limited output from the production technique [].

This research aimed to empower farmers and rural women by promoting cleaner production through the utilization of unused jute sticks, thereby unlocking a new source of income from agricultural residue. It aimed to integrate system dynamics with circular economy and sustainable supply chain theory to quantify environmental and socio-economic outcomes of an agro-waste valorization chain and improve the existing JSC (Jute Stick Charcoal) supply chain. This paper also examines the sustainability theory (Triple Bottom Line) to assess the economic, social, and environmental benefits that support the goals of achieving additional profitability and efficiency in resource management. To mitigate the above problems, this study aims to:

- Empower rural farmers and women by integrating them into the JSC value chain for equitable income opportunities.

- Enhance supply chain efficiency through strategic logistics and technological interventions.

- Evaluate the export potential of JSC and its derivatives for market diversification.

- Simulate supply chain dynamics under three policy scenarios using system dynamics modeling.

The following structure of this paper is as follows: Section 2 outlines the theoretical frameworks. Section 3 reviews relevant literature. Section 4 develops the conceptual model. Section 5 details the methodology. Section 6 presents the modeling design. Section 7 and Section 8 discuss the simulation results and findings, respectively. Section 9 draws implications, and Section 10 concludes with limitations and future research directions.

2. Theoretical Framework of Jute Stick Charcoal

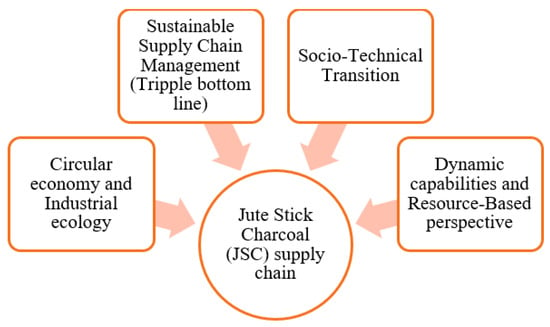

This study draws on various theoretical frameworks to examine the potential of Jute Stick Charcoal (JSC) as an innovation within agro-waste valorization supply chains. These perspectives include industrial ecology, sustainability-based supply chain management, socio-technical transition theory, and the resource-based view of the firm. Together, these frameworks help analyze the JSC supply chain from macro-structural, operational, institutional, and firm-level perspectives. Each is introduced below.

2.1. Industrial Ecology and the Circular Economy

Closing material loops and reducing waste through the 3R principles (reduce, reuse, recycle) related to sustainable developments []. An agricultural byproduct that is typically regarded as waste is put back into industrial production systems in JSC, a classic example of waste-to-resource transformation. Such practice reflects value-retention strategies central to circular value chains [] and reduces dependency on natural resources by utilizing waste from another industry to manufacture charcoal. This would be an example of industrial cooperation from an industrial ecology perspective, where waste materials are used to promote resource efficiency [].

2.2. Sustainability and Supply Chain Management (SSCM)

This study adopts a broader perspective on supply chain management, incorporating the triple bottom line theory of sustainability, encompassing economic, environmental, and social outcomes [,,]. Such a theory can be applied to the jute stick charcoal supply chain processes to help unveil several key benefits for achieving sustainability and profitability. On the ecological side, replacing fuelwood with jute sticks can reduce carbon emissions, as jute is a renewable biomass; however, its full potential has yet to be explored. Socially, the further development of jute sticks might create more rural jobs and empower village women to add greater value to the local and national economy. Lastly, from an economic perspective, JSC opens the doors for new markets, considering cleaner, carbon-based byproducts options for generating more resources. When these elements are combined, JSC appears to offer a promising route to achieving more sustainable and effective supply chain processes, particularly in resource-constrained settings such as Bangladesh and its rural areas.

To further support this theoretical orientation, the study adopts the triple bottom line (TBL) framework as its sustainability lens, aligning its research design and data interpretation accordingly. The framework guides the evaluation of the JSC supply chain not only by identifying operational inefficiencies and export constraints, but also by examining how social inclusion and environmental performance contribute to its broader impact. This alignment ensures that the study’s empirical inquiry remains grounded in the TBL theory throughout its analysis of actors, flows, and outcomes in the supply chain. The research objectives including mapping the supply chain, identifying bottlenecks, and proposing value-enhancing interventions are structured around the three sustainability pillars.

2.3. Socio-Techno Transitions

This research drew on socio-technical transition theory to examine how modest innovations, such as JSC production in rural locations, can stimulate SMEs and larger businesses to adopt renewable energy sources []. Rather than just a technical solution, jute stick charcoal is seen as part of broader social and institutional shifts toward local, resilient production models []. Following grassroots efforts on JSC’s growth, adaptation, expansion, and gains in strategy, policy, or market support, assessing the long-term impact on the surrounding society is crucial. In this way, JSC may transition from a rural practice to a national and global sustainability strategy for connecting more renewable energy sources.

2.4. Dynamic Competences and a Resource-Based Perspective

The dynamic capabilities and resource-based view emphasize the internal process strengths required to build and grow JSC supply chains in rapidly evolving conditions [,]. Jute-related entrepreneurs must develop relevant skills in supply chain process development, resource mobilization, stakeholder collaboration, adaptation of cutting-edge technologies, and navigation of policy. These theories illustrate how JSC supply chain processes evolve through the accumulation of organizational efforts, rather than simply adopting revised technical systems. Such practices help explain how rural firms develop and adopt relevant capacities, applying the circular economy concept to their jute and jute-related byproducts. Among the theoretical foundations, the Triple Bottom Line (TBL) theory serves as the primary analytical lens for the study, as it aligns directly with evaluating economic viability, social attachment, and environmental consequences within the JSC supply chain. The TBL framework enlightens the study’s data interpretation and guides the identification of sustainability-aligned interventions. In addition, the Resource-Based View (RBV) complements this perspective by highlighting the strategic value of underutilized resources such as JSC, especially in the context of export competitiveness and rural industrial development. While socio-technical transition theory also contributes conceptually, particularly to understanding rural innovation and institutional transformation, this research emphasizes system performance and logistics more than long-term regime shifts. Such theoretical alignments enable the study to integrate sustainability, capability growth, and value chain analysis within a unified framework. The integration of these standpoints supports the conceptual model, which visually maps the links between theoretical philosophies, empirical emphasis, and sustainability goals.

2.5. Conceptual Framework

The conceptual framework demonstrates the link between theories and the JSC supply chain perspective. Figure 1 presents four key theories relevant to this JSC context for further development.

Figure 1.

Theoretical framework of JSC supply chain.

This paper presents a revised framework that combines theoretical standpoints to explore the sustainable utilization of jute sticks. Impressions from circular economy and industrial ecology demonstrate how agricultural wastes, often considered unusable, can be intelligently reused through industrial processes to maintain closed loops and shared resource use for subsequent industries []. The framework connects social goals, economic benefits, and ecological impact through a sustainable supply chain process. It also highlights the potential for rural women’s involvement through employment and reduced emissions resulting from the replacement of fuelwood. In this case, socio-technical transition theory explains how slight local innovations, such as rural JSC production, can increase and influence broader energy and industrial systems []. Lastly, the resource-based and dynamic capabilities focus on the internal strengths required for managing circular systems, such as safeguarding additional resources, implementing new methods and technologies, and navigating policy challenges []. Altogether, the above knowledge provides a strong foundation for apprehending the possible and limits of building an inclusive and resilient JSC supply chain from a developing country perspective.

3. Literature Review

This section reviews existing knowledge regarding Jute-related literature based on the scope of the research.

