Laser-Induced Thermal Annealing of CH3NH3PbI3 Perovskite Microwires

Abstract

1. Introduction

2. Materials and Methods

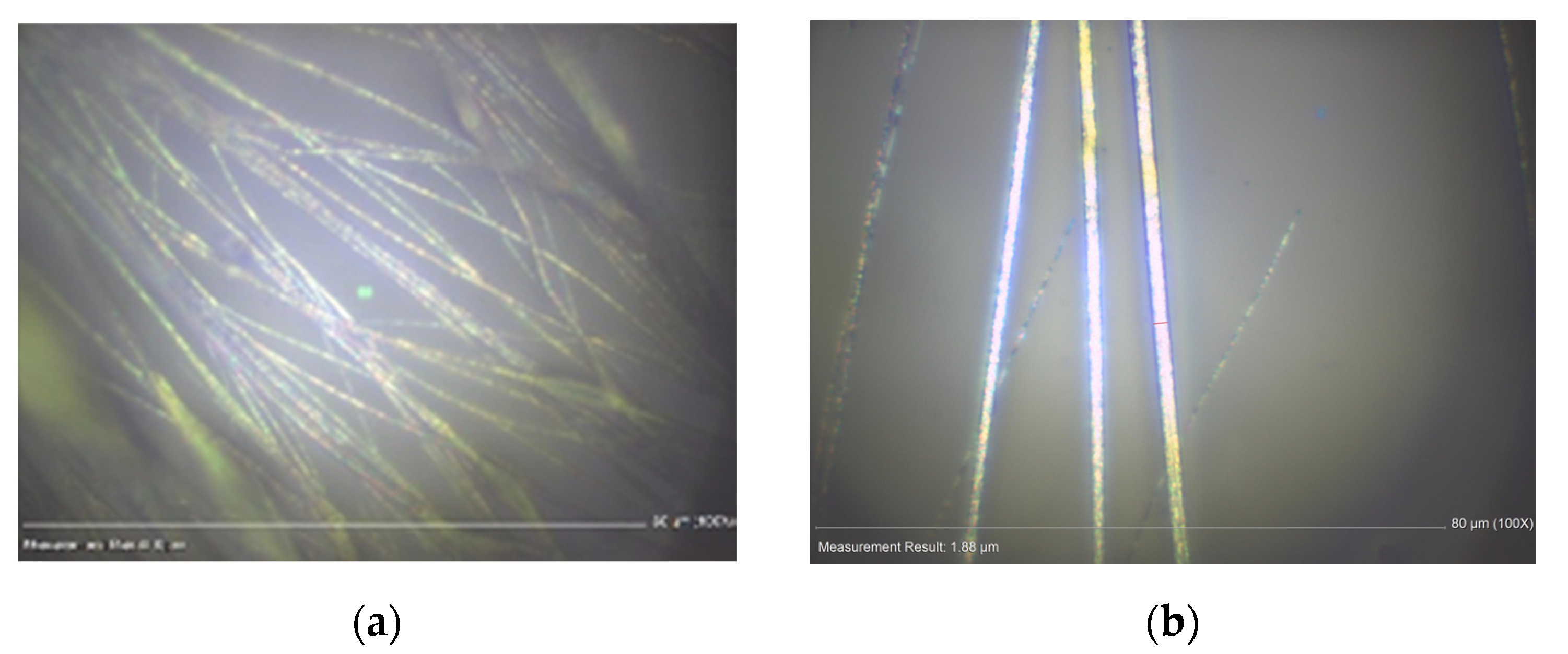

2.1. The Preparation of Perovskite Wires

2.2. The Laser Annealing and the Raman Measurements

