Abstract

Petrochemicals currently represent the predominant global source of energy and consumer products, including the starting materials used in the platform chemical, plastic polymer, and pharmaceutical industries. However, in recent years, the world’s approaches have shifted towards green chemistry and bio-based chemical production in an effort to reduce CO2 emissions and mitigate climate change. Over the past few decades, researchers have discovered that marine metabolites, primarily sourced from invertebrates, can be utilized to create sustainable and renewable chemicals. This review highlights the significance of advancing marine microorganism-based biotechnology and biochemistry in developing effective conversion systems to enhance the biological production of key platform chemicals, including those utilized as biomaterials and for energy. A background in marine metabolite biochemistry lays the groundwork for potential strategies to mitigate dependence on petroleum for consumer products. This is followed by a discussion of petroleum product replacement technologies, green chemistry alternatives, and CO2 mitigation efforts for the production of sustainable and renewable key platform chemicals.

1. Introduction

Petroleum-derived starting materials and platform chemicals offer valuable opportunities for innovation across multiple industries, ranging from pharmaceuticals to the food and beverage sector. By exploring their biochemical applications, we can harness their potential to develop more effective products and solutions that meet our evolving needs. Emphasizing sustainable practices in their use and production can further contribute to a healthier, more responsible future. Petroleum resources are finite and a major contributor to climate change; their depletion results in a surge in prices for energy, materials, and medicines worldwide. The dependency on such petrochemical-based products is one of the biggest challenges facing modern economies and the climate [1,2,3]. Therefore, the focus has shifted to “Green” starting materials sourced from bio-based, renewable sources that are non-toxic, carbon-neutral, biocompatible, and biodegradable [4,5]. Using materials derived from regenerative and sustainable terrestrial and marine sources may help ease environmental pollution and reduce dependence on fossil-based petroleum resources [6]. It has been found that, under favorable market conditions, producing chemicals from renewable resources could reach 113 million tons by 2050, accounting for 38% of the total organic chemical production [7].

Extensive research has revealed that marine metabolites (e.g., monoterpenes, carbohydrates, fatty acids, etc.) are promising candidates for use in various modern sectors. These include both biologically related medical sectors and non-biologically related industrial/biotechnological sectors. Given the unsustainable nature of petroleum-based resources, these marine metabolites could be the key to a more sustainable future [8].

Living systems comprise a complex network of metabolic reactions involving various enzymes and cells, enabling them to function as effective biocatalysts for chemical processes. Protein and cell biocatalysts offer selectivity, controlled reaction sequences, and the capacity to operate under environmentally friendly conditions, facilitating the efficient production of molecules and reducing costs while minimizing environmental impact. Biocatalysis enables the synthesis of chemical structures that may be difficult to achieve with traditional methods. Metabolic reactions produce fine chemicals, including pharmaceuticals and food additives, primarily from basic carbon sources such as glucose and carbon dioxide [9]. Although many of these compounds occur naturally, their commercial availability is often limited due to purification challenges and costs. Bio-based fine chemical synthesis addresses these limitations by sourcing essential components from low-cost materials [10]. The co-production of multiple chemicals from common carbon sources is economically advantageous. Conditions that promote rapid cell growth and efficient extraction methods from microorganisms enhance cost-effectiveness. Bio-production generally occurs at lower temperatures than traditional syntheses, contributing to cost reduction and environmental sustainability. Progress in engineering microorganisms has enabled the production of fuels, bulk chemicals, and valuable medications from inexpensive raw materials. Enzymes within cells can catalyze reactions in a single step, thereby optimizing the production of a wide array of molecules [11,12,13].

