Abstract

Currently, the supplier selection process is considered as an integral part of the supply chain. The appropriate selection of suppliers plays a preponderant role in the performance chain of supply as it determines relevant aspects such as cost management and flexibility of most production processes. Background: It is considered a multi-criteria and multi-objective problem because it includes both qualitative and quantitative factors. Method: To solve the Supplier Selection and Fair Order Allocation Problem (SSFOAP), a hybrid solution methodology based on the best–worst method (BWM) and MMD-TOPSIS techniques in the first phase has been developed to find a robust ranking of suppliers. In the second phase to determine the weight of the objective function, the Linear Programming (LP) approach is used. Results: This proposed model can help decisionmakers find the right orders for each supplier and enable purchasing managers to manage supply chain performance in terms of cost, quality, and service. To test the performance of our solution methodology, we apply our hybrid technique to solve a real case of the Tunisian Electric Society (TSE). Cplex software is used to solve bi-objective programming and to answer strategic questions. Conclusions: The experimental results indicate that the combination of MMD-TOPSIS and bi-objective programming provide effective gain concerning solution quality compared with the given solution of the administrator of TSE.

1. Introduction

The era of globalization has led to intense competition in the industrial sector. To win the competition, every company tries to reduce costs, improve product quality, and improve service quality. One of the important activities in companies in the industrial sector is the selection of suppliers. This activity is directly related to areas of company performance, one of which is financial performance. The selection of suppliers has the aim of building a long-term partnership relationship with suppliers. It is enough for companies to partner with several suppliers, but the relationship must be trusted [1].

To improve company performance, management needs to have a certain strategy in achieving the company’s vision and mission that has been set. Suppliers are business partners who play an important role in ensuring the availability of goods the company needs. In the supply chain concept [2,3], suppliers play a very important role and influence the continuity of the company’s production. Problems in the delivery of goods from the supplier will cause stockouts and long lead times. The most crucial function performed by the purchasing department is to select the best suppliers to improve the supply chain efficiency.

The correct selection of suppliers has been and will be one of the major concerns of the industry in general, and therefore the operation of tools that facilitate the incorporation of strategies that facilitate decision-making processes regardless of the complexity of the scenario, the use of decision methodologies, such as multi-criteria analysis, provides organizations with sufficient capacity to react to complex events to the extent that they can structure the problem and deal with it in a systematic way.

Selecting the best suppliers in the procurement function requires consideration if we are going to rely on single or multiple sourcing purchasing strategies. The SSFOAP is an important strategic decision in the procurement process which the decision-maker optimizes. Many researchers have addressed the importance of these two problems, which is one of the problems that the decision makers in the procurement function need to optimize.

Decision making in an organization is a very important and critical process. One of the significant activities that affects organizational performance is supplier selection. Ideally, supplier selection should not only consider one factor, such as price or other factors, but should also involve many influencing factors. One method that can be used is the TOPSIS method, which was developed by Ching-Lai Hwang and Yoon in 1981. This method chooses the alternative that has the longest geometric distance from the negative ideal solution (NIS) [4,5] and the shortest geometric distance from the positive ideal solution (PIS).

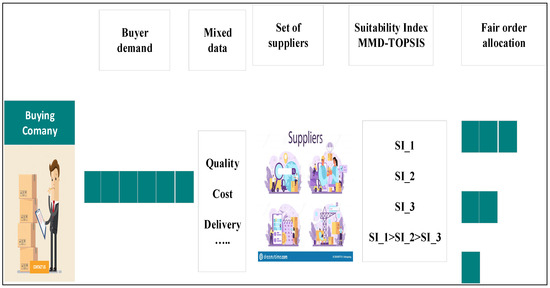

Supply Chain Management is an efficient process consisting of several suppliers, factories, warehouses, and stores. The principal objective of supply chain management is to satisfy the customer demand with efficient use of resources as distribution capacity, inventory, and human resources (e.g., [6,7,8]). According to [9], the supplier selection topic is an MCDM issue that considers mixed criteria (qualitative and quantitative criteria). The relative importance of these criteria and sub-criteria are considered among the principal role of procurement managers. Figure 1 describes the stages of supplier selection and the fair order allocation problem.

Figure 1.

Supplier selection and fair order allocation problem.

Research in the literature has studied the problem of supplier selection and order allocation by using the hybrid MCDM methods and mathematical models. Up to now, no research investigated this problem by combining BWM and MMD-TOPSIS methods to evaluate suppliers. Moreover, reviewing existing literature, we remark that the mathematical optimization models developed to model the order allocation problem between suppliers do not consider the notion of equitable sharing.

The objectives of this research are to first propose a robust methodology that considers mixed data in the supplier selection problem and make the final rang robust by combining the BWM method that is considered the best and worst criteria and the MMD-TOPSIS method which consider the mixed criteria and the meaningfulness normalization procedure that do not consider in standard TOPSIS method. The second objective is to allocate the order quantity proportionality between the different suppliers and make the final result remain robust based on the suitable rank of suppliers obtained by combining the MCDM method.

This research develops a novel approach based on dependent phases for selecting supplier and order quantity allocation issues that take into consideration the BWM method and MMD-TOPSIS procedure in the first phase and the fairness order allocating among different suppliers in the next phase.

In the first step, we determine the criteria weight by the BWM method, and we spread on the MMD-TOPSIS for evaluating the suppliers considering the mixed criteria (qualitative and quantitative criteria). In the second step, we develop an LP to allocate the demand fairly among the select suppliers obtained in the previous phase. The main strategic questions are: What are the evaluating criteria of suppliers? What is the rank of suppliers? How can the order amounts be fairly allocated between suppliers?

