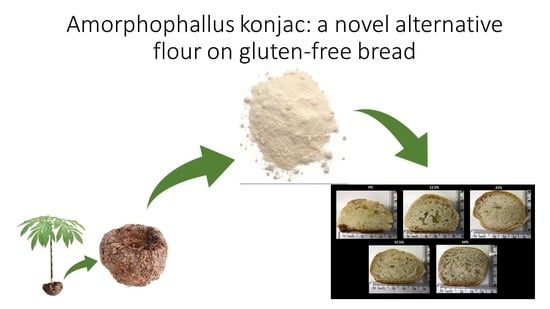

Amorphophallus konjac: A Novel Alternative Flour on Gluten-Free Bread

Abstract

1. Introduction

2. Materials and Methods

2.1. Bread Preparation

2.2. Chemical Characterization

2.3. Color Evaluation

2.4. Texture Analysis

2.5. Specific Volume

2.6. Total Energy Value

2.7. Statistical Analysis

3. Results

3.1. Preparation of Bread Samples and Cooking Quality

3.2. Chemical Characterization

3.3. Specific Volume, Firmness and Color

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Messa, S.; Nabeshima, E.H.; Montenegro, F.M.; Cruz, C.L.d.C.V. Estudo da obtenção de pães de forma sem glúten à base de derivados de mandioca. In Proceedings of the 11th Congresso Interinstitucional de Iniciação Científica—CIIC 2017, Campinas, Brazil, 2–4 August 2017; pp. 1–9. [Google Scholar]

- Pellegrini, N.; Agostoni, C. Nutritional aspects of gluten-free products. J. Sci. Food Agric. 2015, 95, 2380–2385. [Google Scholar] [CrossRef]

- Menga, V.; Amato, M.; Phillips, T.D.; Angelino, D.; Morreale, F.; Fares, C. Gluten-free pasta incorporating chia (Salvia hispanica L.) as thickening agent: An approach to naturally improve the nutritional profile and the in vitro carbohydrate digestibility. Food Chem. 2017, 221, 1954–1961. [Google Scholar] [CrossRef]

- Missbach, B.; Schwingshackl, L.; Billmann, A.; Mystek, A.; Hickelsberger, M.; Bauer, G.; König, J. Gluten-free food database: The nutritional quality and cost of packaged gluten-free foods. PeerJ 2015, 3, e1337. [Google Scholar] [CrossRef]

- Falcomer, A.L.; Santos Araújo, L.; Farage, P.; Santos Monteiro, J.; Yoshio Nakano, E.; Puppin Zandonadi, R. Gluten contamination in food services and industry: A systematic review. Crit. Rev. Food Sci. Nutr. 2018, 60, 479–493. [Google Scholar] [CrossRef]

- Machado, J.; Gandolfi, L.; Coutinho De Almeida, F.; Malta Almeida, L.; Puppin Zandonadi, R.; Pratesi, R. Gluten-free dietary compliance in Brazilian celiac patients: Questionnaire versus serological test. Nutr. Clin. Diet. Hosp. 2013, 33, 46–49. [Google Scholar] [CrossRef]

- Farage, P.; Zandonadi, R.P.; Ginani, V.C.; Gandolfi, L.; Nakano, E.Y.; Pratesi, R. Gluten-free diet: From development to assessment of a check-list designed for the prevention of gluten cross-contamination in food services. Nutrients 2018, 10, 1274. [Google Scholar] [CrossRef] [PubMed]

- Cross, C. Gluten-free industry is healthy, but is the food? CMAJ 2013, 185, E610. [Google Scholar] [CrossRef] [PubMed]

- Melini, V.; Melini, F. Gluten-free diet: Gaps and needs for a healthier diet. Nutrients 2019, 11, 170. [Google Scholar] [CrossRef]

- Sapone, A.; Bai, J.C.; Ciacci, C.; Dolinsek, J.; Green, P.H.R.; Hadjivassiliou, M.; Kaukinen, K.; Rostami, K.; Sanders, D.S.; Schumann, M.; et al. Spectrum of gluten-related disorders: Consensus on new nomenclature and classification. BMC Med. 2012, 10, 13. [Google Scholar] [CrossRef] [PubMed]

- Gadelha de Mattos, Y.; Puppin Zandonadi, R.; Gandolfi, L.; Pratesi, R.; Yoshio Nakano, E.; Pratesi, C. Self-Reported Non-Celiac Gluten Sensitivity in Brazil: Translation, Cultural Adaptation, and Validation of Italian Questionnaire. Nutrients 2019, 11, 781. [Google Scholar] [CrossRef]

- STATISTA. Global Gluten-Free Food Market Value from 2019 to 2025 (in Billion U.S. Dollars). 2018. Available online: https://www.statista.com/statistics/248467/global-gluten-free-food-market-size/#:~:text=The%20global%20market%20for%20gluten,to%208.3%20billion%20U.S.%20dollars (accessed on 20 January 2021).

