Abstract

During recent years, there has been great interest in exploring the potential for high-rate natural gas (NG) injection in North American blast furnaces (BFs) due to the fuel’s relatively low cost, operational advantages, and reduced carbon footprint. However, it is well documented that increasing NG injection rates results in declining raceway flame temperatures (a quenching effect on the furnace, so to speak), with the end result of a functional limit on the maximum injection rate that can be used while maintaining stable operation. Computational fluid dynamics (CFD) models of the BF raceway and shaft regions developed by Purdue University Northwest’s (PNW) Center for Innovation through Visualization and Simulation (CIVS) have been applied to simulate multi-phase reacting flow in industry blast furnaces with the aim of exploring the use of pre-heated NG as a method of widening the BF operating window. Simulations predicted that pre-heated NG injection could increase the flow of sensible heat into the BF and promote complete gas combustion through increased injection velocity and improved turbulent mixing. Modeling also indicated that the quenching effects of a 15% increase in NG injection rate could be countered by a 300K NG pre-heat. This scenario maintained furnace raceway flame temperatures and top gas temperatures at levels similar to those observed in baseline (stable) operation, while reducing coke rate by 6.3%.

1. Introduction

Worldwide, auxiliary fuel injection serves as one of the key technologies by which blast furnace (BF) coke consumption rates are reduced. As with many other industries, iron and steelmaking must also contend with a growing focus on carbon emissions and their impacts, resulting in tighter regulations on emissions or the implementation of carbon taxes by various governments. Through the reduction of coke consumption and by the introduction of some hydrogen to the reduction process via fuels such as natural gas, injected fuels are one of the key levers by which operators can reduce carbon footprint and possibly make the blast furnace more efficient. In addition, these injected fuels typically present a significant economic incentive for their greater use, especially in the case of natural gas (NG) in North America. However, no modification can be undertaken in isolation, and changes to any variable will inevitably require an understanding of how they may impact conditions within the furnace.

With high NG injection rates becoming more and more common in addition to, and sometimes in place of, pulverized coal injection (PCI) in North American BFs, it is increasingly important for operators to understand what impacts NG injection can have on conditions in the furnace and how any disadvantages can be mitigated. Of course, in comparison to PCI, NG injection has some obvious benefits, including reduced carbon footprint and the lack of potential for fines buildup from ash or unburned char. However, the most critical limitation of NG injection results from the production of H2O (and to a lesser extent CO2) from NG combustion. Within the raceway and packed bed, these species will participate in endothermic reactions with the coke bed, consuming heat and causing a drop in reducing gas temperatures. This phenomenon can be easily observed by examining the raceway adiabatic flame temperature (RAFT), calculated theoretically using heat and mass balance modeling based upon the ‘Rist Diagram’ or via approaches such as the AISI (American Iron and Steel Institute) formulation [1,2]. This is the temperature of the furnace gases after all reactions have taken place and the only remaining species are CO, H2, and N2.

While the minimum stable RAFT level will vary between furnaces, recent publications indicate that the majority of North American BFs operate somewhere above 2020 K [1,3]. A falling RAFT can result in furnace instability and reduced productivity, and generally, operators will mitigate such scenarios by increasing the level of oxygen enrichment in the hot blast. Increased O2 levels in the blast, however, are known to cause a decline in furnace top temperatures, potentially leading to condensation of moisture in or near the uptakes and damage to the furnace. While increasing NG injection rates can help to bring the top temperature back up [3], the negative impact of O2 enrichment on top temperatures is stronger than the positive impacts of NG. The competing factors of low top temperatures due to O2 enrichment and low raceway flame temperatures due to NG injection create a functional constraint on the maximum level of NG injection in the BF, with the highest reported levels occurring at around 150–160 kg/mthm (kg per tonne of hot metal produced by the furnace) [1,3].

It is clear then that a method by which flame temperatures could be increased without relying heavily on O2 enrichment could make possible higher rates of NG injection. The approach which appears most obvious here would be to increase the hot blast temperature, as that would supply additional sensible heat to the furnace to counter the low flame temperatures without impacting gas chemistry. However, as many furnaces are already maximizing their available hot blast temperature, this method may not be an option. One may then wish to turn to alternative methods of introducing sensible heat to the furnace. Since NG is typically injected at ambient temperature, the injected gas flow presents the most desirable location for this additional heat, with the added benefit of increasing the gas velocity, which may slightly enhance tuyere exit velocity, as well as improve turbulent mixing with the blast and enhance gas combustion.

Pre-heating NG by a reasonable amount (300–400 K) before injection into the furnace is a concept that has been previously noted in a very limited set of publications and trials. The idea has been explored conceptually by researchers working with heat and mass balance models and lab-scale experimentation [3], and at least one industrial facility has reported attempts at studying and implementing NG pre-heating in operational BFs [4,5]. The aforementioned attempt at implementation was conducted at the OJSC LMZ “Svobodny Sokol” and OJSC “Severstal” BFs, with NG temperature increases of 170K and 75K, respectively, achieved by channeling NG flow through a heat recovery apparatus around the outside of the blowpipe. While gas pre-heating was not applied in isolation, the increase in NG temperature led to a reduction in coke consumption rate in both trialed scenarios, and an increase in the NG coke replacement ratio (the ratio of how much coke can be removed from the furnace burden for a fixed amount of fuel injected into the tuyere) from 1.2:1 to 1.42:1 was observed. Table 1 details additional operating conditions under which the technique was implemented for both furnaces.

Table 1.

Impacts of pre-heated NG injection at OJSC LMZ “Svobodny Sokol” and OJSC “Severstal”. Reproduced with permission from T. Okosun, AISTech 2019; published by AIST, 2019.

The implementation of such gas pre-heating in the field, whether achieved via heat recovery systems or some other method, would require some expenditure for design and installation. With this in mind, it becomes important to develop a more complete understanding just how much value there is in enabling this additional lever for BF control, and what potential efficiency benefits NG pre-heating might present to BF operation in a range of different scenarios. Industry experience can serve as a judge of feasibility for methods of implementation, but focused research is often needed to understand the specific impacts of untested changes in parameters such as NG pre-heating on the BF. Simulation modeling presents an excellent approach for such research, allowing for scientific-based predictions of how changes to input conditions can impact the chemical reactions, temperatures, flow patterns, and other phenomena inside the BF.

Given its comparable speed and low expense when compared to test rigs or other experimental methods, computational fluid dynamics (CFD) modeling has become a key first step in determining the impacts of new operating parameters on multi-phase reacting flow systems. In particular, CFD modeling of the BF has been applied to great effect at the tuyere level by a wide range of researchers exploring methods of optimization for operation. Such modeling has expanded from simplified one-dimensional approaches to full-scale three-dimensional multi-phase flow models of specific regions of the blast furnace [6,7,8,9,10,11,12,13,14]. In particular, the Steel Manufacturing Simulation and Visualization Consortium (SMSVC) at Purdue University Northwest’s (PNW) Center for Innovation through Visualization and Simulation (CIVS) has performed a range of simulation studies on BF performance using a combination of commercial CFD codes and in-house solvers focusing on combustion, tuyere region design, and more [15,16,17,18,19,20,21,22].

This paper details current simulation research on high-rate NG injection in North American BFs, and the impacts of pre-heated NG injection. CFD models of two BFs of similar scale were conducted as part of this research, with one furnace utilizing co-injection of NG and PC, and the other operating on a pure NG injection basis. Modeling was conducted to determine the impacts of gas pre-heating in isolation and in conjunction with other modifications to operation. Observed benefits included increased analogue flame temperatures and a corresponding reduction in furnace coke rate with NG pre-heating. Additionally, CFD modeling indicated that a combined increase in NG injection rate and NG pre-heat could maintain top gas and flame temperatures at baseline levels while achieving a lower coke consumption rate.