The contribution of this paper develops a new, hybrid, MCDM method based on the worst and best criterion and the meaningfulness concept. We combine the Best-Worst method, MMD-TOPSIS method, and bi-objective LP for resolving the SSFOAP. The BWM method is considered to determine the weights of criteria. The MMD-TOPSIS method is applied to rank suppliers. This method is suggested to determine the meaningful suitability index (MSI) of suppliers. Secondly, we define a bi-objective LP to distribute the order quantity fairly between suppliers by considering their meaningful suitability index. Decision-maker considers minimizing the total purchasing cost and the threshold of fair order allocation constraints (such as demand, capacity, Inventory space, etc.).

Our main goal in this study was to address the almost total lack of research evidence on what it means to use an integrated method to solve the fair supplier selection and order allocation problem. We did this by observing and reporting directly on the day-to-day work of a company in selecting suppliers, with particular attention paid to the practices by which these leaders are informed for all practical purposes, as dictated by their specific work.

This Tunisian real-case study is considered to show the efficiency of our proposed integrated approach.

The results obtained show the efficiency and the performance of the proposed approach which makes the decision in the multi-criteria decision process easy and robust, regardless of the measurement scale used in the context of mixed criteria.

In the next section, a literature review on the topics is given. Section 3 is a problem description of SSFOAP. Section 4 develops a solution methodology to find the optimal result of the embedded integer model for a system with real-valued data of TSE Company. Section 5 provides numerical experimental results with a discussion of our contributions to managerial and policy implications for SSFOAP in the Tunisian case study. We conclude the paper in Section 6.

2. Literature Review

2.1. Supplier Selection Problem

The supplier selection process consists of identifying the number of potential suppliers that can be chosen to satisfy the needs of firms and take care of the supply chain. Selecting the best suppliers is an MCDM problem that contains qualitative and quantitative factors.

The successful implementation of SCM is achieved through the strategic selection of suppliers (e.g., [10]). The development of suppliers is a way to increase the competitiveness of the entire supply chain. (e.g., [11,12,13]).

Supplier selection is a significant activity in the enterprise because it can reduce the total cost of goods and grow company competitiveness. In addition, quality of demand, delivery time, and costs enhance the complexity of this supplier selection decision in an increasingly globalized market competition (e.g., [14]).

Ref. [15] identified 23 criteria for supplier selection based on a purchasing manager questionnaire. In [16] they have studied 74 articles discussing the criteria in the supplier selection problem and the authors concluded that the priority of each criterion depends on each purchasing situation. Based on the study of [15,16] the most important criteria for supplier selection are based on the rating.

Ref. [17] have firstly shown that 68 papers (87.18%) consider quality in the process of supplier selection. They showed that delivery is the second popular criterion 82.05% of papers. Ref. [18] summarized the different selection criteria, and they concluded that the most important criteria are price, delivery, and quality. Recently, ref. [9] presented a systematic review of papers published between 2000 and 2017 on this topic.

In fact, in the theory of decision-making aid, the representation of each criterion assigns a performance to each potential action based on a specific scale and takes into consideration a preference system linked to a given point of view. If we consider several points of view, the main objective of the multi-criterion aggregation procedure (MCAP) is to construct a global preference system when takes all the points of view. The statement of “the a is strictly preferred to b” is meaningful only if it is invariant under admissible transformations of scale for each point of view.

Ref. [19] developed the BWM method. It is a multi-criteria decision-making method that considers the best criteria (the criterion has the most important role) and the worst criteria (the criterion that has the opposite role) determined by the decision maker (DM). The BWM is based on an asymmetric pairwise comparison of decision criteria. The DM gives his preferences of the best criterion over all other criteria and her preferences of all criteria over the worst criterion using a number of a predefined scale (e.g., 1–9). The optimization problem is formulated to determine the weights of the different criteria. A new TOPSIS procedure was created via meaningful normalization and the rank reversal for mixed data is proposed by [20].

Recently a decision support tool for supplier evaluation and the selection problem is examined by [21]. The authors propose a mathematical formulation as multi-criteria decision-making (MCDM) to solve the problem. Also, in [22], a combination of analytic network processes with TOPSIS procedure is proposed to give an appropriate MCDM model.

2.2. The Fair Order Allocation Problem

The fair division problem is to divide the items among several partners who value them differently, and each item must be given as a whole to a single person.

There are many research papers related to order quantity allocation, process group communications, and techniques that provide high availability through fault tolerance.

Ref. [23] proposed a mathematical model for single plant order allocation with a genetic algorithm for solving the model to minimize the total time of all orders. Extending previous work, ref. [24] propose intelligent optimization modeling to resolve the multi-product and multi-plant order allocation problem.

Ref. [25] proposed a genetic algorithm (GA) and simulated annealing (SA) to solve a multi-supplier and multi-product order allocation problem with transaction costs over a multi-period.

Deducted from recently researches that price, quality, and work performance are important in determining suppliers while others works introduce other criteria, including social relations, intrapersonal trust, and technological infrastructure. Meanwhile, ref. [26] stated the criteria that should be used in selecting suppliers was quality, quantity, delivery time, and cost. Ref. [27] uses quality, delivery, and environmental handling criteria in the selection of suppliers. In addition to some of the criteria mentioned above, various other studies also convey several different criteria, including [28,29,30].

2.3. Optimization Techniques in the SSFOAP

In purchasing problems, the multiple sourcing strategy is the process of selecting more than one supplier when the single supplier cannot satisfy the buyer’s requirements. In this process, the order quantity is divided between suppliers, and the decision consists of a hybrid of the supplier selection and order quantity allocation issue. In literature, several mathematical models have been proposed to formulate multi-sourcing SSP.

However, the buyer needs to make and optimize the process of SSFOAP due to the inherent interdependency between them and define the objectives and constraints. These issues are considered as two key strategic decisions in purchasing topics.

Some multi-criteria decision-making (MCDM) approaches have been used in literature to evaluate suppliers, such as the AHP method (e.g., [31,32,33]), the ANP technique (e.g., [34,35]), the TOPSIS method (e.g., [36,37]) and the VIKOR method (e.g., [38,39,40,41]).

