Abstract

n-Propyl Propionate (ProPro) is a harmless biodegradable product employed in several fields for the production of drugs, inks, coating, food, and perfume. ProPro is synthesized in an equilibrium reaction for which its yield can be enhanced by constant withdraw of the products as the reaction takes place. Simulated Moving Bed Reactor (SMBR) is a candidate for the production of ProPro with high efficiency as it is a multifunction unit able to simultaneously run reaction and separation, hence shifting the equilibrium reaction toward products. This paper proposes a complete phenomenological model for the ProPro synthesis in a Simulated Moving Bed Reactor (SMBR) packed with the heterogeneous catalyst Amberlyst 46 resin. The operating conditions are defined by the Triangle Theory to design an SMBR unit to produce ProPro efficiently and a comprehensive parameter estimation procedure is employed to obtain more representative parameters. The validated phenomenological model was applied to design an SMBR unit to produce high purity (99.28%) ProPro.

1. Introduction

Traditionally reaction and product purification are carried out in independent units. Multifunctional processes deal with reaction and separation in a single unit; therefore, they are more cost-effective and environmentally safe [1]. Simulated Moving Bed Reactor (SMBR) stands out among multifunctional units due to its efficiency in dealing with equilibrium-limited reactions. It has the capability of removing products from the reaction zone through selective adsorption onto porous catalyst, shifting the equilibrium toward products and, thus, increasing the yield [2,3,4,5]. Periodic switches change inlet (eluent and feed) and outlet (raffinate and extract) streams in a multicolumn system divided into four sections filled in with an adsorptive porous catalyst. The purpose of the SMBR is to simulate liquid and solid counter-current flow as in a True Moving Bed Reactor (TMBR), eliminating the solid flow since it is difficult to handle.

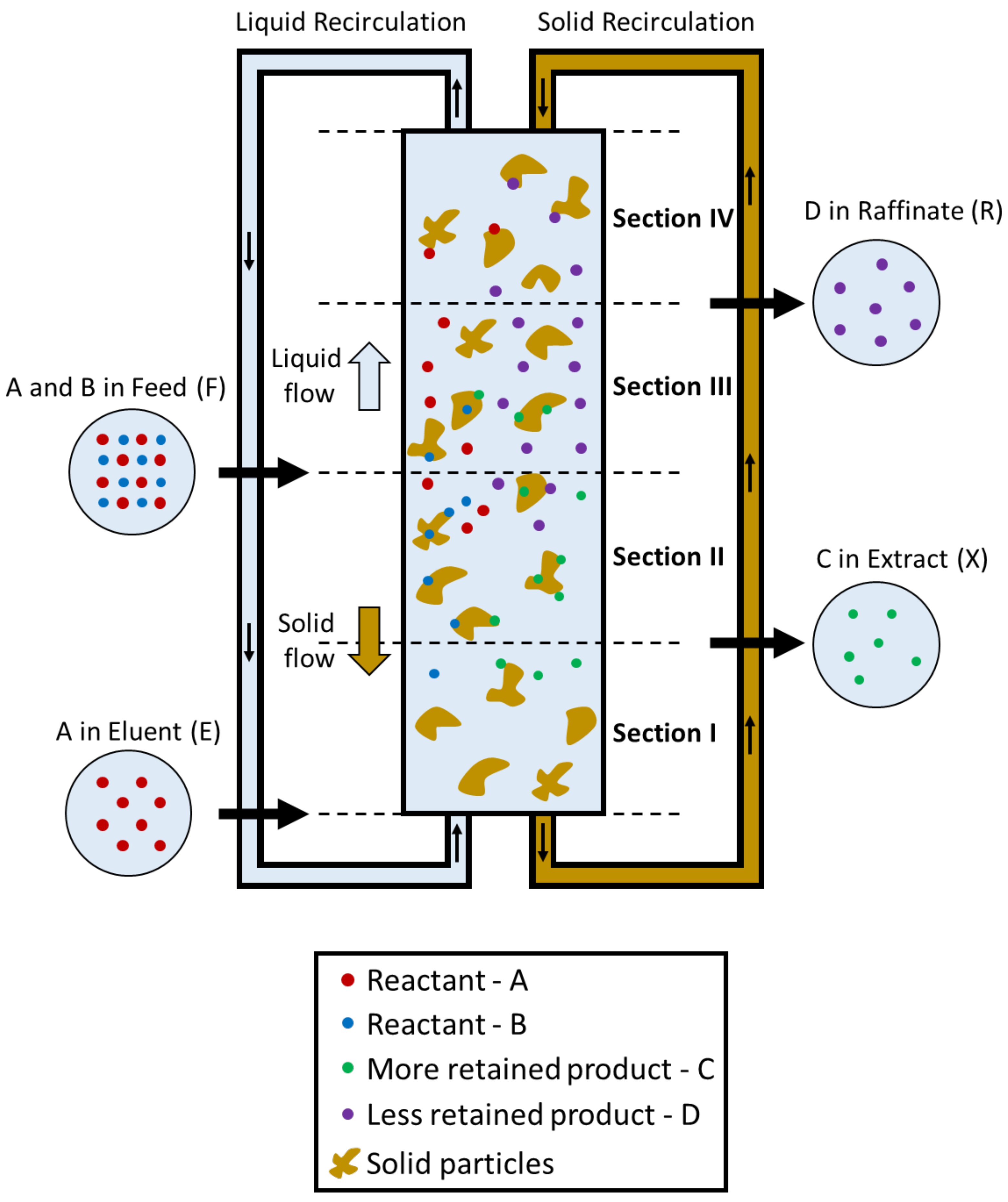

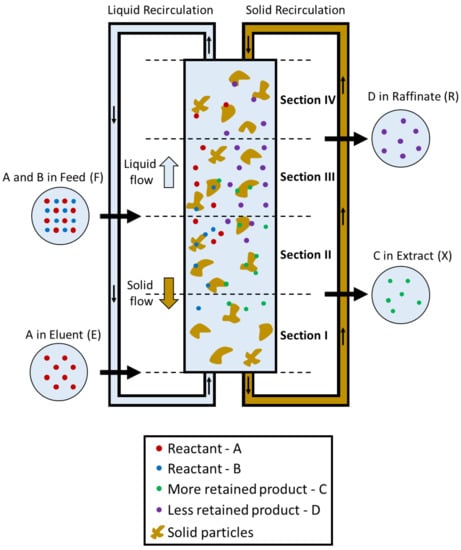

Figure 1 depicts the TMBR for a generic equilibrium reaction:

where and are the reactants and B is the eluent, and are the products, and , b, , and are the respective stoichiometric coefficients in accordance with Figure 1. Components and are introduced into the system in the Eluent (E) and Feed (F) Streams, respectively, whereas the solid phase has more affinity to component , which is selectively removed in the Extract (X) stream. Reaction and separation are carried out in Section II and Section III so that components C and D are removed in the Extract (X) and Raffinate (R) streams, respectively. Eluent and adsorbent are regenerated in Section Iand Section IV, respectively.

Figure 1.

True Moving Bed Reactor unit representations.