2. Methods, Geometry, and Boundary Conditions

2.1. Computational Modeling Methodology

Accurately modeling the multiphase flow physics, chemical reactions, and heat/mass transfer occurring within the blast furnace requires a delicate balance of detailed modeling techniques and reasonable assumptions in order to produce results in a reasonable time frame. This research focuses on the flow, reactions, and heat transfer in the raceway and shaft regions of the BF, and a combination of CFD models are coupled together to predict phenomena. These models have been discussed in far greater detail in previous publications [15,16,17,18,19,20,21,22,23,24,25], so in the interests of brevity, this paper will present a summary of the approach.

The primary assumption made in this modeling approach is based upon the difference in time-scales between the flow of gases and solids in the furnace. Gases ascend through the shaft very quickly in comparison to the descent speed of the solid burden material, allowing for the burden packed bed to be treated as a steady-state porous media that can participate in heat transfer and chemical reactions, as well as influence gas flow. Dispersed solids, such as the pulverized coal in the raceway region, are treated as interpenetrating continuum in the model, with both gas and dispersed phases having their own corresponding conservation equations. Interphase momentum and mass exchange occurs between the particle and gas phases. For this modeling approach, the flow of liquid slag and hot metal are not directly simulated. The presence of liquid below the cohesive zone and its impact on gas flow are accounted for by decreasing the porosity of the packed bed, resulting in a corresponding increase in gas pressure resistance.

Additionally, the most effective way to reduce the computational cost of a BF simulation is to assume that flow input conditions through each tuyere—this would include wind rate, auxiliary fuel injection rates, hot blast temperature, and other parameters—are axisymmetric around the entire furnace. With this assumption made, it is possible to simulate a single tuyere, corresponding raceway cavity, and similarly axisymmetric region of the BF shaft, greatly reducing the total computational cost of a simulation. For a generic BF, the 3D domain of the simulation would include the blowpipe upstream of the tuyere, any fuel injection lances, the tuyere, the raceway boundary and coke bed, and boundaries representing the location of the furnace walls and deadman.

As previously mentioned, the approach in this research utilizes multiple sub-models coupled together to predict conditions in the BF. Specifically, these models are targeted at two major reaction zones, the raceway and the shaft. Gas flow and injected fuel input conditions are specified for the raceway model, which is used to calculate the combustion and other reactions occurring within the raceway. The corresponding species, temperature, and mass flow distribution of reducing gases leaving the raceway region are then mapped into the lower boundary of the BF shaft model, which can then be used to predict macro-level output parameters such as top gas temperature, cohesive zone shape and location, gas utilization, and furnace coke rate.

For easier adjustment of tuyere, blowpipe, and injection lance design and placement, gas combustion, solids combustion, fluid flow, and heat transfer in the blowpipe and tuyere zones are conducted using a Eulerian-based model in ANSYS Fluent® (v19.2, ANSYS, Canonsburg, PA, USA, 2019), a commercial CFD package. The steady-state Navier–Stokes equations are applied to model conditions in this region using the semi-implicit method for pressure linked equations (SIMPLE) scheme with second-order upwind discretization of the transport equations. Turbulence modeling is handled with the standard k-ε turbulence model [26], a common and robust choice for efficient simulation of multiphase flow. Gas phase reactions— including CO, H2, CH4, and coal volatile combustion—are governed by the eddy-dissipation-concept model. Radiation heat transfer is governed in all raceway region simulations by the discrete ordinates (DO) radiation model.

The results of this simulation are then mapped to a two-component approach for simulating the coke bed and raceway cavity downstream of the tuyere. Once the incoming conditions from the tuyere are determined, the size and shape of the raceway in the coke bed is simulated using a transient Eulerian multi-fluid model, conducted again with a second-order application of the SIMPLE scheme in ANSYS Fluent®. The coke bed is treated as a fluidized granular continuous phase, and the gas flow forms a raceway cavity, which can then be frozen. The air phase volume fraction is then used to define the porosity of the coke bed in the raceway, and an in-house CFD solver detailed in previous publications [27,28,29] is applied to predict chemical reactions, gas flow, and heat transfer in a steady-state simulation of flow through the coke bed in the raceway region. In addition to combustion of injected fuels, the coke bed can react with oxygen in the hot blast to generate combustion products and heat, and if sufficient thermal energy is present, reactions of CO2 and H2O with carbon in the coke bed are also possible. Table 2 below contains the kinetic constants for gas-phase reactions of CO, H2, and CH4, as well as coke reactions and coal moisture evaporation and devolatilization.

Table 2.

Key reaction mechanisms and kinetics for the computational fluid dynamics (CFD) raceway combustion model [30,31].

Combustion reactions of solids in the raceway result in the generation of additional gaseous mass. In addition, the significant variations in temperature can result in changes to gas density. These updated values are mapped back into the raceway formation step in the commercial CFD code in the form of cell-specific gas density values and a source term for gas mass, and the simulation of the raceway shape is re-run. This generates a new coke bed porosity distribution (updated raceway shape), and the combustion model can then be repeated as well. This iterative process will converge to an unchanging raceway shape, at which point the final combustion simulation results can be post-processed and mapped onto the CFD shaft model as input conditions.

Using the reducing gas flow rates, species, and temperature inputs from the raceway sub-model, the blast furnace shaft model simulates reducing gas flow through the burden layers in the BF, iron ore reduction and melting, and related phenomena. Computational domains for the BF shaft stretch from the furnace bosh, just above the raceway region, to the furnace top. As mentioned earlier, the flow is assumed to be steady state once the burden distribution is defined—either with a burden distribution sub-model or based on imported burden profiles from industry. This burden profile is used to define the porosity of the packed bed in the simulation, with coke and ore layers each having their own corresponding porosity and resistance to gas flow depending on particle size.

In this packed bed, fluid flow, chemical reactions, and heat and mass transfer between the gas and burden are all simulated by the CFD solver. Species included in the reaction models are CO, CO2, H2, H2O, and N2 in the gas phase and Fe2O3, Fe3O4, FeO, Fe, C, CaO, and MgO in the solid phase. Reactions are primarily gas–solid, though some phase transitions are included, such as moisture evaporation from the burden near the top of the furnace. The most common reactions are, of course, reduction of iron oxides by CO and H2, coke gasification, and carbonate flux decomposition. The primary reactions included in the BF shaft model are listed in Table 3.

Table 3.

Reaction mechanisms used in the CFD shaft model.

Finally, the cohesive zone (CZ) is defined between the iron ore pellet softening and iron liquidus temperatures (1473–1673 K), and in this region, the porosity of the iron ore layers is decreased to almost zero, rendering these areas impermeable to gas flow and generating a layered CZ. The approach allows gas flow to pass through the coke slits while being blocked by the cohesive ore layers. Additional details on the BF shaft model, including information on the burden distribution sub-model, can be found in previous publications [24,32,33,34].

2.2. Blast Furnace Geometry and Simulation Boundary Conditions

Research was conducted via simulation of two different blast furnaces of average size and production for North America located at separate North American steel manufacturing facilities. The geometry for the tuyere and blowpipe regions of both furnaces are unique to their different operations, with one furnace utilizing co-injection of pulverized coal and natural gas and the second using only NG injection. These two operations present ideal test beds for exploring the impacts of injected fuel adjustments, with the co-injection case allowing for comparisons of how a co-injection furnace may react during a loss-of-PCI scenario and the NG-injection furnace highlighting the impacts of NG pre-heating on operation.

