Abstract

In the production process of coal chemical enterprises, there are factors such as dust, poisons, as well as toxic and harmful gases, which seriously restrict the safety and health of employees. It is urgent to strengthen research on occupational safety and health (OSH) of coal chemical enterprises. Research on the influencing factors is very important to improve the level of OSH in coal chemical enterprises. Therefore, this paper analyzed the factors affecting OSH of coal chemical enterprises from four aspects: “human–machine–environment–management”. Then, an influencing factor indicator system was constructed. The weights of the indicator were analyzed using the Analytic Network Process (ANP). On this basis, the primary and secondary indicators of the influencing factors were ranked. Subsequently, the weights of ANP were taken as the influence coefficient between variables, and the System Dynamics (SD) model of OSH control measures was established and analyzed. According to the weights of ANP and the results of SD simulation, management and control measures were proposed to provide theoretical support and method guidance for improving the level of OSH in coal chemical enterprises. Finally, the research results were experimentally applied to coal chemical enterprises. The research results of the paper will improve the level of OSH in coal chemical enterprises of both theoretical and practical applications.

1. Introduction

As we all know, occupational safety and health (OSH) is an indispensable part of enterprise [1]. The OSH of enterprises (especially in high-risk industries) is a complex system. Complexity theory suggests that we see performance as an emergent property, the result of complex interactions and relationships. With inspiration from complexity theory, failures are seen as an emergent property of complexity [2]. The main research object of occupational safety and health is human. As a complex system, the human is affected by many factors, which are far beyond engineering specifications and reliability prediction [3]. In the complex system of nuclear industry, performance and safety culture play a key role in enterprise safety [4,5]. Schneider et al. proposed that in complex adaptive systems, leaders indirectly influence organizations through mediating variables of organizational identity and social movement [6].

On 5 April 2010, a series of explosions occurred inside the Upper Big Branch (UBB) mine in southern West Virginia. This accident reinforced the need for, and importance of, promoting a positive safety culture by routinely evaluating an organization’s safety culture activities and initiatives and by making enhancements and adjustments to ensure that an organization remains proactive and appropriately focused on this important area [7]. Dutta drew on the culture-centered approach to dialogically articulate meanings of workplace risks and injuries, voiced by Bangladeshi migrant construction workers in Singapore [8].

In order to further study and analyze occupational safety and health, factors such as performance, cognition, motivation and safety culture need to be deeply analyzed.

Komljenovic et al. argued that the next level of safety performance will have to consider a transition from coping solely with workplace dangers, to a more systemic model taking organizational risks into consideration. A perspective that may be used in supervisory activities, self-assessments, and minor event investigations, is presented. When ingrained in an organizational culture, such perspective has the highest potential for continuous safety improvement [9]. The strategic approach for improving performance is to reduce human error and manage controls so as to reduce unwanted events and/or mitigate their impact should they occur [10]. Intuition and safety perception will affect the safety status of employees and even enterprises [11]. Kahneman et al. identified the cognitive and motivational biases that are relevant for decision and risk analysis. In addition, they describe some biases that are less relevant because they can be corrected by using logic or decomposing the elicitation task [12].

With the improvement of workers’ awareness of safety and health, more and more companies are paying increasing attention to OSH. The influencing factors of OSH are various. Accurate and effective identification of influencing factors is the key to improve the level of OSH in enterprises.

Komljenovic et al. proposed a high level Risk-Informed Decision-Making framework in Asset Management that integrates risks extreme and rare events as part of an overall risk assessment and management activity. The research focuses on the methodology aimed at identifying, assessing and managing those risks in Asset Management [13]. Panikkar et al. employed a survey instrument predominately developed and administered by Teen Educators to assess occupational health risks [14]. Zytoon et al. studied the OSH conditions of young and aging fishermen compared to middle-aged fishermen in the small- and medium-size (SM) marine fishing sector [15]. Zhou et al. studied the occupational safety and health management methods as well as risk control technology associated with the coal mining industry, including daily management of occupational safety and health, identification and assessment of risks, early warning, and dynamic monitoring of risks [16,17]. Li et al. outlined the implications for the governance of occupational safety and health [18]. Chang et al. used a qualitative method-grounded theory-to collect code, and analyzed the data in order to understand the agencies’ role in occupational accident education and hazard prevention for blue-collar foreign workers in Taiwan [19]. Hansen et al. provided insights into perceptions of potentially unsafe or uncomfortably hot working conditions that can affect occupational health and safety using information provided by the public and workers to the safety regulator in South Australia [20,21]. Anonymous authors in Korea reviewed the requirements for the advancement of occupational safety and health administrative organization and proposed measures to establish an Occupational Safety and Health Executive [22]. Wu et al. reviewed the history of regulatory system of occupational health and safety in China, as well as the current reform of this regulatory system in the country [23].