3.1. Overview of the Global Jute Production

Jute was considered the main cash crop for Bangladesh during the 1960s. Jute has been grown in Bengal since ancient times. It was first utilized extensively in India in the sixteenth century to make garments, mats, ropes, and sacks []. Jute bags and sacks were also key exports to nearby Asian countries. It had become an essential component of the Indian economy by the end of that century. Later, jute became the main export from Bangladesh, generating significant foreign exchange profits from raw fiber, products, and crafts in the 1970s. Due to these significances, jute is traditionally known as the golden fiber in Bangladesh []. Although the once-thriving jute sector lost its dominance, it is now merely an imprint of its former glory due to years of mismanagement and the expansion of the ready-made clothes industry []. However, charcoal made from jute sticks has demonstrated promise in recent years for reviving the former glory of jute, alongside other traditional jute products. Jute stick, the residue of jute plants left after fiber extraction, is roughly 2.5 times the volume of the extracted fiber [].

The jute sector has a significant impact on Bangladesh’s economy and is recognized as a crucial factor from both agricultural and commercial perspectives, which were the historical grounds for jute production in Bangladesh []. Besides Bangladesh, several other major jute-growing countries include India, Myanmar, Nepal, China, Thailand, Indonesia, Malaysia, Taiwan, Brazil, Vietnam, and the Ivory Coast []. However, Bangladesh is still the second-largest jute-producing country. Bangladesh and India jointly contribute around 85% of the world’s jute production and cultivated land []. They also mentioned that Bangladesh cultivated approximately 39% of the world’s jute area, with an average yield of 1.53 tons per hectare from 1961 to 2002 []. Although the industry has experienced turmoil over time, with falling trends in jute area, production, and productivity observed in both Bangladesh and India from 1961 to 2002, it remains a significant business, processing over 2.5 million tons of jute fiber annually []. Most of its use is in producing items such as ropes, curtains, carpets, sacks, etc. [,]. Another study revealed that, after cotton, jute fiber is the second-largest natural fiber consumed globally.

3.2. Jute and JSC Production in Bangladesh []

Despite being cultivated in almost every district of Bangladesh, jute agriculture is particularly advanced in the districts of Faridpur, Tangail, Jessore, Dhaka, Sirajganj, Bogra, and Jamalpur []. The research highlights the jute-producing region in Bangladesh. It is noted that jute has played a crucial role in Bengali culture and the economy for generations, particularly in West Bengal and southwestern Bangladesh []. Bangladesh produces the highest quality jute in the world, which is referred to as the “golden fiber” (sonali ansh). From the initial export by the East India Company in 1793 to the 19th century, the jute trade had its roots in British colonial control [,]. By the 20th century, Scotland’s Dundee industry was trading raw jute. Processing mills emerged to recognize the increasing value of jute goods (such as sacks and carpet backing); the first one was established in 1855, near the Hooghly River in Kolkata [,]. Due to an imbalance caused by the 1947 partition, Bangladesh had to develop its jute processing sector because it inherited premium raw jute stockpiles while processing mills remained in West Bengal, India [,]. Again, jute mills in Jamalpur, Narayanganj, Rajshahi, Pabna, Rajbari, Faridpur, and Khulna currently make jute stick charcoal [].

3.3. Growing Demand for JSC

Jute and Jute products are increasingly gaining popularity and demand due to their environmentally beneficial qualities. A study examines the structure and growth of the jute industry, both before and after Bangladesh gained its independence []. The overall state, significant developments, historical strategies, and possibilities of jute are also examined in this article. The study evaluated the perspectives of scholars, interviewed a select group of significant informants, and conducted a content analysis of historical data. Additionally, a broad range of sources was examined, including government performance reports, records, and the conclusions of individual researchers’ studies. According to this research report, jute-based SMEs and a broad range of diverse jute products could resurrect Bangladesh’s golden fiber sector. The market for a range of jute products in Bangladesh remains an unorganized, specialized, and informal sector []. To take advantage of export incentives, jute mills frequently prioritize exporting semi-processed jute above marketing locally produced, diverse jute goods. As a result, local, diverse jute goods struggle to command competitive prices, hindering their global market standing.

3.4. Seasonal Effect on Jute Production

Jute cultivation is dependent on seasonality, which impacts JSC production as various seasonal effects on Jute production []. The findings showed that pre-monsoon showers occurred in Bangladesh in March and April, providing ideal conditions for seeding and land preparation []. After that, May and June saw moderate to sporadic rain and showers, which kept the soil sufficiently moist for jute plant growth [,]. The crucial light period appears to be close to 12.50 h for both species of jute, which are photoperiodism-short day plants. Jute is a crop that grows in a variety of temperatures. It can tolerate temperatures ranging from 15 °C to 38 °C, possibly reaching 46 °C []. During the jute growing season, rising temperatures and rainfall were seen as a result of global warming.

3.5. Different Costs Associated with Jute Production

Different types of costs are involved in jute and diversified jute product production []. According to the field interviews with farmers, labor expenses account for roughly 84% of the total production cost. Depending on quality and availability, the cost of hiring power tillers accounts for 4.98% of the total cost, while the cost of seed accounts for 3.92%. Triple Super Phosphate (TSP) costs 1.81%, urea costs 2.59%, and muriate of potash (MOP) costs 1.09%. Pesticide expenses, on the other hand, are not precisely measured and are relatively modest [].

3.6. Traditional Use of Jute Stick

Despite their potential value, many jute sticks are discarded or misused, resulting in their classification as agricultural waste []. Once traded as jute sticks, the local communities use these as a solid biomass fuel after extracting the fiber from the jute plant. However, with the increased popularity of gas and electric stoves, local demand for jute sticks declined, leaving a substantial portion unexploited, which created ecological hazards []. Many rural areas still dispose of jute sticks in landfills or throw or burn them in nearby environments due to a lack of available abandoned land, a traditional practice that creates an environmental burden by releasing harmful gases and particulate substances into the air []. Such exposed burning of JS harms local air quality, endangers health, reduces soil fertility, and wastes economic prospects for further value creation. In contrast, jute sticks have long held practical value across various sectors []. Their fibrous texture makes them a valuable raw material in handicrafts and small-scale industries, particularly for weaving items like mats and baskets. They also serve as a low-cost, renewable source of cooking fuel in rural households. Agriculturally, jute sticks can be used as organic mulch to enhance soil quality, retain moisture, and suppress weeds. These different uses demonstrate that materials often regarded as waste can become valuable when utilized in circular production systems.

3.7. Production Process of JSC

Jute sticks and fiber are good raw materials or inputs for making carbon. The production process of JSC from jute sticks []. This research explained the physical and chemical activation methods for producing charcoal from Jute sticks. Long, thin jute sticks are being dried under the open sky by the roadside or at a village yard during this process. Then these dry sticks are burnt in the furnaces for 10 to 12 h. The lids of the furnaces are then closed so that no oxygen can enter them. This source is cost-effective, available, environmentally friendly, and renewable. In factories, Jute Sticks are burnt in large-scale furnaces to produce Jute Stick Carbon, also known as Jute Stick Ashes. Burning dried jute sticks produces a specific type of ash at a designated temperature in specially designed furnaces. Later, they are crushed into jute stick powder. The powder is called “jute stick carbon,” which contains carbon. The jute ashes are kept in this manner for four days, after which workers collect and pack them []. JSC and activated carbon (AC) produced from JSC are low-cost products [,]. They also revealed that the production process of Jute Stick Charcoal is not complex, does not require high-end technology, and is still environmentally friendly. Furthermore, the production process and packaging require only a small number of laborers.