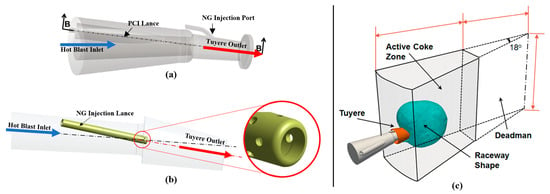

The area beyond the tuyere nose (containing the raceway and coke bed) for a single tuyere was modeled for both furnaces using computational grids. These domains were approximately two meters high and were bounded by the furnace wall and tuyere at the outside and a fixed boundary representing the deadman towards the furnace center. Symmetry conditions were applied on the bounding walls to either side of the raceway. The combination of the specific physical geometry of the tuyere and furnace with the momentum and reactions from the hot blast generated a unique raceway cavity in the coke bed. As mentioned in the previous section, the raceway geometry was defined by applying the calculated void fraction in the raceway formation model to fixed spatial variations of the coke bed porosity. The geometry for the tuyere region of both industry blast furnaces and a generic raceway region geometry are shown in Figure 1.

Figure 1.

(a) Blowpipe and tuyere region simulation domain for co-injection blast furnace (BF); (b) Blowpipe and tuyere region simulation domain for natural gas (NG)-only BF; and (c) Generic raceway region geometry with tuyere and blowpipe position included.

Additionally, simulations of the shaft region of the NG-only blast furnace were conducted. This geometry was far simpler than the raceway, with the furnace walls defining an axisymmetric cylindrical region with a radius that varied depending on height. The burden charge profile for ore and coke layers was provided by the industry partner, with the ore charge weight varying depending on the natural gas injection rate to adjust furnace production and corresponding coke rate in real-world operation.

Boundary conditions were defined for each individual region simulated. In the tuyere/blowpipe regions, the hot blast inflow, NG inflow, and PC carrier gas inflow were defined as mass flow inlets in the CFD solver. At each inlet, fluid temperature, species distribution, and mass flow rate were defined based on furnace operating conditions. PC injection was handled with the discrete phase method (DPM), and the total mass flow influx of PC particles was defined once again based on industry operating conditions. A pressure outlet boundary condition was used for the tuyere exit, with an estimated emissivity and blackbody temperature used to account for radiation heat flux entering the tuyere from the high-temperature coke bed in the raceway.

Mass flow and species distribution for the gas phase were mapped onto the inlet for the raceway region CFD simulation. The DPM concentration at the tuyere outlet plane was mapped as a scalar value to define the volume fraction of the dispersed particle phase for tracking PC movement in the raceway. Similar mass flow inlet and pressure outlet flow boundary conditions were applied in this region, with symmetry conditions applied on the boundaries located on either side of the raceway envelope. Mass flow rates and species distributions were also mapped from the outlet of the raceway region to the inlet of shaft model, and once again, a pressure outlet was used for the out-flow condition at the top of the furnace.

Environmental heat losses were governed by refractory and steel shell thermal conductivity in the blowpipe, with assumed natural convection at average ambient temperatures of ~305 K. In the water-cooled copper tuyere, assumptions were based on typical industry conditions and expectations, with a heat transfer coefficient of ~3000 W/(m2 K) and a freestream temperature of 300 K for cooling water applied. For the furnace walls in the raceway and shaft regions, a basic constant heat flux assumption was applied based on expectations of heat losses to cooling water provided by industry partners.

3. Results

3.1. Co-Injection Blast Furnace

The impact of various parameters and design modifications on the operation of the co-injection furnace simulated in this research were documented in previous publications [15,16,17]. This work focuses in particular on the effects of a significant increase in natural gas injection rate in comparison to standard operating conditions, perhaps in a loss-of-PCI scenario while attempting to maintain production rate. Modeling of this furnace was conducted at typical operating conditions, with a wind rate of ~200,000 Nm3/h, an oxygen enrichment of 34%, a blast temperature of 1408 K, a PCI rate of 85 kg/mthm, and a NG injection rate of 65 kg/mthm. The pulverized coal particle size distribution was provided by industry partners, with an average particle size of 0.046 mm.

While attention was given to the impacts of design and operational changes on conditions in the tuyere region in previous publications [15,16,17], in this research, the focus remained on changes to gas temperature and species distribution in the raceway region. Using the CFD model, it is possible to generate a numerical value that can be easily compared to the raceway adiabatic flame temperature (RAFT) by taking a mass-weighted average of the gas temperature in all computational cells in the domain with less than 0.5% H2O, CO2, and O2 content by volume. This corresponds to the theoretical definition of RAFT as the temperature of all gases once they have been reduced from fuel and oxidizer into CO and H2 (also including inert N2). From this point forward, the CFD-generated value will be referred to as the flame temperature analogue (FTA).

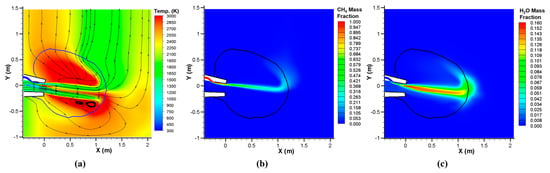

In the baseline scenario, simultaneous injection of NG and PC led to spatial variations in temperature distribution. Coke combustion occurred where unreacted oxygen encountered the coke bed, while the initial NG flame occurred rapidly near the outlet of the tuyere, followed by a sharp reduction in gas temperature in the regions where NG combustion products (particularly H2O) engage in endothermic reactions with coke. PC combustion in recirculation zones within the raceway itself generated larger high temperature regions, which can be observed in Figure 2. The predicted baseline FTA was 2244 K, a difference of 2.1% compared with an expected RAFT of 2293 K.

Figure 2.

(a) Gas temperature contours and flow streamlines for the baseline co-injection BF raceway (raceway boundary shown in blue); (b) Contours of CH4 mass fraction; and (c) Contours of H2O mass fraction.

Operational rules-of-thumb based on industry experience have documented the impacts of increasing or decreasing many tuyere-level parameters on the furnace. Correspondingly, this research aimed to ascertain whether the CFD models used in this study would show similar trends, and if so, to simulate the impacts of a complete loss-of-PCI scenario in which furnace operators attempt to replace all injected fuel with natural gas. Comparisons were conducted with two scenarios in which the ratio between NG and PC injection rates were shifted and all other parameters were held constant. The ratio in the baseline case was 1.31:1 (PC to NG). In Case #1, the ratio was increased to 2.26:1, and in Case #2, the ratio was decreased to 0.87:1. In line with expectations, Case #1 (with a lower NG injection rate) resulted in a high predicted FTA of 2271 K and Case #2 (with a higher NG injection rate) had a lower predicted FTA of 2228 K.

Case #3 took high-rate natural gas operation to an extreme, cutting PCI and increasing the NG injection rate from the baseline value of 65 kg/mthm and increasing it to 150 kg/mthm. The NG in this case was supplied through an NG injection lance. This level of NG injection is generally held as the maximum sustainable for stable operation due to the constraints detailed in Section 1 of this paper (falling RAFT, low top temperatures due to increased O2 enrichment). Aside from the modification to injection, operating conditions in Case #3 were maintained at baseline levels. Figure 3 shows the distribution of gas temperature, CO2, and H2O in the raceway region. Combustion was immediate and was distributed throughout the majority of the tuyere jet, however, gas temperature fell rapidly upon contact with the coke bed as CO2 and H2O underwent the aforementioned endothermic reactions with coke. The FTA in this scenario dropped by more than 11% to 1988 K, a value just below the aforementioned minimum RAFT for North American BFs of 2020 K. It should be noted that the increased injection rate and delivery of NG through a lance resulted in NG pushing away from the tuyere center plane, and it was only once the gas had begun to recirculate in the raceway that higher concentrations were observed on the center plane of the raceway as seen in Figure 3b.

Figure 3.