In the last decade, numerous integrated MCDM methods have been proposed in research to solve supplier selection problems. Ref. [42] developed an improved TOPSIS integrated with BWM to solve green supplier selection in the context of MCGDM problems with intuitionistic fuzzy information. Ref. [43] proposed a grey-based multi-criteria decision-support tool composed of the ‘best–worst method’ (BWM) and TODIM is used to determine social sustainability attribute weights to rank suppliers in a group decision setting.

Ref. [37] integrated the BWM with the fuzzy TOPSIS to rank the green supplier’s selection based on weighted criteria of their green innovation abilities. This integrated approach was applied in the Khuzestan steel company. A hybrid technique is proposed by [44]. The authors combine triangular fuzzy numbers, the BWM, and TOPSIS in random environments for group decision making (GMo-RTOPSIS) to choose the best resilient supply chain partner.

Several related works explore the reputation of supplier selection and the order quantity distribution, and some mathematical models are developed to formulate these problems which are those of [45,46].

In the last decade, various hybrid approaches have been proposed in the literature for solving the SSFOAP. Ref. [47] proposed a hybrid ANP with goal programming and using the decision-maker’s preference to choose the best suppliers. Ref. [48] proposed a combined multi-criteria decision method and multi-objective LP model to solve the SSFOAP decisions. Ref. [34] integrated the ANP and TOPSIS techniques with LP to rank suppliers and allocate the order quantity between them. Ref. [49] presented a hybrid MCDM method by comparing the Fuzzy AHP and the Fuzzy TOPSIS techniques to make the best decision of the supplier selection. In [50], the SSFOAP under uncertain environments is studied by integrating the fuzzy TOPSIS and Multi-Choice Goal Programming methods. Ref. [51] proposed three integrated MCDM methods (AHP, ARAS, and MCGP) to resolve the catering supplier selection problem. Ref. [52] studied green supplier selection by combining two-phase fuzzy goal programming with the intuitionistic fuzzy TOPSIS method.

Although many studies in the literature dealt with the topic of SSFOAP, none of them considered the problem of meaningfulness and fair allocation in the supplier selection process.

So far, no research integrates the BWM with the MMD-TOPSIS method and mathematical programming to choose the supplier and distribute the order quantity problems. Table 1 describes the literature of optimization techniques used in supplier selection with order allocation problems.

Table 1.

Optimization Techniques Review of SSFOAP.

3. Problem Description and Mathematical Model

The distribution system discussed in the proposed model is composed of a set of suppliers indexed by , a single buyer, a single product, and one period. We assume that the buyer has a constant demand “d” that can be purchased by a subset of suppliers at a non-negative unit purchasing price pi, limited capacity Ci, and meaningful suitability index Ii. Then, the strategy questions in this paper are: From which supplier(s) and what order quantity can be split fairly between suppliers?

For formulating this problem, the parameters and decision variables of the mathematical programming are given below:

3.1. Parameters

| Index of the supplier (I = 1,…, n) | |

| Item demand | |

| Item Unit Price | |

| The capacity of supplier | |

| Holding cost | |

| Shortage cost | |

| Storage upper bound | |

| Shortage lower bound | |

| Meaningful suitability index | |

| BT | Total budget |

3.2. Decision Variables

| Number of products ordered proportionally | |

| Product inventory | |

| Product shortage | |

| The positive threshold for equitable distribution of orders | |

| The negative threshold for equitable distribution of orders |

3.3. Mathematical Model

Given the above parameters and decision variables, the bi-objective LP problem is formulated as follows:

Subject to

Two objective functions are given: the total purchasing cost is minimized in Equation (1). The total deviation of MSI between the supplier and supplier is minimized in Equation (2). Equation (3) describes the total demand. The capacity of each supplier is given in Equation (4). The inventory spaces, shortage, and fair allocation are presented in Equations (5)–(7), respectively. We finish our LP with the non-negativity constraint in Equation (8).

4. Integrated BWM-MMD-TOPSIS in SSFOAP

Based on the problem formulation previously described, this study aims to introduce an integrated BWM and MMD-TOPSIS with bi-objective LP to solve the SSFOAP in a real case in the TSE manufacturing system by considering the minimization of the total purchasing cost and the threshold of fair order allocation for each supplier.

The main steps of the proposed integrated approach are:

- (1)

- Phase 1: Apply the BWM-MMD-TOPSIS Method to Compute the MSI of Suppliers’ Selection for Cardinal and Ordinal Data.

- (1)

- Step 1. Establish the performance decision-making matrix.

- (2)

- Step 2. The Best–Worst Method (BWM) to evaluate criteria supplier selection.

- (3)

- Step 3. The Cardinal Data–TOPSIS step (CD-TOPSIS method).

- (4)

- Step 4. The Ordinal Data–TOPSIS step (CD-TOPSIS method).

- (5)

- Step 5. Compute the weighted Euclidean distance.

- (6)

- Step 6. Compute the relative closeness coefficients’s.

- (7)

- Step 7. Rank the suppliers based on the decreasing values of the relative closeness coefficients ci’s.

- (8)

- Step 8. Use the cutoff method to delete suppliers with MSI < ci min.

- (2)

- Phase 2: The Fair Order Allocation

Step 1. Formulate the bi-objective LP model of problem integrated MSI.

Step 2. Solve the bi-objective LP by -constraint method.

Step 3. Determine the optimal fair order quantity using CPLEX software solver.

4.1. Problem Statement: A Real Case Study in TSE Company in Tunisia

TSE is a Tunisian company established in 2012 located in Nabeul city. This company offers work and solutions in general electricity to professionals and individuals and provides services in electrical installation. Its services are installation, troubleshooting and assistance, monitoring, and maintenance. TSE company supplies its needs from five suppliers (Scap, Camilec, Siala, Compto, and Decibel) located in Tunisia, considered among the best suppliers in the electricity sector. In this real study case, we take the case of purchasing one product, which is the electric cable tube 3 × 2.5 mm Ro2V. The best supplier must be selected in the TSE Company according to three purchasing mixed criteria. The data were obtained from decision makers within the organization.