3.8. Use of Jute Stick Charcoal for Different Purposes

Activated carbon produced from charcoal after chemical activation is also utilized in multiple industries as a raw material [,]. Some industries purchase charcoal dust in a semi-finished condition and further process it according to their requirements []. According to their research, the versatile uses of charcoal and activated carbon are increasing daily, replacing other harmful agents used to control pollution. Their work also explained that Jute Stick Charcoal and Activated Carbon produced from jute sticks are excellent agents for removing different toxic chemicals from water and reducing environmental pollution. Besides water purification, charcoal derived from Jute Sticks contributes to food and beverage processing, controlling snow avalanches, purifying municipal drinking water, controlling industrial pollution, capturing radio waves, odor removal, purifying metals, and sewage treatment. The potential of JSC in energy storage, water treatment, and sensor applications in their work []. Various industries depend on mineral-based coal, and we are now considering using Jute Stick Charcoal. JSC-based supercapacitor provides almost five times higher specific capacitance than AC-based supercapacitors []. Their finding revealed a promising future for JSC as a potential candidate for energy storage, which helps effectively utilize renewable energy sources, such as solar and wind power. Research has shown that activated carbon produced from Jute sticks can be a promising agent for removing organic matter from pharmaceutical wastes [].

Jute stick charcoal can be converted into activated carbon, which has shown effectiveness in removing toxic organic compounds from water systems, including industrial effluents such as those from pharmaceutical production. This highlights its potential not only as a sustainable energy source but also as an eco-friendly material for environmental remediation applications. Using AC, it is possible to remove toxic organic substances from water. In another study, it is possible to remove hexavalent chromium [Cr(VI)], a harmful chemical to the eyes, from water using JSC []. Additionally, jute stick-derived activated carbon is a suitable adsorbent for removing harmful textile dyes from water, including acid red, reactive orange, and methylene blue []. AC can be processed from Jute Stick, which is an excellent adsorbent due to its high surface area, porous structure, and many functional groups []. They mentioned that it has potential for industrial use. A study supported by the Bangladesh Enterprise Institute highlighted that Jute Stick Ash is extensively used in the production of water filters, gas masks, toothpaste, anti-toxin drugs, carbon paper, face wash, dry-cell batteries, and dried ink for photocopier machines, among other applications []. Mineral charcoal companies now use this low-cost and eco-friendly substance for water purification.

3.9. Stakeholders of the Jute Products Supply Chain

The supply chain encompasses numerous performers who contribute at various phases, from jute cultivation to final utilization, through successful processing, and diversified jute products are distributed in Bangladesh []. The same research also reveals that the Bangladesh Jute Mills Corporation (BJMC) is a key public organization that serves as the primary point of distribution for jute. Relevant industries collect raw jute from local producers and use supply chain networks to transport it to various processing industries based on its component resources. For instance, jute leaves can be used to make organic tea and other herbal products, while jute sticks contain a high amount of cellulose and lignocellulosic pulp. These components are useful for producing biodegradable packaging and biocomposites due to their fibrous and sustainable properties [,,,]. After extracting useful elements, the unused dry sticks can be reused as inexpensive and eco-friendly raw materials in the automotive and charcoal industries.

Expanding the supply chain structure, where the jute fiber value chain, categorizing key actors such as farmers, small traders (Faria), large traders, jute mills, and the emerging role of Farmer-Producer Organizations (FPOs) []. The study conducted through in-depth interviews reveals that jute typically moves through traditional supply chain channels. For instance, jute growers trade with local brokers, medium-sized to large intermediaries, and ultimate factories for further processing. Nevertheless, this channel incurs substantial transportation costs for small-scale jute producers due to the remote locations. In this situation, farmers cooperatives, such as FPO-led direct sales to factories and processing centers, can increase efficiency, transparency, and consistent revenue distribution. In Assam, the northern part of India, farmers face problems similar to those of their counterparts in Bangladesh []. Farmers in these locations regularly underpay, depend on mediators, and incur excessive costs for transportation and farming equipment, underscoring the need for optimal and healthy farming and business infrastructure and policies. Moreover, new technologies are difficult to adopt due to high costs and a lack of financial resources and technological expertise. Reducing all these barriers is the key to conducting research for a fair and sustainable jute economy.

3.10. Value Chain of JSC

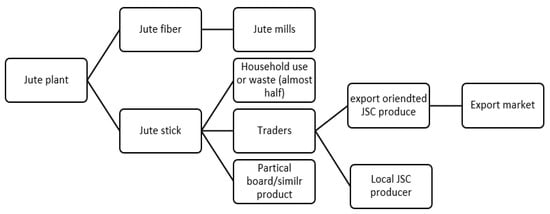

During this research, we conducted interviews with key stakeholders and supply chain participants to gain an understanding of the flow of materials and information within the supply chain. As structured data is unavailable and no prior study has been conducted on this product’s supply chain, stakeholders provided valuable insights. Based on their input, we developed a model (Figure 2) that shows the current JSC supply chain. Farmers extract fibers from jute plants during processing and leave the sticks for household use. A small portion of the jute sticks is sent to traditional factories that produce particleboard or paper, while another portion is sent to local traders. These traders then supply the sticks to producers. There are two types of producers: export-oriented factories that produce and directly export JSC, and other factories that make and sell it to export-oriented factories.

Figure 2.

Traditional supply chain of jute stick charcoal.

There are several value chain steps in the supply process. However, value-added activities are minimal. The local traders sell jute sticks to traders at around $30/MT []. These local traders then sell the sticks to manufacturers at around $40–50 per metric ton []. Manufacturers collect Jute sticks from farmers or traders. It requires 20 metric tons of Jute sticks to produce 3 or 4 metric tons of charcoal. The manufacturer packs this product and exports it to its foreign buyer at $800–1000 []. After import, if the buyer is a manufacturer, they further process it according to their requirements for use as a raw material for the end product. If the importer is a trader, they sell the JSC to the manufacturer. Sometimes, an intermediary processing plant purchases the JSC from the trader, further processes it, and then sells it to the manufacturer.

3.11. Value Chain of Diversified Jute Products

The value chains of diversified jute products encompass various entities, including governmental bodies responsible for policymaking (such as ministries, departments, research institutes, and special projects), exporters, government-owned jute mills, retailers, wholesalers, local traders, purchase centers, intermediaries, and jute growers [,]. In this work, they explored the value-added activities in the value chain from farmers to exporters. Each stakeholder has a significant influence on Bangladesh’s jute production and export activities. The industry demonstrates horizontal differentiation, with the trade-in fiber emerging as a crucial factor for both cost competitiveness and the production of high-quality goods. Additionally, there are other notable value chains within the industry, including fabric production or milling, yarn or fabric transformation, and the production and sale of Jute Diversified Products, catering to both domestic and export markets. Research has also examined the downstream and upstream supply chains of jute products []. It develops a conceptual supply chain model for jute products, focusing mainly on jute fiber, with producers, suppliers, intermediaries, and mills identified as the four major domains. This work highlights the manufacturing and export markets for jute products and discusses the primary supply chain processes for the production and service industries. In his study, the researcher also emphasizes that worldwide awareness of eco-friendly products makes jute and diversified jute products an excellent choice. The study suggests that the Bangladesh jute industry has a significant opportunity in the export market, but it must undergo numerous supply chain activities to execute the export process properly. Additionally, this study highlights the value-added activities of different players at various stages of the supply chain, focusing on storage, underdeveloped areas, and prominent players in this supply chain.