3. Results and Discussions

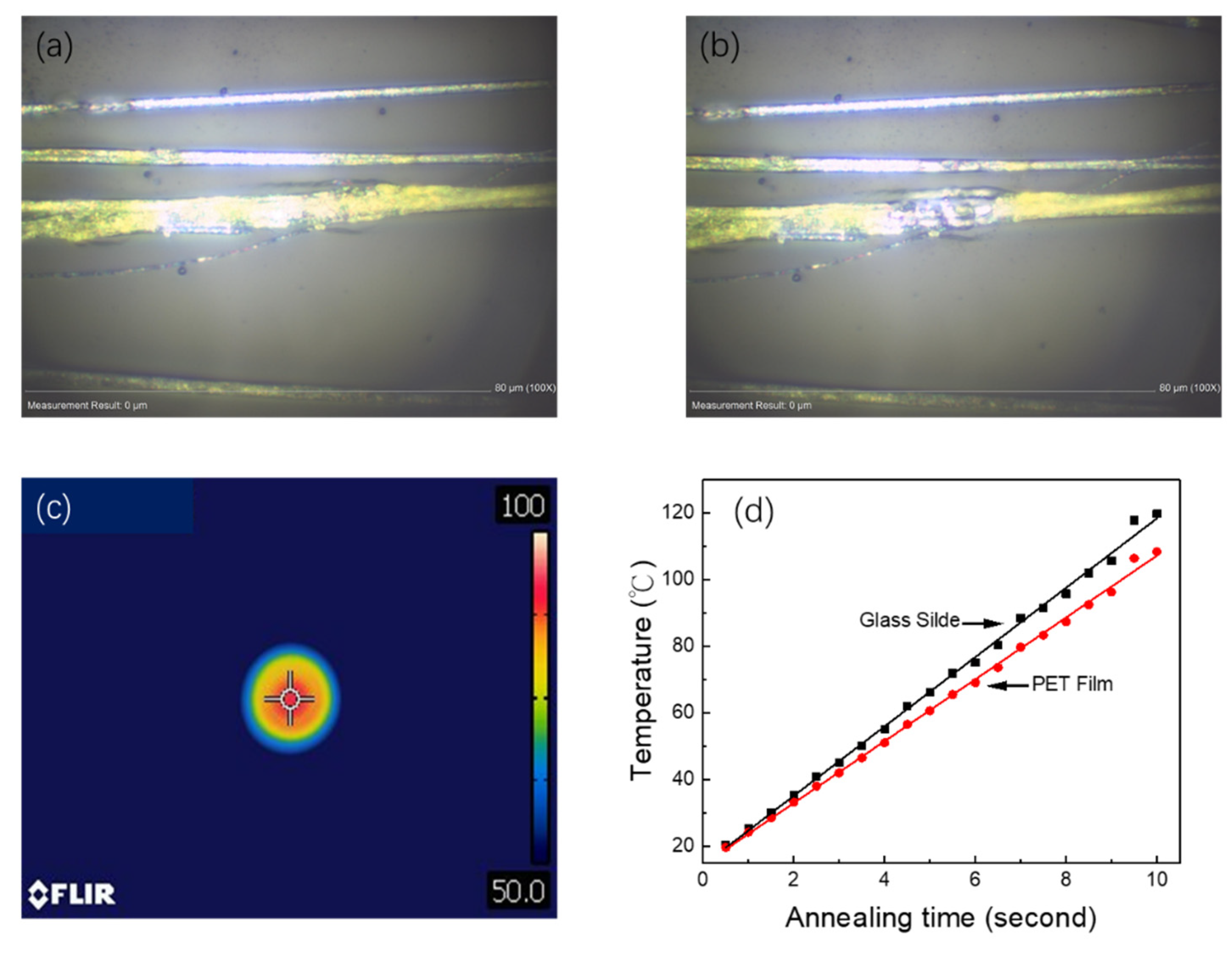

3.1. Laser-Induced Thermal Annealing Process

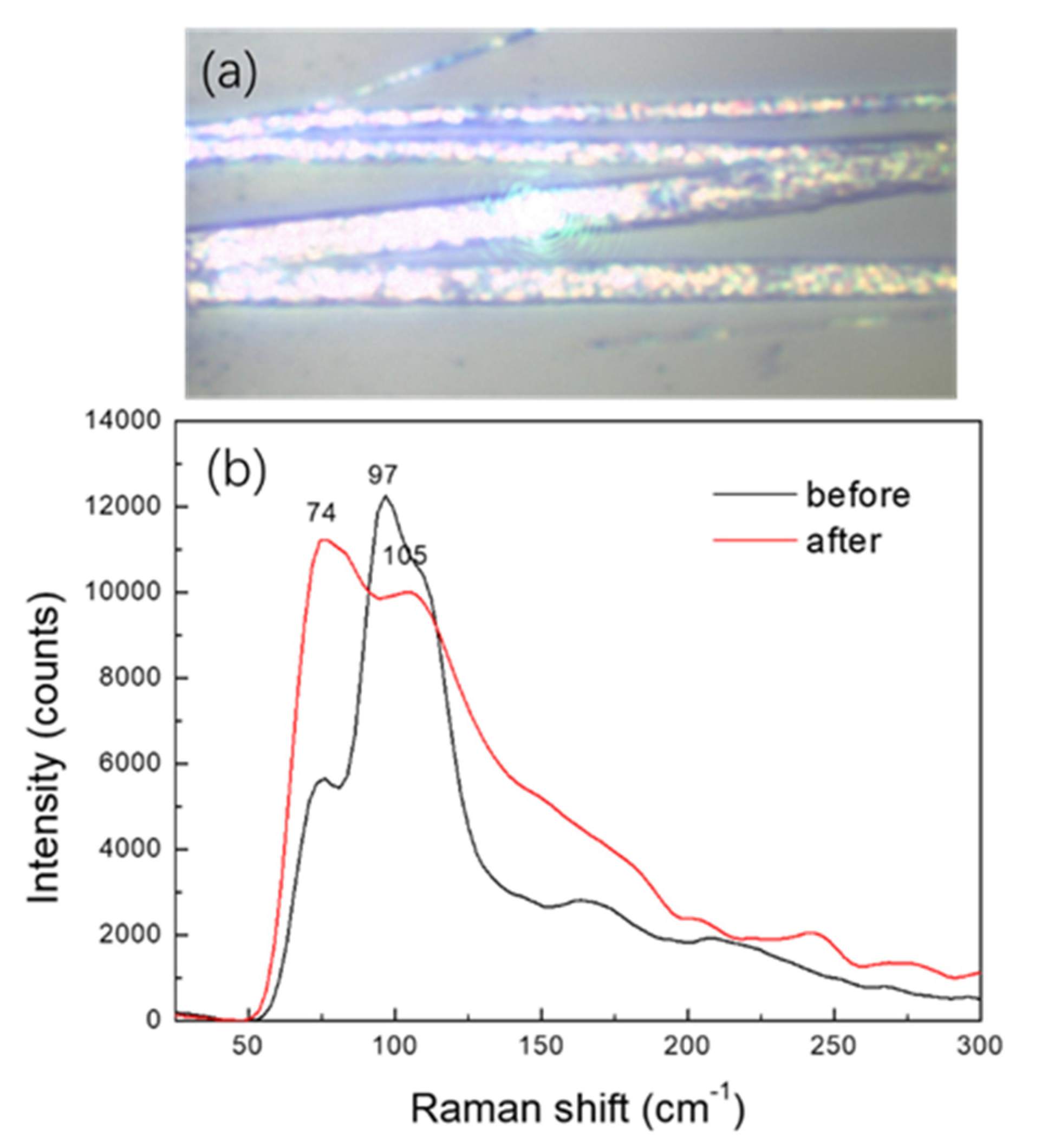

3.2. The Crystallization Improvement of a Single-Point Laser-Induced Annealing