As one of the high-risk industries, the chemical industry has received substantial attention in its OSH. Mannan et al. used statistics to measure safety progress and determine patterns of injury, which will guide further improvements in chemical safety [24]. Hassim et al. did not only compare the existing methods, but also revealed the need of health assessment approaches for chemical process design that abide with the actual occupational health and industrial hygiene concept [25]. Khan et al. aimed to find the attributes of occupational injury among workers in the chemical industry and to enhance safety level. Injury data were collected and processed in terms of different variables, such as age, gender, skills, type of hazard, etc. [26]

Although OSH has been studied in a deep way, there are few studies on the dynamic evolution process of OSH. It is unfavorable to analyze the changing process and rules of the OSH level (especially in coal chemical enterprises). System Dynamics (SD) can simulate the interrelationships of factors and their changing processes in complex systems. Therefore, the evolution of the OSH level can be simulated using SD.

SD is an excellent way to understand a complex system, and there are examples of its use in risk assessment and safety management. Shin et al. developed a system dynamics (SD)-based model of construction workers’ mental processes and safety attitudes [27]. Lu et al. studied replicator dynamics of the evolutionary model to make an optimization analysis of the behaviors of those interested parties and the adjustment mechanism of safety management policies and decisions, based on stability theory of dynamics system and phase diagram analysis [28]. Wu et al. established a system dynamics model of employee’s work-family conflict in the construction industry, and conducted a simulation [29].

In order to make the simulation effect of SD better, it is necessary to quantitatively analyze the relationship between factors. Since the Analytic Network Process (ANP) can more accurately describe the network structure between objective things, it can better calculate the weight of each factor. Therefore, this paper uses ANP to optimize SD. Fang et al. used ANP to empirically analyze the interaction between network evolution decision, driving factors, and green innovation performance, and obtained the interaction relationship model of decision factors, driving factors, and green innovation performance [30]. Nima et al. investigated the applicability of ANP to security-based rank ordering of hazardous facilities such as chemical plants [31].

ANP and SD provide new ideas for the study of OSH in coal chemical enterprises. Based on the analysis of the influencing factors of OSH, this paper used ANP to analyze the weight of each influencing factor to find out the key factors and importance ranking. Then, the SD model of OSH was constructed, combining the results of the ANP analysis. With the influence of different factors, the OSH level of coal chemical enterprises was analyzed, and management and control measures proposed. Finally, management and control measures were applied to coal chemical companies to improve the status of OSH in coal chemical enterprises in practical applications.

2. Analysis of Factors Affecting OSH in Coal Chemical Enterprises

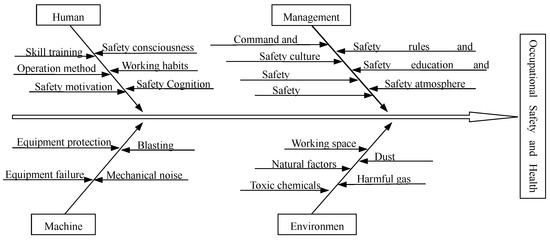

Based on the Chinese occupational safety and health standards, this paper analyzes the influencing factors of OSH of coal chemical enterprises from “human–machine–environment–management”, according to the actual situation of coal chemical enterprises. As shown in Figure 1, the paper uses the Fishbone Diagram [32] to analyze the influencing factors of OSH in coal chemical enterprises.

Figure 1.

Fishbone diagram of occupational safety and health (OSH) influencing factors.

We concluded that the main human factors affecting OSH are skill training, safety consciousness, operation method, working habits, safety motivation, and safety cognition. Management factors include safety culture, safety education and training, command and dispatch, safety rules and regulations, safety supervision, safety atmosphere, and safety performance. Machine factors include equipment protection, blasting, equipment failure and mechanical noise. Environment factors include natural factors, working space, harmful gas, dust, and toxic chemicals.

3. Analysis of the Indicator System of Influencing Factors

3.1. Constructing an ANP Indicator System

According to the analysis of influencing factors, combined with the network structure and steps of ANP, the indicator system of OSH influencing factors of coal chemical enterprises can be divided into target layer and factor layer. The factor layer includes four primary indicators and 19 secondary indicators. By consulting experts and integrating all the factors, the OSH influencing factors indicator system of coal chemical enterprises (Table 1) is finally constructed.

Table 1.

Occupational safety and health (OSH) influencing factors indicator system.

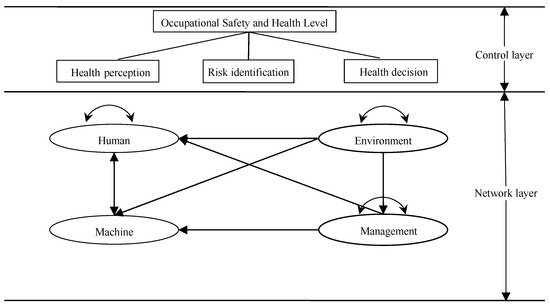

3.2. Building an ANP Structural Model

ANP divides system elements into control layer elements and network layer elements. The network layer consists of all the elements that are affected by the control layer, and they present a network structure that interacts with each other.