Table 1 highlights several unaddressed gaps in prior literature; the following table consolidates the field-based findings to address those gaps. It summarizes stakeholder perceptions, operational procedures, and policy reflections pertinent to developing an integrated JSC supply model.

Table 1.

Comparative Summary of Existing Literature on Jute-Based Products and the Present Study.

Table 1 provides a consolidated view of earlier research and its scope in relation to the present study. From this comparison, it becomes apparent that several critical areas remain insufficiently addressed. The literature review above has covered many areas, but still leaves research gaps in the jute stick charcoal value chain regarding diverse byproducts. Most research studies focus on the scientific aspects of jute fiber and general production, but overlook the dynamics of the supply chain. Additionally, jute can be cultivated in certain climates, such as those found in India, Bangladesh, and the broader subcontinent, where modern technologies have not yet been widely adopted. Additionally, proper supply chain networks and the application of SD methods are often lacking. Thus, this study aims to fill some gaps by providing useful analyses through SD simulation modeling for the future growth of the jute industry.

4. Proposed Supply Chain and Simulation Model

This section discusses the proposed supply chain model, which aims to identify improvements in how JSC is collected, transported, processed, and exported. It will also highlight farmers’ further profitability, reduce costs, establish co-ops, and adopt new technology to overcome current problems.

4.1. Proposed Supply Chain Model

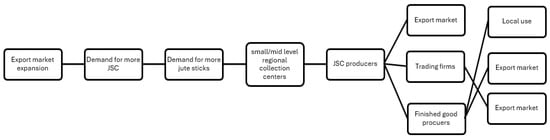

If half of the total 3.2 to 3.5 Metric tons (MT) of jute sticks used to produce JSC, the amount could be 0.45 million MT, and the potential to earn foreign currency is $40–50 million []. Here, we propose a supply chain model (Figure 3) with more variables. In the proposed model, we suggest introducing a small to mid-level regional collection center where farmers will be directly connected and establishing individual trading firms to boost export activities. Besides direct export through the manufacturers, traders can export JSC. Local traders or farmers can sell their jute sticks in the regional center. This concept will give the farmers more power to negotiate with the traders or the owners of collection centers. This collection center intends to connect farmers directly to the process and collect unused jute sticks. If farmers benefit from selling their unused jute sticks, they will be motivated to grow more jute. Establishing this type of collection center requires access to credit lines and the formation of farmer unions. A few regional farmers can establish this collection center and send it directly to the producers. We encourage the formation of farmers’ unions, which may help them benefit from direct government subsidies, training, technological advancements, increased production versatility, and value-added activities. Empowering farmers through this collection center is crucial for making them stakeholders in the JSC supply chain and achieving sustainable economic development.

Figure 3.

Proposed supply chain model for JSC.

4.2. Difference Between the Current Model and the Proposed Model

This proposed model incorporates the idea of forming regional/zonal collection centers to empower farmers. The concept is to collect jute sticks from farmers who mostly use or underutilize their land at these regional centers and then send them to factories. In the proposed model, we suggest analyzing export market demand and formulating policies to expand the market. This amplified demand will help the industry and traders collect unused jute sticks from the remote farmers. The model also suggests reducing the number of intermediaries or traders who supply jute sticks from farmers to manufacturers. If farmers themselves form regional collection centers, they can send the sticks directly to producers, reducing costs and securing better prices for jute sticks. In the current scenario, manufacturers produce JSC and export it in semi-finished condition to international markets. Our new model proposes establishing local factories to process semi-finished JSC into finished charcoal that industries can use as direct raw materials. This approach will help earn more foreign currency and develop JSC-based industries. Our model shows that JSC can continue to be exported in its current form, sold through commercial traders, or further processed into finished JSC products.

4.3. Features of the Proposed Model

One of the major bottlenecks of the existing Jute Stick Charcoal supply chain is the absence of communication technology throughout the supply chain. Our suggested concept utilizes technology to communicate with backward linkage, planning output in response to local and global demand through forward linkage. Communication expertise can significantly enhance the supply chain information for JSC, as it acquires concurrent information from various stakeholders. Real-time coordination between farmers, collection centers, and factories would be made possible through mobile-based technologies (such as SMS alerts and applications), ensuring on-time delivery and reducing the need for intermediaries. Producers could dynamically modify harvests and prices by sharing market demand data (forward linkage) via cloud-based dashboards. In the meantime, industries could immediately convey orders and quality standards to farmers through two-way messaging systems, also known as backward linkage. Chatbots or automated voice calls might even help illiterate farmers. These technologies would increase efficiency without requiring significant infrastructure investments by reducing delays, preventing overproduction, and ensuring more equitable prices through simplified information flow.

The proposed model above allows trading companies to export JSC. The trading company is more knowledgeable about export, global market demand, diversification of export procedures, and an established supply chain. Those already involved in jute fiber or other jute goods export can use this model to gain backward vertical integration and add JSC to their portfolio. This requires an easy export process, regulatory support from the government for traders, and an export credit facility. The proposed model incorporates several variables beyond those currently existing in the supply chain. These variables are government support to reduce the export barriers, easy export procedure, entrepreneurial education, exploring new markets, using the business office of the Bangladesh embassy located in the potential market to build trust and find new buyers, technological support, and low barriers to access credit facilities for farmers and traders to boost exports.

4.4. Current Export Position of Jute and Diversified Jute Products

Bangladesh holds a competitive advantage in the global jute market, where relatively low export costs contribute to increased earnings from jute-based products []. Their research article focuses on the export scenario of Jute products in the international market. In their work, they showed that export volume is gradually increasing. JSC is a significant part of these export commodities and the diverse export potential of jute products in Bangladesh []. The study aimed to present an overview of the market prospects for Jute Diversified Products (JDP), including a discussion of the industry’s history and market conditions. Government data shows that jute accounts for approximately 5% of the foreign earnings and 4% of GDP []. The research indicated a steady yet noteworthy advancement in jute-related industries. This is attributed to an increasing number of people opting for eco-friendly products due to growing environmental concerns. The study highlighted an upward trend in the consumption and popularity of JDPs, indicating a sustained growth in their business potential.

Amin reports in a newspaper article that charcoal is needed in over 3000 firms in China []. For production, the smallest factory requires at least 100 tons of carbon (in the form of charcoal) every month. Charcoal costs between $800 and $900 per MT []. Regarding the amount of jute charcoal imported from Bangladesh, China is the largest importer, followed by Taiwan and Brazil []. Numerous nations have varying levels of need for ashes. The demand for charcoal dust powder from our jute-stick industries is also present in various countries, including Korea, Japan, Malaysia, Hong Kong, Turkey, the United Arab Emirates, Germany, the United States, Australia, Canada, and Mexico. The cost can be highly affordable if the quality can be maintained at international standards.

4.5. Export Potential of JSC

There is a significant untapped global market opportunity for Jute Stick-based charcoal and activated carbon, which could potentially replace more expensive alternatives. An annual export potential of $3.0 to $3.5 billion, as the global activated carbon market is valued at $4.4 billion in 2023 and is expected to reach $7.0 billion by 2028 [,]. The forecasted growth rate is 9.5%. In 2022, the worldwide export value of charcoal was $1.64 billion []. According to this report, Bangladesh has been exporting jute stick charcoal to the global market since 2012. The value of the international market for jute stick carbon is around $1000 per metric ton []. The potential for exporting jute stick carbon is estimated to be worth $3.00 to $3.5 billion per year []. According to the 2024 report, there are approximately 40 factories that produce JSC, but only a few export their products; the others are compelled to sell to other exporters due to the syndicate issue []. The total production of JSC is 7071 MT annually across these 40 factories; however, the export volume in the 2019–2020 fiscal year was 4182.27 tonnes []. However, the report investigates the potential to produce around 0.45 million tons JSC from 3.2 to 3.5 million jute sticks worth around $40–50 million. If at least 50% of jute sticks are utilized in various value-added production, they can produce almost 0.25 million MT annually [].