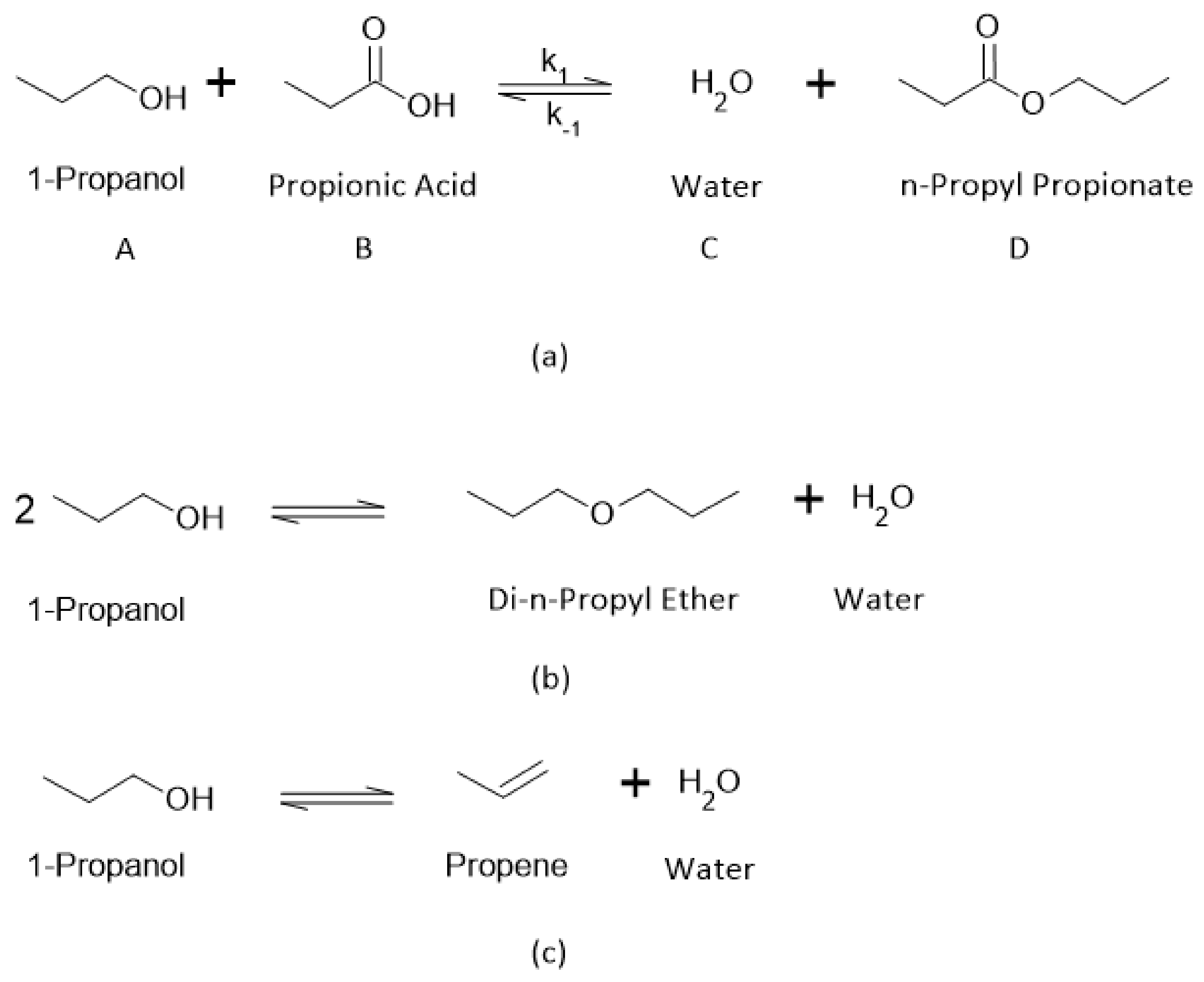

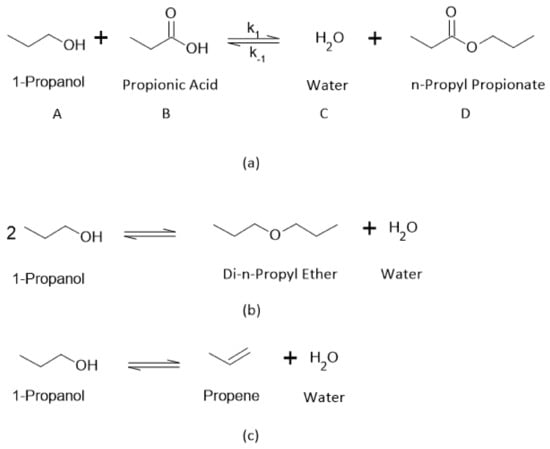

n-Propyl Propionate (ProPro) is an ecofriendly product applied in drugs and ink production, polymerization reactions, coating industry, and as an additive for food and perfume [6]. The U.S. Environmental Protection Agency considers ProPro a harmless air pollutant and it is acknowledged as a biodegradable and non-toxic product. It may be used as an additive for food and perfume due to its pleasant smell and absence of toxicity [1,7,8]. ProPro can be synthesized by a heterogeneous esterification reaction of 1-propanol with propionic acid, also yielding water, as illustrated in Figure 2a. From this point on, and are the reactants 1-propanol and propionic acid, and and are the products’ water and n-propyl propionate, as in (1). and are the kinetic constants for the formation and consumption of ProPro, respectively. 1-propanol might also undergo secondary reactions such as etherification and dehydration, producing di-n-propyl ether and propene (Figure 2b,c, respectively) [9]. These side reactions are undesired due to economic and safety issues, as propene is an easily flammable gas [7]. In order to avoid these side reactions, Amberlyst 46 is employed as a heterogenous catalyst due to its ester prioritization and adsorption of water that shift the equilibrium toward products [10].

Figure 2.

Synthesis of n-Propyl Propionate (a) and secondary reactions (b) and (c).

ProPro synthesis in SMBR unit might be enhanced if representative models are available. Despite its importance, as far as the authors know, only Nogueira et al. (2020) approached ProPro production in SMBR, and Nogueira et al. (2019) studied a fixed bed chromatographic reactor for the production of ProPro [1,6]. These approaches, however, used a simplified model that considers the system as pseudo-homogeneous. Other works investigate the synthesis of ProPro in Reactive Distillation (RD) that presents a complex operation and not so satisfactory results, such as conversion and purities around 90%, whereas SMBR can reach over 99% [6,9,11,12]. This paper, then, proposes a rigorous phenomenological model of a TMBR for synthesizing n-propyl propionate through the esterification of 1-propanol with propionic acid catalyzed with Amberlyst 46 resin. Unlike the literature, we propose a phenomenological model that considers a heterogeneous catalyst that better describes the system’s phenomenology, whereas a pseudo-homogeneous model considers a heterogeneous system as homogeneous. The TMBR model is used to design and optimize an SMBR unit to produce ProPro efficiently using the Triangle Theory.

2. Methodology

As mentioned, previous studies considered a pseudo-homogeneous reaction that simplifies the model. In addition, SMBR modeling bears a high computational burden that can be prevented by substituting it by the TMBR model, which is simpler to be carried out and it is equivalent to SMBR by keeping constant the liquid velocity relative to the solid velocity in the model [13,14,15,16].

The TMBR model herein proposed considers the pilot-scale SMBR unit model LICOSEP1 12–26 by Novasep (Porto, Porto, Portugal) packed with Amberlyst 46 located in the Laboratory of Separation and Reaction Engineering of the University of Porto in Portugal. The characteristics of the unit are shown in Table 1. This section firsly presents the TMBR model considering the heterogenous reaction, followed by its parameter estimation and, finally, the Triangle Theory is used to define the operating conditons that provide succesful reaction and separation.

Table 1.

Unit conditions for simulations of the TMBR unit.

2.1. TMBR Model

A TMBR phenomenological model was developed from mass balance over a bed volume element. The model considers the following:

- A heterogeneous reaction system;

- Isothermal process;

- The bed length and porosity are constant;

- External mass transfer to the particle and internal mass transfer are negligible;

- A plug flow model with axial dispersion;

- Dispersion along radius is negligible;

- Velocity changes along the column because of composition variation and a linear driving force for the mass transfer rate.

The mass balances at the fluid phase and inside the particle are, respectively, given by the following:

where subscripts and denote compounds and TMBR section, is the section length, is the stoichiometric coefficient of component , is the bed porosity, is the axial dispersion coefficient, is the fluid phase concentration, is the adsorbed phase concentration, is the adsorbed concentration of compound in equilibrium with in section , is the molar fraction of compound in the liquid phase in section , is the bulk density, is the section interstitial velocity, is the particle radius, and is the external mass transfer coefficient. This paper applies the Langmuir–Hinshelwood equation for reaction rate . This source term has been shown to successfully represent heterogeneous esterification reactions [17]. In Equation (4), is the kinetic constant, is the equilibrium constant of ProPro synthesis, and , , , and are the adsorption equilibrium constants of 1-propanol, propionic acid, water, and n-propyl propionate, respectively. is the total molar concentration in the liquid phase, which is related to the molar volume of each compound and can be found by the following.

The values of adsorption equilibrium constants for reactants and products were estimated by Nogueira et al. (2018) [18], as shown in Table 2.

Table 2.

Adsorption equilibrium constants for reactants and products.

The kinetic and equilibrium constants, and , are related to the temperature, as expressed by the Arrhenius and Van’t Hoff equations, respectively:

where is the pre-exponential factor, is the activation energy, T is the temperature, R is the universal gas constant, is the pre-exponential factor for equilibrium reaction, and is the reaction enthalpy. , , , and are the kinetic parameters to be estimated. , , , and are the activity:

where is the activity coefficient, obtained by a thermodynamic model. Prudente et al. (2019) studied the Liquid–Liquid Equilibrium (LLE) of the quaternary system of n-Propanol, propanoic acid, propyl propionate, and water and showed that the NRTL (Non-random two-liquid) model describes more precisely the system than the UNIQUAC (Universal Quasichemical) model [19]. The NRTL model is given by the following:

where is the number of components, measures component and interactions, and measures the lack of randomness. The value of is adopted for obtained from Samarov et al. (2016) [20], and are the thermodynamic parameters to be estimated.

The mass transfer coefficient, , is given by the following [18,21]:

where is the particle diameter provided by the manufacturer, is the diffusivity coefficient of compound in the mixture in section , is the diffusion coefficient of component diluted in component , is the viscosity of the pure component , and is the mixture viscosity.