4.2. The Suggested Integrated Model

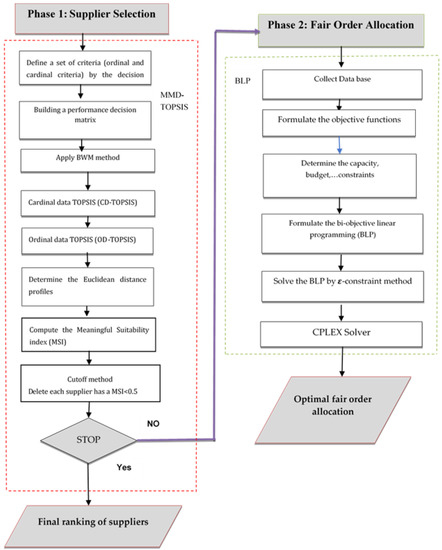

In this section, we present our hybrid integrated model solution that combines the BWM and MMD-TOPSIS procedure with a bi-objective LP (Figure 2). Three separate and dependent steps are described. In the first step, we compute the criteria weights and the MSI of suppliers using the BWM and MMD-TOPSIS methods. We develop a bi-objective LP and we apply the -constraint method used to solve the mathematical model in the second step.

Figure 2.

The hybrid integrated methodology.

4.2.1. Phase 1: Supplier Selection Problem Using BWM and MMD-TOPSIS Method

We suggested the BWM calculate the weights of the different criteria [56]. The TOPSIS method meaningful context to determine the meaningful suitability indexes for five suppliers of a TSE company. The supplier should be ranked by two evaluation ordinal criteria (quality, flexibility) and one cardinal criterion is delivery.

The following discrete gradations are introduced to range the suppliers: Very Good (VG), Good (G), and Intermediate (I). The main steps of the Hybrid BWM and MMD- TOPSIS technique are as follow:

The BWM with Meaningful Mixed Data-TOPSIS Procedure

Step 1. Construct the decision-making matrix: alternative and criteria are given. We construct the performance value of the alternative at the criterion.

Step 2. Determine the criteria weights by BWM

Step 2.1: Determining the best and the worst criteria

Step 2.2: Determining the preferences of the best criteria over all the other criteria.

Calculate the preference of the best criterion with a given number from 1 to 9.

The result is noted as Best-to-Others:

where:> 1

Step 2.3: Defining the preferences of all criteria over the worst: From 1 to 9 and the result is recorded as Others-to-Worst:

where:

Step 2.4: Solving the LP

Minimize the maximum among the set of , and the problem can be formulated by the following model:

s.t.

This min-max programming can be converted to the equivalent model:

S.t.

Step 2.5. Calculate the final criteria weight

The optimal weights and the optimal value of obtained by solving the least model. The optimal value of closer to zero indicates desired consistency.

Step 3: The Cardinal Data–TOPSIS step (CD-TOPSIS procedure)

The CD-TOPSIS technique is a modified TOPSIS technique for cardinal data.

Step 3.1: Compute the reference point which is the maximum distance between two consecutively ordered intra-attribute values

At first, a new reference point is defined to sort the initial attribute values in descending order for attribute, and to calculate the as the following Equation (19):

Step 3.2: Compute the positive ideal PIS and negative ideal NIS solutions

Then, the and are determined based on as the next formula:

Step 3.3: The meaningful normalization procedure for cardinal data

Based on the work of Aouadni et al. in 2017, the meaningful normalization method is:

Step 4: The Ordinal Data-TOPSIS step (OD-TOPSIS)

The OD-TOPSIS procedure could be considered for ordinal data.

Step 4.1: Determine the Superiority and Inferiority Score (I and S score) for each Cj as:

In the previous formulas, the score (resp. is nothing but the number of alternatives “beaten” by (resp. “beating”) alternative. We advise transforming the ordinal initial attribute values, considering the two earlier scores.

Step 4.2: The meaningful normalization procedure for ordinal data

The meaningful normalizing method for ordinal data is defined by Equation (25).

Step 5: Compute the weighted Euclidean distance

The weighted Euclidean distance is calculated by using the Formula (26) and Formula (27).

Step 6: Compute the relative closeness coefficients’s

The suppliers ranged based on the relative closeness coefficients.

Step 7: Assortment of the suppliers based on relative closeness coefficients in decreasing values

Step 8: Apply the cutoff method to delete the supplier that has an MSI < ci min.

We describe the steps of the TOPSIS procedure in the following paragraph.

- Step1: Building a Performance Decision Matrix

Decision makers in the TSE Company create the performance decision matrix with five suppliers and three mixed criteria (Table 1). In the TSE’s, the qualitative and quantitative factors of the supplier selection problem were identified based on a literature review search. After discussion, the decision makers and experts defined quality and flexibility as ordinal criteria and the cardinal criteria are delivery. The five suppliers are compared based on the ordinal scale: VG, G, and I (Table 2).

Table 2.

Performance Decision Matrix.

- Step 2: Determine the Criteria Weights by BWM

In this step, we use the BWM to determine the weight of the decision criteria. We define the best and the worst criterion in this case. The decision maker in the TSE company selects “quality” and “flexibility” as the best and the worst criteria, respectively. The DM preferences of the best criterion over all other criteria are shown in Table 3. The DM preferences of the worst criterion over all other criteria are shown in Table 4.

Table 3.

The DM Preferences (Best Criterion).

Table 4.

The DM Preferences (Worst Criterion).

According to Table 3 and Table 4, the significance weights are w1 = 0.5, w2 = 0.3, and w3 = 0.2, and the CR = 0.1, which indicates a good degree of reliability.

We integrate the weight of criteria in the next step for determining the final rank of suppliers.

- Step 3: Determine the CD-TOPSIS Step

Step 3.1: Compute the using Equation (19):

The delivery time criteria values in the descending order are 5, 4, 3, 3, and 1.