2. Petroleum-Derived Platform Chemicals and Biobased Production

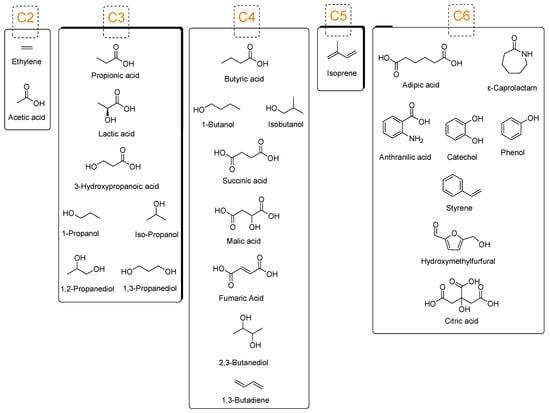

In general, common platform chemicals (Figure 1) are derived from crude oil fractions (obtained from the refineries). They are used as precursors or basis materials for preparing chemical intermediates, building blocks, and polymers. A basic starting material has chemical moieties that act as linkages during polymerization or chemical reactions. The distillation of fossil fuel oil results in natural gas, aromatic compounds, naphtha, methane, ethane, propane, butane, heptane, cyclopentane, and cyclohexane. For example, ethylene has a carbon-carbon double bond that serves as a pi bond to form sigma-bond linkages with an adjacent ethylene molecule during the polymerization stage of polyethylene (PE) production. Building block compounds containing carbon-to-carbon double bonds (e.g., ethylene, isobutylene, acrylonitrile, vinyl chloride, styrene, methyl methacrylate, vinyl acetate, and isoprene) are typically used for addition polymerization [14]. Some platform chemicals, such as monocarboxylic acids (e.g., acetic and propionic acids) and monols (e.g., ethanol, propanol, n-/iso-butanol, and pentanols), are used as precursors to form polymers, followed by chemical reactions that convert them into building block compounds. Table 1 lists the world volume and price production of these platform chemicals.

Figure 1.

Common platform chemicals derived from petroleum that are utilized for petrochemical production.

Table 1.

Global production of essential platform chemicals in the worldwide market by value and volume.

2.1. Two-Carbon Petroleum-Derived Chemicals

2.1.1. Ethylene

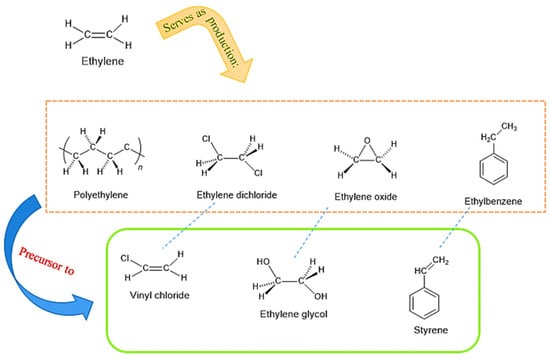

Ethylene (Et), the simplest alkene, is a hydrocarbon with the molecular formula C2H4. Ethylene possesses a carbon-carbon that is industrially separated from natural gas or petroleum through a heat treatment process at 800–900 °C (1470–1650 °F) [78,79,80]. Ethylene is widely utilized in the chemical and plastic polymer industries as a carbon-based material (Figure 2). Its global production was estimated at 120 million tons in 2008, over 150 million tons in 2016, and 305.9 million tons in 2022 [81,82]. A catalyzed hydration of ethylene produces ethanol; hydrogenation yields ethane, for instance. Ethylene is also used to make propan-1-ol by catalytic hydrogenation of propionaldehyde (using ethylene hydroformylation with carbon monoxide and hydrogen in the presence of a catalyst such as cobalt octacarbonyl or rhodium complex, propionaldehyde is produced by the oxo process) [83]. In addition to serving as a precursor to polymers, such as polyethylene, the most commonly used plastic or surfactants (e.g., ethylene oxide and ethylene glycol, polyethylene and polyethylene terephthalate (PET)) can be produced utilizing ethylene and ethylene glycol as building block compounds [84]. Ethylene, as a monomer to produce bioanalogs, such as bioplastics, is a potential solution for replacing petroleum-derived products [85].

Figure 2.

Industrial uses of ethylene for producing polyethylene, ethylene dichloride, ethylene oxide, and ethylbenzene (from left to right; middle illustration). The compounds in the middle illustration are precursors to the compounds shown underneath. In oil refineries, 214 million metric tons of ethylene were produced in 2021 (Table 1). According to the U.S. National Renewable Energy Laboratory (NREL), the use of biomass (e.g., macro/microalgae) to produce bio-ethylene via the dehydration of bioethanol can reduce carbon dioxide (CO2) emissions by 70–80% compared to hydrocarbon processes in the chemical industry.