(1) Control layer

The influencing factors of OSH affect employees’ health perception, risk identification, and decision-making related to health. Therefore, in the control layer of the ANP structural model, OSH is regarded as the target, and health perception (R1), risk identification (R2), and health decision (R3) are taken as criteria.

(2) Network layer

The factors in “human–machine–environment–management” are taken as element groups in the network layer. The network structure is constructed according to the relationship between the influencing factors of OSH (Table 1).

According to the relevant meanings of various influencing factors and expert opinions, the association of indicators is described. As shown in Table 2, “√” indicates that there is a dependency between the two. According to the association of indicators, the ANP structure model shown in Figure 2 is constructed.

Table 2.

Association of influencing factors of OSH.

Figure 2.

Influencing factors of OSH Analytic Network Process (ANP) model.

3.3. Calculating Indicators Weights

Due to the complexity of the principle and process of ANP, and the fact that a lot of elements are involved in ANP, ANP proprietary software (Super Decision, Chinese Version, SUPER DECISION, US) was used to conduct the calculation process. The Super Decision solves the problem that the ANP process is complicated and computationally intensive, and creates convenient conditions for the real application of the ANP model.

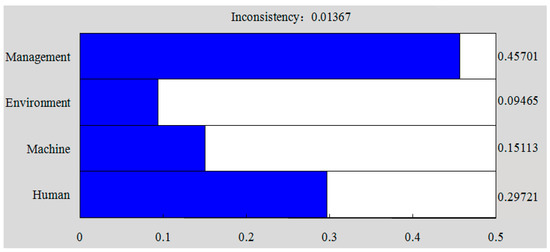

(1) Matrix consistency test

According to the expert’s judgment on the importance of relevant factors, a judgment matrix of the relationship between all factors is constructed. It is generally accepted that the coefficient of the consistency test is less than 0.1 [33]. If it is calculated that the values of all submatrix consistency test results are less than 0.1, it indicates that the consistency test is passed. Figure 3 shows the results of the consistency test.

Figure 3.

Consistency test results.

(2) Final ranking calculation

According to the calculation, the weights of OSH influencing factors can be obtained. The criteria in the control layer are ordered by weight: health decision (0.419), health perception (0.338), risk identification (0.243). It can be seen that health decision, risk identification, and health perception are the most direct factors affecting the OSH of employees. The weights of the primary and secondary indicators of the network layer for OSH are shown in Table 3.

Table 3.

OSH influencing factor weights value.

According to Table 3, it can be concluded that the primary indicators affecting OSH are ranked by Management, Human, Machine, and Environment in order of weight.

The secondary indicators of the Management factors are ranked by Safety culture, Safety performance, Safety supervision, Safety education and training, Safety atmosphere, Safety rules and regulations, Command and dispatch in order of local weight. The secondary indicators of the Human factors are ranked by Working habits, Safety consciousness, Safety cognition, Safety motivation, Operation method, Skill training in order of local weight. The secondary indicators of the Machine factors are ranked by Equipment protection, Mechanical noise, Blasting, Equipment failure in order of local weight. The secondary indicators of the Environment factors are ranked by Harmful gas, Toxic chemicals, Natural factors, Dust, Working space in order of local weight.

The secondary indicators are Safety culture, Working habits, Safety performance, Safety supervision, Safety cognition, Command and dispatch, Safety education and training, Safety rules and regulations, Safety motivation, Safety atmosphere, Safety consciousness, Harmful gas, Equipment protection, Toxic chemicals, Operation method, Dust, Mechanical noise, Skill training, Equipment failure, Natural factors, Blasting, Working space in order of global weight.

Using ANP to rank the indicators affecting OSH by weight, a reference was provided for the development of OSH management and control measures for coal chemical enterprises. In the formulation of measures, the indicators that rank ahead of the weight are taken into account.

4. Simulation Analysis of OSH Management and Control Measures

4.1. Building an SD Model

(1) Establishing a variable set for SD simulation

According to the influencing factors of OSH and the results of ANP calculation, combined with the characteristics of SD simulation, the variables to be studied are divided into state variables, rate variables, auxiliary variables, and constants [34]. As shown in Table 4, the contents in parentheses indicate the names of variables in the SD model.

Table 4.

System Dynamics (SD) simulation variable set.