Therefore:

Step 3.2: Calculate the positive and negative ideal points

Calculate the positive and negative ideal points using Equation (20) and Equation (13): we obtain:

Step 3.3: The meaningful normalization procedure

The normalized performance for the delivery time criteria is given by (Table 4):

Step 4: Determine the OD-TOPSIS step

Step 4.1. Determine the Superiority (S-score) and Inferiority Score (I-Score)

We obtain the results in Table 5 by applying Formula (15) and Formula (16).

Table 5.

The Superiority and Inferiority Scores Matrix.

Step 4.2. The meaningful normalization method for ordinal criteria

In this step, we determine the meaningful normalization by using Formula (4) for cardinal data and Formula (7) for ordinal data (Table 6).

Table 6.

The Meaningful Normalized Matrix for the Ordinal and Cardinal Data.

Step 5. Calculate the Weighted Euclidean Distance (WED)

Apply the Formulas (8) and (9) to calculate the WED (Table 7).

Table 7.

The Weighted Normalized Matrix.

Step 6: Determine the meaningful relative closeness (optimal solution)

At this step, we compute the relative closeness (for each supplier); the result is:

Step 7: The final rank of the suppliers considered the meaningful suitability indices.

The final ranking is as follows: Siala ˃ Scap ˃ Camilec ˃ Compto ˃ Dcbel (Table 7). The first supplier is Siala, which has a meaningful suitability index equal to 0.79.

Step 8: Cutoff method

The cutoff method consists of cutting off the values of a function less than a given number. Alternatively, the decision makers in the TSE Company indicate that the supplier that has a meaningful suitability index less than the standard meaningful suitability index is deleted, and it is not considered in the fair order allocation. The orders will be distributed among the suppliers who have a Meaningful Suitability Index (MSI) greater than or equal to 0.5 and the other suppliers (compto and Dcbel) are eliminated.

4.2.2. Phase 2: Fair Order Allocation

Database Collect for Bi-Objective LP

In TSE Company, the orders must be allocated between the different suppliers where the whole demand is 30,000 m and the full budget (BT) equals 90,000,000 dinars. The supplier capacity (Ci) and the Purchase Price (Pi) are presented in Table 8. The upper and lower bound of storage and shortage is 500 and 400, respectively. A bi-objective LP for SSFOAP is applied in the TSE Company.

Table 8.

Capacity with the Purchasing Price Data.

We have applied the Cplex software to solve the proposed mathematical model. In Table 8 we give the order quantity where it is distributed equitably among five suppliers.

The -Constraint Method

The -constraint method has been used for solving the proposed bi-objective LP. This method transforms the multi-objective optimization problem into a mono-objective by optimizing one of the objectives and using the other as constraints, incorporating them in the constraint part of the model. Assume the following MOMP problem:

where is the vector of decision variables, are the objective functions, and is the feasible region.

The efficient solutions of the problem are obtained by parametrical variation in the RHS of the constrained objective functions (). Selecting the ε is the most important thing in this method because the answers are so sensitive to this parameter. So, the selected ε must be in the range of for each objective function.

Our proposed bi-objective programming for supplier selection and fair order allocation is as follows:

Subject to:

5. Numerical Experiments

This research proposes a new hybrid approach for solving SSFOAP in the TSE Company in Tunisia. Our proposed approach combined mixed data from TOPSIS and bi-objective LP. The main objective of this approach is to rank suppliers and distribute the order quantity equitably among them based on MSI. The results show that the Siala company has the best meaningful suitability index of 0.79; the final robust rank of the suppliers is Siala > Scap > Camelic > Compto > Dcbel (Table 6). Table 9 describe the Optimal Fair Order Allocation without the Cutoff Method

Table 9.

The Optimal Fair Order Allocation without the Cutoff Method.

After using the cutoff method, the command distribution quantity is distributed proportionally among the suppliers. The optimal results indicated that the demand is proportionally distributed among the three suppliers as the most quantity is purchased from the Siala company, with an inventory shortage of 500 mm. The final equitable order allocation between suppliers is presented in Table 10 and the important order quantity is purchased from Siala (Table 9 and Table 10).

Table 10.

The Final Result with the Cutoff Method.

In this section, the advantages of the proposed approach to optimizing SSFOAP will be explored and discussed. This methodology demonstrates that the final rank is accurate and the BWM-MMD-TOPSIS method considers the meaningfulness in mixed data situations and the resistance of rank hitches with the addition or the deletion or replacement of the alternative. Then, mathematical programming is developed as the second step to determine the optimal equitably distribute order allocation among selected suppliers based on an MSI. Moreover, the order allocation between suppliers was not affected by the deletion of the two suppliers and they have a suitability index less than 0.5. The real case in the TSE Company showed the efficiency of our proposed approach.

6. Discussions

However, the literature on the problem of supplier selection and order allocation suffers from the meaningfulness and fairness notions. In addition, there is insufficient research that takes into consideration the context of the mixed data and best–worst criteria in supplier selection.

The best–worst method (BWM) was suggested to address existing deficiencies and the challenges in pairwise comparisons and inconsistency issues in the AHP method. Ref. [19] stated that the root cause of the inconsistency problem in the AHP method is the unreasonable execution of paired comparisons. He reduced the total number of pairwise comparisons to 2n-3 to identify the weight of n criteria.

The MMD-TOPSIS is a method used to improve the normalization procedure of the standard TOPSIS in the context of mixed data and rank reverse to make the final rank of alternatives robust and efficient. Ref. [20] are interested in the meaningfulness of the different monotonic normalization procedures proposed in the standard TOPSIS method and showing those which are meant for each type of scale. They are addressed to the meaningful concept which comes from the theory of measurement to improve the normalization procedure in the standard TOPSIS method.

Our proposed approach combined the BWM and MMD-TOPSIS tried to resolve this drawback and offers a useful tool for decision makers to solve the supplier selection problem which is a complex multi-criteria decision-making process.

Table 3 and Table 4 show the DM preferences of the best criterion (Quality) over all other criteria and the DM preferences of the worst criterion (Flexibility) over all other criteria.

