Influence of Supply Chain Ambidexterity on Supply Chain Sustainability: The Mediating Role of Green Product Innovation

Abstract

1. Introduction

2. Literature Review

2.1. Green Innovation, Supply Chain Ambidexterity, and Sustainability

Synthesis of Literature on Ambidexterity, Green Product Innovation, and Supply Chain Sustainability

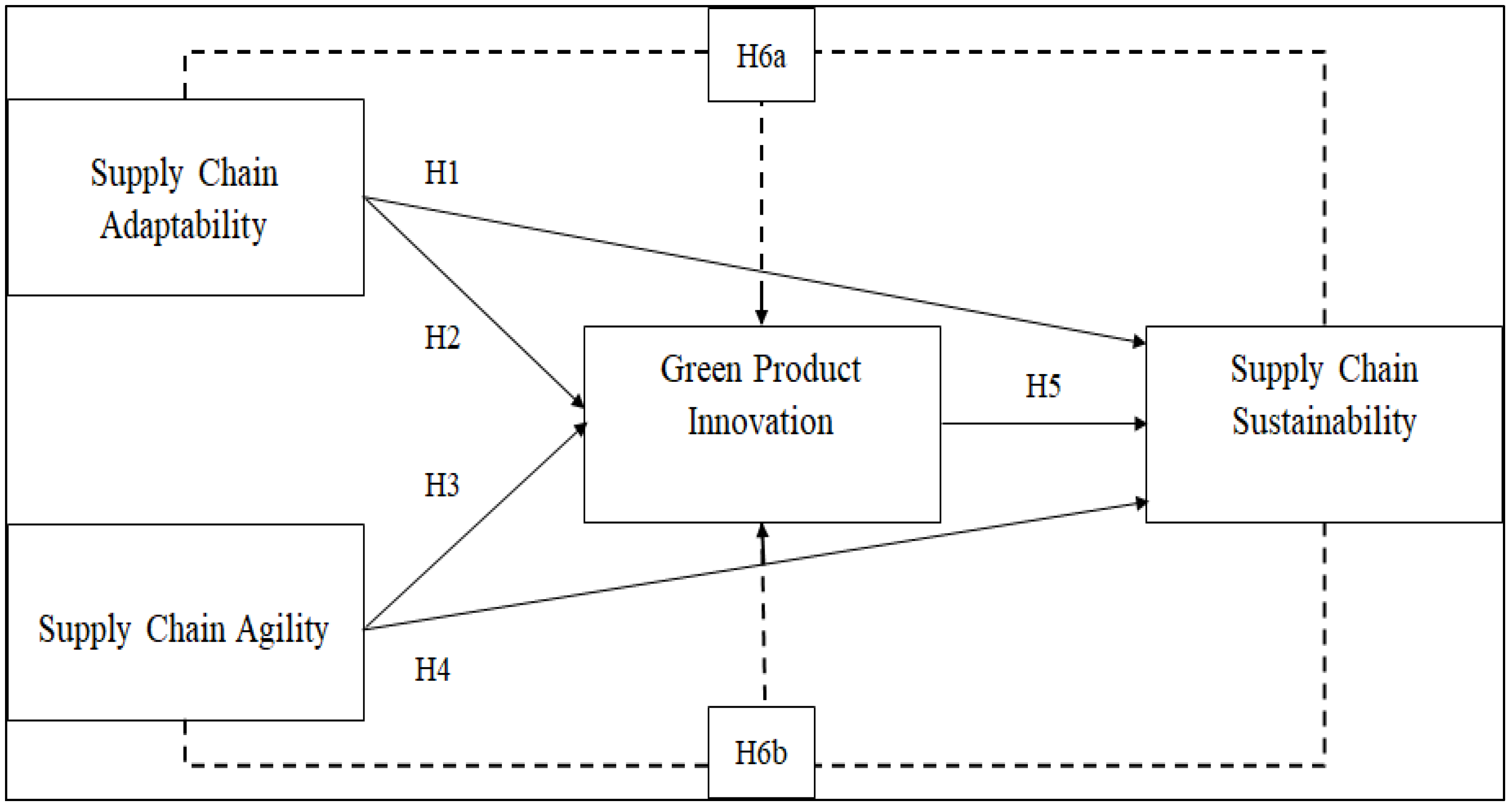

2.2. Hypotheses of the Conceptual Framework