(a) Gas temperature contours and flow streamlines for Case #3 in the co-injection BF raceway (raceway boundary shown in blue); (b) Contours of CO2 mass fraction; and (c) Contours of H2O mass fraction.

The results from this scenario indicated that the CFD modeling techniques applied were able to predict the decline in gas temperatures resulting from high levels of NG injection. Based upon this, the next stage of research aimed to determine the effectiveness of NG pre-heating as a method to counter the decline in predicted FTA and maintain reducing gas temperatures in the furnace. This would serve as a potential method by which a loss-of-PCI scenario could be quickly adapted to in the field, allowing for significantly higher NG injection rates with a much more manageable decline in BF reducing gas temperatures. As previously discussed, NG pre-heating may present another lever for operators beyond adjustments to O2 enrichment, wind rate, and hot blast temperature.

3.2. Natural Gas Injection Blast Furnace

Following the loss-of-PCI study, an investigation of the specific impacts of NG pre-heating throughout the furnace (both in the raceway and shaft regions) was conducted using the NG injection industry blast furnace. While the NG-only BF was roughly 30% larger than the co-injection BF and operated at a slightly higher production rate, CFD modeling of the BF as a trial for this portion of the research allowed for isolation of gas pre-heating impacts, helping to clearly delineate any benefits and drawbacks associated with the approach. The baseline operating conditions for the NG-only BF included a wind rate of 270,000 Nm3/h, an oxygen enrichment of 29%, a hot blast temperature of 1448 K, and an NG injection rate of 95 kg/mthm, among other parameters. Natural gas was injected into the tuyere through a lance with multiple ports around the edges near the tip and a single central port for primary gas flow, as shown in Figure 1b.

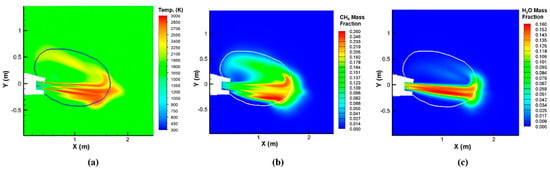

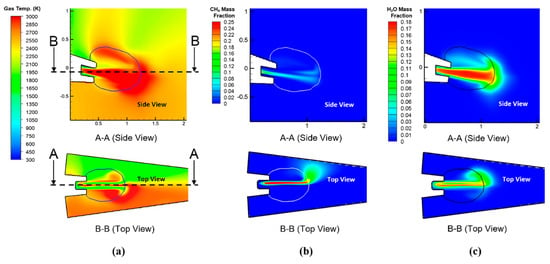

The FTA predicted for baseline operating conditions at the NG-only BF was 2187 K, which compares favorably to the industry RAFT expectation of 2169 K (0.74% difference). When observing conditions within the NG-only furnace raceway, it can be seen that the location and angle of the NG injection lance has a significant impact on the temperature and gas species distributions in the raceway region. Figure 4 shows contours of gas temperature, CH4 mass fraction, and H2O mass fraction. In this case, the NG plume remained to the left (looking from the outside of the furnace in, as if through a peep sight) of the tuyere center plane, as the injection lance was inserted from the right-hand side and pushed gas to the opposite side of the tuyere. This resulted in higher concentrations of NG and NG combustion products on the left-hand side the raceway, leading to a left–right asymmetry in gas temperatures as the CO2 and H2O from NG combustion experienced the expected endothermic reactions with coke.

Figure 4.

Side view (top) and top view (bottom) of contours of (a) temperature; (b) CH4 mass fraction contours; and (c) H2O mass fraction in the raceway region for the NG-only BF baseline case (raceway boundary shown in blue or white).

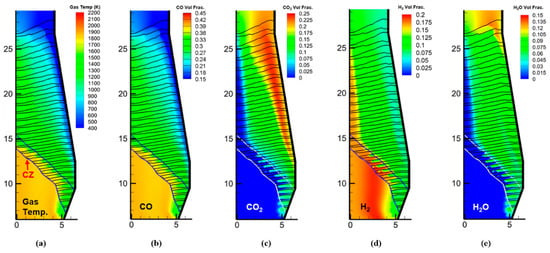

The distributions of gas temperature, mass flow rate, and species distribution were exported from the upper outlet boundary of the raceway region CFD model and were then transferred as importable inlet conditions for the shaft region CFD model. Other required operating conditions for the BF shaft model included the burden distribution—provided by industry collaborators for the baseline scenario and shifts in burden charge weight for increased or decreased NG injection rates—and by-weight moisture content in the charged iron ore and coke layers. The moisture content was of particular interest, as in the wet and cold winter months in some regions of North America, ore moisture content can rise significantly, resulting in impacts on top gas water vapor content and temperature when charged moisture evaporates. For the baseline case, these values were fixed at 2.5% by weight for the ore layers and 6% by weight for the coke layers. Contours of gas temperature and species distribution in the shaft region are shown in Figure 5. Also included are demarcations indicating the location of the burden layers in the furnace and the location of the cohesive zone.

Figure 5.

Cross-section views of contours in the shaft region showing (a) gas temperature contours; (b) CO volume fraction; (c) CO2 volume fraction; (d) H2 volume fraction; and (e) H2O volume fraction.

While the CFD models applied in this research have been extensively validated in previous publications [21,25,26,30,31,32], additional validation against macro-level parameters from the industry operation of this blast furnace was conducted to build confidence in the ability of the included simulations to predict operating conditions for this particular blast furnace. In particular, CFD predictions of coke rate, reducing gas utilization, and average top gas temperature were compared against industrial values for operation corresponding to the scenario investigated in the baseline case. Top gas temperature and CO and H2 utilization values were determined based on averaged readings from a top gas analyzer during standard operation matching the conditions of the baseline case. These comparisons are detailed in Table 4.

Table 4.

Comparison of CFD results against industry data for NG-only BF baseline operation.

The impacts of NG pre-heating on the NG injection BF were first explored with six scenarios beyond the baseline case. These cases, selected based on industry feedback, raised the incoming temperature of injected NG from 300 K to 600 K in 100 K increments. The upper temperature boundary was set at 600 K for this study to avoid scenarios with the potential for NG cracking and soot formation in the transport piping, a practical limitation which might well lead to excessive maintenance and higher costs after implementation. Every other operating condition (hot blast temperature, wind rate, oxygen enrichment, NG injection rate) was held constant for the first set of simulation cases to isolate the impacts of NG pre-heating on phenomena within the raceway region.

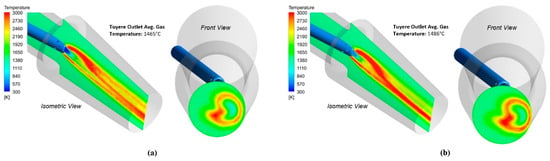

In the tuyere and blowpipe region, the impacts of NG pre-heating were primarily observable in the increased velocity of the incoming NG plume and the increased average temperature. Comparing a scenario in which NG was preheated to 600 K to the baseline case, gas temperatures at the outlet were 1.4% higher and the average gas velocity was 1.8% higher. Additionally, the higher NG injection velocity pushed the combusting gas plume slightly closer to the tuyere wall, which may present reliability concerns during operation unless the lance is retracted, or a larger diameter lance is used. A 6.3% increase in NG combustion before the tuyere exit was also observed, most likely due to the reduced density and increased velocity of NG, which results in improved turbulent mixing. The average turbulent kinetic energy predicted at the tuyere outlet under standard conditions was 326 m2/s2, while with a 300 K NG pre-heat this value rose to 414 m2/s2, a 27% increase. A direct comparison between these two cases is shown in Figure 6.

Figure 6.

Isometric and front views of gas temperature contours on the tuyere center plane (left) and tuyere outlet (right) for (a) the baseline case; and (b) the 300 K NG pre-heat scenario.

