Abstract

Background: Integrating Radio Frequency Identification (RFID) technology into storage areas within the wiring harness manufacturing industry enables real-time component traceability and supports the implementation of fully automated inventory processes. While RFID systems provide continuous data regarding component type, quantity, and location, periodic inventory validation is still required to verify and correct records in the warehouse management system. Methods: This study examines the feasibility of passive ultra-high-frequency (UHF) RFID technology for automatic inventory management in a components warehouse. It also reviews relevant scientific literature on autonomous RFID signal measurement and Synthetic Aperture Radar (SAR)-based localization methods, which are subsequently adapted for inventory applications. An experimental setup is developed to characterize the reading field, hysteresis effects, and the influence of distance and tag orientation on detection performance. Results: The findings indicate that RFID-based automatic inventory is achievable with high accuracy and stability, especially when tag trajectories correspond to areas of high detection probability and antenna polarization is optimally configured. Conclusions: The proposed RFID-based system can be implemented with minimal hardware changes and low investment, thereby improving stock accuracy, traceability, and operational efficiency in automotive component logistics.

1. Introduction

The growing complexity of automotive wiring harness production, combined with the increasing diversity of component variants, demands efficient, accurate, and traceable inventory management systems. Conventional manual or barcode-based inventory methods are labour-intensive and error-prone, particularly in high-mix production environments. Despite these limitations, such approaches remain widely adopted across many industrial sectors due to their low initial cost and established workflows. In the study “Application of Modern Warehouse Technology in the Slovenian Automotive Industry” [1], S. Škerlič et al. conducted an analysis based on a survey developed to understand which factors automotive suppliers consider when deciding which technology to apply in their warehouse management. The research provided valuable insights into the perception of automotive suppliers regarding modern warehouse management technologies and is particularly relevant for suppliers from smaller countries in Central and Eastern Europe. The survey results indicated that automotive suppliers who have been in the industry for a long time prefer to use basic and well-established warehouse technologies, such as barcode systems, rather than increasing the degree of warehouse automation. This raises several questions, such as “What are the real challenges suppliers face when analyzing the possibility of implementing modern technological solutions?” and “If offered a viable, low-cost solution with easy implementation, would they choose to replace barcode technology with a modern and proven reliable alternative (such as RFID)?”

To address the above questions, this study builds upon previous research on the integration of RFID technology into wiring harness storage systems by proposing an automated inventory solution specifically designed for wiring harness component storage. The proposed approach aims to ensure ease of implementation while improving accuracy and efficiency in inventory management.

RFID technology has emerged as a viable solution to these challenges, offering automatic identification of items without line-of-sight and enabling real-time synchronization between physical stock and digital records.

Beyond real-time traceability, the adoption of RFID systems in the storage area provides a significant additional advantage: the potential to achieve fully automatic inventory. However, despite the continuous data provided by RFID readers, total periodic inventory checks remain necessary to validate the database integrity of warehouse management systems.

In the proposed model, passive UHF RFID tags are employed. Their cost-effectiveness and compatibility with industrial RFID standards enable multiple possible implementations of automated inventory.

The subsequent sections of this work are organized as follows:

Section 2 provides a comprehensive review of relevant scientific contributions on UHF RFID technology, focusing on its applications in logistics, manufacturing, and automated inventory systems. Section 3 details the research methodology, including the conceptual RFID model for wiring harness component storage developed during previous research and the integration of automatic inventory solutions, supported by SAR-based localization and autonomous measurement approaches. Section 4 presents the experimental setup and procedures used to characterize the RFID reading field, analyze hysteresis behaviour, and evaluate the influence of tag distance and orientation on detection performance. Section 5 discusses experimental results, highlighting optimal reading zones, hysteresis patterns for single and multiple tags, and the impact of tag orientation on system reliability. Furthermore, it formulates conclusions regarding the feasibility of implementing UHF RFID for automated inventory in wiring harness warehouses, outlines operational validation requirements, and proposes practical measures for industrial adoption. In addition, the study addresses its limitations and proposes directions for future research, including testing under real operational conditions, interference analysis, and multi-tag evaluation to improve system robustness and scalability.

2. State of the Art

RFID (Radio-Frequency Identification) technology has been successfully implemented across various industries to enhance operational efficiency, inventory management, and security. Since 2020, several scientific articles have been published focusing on Ultra-High Frequency (UHF) Radio Frequency Identification (RFID) technologies.

Below, several notable studies relevant to the domain of RFID implementation in logistics, manufacturing, and industrial monitoring are presented.

Buková et al. [2] conducted a case study examining the environmental implications of RFID technology in logistics, focusing on courier companies and logistics centres in Slovakia and the Czech Republic. The studied logistics centre generates approximately 5.7 tonnes of e-waste annually from RFID tags used on pallets. These findings underscore significant sustainability challenges within e-commerce and supply chain operations. To address these issues, the authors recommend strategies such as adopting durable, reusable RFID tags, implementing eco-labelling systems to raise sustainability awareness, and introducing government incentives for advanced RFID recycling solutions. Varese and Pellicelli [3] present a case study on the adoption of RFID technology by Oscalito, an Italian fashion company, to enhance supply chain monitoring and prevent counterfeiting. The integration of RFID delivers significant benefits, including improved production management, automated warehouse operations, and enhanced traceability, which facilitated the acquisition of certifications such as the Italian Identity Certification from Italcheck. By enabling real-time visibility across production and distribution, RFID proves particularly valuable in the textile sector, characterized by fast production cycles and complex traceability requirements.

Qiao et al. [4] propose a comprehensive meat traceability system based on UHF RFID technology to address vulnerabilities that have caused severe food safety incidents. The solution ensures transparency across the entire supply chain—from breeding and slaughtering to retail distribution—using a low-cost UHF RFID reader, an advanced Q-value data collection algorithm, and multi-mode communication (LoRa, USB, RS485, RJ45). Data from farms, logistics, and sales are integrated into a LabVIEW-based platform, providing full visibility for regulators and consumers. This approach enhances food safety compliance, improves logistics efficiency, and strengthens consumer trust through end-to-end traceability. A novel power cable monitoring method was proposed by Gu et al. [5], integrating UHF RFID and deep learning within an edge computing environment to enhance wireless monitoring accuracy. The system uses a passive temperature-sensing RFID tag combining a sensing chip and RFID chip fixed along cable measurement points for real-time thermal monitoring. Results indicate significant advancements in real-time temperature tracking, reducing overheating and failure risks, enabling predictive maintenance through AI-driven temperature forecasting, and achieving fully wireless, passive operation without local power sources.

The research conducted by Gui Linqing et al. [6] proposes a UHF RFID-based localization technique for smart storage systems to overcome challenges such as Non-Line-of-Sight (NLOS) conditions, multi-path propagation, and tag coupling effects. The approach leverages four key features of the Received Signal Strength (RSS) profile—uniqueness, time variation, column dependence, and waveform similarity—to enhance real-time localization accuracy. This solution improves warehouse automation by reducing item misplacement and offers a cost-effective alternative to infrastructure-heavy systems. The case study of Zhang et al. [7] presents the design and optimization of a compact UHF RFID tag thread incorporating a helix dipole antenna for textile integration. Through simulation and experimental validation, the study analyzes the influence of single arm length and helical pitch on resonant frequency and reading range. Findings indicate that resonant frequency decreases with longer arm lengths but increases with larger helical pitch, while reading range is more sensitive to arm length variations. For a 63 mm arm length, increasing pitch initially improves range before causing a decline. The research highlights the potential of optimized RFID tag threads for fabric-based applications, though further studies are needed to assess performance impacts from surrounding materials.

El Bakkali et al. [8] propose a multifunctional dual-band RFID tag antenna capable of operating in both European (865–868.5 MHz) and North American (902–928 MHz) UHF bands. The design, validated through CST Microwave Studio simulations and experimental testing, demonstrates strong agreement between measured and simulated results, confirming a simple, low-cost structure suitable for international RFID applications. Performance was also assessed on various background materials, ensuring practical deployment. Additionally, the study highlights RFID’s growing role in IoT-based health monitoring, accelerated by the COVID-19 pandemic, where RFID enables real-time sensing, passive communication, and identification, reducing complexity and costs in healthcare data collection.

Xiang Ju et al. [9] identify RFID as a key technology for future healthcare systems due to its passive communication and identification capabilities. However, challenges such as energy efficiency, communication standardization, and signal stability persist. The authors call for research on energy-efficient sensors and robust protocols for medical applications. Zuo et al. [10] explore RFID-enabled smart food packaging to ensure safety and quality amid rising online food purchases. Integrated sensors monitor humidity, temperature, gas concentration, and pH. While promising food traceability, challenges remain in biocompatibility, reading range, and security. Profetto, Gherardelli, and Iadanza [11] conducted a comprehensive review of RFID applications in healthcare, emphasizing its potential to enhance patient safety, prevent medical errors, and combat counterfeit pharmaceuticals. The authors conclude that RFID represents a cornerstone of digital transformation in healthcare management systems.

Zeba and Čičak [12] examine Industry 4.0’s impact on manufacturing, emphasizing rapid adaptation and RFID integration for smart factories. RFID enables real-time resource tracking and supports MES–ERP integration, improving planning and efficiency across the value chain. Zhang W., Xu L., and Liu H. [13] explore RFID’s role as a core IoT technology, outlining its principles, global resource-sharing potential, and security challenges. Using a weight function algorithm, they analyze RFID information security and propose solutions, while highlighting key IoT applications. Ali et al. [14] present TagSee, a system using COTS monostatic RFID devices to monitor customer browsing in retail stores. By analyzing RSS and phase changes caused by customer movement, TagSee generates coarse-grained images and tracks multiple users with high accuracy. Implemented with Impinj readers and DogBone tags, it achieves strong performance with minimal training data.

Hu P. [15] proposes a 5G-based architecture for real-time control using batteryless RFID touch sensors in mmWave environments. The system leverages edge computing at 5G base stations and demonstrates superior performance compared to LTE, enabling massive low-cost sensor deployment for tactile Internet applications. Bendavid et al. [16] examine passive UHF RFID-based RTLS in Industry 5.0 to improve asset monitoring and human–robot collaboration. The study reviews RTLS technologies, highlights passive RFID as a cost-effective alternative to active systems, and demonstrates successful implementations in two industrial sites.

Aliakbarian et al. [17] conduct a Life Cycle Assessment of RFID tags, showing that raw material extraction and manufacturing dominate environmental impact. Paper-based tags reduce greenhouse gas emissions by up to 23%, offering a more sustainable alternative and guiding eco-efficient RFID material development. Claucherty et al. [18] investigated the performance of UHF RFID technology across different packaging levels—individual items, cases, and pallets—within supply chain operations. The authors conducted controlled experiments to evaluate read rates under various conditions, including the presence of challenging materials such as liquids and metallic foils. Results indicate that UHF RFID systems can achieve exceptionally high read accuracy (>99.7%) when tag placement and antenna configurations are optimized. The research emphasizes the scalability of RFID solutions for complex logistics environments and highlights practical considerations for deployment, such as mitigating interference and ensuring consistent tag orientation. These findings confirm UHF RFID as a robust alternative to traditional identification methods, supporting automation and real-time visibility in inventory management.

Yu and Wang [19] presented in their study the development of a cost-effective RFID-based wireless terminal designed to enhance logistics and inventory management. The proposed system integrates UHF RFID technology with multi-tag reading capabilities and supports communication protocols such as LoRa and RJ45 for real-time data transmission. The architecture combines hardware and browser/server (B/S) software to enable seamless interaction between the terminal and backend systems. Experimental validation demonstrates that the solution achieves reliable tag identification and efficient data exchange, making it suitable for large-scale logistics operations. The authors emphasize the system’s affordability and adaptability, which are critical for widespread industrial adoption. The research conducted by Taoufik et al. [20], investigates the reliability of passive UHF RFID tags through a combination of simulation and experimental testing. The authors analyze key factors influencing system performance, including electromagnetic propagation, tag orientation, and environmental conditions such as temperature variations. Using commercial RFID equipment and simulation tools, the study evaluates read range and signal integrity under different scenarios. Results indicate that environmental conditions and tag positioning significantly affect read reliability, emphasizing the need for robust design and calibration in industrial applications. The paper provides valuable insights into optimizing RFID systems for consistent performance in real-world environments.