2.2.1. Impact of Supply Chain Adaptability

2.2.2. Impact of Supply Chain Agility

2.2.3. Impact of GPI on Supply Chain Sustainability

2.2.4. Mediating Role of GPI

3. Methodology

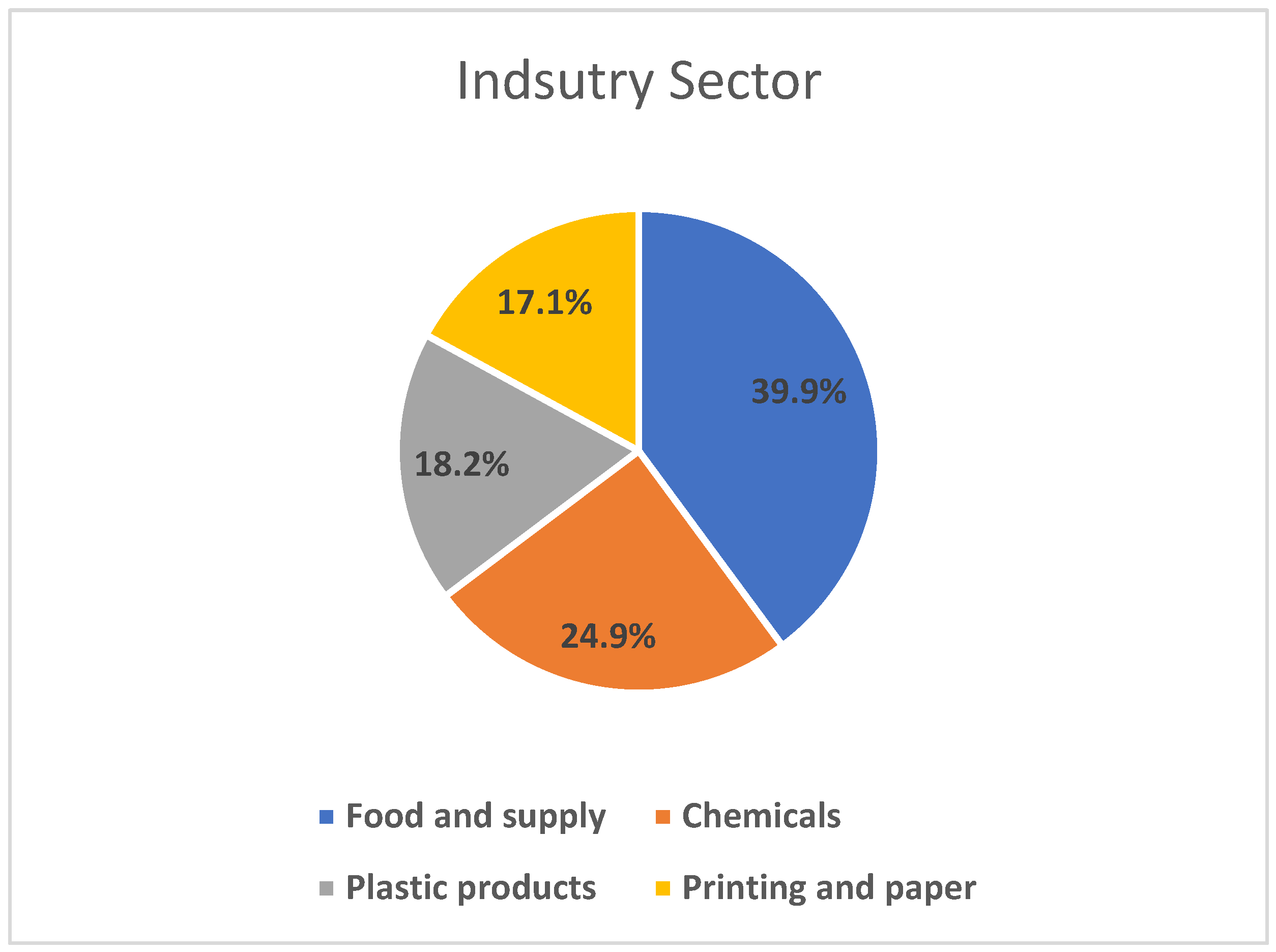

3.1. Sampling Procedure

3.2. Measurement Items

4. Findings

4.1. Descriptive Analysis

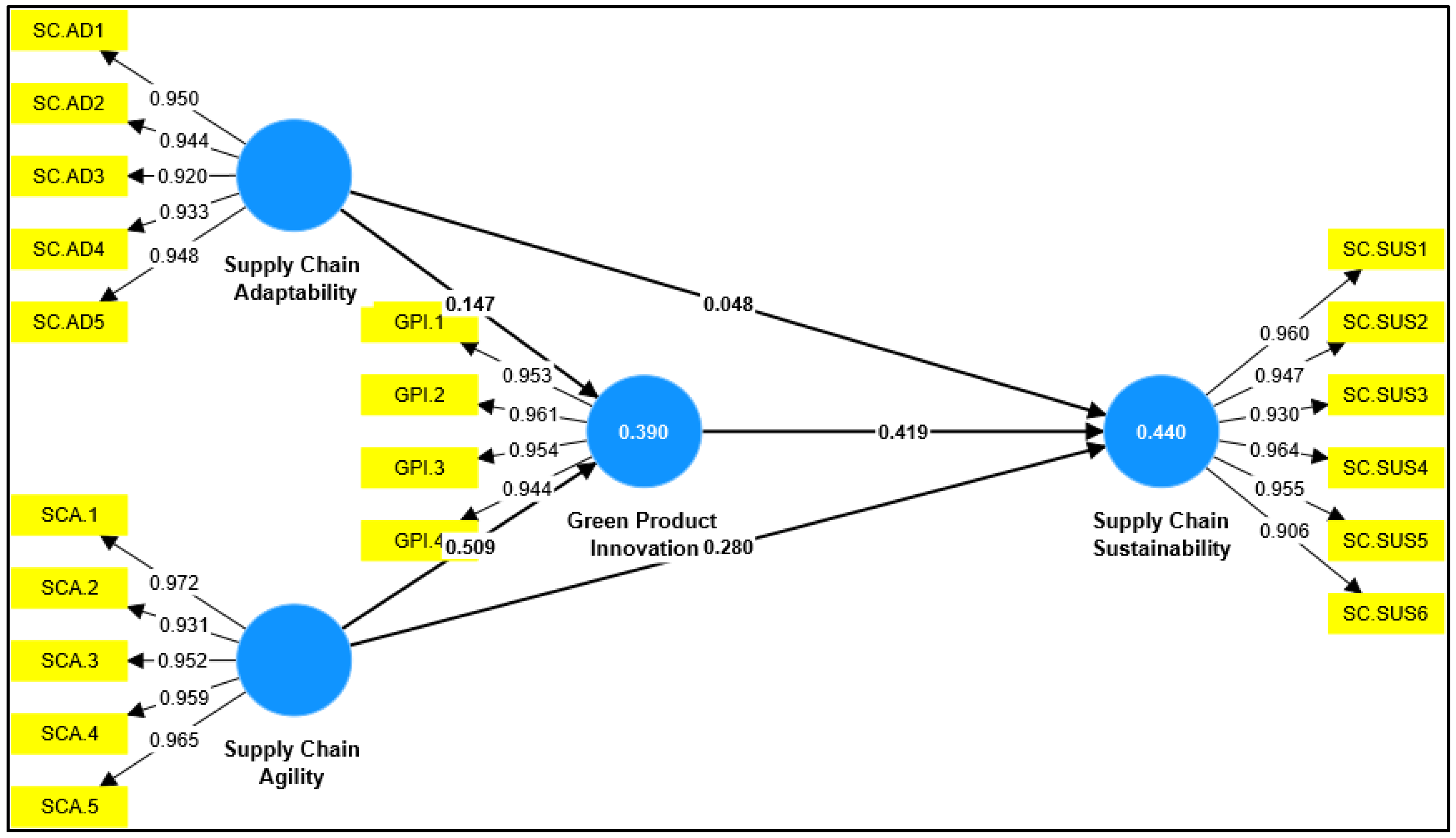

4.2. Structural Equation Modeling

4.2.1. Measurement Model Analysis

4.2.2. Measurement Model Analysis

5. Discussion

Managerial Implications

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Awewomom, J.; Dzeble, F.; Takyi, Y.D.; Ashie, W.B.; Ettey, E.N.Y.O.; Afua, P.E.; Sackey, L.N.; Opoku, F.; Akoto, O. Addressing global environmental pollution using environmental control techniques: A focus on environmental policy and preventive environmental management. Discov. Environ. 2024, 2, 8. [Google Scholar] [CrossRef]

