Abstract

Introduction: This study explores the impact of logistics information technology (LIT) on supply chain relationships and distribution performance in small and medium-sized enterprises (SMEs) using South Africa as a case study. Although digital supply chain solutions are increasingly important, there is limited evidence of SME efficiency in emerging markets using LIT. Methods: This study utilises a survey of 313 SMEs from four South African provinces. Bayesian structural equation modelling (Bayesian SEM) was then used to examine LIT’s effects on distribution performances in terms of timeliness, product availability, and condition. Results: The results show that the adoption of LIT strengthens buyer–seller networks (β = 0.524, CI = [0.434, 0.613]) and improves distribution by enhancing both timeliness performance (β = 0.237, CI = [0.098, 0.372]) and product condition performance (β = 0.175, CI = [0.042, 0.259], β = 0.222, p < 0.001). However, it does not directly enhance product availability performance (β = 0.085, CI = [−0.030, 0.199]), signifying that LIT adoption by itself fails to improve product availability. The results also demonstrate that SME network relationships mediate the connection between LIT adoption and distribution performance metrics. Discussion: This study’s findings contribute to the literature and offer valuable information and guidance to policymakers as they underscore the importance for SMEs to invest in LIT integration and compatibility, as well as inventory optimisation and improved supplier communication to minimise transit time variation. Policymakers should support SMEs’ digital transformation through interventions including funding and training for LIT adoption. This study confirms the essential role of LIT in SME supply chains and illustrates that technology-facilitated relationships enhance distribution performance, which enhances SME competitiveness.

1. Introduction

Recent advances in global logistics and supply chain management, coupled with the rapid integration of logistics information technology (LIT), have fundamentally reshaped business models, allowing organisations to enhance agility, visibility, and efficiency in supply and demand balancing [1,2]. These technological advancements, such as the Internet of Things (IoT), artificial intelligence (AI), blockchain, and advanced data analytics, have revolutionised distribution strategies, fostering real-time inventory tracking, seamless order fulfilment, and omnichannel retailing [3]. However, while large corporations have swiftly adopted these innovations, the extent to which small and medium enterprises (SMEs) leverage LIT to optimise their distribution networks and improve supply chain performance remains underexplored, particularly in emerging economies [4,5,6].

Although prior research highlights the benefits of LIT in large enterprises, there is limited empirical evidence on how SMEs use these technologies to reconfigure their distribution strategies, particularly in an omnichannel retail environment [2,4,5,6]. The evolution from traditional push-and-pull distribution strategies to omnichannel retailing underscores the need for seamless coordination across multiple supply chain nodes [7,8]. Omnichannel retailing, which integrates online and offline distribution channels, relies heavily on LIT for real-time inventory management, demand forecasting, and last-mile delivery optimisation [9,10]. However, SMEs often face barriers such as high implementation costs, technological incompatibility, and limited technical expertise [11,12], raising questions about how effectively they use LIT to strengthen supply chain relationships and distribution performance. South Africa presents an interesting case study to help fill this research gap. In South Africa, SMEs play an important role in economic growth, job creation, and poverty alleviation [10,11]. However, many struggle with sustainability, with a significant proportion failing within their first five years of operation [12,13]. A critical factor influencing their competitiveness is the ability to integrate LIT into their supply chain operations to strengthen buyer–supplier relationships, improve distribution efficiency, and enhance customer satisfaction [14]. Thus, using South Africa as a case study, this study seeks to answer the following:

“To what extent does the adoption of LIT enhance the relationships between the supply chain networks and the performance of the distribution among SMEs in South Africa?”

The research provides quantitative evidence on how LIT adoption influences the relationships and performance of the distribution network of SMEs, using structural equation modelling (SEM) to assess direct and mediated effects. Unlike previous studies that focused on large firms, this research highlights the challenges and opportunities of LIT integration for SMEs, particularly in an emerging market context. The findings offer actionable strategies for SMEs to optimise LIT adoption, improve packaging and product condition performance, and strengthen supply chain collaborations for competitive advantage. By addressing these aspects, this study not only advances academic discourse on LIT and SME supply chains but also provides policymakers and business leaders with insights to foster SME resilience and growth in a digitally driven economy.

This research is globally significant as it identifies structural challenges commonly encountered by SMEs in emerging economies, including inadequate digital infrastructure, disjointed supply chains, and logistical inefficiencies, which are prevalent in Latin America, Southeast Asia, and parts of Africa [15,16,17]. The research outcomes and models, such as the SEM framework, offer a reproducible approach for evaluating technology adoption across diverse environments. Furthermore, the wide-ranging applicability of logistics technologies, such as Radio Frequency Identification (RFID), Warehouse Management System (WMS), and IoT, along with the crucial role of supply chain relationships, underscores the necessity of trust and coordination across various sectors. By aligning with global policy strategies, such as Digital India [18], “Internet Plus [19],” and the EU’s digital initiatives [20], this study provides flexible guidelines for governments and industry players to foster the digital transformation and global competitiveness of SMEs.

The rest of the paper is organised as follows: First is the review on logistics information technologies and the impact on SME network relationship ties. This is followed by the review on relational view theory as well as SME distribution performance in terms of timeliness, product availability, and condition performance. The research hypotheses are proposed accordingly. Next, the research methodology and data analysis are presented and the results are discussed. The paper then provides a summary and uses the findings of this study to make recommendations on the SME distribution relationship network for operational improvement and resilience, which could contribute significantly to overall economic performance. Finally, the paper ends with limitations for future research.

2. Review of Concepts and Literature

2.1. SMEs and the Role of Distribution Information Technology

The efficiency of physical distribution, including inbound and outbound logistics, plays a crucial role in the overall performance of supply chains, particularly for SMEs. Inbound logistics, often referred to as materials management, focuses on the movement and storage of raw materials, while outbound logistics, or physical distribution, ensures that finished products reach customers in a timely and cost-effective manner. For SMEs operating in competitive and resource-constrained environments, such as South Africa’s townships and informal economies, optimising physical distribution is not just a logistical concern but a strategic imperative. Effective distribution improves customer satisfaction, reduces operational costs, and strengthens relationships within the supply chain network, ultimately contributing to business sustainability and growth [21,22,23,24,25,26,27,28,29,30,31]. However, despite their significant contribution to employment and economic development, many South African SMEs struggle with high failure rates, with a substantial proportion closing within two to five years of operation [10,11,12,13,14]. One of the key challenges they face is the inability to integrate advanced logistics information technologies (LITs) into their operations, which limits their ability to compete with larger firms and adapt to dynamic market demands.

Several LIT solutions have emerged to address distribution challenges, each offering distinct advantages for SMEs. Warehouse Management Systems (WMS), for example, leverage technologies such as RFID, IoT, and cloud computing to streamline inventory control, reduce storage inefficiencies, and improve coordination between suppliers and distributors. These systems are particularly valuable in minimising non-value-adding activities, such as excessive stock handling, and in improving responsiveness to supply chain disruptions, a lesson underscored by the COVID-19 pandemic [32,33,34,35,36,37]. However, despite their potential, many SMEs in South Africa remain reluctant to adopt WMS due to perceived high implementation costs and a lack of technical expertise, resulting into technological incompatibility [25,26]. Freight consolidation systems offer another avenue for cost optimisation by allowing SMEs to bundle smaller shipments into larger loads, thus reducing per-unit transportation costs and lowering carbon emissions, a critical consideration in an era of increasing environmental regulation and consumer demand for sustainable practices [22,29,37,38]. Similarly, Electronic Data Interchange (EDI) facilitates seamless B2B transactions by standardising data exchange between supply chain partners, reducing errors, and improving trust and operational efficiency [39,40,41,42,43].