4.6. Limitations and Barriers to Gaining the Complete Potential from JSC

The researchers examined the challenges in the development of jute fiber in Bangladesh []. These include the absence of proper government policies, insufficient jute production, sporadic shutdowns of jute factories, failure to modernize cultivation systems and production plants, inadequate management, the presence of malpractice, declining global demand for jute, and the use of alternative jute sources. The diversified jute industry in Bangladesh is less formal and less structured than the Indian jute industry []. In contrast, Bangladesh ranks second in jute production. However, Bangladesh produces high-quality jute globally, and for many years, it was the largest source of foreign currency earnings. Unfortunately, demand has been declining since the 1980s and 1990s due to the availability of a cheaper plastic alternative. The study indicates that domestic jute use declined due to inefficiencies in government-owned jute mills and the lack of appropriate government policies. However, there is worldwide concern for environmentally friendly products and unstable prices of petroleum products, which are the raw materials for plastics, opening the door for jute and diversified jute products. It suggests that a few versatile jute products, such as reinforced sheets made from jute fiber and geotextile products, show promise for opening up new opportunities.

Additionally, this study identifies several constraints that need to be addressed to achieve better productivity across various forms. These are quality issues that render some jute products unsuitable for the international market; inadequate supply for large quantities; a knowledge gap in product development; a skilled labor shortage; improper training services; unstable orders; and the absence of a forward market. The study identifies an opportunity to offer a formal, structured subcontracting model between large buyers and producers to promote diversified jute products. According to The Business Standard, the jute stick charcoal export sector faces serious challenges due to alleged monopolistic behaviors []. This investigative article explores how the business association, the Bangladesh Charcoal Manufacturers and Exporters Association (BCCMEA), has created a syndicate that restricts market access by limiting shipping to two preferred logistics providers. This has led to a disproportionate increase in container shipping costs $1500 for charcoal compared to $400–500 for other items [], and has restricted export destinations primarily to China. Other issues include factory approvals influenced by bias, attempts to substitute seasoned buyers for preferred partners, and the exclusion of numerous firms from export opportunities. It has been reported that unlicensed factories owned by foreigners operate without regulatory consent and evade taxes by selling through local intermediaries. Some of these intermediaries falsely claim government export incentives. Additionally, producers claim there is discrimination regarding membership fees and that production volumes are frequently exaggerated to obtain extra incentives.

5. Research Methodology

This research aims to develop a simulation-based supply chain model that builds on JSC’s current process and limitations. The simulation models evaluate the dynamics of current variables and several potential variables in the proposed model to optimize the utilization of most jute sticks produced in Bangladesh, as well as the impact of interconnected variables on the proposed model. The primary intention of this simulation is to understand the impact of seasonality, biofertilizer, technology, skilled labor, land size, and government support. This proposed model aims to explore the effects of these variables through a system dynamics simulation model, thereby fulfilling the research objectives. This research employs a system dynamics modeling methodology, executed through Vensim DSS, to simulate the supply chain process for JSC and typical characteristics of agro-industrial ecosystems in Bangladesh [,,]. The system dynamics approach is suitable for understanding complex, non-linear, feedback-driven systems involving multiple stakeholders, policy interactions, and resource flows, typical characteristics of agro-industrial ecosystems, such as the jute sector in Bangladesh.

5.1. Data Collections

This study mainly utilized secondary data to build the simulation model. Subsequently, primary data was employed to validate the secondary data obtained from the JSC processing company. The primary data were used solely to cross-verify information provided by the company and were supplemented by sources such as government portals, academic literature, news articles, and magazines. A total of sixteen participants were selected based on recommendations from the JSC company to authenticate the accuracy of the reported data. Sixteen semi-structured interviews with four farmers, four local traders (faria, i.e., small-scale rural intermediaries), four industry personnel, two supply chain experts in the Khulna and Jessore regions, and two jute stick processors. Both purposive and convenience sampling methods were employed to classify interview participants. Purposive sampling is used to ensure an appropriate representation of the leading supply chain players, including farmers, local dealers, processors, manufacturing employees, and supply chain specialists, based on their active roles in the JSC value chain. Convenience sampling was also applied due to logistical constraints in arranging interviews in rural areas. To facilitate data access, we collaborated with a local private firm that produces and exports jute carbon, operating its business across networks that include farmers, traders, wholesalers, and processors at the JSC industry level. Through their professional network, they arranged contact with relevant stakeholders across different segments of the supply chain. All participants were informed of the research purpose and voluntarily consented to share their insights. The demographic characteristics of the interview participants, including gender, age range, education, experience, income, and location, are summarized in Appendix A (Table A1) to provide contextual background and support the credibility of qualitative insights. All data has been provided by the case firm, which coordinated its supply chain networks.

As the interviews did not involve sensitive personal information, vulnerable populations, or biomedical data, and were conducted with professionals and stakeholders in a public or industry context, no formal ethical clearance was required under institutional or local or national guidelines. This blended sampling approach is considered appropriate for qualitative, exploratory research [,], particularly in informal, rural settings where formal registries are often absent. The objective was to capture rich, context-specific insights rather than to produce statistically generalizable results. Interviews were conducted between March and May 2025 in Bengali, primarily at participants’ workplaces or nearby community spaces to ensure accessibility. Each session lasted between 30 and 60 min. With participant consent, most interviews were audio-recorded; where recording was not possible, detailed field notes were taken. A semi-structured interview guide was used, featuring open-ended questions tailored to each actor group. The guide explored themes such as participants’ role and involvement in JSC activities, ‘production and processing practices’, ‘logistical barriers and distribution’, ‘market access and export readiness’, and ‘views on sustainability and future opportunities’. This structure allowed consistent coverage of key topics while enabling flexibility to pursue emerging insights.

All interviews were transcribed and translated into English for analysis. Observational notes were also collected during field visits to rural markets and charcoal production sites to complement and validate interview data. The study also relies on observations, including site visits to local jute markets and small-scale charcoal production facilities, to capture workflows and constraints in real time. Secondary data was sourced from government trade reports (2018–2023), academic literature, and published export records. Participants were selected using purposive sampling based on their involvement in jute production or trade. All interviews were conducted in accordance with established ethical standards, and informed consent was obtained from all participants.

5.2. Model Development

The study commenced with a comprehensive literature review to identify the process and stakeholders, highlight supply chain bottlenecks, and gather relevant facts. A system dynamics simulation model was developed based on observation and in-depth interviews with the farmers, traders, and experts [,]. The model was created to map interconnected variables, such as jute production and conversion to jute sticks, add value through charcoal production, and align current market flows and policies. The simulation stock-and-flow model utilized key variables through the application of Vensim DSS. Stock variables, such as ‘Jute Production’, ‘Jute Stick’, ‘Raw Jute fiber’, ‘Semi-Finished Charcoal’, ‘Finished Charcoal’, and ‘Activated Carbon’, illustrate the flow of the supply chain from start to end. On the other hand, a flow variable tracks how system dynamics work and changes things over time, from production to process, sales, and ultimately moves the market. Then, some constant and auxiliary variables include factors such as land size, technology use, the amount of activated carbon exported, seasonal effects, and government-favorable and unfavorable variables, which are assigned probability values. Auxiliary variables included government support factors (e.g., subsidy access, export license ease) and constraints (e.g., export taxes, inspection delays), modeled using probability values derived from stakeholder input and policy review.”