Changes to species distribution in the raceway region were minimal, as might be expected given that incoming mass flow rates of fuel and oxygen were held constant. Temperature distributions were also similar between cases, with the largest observable variations occurring in the predicted FTA value (which is itself the first parameter targeted by NG pre-heating). Similarly, in the shaft region, the impacts of NG pre-heating are easiest to observe by directly comparing the changes in top gas temperature and coke rate to the corresponding values from the baseline case. Table 5 details the results from the NG pre-heating simulations at the baseline natural gas injection rate.

Table 5.

Impacts of NG pre-heating on BF operating conditions in the raceway and shaft regions. FTA: flame temperature analogue.

It is clear that NG pre-heating had an observable impact on the predicted FTA value, with each 100 K increase in NG temperature resulting in a 17 K increase in predicted FTA on average. Additionally, the BF coke rate declined by up to 7 kg/mthm at the maximum level of NG pre-heating, indicating the potential for improvements to operational efficiency with this approach.

During the course of this research, the potential of NG pre-heating as a lever to address declining top gas temperatures during winter months in North America due to high burden moisture content was also explored. The CFD shaft model was applied to determine the impact of ore moisture, with results indicating that each 0.5% increase in ore moisture content by weight resulted in a 5 K decline in top gas temperature. This agrees with measurements and experience from both industrial partner facilities modeled in this research. CFD modeling of the impacts of NG pre-heating indicated that each 100 K increase in NG temperature resulted in a 4.5 K drop in average top gas temperature. While this aligns well with blast furnace operational rules-of-thumb (parameters that increase RAFT such as hot blast temperature or oxygen enrichment typically also result in a decline in top gas temperatures) it also means that NG pre-heating alone is unlikely to serve as a direct counter to the low top temperatures observed in high burden moisture content scenarios.

Having established the potential benefits and drawbacks of NG pre-heating in isolation, the next step was to determine whether pre-heating could be applied together with the modification of other variable parameters to widen the BF operating window. For instance, does pre-heating allow for a potential solution to moisture-generated low top temperatures if combined with increased NG injection rates (which typically increase top gas temperature)? Could pre-heating serve as a tool that might enable operators to push higher NG injection rates in the case of the aforementioned loss-of-PCI scenario at a co-injection BF? Or might it be possible to push beyond the typical limit of 150 kg/mthm of NG injection by combining the increased injection rate with NG pre-heating? The next stage of research aimed to answer these questions with a parametric study involving a range of NG injection rates, NG pre-heating levels, and oxygen enrichment levels.

Eight different NG injection rates were simulated for this study. In addition to the baseline NG injection rate of 95 kg/mthm, scenarios were modeled at NG injection rates of 85, 105, 110, 115, 120, 130, 140, and 150 kg/mthm. For each of these new injection rates, the ratio between ore and coke in the burden charge was altered based on industry operation guidelines for the furnace. As the injection rate rose, the ore charge weight was increased while maintaining the same burden distribution, leading to thicker ore layers and a higher potential production rate. NG pre-heating was also tested for each of these injection rates, so each of these eight additional injection rate scenarios had four sub-cases at the same NG temperatures (300 K, 400 K, 500 K, and 600 K) as the baseline case.

While results in the tuyere region are not different enough between cases to merit a full review here, it is important to note that the increased NG injection rates were achieved by simply increasing the mass flow rate of NG into the lance. At the upper end of the injection rate range (140–150 kg/mthm), this results in very high NG velocities exiting the lance, especially when combined with NG pre-heating. A realistic implementation of such high NG injection rates with pre-heating would require a larger diameter injection lance to manage NG injection velocity and avoid potential impingement on the inner surface of the tuyere.

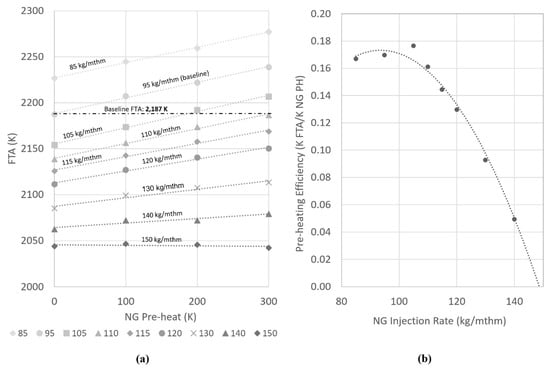

Focusing on the raceway region, the predicted FTA fell quickly with increasing NG injection rate, as expected. Additionally, the FTA increasesd with NG pre-heating for all simulated NG injection rates, save for the 150 kg/mthm scenario. Figure 7 details the predicted FTA results for the full range of cases, with the declining slope of the FTA vs. NG pre-heat as the NG rate (in kg/mthm) increased. These slopes represent the “pre-heating efficiency” of NG pre-heating in raising the predicted FTA (unit increase in FTA per unit increase of NG temperature).

Figure 7.

(a) Predicted FTA vs. NG pre-heat; and (b) NG pre-heating efficiency vs. NG injection rate.

Included in Figure 7 is a marker noting the location of the baseline FTA value that allows for easy comparison with other cases. For instance, at an NG injection rate of 105 kg/mthm (10 kg higher than the baseline), an equivalent FTA to the baseline case could be achieved with an NG pre-heat level of 200 K (NG temperature of 500 K). At 110 kg/mthm, this FTA could be achieved with a pre-heat of a little over 300 K (NG temperature of 600 K). If it is assumed that the furnace remains stable and matches productivity at a given reducing gas temperature with a fixed burden distribution, these comparisons seem to indicate the potential for operators to push higher NG injection rates through the use of pre-heated NG, with relatively minor impacts on furnace operation otherwise.

It is worth noting here that from an NG injection rate of 85 kg/mthm to an injection rate of 105–110 kg/mthm, it appears the NG ”pre-heating efficiency” increased to a maximum of a 0.177 K increase in FTA for each 1 K increase in NG temperature. When the NG injection rate was increased further, the “pre-heating efficiency” began to decline. There are multiple potential causes for this decline. First, the increase in NG injection rate for these cases was not accompanied by a corresponding increase in hot blast O2 enrichment. The NG fuel rate exceeded the available oxygen for combustion around the 110 kg/mthm mark, and pre-heating at injection rates beyond this point likely contributed to NG decomposition. Additionally, the increased injection rate reduced gas residence time inside the raceway and drove the NG plume closer to the tuyere wall due to higher gas velocity, potentially hindering combustion. The combination of these factors likely led to the results observed in the 150 kg/mthm case, in which NG pre-heating actually decreased the predicted FTA.

In addition to the baseline oxygen enrichment level of ~29%, two additional scenarios were added to each case at oxygen enrichment levels of 32% and 35%. In all cases, wind rates were held constant at baseline levels and the volume fraction of oxygen in the wind was adjusted. Figure 8 and Figure 9 show the predicted FTA values for the 32% and 35% oxygen enrichment case sets respectively. As expected, FTA values were inflated for these cases. Additionally, the availability of additional oxygen resulted in improved “pre-heating efficiency” at the higher NG injection rates compared to the baseline oxygen enrichment scenario, though in each set of cases, most benefits from pre-heating had essentially vanished by the 150 kg/mthm injection rate. It is likely that some combination of additional measures such as increased oxygen enrichment, wind rate, and NG pre-heating would be necessary for efficient operation at these high injection rates for this particular furnace.

Figure 8.

Predicted FTA vs. NG pre-heat for (a) the 32% O2 enrichment scenario; and (b) the 35% O2 enrichment scenario.

Figure 9.