Additional technologies, such as barcoding systems, improve inventory accuracy by automating data capture, reducing human error, and accelerating order processing factors that are particularly beneficial for SMEs with limited administrative resources [44,45,46]. Vehicle routing and scheduling tools, powered by AI and real-time traffic monitoring, optimise delivery logistics, minimise fuel consumption, and ensure the timely delivery of orders [47,48,49,50,51,52,53,54,55,56,57,58,59]. Meanwhile, RFID technology provides real-time tracking capabilities, improving supply chain visibility and enabling better demand forecasting [36,44,60,61]. Despite these advancements, the adoption of LIT among South African SMEs remains uneven, often due to financial constraints, infrastructure limitations, and a lack of awareness about the long-term benefits of digital transformation. Addressing these barriers is essential for SMEs to fully leverage LIT in strengthening their distribution networks and enhancing competitiveness.

2.2. Relational View Theory

The relational view theory provides a valuable framework for understanding how SMEs can achieve competitive advantages through strategic interorganisational collaboration. Unlike traditional perspectives such as the view of industry structure or the resource-based view, which focuses on firm-specific capabilities, the relational view emphasises the benefits of shared resources, knowledge exchange, and joint governance mechanisms within a networked environment [62]. For SMEs, which often lack the scale and resources of larger corporations, forming strong distribution partnerships can be a critical differentiator. By integrating LIT into their operations, SMEs can improve coordination with suppliers, logistics providers, and customers, leading to improved forecast accuracy, reduced lead times, and higher delivery performance.

The relational view posits that inter-firm collaboration, when supported by technology, can create synergies that individual firms cannot achieve independently. For example, shared WMS platforms enable SMEs and their partners to synchronise inventory levels, reducing stockouts and excess inventory costs. Similarly, EDI systems facilitate real-time data exchange, minimising delays and improving order fulfilment rates [41,42,43]. These collaborative advantages are particularly relevant in emerging markets, where supply chain inefficiencies—such as fragmented transportation networks and inconsistent information flows—often hinder the growth of SMEs. By adopting a relational approach, SMEs can mitigate these challenges, fostering trust and long-term partnerships that improve supply chain resilience. Furthermore, technology-enabled distribution relationships can lead to cost-sharing arrangements, such as joint freight consolidation, which reduces transportation expenses while improving the reliability of delivery [37,55,57]. In essence, the relational view underscores the importance of LIT not just as an operational tool but as a strategic enabler of network-based competitiveness for SMEs.

2.3. Key Dimensions of Physical Distribution Performance

Physical distribution performance is a multifaceted concept that directly impacts customer satisfaction, operational efficiency, and overall business sustainability. For SMEs, achieving optimal distribution results requires balancing several critical factors, including lead time, product availability, and delivery condition. Lead time reduction is particularly crucial, as prolonged delays increase inventory holding costs, raise the risk of stock obsolescence, and negatively affect customer retention [63]. Longer lead times also require higher levels of safety stocks, which strain the working capital of SMEs, a significant challenge given their typically limited financial buffers.

Inventory and stock availability represent another key dimension, as out-of-stock situations can lead to lost sales and erode customer trust. Advanced technologies such as IoT-enabled demand sensing and blockchain-based traceability systems are increasingly being deployed to improve inventory visibility and replenishment accuracy [63,64]. These tools allow SMEs to respond dynamically to demand fluctuations, minimising excess stock while ensuring product availability. Product condition at the point of delivery is equally critical, especially for perishable goods or high-value items where damage or spoilage can result in financial losses and reputational harm. In sectors such as fresh food retail, for example, customers associate delivery time with product quality, meaning that delays or mishandling can directly influence repurchase intentions [65,66].

To address these challenges, SMEs must adopt a holistic approach to distribution management, integrating LIT solutions that enhance real-time tracking, route optimisation, and collaborative logistics planning. The growing shift toward omnichannel retailing further underscores the need for agile and technology-driven distribution strategies, as customers increasingly expect seamless, fast, and reliable delivery options across multiple platforms. For SMEs, investing in LIT is not just about keeping up with competitors but about building a resilient and customer-centric supply chain capable of sustaining long-term growth in an increasingly digital and interconnected marketplace. Table 1 summarises how each LIT impacts the three dimensions of distribution performance, namely, timeliness, availability, and product condition. LIT impacts the dimensions of physical distribution performance.

Table 1.

LIT impact on dimensions of physical distribution performance.

This illustrates the way focused LIT implementation can tackle various performance aspects at once, generating enhanced advantages for SME supply chains. The incorporation of these technologies not only boosts operational metrics but also fortifies the overall resilience and competitiveness of SME distribution networks.

2.4. Research Hypothesis

Based on the literature review, we hypothesise the following relationships.

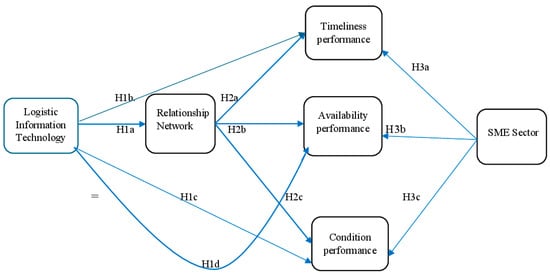

H1a:

The adoption of LIT has a significant effect on the relationships between the supply chain network among SMEs.

H1b:

LIT adoption has a significant effect on the performance of SMEs’ distribution timeliness.

H1c:

LIT adoption has a significant effect on SMEs’ product availability performance.

H1d:

LIT adoption has a significant effect on the performance of SMEs’ product condition.

Therefore, the mediating role of supply chain network relationships hypotheses is proposed.

H2a:

The relationships of the supply chain network mediate the relationship between LIT adoption and timely performance.

H2b:

The relationships of the supply chain network mediate the relationship between LIT adoption and availability performance.

H2c:

The relationships of the supply chain network mediate the relationship between LIT adoption and condition performance.

Furthermore, we hypothesise the following:

H3:

Distribution performances significantly vary across SME sectors.

This hypothesis translates into the following sub-hypotheses:

H3a:

Timeliness performances significantly vary across SME sectors.

H3b:

Availability performances significantly vary across SME sectors.

H3a:

Product condition performances significantly vary across SME sectors.

The hypothesised relationships are represented in the path diagram in Figure 1.

Figure 1.

Path diagram of hypothesised relationships.

3. Methodology

3.1. Research Approach, Sampling, and Questionnaire Design

This research takes a positivist approach and is quantitative research in nature. A questionnaire was used to collect data. The target population for this study is SME retailers and logistics operators within the distribution channel in South Africa. A sample of 400 SMEs from different retailers was drawn from the SMEs available to conduct this study. The samples were drawn from a registered retailer network used by Sol Plaatje University’s work integrated learning programme and the W&RSETA employer database throughout the country, as well as the registered SME database of municipalities.

Non-probability sampling techniques with a focus on purposive and convenience sampling techniques were used. These techniques are appropriate because they allow for the selection of retailers based on availability, ease of access, and suitability for this study. Pre-test interviews were conducted among retailers located within Kimberley to inform a more effective survey instrument. Measurement items were assessed using a five-point Likert scale ranging from 1 (strongly disagree) to 5 (strongly agree). A five-point Likert scale is necessary because the development and implementation of distribution strategies may differ from one retail organisation to another.

The questionnaire has four sections. Section A presents the demographic details of SMEs, Section B measures logistics information technology, Section C measures the relationship network concept, and lastly, Section D measures the physical distribution concepts. The measurement items from several questionnaires were adapted to the context of this study. Logistics information technology items were adapted from [67] (p. 140). Regarding the relationship network measurement items, the researchers identified seven distribution strategies through a literature review, which were validated by retail managers. These distribution strategies represent the main criteria in which the measurement items were developed and items measuring physical distribution were adapted from [68] (p. 41).

3.2. Measurement and Structural Models

In modelling the mediation role of the distribution network relationship in terms of logistics information technology’s impact on the performance of SMEs, factor analysis frameworks (exploratory and confirmatory) and structural equation modelling were used. These modelling frameworks are appropriate for this study because our variables of interest are latent in nature, and the covariance-structural equation modelling approach allows for their estimation and validation. In addition, since we aim to test hypotheses, the covariance-SEM approach is more appropriate. Exploratory factor analysis was specifically used to create the summated scale latent variables needed to measure the variables of interest, and the confirmatory factor analysis was then used to validate or assess the usefulness of the constructed latent variables for structural relationship modelling. Structural equation modelling was then used to model the relationship among the variables.