According to the results of Table 3 and Table 4, the final priority weights of the different mixed criteria of suppliers in the TSE Company show that the quality of the supplier had the greatest importance by 0.5.

The results of the BWM method integrate into the MMD-TOPSIS method to rank suppliers. The final result in Table 9 demonstrates that of the suppliers, Siala is the best supplier by 0.79 and the final rank is Siala > Scap > Camelic > Compto > Dcbel.

We integrate the results of the proposed MCDM method in bi-objective linear programming because of constraints, such as capacity, budget, and demand. We considered the fair distribution orders among suppliers as constraints which have not been studied in the supplier selection literature. Table 9 shows that the optimal results indicated that the demand is proportionally distributed among the five suppliers. To show the efficiency and robustness of our proposed approach, we apply the principle of the cutoff method when deleting the supplier that has a weight less than 0.5. The final rank remains the same after deleting the worst suppliers, Compto and Dcbel. The final results are present in Table 10 which indicate that the order allocation between suppliers remains equitable and the important order quantity is purchased from the best supplier Siala.

7. Conclusions

In this work, issues related to the current practice of supplier selection in the TSE Company were analyzed. A hybrid approach combining the BWM, MMD-TOPSIS, and BLP for resolving the problem of SSFOAP. This approach is founded on two main phases. The first consists of applying the BWM and MMD-TOPSIS method for determining the weights of selection criteria and for ranking suppliers established on the meaningful suitability index. In the second phase, we developed a bi-objective LP to optimize equitable order allocation.

The solution suggested building a reliable and efficient process for supplier selection in this company, which is shown in Figure 2. We have developed the process shown in Figure 2, focused on supplier selection in TSE. In addition, each of the specific objectives proposed in this work has also been achieved. The supplier selection criteria having been established thanks to the multifunctional collaboration of the company, the enveloping analysis of the data was retained for the preselection of the suppliers, and for the final selection, an LP model was used as a whole. Likewise, the applicability of the MCDM approach, MMD-TOPSIS, to the problem chosen by the company has been demonstrated.

The final results show that the orders are allocated proportionally between the different suppliers that considers their meaningful suitability indices. For future research, we propose to integrate an MCDM method for determining the criteria weights and apply it to the green supplier selection problem.

The managerial implications of the above-demonstrated results in the real case in TSE are: This study provides a robust methodology for decision makers in the company who must make decisions of supplier selection and order allocation fairly in a complex, real-world environment. The new hybrid method proposed in this research is an efficient and reliable tool to solve the process of SSFOAP and to make this complex problem, in reality, easier and more robust for the decision makers in the company compared with the other hybrid methods proposed in the literature. The proposed framework can be applied to solve the studied issues considering the economic, environmental, and social criteria in a sustainable context.

The Integrated MMD-TOPSIS method prioritizes sustainability criteria based on ordered comparisons, which is ideal for supplier selection, despite some limitations caused by the availability of information and the degree of uncertainty present in the selection process providers. Thus, the presented application of the MMD-TOPSIS model constitutes an a posteriori starting point to extend the use of multidisciplinary criteria in the field of sustainability in a more rigorous way.

In addition to obtaining the alternative weighting of priority criteria and sub-criteria, the TSE Company can also make decisions in the selection and evaluation of the best suppliers, not only by considering one or two criteria but also by considering several alternative criteria. This is the advantage of the integrated method because this method can show the consideration of an alternative that is considered to have a weakness that is quite influential, but on the other hand, it has advantages that need to be considered.

The novel hybrid approach proposed in this work is robust, flexible, and reliable in solving supplier selection and order allocation issues. This research has certain limitations: (i) the results are not generalized in other real cases, and we have applied the methodology on only the case in the TSE company; (ii) we do not take into consideration the hard case in the order allocation problem and we only study the case of one product and one period, and we did not compare the obtained results with another framework in the literature.

Future work in this area may include an application of this methodology in other issues in logistics. Then, a larger set of real cases must be examined to consider other factors and constraints (fuzzy and stochastic data), especially after the period of COVID-19, when new developments and trends have emerged in logistics.

Author Contributions

Conceptualization, S.A. and J.E.; methodology, J.E.; software, S.A.; validation, S.A. and J.E.; formal analysis, J.E.; investigation, S.A.; resources, S.A.; data curation, J.E.; writing—original draft preparation, S.A.; writing—review and editing, J.E.; visualization, S.A.; supervision, J.E.; project administration, S.A. and J.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Euchi, J.; Frifita, S. Hybrid metaheuristic to solve the “one-to-many-to-one” problem: Case of distribution of soft drink in Tunisia. Manag. Decis. 2017, 55, 136–155. [Google Scholar] [CrossRef]

- Euchi, J. (Ed.) Transportation, Logistics, and Supply Chain Management in Home Healthcare: Emerging Research and Opportunities: Emerging Research and Opportunities; IGI Global: Hershey, PA, USA, 2019. [Google Scholar]

- Hu, Z.; Parwani, V.; Hu, G. Closed-Loop Supply Chain Network Design under Uncertainties Using Fuzzy Decision Making. Logistics 2021, 5, 15. [Google Scholar] [CrossRef]

- Elleuch, M.A.; Anane, M.; Euchi, J.; Frikha, A. Hybrid fuzzy multi-criteria decision making to solve the irrigation water allocation problem in the Tunisian case. Agric. Syst. 2019, 176, 102644. [Google Scholar] [CrossRef]

- Euchi, J.; Bouzidi, D.; Bouzid, Z. Interpretive structural modeling technique to analyze the interactions between the factors influencing the performance of the reverse logistics chain. Glob. J. Flex. Syst. Manag. 2019, 20, 43–55. [Google Scholar] [CrossRef]

- Bahramimianrood, B.; Bathae, M. The Impact of Information Technology on Knowledge Management in the Supply Chain. J. Sci. Manag. Tour. Lett. 2021, 2021, 1–6. [Google Scholar]