Component composition varies along the bed, therefore changing the section interstitial velocity, as given by the following:

for which its boundary conditions are as follows.

The concentration of component in section in the adsorbed phase, in equilibrium with the fluid phase concentration, is given by the Langmuir adsorption isotherm equation for liquid phase adsorption [18,19,20]:

where and are Langmuir adsorption parameters for which its values were estimated by Nogueira et al. (2019) [18].

The initial and boundary conditions for any are defined as follows:

where superscript regards to eluent, and is the inlet concentration of species in a section . At , we have the following:

and the boundary conditions for the eluent (), extract (), feed (), and raffinate () nodes are, respectively, given by the following:

where is the enantiomer concentration in the feed stream. Concentrations in the adsorbed phase in the beginning of a section are equal to the final concentrations of the previous ones, as shown as follows.

The global mass balance for each node considering the inlet and outlet streams for each section can be expressed as follows.

TMBR performance is measured by purity, conversion, eluent consumption, and productivity, as given by the following:

where and are the extract and raffinate purities, is the conversion, EC and denote eluent consumption and unit productivity, and is the volume of the bed.

2.2. Parameter Estimations

Herein, a default PSO (Particle Swarm Optimization) from MATLAB combined with a gradient method was employed to perform the estimations of thermodynamic and kinetic parameters separately in order to find the sets of model parameters that better fit experimental results.

Kinetic experimental data were obtained from [7]. The author carried out a parameter estimation widely used in works related to ProPro synthesis in batch reactor [1,22,23]. The author employed linearization technique to adjust a set of parameters of the Arrhenius and Van´t Hoff equations. This approach can mask or not cover entirely the results, since this system is non-linear. Moreover, it relies only on the R-square parameters for fitness, which can be easily biased. Herein, parameters are estimated simultaneously considering different sets of experimental data from [7] that respect its non-linearity.

Thermodynamic experimental data were obtained from Samarov et al. (2016)’s LLE at 313.15 K [20]. The authors estimated the thermodynamic parameters within a temperature range from 293.15 to 333.15. Herein, the thermodynamic parameters are estimated at 313.15 K that is the operating temperature.

2.3. Unit Design and Optimization

The optimization and design of the TMBR unit must guarantee that reaction and separation work efficiently and simultaneously. The equilibrium Triangle Theory is an approach, usually employed in TMB/SMB design and optimization, for which its goal is to determine the necessary conditions for liquid and solid regeneration in recycling stream [24,25]. It firstly sets the limits for fluid internal and solid flow rates ratio, as given by the following:

where is the solid velocity (). Herein, the limits for the ratios, and (Upper and Lower Bounds), were established by previous investigation by the equilibrium theory. A Safety Factor, SF, is added to and due to the mass transfer resistance in the system [6], wherein SF equals 1.7 was adopted based on previous studies. The second step in the equilibrium triangle theory is to determine a suitable switching time value by a reactive separate reactive region for a particular purity requirement. A sensitivity analysis indicated a value of 60 min for suitable switching time. The second step in the triangle theory is carried out by process simulations and performance parameter determination with different values of and starting with low feed and extract flow rate values. The simulation is repeated with a gradual increase in the extract flow rate up to the two reactive separation region limits. Then the simulation is carried out repeatedly with an increase in the feed flow rate with different extract flow rate up to the separation region closure, i.e., maximization of the feed flow rate within purity restriction.

3. Results

The Triangle Theory is applied to define operating conditions (Table 3) that enable reaction and separation with a purity of above 90%.

Table 3.

Operation conditions.

The TMBR model relies on thermodynamic and kinetic parameters that need to be estimated. Experimental data were obtained from literature, and parameters were estimated by PSO combined with a gradient method. Results are shown in Table 4 and Table 5 together with parameters estimated in the literature. Table 6 presents the Root-Mean Square Deviation (RMDS) between the experimental data from the literature and simulation results obtained with the heterogeneous model using, respectively, the kinetic and thermodynamic parameters estimated in this study and the ones from the literature. It provides a comparison between the parameters estimated here and the literature.

Table 4.

Kinetic parameters for heterogeneous and pseudo-homogeneous.

Table 5.

NRTL thermodynamic parameters for heterogeneous and pseudo-homogeneous at 313.15 K.

Table 6.

RMDS between experimental results and simulations results using the parameters estimated in this work and parameters from literature.

As shown in Table 6, the RMDS value for parameters estimated in the present work is significantly smaller than the parameter from the literature. Therefore, the estimated parameters for the heterogeneous model are more suitable to be used in the present context. As Amberlyst 46 is a heterogeneous catalyst, the Langmuir–Hinshelwood equation employment suits the system better.

Appling the operating conditions from Table 3 and the estimated parameters, the performance parameters were calculated from Equations (31)–(35). The equilibrium conversion of 99.28% was observed. The possibility of removing products from the reaction medium is a benefit of moving bed reactors that enable higher conversion percentages, as evidenced in Table 7.

Table 7.

TMBR Performance parameters.