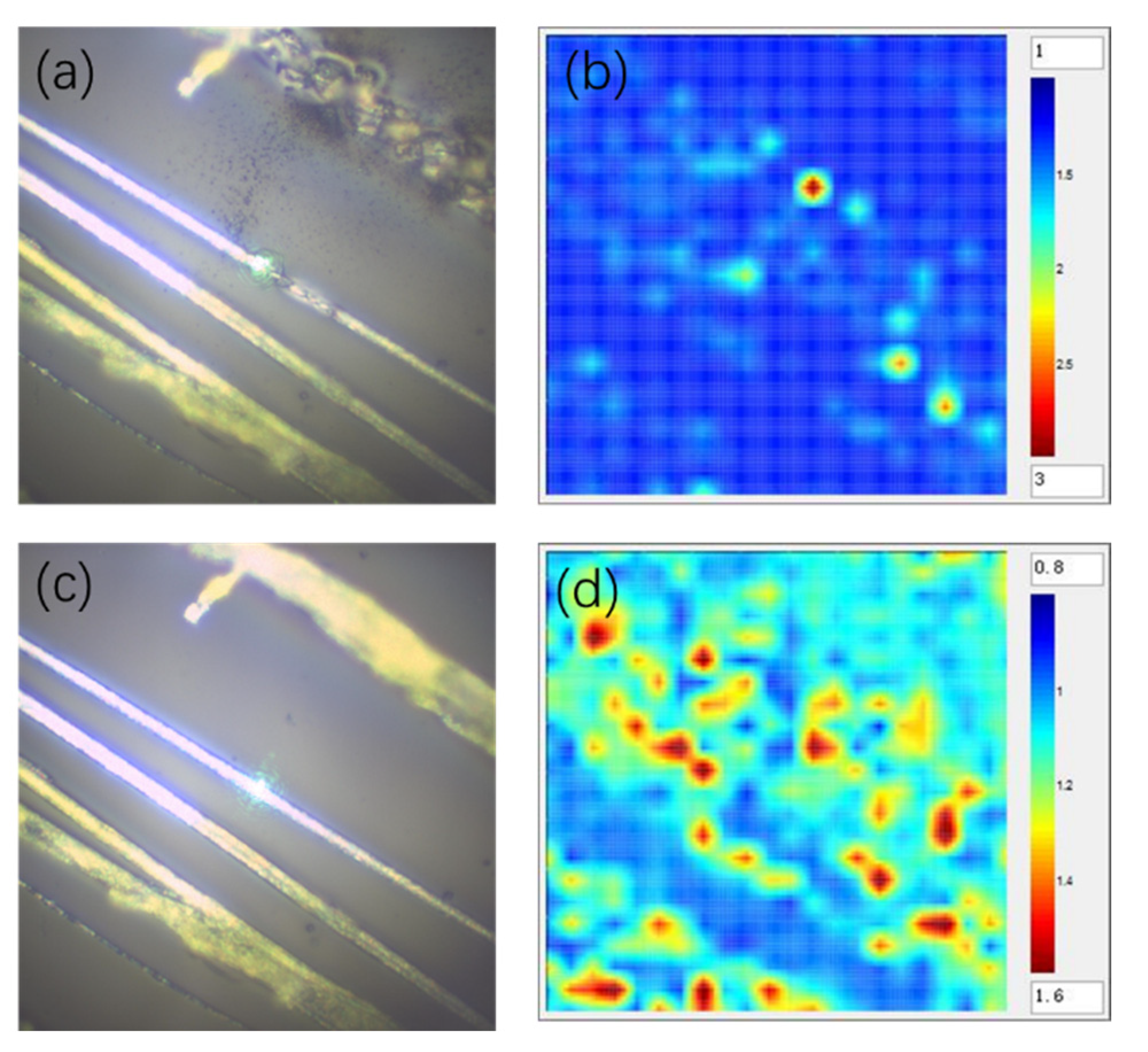

3.3. The Crystallization Improvement of the Perovskite MWs Due to the Laser Annealing Process

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jung, H.S.; Park, N.G. Perovskite Solar Cells: From Materials to Devices. Small 2015, 11, 10–25. [Google Scholar] [CrossRef]

- Chen, L.C.; Chen, C.C.; Chen, J.C.; Wu, C.G. Annealing effects on high-performance CH3NH3PbI3 perovskite solar cells prepared by solution-process. Sol. Energy 2015, 122, 1047–1051. [Google Scholar] [CrossRef]