- Houben, A.; Höchstötter, A.; Becker, T. Possibilities to increase the quality in gluten-free bread production: An overview. Eur. Food Res. Technol. 2012, 235, 195–208. [Google Scholar] [CrossRef]

- Bagolin do Nascimento, A.; Fiates Rataichesck Medeiros, G.; Teixeira, E. Availbility, cost and nutitional composition of gluten-free products. Br. Food J. 2013, 116, 1842–1852. [Google Scholar] [CrossRef]

- Pszczola, D.E. The rise of gluten-free. Food Technol. 2012, 66, 55–66. [Google Scholar]

- Foste, M.; Verheyen, C.; Jekle, M.; Becker, T. Fibres of milling and fruit processing by-products in gluten-free bread making: A review of hydration properties, dough formation and quality-improving strategies. Food Chem. 2019, 306, 125451. [Google Scholar] [CrossRef]

- Queiroz, M.B.; Nabeshima, E.H. Naturalidade e Autenticidade. In Brasil Bakery & Confectionery Trends; ITAL: Campinas, Brazil, 2020; pp. 158–195. [Google Scholar]

- Zandonadi, R.P.; Botelho, R.B.A.; Araújo, W.M.C. Psyllium as a Substitute for Gluten in Bread. J. Am. Diet. Assoc. 2009, 109, 1781–1784. [Google Scholar] [CrossRef]

- Chua, M.; Baldwin, T.C.; Hocking, T.J.; Chan, K. Traditional uses and potential health benefits of Amorphophallus konjac K. Koch ex N.E.Br. J. Ethnopharmacol. 2010, 128, 268–278. [Google Scholar] [CrossRef]

- Choi, K.H.; Kim, S.T.; Bin, B.H.; Park, P.J. Effect of konjac glucomannan (Kgm) on the reconstitution of the dermal environment against uvb-induced condition. Nutrients 2020, 12, 2779. [Google Scholar] [CrossRef] [PubMed]

- Impaprasert, R.; Piyarat, S.; Sophontanakij, N.; Sakulnate, N.; Paengkanya, S.; Borompichaichartkul, C.; Srzednicki, G. Rehydration and textural properties of dried konjac noodles: Effect of alkaline and some gelling agents. Horticulturae 2017, 3, 20. [Google Scholar] [CrossRef]

- Zannini, E.; Jones, J.M.; Renzetti, S.; Arendt, E.K. Functional Replacements for Gluten. Annu. Rev. Food Sci. Technol. 2012, 3, 227–245. [Google Scholar] [CrossRef]

- Li, B.; Xia, J.; Wang, Y.; Xie, B. Grain-Size Effect on the Structure and Antiobesity Activity of Konjac Flour. J. Agric. Food Chem. 2005, 53, 7404–7407. [Google Scholar] [CrossRef]

- Chen, H.-L.; Cheng, H.-C.; Liu, Y.-J.; Liu, S.-Y.; Wu, W.-T. Konjac acts as a natural laxative by increasing stool bulk and improving colonic ecology in healthy adults. Nutrition 2006, 22, 1112–1119. [Google Scholar] [CrossRef]

- Li, B.; Shah, B.R.; Wang, L.; Liu, S.; Li, Y.; Wei, X.; Jin, W.; Li, Z. Health benefits of konjac glucomannan with special focus on diabetes. Bioact. Carbohydr. Diet. Fibre 2015, 5, 179–187. [Google Scholar] [CrossRef]

- Nakamura, R.; Teshima, Y.; Miura, M.; Konishi, F. Effect of Adding Glucomannan on the Rheological Properties, Sensory Characteristics and Staling of Gluten-free Rice Bread. J. Home Econ. Jpn. 2016, 67, 141–150. [Google Scholar] [CrossRef]

- Moore, M.M.; Schober, T.J.; Dockery, P.; Arendt, E.K. Textural comparison of gluten-free and wheat-based doughs, batters and breads. Cereal Chem. 2004, 81, 567–575. [Google Scholar] [CrossRef]