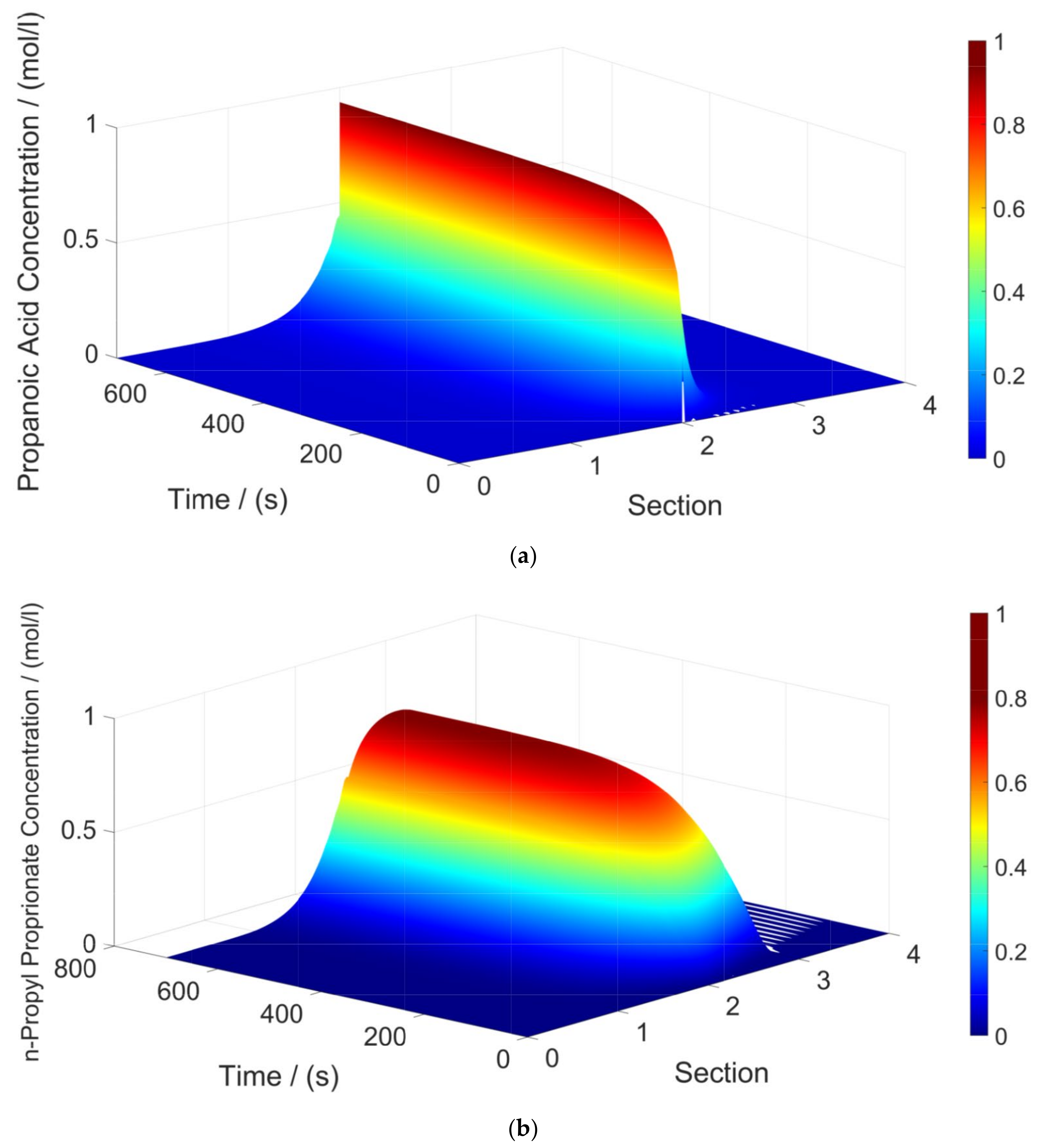

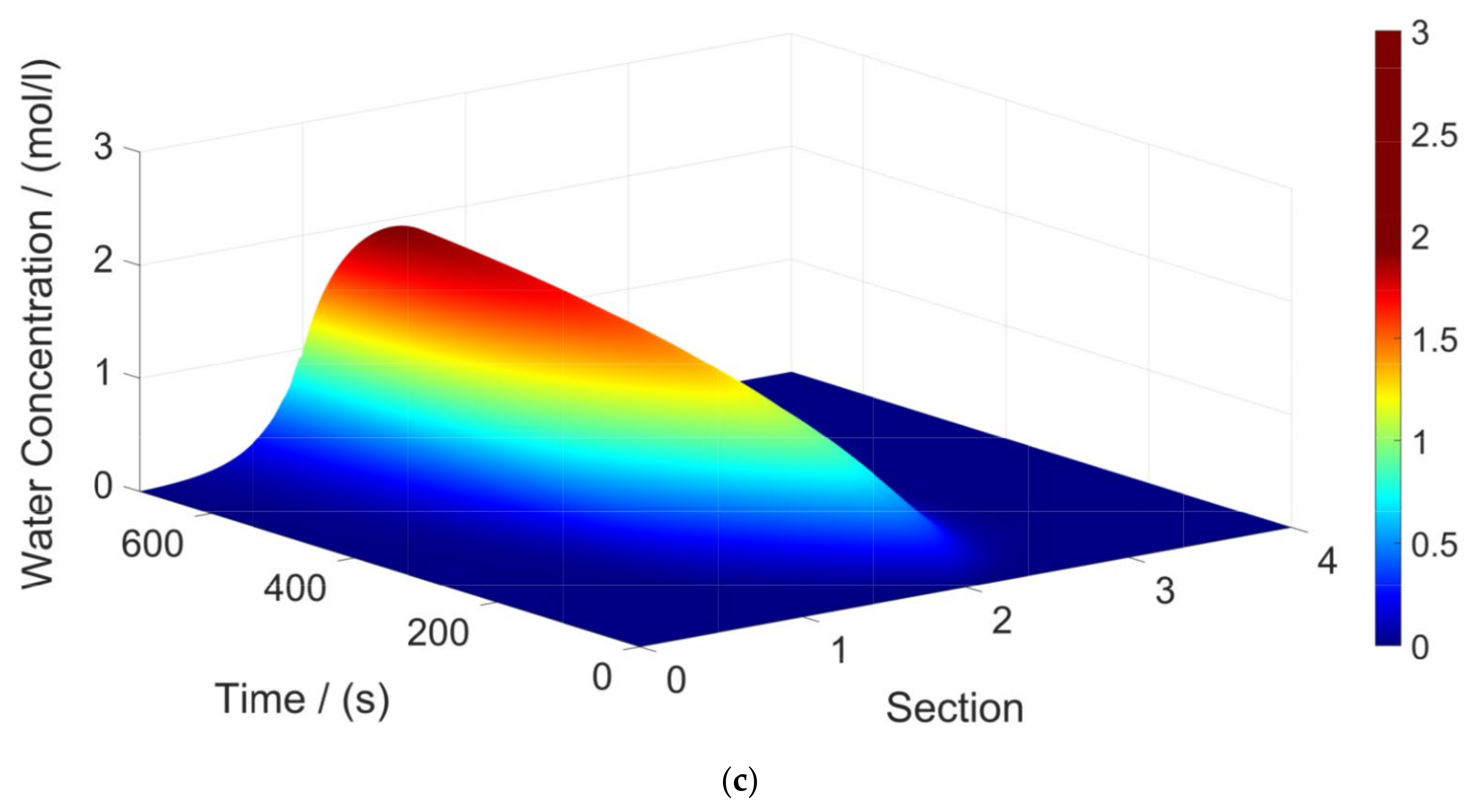

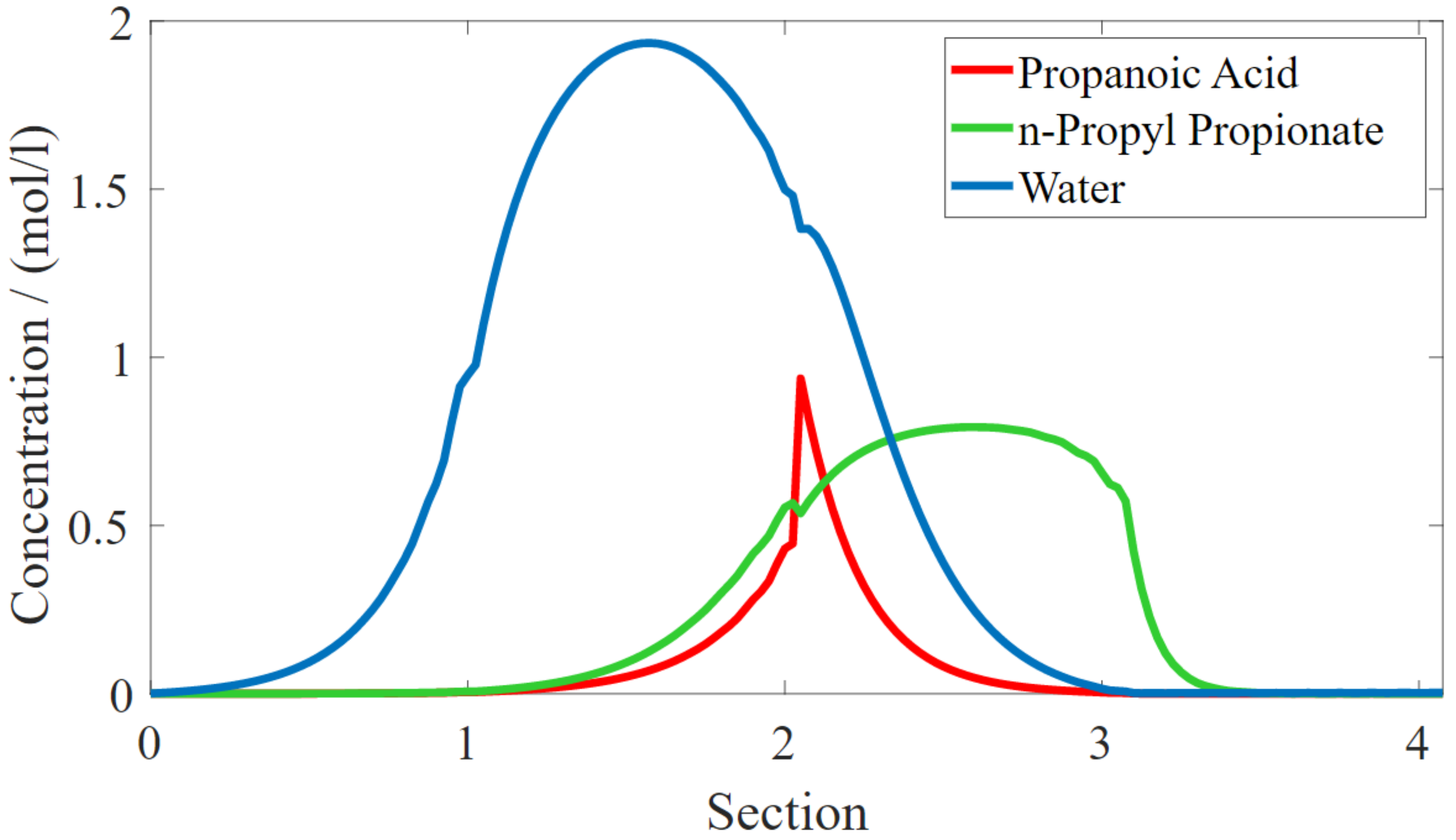

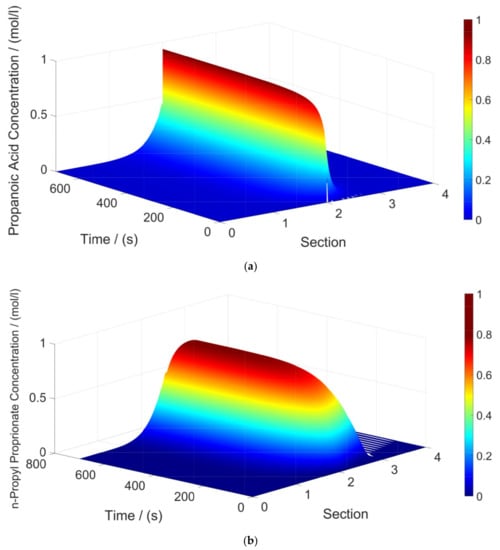

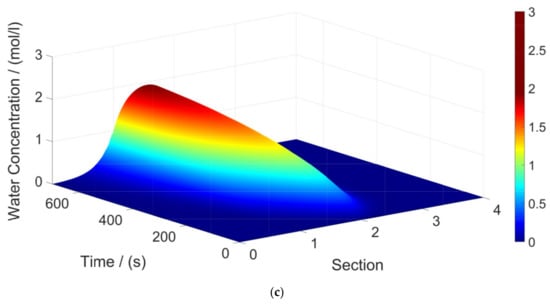

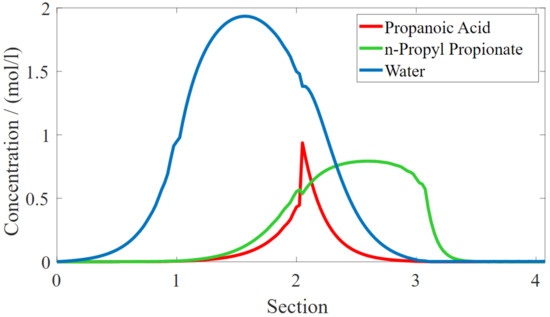

The results obtained for the optimal point are presented in Figure 3. It shows the concentration profiles along the columns and sections for propanoic acid, n-propyl propionate, and water singly in 3D graphics. In turn, Figure 4 shows the concentration profiles along the sections for the reactants and products together in a 2D graphic. It is worth observing that 1-propanol is the eluent and is not presented in Figure 3 and Figure 4. Its concentration is higher than the others and virtually does not change over time and sections. As it is possible observe from the concentration profiles that the unit can promote the separation of the product water from the reaction area (Section II), shifting the equilibrium to yield more n-propyl propionate. Therefore, this results in a reaction conversion close to 100%. Moreover, it is possible to observe that the ProPro is collected at the end of Section III with high purity, which agrees with Table 7.

Figure 3.

TMBR concentration profile along sections and time for (a) propanoic acid, (b) n-propyl propionate, and (c) water in a transient evolution.

Figure 4.

TMBR concentration profile for propanoic acid, n-propyl propionate and water along sections in the cyclic steady state.