The study presented by Spiridon et al. [21], addresses the design challenges of frequency synthesizers for software-defined radio (SDR) transceivers, focusing on optimizing phase noise, silicon area, and power consumption. The authors analyze the main contributors to phase noise in PLL-based synthesizers, including the reference oscillator, VCO, and loop filter components. They propose a fractional-N PLL architecture combined with Johnson-counter-based quadrature LO generation, enabling wideband operation (3–6 GHz) while maintaining low phase noise (−96 dBc/Hz at 100 kHz offset) and reduced power consumption. The design was implemented in 0.13 μm CMOS technology, demonstrating competitive performance compared to conventional solutions. Although the study focuses on SDR transceivers, its findings are highly relevant to UHF RFID reader design. RFID readers require stable local oscillators and low phase noise to ensure reliable tag interrogation and minimize bit errors during EPC Gen2 communication. The proposed PLL architecture and optimization strategies can be adapted to RFID readers operating in the UHF band (860–960 MHz), where phase noise impacts modulation accuracy and read range. Furthermore, the emphasis on low power and compact design aligns with the growing demand for portable and embedded RFID solutions in industrial environments.

The literature reveals that while RFID research spans environmental assessment, anti-counterfeiting, traceability, sensing, localization, antenna/tag design, logistics integration, and convergence with advanced computing, authors consistently call for broader validation and system-level perspectives. Environmental and LCA studies emphasize the need to extend analysis beyond tag materials to include readers, antennas, middleware, and operational profiles, and to link outcomes to actionable logistics design choices [2,17]. Sector-specific case studies in fashion, food, and healthcare acknowledge functional benefits but highlight gaps in scalability, interoperability with standards, and transferability to complex, safety-critical supply chains, particularly those in automotive contexts [3,4,9,10,11,12,13,18,19].

From a technical standpoint, authors underscore insufficient empirical validation of RFID performance under metal-dense, interference-prone conditions and dynamic operations. Advances in non-line-of-sight localization and UHF antenna/tag optimization require deployment guidance for dense racking, proximity to cable bundles, and manufacturing tolerances, with rigorous evaluation of detuning, multipath, polarization mismatch, and durability under real handling cycles [6,7,8,20]. Convergent approaches that integrate RFID with edge computing, deep learning, and 5G are identified as promising but under-tested for latency, reliability, and resilience in EMI-rich, brownfield environments, leaving their incremental value over simpler configurations uncertain [5,15,16]. In parallel, hardware reliability and RF front-end trade-offs remain largely confined to simulation or lab settings, with authors noting the absence of full-scale industrial validation frameworks [20,21].

Operationally, the cited works point to a lack of end-to-end deployment playbooks: antenna placement and power tuning for dense metal layouts, robust collision handling for high tag populations, attachment durability for cable-related items, and production-grade integration with WMS/ERP in multi-actor supply chains [12,13,18,19]. Authors further identify unresolved questions on cost, scalability, and maintainability, particularly for small and medium-sized suppliers, and call for standardized benchmarking methodologies (KPIs, test scenarios, acceptance thresholds) to enable comparability and technology transfer from pilots to production [2,16,17,18]. The identified gaps point out the need of low-cost, easy-to-deploy RFID solutions and seamless enterprise integration, suitable for metal-rich, high-variability warehouses—including those managing wiring harness components [2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21].

While direct studies on UHF RFID implementation for wiring harness component storage systems remain limited, these related works collectively demonstrate the technological maturity and interdisciplinary potential of RFID. They establish a foundation for applying RFID-driven automation to automotive component logistics, supporting both operational efficiency and sustainability.

3. Materials and Methods

3.1. Research in Automatic Inventory Possibilities

A significant advantage of implementing RFID technology in the storage area is the possibility of performing a fully automated inventory. Although the implemented RFID system provides real-time data regarding the type, quantity, and location of components, the need for periodic stock inventory is not completely eliminated. Conducting a comprehensive inventory of the stored items remains essential to verify and, if necessary, correct the quantity and positioning of components recorded in the database of the integrated warehouse management system. In previous research it was proposed a conceptual model for RFID implementation within a harness maker’s components warehouse [22]. The passive tags that were attached to pallets, boxes, and shelves are based on UHF RFID technology, enabling several options for automated inventory operations.

There are several approaches through which real-time inventory management can be achieved using RFID technology. Among the most used are portable RFID readers, remote-controlled vehicles equipped with UHF RFID readers, and fixed reader systems installed either on the ceiling or directly on storage shelves. These solutions generally rely on estimating the distance between the RFID tag and the antenna by analyzing the amplitude of the backscattered signal, measured through the Received Signal Strength Indicator (RSSI). This parameter plays a particularly important role when adopting mobile solutions for automated inventory operations.

In the study “Autonomous System for UHF RFID Signal Measurement in Industrial Environment” [23], the authors focused on the development of an autonomous UHF RFID signal measurement system in different industrial environment. The classical method of measuring the electromagnetic field emitted by the RFID antenna to determine the power required to read the RFID tags in relation to their location and that of recording the RSSI index value of the tag when using a constant power level of the RFID reader, requires many manual operations, data evaluation, takes a long time and does not exclude the risk of human error. The developed system, allows automatic horizontal and vertical measurements, without requiring the presence of an operator at the time of the measurement.

It moves based on predefined routes and is composed of a mobile platform equipped with:

- -

- UHF RFID etalon tag, which has the advantage of moving relative to the UHF RFID antennas on a predetermined trajectory horizontally and vertically using a robotic carriage with an elevator

- -

- Battery-assisted UHF RFID tags (semi-active), which allow detection of the signal below the usual level for passive UHF RFID tags

- -

- Dipole antenna (half-wave) with dimensions of 150 mm× 40 mm

This autonomous approach enhances the accuracy of RSSI-based measurements and supports optimization of RFID system deployment in industrial settings.

The solution chosen for the periodic inventory must meet the following conditions:

- to be easy to apply

- have a low investment cost

- not be sensitive to interference

- to provide high accuracy of the data provided

Another significant contribution is the work “SAR-Based Localisation of UHF-RFID Tags in Smart Warehouses” [24], which introduces two approaches to the localization of RFID-tagged items by the multi-aperture SAR method:

- SAR-WA (Single-Aperture Trajectory Method), using data collected from consecutive tag positions along one trajectory

- MT-SAR (Multi-Trajectory Method), which integrates data from several trajectories to enhance localization accuracy

Experiments conducted in a closed warehouse, at the University of Pisa, employed a mobile robot with differential drive kinematics, equipped with an Impinj Speedway R420 UHF-RFID reader, four Time-7 Compact Outdoor RAIN RFID antennas, a Slamtec RPLidar A34 laser rangefinder, and a mini-PC for data acquisition. The RFID tags were positioned at floor level to allow accurate trajectory mapping via the LIDAR system.

The two approaches of the SAR method were tested and analyzed within the conducted experiment. The obtained results confirmed that the MT-SAR method offers higher accuracy regarding the position of the tags than the SAR-WA method. Following the five test sequences performed, the measurements showed that the MT-SAR method allows localization with an error of only a few centimetres (between 2 and 4 cm).