- Andrade de Aguiar, L.; Bobrowski Rodrigues, D.; Vieira Queiroz, V.A.; Melo, L.; de Lacerde de Oliviera Pineli, L. Comparison of two rapid descriptive sensory techniques for profiling and screening of drivers of liking of sorghum breads. Food Res. Int. 2020, 106, 892–900. [Google Scholar] [CrossRef]

- Canga, A.G.; Martínez, N.F.; Sahagún, A.M.; Vieitez, J.J.G.; Liébana, M.J.D.; Pardo, Á.P.C.; Robles, L.J.C.; Sierra, M. Glucomanano: Propiedades y aplicaciones terapéuticas. Nutr. Hosp. 2004, 19, 45–50. [Google Scholar]

- Araújo, W.M.C.; Botelho, R.B.A.; Pilla, N.M.; Borgo, L.A. Alquimia dos Alimentos, 2nd ed.; Senac: Brasilia, Brazil, 2014. [Google Scholar]

- Encina-Zelada, C.R.; Cadavez, V.; Teixeira, J.A. Bread by a Mixture Design of Xanthan, Guar, and Hydroxypropyl Methyl Cellulose Gums. Foods 2019, 8, 156. [Google Scholar] [CrossRef]

- Izidoro, D.R.; Scheer, A.d.P.; Negre, M.F.d.O.; Haminiuk, C.W.I.; Sierakowski, M.-R. Avaliação físico-química, colorimétrica e aceitação sensorial de emulsão estabilizada com polpa de banana verde. Rev. Inst. Adolfo Lutz 2008, 67, 167–176. [Google Scholar]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists, 19th ed.; AOAC International: Rockville, MD, USA, 2012. [Google Scholar]

- AOCS. Approved Procedure Am 5-04 Rapid Determination of Oil/Fat Utilizing High Temperature Solvent Extraction; AOCS: Urbana, IL, USA, 2004; pp. 4–6. [Google Scholar]

- Little, A. A research note off on a tangent. J. Food Sci. 1975, 40, 410–411. [Google Scholar] [CrossRef]

- Mclellan, M.R.; Lind, L.R.; Kime, R.W. Hue Angle Determinations and Statistical. J. Food Qual. 1994, 18, 235–240. [Google Scholar] [CrossRef]

- Maskan, M. Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying. J. Food Eng. 2001, 48, 177–182. [Google Scholar] [CrossRef]

- Francis, F.J. The origin of tan-1 a/b. J. Food Sci. 1975, 40, 412. [Google Scholar] [CrossRef]

- American Association of Cereal Chemists. AACC 74-09.01: Measurement of Bread Firmness by Universal Testing Machine; AACC: St. Paul, MN, USA, 1999. [Google Scholar]

- AACC. Approved Methods of the American Association of Cereal Chemists, 10th ed.; AACC: St. Paul, MN, USA, 2000. [Google Scholar]

- Ribeiro, P.; de Morais, T.B.; Colugnati, F.A.B.; Sigulem, D.M. Tabelas de composição química de alimentos: Análise comparativa com resultados laboratoriais. Rev. Saude Publica 2003, 37, 216–225. [Google Scholar] [CrossRef] [PubMed]

- Evangelho, J.A.; Pinto, V.Z.; Zavareze, R.E.; Vanier, L.N.; Dias, A.R.G.; Barbosa, L.M.P.B. Propriedades tecnológicas e nutricionais de pães preparados com diferentes proporções de farinha de arroz e farinha de arroz extrusada. Rev. Bras. Agrocienc. 2012, 18, 264–282. [Google Scholar]

- Jacomino, A.P.; Mendonça, K.; Kluge, R.A. Armazenamento refrigerado de limões “Siciliano” tratados com etileno. Rev. Bras. Frutic. 2003, 25, 45–48. [Google Scholar] [CrossRef]

- FMCG NEWS GLOBAL. Global Bread and Bakery Consumption Continues to Experience Modest Growth. 2018. Available online: https://www.bizcommunity.com/Article/1/162/176273.html (accessed on 28 April 2019).

- Eglite, A.; Kunkulberga, D. Foodbalt 2017 Bread Choice and Consumption Trends. In Proceedings of the 11th Baltic Conference on Food Science and Technology “Food Science and Technology in a Changing World”, Jelgava, Latvia, 27–28 April 2017; pp. 178–182. [Google Scholar] [CrossRef]

- The World Bank Global consumption database: Bread. Available online: http://datatopics.worldbank.org/consumption/product/Bread (accessed on 28 April 2019).