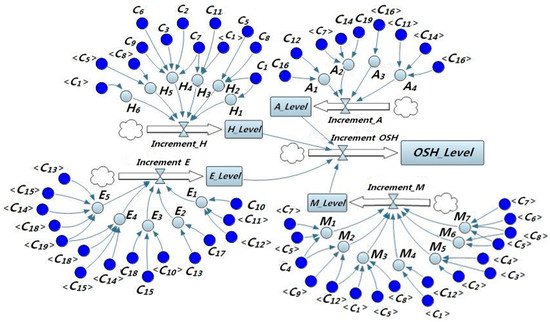

(2) Establish the SD model for OSH management control measures

In order to make the SD model more reliable, it is necessary to combine the weight analysis of ANP to establish the quantitative relationship between variables. Their quantitative relationship is shown in Equations (1)–(5).

where, OSH is Occupational safety and health level, H is Human factors, M is Management factors, A is Machine factors, E is Environment factors.

where, H1 is Skill training, H2 is Safety consciousness, H3 is Operation method, H4 is Working habits, H5 is Safety motivation, H6 is Safety cognition.

where, M1 is Command and dispatch, M2 is Safety rules and regulations, M3 is Safety culture, M4 is Safety education and training, M5 is Safety supervision, M6 is Safety atmosphere, M7 is Safety performance.

where, A1 is Equipment protection, A2 is Blasting, A3 is Equipment failure, A4 is Mechanical noise.

where, E1 is Working space, E2 is Dust, E3 is Natural factors, E4 is Toxic chemicals, E5 is Harmful gas.

OSH = 0.29721 × H + 0.45701 × M + 0.15113 × A + 0.09465 × E

H = 0.12232 × H1 + 0.18708 × H2 + 0.14579 × H3 + 0.20821 × H4 + 0.15996 × H5 + 0.17664 × H6

On the premise of ensuring the correctness of the simulation results and improving the simulation speed, the simulation error is set through repeated testing, simulation and debugging. The coefficients of the above five equations, that is, the weight error e1 of ANP is 0.00001. The error e2 in the system dynamics composed of Equations (1)–(5) is 0.000005, that is, when the value of the state variable of the system differs 0.000005 from the previous time, the system stops simulation.

Based on Equations (1)–(5) and Table 4, combined with the characteristics of SD common software AnyLogic (8.3.3, The AnyLogic Company, Chicago, IL, US), the SD model of OSH management and control measures is established. The SD model is shown in Figure 4. The symbol meaning in Figure 4 can be referred to Table 4.

Figure 4.

Management and Control Measures System Dynamics (SD) Model.

(3) Determining simulation parameters

In the paper, the simulation time is set to 24 months and the simulation step is set to 1 month. The weights obtained by ANP are used as the influence coefficients between variables to construct a functional relationship of them. Combined with the nature of the variables, the functional relationship, and the actual requirements of the model, the initial values of the constants and state variables are finally determined after repeated adjustments and experiments. In this paper, the initial value of the constant is set to 0, that is, no control measures are taken. The initial value of the state variable is set to 0.3.

4.2. Simulation Analysis

(1) Initial state simulation

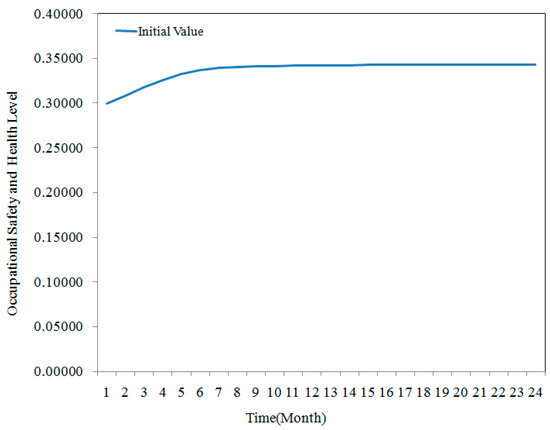

In the initial state, the model shown in Figure 4 is simulated, and the simulation results are shown in Figure 5.

Figure 5.

OSH level initial state SD simulation.

As can be seen from Figure 5, in the initial state, the overall OSH level is on the rise, but the increase is not large, and the maximum value is around 0.35000. There is a sharp increase for the first 6 months; from the 7th month to the 9th month, the increase is slower; from the 10th month to the 24th month, where there is only a small increase. It shows that under the current safety conditions, the coal chemical industry will have an increase in OSH levels, but in the end it will remain at a lower level.

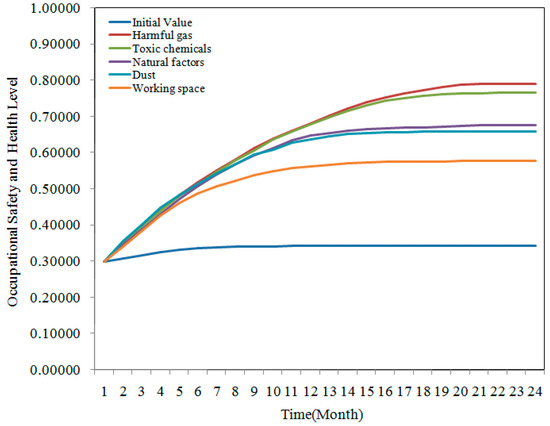

(2) Simulation of a single measure

The paper simulates OSH management and control measures by changing constants. On the basis of the initial state simulation, the value of the constant is increased to simulate the change of OSH level after coal chemical enterprises adopt certain measures.