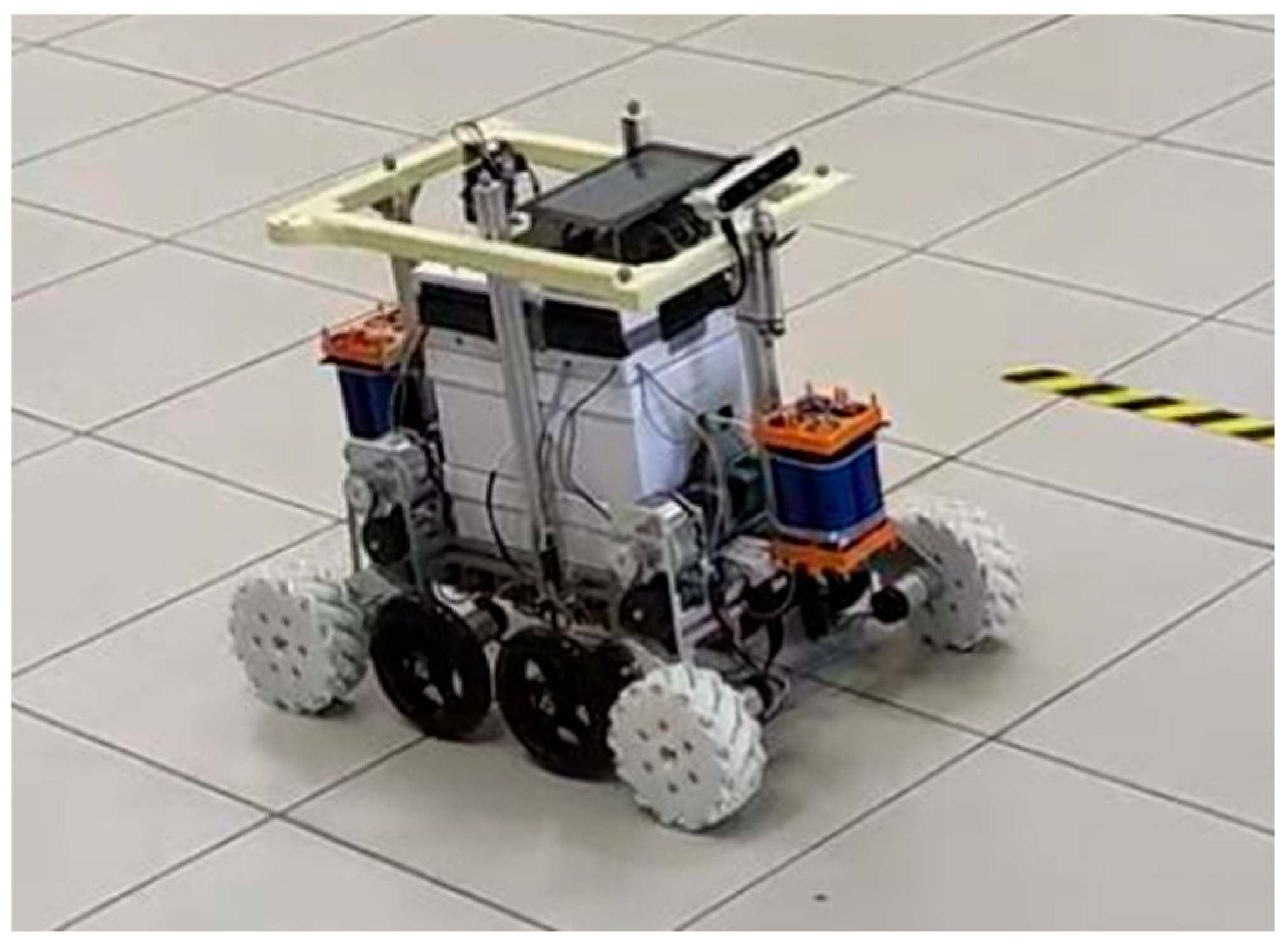

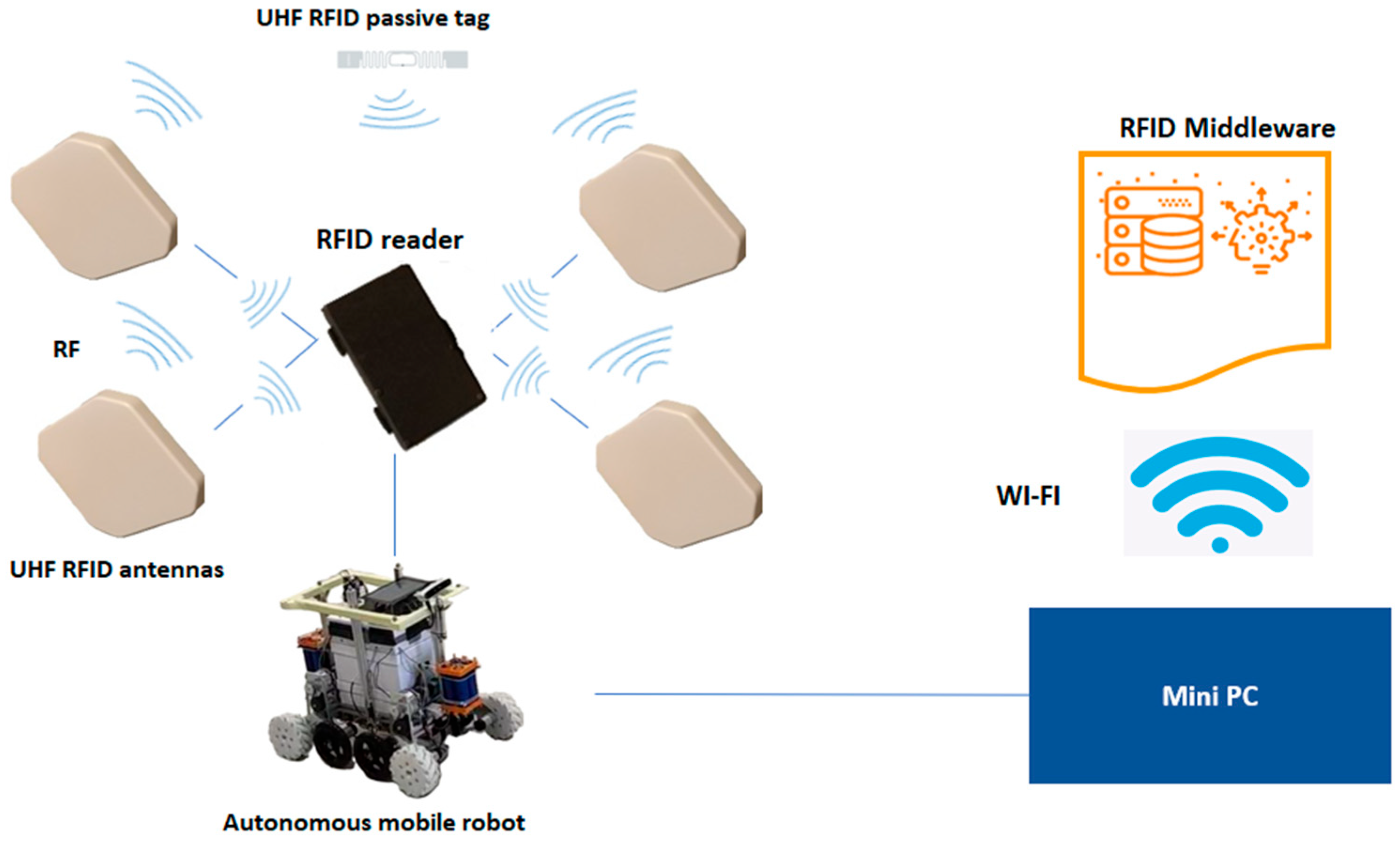

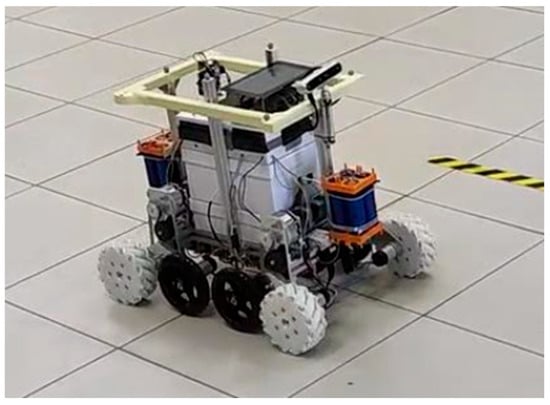

The robot shown in Figure 1 can be equipped with all the necessary hardware for UHF RFID signal measurement and for determining the optimal reading trajectory within the targeted industrial environment. It can also be integrated into the configuration of the automated inventory system.

Figure 1.

Autonomous mobile robot with differential rotation and dual mounting rails for the RFID system. Source: Personal contribution.

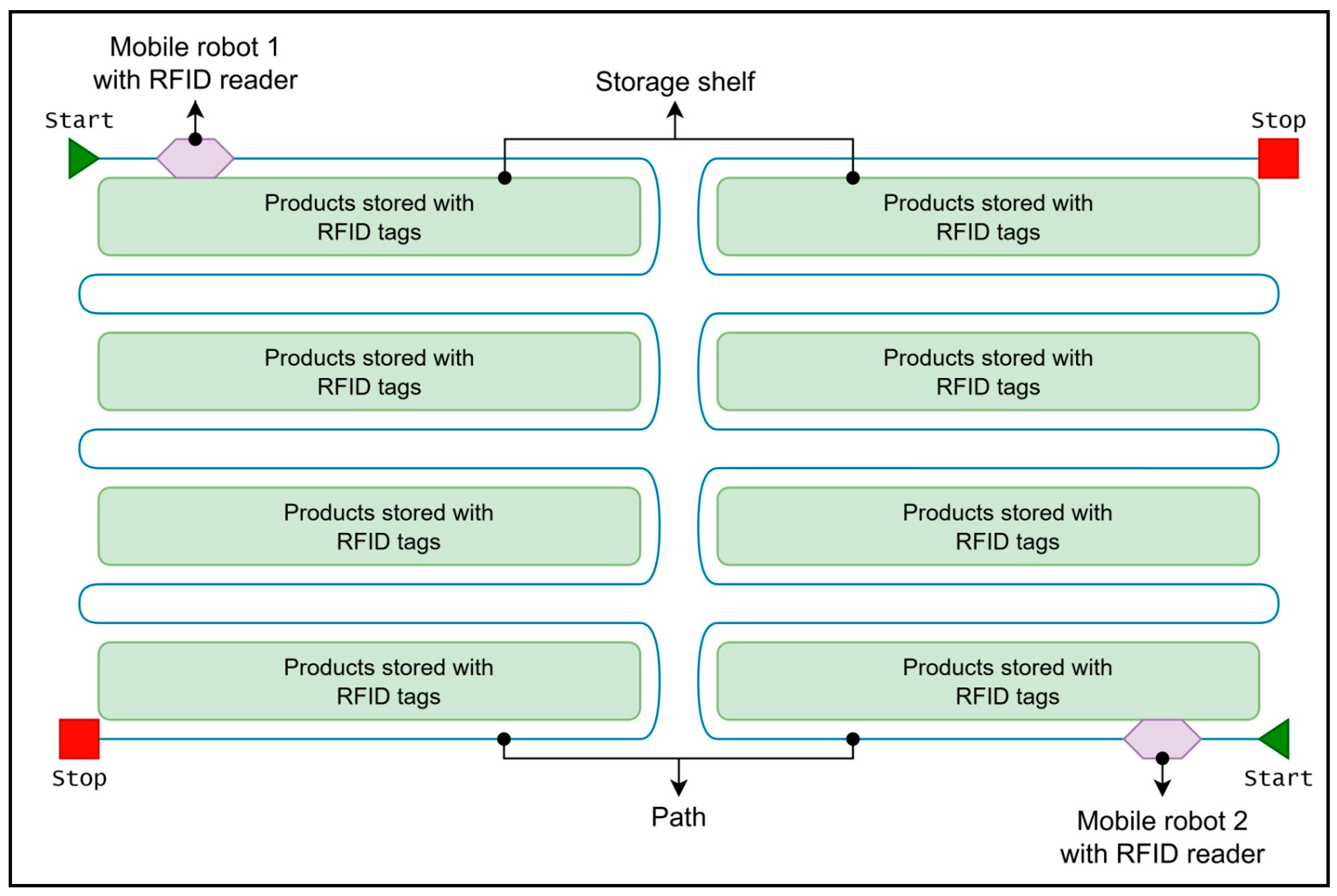

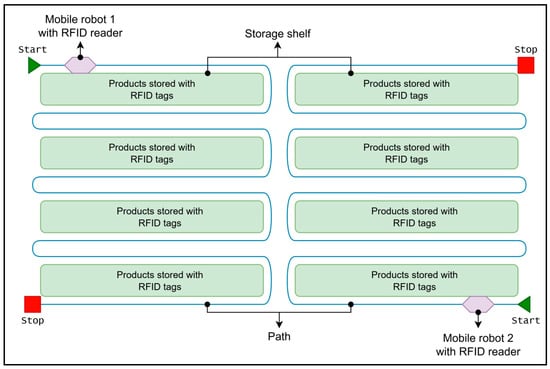

Figure 2 illustrates a typical reading trajectory that can be integrated into warehouse inventory workflows to ensure consistent coverage of RFID-tagged components.

Figure 2.

Reading trajectory example for warehouse inventory workflows. Source: Personal contribution.

3.2. Integration of Automatic Inventory into the Conceptual RFID Model

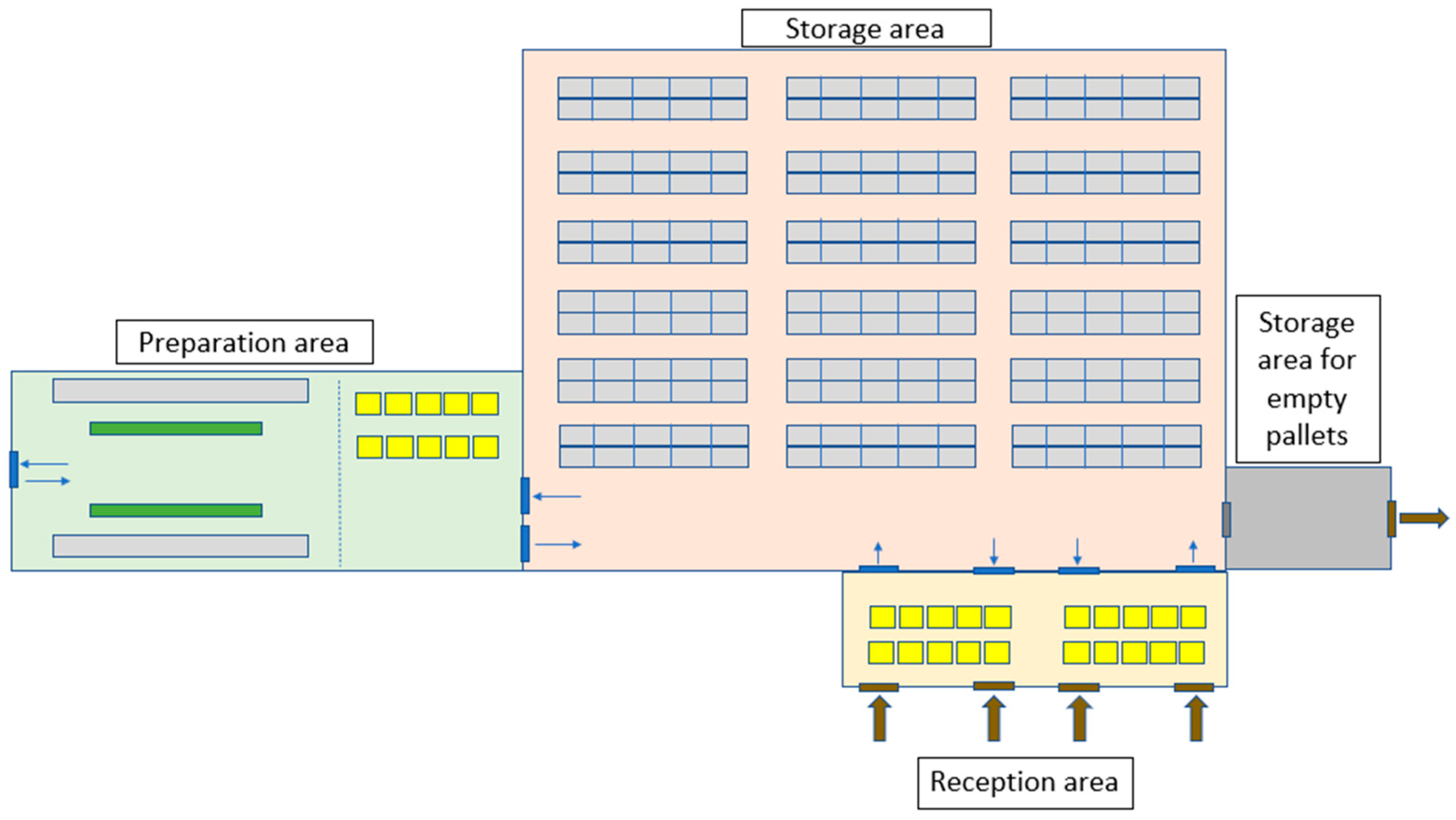

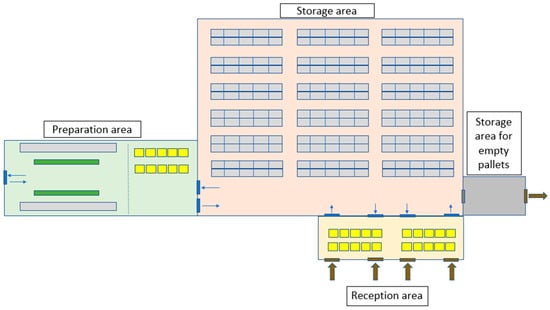

In the conceptual model developed in a previous study [22], a storage system was structured to respond to the specific of components warehouse for harness makers in the automotive industry. An RFID UHF system was configured to be implemented in all the areas of the warehouse, with the purpose of giving a simple and flexible version of RFID system that could be implemented with low investment costs in almost any existing warehouse.

The warehouse is composed by four areas as described in Figure 3:

Figure 3.

Wiring harness components warehouse layout [22].

Considering the complexity of the wiring harness assembly process and the growing diversity of components that must be managed in real time, RFID technology was identified as the most appropriate approach to ensure efficient traceability, accurate inventory control, and improved synchronization between the production and logistics stages.