- Turkut, G.M.; Cakmak, H.; Kumcuoglu, S.; Tavman, S. Effect of quinoa flour on gluten-free bread batter rheology and bread quality. J. Cereal Sci. 2016, 69, 174–181. [Google Scholar] [CrossRef]

- Horstmann, S.W.; Foschia, M.; Arendt, E.K. Correlation analysis of protein quality characteristics with gluten-free bread properties. Food Funct. 2017, 8, 2465–2474. [Google Scholar] [CrossRef] [PubMed]

- Saueressig, A.L.C.; Kaminski, T.A.; Escobar, T.D. Inclusion of dietary fiber in gluten-free breads. Braz. J. Food Technol. 2016, 19, e2014045. [Google Scholar]

- Wang, K.; Lu, F.; Zhao, L.; Han, C. Recent developments in gluten-free bread baking approaches: A review. Food Sci. Technol. 2017, 37 (Suppl. 1), 1–9. [Google Scholar] [CrossRef]

- Cornicelli, M.; Saba, M.; Machello, N.; Silano, M.; Neuhold, S. Nutritional composition of gluten-free food versus regular food sold in the Italian market. Dig. Liver Dis. 2018, 50, 1305–1308. [Google Scholar] [CrossRef]

- Roman, L.; Belorio, M.; Gomez, M. Gluten-Free Breads: The Gap Between Research and Commercial Reality; Blackwell Publishing Inc.: Hoboken, NJ, USA, 2019; Volume 18, pp. 690–702. [Google Scholar]

- Brandão, S.S.; Lira, H.d.L. Tecnologia de Panificação e Confeitaria; EDUFRPE: Recife, Brazil, 2011; ISBN 9788579460852. [Google Scholar]

- Jamieson, J.A.; Weir, M.; Gougeon, L. Canadian packaged gluten-free foods are less nutritious than their regular gluten-containing counterparts. PeerJ 2018, 6, e5875. [Google Scholar] [CrossRef] [PubMed]

- Parry, J.M. Konjac Glucomannan. In Food Stabilizers, Thickeners and Gelling Agents; Wiley-Blackwell: Hoboken, NJ, USA, 2010; pp. 216–234. [Google Scholar]

- Ministério da Saúde—Agência Nacional de Vigilância Sanitária. RDC No 54, de 12 de Novembro de 2012; Ministério da Saúde—Agência Nacional de Vigilância Sanitária: Brasília, Brazil, 2012.

- Calvo-Lerma, J.; Crespo-Escobar, P.; Martínez-Barona, S.; Fornés-Ferrer, V.; Donat, E.; Ribes-Koninckx, C. Differences in the macronutrient and dietary fibre profile of gluten-free products as compared to their gluten-containing counterparts. Eur. J. Clin. Nutr. 2019, 73, 930–936. [Google Scholar] [CrossRef]

- Capriles, V.D.; Arêas, J.A.G. Novel Approaches in Gluten-Free Breadmaking: Interface between Food Science, Nutrition, and Health. Compr. Rev. Food Sci. Food Saf. 2014, 13, 871–890. [Google Scholar] [CrossRef]

- Larretxi, I.; Churruca, I.; Navarro, V.; Miranda, J.; Lasa, A.; Bustamante, M.A.; Simon, E. Impact of analytically measured fiber and resistant starch from gluten free products on celiac peoples diet. J. Pre Proof 2019, 70, 110586. [Google Scholar]

- Hager, A.S.; Arendt, E.K. Influence of hydroxypropylmethylcellulose (HPMC), xanthan gum and their combination on loaf specific volume, crumb hardness and crumb grain characteristics of gluten-free breads based on rice, maize, teff and buckwheat. Food Hydrocoll. 2013, 32, 195–203. [Google Scholar] [CrossRef]

- Sandri, L.T.B.; Santos, F.G.; Fratelli, C.; Capriles, V.D. Development of gluten-free bread formulations containing whole chia flour with acceptable sensory properties. Food Sci. Nutr. 2017, 5, 1021–1028. [Google Scholar] [CrossRef]

- Moore, M.M.; Heinbockel, M.; Dockery, P.; Ulmer, H.M.; Arendt, E.K. Network formation in gluten-free bread with application of transglutaminase. Cereal Chem. 2006, 83, 28–36. [Google Scholar] [CrossRef]