- Euchi, J. Hybrid adaptive memory programming to optimise the multi-commodity many to many vehicle routing problem. Int. J. Math. Oper. Res. 2020, 17, 492–513. [Google Scholar] [CrossRef]

- Moussi, R.; Euchi, J.; Yassine, A.; Ndiaye, N.F. A hybrid ant colony and simulated annealing algorithm to solve the container stacking problem at seaport terminal. Int. J. Oper. Res. 2015, 24, 399–422. [Google Scholar] [CrossRef]

- Aouadni, S.; Aouadni, I.; Rebaï, A. A systematic review on supplier selection and order allocation problems. J. Ind. Eng. Int. 2019, 15, 267–289. [Google Scholar] [CrossRef]

- Huang, S.H.; Uppal, M.; Shi, J. A product driven approach to manufacturing supply chain selection. Supply Chain Manag. Int. J. 2002, 7, 189–199. [Google Scholar] [CrossRef]

- Dutta, P.; Jaikumar, B.; Arora, M. Applications of data envelopment analysis in supplier selection between 2000 and 2020: A literature review. Bus. Anal. Oper. Res. 2021, 2021, 1–56. [Google Scholar] [CrossRef]

- Euchi, J. Genetic scatter search algorithm to solve the one-commodity pickup and delivery vehicle routing problem. J. Model. Manag. 2017, 12, 2–18. [Google Scholar] [CrossRef]

- Lee, A.H.; Kang, H.Y.; Lai, C.M.; Hong, W.Y. An integrated model for lot sizing with supplier selection and quantity discounts. Appl. Math. Model. 2013, 37, 4733–4746. [Google Scholar] [CrossRef]

- Orji, I.J.; Ojadi, F. Investigating the COVID-19 pandemic’s impact on sustainable supplier selection in the Nigerian manufacturing sector. Comput. Ind. Eng. 2021, 160, 107588. [Google Scholar] [CrossRef]

- Dickson, G.W. An analysis of vendor selection systems and decisions. J. Purch. 1966, 2, 5–17. [Google Scholar] [CrossRef]

- Weber, C.A.; Current, J.R.; Benton, W.C. Vendor selection criteria and methods. Eur. J. Oper. Res. 1991, 50, 2–18. [Google Scholar] [CrossRef]

- Ho, W.; Xu, X.; Dey, P.K. Multi-criteria decision making approaches for supplier evaluation and selection: A literature review. Eur. J. Oper. Res. 2010, 202, 16–24. [Google Scholar] [CrossRef]

- Thiruchelvam, S.; Tookey, J.E. Evolving trends of supplier selection criteria and methods. Int. J. Automot. Mech. Eng. 2011, 4, 437–454. [Google Scholar] [CrossRef]

- Rezaei, J. Best-worst multi-criteria decision-making method. Omega 2015, 53, 49–57. [Google Scholar] [CrossRef]

- Aouadni, S.; Rebai, A.; Turskis, Z. The meaningful mixed data TOPSIS (TOPSIS-MMD) method and its application in supplier selection. Stud. Inform. Control 2017, 26, 353–363. [Google Scholar] [CrossRef]

- Lopes, A.P.; Rodriguez-Lopez, N. A Decision Support Tool for Supplier Evaluation and Selection. Sustainability 2021, 13, 12387. [Google Scholar] [CrossRef]

- Chen, C.H. A Hybrid Multi-Criteria Decision-Making Approach Based on ANP-Entropy TOPSIS for Building Materials Supplier Selection. Entropy 2021, 23, 1597. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.X.; Wong, W.K.; Leung, S.Y.S.; Fan, J.T.; Chan, S.F. A genetic-algorithm-based optimization model for scheduling flexible assembly lines. Int. J. Adv. Manuf. Technol. 2008, 36, 156–168. [Google Scholar] [CrossRef]

- Guo, C.; Li, X. A multi-echelon inventory system with supplier selection and order allocation under stochastic demand. Int. J. Prod. Econ. 2014, 151, 37–47. [Google Scholar] [CrossRef]

- Esfandiari, N.; Seifbarghy, M. Modeling a stochastic multi-objective supplier quota allocation problem with price-dependent ordering. Appl. Math. Model. 2013, 37, 5790–5800. [Google Scholar] [CrossRef]

- Gnanasekaran, S.; Velappan, S. Application of Analytical Hierarchy Process in Supplier Selection: An Automobile Industry Case Study. South Asian J. Manag. 2006, 13, 89–100. [Google Scholar]

- Magdalena, R. Supplier selection for food industry: A combination of Taguchi loss function and fuzzy analytical hierarchy process. Asian J. Technol. Manag. 2012, 5, 13–22. [Google Scholar]

- Al-Tit, A.; Omri, A.; Euchi, J. Critical success factors of small and medium-sized enterprises in Saudi Arabia: Insights from sustainability perspective. Adm. Sci. 2019, 9, 32. [Google Scholar] [CrossRef]

- You, S.Y.; Zhang, L.J.; Xu, X.G.; Liu, H.C. A new integrated multi-criteria decision making and multi-objective programming model for sustainable supplier selection and order allocation. Symmetry 2020, 12, 302. [Google Scholar] [CrossRef]

- Euchi, J.; Chabchoub, H. A hybrid tabu search to solve the heterogeneous fixed fleet vehicle routing problem. Logist. Res. 2010, 2, 3–11. [Google Scholar] [CrossRef]

- Chen, P.S.; Wu, M.T. A modified failure mode and effects analysis method for supplier selection problems in the supply chain risk environment: A case study. Comput. Ind. Eng. 2013, 66, 634–642. [Google Scholar] [CrossRef]

- Deng, S.; Aydin, R.; Kwong, C.K.; Huang, Y. Integrated product line design and supplier selection: A multi-objective optimization paradigm. Comput. Ind. Eng. 2014, 70, 150–158. [Google Scholar] [CrossRef]