Therefore, the system based on RFID UHF technology, shown in Figure 3, was implemented in the warehouse, composed of the following elements:

- RFID portals: placed at every entrance/exit between the areas of the warehouse and between the exterior and the warehouse

- Forklift trucks equipped with an RFID system

- RFID UHF passive tags mounted on the pallets, boxes, and shelves

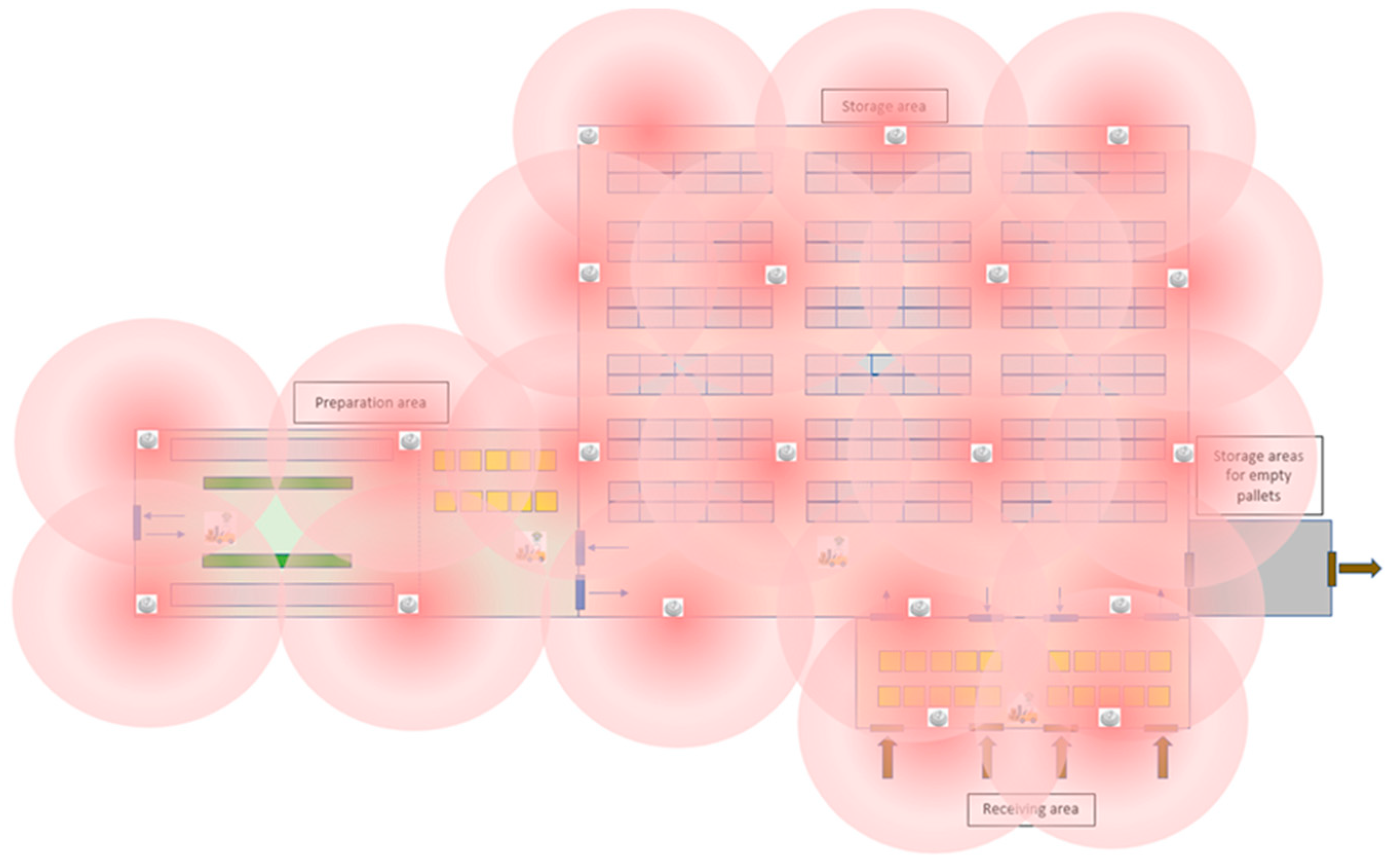

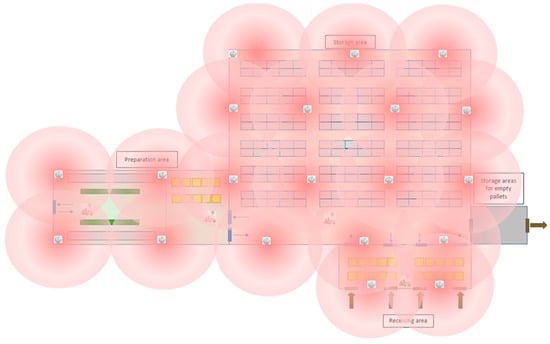

- RFID puck dots: active tags installed in all the areas of the warehouse (Figure 4) to complete the track and trace functionality

Figure 4. RFID puck dot implementation [22].

Figure 4. RFID puck dot implementation [22].

Errors in the inventory of the wiring components can lead to major productions delays or even quality issues. If a component is out of stock but appears available in the system, it could lead to the blockage of the assembly line due to the impossibility to find a compatible component to replace it in time. This is why the warehouse should be equipped with technology that does not leave room for human error. The objective of this study is to enhance the conceptual RFID model by incorporating automated inventory functionality. The aim is to develop a system capable of managing both the quantity and variety of wiring harness components, from supplier delivery through to the wiring harness assembly line.

The approach presented in this paper adapts the robot-based SAR localization concept to the conceptual RFID implementation model designed for a wiring harness components warehouse.

In the automatic inventory implementation phase, a robot with a configuration similar to the one proposed in the paper “SAR-based localization of UHF-RFID tags in smart warehouses” can be used to perform the measurements specific to each work environment and to establish the reference readings of the tags, based on the MT-SAR method and taking into account interferences from the warehouse. Mapping the warehouse with the help of the laser should be used to establish the parameters and the optimal route for the automatic inventory.

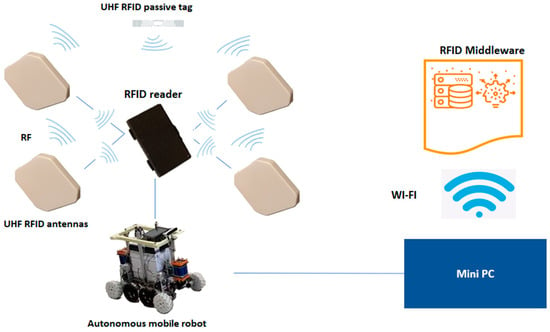

An autonomous mobile robot equipped with UHF RFID technology was proposed for periodic inventory operations. Within the theoretical model, the following configuration was chosen (Figure 5):

Figure 5.

RFID robot configuration. Source: Personal contribution.

- A four-wheel-drive autonomous mobile robot with differential rotation and dual mounting rails for the RFID system.

- An UHF RFID reader.

- Four RFID antennas (UHF band).

- A portable mini-PC responsible for data collection, filtering, and transmission to the RFID middleware.

4. Experimental Results

To validate the applicability of RFID technology in automatic inventory processes within the warehouse of a wiring harness manufacturer, experimental measurements were conducted focusing on the characterization of the reading field, the determination of hysteresis limits, and the analysis of performance dependence on tag distance and orientation.

The objectives of the experiment included identifying the optimal reading zones of the RFID antenna by delimiting stable regions and dead zones, analyzing the hysteresis phenomenon for both singular and multiple tags to understand signal persistence and its impact on inventory accuracy, and evaluating the influence of tag orientation on detection range and reliability.

The tests were carried out under controlled laboratory conditions to eliminate external variables that could affect the RFID system’s performance. The antenna and tags were positioned on a test bench with predefined coordinates, ensuring reproducible and precise movement along the X and Y axes. Measures were taken to minimize external electromagnetic interference by isolating the test area from radio wave sources or equipment operating in the same frequency band. Through this approach, the measurements accurately reflect the intrinsic characteristics of the antenna–tag system, enabling a clear analysis of the effects of distance, orientation, and tag configuration without the influence of perturbing factors typically present in real industrial environments.

4.1. Experimental Methodology

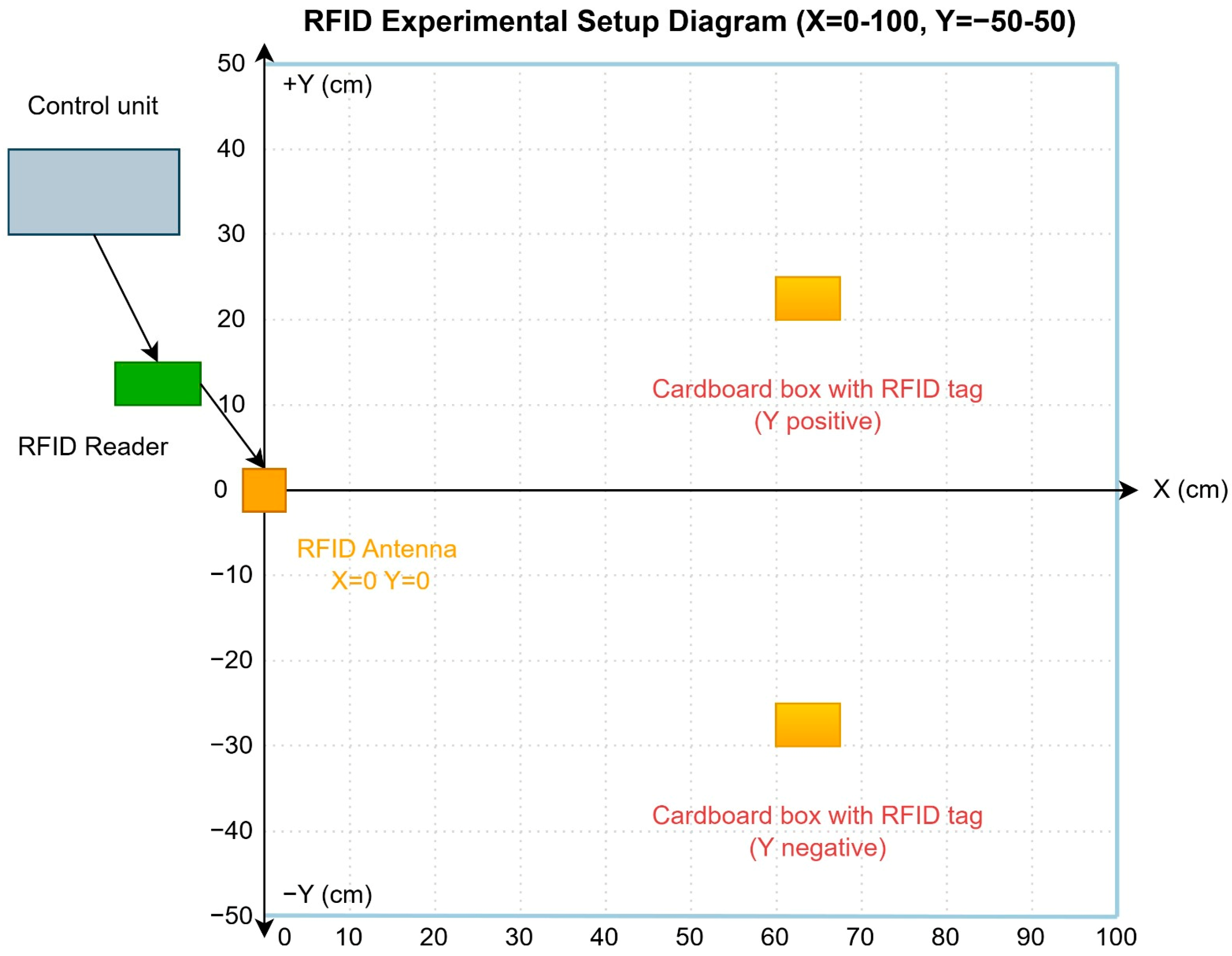

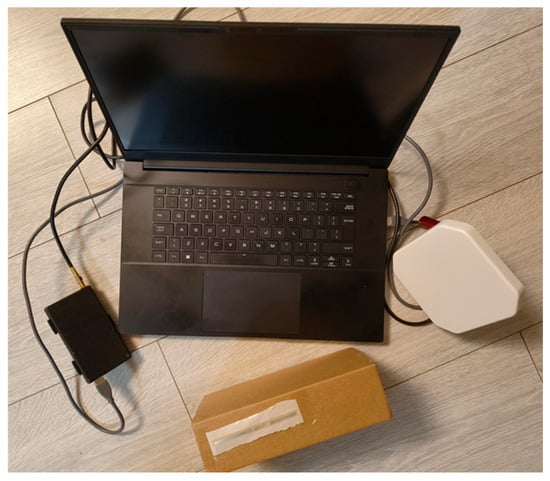

The equipment, presented in Figure 6, consisted of:

Figure 6.

Equipment used. Source: Personal contribution.

RFID antenna: A patch-type antenna employed for generating the reading field and connected to the RFID reader, positioned at the origin of the coordinate system (X = 0, Y = 0).

RFID reader: responsible for interrogating the tags and transmitting the acquired data to the control unit. The data were recorded in real time throughout the experiment.

Control unit: A laptop configured with dedicated software designed for collecting and processing raw reading data.

RFID tags: Passive tags attached to cardboard boxes to replicate the real operating conditions found in the component warehouse of a wiring harness manufacturer. The tags were progressively introduced into the reading field, moving along the X and Y axes.