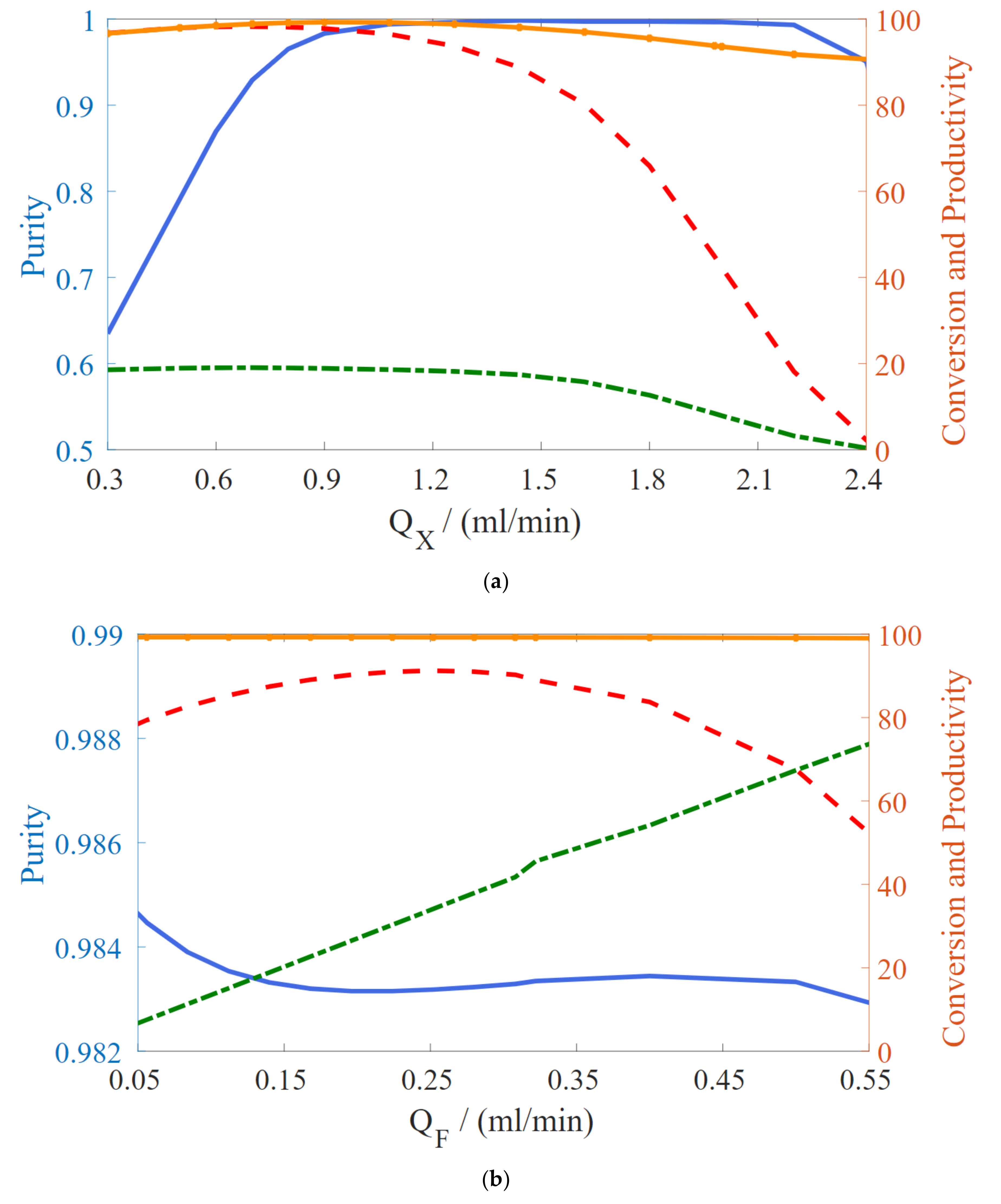

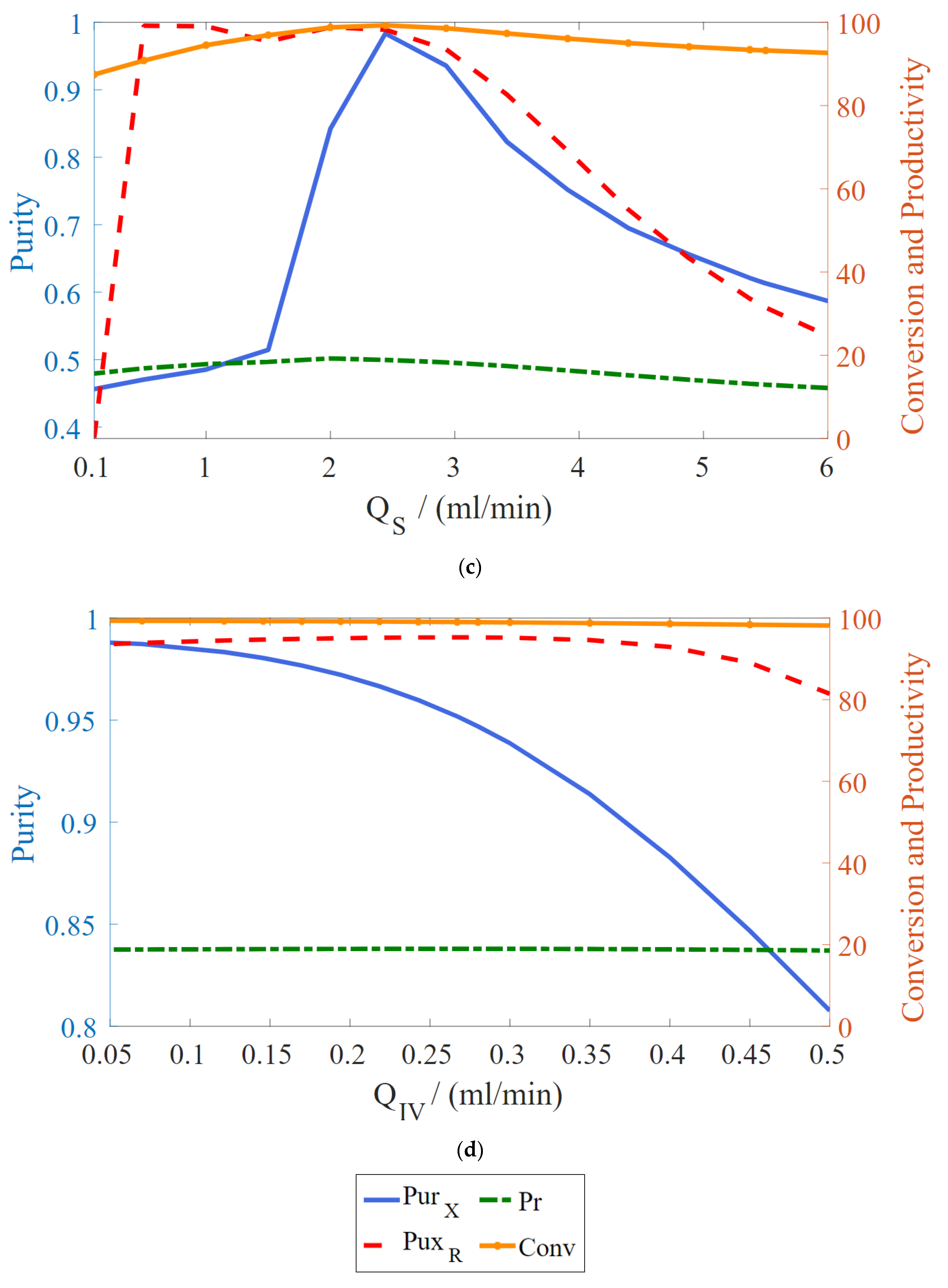

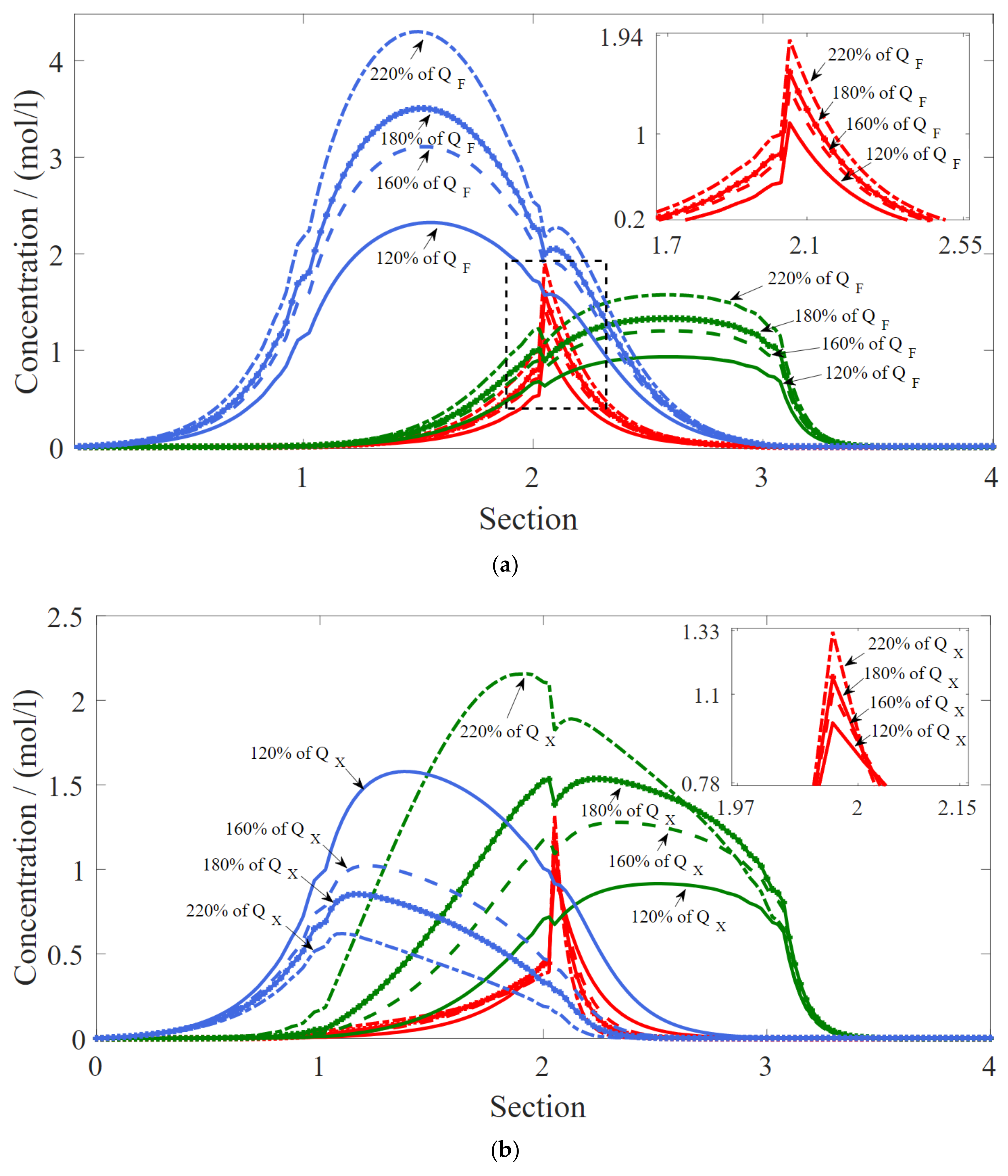

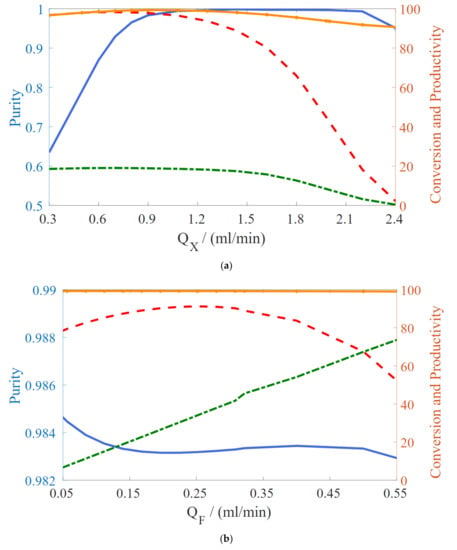

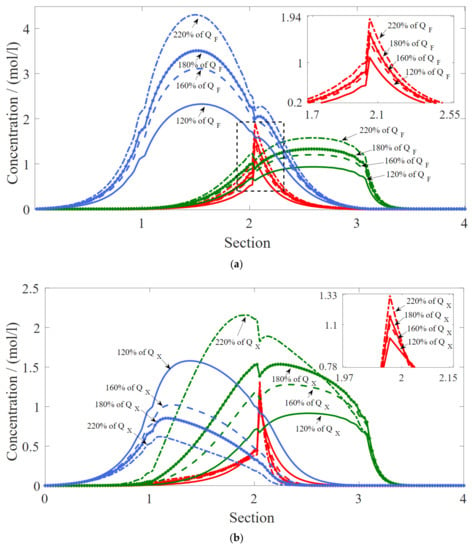

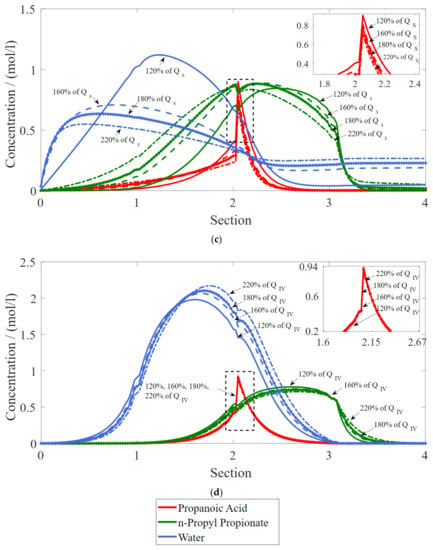

For the sake of performance assessment, changes in the operating condition were performed to analyze the process behavior, as shown in Figure 5. As observed, the extract and raffinate purities ( and ) are very sensitive to flow rate variations, except for variations on the feed flow rate. decreases with the increase in feed () and recycle () flow rates, whereas increases in extract () and solid () flow rates yield an increase in extract purity followed by a further decrease. Conversion () and productivity () do not change as much. As expected, productivity shows a significant increase as the feed flow rate increases and a drop as the solid flow rate increases.

Figure 5.

Performance parameter behaviors with variations of (a) feed (), (b) extract (), (c) solid (), and (d) recycle () flow rates.