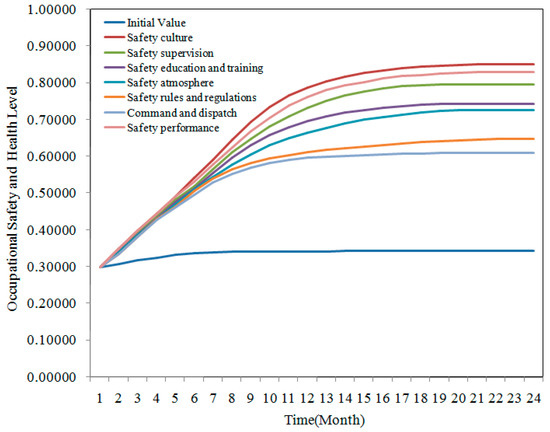

Figure 6 is a simulation trend of measures to enhance management. It can be seen that after the implementation of many management measures, the OSH level has increased significantly compared with the initial value, between 0.60000–0.85000. The effect of management measures from large to small is Safety culture, Safety performance, Safety supervision, Safety education and training, Safety atmosphere, Safety rules and regulations, Command and dispatch.

Figure 6.

SD simulation of management factor measures.

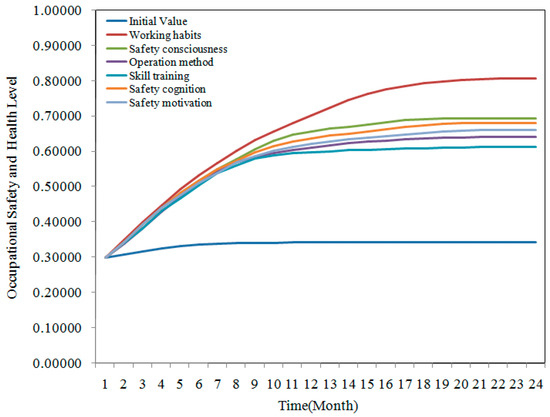

It can be seen from Figure 7 that after the implementation of human measures, the OSH level has increased significantly compared with the initial value, and finally reached somewhere between 0.55000 and 0.80000. The effect of human measures from large to small is Working habits, Safety consciousness, Safety cognition, Safety motivation, Operation method, Skill training.

Figure 7.

SD simulation of human factor measures.

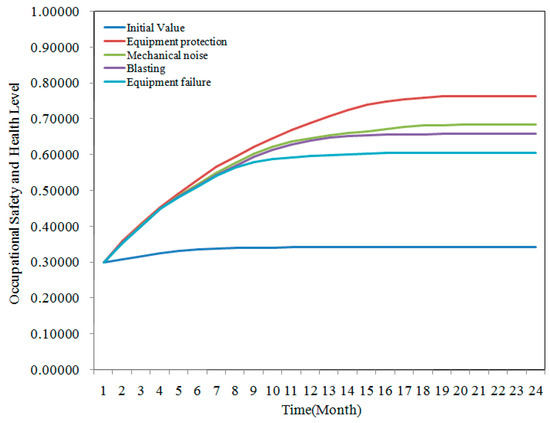

Figure 8 is a simulation trend of measures to enhance mechanical aspects. It can be seen that after the implementation of the measures, the OSH level has increased significantly compared with the initial value, and is finally between 0.60000 and 0.80000. The effect of machine measures from large to small is Equipment protection, Mechanical noise, Blasting, Equipment failure.

Figure 8.

SD simulation of machine factor measures.

It can be seen from Figure 9 that after the implementation of the measures, the OSH level has increased significantly compared with the initial value, and finally reached somewhere between 0.50000 and 0.80000. The effect of environment measures from large to small is Harmful gas, Toxic chemical, Natural factors, Dust, Working space.

Figure 9.

SD simulation of environment factor measures.

As can be seen from Figure 5, Figure 6, Figure 7, Figure 8 and Figure 9, after taking different measures, the OSH level has increased at varying degrees, and the effect is obvious. It should be noted that although the OSH level has improved, it has not exceeded 0.85000. In order to explore more effective management and control measures, the paper will discuss in depth the implementation effect of combined measures.

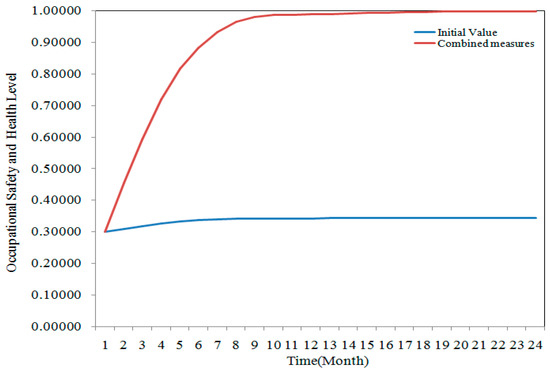

(3) Combined measure simulation

The combined management and control measures refer to the comprehensive use of a variety of means to improve the OSH, and ultimately achieve the purpose of effectively improving the level of OSH. This paper proposes combined management and control measures from Human, Machine, Environment, Management, etc. The simulation results are shown in Figure 10.