- Djordjević, M.; Šoronja-Simović, D.; Nikolić, I.; Djordjević, M.; Šereš, Z.; Milašinović-Šeremešić, M. Sugar beet and apple fibres coupled with hydroxypropylmethylcellulose as functional ingredients in gluten-free formulations: Rheological, technological and sensory aspects. Food Chem. 2019, 295, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Esteller, M.S.; Amaral, R.L.; Da Silva Lannes, S.C. Effect of sugar and FAT replacers on the texture of baked goods. J. Texture Stud. 2004, 35, 383–393. [Google Scholar] [CrossRef]

- Giannou, V.; Tzia, C. Frozen dough bread: Quality and textural behavior during prolonged storage—Prediction of final product characteristics. J. Food Eng. 2007, 79, 929–934. [Google Scholar] [CrossRef]

- Arcanjo, F.M. Development and Characterization of Gluten-Free Bread Enriched with Maca (Lepidium meyenii), Canary Seed (Phanaris canariensis) and Niger (Guizotia abyssinica) flours. Master’s Thesis, Universidade Tecnológica Federal do Paraná, Medianeira, Brazil, 2017. [Google Scholar]

- Rios, M.B.; Iriondo-Dehond, A.; Iriondo-Dehond, M.; Herrera, T.; Dolores, M. Effect of Coffee Cascara Dietary Fiber on the Physicochemical, Nutritional and Sensory Properties of a Gluten-Free Bread Formulation. Molecules 2020, 25, 1358. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira, F.C.; Coimbra, J.S.d.R.; de Oliveira, E.B.; Zuñiga, A.D.G.; Rojas, E.E.G. Food Protein-polysaccharide Conjugates Obtained via the Maillard Reaction: A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 1108–1125. [Google Scholar] [CrossRef] [PubMed]

- van Riemsdijk, L.E.; Van der Goot, A.J.; Hamer, R.J.; Boom, R.M. Preparation of gluten-free bread using a meso-structured whey protein particle system. J. Cereal Sci. 2011, 53, 355–361. [Google Scholar] [CrossRef]

| Percentage of Konjac Flour in Bread Formulations | |||||

|---|---|---|---|---|---|

| 0 | 12.5 | 25 | 37.5 | 50 | |

| % of cooking weigh loss | 17 | 20 | 27.70 | 32.50 | 32.50 |

| Cooking factor | 0.83 | 0.80 | 0.72 | 0.68 | 0.68 |

| Cooking time (Minutes) | 24 | 24 | 30 | 30 | 33 |

| Konjac Flour Percentage in Bread Formulations | |||||

|---|---|---|---|---|---|

| 0 | 12.5 | 25 | 37.5 | 50 | |

| Protein (g/100 g) | 5.9 ± 0.37 a | 4.94 ± 0.27 b | 4.0 ± 0.41 c | 3.88 ± 0.16 c | 2.95 ± 0.41 d |

| Lipid (g/100 g) | 10.84 ± 0.19 a | 8.13 ± 0.14 b | 5.59 ± 0.12 c | 3.89 ± 0.64 d | 3.59 ± 0.09 d |

| Carbohydrates (g/100 g) | 56.70 ± 0.54 a | 37.21 ± 0.69 b | 30.73 ± 0.27 c | 31.81 ± 0.59 c | 22.37 ± 0.27 d |

| Moisture (g/100 g) | 23.90 ± 0.28 e | 39.98 ± 0.56 d | 46.88 ± 0.48 b | 43.97 ± 0.42 c | 51.54 ± 0.86 a |

| Ash content (g/100 g) | 1.85 ± 0.03 a | 1.56 ± 0.01 bcd | 1.64 ± 0.04 bcd | 1.54 ± 0.08 cd | 1.66 ± 0.00 bc |

| Dietary Fibers (g/100 g) | 0.82 ± 0.02 e | 8.19 ± 0.01 d | 11.16 ± 0.09 c | 14.92 ± 0.06 b | 17.90 ± 0.32 a |

| Resistant Starch (g/100 g) | 0.64 ± 0.09 c | 0.67 ± 0.04 c | 0.70 ± 0.02 b | 0.75 ± 0.07 a | 0.70 ± 0.01 b |

| Energy value (kcal/100 g) | 347.93 ± 1.6 a | 241.73 ± 2.8 b | 189.19 ± 2.1 c | 177.76 ± 3.7 d | 133.55 ± 1.8 e |