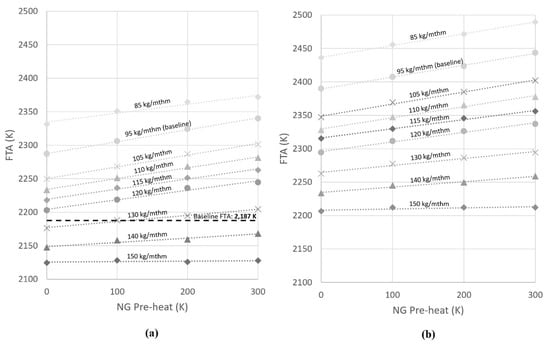

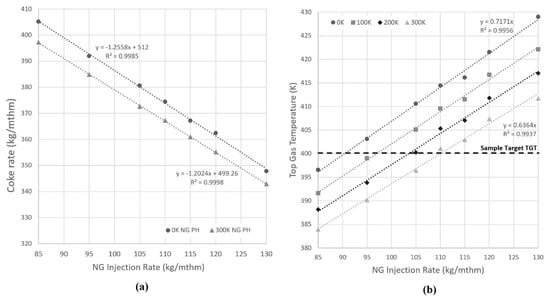

(a) Predicted BF coke rate for 0 K and 300 K NG pre-heat vs. NG injection rate; and (b) Predicted average top gas temperature for all NG pre-heat levels vs. NG injection rate.

For the shaft region, simulations focused on the baseline oxygen enrichment scenario with increases to NG injection rate that would require no adjustments to the existing infrastructure at the industry partner facility. These cases aimed to determine the combined impacts of NG pre-heating and increased NG injection rates on the furnace top gas temperature and coke rate. Figure 9 shows the predicted impacts of NG injection rates (from 85 to 130 kg/mthm) on furnace coke rate and top gas temperature.

While changes in both coke rate and top gas temperature due to NG injection rate remained linear through the range of 85–130 kg/mthm, two trends appeared from the impacts of NG pre-heating. First, it appears that the coke rate savings observed from pre-heating decline at the higher NG injection rates, likely due to the aforementioned limiting factors in the raceway. Second, the impact of pre-heating on top gas temperature appears to become more significant as the injection rate rises, with a larger drop in top gas temperature observed for each 100 K pre-heat at the higher end of the injection rate range. The increased decomposition of NG in the raceway in lieu of gas combustion will result in reducing gas compositions with a balance shifted slightly towards H2 (as carbon from the NG will deposit in the solid phase and require CO2 or O2 to convert it into reducing gas), and modeling predicts that this shift promotes endothermic hydrogen reduction reactions. Specifically, simulations predicted that the increase from an NG temperature of 300 K to 600 K would result in a 1.8% increase in wustite reduction by H2 in the shaft for the 130 kg/mthm NG injection rate scenario. In comparison, the same increase in NG temperature results in only a 0.77% increase in the wustite-H2 reduction reaction for the 85 kg/mthm NG injection rate scenario. Since wustite reduction by H2 consumes ~25 kJ/mol, while wustite reduction by CO releases 16 kJ/mol, this shift towards H2 reduction (together with the reduction in available heat due to NG cracking rather than combusting) seems to explain the increasing detrimental impact on top gas temperatures. Further research in this area could prove illuminating when exploring high natural gas injection rates and their impacts on the furnace.

Overall, the modeling predicts that the NG injection rate will have a far more significant impact on predicted coke rate than NG pre-heating, which is to be expected given the additional shifts in gas composition and reduction reactions under higher NG injection conditions. For top gas temperature, the impacts between the two parameters are more similar, and it is in this region that the greatest benefits of combining NG pre-heating and increased NG injection rates can be observed. Selecting a sample acceptable top gas temperature value of 400 K (125 °C) and moving across the range of NG injection rates, it is clear that there are numerous combinations of NG injection rate and NG pre-heat level that provide an average top gas temperature close to matching the criterion (95 kg/mthm NG injection rate and 100 K pre-heat, 105 kg/mthm NG injection rate and 200 K pre-heat, 110 kg/mthm NG injection rate and 300 K pre-heat).

4. Discussion

4.1. Potential Impacts and Benefits of NG Pre-Heating

Both in isolation and in concert with modest increases in NG injection rate, pre-heating of NG before injection into the BF appears to present an additional method by which operators could improve the operating efficiency of their furnaces and widen the window of stable operating conditions. CFD modeling results indicated that there were observable benefits to blast furnace coke rates from pre-heating NG up to a temperature of 600 K, though this did result in a decline in top gas temperatures, similar to the expected impacts from increased hot blast temperature or other parameters that result in a boost to FTA (RAFT). While the predicted 7 kg/mthm decrease in BF coke rate in this scenario was a desirable outcome, the corresponding decline of 13 K in top gas temperature may lead to top gas temperatures lower than 373 K (100 °C) and the possibility of condensation of water vapor in the uptakes. However, by combining higher NG temperatures with an increased NG injection rate, significant benefits to the BF coke rate can be achieved while maintaining constant levels for both FTA and top gas temperature (TGT). A set of such cases are outlined in Table 6. Scenario #1 has the standard operating conditions from the baseline case, with an NG pre-heat of 300 K. Scenarios #2 and #3 apply combinations of NG pre-heating with increased NG injection rates (using the levels at which pre-heating was most effective for this BF) to maintain the FTA and TGT at or near baseline levels while allowing for the furnace to operate at a lower coke rate.

Table 6.

Potential operating condition modifications and corresponding economic impacts. TGT: top gas temperature.

The CFD simulations conducted for Scenario #3, using a 110 kg/mthm NG injection rate and a 300 K NG pre-heat, predicted an FTA of 2186 K (1 K lower than baseline) and a TGT of 401 K (2 K lower than baseline). However, in this case, the BF coke rate decreased from 392 kg/mthm in the baseline to 367 kg/mthm (25 kg/mthm lower), presenting the potential for significant savings. Of course, it is necessary to consider the potential costs and safety concerns involved in pre-heating the NG, as the effort would likely be greatly dependent on the exact method of NG pre-heating.

It is worth returning here to the concept of using high-rate NG injection to compensate for a loss-of-PCI situation at a co-injection BF. Clearly, NG pre-heating presents a net benefit to predicted FTA. While not enough to entirely counter the decline seen in the NG-only operation case at the co-injection BF, applying pre-heating at higher NG injection rates (up to the 120–130 kg/mthm mark) would likely enable furnace operators to maintain stable operation in a loss-of-PCI scenario. In the NG-only furnace, balancing NG injection rate with various levels of NG pre-heating allows for the furnace FTA and TGT to remain at baseline levels. Similarly, it is expected that this strategy could be applied for furnaces with lower total levels of injectants (such that acceptable RAFTs could be achieved), or furnaces with the flexibility to supply additional oxygen through enrichment or wind to further supplement the pre-heating impacts.

4.2. Conceptual Methods for Achieving NG Pre-Heating

Several potential methods could be used to achieve an increase in NG temperature from ambient (~300 K or 25 °C) temperature to the range of pre-heating explored in this study (~600 K or 325 °C). From a practical standpoint, it would likely be best to apply a pre-heating method that does not require any additional heat sources or fuel use in order to maximize the operating expense reduction benefits highlighted in the previous section. It is clear that a single capital investment to develop and implement an NG pre-heating system with minimal ongoing costs would certainly be more attractive to BF operators than the alternative. The previously reported exploration of NG pre-heating at two Russian BFs [4,5] approached the concept from this angle, electing to route the incoming ambient NG through cooling flanges around the exterior of the blowpipe and elbow in an effort to capture heat that would otherwise be lost to the environment from the hot blast and direct it back into the BF.