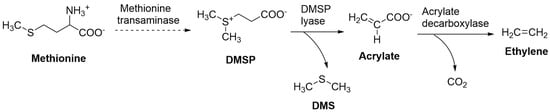

Figure 3 describes an alternative way for marine algae to produce ethylene (ethene) from acrylate [H2C=CH-COO–]. Acrylate is a precursor of ethylene [86,87] and can be cleaved from the secondary metabolite b-dimethylsul-phoniopropionate [DMSP (CH3)2S + CH2CH2COO–)] in an enzymatic reaction that also creates the volatile trace gas dimethyl sulfide (DMS [(CH3)2S]). The enzyme responsible for this reaction, DMSP lyase, has been found in several algal taxa, including benthic macroalgae and pelagic phytoplankton [88,89]. DMSP is an essential metabolite in many marine algae, accounting for between 48% and 100% of sulphur fluxes and 5% and 15% of carbon fluxes in marine microbial ecosystems [90]. Even though little research has been conducted on acrylate biosynthesis in marine organisms, it is noteworthy that DMSP-containing algal taxa have a high potential to produce it.

Additionally, DMSP is synthesized from methionine [91], the same amino acid that ultimately produces ethylene in higher plants. Among the various types of benthic algae, red and green macroalgae, also known as rhodophytes and chlorophytes, are the primary producers of DMSP and DMS [92]. These taxa are known to release ethylene. In a study, Broadgate et al. [93] showed that ten species of seaweed can produce ethylene. However, Ulva intestinalis, a chlorophyte, was found to have the highest ethene production rate, producing 62.93 pmol g−1 dry weight h−1. This species uses DMSP as its principal osmolyte, approximately 25 mmol kg−1 [94]. Additionally, experiments conducted by Watanabe and Kondo [86] showed that Codium latum (green alga), Porphyra tenera, P. aborescens (red algae), and several brown algae (phaeophytes) also produce ethylene. In another evaluation, only red and green algae showed the ability to synthesize ethylene. This production can be increased by adding the auxin hormone indole-3-acetic acid (IAA) and can be further enhanced by adding acrylate. It has been observed that P. perforata also produces ethylene [95], while the acellular macroscopic chlorophyte A. mediterranea uses ethylene for developmental differentiation [96].

Figure 3.

Possible pathways for the production of ethylene by marine algae. DMS, DMSP, methionine transaminase [91], DMSP lyase [88], and acrylate decarboxylase [97].

2.1.2. Acetic Acid

Acetic acid, a carboxylic acid (an important C2 platform chemical), has the molecular formula C2H4O2, containing a carboxyl functional group attached to a methyl group. Among the products that are manufactured from this acid are vinyl acetate, acetic anhydride, and cellulose acetate, so vinyl acetate and acetic anhydride, known as building block compounds, form polymers such as polyvinyl acetate (PVA) and cellulose acetate. Acetic acid is produced by acetaldehyde oxidation, methanol carbonylation, and butane liquid-phase oxidation processes. The global acetic acid production was determined at 7 million tons in 2007 [98].

2.2. Three-Carbon Petroleum-Derived Chemicals

In industry, propionic acid (C3H6O2) is mainly produced through petrochemical routes, using ethylene as a starting material [99] and the oxidation of petrochemical raw materials such as propane or propionaldehyde [100]. Propionic acid is used extensively, including in the production of herbicides, cellulose fibers, perfumes, and pharmaceuticals [101].

2.2.1. Lactic Acid

Lactic acid (LA) (2-hydroxypropanoic acid) and 3-hydroxypropionic acid contain a hydroxyl group and a carboxyl group with molecular formula C3H6O3, and are multipurpose building blocks. They are well-known for manufacturing biodegradable polyesters, such as polylactide (PLA) and poly(3-hydroxypropionate). In 2007, world lactic acid production was estimated at 150,000 tons [98]. Currently, the production of 3-hydroxypropionic acid largely depends on petrochemical-synthetic pathways such as 1,3-propanediol, 3-hydroxypropionaldehyde oxidation, and acrylic acid hydration. Furthermore, lactic acid, a low molecular weight organic acid, has applications in various fields such as food, chemical, pharmaceutical, and medical. It can also be utilized to produce PLA, which is a safe, biocompatible, and biodegradable polymer that is a common material in the cosmetic industry. This alpha-hydroxyl acid also plays a crucial role in numerous biochemical pathways. Specifically, the use of lactic acid in the pharmaceutical and medical industries has become widespread for manufacturing purposes as follows:

- (a)

- Parenteral/I.V. solutions: Used to replenish body fluids and electrolytes [102] like Lactated Ringer’s and dialysis solutions;

- (b)

- Dialysis solutions: Sodium acetate is used as a dialysate fluid, but researchers recommend L(+) lactate for its fewer side effects [103];

- (c)

- Lactide glycolide copolymers: Favored for implantable drug delivery due to their biocompatibility and ability to dissolve in the body, making them suitable for drug-releasing matrices [104,105,106];

- (d)

- Ammonium lactate: Important for pharmaceutical uses, effective in moisturizing skin and treating severe dryness, also mitigates the drying effects of topical corticosteroids [107,108];

- (e)

- Mineral lactate formulations: Effective in treating anemia, hypertension, and osteoporosis, with key minerals including ferrous, calcium, manganese, magnesium, and zinc lactates [109];

- (f)

- Chiral synthesis: Central to pharmaceuticals, using natural chiral building blocks like lactic acid, with both (R) and (S) isomers available in high purities for cost-effective and versatile production [110].