Test surface: A transparent glass surface marked with X and Y coordinate axes, used to ensure the precise positioning of tags relative to the antenna.

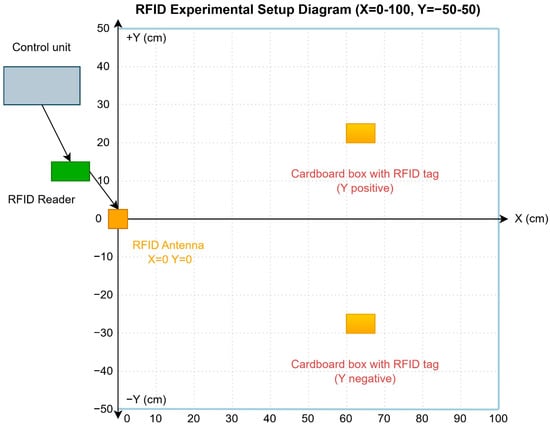

The experimental setup is represented in Figure 7.

Figure 7.

Schematic representation of the RFID experimental setup. Source: Personal contribution.

Measurement protocol:

Reading field mapping: Detection tests were carried out on an X–Y grid, recording the coordinates at which the first successful tag reading occurred.

Hysteresis analysis: Entry and exit distances from the reading field were recorded for both single tags and multiple-tag packaging, in order to assess signal persistence and detection stability.

Orientation influence: For Y = 0, the tags were tested at angles of 30°, 45°, 60°, 90°, and 180° relative to the plane of the antenna to evaluate the impact of orientation on reading performance.

Laboratory conditions: All measurements were conducted in a controlled environment, free of metallic structures and interference sources, to eliminate external variables that could affect the accuracy of the results.

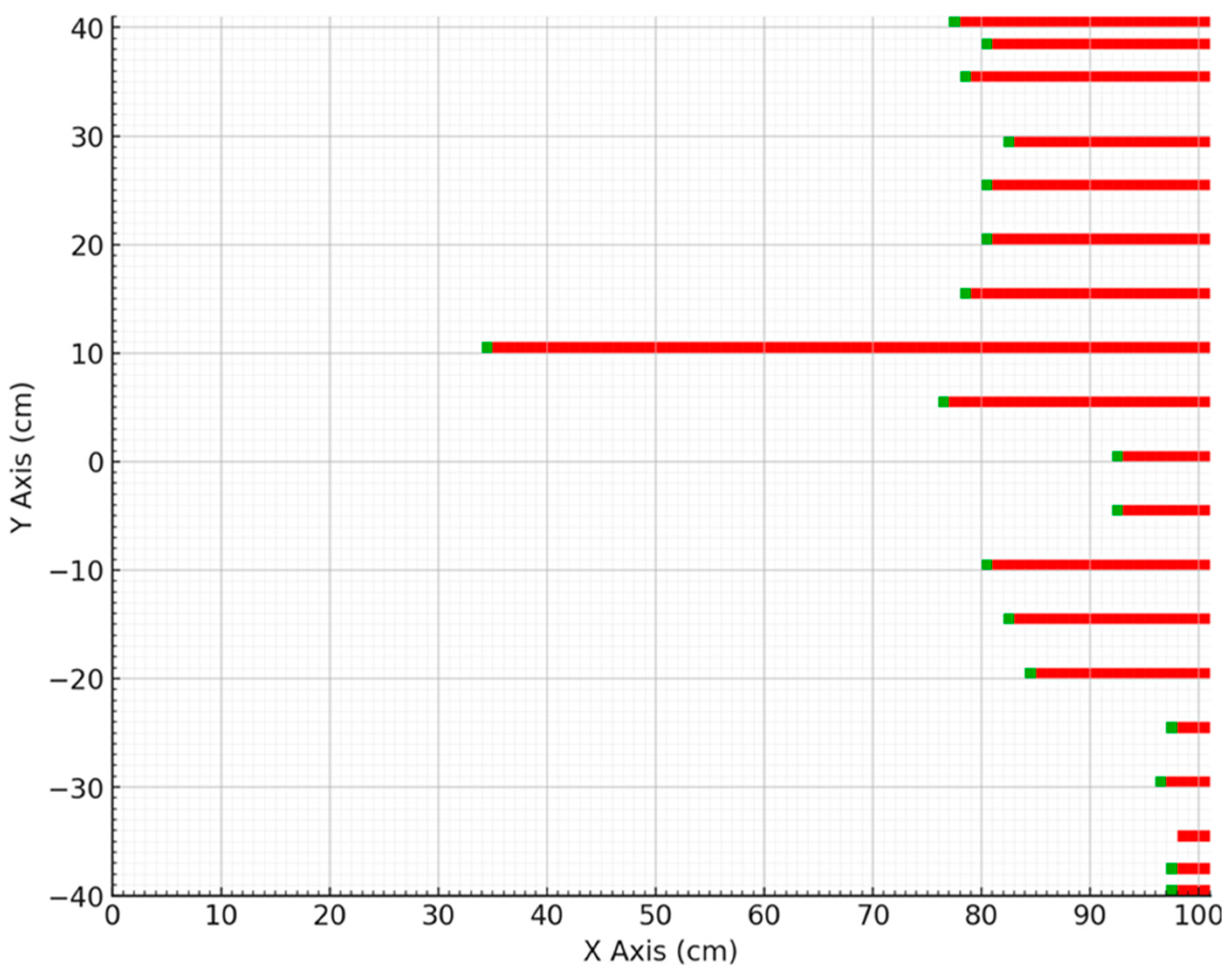

4.1.1. Reading Field Mapping

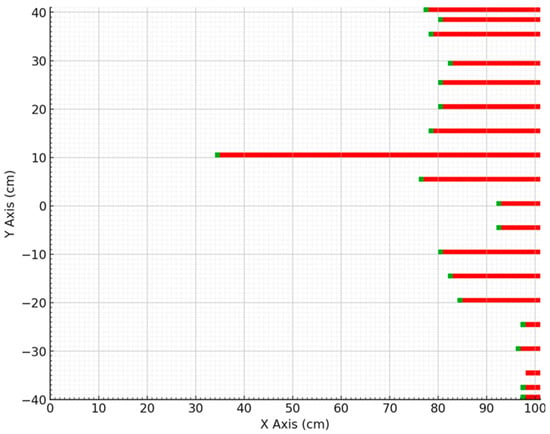

To identify the reading field, the RFID tag was gradually moved toward the antenna, and the coordinates corresponding to the entry points into the reading zone were recorded to map the detection field. Data were collected using a table configured with X and Y axis values, where the coordinates corresponding to successful tag detections were marked with the value “1.” Based on these recordings, the reading field of the antenna was outlined and subsequently represented in Figure 8.

Figure 8.

Tag Entry Map within the Reading Field. Source: Personal contribution.

Antenna positioning:

The antenna was positioned at the origin (0, 0) of the X and Y coordinate axes.

The X-axis (0–100 cm) represents the distance from the antenna, indicating how far the tag was moved in front of it.

The Y-axis (−50 to +50 cm) represents the lateral deviation from the central axis of the antenna (left–right direction).

Shape of the detected reading zone observed in the graph:

The reading field exhibits an irregular shape, which is typical for UHF RFID antennas, where the radiation lobes create discontinuous “islands” of detection.

The green zones (value = 1, corresponding to detected tags) are predominantly located in the range X = 80–100 cm.

Several “windows” of non-detection (red areas) appear even in regions relatively close to the antenna. These gaps in the radiation field are caused by electromagnetic wave interference, which leads to localized signal cancellation.

Interpretation of the RFID Reading Field Distribution:

The analysis of the experimental results obtained from mapping the RFID antenna’s reading field—positioned at the origin (0, 0)—reveals clear differences between the initial detection zone and the retention zone. The nearest coordinate at which tag identification was initiated was (34, 10), representing the lower boundary of the entry area. In most cases, the first readings occurred at greater distances, predominantly within X ≈ 80–100 cm and Y ≈ ±30 cm, indicating that detection probability peaks within a well-defined central corridor and decreases sharply near the antenna.

Once detected, the transponder remained readable as it approached the antenna, down to approximately 5 cm. This behaviour confirms the presence of operational hysteresis, where the conditions for initiating detection are stricter than those for maintaining it.

Practically, these results suggest that stable operation requires aligning tag trajectories with the high-probability acquisition zone (X ≈ 80–100 cm, Y ≈ ±30 cm). Although short-range retention is advantageous, it cannot compensate for an unstable entry into the field. Therefore, performance optimization should focus on adjusting antenna orientation and polarization or employing additional antennas to mitigate field discontinuities. The comparison between entry and retention maps can also be used as a methodological tool to evaluate reading field robustness and support RFID system design decisions.

4.1.2. Hysteresis (Single Packaging Unit)

To identify the entry and exit points within the reading field, the same procedure used for field mapping was applied, with the RFID tag being moved progressively toward the reader. Based on the previous readings, predefined detection coordinates were established along the X-axis, while the corresponding Y-axis coordinates were recorded for both the entry and exit positions, presented in Table 1. The only exception was represented by the entry and exit points located on the X-axis for Y = 0.

Table 1.

Coordinates of Entry and Exit Points within the Reading Field.