- Madhu, S.S.; Nagarjuna, P.; Kumar, P.N.; Singh, S.P.; Deepa, M.; Namboothiry, M.A.G. Efficient organic-inorganic hybrid perovskite solar cells processed in air. Phys. Chem. Chem. Phys. 2014, 16, 24691–24696. [Google Scholar] [CrossRef][Green Version]

- Gao, P.; Gratzel, M.; Nazeeruddin, M.K. Organohalide lead perovskites for photovoltaic applications. Energy Environ. Sci. 2014, 7, 2448–2463. [Google Scholar] [CrossRef]

- Green, M.A.; Ho-Baillie, A.; Snaith, H.J. The emergence of perovskite solar cells. Nat. Photonics 2014, 8, 506–514. [Google Scholar] [CrossRef]

- Yusoff, A.B.; Gao, P.; Nazeeruddin, M.K. Recent progress in organohalide lead perovskites for photovoltaic and optoelectronic applications. Coord. Chem. Rev. 2018, 373, 258–294. [Google Scholar] [CrossRef]

- Yusoff, A.B.; Nazeeruddin, M.K. Organohalide Lead Perovskites for Photovoltaic Applications. J. Phys. Chem. Lett. 2016, 7, 851–866. [Google Scholar] [CrossRef]

- Sum, T.C.; Mathews, N. Advancements in perovskite solar cells: Photophysics behind the photovoltaics. Energy Environ. Sci. 2014, 7, 2518–2534. [Google Scholar] [CrossRef]

- Jeon, N.J.; Noh, J.H.; Kim, Y.C.; Yang, W.S.; Ryu, S.; Seok, S.I. Solvent engineering for high-performance inorganic-organic hybrid perovskite solar cells. Nat. Mater. 2014, 13, 897–903. [Google Scholar] [CrossRef]

- Xiao, Z.G.; Dong, Q.F.; Bi, C.; Shao, Y.C.; Yuan, Y.B.; Huang, J.S. Solvent Annealing of Perovskite-Induced Crystal Growth for Photovoltaic-Device Efficiency Enhancement. Adv. Mater. 2014, 26, 6503–6509. [Google Scholar] [CrossRef]

- Ke, W.; Xiao, C.; Wang, C.; Saparov, B.; Duan, H.S.; Zhao, D.; Xiao, Z.; Schulz, P.; Harvey, S.P.; Liao, W. Employing Lead Thiocyanate Additive to Reduce the Hysteresis and Boost the Fill Factor of Planar Perovskite Solar Cells. Adv. Mater. 2016, 28, 5214–5221. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.G.; Chiang, C.H.; Tseng, Z.L.; Nazeeruddin, M.K.; Hagfeldt, A.; Grätzel, M. High efficiency stable inverted perovskite solar cells without current hysteresis. Energy Environ. Sci. 2015, 8, 2725–2733. [Google Scholar] [CrossRef]

- Wilkes, G.C.; Deng, X.; Choi, J.J.; Gupta, M.C. Laser Annealing of TiO2 Electron-Transporting Layer in Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2018, 10, 41312–41317. [Google Scholar] [CrossRef]

- Li, F.M.; Zhu, W.D.; Bao, C.X.; Yu, T.; Wang, Y.Q.; Zhou, X.X.; Zou, Z.G. Laser-assisted crystallization of CH3NH3PbI3 films for efficient perovskite solar cells with a high open-circuit voltage. Chem. Commun. 2016, 52, 5394–5397. [Google Scholar] [CrossRef] [PubMed]

- Jeon, T.; Jin, H.M.; Lee, S.H.; Lee, J.M.; Park, H.I.; Kim, M.K.; Lee, K.J.; Shin, B.; Kim, S.O. Laser Crystallization of Organic–Inorganic Hybrid Perovskite Solar Cells. ACS Nano 2016, 10, 7907–7914. [Google Scholar] [CrossRef] [PubMed]

- Malyukov, S.; Sayenko, A.; Klunnikova, Y. Laser Annealing of Perovskite Solar Cells Thin Film Structure. In Proceedings of the 2018 International Russian Automation Conference (RusAutoCon), Sochi, Russia, 16–23 September 2018; pp. 1–4. [Google Scholar]