The measurement model consists of three exogenous and three endogenous constructs. The exogenous constructs are logistics information technology usage and the distribution network relationship while the endogenous constructs are timeliness performance, availability, performance, and condition performance. The exogenous constructs were hypothesised to be measured by 6 items or indicants each. On the other hand, timeliness performance was hypothesised to be measured by 19 items and availability performance was also hypothesised to be measured by 19 items. Condition performance was hypothesised to be measured by 7 items.

The structural model consists of the one non-latent construct named the SME sector and two exogenous and three endogenous constructs, as stated in the preceding paragraph. The SME sector variable is a categorical variable created by an assigned number from 1 to 6, where the numbers indicate the sector to which an SME belongs, as indicated in Table 1. To assess sectoral variations in distribution performances, the sectoral variable (which categorises the different sectors of the SMEs) was included in the structural equations for distribution performances.

4. Data Analysis and Results

4.1. Descriptive Statistics and Data Analysis

4.1.1. Descriptive Statistics

The questionnaires were disseminated by research assistants selected from final bachelor’s degree at university across the provinces of South Africa. Approximately 10 of these research assistants were trained as fieldworkers to manage the face-to-face data collection process. The research assistants supported the authors in collecting empirical data particularly during university breaks. They were allocated between three and four months to complete the data collection. By employing structural equation statistical modelling, this study targeted a sample size of 400 SMEs, comprising both retailers and logistics operators in the distribution channel. Of the 400 distributed questionnaires, 322 were returned (representing 81% return rate). Nine of the returned questionnaires were either incorrectly filled or there were missing information, thus they were omitted from the data which reduced the final sample size to 313. After the data was appropriately coded by assigning values to categorical items, the individual items/variables were checked for the presence of outliers using the Tukey’s fences outlier detection method and no extreme values were found in any of the variables. Table 2 provides a summary of the data.

Table 2.

Profile of SMEs.

From the table, most of the SMEs are in the northern Cape Province while very few are in Gauteng. A large proportion of the SMEs have also been in existence for more than 5 years. Most of the organisations (76%) also had turnovers of more than ZAR 500,000 (about USD 28,000) and most of them were classified as medium organisations. The predominant sectors for SMEs include food, beverages, and tobacco in speciality stores (35.5%) and textiles, clothing, footwear, and leather goods (29.4%). Large proportions of the respondents were people of high and considerable privileged positions (CEO/director/owner, manager, supervisor, salesperson, administrator, or officer), about 95%.

4.1.2. Exploratory and Confirmatory Factor Analysis

When testing for the assumptions underlying the factor analysis, the multivariate Shapiro–Wilk test was used to test for the presence or absence of normality in the data, while the Kaiser–Meyer–Olkin (KMO) test, the Bartlett test of sphericity, and the determinant test were used to assess the factorability of the data. The results of the test are summarised in Table 3. The results provide evidence that the data are factorable because the KMO value is above the conventional 0.6, the Bartlett sphericity test p-value is below 5%, and the determinant of the correlation matrix is positive. The results provide evidence that the data are factorable because the KMO value is above the conventional 0.6, the Bartlett sphericity test p-value is below 5%, and the determinant of the correlation matrix is positive. Furthermore, the data is not normally distributed since the p-value is less than 5%. These observations suggest that factor analysis can be performed on the data, and the robust maximum likelihood approach should be used to estimate the factor model to account for the nonnormality.

Table 3.

Normality and factorability tests.

In selecting items to represent each of the hypothesised constructs (logistics information technology, relationship networks, timeliness performance, availability performance, and condition performance), a factor loading cut-off of 0.7 was used, after which summated scales were constructed to represent each of the constructs. Before the summated scales were used to perform the structural equation modelling, confirmatory factor analysis was performed to assess the internal consistency and validity of the summated scales. However, the use of summated scale score to represent a reflective indicator construct results in inconsistent structural estimates of the relationships between the construct and other variables because it ignores the effects of measurement error; thus, we explicitly model the error variance in the SEM model to account for measurement error. The associated items and their factor loadings for each of the constructs are reported in Table 4.

Table 4.

Construct validity and internal consistency.

A well-constructed summated scale should demonstrate convergent validity, discriminant validity, and internal consistency. Convergent validity is assessed using the Average Variance Extracted (AVE), while discriminant validity is evaluated through the Heterotrait/Monotrait (HTMT) ratio. Internal consistency is examined using both Composite Reliability (CR) and Cronbach’s alpha. In addition, the summated scales should be supported by confirmatory factor analysis. In this regard, the Chi-square test for RMSEA ≤ 0.050 should be significant (p-value < 0.05) while the SRMR < 0.08, and both the Comparative Fit Index (CFI) and Tucker–Lewis Index (TLI) should exceed 0.90. The results, summarised in Table 5, indicate that all HTMT values fall well below the conservative threshold of 0.85, confirming strong discriminant validity. AVE values exceed 0.50 for all constructs, supporting convergent validity. CR values are above 0.70, and Cronbach’s alpha ranges between 0.70 and 0.90, demonstrating satisfactory internal consistency. Furthermore, the CFA model exhibits acceptable fit, with CFI and TLI values above 0.90, SRMR at 0.058 (below the 0.08 threshold), and RMSEA ≤ 0.050 for the hypothesis test with a p-value of 0.0001, indicating excellent parsimony. Collectively, these findings affirm that the measurement model is both statistically robust and conceptually well-defined across constructs; thus, they can be used to model the relationships among the hypothesised variables in this study.

Table 5.

Heterotrait/Monotrait ratio and goodness-of-fit of latent constructs.

4.1.3. Diagnostics Test for Estimated Structural Models

Bayesian structural equation modelling (Bayesian SEM) is particularly advantageous for research involving non-normal data and small sample sizes, as it does not rely on large-sample theory or multivariate normality assumptions. Instead, it uses prior distributions and Markov Chain Monte Carlo (MCMC) techniques to generate stable parameter estimates and credible intervals [69,70] (Kaplan & Depaoli, 2012; Merkle & Rosseel, 2018). Unlike frequentist SEM approaches such as robust maximum likelihood, which rely on point estimates and bootstrapped standard errors, Bayesian SEM computes the full posterior distribution of path estimates directly from posterior samples. This allows for full uncertainty propagation by capturing joint variability among parameters, resulting in more accurate and interpretable credible intervals especially in mediation analysis, where indirect effects often involve complex dependencies and small effect sizes [71] (Yuan & MacKinnon, 2009).

Bayesian SEM also offers flexible model evaluation tools such as Posterior Predictive checks, making it ideal for complex models like hierarchical or mixture structures [72] (Hong et al., 2024). Furthermore, credible intervals in Bayesian SEM provide intuitive interpretability: a 95% credible interval reflects a 95% probability that the parameter lies within that range, given the observed data and specified priors. This contrasts with frequentist confidence intervals, which refer to long-run coverage across repeated samples and can be conceptually misleading in single-study inference [73] (Wei, Nathoo, & Masson, 2023).

In comparison, covariance-based SEM (CB-SEM) typically employs maximum likelihood estimation, which is sensitive to non-normality and requires large samples for reliable inference [74] (Hair et al., 2025). While robust variants of CB-SEM exist, they still struggle with extreme distributional violations. Partial Least Squares SEM (PLS-SEM) is more tolerant of small samples and non-normality but prioritises prediction over theory testing and lacks global goodness-of-fit measures [75] (Hair et al., 2016). Therefore, Bayesian SEM offers a theoretically sound and robust alternative framework that combines the theoretical rigour of CB-SEM with the flexibility of PLS-SEM, making it the most suitable choice for modelling under non-ideal data conditions, particularly in mediation analysis. Table 6 also summarises the goodness-of-fit measures.

Table 6.