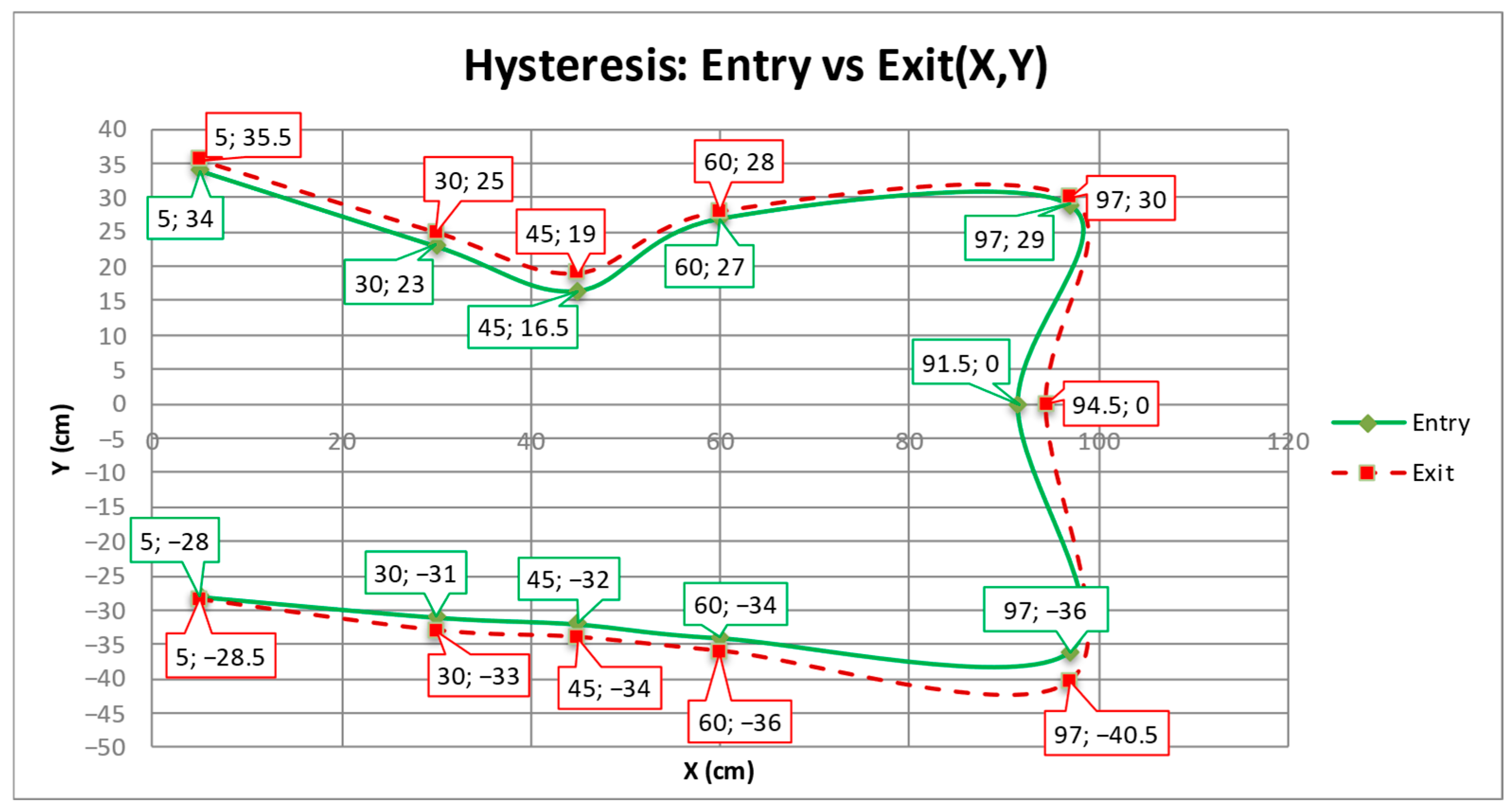

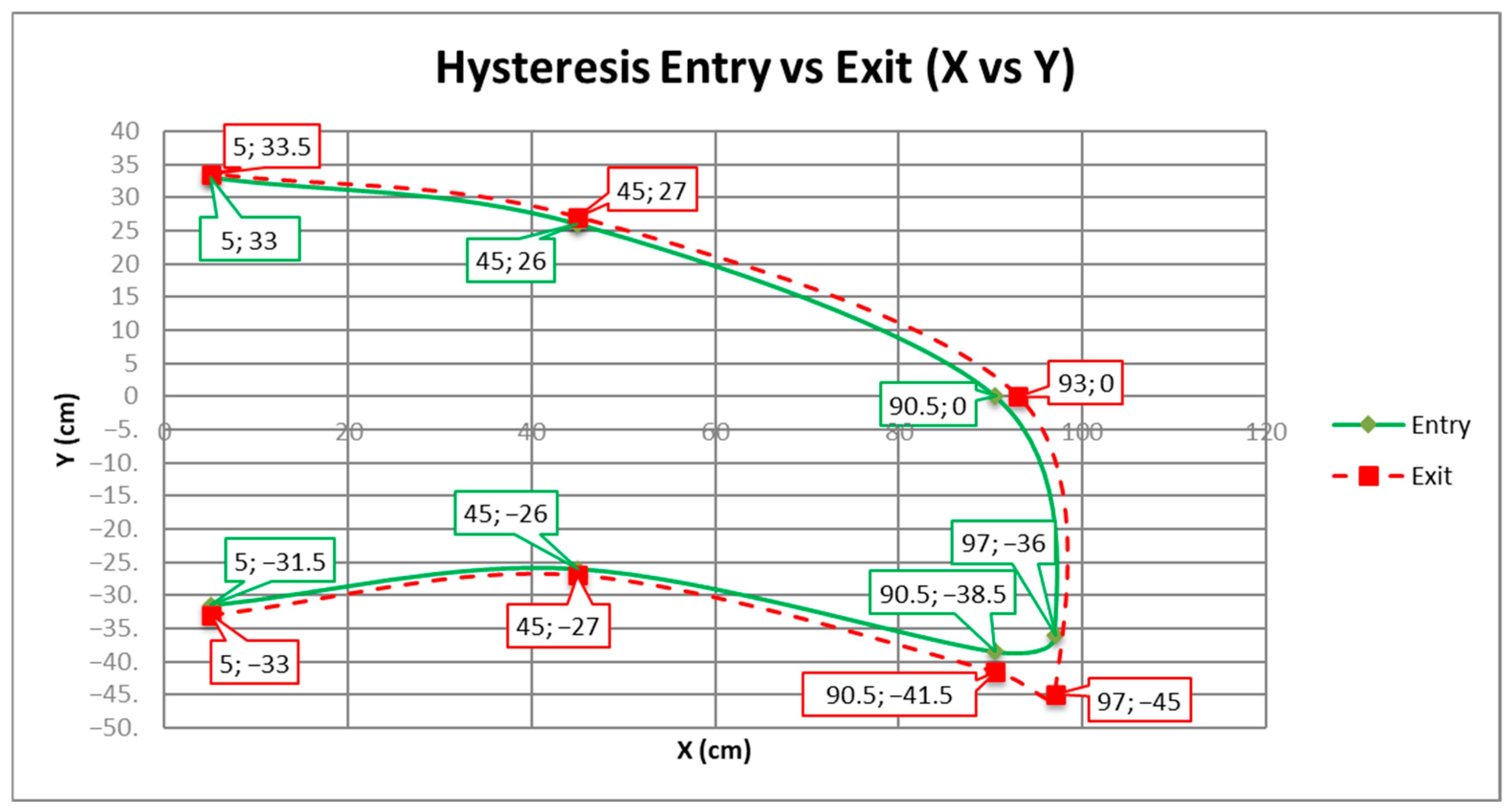

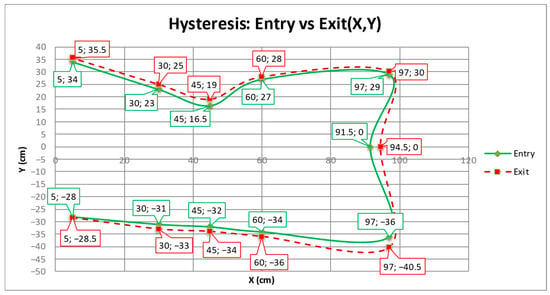

Based on these recordings, the entry and exit curves of the antenna’s reading field were defined and are illustrated in the graph from Figure 9.

Figure 9.

Hysteresis Graph (Single Packaging Unit). Source: Personal contribution.

Data and Graph Analysis:

- General structure of the reading field:

The entry and exit coordinates obtained within the range X = 5–97 cm and Y = −40.5…+35.5 cm describe a reading field with considerable lateral extension and a clearly defined active region. The distribution of entry and exit points highlights both a central stability zone and peripheral regions where the hysteresis phenomenon is more pronounced.

- 2.

- Hysteresis description:

- Proximal zone (X = 5–30 cm): The difference between entry and exit points ranges from approximately 1 to 2.5 cm (e.g., entry at Y = −28 cm and exit at Y = −28.5 cm; entry at Y = 23 cm and exit at Y = 25 cm). This small variation confirms high stability and a well-defined detection threshold.

- Median zone (X = 45–60 cm): The adjustment introduced for the exit point at X = 60 cm and Y = −36 cm results in a hysteresis of about 2 cm on the negative Y-axis, compared to the 1–2 cm differences observed previously. However, this interval still exhibits good reading reproducibility with moderate deviations.

- Distal zone (X = 91.5–97 cm): Hysteresis increases significantly, especially on the negative side of the Y-axis (entry at −36 cm and exit at −40.5 cm → difference of 4.5 cm). On the positive side, the amplitude of the phenomenon remains low (entry at 29 cm, exit at 30 cm).

- 3.

- Electromagnetic field asymmetry:

The extension of the field is more pronounced on the negative Y-axis (−40.5 cm) than on the positive side (+35.5 cm). This asymmetry indicates a non-uniform distribution of field intensity, where secondary lobes or reflections may cause differences in the depth of the reading zone.

- 4.

- Optimal tag passage zone:

Comparative analysis shows that the interval X = 30–60 cm represents the optimal region for the passage of tagged subunits. Within this range, the hysteresis amplitude remains low and constant, ensuring high predictability of the reading process.

The results confirm that RFID field hysteresis is dependent on lateral position and the polarity of the Y-axis. The variation observed at X = 60 cm shows a slight increase in the entry–exit gap on the negative side, though this does not compromise the overall stability of the central zone. Overall, the median region (X = 30–60 cm) provides the most reliable and reproducible identification area, while the field extremities (X ≥ 90 cm) exhibit more pronounced hysteresis, particularly along the negative direction.

4.1.3. Hysteresis (Multiple Packaging Subunits)

To test the feasibility of the proposed method for automatic inventory of components stored for wiring harness assembly, as well as to simulate the inventory process of packaging subunits, RFID tags were attached to two cardboard boxes, which were then placed inside a larger cardboard container. This assembly was used to identify the entry and exit points within the reading field when multiple tags were read simultaneously. The coordinates of entry and exit point within the reading field are registered in Table 2.

Table 2.

Coordinates of Entry and Exit Points within the Reading Field.

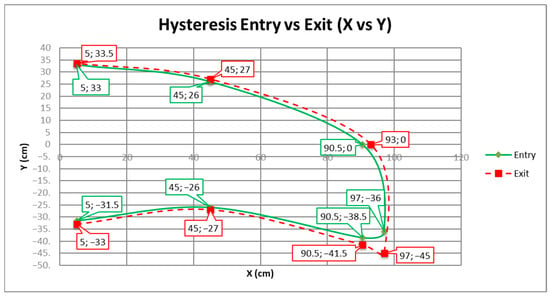

Based on these recordings, the entry and exit curves of the antenna’s reading field were defined and are illustrated in the graph from Figure 10.

Figure 10.

Hysteresis Graph (Multiple Packaging Subunits). Source: Personal contribution.

Data and Graph Analysis:

- General structure of the reading field:

Measurements performed within the range X = 5–97 cm and Y = −45…+33.5 cm reveal a well-defined active detection zone, though with a non-uniform distribution depending on the lateral distance from the antenna. The presence of two packaging levels causes a slight displacement of both the entry and exit points toward more extreme Y-axis values compared to the previous single-unit case.

- 2.

- Description of hysteresis:

- Proximal zone (X = 5 cm): The entry–exit difference is approximately 1.5 cm on the negative side (−31.5 vs. −33 cm) and about 0.5 cm on the positive side (+33 vs. +33.5 cm). These small variations confirm a high level of field stability near the antenna.

- Median zone (X = 45 cm): The readings are nearly overlapping (−26 vs. −27 cm; +26 vs. +27 cm), indicating a hysteresis of less than 1 cm and suggesting a clear and reproducible detection threshold.

- Distal zone (X = 90.5–97 cm): Here, hysteresis becomes significantly more pronounced. At X = 90.5 cm, the entry–exit difference reaches approximately 3 cm on the negative side (−38.5 vs. −41.5 cm), and at X = 97 cm it increases up to about 9 cm (−36 vs. −45 cm). This behaviour indicates a prolonged signal persistence after the tag has moved beyond the initial entry boundary of the reading field.

- 3.

- Field asymmetry:

A wider field extension is observed on the negative Y-axis (−45 cm) compared to the positive side (+33.5 cm). This asymmetry is accentuated by the presence of the larger packaging unit, which may cause partial shielding and radio wave reflection effects.

- 4.

- Optimal tag passage zone:

The data indicate that the most stable and reproducible detection region lies within X = 5–45 cm, where entry–exit differences are minimal and hysteresis is nearly absent. Conversely, the outer regions (X ≥ 90.5 cm) exhibit pronounced hysteresis and strong asymmetry, making them less suitable for the passage of packaged subunits.

- 5.