- Dweiri, F.; Kumar, S.; Khan, S.A.; Jain, V. Designing an integrated AHP based decision support system for supplier selection in automotive industry. Expert Syst. Appl. 2016, 62, 273–283. [Google Scholar] [CrossRef]

- Lin, C.T.; Chen, C.B.; Ting, Y.C. An ERP model for supplier selection in electronics industry. Expert Syst. Appl. 2011, 38, 1760–1765. [Google Scholar] [CrossRef]

- Dou, Y.; Zhu, Q.; Sarkis, J. Evaluating green supplier development programs with a grey-analytical network process-based methodology. Eur. J. Oper. Res. 2013, 233, 420–431. [Google Scholar] [CrossRef]

- Memari, A.; Dargi, A.; Jokar, M.R.A.; Ahmad, R.; Rahim, A.R.A. Sustainable supplier selection: A multi-criteria intuitionistic fuzzy TOPSIS method. J. Manuf. Syst. 2019, 50, 9–24. [Google Scholar] [CrossRef]

- Javad, M.O.M.; Darvishi, M.; Javad, A.O.M. Green supplier selection for the steel industry using BWM and fuzzy TOPSIS: A case study of Khouzestan steel company. Sustain. Futures 2020, 2, 100012. [Google Scholar] [CrossRef]

- Fei, L.; Deng, Y.; Hu, Y. DS-VIKOR: A new multi-criteria decision-making method for supplier selection. Int. J. Fuzzy Syst. 2019, 21, 157–175. [Google Scholar] [CrossRef]

- Gao, H.; Ju, Y.; Gonzalez, E.D.S.; Zhang, W. Green supplier selection in electronics manufacturing: An approach based on consensus decision making. J. Clean. Prod. 2020, 245, 118781. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, K.; Zeng, B.; Xu, H.; Yang, Y. Supplier selection in nuclear power industry with extended VIKOR method under linguistic information. Appl. Soft Comput. 2016, 48, 444–457. [Google Scholar] [CrossRef]

- You, X.Y.; You, J.X.; Liu, H.C.; Zhen, L. Group multi-criteria supplier selection using an extended VIKOR method with interval 2-tuple linguistic information. Expert Syst. Appl. 2015, 42, 1906–1916. [Google Scholar] [CrossRef]

- Tian, Z.P.; Wang, J.Q.; Zhang, H.Y. An integrated approach for failure mode and effects analysis based on fuzzy best-worst, relative entropy, and VIKOR methods. Appl. Soft Comput. 2018, 72, 636–646. [Google Scholar] [CrossRef]

- Bai, C.; Kusi-Sarpong, S.; Badri Ahmadi, H.; Sarkis, J. Social sustainable supplier evaluation and selection: A group decision-support approach. Int. J. Prod. Res. 2019, 57, 7046–7067. [Google Scholar] [CrossRef]

- Gan, J.; Zhong, S.; Liu, S.; Yang, D. Resilient supplier selection based on fuzzy BWM and GMo-RTOPSIS under supply chain environment. Discret. Dyn. Nat. Soc. 2019, 2019, 2456260. [Google Scholar] [CrossRef]

- Cárdenas-Barrón, L.E.; González-Velarde, J.L.; Treviño-Garza, G. A new approach to solve the multi-product multi-period inventory lot sizing with supplier selection problem. Comput. Oper. Res. 2015, 64, 225–232. [Google Scholar] [CrossRef]

- Pazhani, S.; Ventura, J.A.; Mendoza, A. A serial inventory system with supplier selection and order quantity allocation considering transportation costs. Appl. Math. Model. 2016, 40, 612–634. [Google Scholar] [CrossRef]

- Aouadni, S.; Allouche, M.A.; Rebaï, A. Supplier selection: An analytic network process and imprecise goal programming model integrating the decision-maker’s preferences. Int. J. Oper. Res. 2013, 16, 137–154. [Google Scholar] [CrossRef]

- Sodenkamp, M.A.; Tavana, M.; Di Caprio, D. Modeling synergies in multi-criteria supplier selection and order allocation: An application to commodity trading. Eur. J. Oper. Res. 2016, 254, 859–874. [Google Scholar] [CrossRef]

- Junior, F.R.L.; Osiro, L.; Carpinetti, L.C.R. A comparison between Fuzzy AHP and Fuzzy TOPSIS methods to supplier selection. Appl. Soft Comput. 2014, 21, 194–209. [Google Scholar] [CrossRef]

- Rouyendegh, B.D.; Saputro, T.E. Supplier selection using integrated fuzzy TOPSIS and MCGP: A case study. Procedia Soc. Behav. Sci. 2014, 116, 3957–3970. [Google Scholar] [CrossRef]

- Fu, Y.K. An integrated approach to catering supplier selection using AHP-ARAS-MCGP methodology. J. Air Transp. Manag. 2019, 75, 164–169. [Google Scholar] [CrossRef]

- Kilic, H.S.; Yalcin, A.S. Modified two-phase fuzzy goal programming integrated with IF-TOPSIS for green supplier selection. Appl. Soft Comput. 2020, 93, 106371. [Google Scholar] [CrossRef]

- Amid, A.; Ghodsypour, S.H.; O’Brien, C. A weighted max–min model for fuzzy multi-objective supplier selection in a supply chain. Int. J. Prod. Econ. 2011, 131, 139–145. [Google Scholar] [CrossRef]

- Nazari-Shirkouhi, S.; Shakouri, H.; Javadi, B.; Keramati, A. Supplier selection and order allocation problem using a two-phase fuzzy multi-objective linear programming. Appl. Math. Model. 2013, 37, 9308–9323. [Google Scholar] [CrossRef]

- Haldar, A.; Banerjee, D.; Ray, A.; Ghosh, S. An integrated approach for supplier selection. Procedia Eng. 2012, 38, 2087–2102. [Google Scholar] [CrossRef][Green Version]

- Euchi, J.; Sadok, A. Hybrid genetic-sweep algorithm to solve the vehicle routing problem with drones. Phys. Commun. 2021, 44, 101236. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).