Goodness-of-fit measures and fit indices.

A good, fitted Bayesian model should have Potential Scale Reduction Factor (Rhat) values approximately equal to 1 for all the parameters and the Posterior Predictive p-value should fall within 0.05 and 0.95 for an acceptable or good fit. The coefficient of determination (R2) should also be large; however, if the goal is to assess relationships rather than predict outcomes, as is the case in this study, [76] argues that a low R2 (as low as 0.10) is acceptable if the estimated paths are statistically significant. From Table 5, the Rhat value for all parameters ranges from 0.99 to 1.004, which suggests that the Markov chains have mixed well and that the posterior estimates are reliable. In addition, the Posterior Predictive p-value is 0.299, which is within the acceptable range. In addition, the individual models have moderate explanatory power ranging from 0.139 to 0.278. These results suggest that the full model is a good fit to the data and thus suitable for making inferences.

4.2. Pathway Model and Discussion

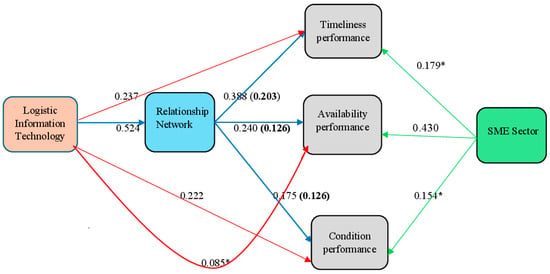

As the estimated structural equation models have been validated, the results are now discussed. Table 7 and Figure 2 summarise the estimated regression estimates.

Table 7.

Estimated impacts.

Figure 2.

Path diagram of estimates. * indicate variable is not significant and values in brackets represent mediation effects.

An estimate is significant if the credible interval (CI) does not contain zero and insignificant if it contains zero. The findings support Hypothesis 1 (H1a), confirming that the adoption of logistics information technology (LIT) significantly strengthens the relationships between the supply chain network relationships (β = 0.524, CI = [0.434, 0.613]). SMEs that leveraged technologies such as electronic data exchange (EDI), barcoding systems, and freight consolidation reported improved collaboration with suppliers and buyers. These technologies facilitate real-time data sharing, accurate inventory tracking, and streamlined order fulfilment, fostering stronger interorganisational ties. This aligns with relational view theory, which posits that technology-enabled collaboration enhances competitive advantage through shared resources of which communication, coordination, and relationship trust play significant roles [62]. Thus, an increase in the usage of LIT for an SME is significantly associated with an increase in the impact of its supply chain relationship networks.

This study slightly supports H1b, showing a moderate significant direct effect of LIT on timeliness performance (β = 0.237, CI = [0.098, 0.372]). This indicate that though the SMEs recognised the importance of LIT on timely distribution performance, supply chain demand, and order management, related factors may influence timeliness [76]. However, technologies such as vehicle routing/scheduling systems and Warehouse Management Systems (WMS) improve delivery speed, reduce lead times, and enhance order fulfilment efficiency. The result for H1c (β = 0.085, CI = [−0.030, 0.199]) is not statistically significant. Consistent with H1b, it is evident that both product timeliness and availability are closely associated, highlighting the importance of appropriately timed and located product availability for distribution efficacy. Distribution strategy encompasses the planning, execution, and management of the efficient and effective forward/reverse flow and storage of goods, services, finances, and pertinent information through a distribution channel to satisfy customer demands and gain a lasting competitive edge. Utilising technologies such as RFID, IoT-enabled inventory management systems, and demand prediction tools enhances inventory visibility, thereby decreasing instances of product stockouts [77]. Nonetheless, without a network of relationships, simply adopting LIT may not have a direct effect on enhancing product availability. H1d receives modest support (β = 0.175, CI = [0.042, 0.259]). Despite potential impacts from aspects like product vulnerability and optimisation of the transportation network on product condition performance, integrating LIT without collaboration across the supply chain network might not effectively mitigate the risks related to product conditions during transit. Nevertheless, technologies such as RFID, WMS, and various systems related to vehicle routing/scheduling can enhance the physical quality and integrity of products during storage, handling, and distribution. This is consistent with the conclusions of [54], who note that technology affects product condition by enhancing tracking, handling, and monitoring during transit.

In general, incorporating information technology into H1a through H1d has not only improved internal collaboration among operational departments in SMEs, but has also facilitated the development of a more robust supply chain network with trading partners [76]. The goals of the supply chain networking relationship among organisations are to improve customer service delivery and sustain competitive advantage over rivals. Despite national competitive challenges, SMEs are continuously faced with challenges of economies of scale due to network integration and development, which has, for a long-time, deprived SMEs, especially medium enterprises’ opportunities to compete effectively on a global scale to leverage comparative advantages emanating from global interdependences among countries [2,77].

As the need for global trade intensifies, the growth of information technology, especially integrated flows of products or service, and demand flows has reconfigured the supply chain model to become more digital. The digital supply chain means digital material management and digital physical distribution. On the retail level, the digitalisation of the physical distribution dimensions of supply chains has resulted in new forms of competition among organisations, which, to a greater extent, has enabled collaborative networking advantages for SMEs [2]. For example, SMEs rated the integration of a freight consolidation system, EDI, and bar coding-related LIT systems as the most integrated communication system to enhance networking relationships (factor loadings: 0.6710, 0.8774, 0.8667, and 0.8426), respectively. These logistics information systems improve buyer–supplier relationships and strengthen collaboration due to efficient and effective inventory control and replenishment within the entire supply chain. The integration of inventory control systems can help mitigate unanticipated disruptions that hinder seamless flows of inventory, information, and finance across operational activities within a supply chain, for example, manufacturing, warehouse, transportation, materials handling, and distribution operations. As such, network relationships between larger organisations and SMEs, as well as SMEs and government stakeholders, are enhanced due to the integration of LIT. Therefore, for this study, related LIT systems such as freight consolidation, EDI, and automatic identification and data capture systems that facilitate accurate and real-time inventory visibility, optimum supply chain responsiveness, and efficiency are regarded as digital supply chain drivers for SMEs to achieve supply chain network advantages. As observed in Table 3, according to factor loadings, the majority of retail SMEs confirmed that the integration of information technology, their seamless response to customer orders and experiences, has intensified across all distribution channels, including in-store, mobile, and online. This term is called ‘omnichannel distribution’, which is possible through the relationship between vertical and horizontal distribution networks [14,78]. With this, the flexibility of direct shipment integration, centralised and decentralised warehouse distribution integration, and pull–push inventory supplier integrations is possible.

This study confirms H2a because the impact of LIT mediation on timeliness performance is significant and positive (β = 0.203, CI = [0.119, 0.287]), which accounts for 46.1% (0.203/0.440) of the total effect of LIT on timeliness performance. This implies that while LIT directly improves delivery speed, its effectiveness is enhanced when SMEs maintain strong supplier–customer relationships, enabling synchronised logistics operations. Technologies such as Electronic Data Interchange (EDI) and vehicle routing systems improve real-time communication, reducing delays in order processing and transportation. This aligns with prior research (see, e.g., [23,24], which highlights how digital integration minimises lead times by synchronising supply chain activities.

Hypothesis 2 (H2b) is supported, and the mediation contributes 59.7% (0.126/0.211) of the total effect of LIT on availability performance. The mediation impact is also positive and significant (β = 0.126, CI = [0.059, 0.193]) although the impact is relatively weaker. This suggests that information sharing and joint inventory planning within networked supply chains are critical to minimise stock shortages. Although the adoption of LIT directly increases inventory visibility, its full potential is realised when SMEs leverage network links for demand forecasting and stock replenishment. For example, Warehouse Management Systems (WMS) and barcoding technologies reduce stockouts by improving inventory accuracy across supply chain nodes [32]. This finding corroborates the relational view theory [79], emphasising that interorganisational trust and coordination facilitated by LIT enhance resource sharing and operational efficiency.