Uchida and Murata [111] were the first to discover a method for producing lactic acid and ethanol through the fermentation of Ulva pinnatifida seaweed. They used cellulase for saccharification and a microbial consortium of Lactobacillus brevis, Debaryomyces hanseni var. hansenii, and Candida zeylanoides with yeast for cultivation. Adding this microbial consortium along with cellulase-induced lactic acid and ethanol fermentation in various kinds of seaweed. In a research conducted by Hwang et al. [112], they investigated using five different Lactobacilli strains for lactic acid production from hydrolysates of Enteromorpha prolifera. The results showed that the tested strains were more efficient in using E. prolifera hydrolysate for lactic acid production compared to corn stover hydrolysate. This could be due to differences in the composition of monosaccharides and lower furan content in macroalgae hydrolysate. This study supports the use of macroalgae carbohydrate hydrolysates as a competitive feedstock for biochemical production [112,113]. A similar study was performed by Mazumdar et al. [114], who tested an engineered E. coli strain containing the Streptococcus bovis/equinus L-lactate dehydrogenase to produce L-lactate from brown macroalgae Laminaria japonica hydrolysates as a carbon source [114]. Jang et al. [115] carried out both acid (H2SO4) and alkaline (NH4OH) hydrolysis of L. japonica to create a substrate for LA production in which the obtained mannitol was bioconverted into lactic acid by L. rhamnosus. In their following experiment, the researchers utilized a sulphuric acid hydrolysate of Gelidium amansii as the primary carbon source for lactic acid production by L. rhamnosus KY-3. They eliminated inhibitor components, including 5-HMF, furfural, and phenol. Monosugars glucose and galactose were converted into lactic acid. The resulting mixture contained a small quantity of acetic acid, formic acid, and ethanol [116].

2.2.2. 1-Propanol and Isopropanol

Alcohols such as 1-propanol and isopropanol can be utilized instead of methanol as the esterification reagent, and the esters formed exhibit decreased crystallization at low temperatures [117]. In the petroleum industry, 1-propanol is chemically synthesized from ethane, carbon monoxide, and hydrogen, whereas isopropanol is made from the hydration reactions between water and propene [118].

2.2.3. Propanediols

1,2-propanediol (PDO) and 1,3-propanediol are linear aliphatic glycols composed of two hydroxyl functional groups. These propanediols are base compounds for the production of polyester resins, antifreeze and de-icing agents, detergents, pharmaceuticals, cosmetics, and food products [36]. Specifically, monomer 1,3-PDO is broadly tapped for creating polymers extending from terephthalate to polyester polytrimethylene terephthalate (PTT). Both 1,2-PDO and 1,3-PDO are mostly gained chemosynthetically from propylene oxide and propenal, respectively [35,119]. 1,2-PD could be bioproduced from marine microorganisms. Merriman [37] achieved a promising outcome by optimizing the production of 1,2-PD through an algae fiber system using Thermoanaerobacterium thermosaccharolyticum bacteria. The extracts derived from the process contained various sugars, specifically C5 sugars such as xylose and arabinose, along with C6 sugars like glucose, galactose, and mannose. These sugars were subsequently bioconverted into 1,2-PD. Although Merriman’s study did not use real algal biomass, Merriman [37] recommends using U. lactuca, known for its high carbohydrate content, to potentially improve production processes. Additionally, research by Bikker et al. [120] has shown that 1,2-PD can be produced from U. lactuca biomass in combination with Clostridium beijerinckii NCIMB 8052. The study also noted that when sugars like glucose, rhamnose, and xylose were consumed at low concentrations, the main products formed were acetone, butanol, and ethanol (ABE).

2.3. Four-Carbon Petroleum-Derived Chemicals

2.3.1. Butyric Acid

Butyric acid, a four-carbon aliphatic fatty acid, is a starting material for the formation of cellulose acetate butyrate. It is yielded either by chemically oxidizing butane or butyraldehyde [121]. It has many applications in the food, perfume, and polymer industries (photographic films and eyeglass frames) [122].