5.3. Simulation Scenarios

This study frames three plausible scenarios for jute stick waste in the jute sector. Each scenario simulates a diverse combination of government policies, technological advancements, efficiency, and the availability of skilled labor. The goal is to assess how changes in variables and their values for support and resource use levels might affect sector performance. These scenarios illustrate potential consequences based on whether the remaining challenges are addressed, moderately managed, or left unresolved. Three simulation scenarios were constructed, which are listed in Table 2 below:

Table 2.

Key Features of Improved, Current, and Worst Case Scenarios.

Each scenario was simulated to see the model’s behavior for a 20-year horizon [,]. Key performance indicators (KPIs) encompassed the volume of jute production, jute stick operation, raw jute fiber traded, charcoal production, activated carbon profit, and the amount of unused jute or jute products.

5.4. Model Calibration and Validation

The model was calibrated using information provided by government and industry sources [,,]. Rational consistency and face validity were confirmed by visually assessing how the model reflected real-world behavior and by collecting stakeholder feedback across several rounds. Model behavior was validated through pattern matching and trend alignment with historical production data from farmers, traders, and government sources. Sensitivity testing was then used to examine how variations in key variables [,], such as conversion efficiency and the rate of technology adoption, affected the outcomes.

5.5. Software and Tools

Vensim DSS 6.01b was used for simulation modeling and calibration to identify three scenarios and their results. Vensim DSS is renowned for its robust performance in handling feedback loops, policy testing, and long-term forecasting [,]. This application generates graphical outputs to help understand how the system behaves over time, how variables compare, and how different variables influence different situations. Although Vensim DSS enables strong feedback visualization, the model’s accuracy depends on the reliability of the input data and the simplified assumption of linear policy influence.

6. System Dynamics Model on JSC

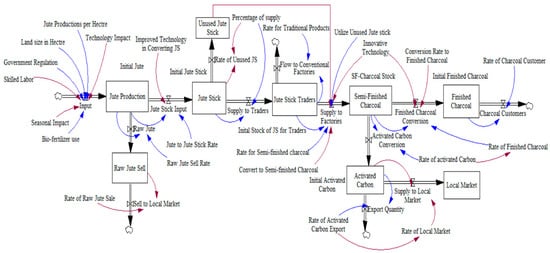

SD modeling is particularly suitable for the JSC context due to its ability to capture complex, multi-stakeholder subsystems characterized by feedback loops, information delays, and nonlinearities. The rural nature of the JSC supply chain also presents limited data; constructing integrated modeling is a more suitable method than agent-specific optimization. SD allows scenario testing under policy shifts, behavioral changes over time, and integrated system effects and efforts, making it a helpful framework for strategic decision-making. Figure 4 illustrates the model, along with the JS conversion process followed by charcoal and activated carbon, portraying the production, trade, and market dynamics within a sustainable resource ecosystem. The model also combined agronomic inputs, technological modernizations, and value-added product developments through several feedback mechanisms.

Figure 4.

System dynamics of the JSC supply chain with existing variables.

6.1. Classification of Variables

The above model includes various types of variables, such as stocks, constants, and auxiliaries. Table 3 classifies them based on system dynamics resolutions:

Table 3.

Variable Classification.

6.2. Supply Chain Process Flow Overview

The jute supply chain plays a crucial role in determining the optimal production of jute stick charcoal. The following summarizes each process stage from jute cultivation to the final phases of substantial conversion.

- Stage 1: Jute Production: The system begins with inputs, which include land, high-quality seeds, a suitable environment, irrigation, labor, government subsidies, and technological support. These inputs influence Jute Production, the primary stock for further conversion or market supply.

- Stage 2: Raw Jute Fiber vs. JS Conversion: The produced jute is separated into two fragments: one part is traded directly (raw jute fiber), and the other portion is processed into jute sticks. Fiber production from the jute plant is approximately 5–7% [], corresponding to a conversion ratio of 15:1 to 20:1, depending on variety-specific factors such as weather, season, labor, demand, and technology. After jute fiber removal, around 12.5% of the jute sticks are produced from the jute plant []. However, it hinges on technological and seasonal effects.

- Stage 3: Jute Stick Operation: When it comes to jute sticks, the stocks are either stockpiled, traded to brokers, or left unused due to uncertainty. The unused jute stick serves as a critical gauge of incompetence, which is one of the main objectives of this research: to identify better opportunities for improved conversion. One of the best ways to expand the jute stick processing network through the intermediaries channel for greater efficiency.

- Stage 4: Manufacturing Jute Stick Charcoal and Activated Carbon: The next level process involves identifying suitable factories that possess conversion technologies to process jute sticks into semi-finished charcoal, which is then further converted into Finished charcoal or activated carbon, depending on the technology and market needs.

- Stage 5: Distribution to the relevant Market: The final products for each level are supplied to the local market and exported using proper intermediaries. They are either sold in the Local Market or exported. Market demand then regulates the following production decisions and capacity upgrades.

6.3. Identified Feedback Loops

The simulation model comprises numerous feedback loops where causality forms a closed circle, beginning and ending at the same variable. These loops define dynamic system behavior:

- Reinforcing Loop 1: Technology-Reinforced Production Loop (R1)

- Path: Technology Impact → Improved conversion → Higher Jute Stick Use → Increased Factory Supply → Higher Charcoal Output → More Revenue → Reinforcement of Technology Investment → Technology Impact

- Incorporating cutting-edge technology increases the efficacy [] of jute stick-related carbon conversion, yields a relatively higher output, and generates additional revenue, confirming the need for further investment in modern technology and effecting a reinforcing cycle that promotes progress.

- Balancing Loop 2: Charcoal Market Saturation Loop (B1)

- Path: Finished Charcoal → Supply to Local Market → Rate of Customer Purchase → Inventory Level → Reduced Need for Conversion → Less Finished Charcoal

- The improved-quality charcoal becomes more accessible in local and international markets, but consumer demand is gradually declining due to a lack of knowledge [], which can slow down charcoal production and help balance supply and demand, thereby avoiding overproduction.

- Balancing Loop 3: Unused Stick Recovery Loop (B2)

- Path: Unused Jute Stick → Pressure for Innovative Technology → Higher Conversion Rate → Reduced Unused Stick → Lower Unused Stock

- Additionally, unused jute sticks trigger innovation, improving conversion rates and reducing waste. This loop is intended to stabilize inefficiencies.

- Reinforcing Loop 4: Export-Driven Growth Loop (R2)

- Path: Activated Carbon → Export Quantity → Market Revenue → Investment in production Capacity/efficiency → More Activated Carbon

- The increased export of AC generates additional foreign revenue [], stimulates capacity development, improves export potential, and inspires growth.

- Reinforcing Loop 5: Demand-Stimulated Production Loop (R3)

- Path: Charcoal Customer Demand → Rate of Charcoal Conversion → Finished Charcoal Stock → Market Supply → Meeting Demand → Sustained Customer Demand

- The increased export of activated carbon can generate additional revenue, which will likely encourage industry capacity growth, enhance export market potential, and contribute to maintaining a positive cycle of continuous improvements and expansions.