Hypothesis 2 (H2c) is also supported because of the significant positive mediation effect (β = 0.126, CI = [0.065, 0.188]), which contributes 41.7% (0.126/0.302) of the total effect of LIT on conditional performance. Just like the impact of LIT on availability performance, its impact on condition performance is also relatively weak. This implies that LIT alone is not sufficient to guarantee product quality; thus, SMEs must complement technology with better packaging standards and logistics coordination (for example, IoT-enabled condition monitoring). The weaker mediation suggests that product condition depends more on physical logistics practices (e.g., protective packaging, handling protocols) than digital integration alone. This aligns with the findings of [65,80], who note that product condition is influenced by both technology and physical logistics coordination. In general, distribution performance with respect to timeliness is important because it enhances consumer dependency trust due to consistent response times, timely delivery of orders, higher order fulfilment throughputs, shorter lead times, and rapid delivery performance [62]. Physical distribution performance in terms of availability performance is enhanced due to the presence of LIT-powered supply chain network relationships. For example, the participating SMEs reported on billing accuracy; consistent inventory availability when ordered; availability of order status information; customer service in terms of convenient return procedures; decentralised supplier inventory availability near the SMEs facility; and the flexibility of additional inventory than needed due to anticipated increases in orders. The condition of the products in terms of protective and convenient packaging, as well as the accurate and undamaged delivery of the order/product at the time of arrival, is an essential distribution fulfilment goal in the supply chain, especially in the age of the Internet of Things and electronic retailing [81,82,83,84,85,86]. Physical distribution performance in supply chain objectives is to meet the inventory control objectives of various organisations, which involves the integration of transport, warehouse, and material handling technologies to achieve customer service objectives. Therefore, the performance of the condition is as important as the performance of the availability and timeliness distribution in the supply chain. As such, the non-achievement of desired product condition performance by SMEs may be based on the lack of proper material handling and control within the supply chain, which can be enhanced through the integration of information and communication technology compatible with LIT.

Hypothesis 3 (H3a, b, and c) suggests that distribution performances significantly differ among SME sectors. This study’s findings offer partial support, since only H3a is confirmed by the analysis. In particular, the SME sector’s effect on availability performance is statistically significant (β = 0.430, CI = [0.202, 0.655]), while its impacts on product condition (β = 0.241, CI = [0.134, 0.353]) and timeliness (β = 0.179, CI = [–0.100, 0.445]) performances are not significant. This indicates that sectoral differences influence distribution performance selectively, likely due to variations in infrastructure, access to inputs, inventory and demand management practices, or logistical constraints specific to each sector. This suggests the need for sector-specific strategies for inventory and distribution management. Furthermore, the absence of significant sectoral effects on timeliness and condition performance implies that these aspects might be more influenced by firm-level capabilities, network strength, or technology use, rather than sectoral factors.

5. Conclusions

This study validates that the adoption of LIT strengthens the relationships between the supply chain networks, which in turn improves the performance of the distribution. However, product condition performance remains a challenge, requiring additional logistics investments. Sector-specific strategies are needed to maximise LIT benefits. For example, retail SMEs gain the most from inventory-focused LIT, whereas manufacturing and pharmaceutical SMEs require specialised tools for production coordination and regulatory compliance. The research underscores the need for holistic digital transformation in small and medium enterprises, combining technology, collaboration, and operational best practices to achieve supply chain resilience in emerging markets. Policymakers, business leaders, and academic researchers should recognise these nuances to drive inclusive digital transformation across SME ecosystems. This study contributes to relational view theory by demonstrating how technology-enabled networks drive the performance of SME distribution, offering practical insights into the integration of the digital supply chain in emerging markets.

5.1. Theoretical Implications

These findings reinforce a Contingency Theory perspective, emphasising that the effectiveness of logistics and information technologies (LIT) in enhancing distribution performance is contingent upon sector-specific operational contexts. The significant sectoral variation in availability performance suggests that external structural factors such as supply chain complexity, infrastructure access, and input volatility play critical roles in shaping availability performance. This underscores the need for adaptive and sector-sensitive strategies, as uniform LIT interventions may fail to address the nuanced challenges faced by SMEs across different industries. Conversely, the absence of significant sectoral effects on timeliness and condition performance suggests that these dimensions are more strongly influenced by firm-level capabilities such as process efficiency, digital adoption, and network integration. This aligns with Resource-Based Theory, which emphasises that internal, strategically valuable resources and competencies are central to sustaining competitive advantage, particularly in performance areas requiring operational agility and precision. Together, these insights suggest that while sectoral context is critical for availability performance, timeliness and condition performances may be more significantly improved through firm-specific capability development and strategic resource deployment.

5.2. Practical Implications

Customised LIT adoption strategies are essential. For example, retail SMEs focus on integrating tools for omnichannel operation, such as cloud-based WMS and EDI, to ensure the smooth management of inventory across online and offline channels. The findings on LIT in South African SMEs reveal mechanisms that are broadly applicable across global markets, provided regional contexts are considered. LIT tools like EDI, RFID, and WMS universally enhance supply chain visibility and coordination, but their effectiveness varies by sector—retail benefits from inventory systems, manufacturing from production coordination, and pharmaceutical from cold-chain monitoring.

Given the similarities of LIT adoption challenges among retail SMEs in the developing world, the findings can assist retail SMEs in other regions such as Southeast Asia, Latin America, and the rest of Africa to mitigate the negative effects digital transformations in supply chains. This study further validates relational view theory, showing that performance gains stem from technology-enabled collaboration rather than technology alone, a principle relevant from African SMEs integrating supplier platforms to Western firms deepening digital partnerships. Crucially, infrastructure and policy support shape the impact of LIT, with low-connectivity regions adapting simpler tools like SMS tracking, while high-tech economies embrace AI-driven logistics. As omnichannel distribution becomes a global norm, SMEs everywhere can apply these insights by tailoring LIT to sector needs, fostering digital relationships, leveraging scalable tech, and advocating for enabling policies.

5.3. Key Recommendations

SMEs should improve LIT compatibility by embracing interoperable technologies like cloud-based WMS and IoT sensors to increase supply chain transparency. Implementing joint training programmes and using shared LIT platforms to strengthen supplier collaboration, optimising inventory, and delivery management. SMEs should allocate resources not just for protective packaging, but also for improving product availability and promptness, alongside integrating software and processes for inventory tracking and control, as well as automating handling systems to reduce damages during transit.

Governments should take advantage of the opportunity to revolutionise the digital landscape by investing in the adoption of SME-LIT, with a strong emphasis on transformative sectors such as retail, which are crucial for driving SMEs toward comprehensive digitalisation. By crafting sector-specific innovative LIT subsidies, such as targeted grants that enable manufacturing SMEs to embrace IoT-based cold storage technology, governments can catalyse growth and foster a vibrant economy. This strategic method not only drives technological progress but also empowers companies to succeed in a more digitalised environment. In addition, it improves the interaction between SMEs and the government supply chain, which is predominantly dominated by private partnerships in South Africa.

Associations of larger organisations can be made aware of the benefits of offering sector-specific training for further education SMEs to enhance their proficiency in utilising diverse LIT for efficient, agile inventory management and to secure competitive advantages. The capabilities of supply chain networks within SMEs are anticipated to offer greater competitive advantages, particularly in terms of their ability to compete on an international scale, which in turn will boost the return on investment of SMEs, facilitate sustainable business growth, and contribute to long-term economic development. Consequently, it is essential to prioritise aligning technology objectives across all sectors of SMEs in South Africa.

5.4. Limitations and Suggestions for Future Research

In addition to being restricted to four (4) provinces (Northern Cape, Eastern Cape, Free State, and Gauteng) in South Africa, which limits the ability to generalise the findings to all SMEs, this study is further impacted by a cross-sector sampling bias. The SME sample in this study comprises the retail sector (65%), limiting its applicability to manufacturing SMEs. In this study, the differences in distribution performance among SME sectors are generalised rather than specific. Nuances specific to the sector, such as variations between manufacturing and retail, require a more in-depth investigation, which could be the focus of future research. Longitudinal studies could examine the progression of LIT adoption in SMEs over time and assess the impact of AI-driven logistics on further optimising distribution networks within SMEs.