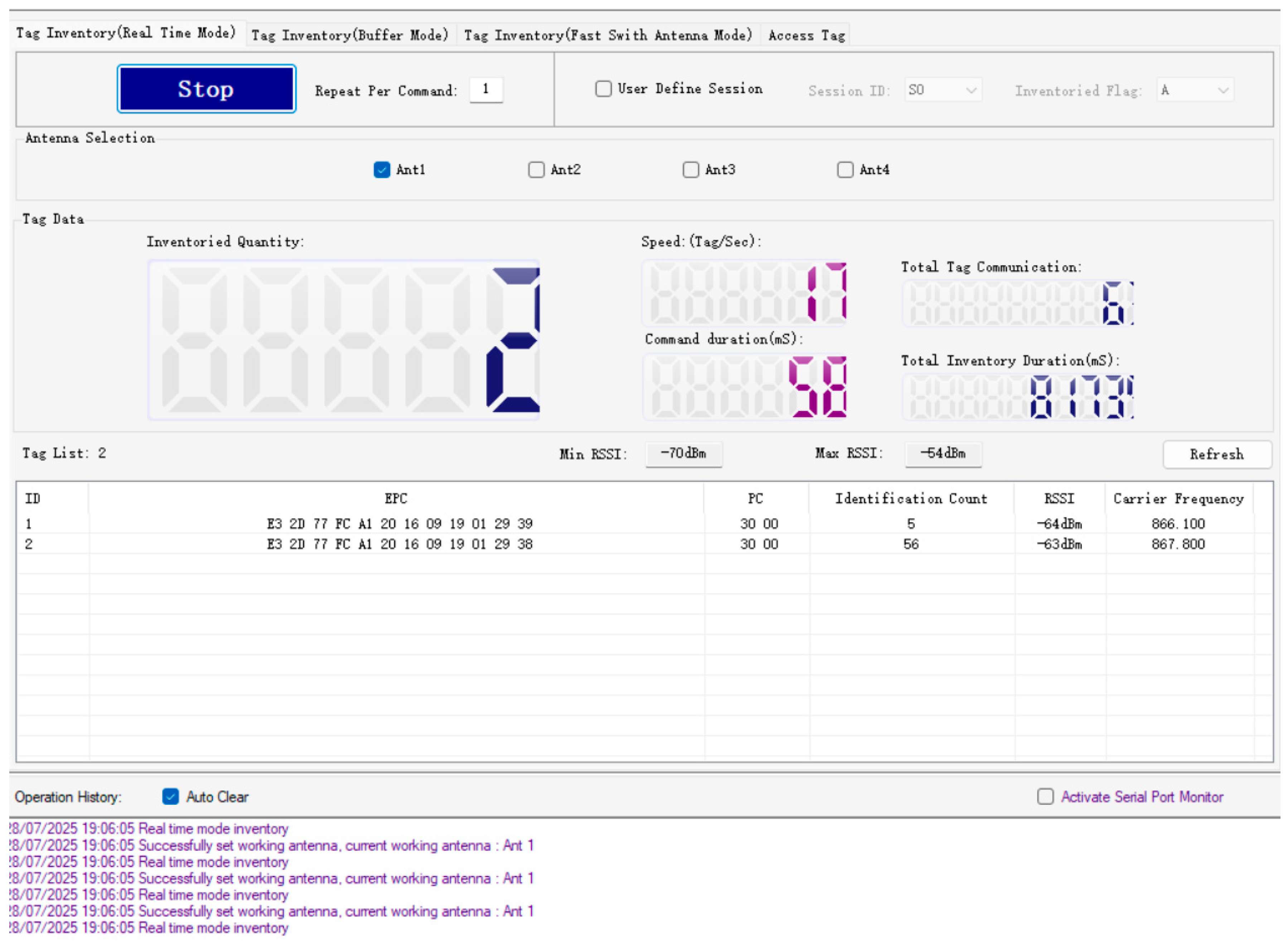

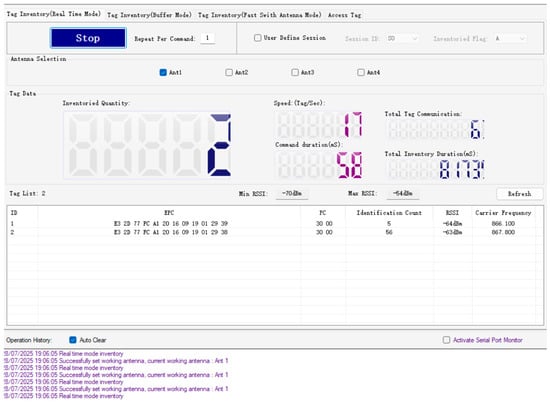

- Reading accuracy with multiple tags:

The test results confirm that all readings were performed with optimal accuracy. The reader correctly identified the number of tags entering the reading field, and no delays or reading errors were detected during the experiment. An example of multiple tags detection is presented in Figure 11.

Figure 11.

Example of Multiple Tag Identification. Source: Personal contribution.

In the case of packaging subunits, the hysteresis phenomenon becomes more pronounced at greater distances from the antenna, particularly on the negative side of the Y-axis. However, the median (X = 45 cm) and proximal (X = 5 cm) zones provide optimal conditions for tag identification, characterized by clear detection thresholds and minimal hysteresis. These results confirm that, for logistic flows involving packaging subunits, the optimal trajectory for tag passage is located within the central and near-field regions, while the outer areas should be avoided due to pronounced Y-axis asymmetries relative to the X-axis.

4.1.4. Comparison of Hysteresis: Single Tag vs. Multiple Tags

- General structure of the reading field:

- Single packaging unit (one tag): The active reading zone extends uniformly within the range X = 5–97 cm, with detections occurring on both the positive and negative sides of the Y-axis. The Entry and Exit curves are closely aligned in the central region, showing only moderate deviations toward the periphery.

- Packaging subunits (multiple tags): The reading field becomes more irregular, with Exit points extending further along the negative side of the Y-axis. The additional packaging layers introduce reflection and shielding effects, altering the field distribution.

- Hysteresis description:

- Single tag: Hysteresis remains low (1–2 cm) in the central region (X = 30–60 cm), but increases toward the outer limits, reaching approximately 4.5 cm at X = 97 cm.

- Multiple tags: Hysteresis stays small (≈1 cm) within X = 5–45 cm, yet becomes significantly more pronounced at larger distances—at X = 97 cm, the Entry–Exit difference reaches approximately 9 cm. This confirms a stronger persistence of detection when multiple tags are simultaneously present within the same package.

- Field asymmetry:

- Single tag: The field extension is relatively balanced, with a slight predominance on the negative side of the Y-axis (−40.5 cm vs. +35.5 cm).

- Multiple tags: The asymmetry becomes more evident, with detections extending to −45 cm on the negative side, while being limited to +33.5 cm on the positive side. This difference indicates that the interaction of radio waves with complex packaging structures particularly affects the negative Y-axis region.

- Optimal tag passage zone:

- Single tag: The optimal zone lies within X = 30–60 cm, where hysteresis is minimal and the Entry/Exit curves remain stable.

- Multiple tags: The optimal interval narrows to X = 5–45 cm, as for X ≥ 90 cm the field becomes unstable, and hysteresis increases sharply.

The comparative analysis demonstrates that multiple-tag packaging (two RFID-tagged boxes placed inside a larger container) leads to increased hysteresis and enhanced field asymmetry, especially along the negative Y-axis and at greater distances from the antenna (X ≥ 90 cm). Conversely, the central and near-field regions remain the most robust for both configurations, though with a narrower stable range in the case of packaged subunits.

These results highlight the importance of maintaining controlled tag trajectories and adapting the RFID system configuration to the specific characteristics of the packaging used, ensuring accurate and repeatable detection in automated logistics flows.

4.1.5. Distance and Orientation (Y = 0)

For this test, variation along the Y-axis was eliminated, while predefined positions on the X-axis and specific tag orientation angles relative to the antenna were established. Successive measurements were performed, and it was recorded whether tag detection occurred for each position. Successful identification was marked with the value “1,” whereas the absence of detection was marked with the value “0,” as presented in Table 3.

Table 3.

Coordinates of Entry and Exit Points within the Reading Field.

- Entry Thresholds (Entry_X_any)

- 30°: The first reading occurred at X = 5 cm and remained stable up to 90 cm.

- 45°: Detection also started at X = 5 cm but was lost at X = 90 cm, indicating a slightly shorter effective range than at 30°.

- 60°: Readings were obtained from X = 5 cm to 70 cm, with signal loss occurring beyond this point, showing a reduced reading range.

- 90°: Detection was limited to X = 5–15 cm, after which the signal disappeared completely, indicating very weak coupling.

- 180°: Detection was maintained from X = 5 cm up to 75 cm, followed by a sharp decrease, suggesting a more stable but clearly bounded behaviour compared to 60°.

- Maximum Reading Range (Rmax)

- 30°: ≈ 90 cm → optimal orientation for detection.

- 45° and 60°: ≈ 80 cm → good performance, slightly lower than at 30°.

- 180°: ≈ 75 cm → stable up to this distance, then drops sharply.

- 90°: ≈ 15 cm → very short range, indicating an unfavourable angle.

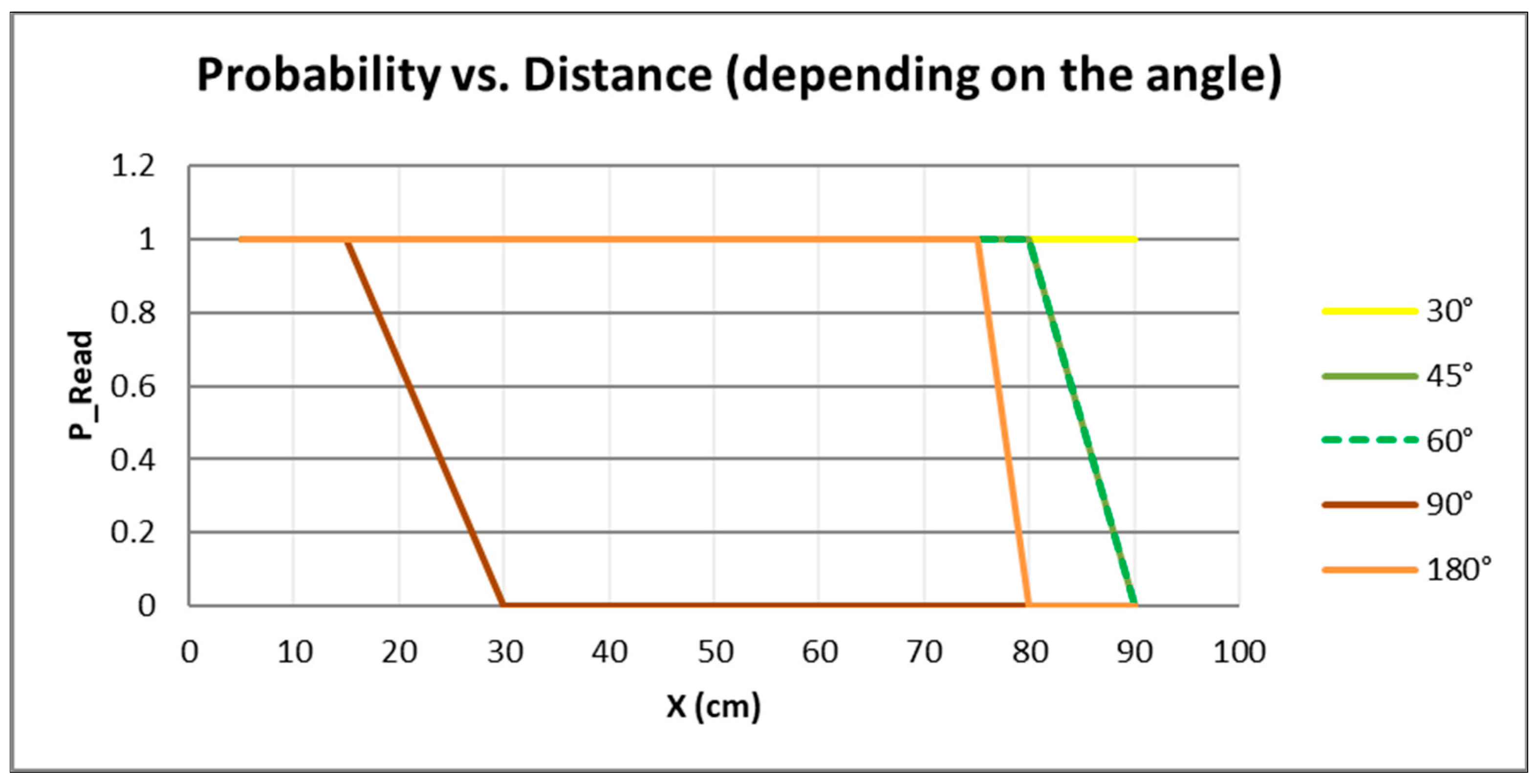

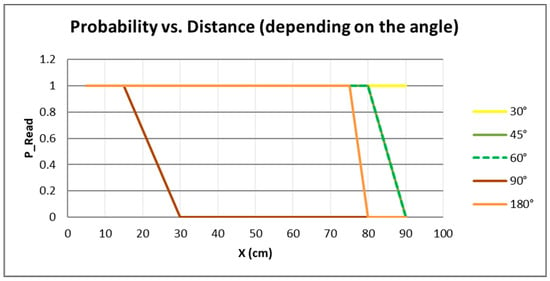

Probability vs. Distance:

The impact of distance and angles on tag identification presented in Figure 12 is described as it follows:

Figure 12.

Impact of Distance and Angle on Tag Identification. Source: Personal contribution.

The curves corresponding to 30°, 45°, and 60° overlap up to approximately 70 cm, but diverge at greater distances—the 30° orientation remains active up to 90 cm, whereas the 45° and 60° angles lose detection earlier.

The 180° curve shows a stable reading zone, with a well-defined limit around 75 cm.

The 90° curve drops sharply at 15 cm, indicating an unfavourable orientation with a very narrow effective reading field.