- Al-khawaldah, R.A.; Al-zoubi, W.K.; Alshaer, S.A.; Almarshad, M.N.; ALShalabi, F.S.; Altahrawi, M.H.; Al-hawary, S.I. Green supply chain management and competitive advantage: The mediating role of organizational ambidexterity. Uncertain Supply Chain Manag. 2022, 10, 961–972. [Google Scholar] [CrossRef]

- Hayat, K.; Qingyu, Z. The synergistic effects of green innovation strategies on sustainable innovative performance with the mediation of green innovative competitive advantage. Corp. Soc. Respon. Environ. Manag. 2024, 31, 4172–4189. [Google Scholar] [CrossRef]

- Sun, Y.; Sun, H. Green innovation strategy and ambidextrous green innovation: The mediating effects of green supply chain integration. Sustainability 2021, 13, 4876. [Google Scholar] [CrossRef]

- Cancela, B.L.; Coelho, A.; Duarte Neves, M.E. Greening the business: How ambidextrous companies succeed in green innovation through to sustainable development. Bus. Strateg. Environ. 2023, 32, 3073–3087. [Google Scholar] [CrossRef]

- Stei, G.; Rossmann, A.; Szász, L. Leveraging organizational knowledge to develop agility and improve performance: The role of ambidexterity. Int. J. Oper. Prod. Manag. 2024, 44, 1446–1466. [Google Scholar] [CrossRef]

- Hashem, G.; Aboelmaged, M.; Ahmad, I. Proactiveness, knowledge management capability and innovation ambidexterity: An empirical examination of digital supply chain adoption. Manag. Decis. 2024, 62, 129–162. [Google Scholar] [CrossRef]

- Ahmad, F.; Khokhar, S. Examining the impact of sustainable supply chain management practices and supply chain ambidexterity on sustainability performance. Oper. Suppl. Chain. Manag. Int. J. 2024, 17, 179–190. [Google Scholar] [CrossRef]

- Mishra, N.K.; Pande Sharma, P.; Chaudhary, S.K. Redefining agile supply chain practices in the disruptive era: A case study identifying vital dimensions and factors. J. Glob. Oper. Strat. Sourc. 2025, 18, 64–90. [Google Scholar] [CrossRef]

- Wamba, S.F.; Dubey, R.; Gunasekaran, A.; Akter, S. The performance effects of big data analytics and supply chain ambidexterity: The moderating effect of environmental dynamism. Int. J. Prod. Econ. 2020, 222, 107498. [Google Scholar] [CrossRef]

- Jum’a, L.; Zighan, S.; Alkalha, Z. Influence of supply chain digitalization on supply chain agility, resilience and performance: Environmental dynamism as a moderator. J. Manufac. Tech. Manag. 2025, 36, 798–819. [Google Scholar] [CrossRef]

- Alamsjah, F.; Yunus, E.N. Achieving Supply Chain 4.0 and the Importance of Agility, Ambidexterity, and Organizational Culture: A Case of Indonesia. J. Open Innov. Techno. Mark. Compl. 2022, 8, 83. [Google Scholar] [CrossRef]

- Jermsittiparsert, K.; Pithuk, L. Exploring the Nexus Between Supply Chain Ambidexterity, Supply Chain Agility, Supply Chain Adaptability and The Marketing Sensing of Manufacturing Firms in Indonesia. Human. Soc. Scinc. Rev. 2019, 7, 555–562. [Google Scholar] [CrossRef]

- Jum’a, L. The impact of green supply chain management practices on sustainable development goals: The case of mining sector in Jordan. Environ. Develop. 2023, 48, 100934. [Google Scholar] [CrossRef]