6.4. System Insights and Policy Relevance

The model discovers important system and policy insights, which are below:

- Cutting-edge technological advances are the principal driving force behind growing production and efficiency.

- The overstocking of idle jute sticks indicates waste and presents an opportunity for circular economy resolutions in the surrounding society.

- Byproducts like activated carbon are one of the main drivers to consider the export market worldwide.

- To prevent surplus or stockpiling for the charcoal sub-sector, having a balanced market supply for both main products and associated waste materials and byproducts is critical.

This SD model effectively demonstrated the interrelationships among agricultural production, waste collection and utilization, technical know-how, and market-driving forces. Academicians and policymakers can help farmers to increase jute yield, reduce waste, improve waste conversion, and balance market supply and demand by studying feedback loops. The system enables farmers and decision-makers to make better choices through rigorous planning for jute-based industries, as well as the use and export of byproducts.

7. Results and Discussion

In Bangladesh, jute has long been recognized for its golden fiber, and jute leaves are a valuable biological raw material for various industries []. However, the potential of its valuable byproducts, such as jute sticks and activated carbon, remains largely untapped. With increasing global demand for eco-friendly fuels and carbon-based products, there is a substantial opportunity to transform jute sticks into value-added outputs such as charcoal and activated carbon. This necessitates an integrated, data-driven approach to optimize the entire supply chain, from the farm field to export. This paper aims to simulate the behavior of the jute supply chain under fluctuating circumstances, providing insights into the impacts of policy, stakeholder coordination, and long-term sustainability. The following section presents the outcomes of these simulations, compares scenarios, and draws implications for both national development and international trade.

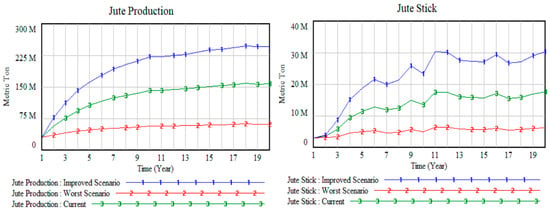

7.1. Jute Production and Jute Stick

Figure 5 demonstrates the production trends over 20 years under three discrete scenarios: Improved, Current, and Worst. These forecasts are modeled to consider crucial factors such as the implementation of cutting-edge technology, the use of organic or biofertilizers, government policy support, skilled labor availability, seasonal effects, and supply chain efficiency. In the ‘Jute Production’ grid, the improved scenario (blue line 1) determines a sharp and stable growth, reaching approximately 275 million metric tons by Year 20. This outcome suggests that jute production can be significantly increased when favorable variables, such as innovative farming technologies, effective land utilization, and government support through policy, are implemented. The current scenario (green line 3) shows stable growth, tapering off near 150 million metric tons, which is significantly lower than the improved scenario outcomes. Conversely, the worst-case scenario (red line 2) remains under 50 million, indicating weak management, underprivileged policies, labor inefficiency, and other agricultural inputs.

Figure 5.

Scenario-Based Simulation of Jute Production and Jute Stick Output.

Likewise, in the ‘Jute Stick’ graph, the improved scenario again leads with output growing up to around 30 million metric tons, shifting slightly but consistently outperforming the others. This progress is directly linked to increased jute production and higher conversion rates, both influenced by improved technology and more efficient factory processing. The current scenario trails a stable middle route, reaching roughly 17 million metric tons, although the worst scenario remains flat at below 10 million metric tons, inferring partial jute stick conversion due to weak post-harvest systems and a lack of innovation in processing. Overall, the analysis clearly indicates that the improved scenario yields the best results in both jute and jute stick production. This achievement is attributed to the deliberate integration of vital enabling factors, including contemporary technology, effective policies, resource optimization, and value chain efficiency. On the other hand, the worst-case consequences serve as a cautionary baseline, where a lack of advancement and systemic inefficiencies can severely limit potential.

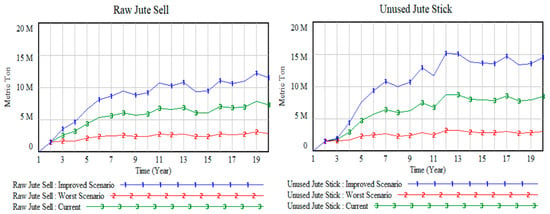

7.2. Raw Jute and Unused Jute Stick

Figure 6 reflects two distinct but interconnected aspects of the jute production system, each projected over 20 years across three scenarios: Improved, Current, and Worst. Factors including technology, biofertilizer use, seasonal effects, government policies, skilled labor, and supply chain efficiency guide these simulations. In the ‘Raw Jute Sell’ graph, we observe a steady increase in output under the improved scenario, peaking at around 12 million metric tons by Year 20. This reflects stronger jute cultivation practices and a well-functioning fiber market. It is important to note that raw jute fiber has historically been the primary commercial product of the jute sector. The current scenario follows a moderate growth path, stabilizing around 7 million metric tons, while the worst-case scenario remains below 3 million metric tons, signaling stagnation due to limited market access or production inefficiencies.

Figure 6.

Scenario-Based Simulation of ‘Raw Jute Sell’ and ‘Unused Jute Stick’.

The ‘Unused Jute Stick’ graph tells a more transformative story. Under the current scenario, most farmers and traders do not utilize jute sticks efficiently. These byproducts often go to waste, contributing to relatively high levels that stabilize at around 9 million metric tons. However, our research focused on redirecting this unused jute stick into the leading supply chain, specifically for charcoal and activated carbon production. The result, evident in the improved scenario, shows a controlled increase and eventual plateau of unused stock, as more sticks are absorbed into value-adding processes. The worst-case scenario reflects underutilization but less accumulation due to lower overall production. This analysis highlights the hidden potential within the jute value chain. While raw jute continues to dominate traditional markets, the innovation lies in leveraging jute sticks, once considered agricultural waste, as a raw material for environmentally beneficial products. Integrating unused resources into the production system reduces waste and expands economic opportunities. The improved scenario illustrates how targeted involvement and systemic effectiveness can enhance sustainability outcomes in the jute sector.

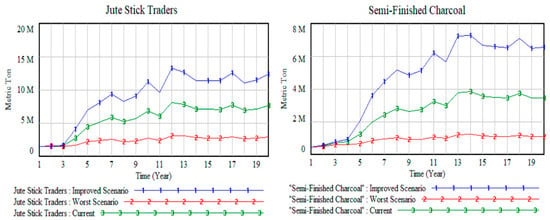

7.3. Jute Stick Traders and Semi-Finished Charcoal

Figure 7 illustrates the intermediate stages of the jute stick value chain under three simulated scenarios—Improved, Current, and Worst—across a 20-year projection. Technological advancements, skilled labor, policy incentives, seasonal patterns, and supply chain efficiency influence these simulations. The Jute Stick Traders graph illustrates how the volume of traded jute sticks fluctuates in response to system performance. Under the improved scenario, the trading volume grows steadily and stabilizes around 13–15 million metric tons. This trend reflects a responsive supply chain where increased jute production and better stick collection mechanisms encourage active market engagement. The current scenario stabilizes at around 8 million metric tons, suggesting moderate but suboptimal utilization. In contrast, the worst-case scenario remains below 4 million metric tons, which may indicate poor organization, low incentives, or a lack of awareness regarding jute sticks as a viable commodity. The Semi-Finished Charcoal graph illustrates the efficiency of converting jute sticks into semi-finished charcoal, a crucial input for producing finished charcoal and activated carbon. The improved scenario shows consistent growth, with output reaching nearly 7 million metric tons, highlighting the effectiveness of innovative conversion technologies and efficient industrial processes. The current scenario indicates slower but visible growth, plateauing around 4 million metric tons, which could be attributed to limited factory capacity or an inconsistent supply of usable sticks. Meanwhile, the worst-case scenario stays below 2 million metric tons, indicating minimal processing activity and poor technological penetration.