- Trinh, X.L.; Tran, N.H.; Seo, H.; Kim, H.C. Enhanced performance of perovskite solar cells via laser-induced heat treatment on perovskite film. Sol. Energy 2020, 206, 301–307. [Google Scholar] [CrossRef]

- Tiguntseva, E.; Saraeva, I.; Kudryashov, S.; Ushakova, E.; Komissarenko, F.; Ishteev, A.; Tcypkin, A.; Haroldson, R.; Milichko, V.; Zuev, D.; et al. Laser Post-Processing of Halide Perovskites for Enhanced Photoluminescence and Absorbance. J. Phys. Conf. Ser. 2017, 917, 062002. [Google Scholar] [CrossRef]

- Ai-Jun, Y. Research on Test Method for Perovskite Solar Cell Based on Solar Simulator. J. Astronaut. Metrol. Meas. 2018, 38, 60–66. [Google Scholar]

- Chen, J.; Zhou, S.; Jin, S.; Li, H.; Zhai, T. Crystal organometal halide perovskites with promising optoelectronic applications. J. Mater. Chem. C 2015, 4. [Google Scholar] [CrossRef]

- Quarti, C.; Grancini, G.; Mosconi, E.; Bruno, P.; Ball, J.M.; Lee, M.M.; Snaith, H.J.; Petrozza, A.; De Angelis, F. The Raman Spectrum of the CH(3)NH(3)Pbl(3) Hybrid Perovskite: Interplay of Theory and Experiment. J. Phys. Chem. Lett. 2014, 5, 279–284. [Google Scholar] [CrossRef] [PubMed]

- Quarti, C.; Katan, C.; Even, J. Physical properties of bulk, defective, 2D and 0D metal halide perovskite semiconductors from a symmetry perspective. J. Phys. Mater. 2020, 3. [Google Scholar] [CrossRef]

- Zhu, P.C.; Gu, S.; Shen, X.P.; Xu, N.; Tan, Y.L.; Zhuang, S.D.; Deng, Y.; Lu, Z.D.; Wang, Z.L.; Zhu, J. Direct Conversion of Perovskite Thin Films into Nanowires with Kinetic Control for Flexible Optoelectronic Devices. Nano Lett. 2016, 16, 871–876. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Tang, Y.; Chen, F.; Manohari, A.G.; Zhu, Y.; Shi, Z.; Xu, C. Fabrication of self-assembly polycrystalline perovskite microwires and photodetectors. J. Cryst. Growth 2016, 454, 121–127. [Google Scholar] [CrossRef]

- Ledinsky, M.; Loper, P.; Niesen, B.; Holovsky, J.; Moon, S.J.; Yum, J.H.; De Wolf, S.; Fejfar, A.; Ballif, C. Raman Spectroscopy of Organic-Inorganic Halide Perovskites. J. Phys. Chem. Lett. 2015, 6, 401–406. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Wang, Z.; Wu, R.-J.; Cheng, H.-L.; Chui, H.-C. Laser-Induced Thermal Annealing of CH3NH3PbI3 Perovskite Microwires. Photonics 2021, 8, 30. https://doi.org/10.3390/photonics8020030

Chen X, Wang Z, Wu R-J, Cheng H-L, Chui H-C. Laser-Induced Thermal Annealing of CH3NH3PbI3 Perovskite Microwires. Photonics. 2021; 8(2):30. https://doi.org/10.3390/photonics8020030

Chicago/Turabian StyleChen, Xiaoming, Zixian Wang, Ren-Jie Wu, Horng-Long Cheng, and Hsiang-Chen Chui. 2021. "Laser-Induced Thermal Annealing of CH3NH3PbI3 Perovskite Microwires" Photonics 8, no. 2: 30. https://doi.org/10.3390/photonics8020030

APA StyleChen, X., Wang, Z., Wu, R.-J., Cheng, H.-L., & Chui, H.-C. (2021). Laser-Induced Thermal Annealing of CH3NH3PbI3 Perovskite Microwires. Photonics, 8(2), 30. https://doi.org/10.3390/photonics8020030