Figure 10.

SD simulation of combined measures.

It can be clearly seen from Figure 10 that the OSH level under the combined measures rose rapidly in the first 6 months. After the 7th month–10th month of evolution, it gradually stabilized and finally reached 0.99699. It shows that the combination of measures is more effective, and is an easier way to improve the OSH of enterprises.

4.3. Practical Application Research of Combined Measures

According to the ANP and SD analysis, referring to the Interim Provisions on the Occupational Health Supervision and Management of Workplaces and other relevant regulations, we took Hongxing Company as the research object. Taking into account the actual situation of the company, OSH management and control measures were formulated to protect the long-term healthy development of the company.

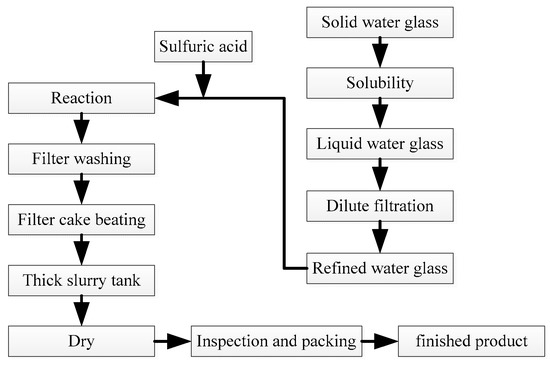

The production plant of Hongxing Company has a steel-structured double layer structure. At present, there are batch workshops, production workshops, packaging workshops, and hot air furnace workshops. The production and operation of each workshop are normal. The company mainly produces silica, the specific process is shown in Figure 11.

Figure 11.

Process flow chart.

According to the actual operation of the company, as well as the design of the plant and the process flow, the plant layout is re-arranged with reference to the requirements of the combined management and control measures. The reaction device for dispersing harmful gases is placed on the second floor of the plant, and the slurry pump and other equipment that generate noise and vibration are placed at the bottom of the plant, and effective sound insulation and vibration reduction measures are taken. The pipeline for conveying sulfuric acid has the properties of sealing, pressure resistance, corrosion resistance, etc. and it does not pass through an auxiliary room where the worker often stays or passes.

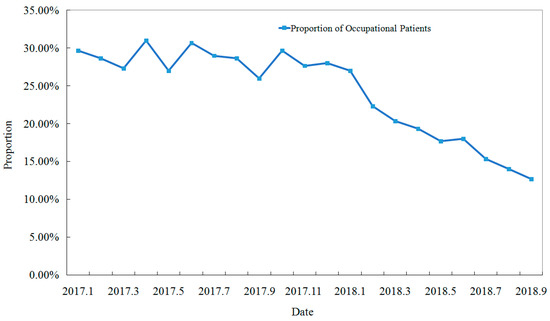

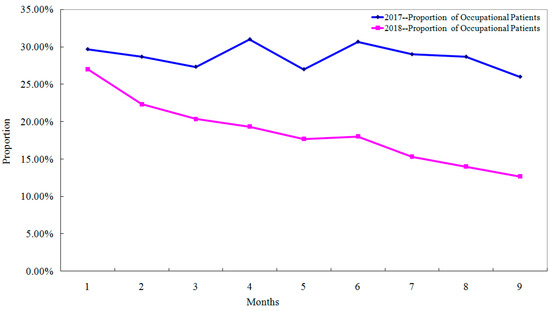

The effect of the control measures was further verified by analyzing the proportion of occupational patients in Hongxing Company in 21 months. As shown in Figure 12, a chart showing the change in the trend of occupational diseases in the company from January 2017 to September 2018.

Figure 12.

Trends in the proportion of occupational patients in Hongxing Company from January 2017 to September 2018.

As can be seen from Figure 12, the proportion of the company’s monthly occupational patients in 2017 is 28.33%. At the beginning of 2018, after the implementation of the management and control measures, the proportion of the occupational patients fell to 27.00%. It shows that management and control measures have begun to take effect. From January 2018 to September 2018, the proportion of occupational patients in the company drops rapidly, from 27.00% to 12.67%. It demonstrates that the control measures are effective.

In order to analyze the proportion of occupational patients before and after the implementation of management and control measures more clearly, the paper compares the proportion of occupational patients in the same month in 2017 and 2018, as shown in Figure 13.

Figure 13.

Comparison of the proportion of occupational patients in the company in the same month of 2017 and 2018.

As can be seen from Figure 13, the proportion of occupational patients decreased significantly in the same month of 2018 and 2017, and this trend became more and more obvious over time.

5. Conclusions

Based on the actual situation of coal chemical enterprises, this paper analyzed the influencing factors of OSH in coal chemical enterprises by combining ANP and SD, and simulated the combined management and control measures to further reduce the number of occupational patients in coal chemical enterprises and improve their OSH level. The main conclusions are as follows:

(1) The influencing factors of OSH in coal chemical enterprises were analyzed from four aspects of Human, Machine, Environment, and Management respectively, using the Fishbone Diagram.