5.5. Ethical Considerations

The main data collection involves human subjects, primarily targeting individuals with moderate to significant influence and concern about the relevant project matters. Comprehensive ethical protocols were adhered to throughout the study. Ethical clearance was secured from the Sol Plaatje University Senate Research Ethics Committee (Grant number: MIT9YR2022).

Author Contributions

Conceptualization, O.O., A.A., A.M., R.E.M. and E.A.N.D.; methodology, O.O., A.A., A.M., R.E.M. and E.A.N.D.; software, A.A.; validation, O.O., A.A., A.M., R.E.M. and E.A.N.D.; formal analysis, O.O., A.A., A.M., R.E.M. and E.A.N.D.; investigation, O.O., A.A., A.M., R.E.M. and E.A.N.D.; resources, O.O., A.A., A.M., R.E.M. and E.A.N.D.; data curation, O.O. and A.A.; writing—original draft preparation, O.O., A.A., A.M., R.E.M. and E.A.N.D.; writing—review and editing, O.O., A.A., A.M., R.E.M. and E.A.N.D.; visualization, O.O., A.A., A.M., R.E.M. and E.A.N.D.; supervision, O.O., A.A., A.M., R.E.M. and E.A.N.D.; project administration, O.O.; funding acquisition, O.O. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by Sol Plaatje University under the MIT Grant number: MIT9YR2022.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and the protocol was approved by the Sol Plaatje University Senate Research Ethics Committee of MIT9YR2022 on 18 August 2022.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data used in this study is available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Raji, M.A.; Olodo, H.B.; Oke, T.T.; Addy, W.A.; Ofodile, O.C.; Oyewole, A.T. The digital transformation of SMES: A comparative review between the USA and Africa. Int. J. Manag. Entrep. Res. 2024, 6, 737–751. [Google Scholar] [CrossRef]

- Chabalala, K.; Boyana, S.; Kolisi, L.; Thango, B.; Matshaka, L. Digital Technologies and Channels for Competitive Advantage in SMEs: A Systematic Review, Available at SSRN 4977280 [Preprint]. 2024. Available online: https://ssrn.com/abstract=4977280 (accessed on 3 December 2024).

- Tetouani, S.; Chouar, A.; Lmariouh, J.; Soulhi, A.; Elalami, J. A “Push-Pull” rearrangement while routing for a driverless delivery vehicle. Cogent Eng. 2019, 6, 1567662. [Google Scholar] [CrossRef]

- Botha, L.; Human, L.I.; Rossouw, M.E.; Nel, J.D. A framework to drive business growth in developing countries using omni-channel strategies. Int. J. Bus. Perform. Manag. 2023, 24, 344–374. [Google Scholar] [CrossRef]

- Febriani, A.; Sopha, B.M.; Wibisono, M.A. Dynamic capabilities for omnichannel transformation in MSMEs: A comparative case study of fashion and furniture sectors. J. Open Innov. Technol. Mark. Complex. 2025, 11, 100498. [Google Scholar] [CrossRef]

- Mrutzek-Hartmann, B.; Kotzab, H.; Yumurtacı Hüseyinoğlu, I.Ö.; Kühling, S. Omni-channel retailing resources and capabilities of SME specialty retailers–insights from Germany and Turkey. Int. J. Retail. Distrib. Manag. 2022, 50, 1129–1155. [Google Scholar] [CrossRef]

- Edison, H.; Wang, X.; Conboy, K. Comparing methods for large-scale agile software development: A systematic literature review. IEEE Trans. Softw. Eng. 2021, 48, 2709–2731. [Google Scholar] [CrossRef]

- Mrugalska, B.; Ahmed, J. Organizational agility in industry 4.0: A systematic literature review. Sustainability 2021, 13, 8272. [Google Scholar] [CrossRef]

- Tang, W.; Wang, T.; Xu, W. Sooner or Later? The Role of Adoption Timing in New Technology Introduction. Prod. Oper. Manag. 2022, 31, 1663–1678. [Google Scholar] [CrossRef]

- Pulka, B.M.; Gawuna, M.S. Contributions of SMEs to employment, gross domestic product, economic growth and development. Jalingo J. Soc. Manag. Sci. 2022, 4, 1–18. [Google Scholar]

- Enaifoghe, A.; Vezi-Magigaba, M.F. Conceptualizing the role of entrepreneurship and SME in fostering South Africa’s local economic development. Int. J. Res. Bus. Soc. Sci. 2023, 12, 96–105. [Google Scholar] [CrossRef]

- Cant, M.C.; Wiid, J.A. Establishing the challenges affecting South African SMEs. Int. Bus. Econ. Res. J. (Online) 2013, 12, 707. [Google Scholar] [CrossRef]

- Cant, M.C.; Erdis, C.; Sephapo, C.M. Business survival: The constraints experienced by South African SMEs in the financial sector. Int. J. Acad. Res. Bus. Soc. Sci. 2014, 4, 565. [Google Scholar] [CrossRef]

- Saghiri, S.; Bernon, M.; Bourlakis, M.; Wilding, R. Omni-channel logistics special issue. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 362–364. [Google Scholar] [CrossRef]

- Ferreira, L.; Steenkamp, E. Strategic intra-regional trade in Sub-Saharan Africa: Lessons from Southeast Asia. Afr. J. Dev. Stud. 2025, 15, 187–213. [Google Scholar]

- Masongsong, A.C.; Ulep, S.J.; Abante, M.V.; Cagang, M.L.; Vigonte, F. Digital Transformation of International Trade for SMEs in Developing Countries: Opportunities, Challenges. Available online: https://ssrn.com/abstract=4740033 (accessed on 23 February 2025).

- Mer, A.; Virdi, A.S. Decoding the challenges and skill gaps in small-and medium-sized enterprises in emerging economies: A review and re-search agenda. In Contemporary Challenges in Social Science Management: Skills Gaps and Shortages in the Labour Market; Emerald Publishing Limited: Leeds, UK, 2024; pp. 115–134. [Google Scholar]

- Singh, S.; Singh, R. Economic Imperatives of Evolving National Digital Policy: A Call for a Modern Industrial Policy Framework in India. Int. Trade J. 2022, 36, 572–593. [Google Scholar] [CrossRef]

- Feng, Z. Strategies for SMEs to develop international business in the context of internet plus. Acad. J. Bus. Manag. 2023, 5, 97–100. [Google Scholar] [CrossRef]

- Teixeira, J.E.; Tavares-Lehmann, A.T.C. Industry 4.0 in the European union: Policies and national strategies. Technol. Forecast. Soc. Change 2022, 180, 121664. [Google Scholar] [CrossRef]

- Thaichon, P.; Phau, I.; Weaven, S. Moving from multi-channel to Omni-channel retailing: Special issue introduction. J. Retail. Consum. Serv. 2022, 65, 102311. [Google Scholar] [CrossRef]

- Tien, N.H.; Hung-Anh, D.B.; Thuc, T.D. Global Supply Chain And Logistics Management; Academic Publications: Delhi, India, 2019. [Google Scholar]

- Mehrsai, A.; Karimi, H.R.; Thoben, K.D.; Scholz-Reiter, B. Using Metaheuristic and Fuzzy System for the Optimization of Material Pull in a Push-Pull Flow Logistics Network. Math. Probl. Eng. 2013, 2013, 359074. [Google Scholar] [CrossRef]

- Rau, H.; Budiman, S.D.; Monteiro, C.N. Improving the sustainability of a reverse supply chain system under demand uncertainty by using postponement strategies. Waste Manag. 2021, 131, 72–87. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Vilkas, M.; Grybauskas, A.; Amran, A. Drivers and barriers of Industry 4.0 technology adoption among manufacturing SMEs: A systematic review and transformation roadmap. J. Manuf. Technol. Manag. 2022, 33, 1029–1058. [Google Scholar] [CrossRef]