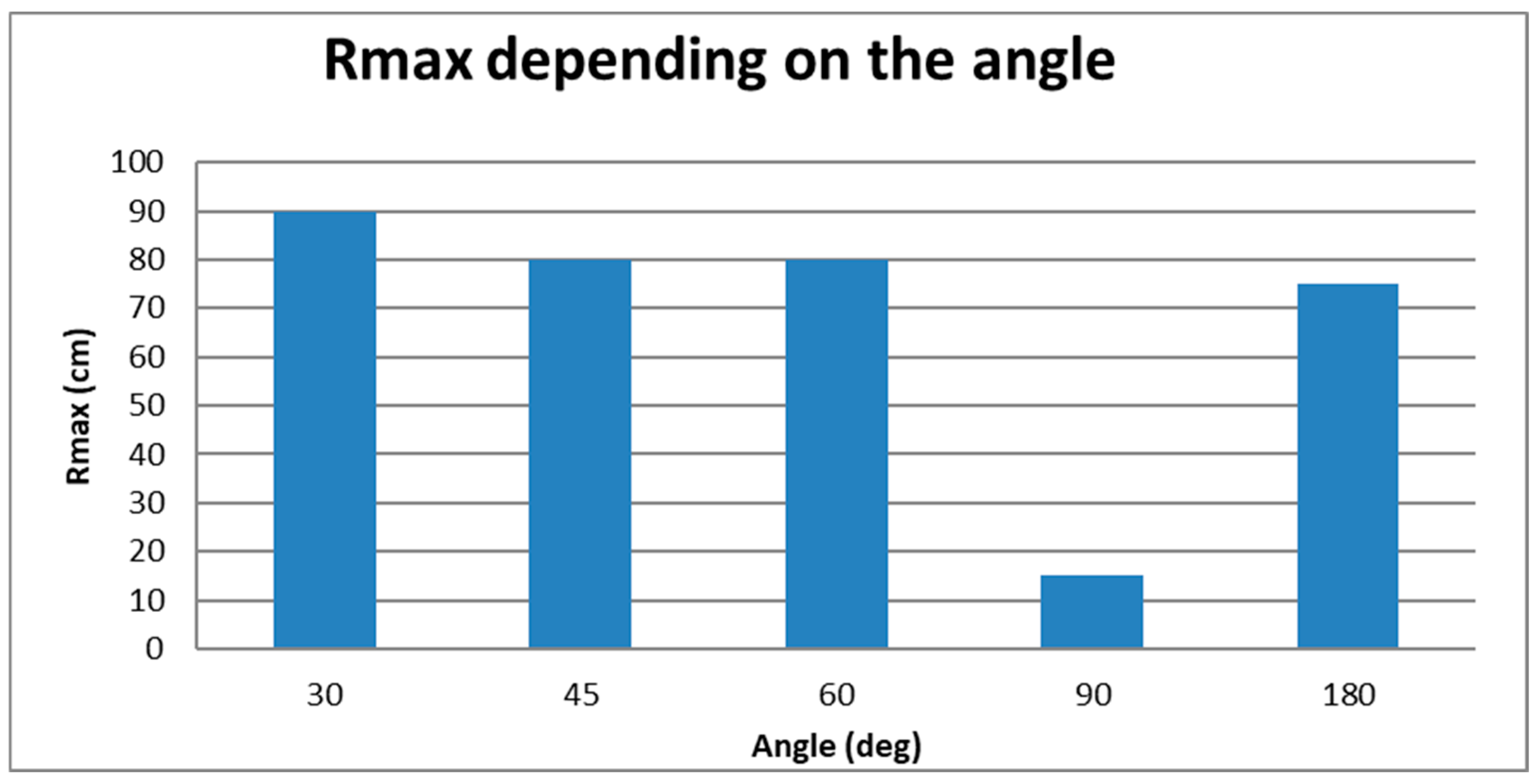

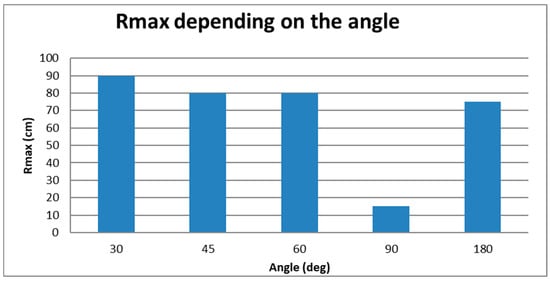

The influence of Tag Orientation on Maximum Reading Range is presented in Figure 13.

Figure 13.

Maximum reading range depending on the angle. Source: Personal contribution.

The graph confirms that a 30° orientation provides the best performance, followed by 45°, 60°, and 180°, while 90° clearly represents the weakest configuration.

The results indicate a strong dependence of RFID antenna performance on tag orientation:

- Orientations between 30° and 60° provide the most favourable detection conditions, with maximum reading distances of up to 80–90 cm.

- The 180° orientation allows stable reading up to approximately 75 cm, although it becomes sensitive at longer distances.

- The 90° orientation is critical, limiting detection to less than 20 cm, suggesting an unfavourable alignment between the electromagnetic field and the tag plane.

These findings confirm that polarization and the relative orientation between the antenna and the tag have a decisive influence on the overall performance of the RFID system.

This study addresses the need identified during the research gap analysis for a low-cost, easy-to-deploy RFID solution that can be seamlessly integrated and is suitable for metal-rich, high-variability warehouse environments. Combined with the results obtained during the experimental phase, these characteristics also make the proposed solution easier to validate in real industrial settings.

5. Conclusions

The proposed system can be implemented easily, requiring minimal changes to existing equipment or software, which keeps investment costs low. Automated periodic inventory enables optimal component stock management, reduces assembly-line supply errors, and supports crisis management during temporary component or raw-material shortages. Experimental validation was conducted in controlled laboratory conditions that do not fully represent real industrial environments. Tests excluded electromagnetic interference and used only one tag type. Future research will include various tag types to assess how tag selection affects system performance. Analysis shows that RFID system performance depends on field geometry, hysteresis, tag quantity, and orientation. Central and near-field zones offer stable readings and clear thresholds, while complex packaging and 90° misalignment reduce detection reliability. Optimal performance occurs with tag orientations between 30° and 60°, maximizing reading range and stability. Operational validation is critical to ensure the reliability of UHF RFID-based inventory systems in industrial settings. Future efforts should begin with a standardized storage structure for consistent container positioning and layout, followed by accurate tag placement and container orientation to improve read accuracy; establish and validate an optimized route for the unmanned guided vehicle under real conditions to ensure complete coverage and accurate data capture; define a reference reading during validation to serve as a benchmark for autonomous operation; conduct an interference study to identify and address external magnetic fields that may affect RFID signals, ensuring system robustness. By adopting these measures, manufacturers and logistics providers can transition from manual or barcode-based inventory methods to fully automated RFID systems, reducing labor costs, minimizing errors, and improving efficiency. Integrating with IoT platforms and warehouse management systems can also enable real-time analytics and predictive inventory control. Practically, these findings highlight the importance of standardizing tag orientation, managing logistic flows through stable field zones, and validating multi-package configurations for reliable identification. Wiring harness manufacturers and other automotive suppliers can improve warehouse efficiency, inventory control, and process visibility by adopting RFID technology. Increasing management awareness of modern automation technologies is essential to align industrial practices with current capabilities.

Author Contributions

Conceptualization, I.I. and C.-A.P.; Methodology, I.I., C.L.P. and C.-A.P.; Software, I.I. and C.-A.P.; Validation, I.I., C.L.P. and F.C.; Formal analysis, I.I., C.-A.P., F.C. and C.E.C.; Investigation, I.I., C.L.P. and C.-A.P.; Resources, C.L.P., T.G.D. and C.E.C.; Data curation, I.I., C.L.P. and C.-A.P.; Writing—original draft, I.I., C.L.P., C.-A.P. and F.C.; Writing—review and editing, I.I., C.L.P., T.G.D. and C.E.C.; Visualization, C.L.P., T.G.D. and C.E.C.; Supervision, C.L.P., T.G.D. and C.E.C.; Project administration, I.I.; Funding acquisition, I.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Škerlič, S.; Muha, R.; Sokolovskij, E. Application of modern warehouse technology in the Slovenian automotive industry. Transport 2017, 32, 415–425. [Google Scholar] [CrossRef]

- Bukova, B.; Tengler, J.; Brumercikova, E.; Brumercik, F.; Kissova, O. Environmental Burden Case Study of RFID Technology in Logistics Centre. Sensors 2023, 23, 1268. [Google Scholar] [CrossRef] [PubMed]

- Varese, E.; Claudia Pellicelli, A. The RFId Technology for Monitoring the Supply Chain and for Fighting Against Counterfeiting: A Fashion Company Case Study; IntechOpen: Rijeka, Croatia, 2020. [Google Scholar] [CrossRef]

- Qiao, J.; Hao, M.; Guo, M. Design of Meat Product Safety Information Chain Traceability System Based on UHF RFID. Sensors 2023, 23, 3372. [Google Scholar] [CrossRef] [PubMed]

- Gu, X.; Shang, J.; Shen, C. Power cable monitoring method based on UHF-RFID and deep learning in edge computing environment. J. Eng. 2024, 2024, 12407. [Google Scholar] [CrossRef]

- Gui, L.; Xu, S.; Xiao, F.; Shu, F.; Yu, S. Non-Line-of-Sight Localization of Passive UHF RFID Tags in Smart Storage Systems. IEEE Trans. Mob. Comput. 2021, 21, 3731–3743. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, J.; Yan, X.; Yang, X. Structure optimization of an ultrahigh frequency radio frequency identification tag thread based on the normal mode helix dipole antenna. Text. Res. J. 2020, 91, 523–532. [Google Scholar] [CrossRef]

- El Bakkali, M.; Ennasar, M.A.; El Mrabet, O.; García, R.F. Design and experimental validation of a multifunction Single layer UHF-RFID Tag antenna. Adv. Electromagn. 2022, 11, 22–29. [Google Scholar] [CrossRef]

- Xiang, J.; Zhao, A.; Tian, G.Y.; Woo, W.; Liu, L.; Li, H. Prospective RFID Sensors for the IoT Healthcare System. J. Sensors 2022, 2022, 8787275. [Google Scholar] [CrossRef]

- Zuo, J.; Feng, J.; Gameiro, M.G.; Tian, Y.; Liang, J.; Wang, Y.; Ding, J.; He, Q. RFID-based sensing in smart packaging for food applications: A review. Future Foods 2022, 6, 100198. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Profetto, L.; Gherardelli, M.; Iadanza, E. Radio Frequency Identification (RFID) in health care: Where are we? A scoping review. Health Technol. 2022, 12, 879–891. [Google Scholar] [CrossRef] [PubMed]

- Zeba, G.; Čičak, M. Application of RFID Technology for Better Efficiency of Resource Planning. In New Technologies, Development and Application III (NT 2020); Karabegović, I., Ed.; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2020; Volume 128. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, L.; Liu, H. Application Research of RFID Information in the Era of Internet of Things. In Urban Intelligence and Applications; Yuan, X., Elhoseny, M., Shi, J., Eds.; Communications in Computer and Information Science; Springer: Singapore, 2020; Volume 1319. [Google Scholar] [CrossRef]

- Ali, K.; Liu, A.X.; Chai, E.; Sundaresan, K. Monitoring browsing behavior of customers in retail stores via RFID imaging. IEEE Trans. Mob. Comput. 2020, 21, 1034–1048. [Google Scholar] [CrossRef]

- Hu, P. A 5G NR based System Architecture for Real-Time Control with Batteryless RFID Sensors. In Proceedings of the 2020 IEEE International Systems Conference (SysCon), Montreal, QC, Canada, 20–23 August 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–6. [Google Scholar]

- Bendavid, Y.; Rostampour, S.; Berrabah, Y.; Bagheri, N.; Safkhani, M. The Rise of Passive RFID RTLS Solutions in Industry 5.0. Sensors 2024, 24, 1711. [Google Scholar] [CrossRef] [PubMed]

- Aliakbarian, B.; Ghirlandi, S.; Rizzi, A.; Stefanini, R.; Vignali, G. Life cycle assessment of plastic and paper-based ultra high frequency RFID tags. Int. J. RF Technol. Res. Appl. 2023, 14, 17–32. [Google Scholar] [CrossRef]

- Claucherty, E.; Cummins, D.; Aliakbarian, B. RFID Unpacked: A Case Study in Employing RFID Tags from Item to Pallet Level. Electronics 2025, 14, 278. [Google Scholar] [CrossRef]

- Yu, X.; Wang, Z. Design and Implementation of a Low-Cost Universal RFID Wireless Logistics Terminal. J. Sens. 2021, 2021, 9755258. [Google Scholar] [CrossRef]

- Taoufik, S.; El Oualkadi, A.; Temcamani, F.; Dherbécourt, P. Simulation and Experimentation of an RFID System in the UHF Band for the Reliability of Passive Tags. HAL Open Archive. 2015. Available online: https://hal.science/hal-01171801/document (accessed on 4 January 2026).

- Spiridon, S.; Spiridon, F.; Dan, C.; Bodea, M. Phase Noise and Area–Power Trade-off in Frequency Synthesizers for Software-Defined Radio Transceivers. Sci. Bull. UPB Ser. C 2010, 72, 138–148. [Google Scholar]

- Stefan Iorga, I.; Popescu, A.C.; Popa, C.L.; Dobrescu, T.G.; Cotet, C.E. The usage of RFID technology in wiring component storage systems. Proc. Manuf. Syst. 2021, 16, 109–116. [Google Scholar]

- Svub, J.; Stasa, P.; Benes, F.; Vojtech, L.; Neruda, M.; Brozek, T. Autonomous System for UHF RFID Signal Measurement in Industrial Environment. In Proceedings of the 11th IFIP Wirelessand Mobile Networking Conference (WMNC2018), Valletta, Malta, 3–5 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 81–86. [Google Scholar]

- Bernardini, F.; Motroni, A.; Nepa, P.; Buffi, A.; Tellini, B. SAR-based Localization of UHF-RFID Tags in Smart Warehouses. In Proceedings of the 2020 5th International Conference on Smart and Sustainable Technologies, Split, Croatia, 23–26 September 2020; IEEE: Piscataway, NJ, USA, 2018; pp. 1–6. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.