- Khan, A.; Chen, C.C.; Lu, K.H.; Wibowo, A.; Chen, S.C.; Ruangkanjanases, A. Supply Chain Ambidexterity and Green SCM: Moderating Role of Network Capabilities. Sustainability 2021, 13, 5974. [Google Scholar] [CrossRef]

- Hsu, C.H.; He, X.; Zhang, T.Y.; Chang, A.Y.; Liu, W.L.; Lin, Z.Q. Enhancing Supply Chain Agility with Industry 4.0 Enablers to Mitigate Ripple Effects Based on Integrated QFD-MCDM: An Empirical Study of New Energy Materials Manufacturers. Mathematics 2022, 10, 1635. [Google Scholar] [CrossRef]

- Eckstein, D.; Goellner, M.; Blome, C.; Henke, M. The performance impact of supply chain agility and supply chain adaptability: The moderating effect of product complexity. Int. J. Prod. Res. 2015, 53, 3028–3046. [Google Scholar] [CrossRef]

- Pasupuleti, V.; Thuraka, B.; Kodete, C.S.; Malisetty, S. Enhancing supply chain agility and sustainability through machine learning: Optimization techniques for logistics and inventory management. Logistics 2024, 8, 73. [Google Scholar] [CrossRef]

- Chan, H.K.; Yee, R.W.Y.; Dai, J.; Lim, M.K. The moderating effect of environmental dynamism on green product innovation and performance. Int. J. Prod. Econ. 2016, 181, 384–391. [Google Scholar] [CrossRef]

- Jum’a, L.; Zimon, D.; Ikram, M.; Madzík, P. Towards a sustainability paradigm; the nexus between lean green practices, sustainability-oriented innovation and Triple Bottom Line. Int. J. Prod. Econ. 2022, 245, 108393. [Google Scholar] [CrossRef]

- Kara, K.; Edinsel, S. The mediating role of green product innovation (GPI) between green human resources management (GHRM) and green supply chain management (GSCM): Evidence from automotive industry companies in Turkey. Suppl. Chain Forum Int. J. 2023, 24, 488–509. [Google Scholar] [CrossRef]

- Jum’a, L.; Zimon, D.; Sroufe, R.; Tyan, J. Sustainable supply chain management’s impact on triple bottom line performance: Does the firm size matter? Corp. Soc. Rapson. Environ. Manag. 2024, 31, 4673–4693. [Google Scholar] [CrossRef]

- Alamsjah, F.; Asrol, M. Supply chain ambidexterity and performance under uncertainty: The case of inter-island logistics in Indonesia. Uncertain Supply Chain Manag. 2023, 10, 759–770. [Google Scholar] [CrossRef]

- Rojo, A.; Llorens-Montes, J.; Perez-Arostegui, M.N. The impact of ambidexterity on supply chain flexibility fit. Suppl. Chain Manag. Int. J. 2016, 21, 433–452. [Google Scholar] [CrossRef]

- Rintala, O.; Laari, S.; Solakivi, T.; Töyli, J.; Nikulainen, R.; Ojala, L. Revisiting the relationship between environmental and financial performance: The moderating role of ambidexterity in logistics. Int. J. Prod. Econ. 2022, 248, 108479. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, X.; Jiang, W.; Feng, T. Does second-order social capital matter to green innovation? The moderating role of governance ambidexterity. Sustain. Product. Consump. 2021, 25, 271–284. [Google Scholar] [CrossRef]

- Aftab, J.; Veneziani, M.; Sarwar, H.; Ishaq, M.I. Organizational ambidexterity, firm performance, and sustainable development: Mediating role of entrepreneurial orientation in Pakistani SMEs. J. Clean. Prod. 2022, 367, 132956. [Google Scholar] [CrossRef]

- Belhadi, A.; Kamble, S.; Gunasekaran, A.; Mani, V. Analyzing the mediating role of organizational ambidexterity and digital business transformation on industry 4.0 capabilities and sustainable supply chain performance. Supply Chain. Manag. Int. J. 2022, 27, 696–711. [Google Scholar] [CrossRef]