(2) ANP was used to analyze the weights of the influencing factors. The results indicate that the primary indicators affecting OSH are Management, Human, Machine, and Environment, according to weights. The global weights of the secondary indicators indicate that the weights of factors such as Safety culture, Working habits, Harmful gas, Equipment protection, Toxic chemicals, Dust, Mechanical noise are large, which are the key factors for the formulation of management and control measures.

(3) The SD model of OSH management and control measures was constructed. It was found that through simulation, the effect of adopting combined management and control measures was better than that of implementing a single measure.

(4) The research results of the paper were experimentally applied to the coal chemical company—Hongxing Company. It can be seen from the statistics that the combined management and control measures have effectively reduced the proportion of the company’s occupational patients and improved the company’s OSH level.

The research results of the paper provide a theoretical basis and application direction for the research of OSH management and control technology in coal chemical enterprises. In the future, the research results of this paper will continue to be promoted to other similar enterprises to improve the OSH level of the whole industry.

Author Contributions

K.Y. and L.Z. constructed the thesis ideas; L.W. and W.J. analyzed the data; C.H. contributed analysis tools; K.Y. and L.Z. wrote the paper.

Funding

This research was funded by National Natural Science Foundation of China: 51474138, National Natural Science Foundation of China: 51574157, National Natural Science Foundation of China: 51804180.

Acknowledgments

The authors would like to thank the authors of the references.

Conflicts of Interest

The authors declare no conflict of interest

References

- Watterson, A. Occupational Safety and Related Impacts on Health and the Environment. Int. J. Environ. Res. Public Health 2017, 13, 988. [Google Scholar] [CrossRef] [PubMed]

- Dekker, S.; Cilliers, P.; Hofmeyr, J.-H. The complexity of failure: Implications of complexity theory for safety investigations. Safety Sci. 2011, 49, 939–945. [Google Scholar] [CrossRef]

- Ellis, K. Looking beyond Operator—Putting People in the Mix. NEI Magazine. 2014. Available online: http://www.neimagazine.com/features/featureputting-people-in-the-mix-4321534/ (accessed on 18 July 2014).

- Mosey, D. Looking beyond Operator—Putting People in the Mix. NEI Magazine. 2014. Available online: http://www.neimagazine.com/features/featurelooking-beyond-the-operator-4447549/ (accessed on 26 November 2014).

- Ellis, K. Looking Beyond Operator—Putting People in the Mix. NEI Magazine. 2014. Available online: http://www.neimagazine.com/features/featureputting-people-in-the-mix-part-2-4322674/ (accessed on 21 July 2014).

- Schneider, M.; Somers, M. Organizations as complex adaptive systems: Implications of Complexity Theory for leadership research. Leadersh. Quart. 2006, 17, 351–365. [Google Scholar] [CrossRef]

- US NRC, Safety Culture Communicator, Case Study 4: April 2010 Upper Big Branch Mine Explosion—29 Lives Lost, Washington D.C. 2012. Available online: http://pbadupws.nrc.gov/docs/ML1206/ML12069A003.pdf (accessed on 1 March 2012).

- Dutta, M.J. Migration and Health in the Construction Industry: Culturally Centering Voices of Bangladeshi Workers in Singapore. Int. J. Environ. Res. Public Health 2017, 14, 132. [Google Scholar] [CrossRef] [PubMed]

- Komljenovic, D.; Loiselle, G.; Kumral, M. Organization: A new focus on mine safety improvement in a complex operational and business environment. Int. J. Min. Sci. Technol. 2017, 27, 617–625. [Google Scholar] [CrossRef]

- Department of Energy, DoE. Human Performance Improvement Handbook, vol. 1, DOE Standard, Washington D.C. 2009. Available online: https://www.standards.doe.gov/standards-documents/1000/1028-BHdbk-2009-v1 (accessed on 22 June 2009).

- Kahneman, D. Thinking, Fast and Slow; Farrar, Straus and Giroux: New York, NY, USA, 2012. [Google Scholar]

- Montibeller, G.; Winterfeldt, D. Cognitive and Motivational Biases in Decision and Risk Analysis. Risk Anal. 2015, 35, 1230–1251. [Google Scholar] [CrossRef] [PubMed]

- Komljenovic, D.; Gaha, M.; Abdul-Nour, G.; Langheit, C.; Bourgeois, M. Risks of Extreme and Rare Events in Asset Management. Safety Sci. 2016, 88, 129–145. [Google Scholar] [CrossRef]

- Panikkar, B.; Woodin, M.A.; Brugge, D. Occupational Health and Safety Experiences among Self-Identified Immigrant Workers Living or Working in Somerville, MA by Ethnicity, Years in the US, and English Proficiency. Int. J. Environ. Res. Public Health 2012, 9, 4452–4469. [Google Scholar] [CrossRef] [PubMed]