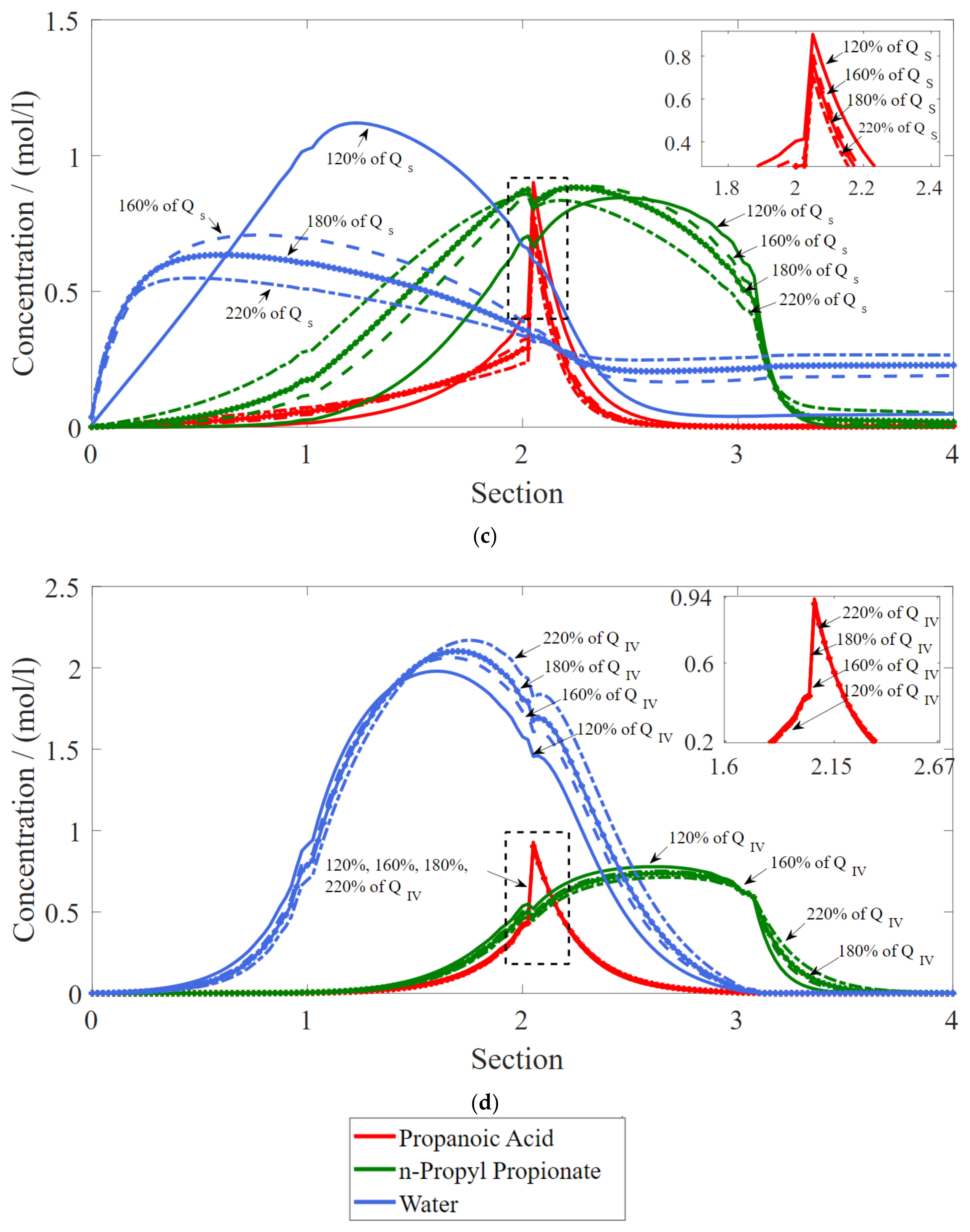

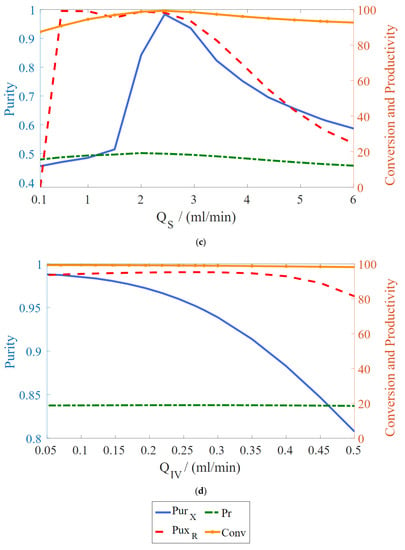

The behavior of Figure 3 and Figure 4 is explained by the analysis of the concentration profiles. Thus, the evaluation of the concentration profiles was also carried out with variations of the operating conditions, as shown in Figure 6. Reactants are fed between Section II and Section III, which justifies the higher concentration of propionate acid in Section II in Figure 6a–d. Pure water and ProPro must be removed, respectively, at the end of Section I and Section III. Any other compounds in these nodes means contamination in the extract and raffinate streams. Contamination of ProPro in the extract product can be observed in Figure 6a with the increase in extract flow rate. In other words, as the extract flow rate increases, the fluid flow rate in Section III and Section II decreases; therefore, not only water is carried with the solid toward the extract but also ProPro and the acid, and the reaction conversion is further reduced. An increase in feed flow rates in Figure 6b yields a higher concentration of products. Therefore, higher productivity. However, the water front starts to contaminate the raffinate stream. With the increase in solid flow rates in Figure 6c, the solid is not fully regenerated. Thus, the column is contaminated with the water dragged by the solid. In addition, the lighter components are also dragged by the solid. In turn, an increase in the recycle flow rates in Figure 6d does not affect the internal profile, which indicates that Section IV of the TMBR is more than enough to regenerate the eluent in the range studied.

Figure 6.

Concentration behaviors with variations of (a) feed (), (b) extract (), (c) solid (), and (d) recycle () flow rates.

4. Conclusions

This article proposes a phenomenological model for the production of n-Propyl Propionate in a Simulated Moving Bed Reactor (SMBR) packed with a heterogeneous adsorptive catalyst, Amberlyst 46 resin. A comprehensive methodology to estimate the thermodynamic and kinetic parameters was presented. Experimental data from the literature were used to estimate the parameters yielding a validated model with experimental data in its fundamental levels. This paper proposes a novel heterogeneous model for producing n-Propyl Propionate in SMBR. The results demonstrated that it is possible to achieve conversions and purities higher than 98% in this process. Therefore, providing the literature with solid evidence that the SMBR can be a reliable, efficient, and environmentally friendly route for ProPro production.

The results also show that it is possible to produce a 99.28% conversion of n-Propyl Propionate with 98.30% and 98.90% of purity in the raffinate and extract, respectively, as well as a productivity of 18.88 with an eluent consumption of 10.40 . This result points out that the production of n-Propyl Propionate from an SMBR is feasible, as long as economic and scale factors are taken in consideration in future studies.

Author Contributions

Conceptualization, I.B.R.N. and R.S.; methodology, I.B.R.N., R.S. and A.P.; writing—original draft preparation, I.B.R.N., R.S., A.P. and C.R.; writing—review and editing, I.B.R.N., R.S., J.M.L., A.P., C.R. and A.E.R.; supervision, I.B.R.N., K.V.P., A.E.R., A.N.R. and J.M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001. This work was also financially supported by Base Funding UIDB/50020/2020 of the Associate Laboratory LSRE-LCM funded by national funds through FCT/MCTES (PIDDAC); FCT—Fundação para a Ciência e Tecnologia under CEEC Institutional program.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Activity (dimensionless)/ 1-propanol stoichiometric coefficient | |

| Reactant 1-propanol | |

| Propionic acid stoichiometric coefficient | |

| Reactant propionic acid | |

| ) / Water stoichiometric coefficient | |

| Product water | |

| ) | |

| Conversion () | |

| n-propyl propionate stoichiometric coefficient | |

| Diffusivity coefficient () | |

| Particle diameter () | |

| Axial dispersion coefficient () | |

| Activation energy () | |

| EC | Eluent consumption () |

| Thermodynamic parameter () | |

| NRTL model parameter (dimensionless) | |

| Reaction enthalpy () | |

| Kinetic constants () | |

| Langmuir adsorption parameter ()/Adsorption equilibrium constants () | |

| Pre-exponential factor () | |

| Equilibrium constant (dimensionless) | |

| External mass transfer coefficient () | |

| Pre-exponential factor for equilibrium reaction (dimensionless) | |

| Length () | |

| Lower bound (dimensionless) | |

| Number of components | |

| Purity (%) | |

| Productivity () | |

| Adsorbed phase concentration () | |

| Adsorbed phase concentration in equilibrium with c () | |

| n-Propyl Propionate | |

| Flow rate () | |

| Langmuir adsorption parameter (mol/l) | |

| Reaction rate () | |

| Universal gas constant () | |

| Particle radius (dm) | |

| Temperature (K) | |

| Time () | |

| Velocity () | |

| Upper bound (dimensionless) | |

| Stoichiometric coefficient | |

| Molar volume () | |

| Volume of the bed () | |

| Dimensionless axial position in the bed / Molar fraction (Dimensionless) | |

| Axial position in the bed () | |

| Subscripts and Superscripts | |

| A | Reactant 1-propanol |

| B | Reactant propionic acid |

| C | Product water |

| D | Product n-propyl propionate |

| Eluent stream | |

| Feed stream | |

| Component | |

| I | Section 1 |

| II | Section 2 |

| III | Section 3 |

| IV | Section 4 |

| Component | |

| TMBR section | |

| Mixture | |

| Raffinate stream | |

| Solid | |

| Extract stream | |

| 0 | Diluted component |

| Greek Symbols | |

| Number of non-randomness in the systems (dimensionless) | |

| Bed porosity (dimensionless) | |

| Activity coefficients (dimensionless) | |

| Fluid viscosity () | |

| Bulk density () | |

| NRTL model parameter (dimensionless) | |

References

- Nogueira, I.B.R.; Faria, R.P.V.; Rodrigues, A.E.; Loureiro, J.M.; Ribeiro, A.M. Chromatographic Studies of N-Propyl Propionate, Part II: Synthesis in a Fixed Bed Adsorptive Reactor, Modelling and Uncertainties Determination. Comput. Chem. Eng. 2019, 128, 164–173. [Google Scholar] [CrossRef]