| Konjac Flour Percentage in Bread | |||||

|---|---|---|---|---|---|

| 0 | 12.5 | 25 | 37.5 | 50 | |

| Specific Volume | 1.44 ± 0.06 e | 1.61 ± 0.06 d | 1.96 ± 0.06 b | 2.10 ± 0.12 a | 2.05 ± 0.10 ab |

| Firmness (g) | * | 4505.00 ± 343.97 a | 2508.31 ± 40.94 b | 1469.53 ± 39.91 c | 2334.90 ± 77.05 b |

| Konjac Flour (%) | Crust Color | ||

|---|---|---|---|

| C* | h* | ΔE* | |

| 0 | 34.39 ± 2.37 a | 78.14 ± 2.25 a | --- ** |

| 12.5 | 33.22 ± 0.29 a | 69.65 ± 5.75 d | 5.86 ± 3.14 a |

| 25 | 24.53 ± 0.58 b | 70.52 ± 2.65 c | 7.17 ± 1.49 a |

| 37.5 | 23.10 ± 0.70 b | 74.43 ± 2.73 b | 7.77 ± 0.95 a |

| 50 | 21.85 ± 0.45 b | 73.76 ± 2.78 c | 8.54 ± 0.46 a |

| Crumb color | |||

| C* | h* | ΔE* | |

| 0 | 26.55 ± 0.56 a | 85.83 ± 0.24 a | --- ** |

| 12.5 | 22.37 ± 0.15 b | 85.06 ± 0.23 b | 5.95 ± 0.44 c |

| 25 | 16.75 ± 0.86 c | 86.03 ± 0.29 a | 10.23 ± 0.71 b |

| 37.5 | 14.12 ± 0.70 d | 86.26 ± 0.30 a | 13.24 ± 0.60 a |

| 50 | 14.61 ± 0.51 d | 84.76 ± 0.12 b | 14.14 ± 0.93 a |

| Bottom color | |||

| C* | h* | ΔE* | |

| 0 | 32.56 ± 4.10 a | 60.35 ± 6.11 a | --- ** |

| 12.5 | 31.32 ± 2.75 a | 60.25 ± 2.95 a | 3.88 ± 0.80 b |

| 25 | 24.84 ± 2.97 ab | 56.93 ± 4.59 a | 8.86 ± 2.87 ab |

| 37.5 | 20.41 ± 1.77 b | 59.71 ± 1.43 a | 11.35 ± 1.92 a |

| 50 | 20.44 ± 1.16 b | 57.46 ± 0.81 a | 11.06 ± 1.64 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laignier, F.; Akutsu, R.d.C.C.d.A.; Maldonade, I.R.; Bertoldo Pacheco, M.T.; Silva, V.S.N.; Mendonça, M.A.; Zandonadi, R.P.; Raposo, A.; Botelho, R.B.A. Amorphophallus konjac: A Novel Alternative Flour on Gluten-Free Bread. Foods 2021, 10, 1206. https://doi.org/10.3390/foods10061206

Laignier F, Akutsu RdCCdA, Maldonade IR, Bertoldo Pacheco MT, Silva VSN, Mendonça MA, Zandonadi RP, Raposo A, Botelho RBA. Amorphophallus konjac: A Novel Alternative Flour on Gluten-Free Bread. Foods. 2021; 10(6):1206. https://doi.org/10.3390/foods10061206

Chicago/Turabian StyleLaignier, Fernanda, Rita de Cássia Coelho de Almeida Akutsu, Iriani Rodrigues Maldonade, Maria Teresa Bertoldo Pacheco, Vera Sônia Nunes Silva, Marcio Antônio Mendonça, Renata Puppin Zandonadi, António Raposo, and Raquel Braz Assunção Botelho. 2021. "Amorphophallus konjac: A Novel Alternative Flour on Gluten-Free Bread" Foods 10, no. 6: 1206. https://doi.org/10.3390/foods10061206

APA StyleLaignier, F., Akutsu, R. d. C. C. d. A., Maldonade, I. R., Bertoldo Pacheco, M. T., Silva, V. S. N., Mendonça, M. A., Zandonadi, R. P., Raposo, A., & Botelho, R. B. A. (2021). Amorphophallus konjac: A Novel Alternative Flour on Gluten-Free Bread. Foods, 10(6), 1206. https://doi.org/10.3390/foods10061206