- Zhang, Q.; Pan, J.; Feng, T. Green supplier integration and environmental performance: Do environmental innovation and ambidextrous governance matter? Int. J. Physic. Disturb. Logist. Manag. 2020, 50, 693–719. [Google Scholar] [CrossRef]

- Melaku, T.; Mekonnen, Z.; Tucho, G.T.; Viana, J.; Årdal, C.; Jahre, M. Resilience and Adaptability in Paracetamol Supply Chains: A Systems Perspective on COVID-19 Challenges and Responses in Ethiopia. Logistics 2025, 9, 15. [Google Scholar] [CrossRef]

- Shan, H.; Li, Y.; Shi, J. Influence of Supply Chain Collaborative Innovation on Sustainable Development of Supply Chain: A Study on Chinese Enterprises. Sustainability 2020, 12, 2978. [Google Scholar] [CrossRef]

- Mirghafoori, S.H.; Andalib, D.; Keshavarz, P. Developing Green Performance Through Supply Chain Agility in Manufacturing Industry: A Case Study Approach. Corpo. Soc. Respons. Environ. Manag. 2017, 24, 368–381. [Google Scholar] [CrossRef]

- Saudi, M.H.M.; Sinaga, O.; Zainudin, Z. The Effect of Green Innovation in Influencing Sustainable Performance: Moderating role of Managerial Environmental Concern. Int. J Sup. Chain. Mgt. 2019, 8, 303–310. [Google Scholar]

- Seman, N.A.A.; Govindan, K.; Mardani, A.; Zakuan, N.; Saman, M.Z.M.; Hooker, R.E.; Ozkul, S. The mediating effect of green innovation on the relationship between green supply chain management and environmental performance. J. Clean. Prod. 2019, 229, 115–127. [Google Scholar] [CrossRef]

- Mohamed, S.K.; Haddad, S.; Barakat, M.; Rosi, B. Blockchain Technology Adoption for Improved Environmental Supply Chain Performance: The Mediation Effect of Supply Chain Resilience, Customer Integration, and Green Customer Information Sharing. Sustainability 2023, 15, 7909. [Google Scholar] [CrossRef]

- Awwad, A.; Anouze, A.L.M.; Ndubisi, N.O. Green Customer and Supplier Integration for Competitive Advantage: The Mediation Effect of Sustainable Product Innovation. Sustainability 2022, 14, 10153. [Google Scholar] [CrossRef]

- Malhotra, N.K. Marketing Research: An Applied Orientation, 6th ed.; Prentice Hall: Englewood Cliffs, NJ, USA, 2010. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 8th ed.; Cengage: Boston, MA, USA, 2019. [Google Scholar]

- Eslami, M.H.; Jafari, H.; Achtenhagen, L.; Carlbäck, J.; Wong, A. Financial performance and supply chain dynamic capabilities: The Moderating Role of Industry 4.0 technologies. Int. J. Prod. Res. 2021, 62, 8092–8109. [Google Scholar] [CrossRef]

- Zheng, G.W.; Siddik, A.B.; Masukujjaman, M.; Fatema, N. Factors affecting the sustainability performance of financial institutions in Bangladesh: The role of green finance. Sustainability 2021, 13, 10165. [Google Scholar] [CrossRef]

- Ringle, C.M.; Wende, S.; Becker, J.M. SmartPLS 3. SmartPLS GmbH, Boenningstedt. J. Serv. Scien. Manag. 2015, 10, 32–49. [Google Scholar]

- Fornell, C.; Larcker, D.F. Structural Equation Models with Unobservable Variables and Measurement Error: Algebra and Statistics. J. Market. Res. 1981, 18, 382–388. [Google Scholar] [CrossRef]

- Byrne, B.M. Structural Equation Modeling with AMOS: Basic Concepts, Applications, and Programming, 2nd ed.; Routledge: Oxfordshire, UK, 2013. [Google Scholar]