- Shahadat, M.H.; Nekmahmud Argon, N.; Pejman Ebrahimi, P.; Fekete-Farkas, M. Digital Technology Adoption in SMEs: What Technological, Environmental and Organizational Factors Influence in Emerging Countries? Glob. Bus. Rev. 2023, 24, 1–27. [Google Scholar] [CrossRef]

- Yuliawati, E.; Brilliana, C.; Rahmawati, N.; Trihastuti, D. Performance Evaluation of Logistics Service Provider (LSP) in FMCG Companies Using Physical Distribution Service Quality (PDSQ) Dimension: Case Study. J. Appl. Eng. Technol. Sci. (JAETS) 2023, 5, 101–111. [Google Scholar] [CrossRef]

- Rushton, A.; Croucher, P.; Baker, P. The Handbook of Logistics and Distribution Management: Understanding the Supply Chain; Kogan Page Publishers: London, UK; New York, NY, USA; New Delhi, India, 2022; Available online: https://books.google.com/books?hl=en&lr=&id=-jlUEAAAQBAJ&oi=fnd&pg=PR1&dq=physical+distribution+activities&ots=w_obrrYlGC&sig=pD38JMvyKq5IXddgtL3NSHeBG8g (accessed on 3 December 2024).

- Raja Santhi, A.; Muthuswamy, P. Influence of blockchain technology in manufacturing supply chain and logistics. Logistics 2022, 6, 15. [Google Scholar] [CrossRef]

- Melkonyan, A.; Gruchmann, T.; Lohmar, F.; Kamath, V.; Spinler, S. Sustainability assessment of last-mile logistics and distribution strategies: The case of local food networks. Int. J. Prod. Econ. 2020, 228, 107746. [Google Scholar] [CrossRef]

- Panigrahi, R.; Shrivastava, A.K.; Nudurupati, S.S. Impact of inventory management on SME performance: A systematic review. Int. J. Product. Perform. Manag. 2024, 73, 2901–2925. [Google Scholar] [CrossRef]

- Gu, M.; Yang, L.; Huo, B. The impact of information technology usage on supply chain resilience and performance: An ambidextrous view. Int. J. Prod. Econ. 2021, 232, 107956. [Google Scholar] [CrossRef]

- Abushaikho, I.; Salhied, L.; Towers, N. Improving distribution and business performance through lean warehousing. Int. J. Retail. Distrib. Manag. 2018, 46, 780–800. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, Q.; Chen, G.; Seng, D. A combined method for short-term traffic flow prediction based on recurrent neural network. Alex. Eng. J. 2021, 60, 87–94. [Google Scholar] [CrossRef]

- Lee, C.K.M.; Lv, Y.; Ng, K.K.H.; Ho, W.; Choy, K.L. Design and application of Internet of Things based Warehouse Management System for Smart Logistics. Int. J. Prod. Res. 2018, 56, 2753–2768. [Google Scholar] [CrossRef]

- Baruffaldi, G.; Accorsi, R.; Manzini, R. Warehouse management system customization and information availability in 3pl companies: A decision-support tool. Ind. Manag. Data Syst. 2018, 119, 251–273. [Google Scholar] [CrossRef]

- Tyan, J.C.; Wang, F.; Du, T.C. An evaluation of freight consolidation policies in global third party logistics. Omega 2003, 31, 55–62. [Google Scholar] [CrossRef]

- Tiwari, S.; Wee, H.M.; Zhou, Y.; Tjoeng, L. Freight consolidation and containerization strategy under business as usual scenario & carbon tax regulation. J. Clean. Prod. 2021, 279, 123270. [Google Scholar] [CrossRef]

- McKnight, D.H.; Lankton, N.K.; Nicolaou, A.; Price, J. Distinguishing the effects of B2B information quality, system quality, and service outcome quality on trust and distrust. J. Strateg. Inf. Syst. 2017, 26, 118–141. [Google Scholar] [CrossRef]

- Hung, J.L.; He, W.; Shen, J. Big data analytics for supply chain relationship in banking. Ind. Mark. Manag. 2020, 86, 144–153. [Google Scholar] [CrossRef]

- Sumah, B.; Masudin, I.; Zulfikarijah, F.; Restuputri, D.P. Logistics Management and Electronic Data Interchange Effects on Logistics Service Providers’ Competitive Advantage. J. Bus. Econ. Anal. 2020, 3, 171–194. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Papadopoulos, T.; Dubey, R.; Wamba, S.F.; Childe, S.J.; Hazen, B.; Akter, S. Big data and predictive analytics for supply chain and organizational performance. J. Bus. Res. 2017, 70, 308–317. [Google Scholar] [CrossRef]

- Benitez, G.B.; Ayala, N.F.; Frank, A.G. Chapter 19 - How Can SMEs Participate Successfully in Industry 4.0 Ecosystems? The Digital Supply Chain, MacCarthy, B.L., Ivanov, D., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 325–339. ISBN 9780323916141. [Google Scholar] [CrossRef]

- Moufaddal, M.; Benghabrit, A.; Bouhaddou, I. A Cyber-Physical Warehouse Management System Architecture in an Industry 4.0 Context. Artif. Intell. Ind. Appl. 2020, 125–148. [Google Scholar] [CrossRef]

- Cano, J.; Salazar-Arrieta, F.; Gómez-Montoya, R.; Cortés, P. Disruptive and Conventional Technologies for the Support of Logistics Processes: A Literature Review. Int. J. Technol. 2021, 12, 448–460. [Google Scholar] [CrossRef]

- Vuorio, A.; Torkkeli, L.; Sainio, L.M. Service innovation and internationalization in SMEs: Antecedents and profitability outcomes. J. Int. Entrep. 2020, 18, 92–123. [Google Scholar] [CrossRef]

- Asdecker, B. Building the E-Commerce Supply Chain of the Future: What Influences Consumer Acceptance of Alternative Places of Delivery on the Last-Mile. Logistics 2021, 5, 90. [Google Scholar] [CrossRef]

- Shretta, R.; Johnson, B.; Smith, L.; Doumbia, S.; De Savigny, D.; Anupindi, R.; Yadav, P. Costing the supply chain for delivery of ACT and RDTs in the public sector in Benin and Kenya. Malar. J. 2015, 14, 57. [Google Scholar] [CrossRef]

- Zarouk, Y.; Mahdavi, I.; Rezaeian, J.; Santos-Arteaga, F.J. A novel multi-objective green vehicle routing and scheduling model with stochastic demand, supply, and variable travel times. Comput. Oper. Res. 2022, 141, 105698. [Google Scholar] [CrossRef]

- Bhide, S.; Chakurkar, P. Decentralized Deep Reinforcement Learning for Intelligent Transportation Systems. In Proceedings of the 2024 International Conference on Advancements in Smart, Secure and Intelligent Computing (ASSIC), Bhubaneswar, India, 27–29 January 2024; pp. 1–7. [Google Scholar]

- Ray, S.; Soeanu, A.; Berger, J.; Debbabi, M. The multi-depot split-delivery vehicle routing problem: Model and solution algorithm. Knowl.-Based Syst. 2014, 71, 238–265. [Google Scholar] [CrossRef]

- Ehmke, J.F.; Mattfeld, D.C. Vehicle Routing for Attended Home Delivery in City Logistics. Procedia-Soc. Behav. Sci. 2012, 39, 622–632. [Google Scholar] [CrossRef][Green Version]

- Stock, G.N.; Greis, N.P.; Kasarda, J.D. Enterprise Logistics and Supply Chain Structure: The Role of Fit. J. Oper. Manag. 2000, 18, 531–547. [Google Scholar] [CrossRef]

- Holguín-Veras, J.; Sánchez-Díaz, I. Freight Demand Management and the Potential of Receiver-Led Consolidation programs. Transp. Res. Part A Policy Pract. 2016, 84, 109–130. [Google Scholar] [CrossRef]