- Zytoon, M.A.; Basahel, A.M. Occupational Safety and Health Conditions Aboard Small- and Medium-Size Fishing Vessels: Differences among Age Groups. Int. J. Environ. Res. Public Health 2017, 14, 229. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.J.; Cao, Q.G.; Yu, K.; Wang, L.L.; Wang, H.B. Research on Occupational Safety, Health Management and Risk Control Technology in Coal Mines. Int. J. Environ. Res. Public Health 2018, 15, 868. [Google Scholar] [CrossRef]

- Jiang, L.; Kong, P.; Shu, J.; Fan, K. Numerical Analysis of Support Designs Based on a Case Study of a Longwall Entry. Rock Mech. Rock Eng. 2019. [Google Scholar] [CrossRef]

- Li, S.; Chen, H.; Huang, X.; Long, R. Who Has Higher Willingness to Pay for Occupational Safety and Health? Views from Groups with Different Public Identities and Differences in Attention. Int. J. Environ. Res. Public Health 2018, 15, 1667. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.C.; Wang, M.C.; Liao, H.C.; Cheng, S.F.; Wang, Y.H. Hazard Prevention Regarding Occupational Accidents Involving Blue-Collar Foreign Workers: A Perspective of Taiwanese Manpower Agencies. Int. J. Environ. Res. Public Health 2016, 13, 706. [Google Scholar] [CrossRef]

- Hansen, A.; Pisaniello, D.; Varghese, B.; Rowett, S.; Hanson-Easey, S.; Bi, P.; Nitschke, M. What Can We Learn about Workplace Heat Stress Management from a Safety Regulator Complaints Database? Int. J. Environ. Res. Public Health 2018, 15, 459. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Li, P.; Liu, G.; Cheng, W.; Liu, Z. Development of cement dust suppression technology during shotcrete in mine of China-A review. J. Loss Prev. Process Ind. 2018, 55, 232–242. [Google Scholar] [CrossRef]

- Jung, J. A Study on the Necessity and Action Plan of Establishment of Occupational Safety and Health Executive in Korea. J. Korean Soc. Occup. Environ. Hyg. 2017, 27, 1–12. [Google Scholar]

- Wu, F.; Chi, Y. Regulatory system reform of occupational health and safety in China. Ind. Health 2015, 53, 300–306. [Google Scholar] [CrossRef] [PubMed]

- Mannan, M.S.; O’Connor, T.M.; Keren, N. Patterns and trends in injuries due to chemicals based on OSHA occupational injury and illness statistics. J. Hazard. Mater. 2009, 163, 349–356. [Google Scholar] [CrossRef]

- Hassim, M.H. Comparison of methods for assessing occupational health hazards in chemical process development and design phases. Curr. Opin. Chem. Eng. 2016, 14, 137–149. [Google Scholar] [CrossRef]

- Khan, M.M.; Halim, Z.I.; Iqbal, M. Attributes of occupational injury among workers in the chemical industry and safety issues. Int. J. Occup. Safety Ergon. 2006, 12, 327–341. [Google Scholar] [CrossRef]

- Shin, M.; Lee, H.S.; Park, M.; Moon, M.; Han, S. A system dynamics approach for modeling construction workers’ safety attitudes and behaviors. Accid. Anal. Prev. 2014, 68, 95–105. [Google Scholar] [CrossRef] [PubMed]

- Lu, R.; Wang, X.; Yu, H.; Li, D. Multiparty Evolutionary Game Model in Coal Mine Safety Management and Its Application. Complexity 2018, 2018, 9620142. [Google Scholar] [CrossRef]

- Wu, G.; Duan, K.; Zuo, J.; Yang, J.; Wen, S. System Dynamics Model and Simulation of Employee Work-Family Conflict in the Construction Industry. Int. J. Environ. Res. Public Health 2016, 13, 1059. [Google Scholar] [CrossRef] [PubMed]

- Fang, W.; Tang, L.; Cheng, P.; Ahmad, N. Evolution Decision, Drivers and Green Innovation Performance for Collaborative Innovation Center of Ecological Building Materials and Environmental Protection Equipment in Jiangsu Province of China. Int. J. Environ. Res. Public Health 2018, 15. [Google Scholar] [CrossRef] [PubMed]

- Khakzad, N.; Reniers, G.; van Gelder, P. A multi-criteria decision making approach to security assessment of hazardous facilities. J. Loss Prev. Process Ind. 2017, 48, 234–243. [Google Scholar] [CrossRef]

- Cao, Q. Safety Systems Engineering; China Coal Industry Publishiing House: Beijing, China, 2010. [Google Scholar]

- Xie, Q. Fuzzy Comperhensive Evaluation on Person-Job Fit in Enterprises Based on ANP; Tianjin University of Commerce: Tianjin, China, 2012. [Google Scholar]

- Wang, Q. System Dynamics; Science Press: Beijing, China, 2009. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).