- Pereira, C.S.M.; Gomes, P.S.; Gandi, G.K.; Silva, V.M.T.M.; Rodrigues, A.E. Multifunctional Reactor for the Synthesis of Dimethylacetal. Ind. Eng. Chem. Res. 2008, 47, 3515–3524. [Google Scholar] [CrossRef]

- Santana, V.V.; Martins, M.A.F.; Rodrigues, A.E.; Loureiro, J.M.; Ribeiro, A.M.; Nogueira, I.B.R. Transient Analysis of True/Simulated Moving Bed Reactors: A Case Study on the Synthesis of n-Propyl Propionate. Comput. Chem. Eng. 2020, 137, 106820. [Google Scholar] [CrossRef]

- Wang, J.; Tian, Y.; Li, Y.; Xu, J.; Yu, W.; Ray, A.K. Multi-Objective Optimization of Non-Isothermal Simulated Moving Bed Reactor: Methyl Acetate Synthesis. Chem. Eng. J. 2020, 395, 125041. [Google Scholar] [CrossRef]

- Shi, Q.; Gonçalves, J.C.; Ferreira, A.F.P.; Rodrigues, A.E. Simulated Moving Bed Reactor for P-Xylene Production: Modeling, Simulation, and Optimization. Chem. Eng. Sci. 2020, 225, 115802. [Google Scholar] [CrossRef]

- Nogueira, I.B.R.; Viena, V.; Rodrigues, A.E.; Loureiro, J.M.; Ribeiro, A.M. Dynamics of a True Moving Bed Reactor: Synthesis of n-Propyl Propionate and an Alternative Optimization Method. Chem. Eng. Process.-Process Intensif. 2020, 148, 107821. [Google Scholar] [CrossRef]

- Duarte, C.F.M. Production of TAME and N-Propyl Propionate by Reactive Distillation; University of Porto: Porto, Portugal, 2006. [Google Scholar]

- The Dow Chemical Company. Amberlyst 46 ®. No. 177, 3028. 2014. Available online: https://www.lenntech.com/Data-sheets/Dow-Amberlyst-46-L.pdf (accessed on 15 September 2021).

- Cruz-Díaz, M.; Buchaly, C.; Kreis, P.; Pérez-Cisneros, E.S.; Lobo-Oehmichen, R.; Górak, A. Synthesis of N-Propyl Propionate in a Pilot-Plant Reactive Distillation Column: Experimental Study and Simulation. Comput. Chem. Eng. 2012, 39, 118–128. [Google Scholar] [CrossRef]

- Lundquist, E.G. Catalyzed Esterification Process. U.S. Patent 5,426,199, 20 June 1995. [Google Scholar]

- Dai, X.; Ye, Q.; Yu, H.; Suo, X.; Li, R. Design and Control of Dividing-Wall Column for the Synthesis of n-Propyl Propionate by Reactive Distillation. Ind. Eng. Chem. Res. 2015, 54, 3919–3932. [Google Scholar] [CrossRef]

- Xia, H.; Dai, X.; Ye, Q.; Feng, S.; Li, R.; Suo, X. Design and Control of Entrainer-Assisted Reactive Distillation for N-Propyl Propionate Production. Comput. Chem. Eng. 2017, 106, 559–571. [Google Scholar] [CrossRef]

- Constantino, D.S.M.; Pereira, C.S.M.; Faria, R.P.V.; Loureiro, J.M.; Rodrigues, A.E. Simulated Moving Bed Reactor for Butyl Acrylate Synthesis: From Pilot to Industrial Scale. Chem. Eng. Process. Process Intensif. 2015, 97, 153–168. [Google Scholar] [CrossRef]

- Constantino, D.S.M.; Faria, R.P.V.; Pereira, C.S.M.; Loureiro, J.M.; Rodrigues, A.E. Enhanced Simulated Moving Bed Reactor Process for Butyl Acrylate Synthesis: Process Analysis and Optimization. Ind. Eng. Chem. Res. 2016, 55, 10735–10743. [Google Scholar] [CrossRef]

- Azevedo, D.C.S.; Rodrigues, A.E. Design Methodology and Operation of a Simulated Moving Bed Reactor for the Inversion of Sucrose and Glucose-Fructose Separation. Chem. Eng. J. 2001, 82, 95–107. [Google Scholar] [CrossRef]

- Santos, R.V.A.; Prudente, A.N.; Ribeiro, A.M.; Rodrigues, A.E.; Loureiro, J.M.; Martins, M.A.F.; Pontes, K.V.; Nogueira, I.B.R. Global Approach for Simulated Moving Bed Model Identification: Design of Experiments, Uncertainty Evaluation, and Optimization Strategy Assessment. Ind. Eng. Chem. Res. 2021, 60, 7904. [Google Scholar] [CrossRef]

- Lilja, J.; Murzin, D.Y.; Salmi, T.; Aumo, J.; Maäki-Arvela, P.; Sundell, M. Esterification of Different Acids over Heterogeneous and Homogeneous Catalysts and Correlation with the Taft Equation. J. Mol. Catal. A Chem. 2002, 182, 555–563. [Google Scholar] [CrossRef]

- Nogueira, I.B.R.; Faria, R.P.V.; Requião, R.; Koivisto, H.; Martins, M.A.F.; Rodrigues, A.E.; Loureiro, J.M.; Ribeiro, A.M. Chromatographic Studies of N-Propyl Propionate: Adsorption Equilibrium, Modelling and Uncertainties Determination. Comput. Chem. Eng. 2018, 119, 371–382. [Google Scholar] [CrossRef]

- Prudente, A.N.; Santana, D.D.; Pontes, K.V.; Loureiro, J.M.; Ribeiro, A.M.; Nogueira, I.B.R. Engineering: Parameter Estimation of a Liquid-Liquid Equilibrium for the Quaternary System n-Propanol, Propanoic Acid, Propyl Propionate and Water Though the Exploration and Exploitation Technique. In Proceedings of the Congresso de Métodos Numéricos em Engenharia, Guimarães, Portugal , 1–3 July 2019; pp. 1097–1107. [Google Scholar]

- Samarov, A.; Toikka, M.; Trofimova, M.; Toikka, A. Liquid-Liquid Equilibrium for the Quaternary System Propionic Acid + n-Propanol + n-Propyl Propionate + Water at 293.15, 313.15 and 333.15 K. Fluid Phase Equilib. 2016, 425, 183–187. [Google Scholar] [CrossRef] [Green Version]

- Constantino, D.S.M.; Pereira, C.S.M.; Faria, R.P.V.; Ferreira, A.F.P.; Loureiro, J.M.; Rodrigues, A.E. Synthesis of Butyl Acrylate in a Fixed-Bed Adsorptive Reactor over Amberlyst 15. AIChE J. 2015, 61, 1263–1274. [Google Scholar] [CrossRef]

- Buchaly, C.; Kreis, P.; Górak, A. Hybrid Separation Processes-Combination of Reactive Distillation with Membrane Separation. Chem. Eng. Process. Process Intensif. 2007, 46, 790–799. [Google Scholar] [CrossRef]

- Xu, H.; Ye, Q.; Zhang, H.; Qin, J.; Li, N. Design and Control of Reactive Distillation-Recovery Distillation Flowsheet with a Decanter for Synthesis of N-Propyl Propionate. Chem. Eng. Process. Process Intensif. 2014, 85, 38–47. [Google Scholar] [CrossRef]

- Lode, F.; Houmard, M.; Migliorini, C.; Mazzotti, M.; Morbidelli, M. Continuous Reactive Chromatography. Chem. Eng. Sci. 2001, 56, 269–291. [Google Scholar] [CrossRef]

- Sporti, G.; Masi, M.; Carrà, S. Optimal Desgin of Multicomponent Cuntercurrent Adsorption Separation Processes Involving Nonlinear Equilibria. Chem. Eng. Sci. 1989, 44, 1329–1345. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).