2.3.2. Butanol

Butanol, a four-carbon alcohol, is a basic organic chemical with the molecular formula C4H10O. Current commercial production of butanol is based on petroleum-derived chemicals, which are produced by a two-step process involving the hydroformylation of propene to gain butyraldehyde and subsequent hydrogenation. It showed applications in industrial solvents and plays a role in producing important chemicals such as acetates, acrylate esters, amines, amino resins, butyl acrylates, glycol ethers, and methacrylates as intermediates. Butanol is an excellent solvent for manufacturing antibiotics, vitamins, and hormones, as well as a diluent for brake fluid formulations [123,124]. The European Medicines Agency (EMA) has declared that n-butanol is utilized as a preservative or stabilizing solvent in veterinary medicinal products. Additionally, n-butanol is used as a flavoring agent in various food products such as butter, cream, liquor, rum, and whiskey. It is also used as an extractant in food production to manufacture hormones, antibiotics, and vitamins. Additionally, n-butanol serves as a solvent for industrial and cleansing activities. The worldwide butanol market was valued at around USD 7 billion in 2020 and is projected to reach nearly 9 billion by 2026, with growth at a CAGR of 3.7% from 2021 to 2026 [125]. 1-butanol derivatives, butyl acrylate, and methacrylate esters can be applied for the production of latex surface coatings, enamels, and lacquers, while isobutanol ester derivatives, such as diisobutyl phthalate, are used as plasticizer agents [123,126].

In the past decade, numerous reports have been published on utilizing the macroalgae Ulva lactuca to produce n-butanol in a mixture of ABE [127,128,129]. Butanol can be made through bacterial fermentation with Clostridium strains such as Clostridium acetobutylicum or C. beijerinckii. This process is traditionally known as ABE fermentation. Macroalgae, specifically green and brown seaweeds, have also been researched for the production of acetone, butanol, ethanol, acetic, and butyric acids by Clostridium beijerinckii and C. saccharoperbutylacetonicum. Additionally, acetic and butyric acids can be produced by C. acetobutylicum (ca. 3–4 gABEglucose−1) [128,129,130]. Aqueous extracts of the brown algae Saccharina spp., which contain mannitol and laminarin, were subject to fermentation by C. acetobutylicum ATCC 824 to achieve butanol and ABE (yields: at 0.12 g g−1 and 0.16 g g−1, respectively, which are relatively low, but these can be improved to make industrial-scale acetone, butanol, and ethanol fermentations of brown seaweed economically feasible) [127].

2.3.3. Succinic Acid

Succinic acid (SA) is a four-carbon platform chemical generally produced commercially, primarily by hydrogenation of petroleum-based maleic acid or via the oxidation of butanediol [131], with applications in antifreeze liquids, coolants, solvents, pigments, polyesters, intermediates for the chemical industry (1,4-butanediol: BDO, derivatives), plasticizers, etc. [132]. SA serves as a building block for the synthesis of several industrial chemicals, including lacquers, sequestrants, buffers, and neutralizing agents [133]. Moreover, SA can be esterified to produce dimethyl succinate, a solvent marketed as environmentally friendly [134]. Water cooling systems for vehicles [135] are also used to improve the flotation of various ores and water repellency in the leather industry [136]. SA also promotes propionate production in the rumen and acts as a glycogenic material and a precursor for protein synthesis. This makes it a potential additive for animal feed for both ruminants and monogastric animals such as pigs, which could help reduce the usage of antibiotics like monocin and lasalocid in specific animal feeds. The crude succinate salt produced from carbohydrates could potentially find new markets as a product for animals [137]. Bioproduced SA has a broad spectrum of potential applications, ranging from pharmaceuticals and resins to the food industry, polyurethanes, cosmetics, de-icing solutions, solvents, and fine chemicals. As a platform chemical derived from renewable resources, it shows great promise. In the SA production, glucose and mannitol hydrolysates from the Laminaria japonica seaweed were used as carbon sources by engineered E. coli BS002 and recombinant E. coli KLPPP. (yielded: 17.4 and 22.4 g L−1, respectively) [138]. Palmaria palmata, a type of red algae, was subjected to pre-treatment and enzymatic hydrolysis, which resulted in a mixture of glucose and galactose sugars. The SA yield on galactose was almost three times higher than on glucose. In 2015, Alvarado-Morales and colleagues proposed an integrated biorefinery approach that aimed to produce SA and direct the by-products for food, added value products, and bioenergy production by converting extracted sugar from macroalgae Laminaria digitata to SA using Actinobacillus succinogenes 130Z (yield: 0.50 g (L h)−1) [139].