- Guastaroba, G.; Speranza, M.G.; Vigo, D. Intermediate Facilities in Freight Transportation Planning: A Survey. Transp. Sci. 2016, 50, 763–789. [Google Scholar] [CrossRef]

- Harmon, R.L. Reinventing the Warehouse: World Class Distribution Logistics; Simon and Schuster: New York, NY, USA, 1993. [Google Scholar]

- Holguín-Veras, J.; Leal, J.A.; Sanchez-Diaz, I.; Browne, M.; Wojtowicz, J. State of the art and practice of urban freight management Part II: Financial approaches, logistics, and demand management. Transp. Res. Part A Policy Pract. 2020, 137, 383–410. [Google Scholar] [CrossRef]

- Osman, M.C.; Huge-Brodin, M.; Ammenberg, J.; Karlsson, J. Exploring green logistics practices in freight transport and logistics: A study of biomethane use in Sweden. Int. J. Logist. Res. Appl. 2022, 26, 548–567. [Google Scholar] [CrossRef]

- Konstantakopoulos, G.D.; Gayialis, S.P.; Kechagias, E.P. Vehicle routing problem and related algorithms for logistics distribution: A literature review and classification. Oper. Res. 2022, 22, 2033–2062. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A systematic review towards a new logistics system. Int. J. Prod. Res. 2019, 58, 18–43. [Google Scholar] [CrossRef]

- Zhong, R.; Huang, G.; Lan, S.; Dai, Q.Y.; Chen, X.; Zhang, T. A big data approach for logistics trajectory discovery from RFID-enabled production data. Int. J. Prod. Econ. 2015, 165, 260–272. [Google Scholar] [CrossRef]

- Dyer, J.H.; Singh, H. The relational view: Cooperative strategy and sources or interorganisaitonal competitive advantage. Acad. Manag. Rev. 1998, 23, 600–679. [Google Scholar] [CrossRef]

- Wu, H.; Li, Z.; King, B.; Ben Miled, Z.; Wassick, J.; Tazelaar, J.A. Distributed Ledger for Supply Chain Physical Distribution Visibility. Information 2017, 8, 137. [Google Scholar] [CrossRef]

- Moussaoui, I.; Williams, B.D.; Hofer, C.; Aloysius, J.A.; Waller, M.A. Drivers of Retail On-Shelf Availability: Systematic Review, Critical Assessment, and Reflections on the Road Ahead. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 516–535. [Google Scholar] [CrossRef]

- Kaswengi, J.; Lambey-Checchin, C. How logistics service quality and product quality matter in the retailer–customer relationship of food drive-throughs: The role of perceived convenience. Int. J. Phys. Distrib. Logist. Manag. 2020, 50, 535–555. [Google Scholar] [CrossRef]

- Davis-Sramek, B.; Ishfaq, R.; Gibson, B.J.; Defee, C. Examining retail business model transformation: A longitudinal study of the transition to omnichannel order fulfilment. Int. J. Phys. Distrib. Logist. Manag. 2020, 50, 557–576. [Google Scholar] [CrossRef]

- Zakaria, H.; Zailani, S.; Fernando, Y. Moderating Role of Logistics Information Technology on the Logistics Relationships and Logistics Service Quality. Oper. Supply Chain. Manag. 2010, 3, 134–147. [Google Scholar] [CrossRef]

- Bienstock, C.C.; Mentzer, J.T.; Bird, M.M. Measuring Physical Distribution Service Quality. J. Acad. Mark. Sci. 1997, 25, 31–44. [Google Scholar] [CrossRef]

- Kaplan, D.; Depaoli, S. Bayesian structural equation modeling. In Handbook of Structural Equation Modeling; Hoyle, R.H., Ed.; The Guilford Press: New York, NY, USA, 2012; pp. 650–673. [Google Scholar]

- Merkle, E.C.; Rosseel, Y. blavaan: Bayesian Structural Equation Models via Parameter Expansion. J. Stat. Softw. 2018, 85, 1–30. [Google Scholar] [CrossRef]

- Yuan, Y.; MacKinnon, D.P. Bayesian mediation analysis. Psychol. Methods 2009, 14, 301–322. [Google Scholar] [CrossRef]

- Hong, H.; Vispoel, W.P.; Martinez, A.J. Applying SEM, Exploratory SEM, and Bayesian SEM to Personality Assessments. Psych 2024, 6, 111–134. [Google Scholar] [CrossRef]

- Wei, Z.; Nathoo, F.S.; Masson, M.E.J. Investigating the Relationship Between the Bayes Factor and the Separation of Credible Intervals. University of Victoria. 2023. Available online: https://onlineacademiccommunity.uvic.ca/lindsaylab/wp-content/uploads/sites/4861/2023/03/Bayesian-Credible-Intervals.pdf (accessed on 3 December 2024).

- Hair, J.F.; Babin, B.J.; Ringle, C.M.; Sarstedt, M. Covariance-based structural equation modeling (CB-SEM): A SmartPLS 4 software tutorial. J. Mark. Anal. 2025, June, 1–16. [Google Scholar] [CrossRef]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM), 2nd ed.; SAGE Publications: Los Angeles, LA, USA, 2017. [Google Scholar]

- Amoako, T.; Sheng, Z.H.; Dogbe, C.S.K.; Pomegbe, W.W.K. Assessing the Moderation Role of ICT in the Relationship Between Supply Chain Integration and SME Performance. J. Ind. Integr. Manag. 2022, 7, 203–233. [Google Scholar] [CrossRef]

- Dubihlela, J.; Omoruyi, O. Barriers to effective supply chain management, implementation, and impact on business performance of SMEs in South Africa. J. Appl. Bus. Res. 2014, 30, 1019. [Google Scholar] [CrossRef]

- Saghiri, S.; Mirzabeiki, V. Omni-channel integration: The matter of information and digital technology. Int. J. Oper. Prod. Manag. 2021, 41, 1660–1710. [Google Scholar] [CrossRef]

- Hugos, M.H. Essentials of Supply Chain Management, 5th ed.; Wiley & Sons: Hoboken, NJ, USA, 2024. [Google Scholar]

- Grant, D.B.; Trautrims, A.; Wong, C.Y. Sustainable Logistics and Supply Chain Management: Principles and Practices for Sustainable Operations and Management, 2nd ed.; Kogen Page: London, UK, 2017. [Google Scholar]

- Keshipour, B.; Kangaarloye, S.J.; Sales, J.B. Study of ranking factors affecting the implementation of timely management of goods and equipment and its evaluation criteria in the power distribution company of the whole country using fuzzy AHP and fuzzy DEMATEL. Adv. Math. Financ. Appl. 2023, 8, 1239–1263. [Google Scholar]

- Reaidy, P.J.; Gunasekaran, A.; Spalanzani, A. Bottom-up approach based on Internet of Things for order fulfilment in a collaborative warehousing environment. Int. J. Prod. Econ. 2015, 159, 29–40. [Google Scholar] [CrossRef]

- De Vass, T.; Shee, H.; Miah, S.J. The effect of “Internet of Things” on supply chain integration and performance: An organisational capability perspective. Australas. J. Inf. Syst. 2018, 22. Available online: http://journal.acs.org.au/index.php/ajis/article/view/1734 (accessed on 4 December 2024). [CrossRef]

- Ozili, P.K. The Acceptable R-Square in Empirical Modelling for Social Science Research. In Advances in Knowledge Acquisition. Transfer, and Management; IGI Global: Hershey, PA, USA, 2023; pp. 134–143. Available online: https://www.irma-international.org/viewtitle/320215/?isxn=9781668468593 (accessed on 4 December 2024).

- Al Shukaili, S.M.S.; Jamaluddin, Z.; Zulkifli, N. The impact of strategic inventory management on logistics organization’s performance. Int. J. Bus. Technol. Manag. 2023, 5, 288–298. [Google Scholar]

- Pasupuleti, V.; Thuraka, B.; Kodete, C.S.; Malisetty, S. Enhancing supply chain agility and sustainability through machine learning: Optimization techniques for logistics and inven-tory management. Logistics 2024, 8, 73. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).