- Dong, T.; Yin, S.; Zhang, N. The Interaction Mechanism and Dynamic Evolution of Digital Green Innovation in the Integrated Green Building Supply Chain. Systems 2023, 11, 122. [Google Scholar] [CrossRef]

| Study | Independent Variables | Dependent Variables | Other Variables (Mediating/ Moderating) |

|---|---|---|---|

| Ahmad and Khokhar [8] | Sustainable supply chain management (SSCM) practices | Sustainability performance | Supply chain ambidexterity |

| Stei et al. [6] | Organizational ambidexterity (Exploration and exploitation) | Organizational agility and performance | Environmental competitiveness (a firm’s ability to gain a competitive advantage through environmentally sustainable practices) |

| Cancela et al. [5] | Ambidexterity (Exploration and exploitation) | GPI, business performance | Consumer pressure |

| Kara and Edinsel [21] | GHRM | GSCM | GPI |

| Aftab et al. [27] | Ambidexterity in organizations | Company’s successful financial performance, environmental sustainability | Entrepreneurial mindset |

| Alamsjah and Yunus [12] | Supply chain ambidexterity | SC 4.0 Maturity (the extent to which a company has adopted Industry 4.0 technologies within its supply chain operations) | Supply chain agility |

| Alamsjah and Asrol [23] | Supply chain ambidexterity | Supply chain performance | Agile and lean supply chain |

| Al-khawaldah et al. [2] | Green supply chain practices | Competitive advantage | Organizational ambidexterity |

| Belhadi et al. [28] | Organizational ambidexterity and Industry 4.0 capabilities | Sustainable performance | Digital business transformation, circular business models |

| Rintala et al. [25] | Ambidexterity | Economic and environmental sustainability | Exploratory orientation (Refers to a firm’s strategic focus on experimentation, risk-taking, and the pursuit of novel opportunities) |

| Khan et al. [15] | Ambidextrous supply chain | GSCM | Networking capabilities (Denote a firm’s ability to build, manage, and leverage relationships with external partners such as suppliers and customers) |

| Sun and Sun [4] | Ambidextrous green innovation | Green innovation strategy | Green supply chain integration |

| Zhang et al. [29] | Green supplier integration | Environmental performance | Ambidextrous management |

| Jermsittiparsert and Pithuk [13] | Supply chain ambidexterity, agility, adaptability | Market sensing (Involves the firm’s capacity to detect, interpret, and respond to emerging market trends, customer needs, and competitive dynamics) | Agility, adaptability |

| Constructs | Measurement Items | Sources |

|---|---|---|

| Supply Chain Adaptability |

| [10,17] |

| Supply Chain Agility |

| [10,11,39] |

| Green product innovation (GPI) |

| [19,21] |

| Supply Chain Sustainability |

| [20,22,40] |

| Constructs | Mean | Std. Deviation | Skewness | Std. Error | Kurtosis | Std. Error |

|---|---|---|---|---|---|---|

| Supply Chain Adaptability | 3.7873 | 0.95563 | −1.238 | 0.131 | 1.371 | 0.261 |

| Supply Chain Agility | 3.9647 | 0.95050 | −1.643 | 0.131 | 2.490 | 0.261 |

| GPI | 4.0007 | 0.93415 | −1.614 | 0.131 | 2.202 | 0.261 |

| Supply Chain Sustainability | 3.6479 | 1.00780 | −1.230 | 0.131 | 0.750 | 0.261 |

| Constructs | Items | Factor Loadings | Cronbach’s Alpha | Composite Reliability | AVE |