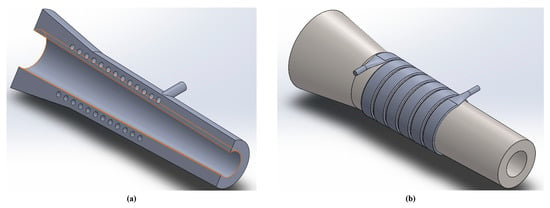

Some preliminary CFD modeling of similar concepts was undertaken for the industry BF studied in this research. Some sample designs of a blowpipe-based heat exchanger or heat recovery system were explored, including in-refractory channels and an exterior piping wrap similar to the concepts shared in previous publications. A visualization of these potential designs is shown in Figure 10.

Figure 10.

Conceptual designs for (a) the blowpipe channel NG pre-heater; and (b) the exterior wrap NG pre-heater.

Preliminary CFD simulations of convection heat transfer using the blowpipe channel NG pre-heater were conducted using baseline operating conditions (hot blast temperature, wind rate, and natural gas injection rate). These simple trials predicted a NG pre-heat of 170 K (NG temperature of 470 K) by the end of the channel, though the exact impact of this heat exchanger design on the hot blast temperature flowing through the blowpipe has yet to be determined. A potential loss in hot blast temperature would certainly be a significant detractor from such a design implementation and might serve to encourage the exploration of alternative approaches.

In addition, these designs present significant complexity in a region of the BF that can already have a great deal of design constraints, so it may be beneficial to explore methods for pre-heating elsewhere. A heat recovery system based around the exhaust or ambient heat losses from the BF hot stoves may present an acceptable solution, and future work may focus on determining the viability of such a system in terms of achievable NG pre-heat and specific impacts on BF coke rate, top gas temperature, and FTA.

4.3. Industrial Perspective on Feasibility of Implementation

The computational simulations conducted in this research indicate that pre-heating of natural gas prior to injection into the blast furnace could offer process benefits. However, modeling does not consider the effort required for industrial implementation and the associated difficulties that such an effort might present.

Several routes to pre-heating exist, recuperative (including waste heat), on-demand, and in-situ partial combustion; each route having a certain level of technical maturity, capability, controllability, as well as CAPEX and OPEX characteristics that are plant unique. Conceptually, most of the identified heating technologies would heat gas sourced singly from the main furnace distribution line, i.e., all the injected natural gas would be passed through a single recuperative heater, while the heating routes illustrated in Figure 10 would heat individually closer to the point of consumption.

Implementation for the single source is somewhat easier, although potentially more expensive, as much of the construction and commissioning could be completed while the furnace remains online. However, pre-heating via the blowpipe route would require an outage of suitable length to change all the blowpipes, or a planned approach to replace at regular intervals, which could take several years and leave the furnace with unbalanced pre-heating in the meantime.

Industrial consideration also needs to be given for material selection (pipes, valves, and seals need to be capable of operating at higher temperatures) and process control (which may have varying feasibility depending on the route chose, i.e., blowpipe heating). In addition, modified operating and maintenance practices would need to be developed, and safety protocols would also require careful review. One example would be RAFT control, which is widely adopted as a key variable in ironmaking. Typically, front-line operators use a simple empirical model such as the AISI RAFT model equation to determine real-time RAFT values. As currently defined, this model does not account for pre-heating of natural gas. Similarly, the well-known operating rules-of-thumb would need expansion to include the effect of pre-heating temperature on RAFT, top heat, fuel rate, and productivity.

5. Conclusions

CFD modeling techniques were applied to ascertain the predicted impacts of varied NG injection rates and pre-heating levels on operation at two different industrial BFs. Simulations indicated that there is a clear possibility to utilize NG pre-heating in conjunction with increased NG injection rates to provide an avenue for improved BF operating efficiency (reduced coke rates while maintaining stable raceway flame and top gas temperatures). Impacts of NG pre-heating in isolation appear linear, though the slope changes significantly with NG injection rate, and the benefits disappear quickly when pushing towards injection rates above 140 kg/mthm. The application of NG pre-heating also appears to have a similar negative impact on top gas temperatures as that of other parameters that increase furnace RAFT, such as hot blast temperature or oxygen enrichment. However, this impact is small enough that it can be offset by the increased NG injection rates made possible under these operating conditions.

As noted in the discussion section, achieving NG pre-heating could be approached from a multitude of different avenues, including pre-combustion or an upstream recuperative heater. Some initial simulation testing of a conceptual system for heating NG near the BF blowpipe indicated that sufficient heating could be provided to the incoming NG to achieve the predicted benefits explored in this research. However, any industrial implementation would doubtless need to account for the control mechanisms, CAPEX considerations, and other limitations that would figure into such a system in a real-world environment. The difficulties and costs would need to be weighed against the potential benefits, with an eye towards furnace life-span and the potential operational flexibility and return on investment that an NG pre-heating system would enable.

Author Contributions

Conceptualization, T.O., J.D., and S.S.; Data curation, S.N.; Formal analysis, T.O. and S.N.; Investigation, T.O., S.N., J.D., S.R., and S.S.; Methodology, T.O. and C.Z.; Project administration, C.Z.; Resources, T.O. and C.Z.; Software, T.O. and S.N.; Supervision, T.O. and C.Z.; Validation, T.O., S.N., J.D., S.R., and S.S.; Visualization, T.O. and S.N.; Writing—original draft, T.O. and S.S.; Writing—review and editing, T.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors would like to thank the agencies and companies involved in supporting previous and current development of blast furnace research at PNW, including AK Steel, AISI, AIST, ArcelorMittal, the U.S. Dept. of Energy, the Indiana 21st Century Technology and Development Fund, Praxair, U.S. Steel, Stelco, Union Gas, and all members of the Steel Manufacturing Simulation and Visualization Consortium (SMSVC). In particular, the authors would like to acknowledge Megha Jampani of Linde plc for her contributions to conceptual development. The support of many individual industry collaborators, along with CIVS staff and students, are also appreciated.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pistorius, P.C.; Gibson, J.; Jampani, M. Natural Gas Utilization in Blast Furnace Ironmaking: Tuyère Injection, Shaft Injection and Prereduction. In Applications of Process Engineering Principles in Materials Processing, Energy and Environmental Technologies; Springer: Cham, Switzerland, 2017; pp. 283–292. [Google Scholar]

- Peacey, J.G.; Davenport, W.G. The Iron Blast Furnace: Theory and Practice; Pergamon Press: Oxford, UK, 1979; pp. 44–57. [Google Scholar]

- Geerdes, M.; Chigneau, R.; Kurunov, I.; Lingiardi, O.; Ricketts, J. Modern Blast Furnace Ironmaking: An Introduction, 2nd ed.; IOS Press: Amsterdam, The Netherlands, 2015; pp. 59–75. [Google Scholar]

- Feshchenko, S.A.; Pleshkov, V.I.; Lizunov, B.N.; Lapshin, A.A.; Soveiko, K.N.; Loginov, V.N.; Vasil’ev, L.E. Making Blast-Furnace Smelting More Efficient through the Injection of Heated Natural Gas. Metallurgist 2007, 51, 605–611. [Google Scholar] [CrossRef]

- Feshchenko, S.A.; Pleshkov, V.I.; Loginov, V.N.; Kurunov, I.F. Synergetic Effect of Natural Gas Pre-heating Prior to its Injection into a Blast Furnace. In Proceedings of the AISTech 2008, Pittsburgh, PA, USA, 5–8 May 2008; p. 6. [Google Scholar]

- Zhen, M.; Zhou, Z.; Yu, A.B.; Shen, Y. CFD-DEM Simulation of Raceway Formation in an Ironmaking Blast Furnace. Powder Technol. 2017, 314, 542–549. [Google Scholar]