Figure 7.

Scenario-Based Simulation of Jute Stick Traders and Semi-finished Charcoal.

These graphs collectively highlight a critical transition zone in the jute stick supply chain, spanning the transformation from raw agricultural residue to industrial fuel and carbon-based products. A robust trading ecosystem facilitates the smooth flow of materials, ensuring that factories are adequately stocked to maintain a steady charcoal output. The improved scenario demonstrates the benefits of systemic coordination, policy support, and targeted investment in logistics and processing infrastructure. On the other hand, the current and worst scenarios reveal the risks of underutilized potential and fragmentation. Ultimately, this model segment reinforces the idea that market connectivity and industrial readiness must evolve hand-in-hand to maximize value from jute sticks. Strengthening traderfactory relationships and improving conversion efficiency are both essential to a sustainable, profitable bio-based industry.

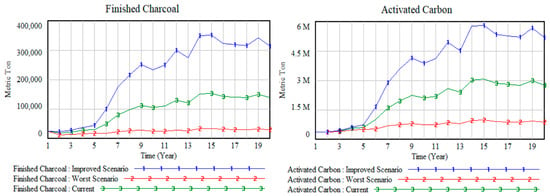

7.4. Finished Charcoal and Activated Carbon

Figure 8 represents the final stages of value addition within the jute stick utilization chain, projected over 20 years under three scenarios: Improved, Current, and Worst. These simulations integrate the cumulative effects of upstream factors such as technology integration, skilled labor availability, government policy support, efficient logistics, and seasonal adaptability. In the Finished Charcoal graph, the improved scenario exhibits a substantial and sustained rise in output, reaching nearly 400,000 metric tons by Year 20. These results are from advanced conversion processes, a steady supply of jute sticks, and a functioning semi-finished charcoal flow. The current scenario stabilizes at around 200,000 metric tons, reflecting partial technological adoption and moderate market demand. On the other hand, the worst-case scenario barely exceeds 50,000 metric tons, indicating underinvestment, technological stagnation, and minimal stick conversion efficiency.

Figure 8.

Scenario-Based Simulation of Finished Charcoal and Activated Carbon.

The Activated Carbon graph displays a similar pattern, with the improved scenario reaching a peak of over 5.5 million metric tons. This suggests that activated carbon can become a significant value-added product when the system is optimized, particularly in terms of industrial capacity and export readiness. The current scenario achieves a reasonable output of around 3 million metric tons but remains far from its full potential. The worst-case scenario remains below 1.5 million metric tons, indicating lost opportunities in domestic utilization and the global carbon market. Together, these graphs highlight the importance of end-stage product development in maximizing the economic and environmental value of jute sticks.

To provide a clearer view of how the system evolves under different scenarios, Appendix A (Table A2) presents a comparative table of selected key stock variables (e.g., Finished Charcoal, Jute Production, Jute Stick) across time steps 4 to 20. Appendix A, Table A3, presents a statistical summary of the SD simulation for three scenarios, showing variability and stability through mean, median, and normalized (Norm) measures. The improved scenario consistently outperforms both the current and worst-case scenarios in terms of value addition, resource flow, and market output, validating the potential impact of systemic interventions. While earlier stages focus on cultivation and processing, these outputs depend on a synchronized, demand-driven supply chain that spans collection and trading through factory readiness and customer outreach. The improved scenario yields the highest results, validating our research hypothesis that system-level efficiency and targeted innovation can unlock large-scale sustainability and profitability. Transitioning from finished charcoal to activated carbon represents a leap toward green industrialization, and the simulated outputs strongly reinforce the benefits of an integrated, policy-supported, and innovation-led system.

7.5. Sensitivity Analysis

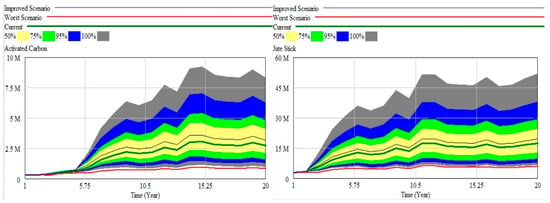

A sensitivity analysis was conducted to assess the model’s reliability and structural validity by examining how rapid changes in key variables affect system behavior. Five constant variables were considered to test the sensitivity analysis: ‘Government Regulation’ (low value 0.6–high value 1.4), ‘Technology Impact’ (0.7–1.3), ‘Skilled Labor’ (0.7–1.3), ‘Seasonal Impact’ (0.6–1.3), and ‘Innovative Technology’ (0.7–1.3), all set using a random-uniform distribution. The graph shows that even when the input varies from very low to high, the results remain consistent, as shown in Figure 9. This confirms the system responds well to positive interventions, especially in tech and labor, which are important for scaling up value-added jute products.

Figure 9.

Sensitivity analysis on Jute Sticks and Activated Carbon.

The above findings from distinct scenarios and their outputs demonstrate that desired policy, technology, labor, and other inputs can significantly increase production, processing efficiency, and JSC byproducts. Sensitivity analysis further validates the model’s structure and reliability under a wide range of variable changes, offering valuable insights for sustainable outcomes in the jute industry.

8. Findings

This study initially aimed to develop a comprehensive SD simulation of the Jute Stick Charcoal (JSC) supply chain in Bangladesh. The model has utilized macro-level data from the government site and farm and industry-level data from relevant farmers, intermediaries, and various industry personnel to inform its development. To do so, the research involved identifying the entire supply chain process from relevant stakeholders and pinpointing the variables. Among the identified variables, the paper integrated the most critical variables, which are treated as driving forces of the jute supply chain. After numerous trials, the model replicates current outputs, which then enables the study to create two possible scenarios based on stakeholders’ demands and farmers’ capacity to address the situation. Once the model runs for 20 years under three current, Improved, and Worst scenarios. The model comprises six fundamental and critical variables of Jute Production, Jute Stick Utilization, Raw Jute fiber, Jute Stick Trade, Charcoal Conversion, and Activated Carbon Production, each represented by stocks, flows, auxiliaries, and constants.

The simulation discloses the following findings based on the specific objectives.

8.1. Objective 1: To Empower Jute Farmers by Integrating Them into the Jute Stick Supply Chain for Better Productivity and Profitability

- Under the improved scenario, jute production increases significantly, reaching 275 million metric tons by Year 20. This consistent growth offers more byproducts (jute sticks), which creates additional income routes for farmers.

- The investigation reveals that organized jute collection and trading networks contribute to a 15 million metric ton increase in volume. Consequently, such an increment helps farmers earn additional income from unused and waste materials, which were once treated as agricultural waste.

- Findings also show that reducing unused jute sticks under an improved simulation scenario decreased from over 9 million to around 3 million metric tons, reflecting better farmer integration into a productive supply chain.

Thus, the above findings help us understand that the improved scenario will empower the farmers more than the present scenario.

8.2. Objective 2: To Improve the Efficiency of the Current Jute Supply Chain for Better Outcomes

- In the semi-finished charcoal variable, the improved simulated scenario reaches 7 million metric tons by Year 20, compared to 2 million in the worst-case scenario. This demonstrates significant improvement in production efficiency and resource utilization.