|---|---|---|---|---|---|

| GPI | GPI.1 | 0.953 | 0.966 | 0.975 | 0.909 |

| GPI.2 | 0.961 | ||||

| GPI.3 | 0.954 | ||||

| GPI.4 | 0.944 | ||||

| Supply Chain Adaptability | SC.AD1 | 0.950 | 0.967 | 0.974 | 0.882 |

| SC.AD2 | 0.944 | ||||

| SC.AD3 | 0.920 | ||||

| SC.AD4 | 0.933 | ||||

| SC.AD5 | 0.948 | ||||

| Supply Chain Sustainability | SC.SUS1 | 0.960 | 0.975 | 0.980 | 0.891 |

| SC.SUS2 | 0.947 | ||||

| SC.SUS3 | 0.930 | ||||

| SC.SUS4 | 0.964 | ||||

| SC.SUS5 | 0.955 | ||||

| SC.SUS6 | 0.906 | ||||

| Supply Chain Agility | SCA.1 | 0.972 | 0.976 | 0.982 | 0.914 |

| SCA.2 | 0.931 | ||||

| SCA.3 | 0.952 | ||||

| SCA.4 | 0.959 | ||||

| SCA.5 | 0.965 |

| Constructs | 1. | 2. | 3. | 4. |

|---|---|---|---|---|

| 0.953 | |||

| 0.517 | 0.939 | ||

| 0.616 | 0.726 | 0.956 | |

| 0.616 | 0.467 | 0.572 | 0.944 |

| Constructs | 1. | 2. | 3. | 4. |

|---|---|---|---|---|

| ||||

| 0.534 | |||

| 0.633 | 0.481 | ||

| 0.633 | 0.748 | 0.586 |

| Paths | Beta | t-Statistics | p-Values | Results |

|---|---|---|---|---|

| H1. SC Adaptability -> SC Sustainability | 0.048 | 0.806 | 0.420 n.s. | Not Supported |

| H2. SC Adaptability -> GPI | 0.147 | 2.773 | 0.006 ** | Supported |

| H3. SC Agility -> GPI | 0.509 | 7.777 | 0.000 *** | Supported |

| H4. SC Agility -> SC Sustainability | 0.280 | 4.177 | 0.000 *** | Supported |

| H5. GPI -> SC Sustainability | 0.419 | 6.495 | 0.000 *** | Supported |

| H6a. SC Adaptability -> GPI -> SC Sustainability | 0.062 | 2.404 | 0.016 * | Supported |

| H6b. SC Agility -> GPI -> SC Sustainability | 0.213 | 5.617 | 0.000 *** | Supported |

| Hypothesis | The Study’s Finding | Related Studies | Consistency/Difference |

|---|---|---|---|

| H1: Supply chain adaptability → Supply chain sustainability | Not supported | [10,12,13,17,24] | Differs—prior studies found a significant direct effect; this study suggests adaptability alone is insufficient without green innovation. |

| H2: Supply chain adaptability → GPI | Supported | [4,15,21] | Consistent—aligns with findings that adaptability enables collaboration and technology adoption essential for green innovation. |

| H3: Supply chain agility → GPI | Supported | [5,13,29] | Consistent—confirms agility enhances responsiveness to supply chain sustainability demands and facilitates innovation. |

| H4: Supply chain agility → Supply chain sustainability | Supported | [10,12,13] | Consistent—reinforces the role of agility in improving supply chain responsiveness, efficiency, and environmental outcomes. |

| H5: GPI → Supply chain sustainability | Supported | [2,5,19,21,33] | Consistent—echoes prior work showing that eco-friendly product development improves supply chain sustainability performance. |

| H6a: GPI mediates SC adaptability → SC sustainability | Supported | [4,21] | Partial alignment—prior work suggested indirect effects; this study confirms the mediation empirically in a Jordanian context. |

| H6b: GPI mediates SC agility → SC sustainability | Supported | [4,19,33,36] | Consistent—supports the bridging role of GPI between agile capabilities and supply chain sustainability outcomes. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jum’a, L.; Zaid, A.A.; Othman, M. Influence of Supply Chain Ambidexterity on Supply Chain Sustainability: The Mediating Role of Green Product Innovation. Logistics 2025, 9, 87. https://doi.org/10.3390/logistics9030087

Jum’a L, Zaid AA, Othman M. Influence of Supply Chain Ambidexterity on Supply Chain Sustainability: The Mediating Role of Green Product Innovation. Logistics. 2025; 9(3):87. https://doi.org/10.3390/logistics9030087

Chicago/Turabian StyleJum’a, Luay, Ahmed Adnan Zaid, and Mohammed Othman. 2025. "Influence of Supply Chain Ambidexterity on Supply Chain Sustainability: The Mediating Role of Green Product Innovation" Logistics 9, no. 3: 87. https://doi.org/10.3390/logistics9030087

APA StyleJum’a, L., Zaid, A. A., & Othman, M. (2025). Influence of Supply Chain Ambidexterity on Supply Chain Sustainability: The Mediating Role of Green Product Innovation. Logistics, 9(3), 87. https://doi.org/10.3390/logistics9030087