- Yeh, C.P.; Du, S.W.; Tsai, C.H.; Yang, R.J. Numerical Analysis of Flow and Combustion Behavior in Tuyere and Raceway of Blast Furnace Fueled with Pulverized Coal and Recycled Top Gas. Energy 2012, 42, 233–240. [Google Scholar] [CrossRef]

- Babich, A.; Senk, D.; Gudenau, H.W. An Outline of the Process. In Ironmaking; Verlag Stahleisen GmbH: Dusseldorf, Germany, 2016; pp. 180–185. [Google Scholar]

- Vuokila, A.; Mattila, O.; Keiski, R.L.; Muurinen, E. CFD Study on the Heavy Oil Lance Positioning in the Blast Furnace Tuyere to Improve Combustion. ISIJ Int. 2017, 57, 1911–1920. [Google Scholar] [CrossRef]

- Austin, P.R.; Nogami, H.; Yagi, J. A Mathematical Model of Four Phase Motion and Heat Transfer in the Blast Furnace. ISIJ Int. 1997, 37, 458–467. [Google Scholar] [CrossRef]

- Natsui, S.; Ueda, S.; Nogami, H.; Kano, J.; Inoue, R.; Ariyama, T. Analysis of Non-Uniform Gas Flow in Blast Furnace Based on DEM-CFD Combined Model. Steel Res. Int. 2011, 82, 964–971. [Google Scholar] [CrossRef]

- Kon, T.; Natsui, S.; Matsuhashi, S.; Ueda, S.; Inoue, R.; Ariyama, T. Influence of Cohesive Zone Thickness on Gas Flow in Blast Furnace Analyzed by DEM-CFD Model Considering Low Coke Operation. Steel Res. Int. 2013, 84, 1146–1156. [Google Scholar] [CrossRef]

- Majeski, A.; Runstedtler, A.; D’Alessio, J.; Macfadyen, N. Injection of Pulverized Coal and Natural Gas into Blast Furnaces for Iron-making: Lance Positioning and Design. ISIJ Int. 2015, 55, 1377–1383. [Google Scholar] [CrossRef]

- Dong, X.F.; Yu, A.B.; Chew, S.J.; Zulli, P. Modeling of Blast Furnace with Layered Cohesive Zone. Metall. Mater. Trans. B 2010, 41, 330–349. [Google Scholar] [CrossRef]

- Fu, D.; Zheng, D.; Zhou, C.Q.; D’Alessio, J.; Ferron, K.J.; Zhao, Y. Parametric Studies on PCI Performances. In Proceedings of the ASME/JSME 2011 8th Thermal Engineering Joint Conference, Paper No. AJTEC2011-44608, Honolulu, HI, USA, 13 March 2011. [Google Scholar]

- Chen, Y.; Fu, D.; Zhou, C.Q. Numerical Simulation of the Co-Injection of Natural Gas and Pulverized Coal in Blast Furnace. In Proceedings of the AISTech 2013, Pittsburgh, PA, USA, 6–9 May 2013; pp. 573–580. [Google Scholar]

- Silaen, A.K.; Okosun, T.; Chen, Y.; Wu, B.; Zhao, J.; Zhao, Y.; D’Alessio, J.; Capo, J.; Zhou, C.Q. Investigation of High Rate Natural Gas Injection through Various Lance Designs in a Blast Furnace. In Proceedings of the AISTech 2015, Cleveland, OH, USA, 4–7 May 2015; pp. 1536–1549. [Google Scholar]

- Okosun, T.; Street, S.; Chen, Y.; Zhao, J.; Wu, B.; Zhou, C.Q. Investigation of Co-Injection of Natural Gas and Pulverized Coal in a Blast Furnace. In Proceedings of the AISTech 2015, Cleveland, OH, USA, 4–7 May 2015; pp. 1581–1594. [Google Scholar]

- Okosun, T.; Street, S.J.; Zhao, J.; Wu, B.; Zhou, C.Q. Investigation of Dual Lance Designs for Pulverized Coal and Natural Gas Co-Injection. In Proceedings of the AISTech 2016, Pittsburgh, PA, USA, 16–19 May 2016; pp. 581–594. [Google Scholar]

- Okosun, T.; Street, S.J.; Zhao, J.; Wu, B.; Zhou, C.Q. Influence of Conveyance Methods for Pulverized Coal Injection in a Blast Furnace. Ironmak. Steelmak. 2017, 44, 513–525. [Google Scholar] [CrossRef]

- Okosun, T.; Liu, X.; Silaen, A.K.; Barker, D.; Dybzinksi, D.P.; Zhou, C.Q. Effects of Blast Furnace Auxiliary Fuel Injection Conditions and Design Parameters on Combustion Characteristics and Injection Lance Wear. In Proceedings of the AISTech 2017, Nashville, TN, USA, 8–11 May 2017; p. 11. [Google Scholar]

- Okosun, T.; Nielson, S.; D’Alessio, J.; Klaas, M.; Street, S.J.; Zhou, C.Q. Investigation of High-Rate and Pre-heated Natural Gas Injection in the Blast Furnace. In Proceedings of the AISTech 2019, Pittsburgh, PA, USA, 6–9 May 2019; p. 15. [Google Scholar]

- Okosun, T.; Silaen, A.K.; Zhou, C.Q. Review on Computational Modeling and Visualization of the Ironmaking Blast Furnace at Purdue University Northwest. Steel Res. Int. 2019, 90, 1900046. [Google Scholar] [CrossRef]

- Fu, D. Numerical Simulation of Ironmaking Blast Furnace Shaft. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, May 2014. [Google Scholar]

- Okosun, T. Numerical Simulation of Combustion in the Ironmaking Blast Furnace Raceway. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, May 2018. [Google Scholar]

- Launder, B.; Spalding, D. Lectures in Mathematical Models of Turbulence; Academic Press: New York, NY, USA, 1972. [Google Scholar]

- Gu, M.; Zhang, M.; Selvarasu, N.K.C.; Zhao, Y.; Zhou, C.Q. Numerical Analysis of Pulverized Coal Combustion inside Tuyere and Raceway. Steel Res. Int. 2008, 79, 17–24. [Google Scholar] [CrossRef]

- Gu, M.; Chen, G.; Zhang, M.; Huang, D.; Chaubal, P.; Zhou, C.Q. Three-dimensional Simulation of the Pulverized Coal Combustion inside Blast Furnace Tuyere. Appl. Math. Model. 2010, 34, 3536–3546. [Google Scholar] [CrossRef]

- Huang, D.; Tian, F.; Chen, N.; Zhou, C.Q. A Comprehensive Simulation of the Raceway Formation and Combustions. In Proceedings of the AISTech 2009, St. Louis, MO, USA, 4–7 May 2009. [Google Scholar]

- Zhou, L. Combustion Theory and Chemical Fluid Dynamics; Science Press: Beijing, China, 1986. [Google Scholar]

- Peters, N. Premixed Burning in Diffusion Flames. Int. J. Heat Mass Transf. 1979, 22, 691–703. [Google Scholar] [CrossRef]

- Fu, D.; Huang, F.; Tian, F.; Zhou, C.Q. Burden Descending and Redistribution in a Blast Furnace. In Proceedings of the AISTech 2010, Pittsburgh, PA, USA, 3–6 May 2010. [Google Scholar]

- Zhou, C.Q. Minimization of Blast Furnace Fuel Rate by Optimizing Burden and Gas Distribution. In Final Technical Report to U.S. Department of Energy (DOE); Purdue University: West Lafayette, IN, USA, 2012. [Google Scholar]

- Fu, D.; Chen, Y.; Rahman, M.d.T.; Zhou, C.Q. Prediction of the Cohesive Zone in a Blast Furnace. In Proceedings of the AISTech 2011, Indianapolis, IN, USA, 2–5 May 2011. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).