2.3.4. 2,3-Butanediol

2,3-Butanediol (2,3-BDO) is a crucial platform chemical widely used as an antifreeze agent. Its dehydration products have a broad range of applications, such as fuel additives, rubber production, food flavoring, and bacteriostatic additives [140]. Recently, researchers engineered an E. coli strain to efficiently produce 2,3-BDO and acetoin (A) using brown algae hydrolysate. The E. coli microaerobically utilized mannitol and glucose to synthesize 2,3-BDO + A fermentation products [141].

2.3.5. Malic Acid

Malic acid is an intermediate in the TCA cycle composed of two stereoisomers: the left-handed L-form and the right-handed D-form. Only L-malic acid is found in biological systems [142]. A variety of microorganisms have been observed to obtain L-malic acid [143]. Fungi, such as Aspergillus species and Schizophyllum commune, can produce a significant amount of L-malic acid from sugars through fermentation. Aspergillus flavus, for example, can produce 113 g L−1 of L-malic acid from 120 g L−1 of glucose. In another study, S. commune was used for the production of 43 g L−1 of L-malic acid from 50 g L−1 of glucose in an 8-L air-lift column fermentor in 110 h [144].

2.3.6. Fumaric Acid

The pharmaceutical industry uses fumaric acid to manufacture alexipharmic sodium dimercaptosuccinate and ferrous fumarate, which are used as optical bleaching agents. Additionally, fumaric acid esters, such as ethyl hydrogen fumarate, monoethyl fumarate, and dimethyl fumarate, are used to treat psoriasis patients who are not able to produce fumaric acid in their skin when exposed to light and multiple sclerosis (MS) [145,146,147]. Recently, it has been discovered that fumaric acid possesses antibacterial properties in Aloe vera L. [148]. Additionally, fumaric acid can be bioproduced through fermentation using Rhizopus species [145].

2.4. Five-Carbon Petroleum-Derived Chemicals

Isoprenes

Isoprene is a five-carbon building block for the synthesis of diverse polymers. The key source of isoprene is a by-product of ethylene generation by cracking naphtha. Isoprene yields are typically 2–5 wt% based on ethylene, although it may be increased by starting with a heavier raw material such as diesel. The first industrial synthesis of isoprene began with the dimerization of propylene to 2-methyl-1-pentene. This substance is then isomerized to 2-methyl-2-pentene, which is subsequently cracked with loss of methane to prepare isoprene; although the highly frequently used synthetic method is acid-catalyzed addition of formaldehyde to isobutene (Prins reaction) [131]. In living systems, isoprenoids represent the most remarkable and diverse group of natural products, with over 40,000 structurally distinct compounds critical to the survival of all classes of living organisms. These molecules are not just important; they are fundamental to essential biological functions, including respiration, electron transport, maintenance of membrane fluidity, hormone signaling, photosynthesis, and antioxidation, as well as the precise localization and regulation of protein activities [149,150]. Moreover, certain isoprenoids like carotenoids are strategically produced for commercial use as vital nutritional and medicinal additives, underscoring their importance in our health and well-being [151]. Isoprenoids are synthesized through a series of definitive condensations of five-carbon precursors: isopentenyl diphosphate (IPP) and its allyl isomer, dimethylallyl diphosphate (DMAPP). These precursors are generated via two established pathways: the mevalonate (MVA) pathway, predominant in most eukaryotes, and the 2-C-methyl-D-erythritol-1,4-phosphate (MEP) pathway, which operates in prokaryotes. The enzyme prenyltransferase is responsible for condensing IPP and DMAPP to produce key compounds known as prenyl pyrophosphates, including geranyl pyrophosphate (GPP), farnesyl pyrophosphate (FPP), geranylgeranyl pyrophosphate (GGPP), and various polyprenyl pyrophosphates. Prenyl pyrophosphates are decisively transformed into monoterpenes, sesquiterpenes, diterpenes, triterpenes, tetraterpenes, and polyprenyl side chains. The remarkable chemical diversity of isoprenoids is driven by specific terpene synthases and modifying enzymes, particularly cytochromes P450. Synthetic bioengineering strategies significantly enhance isoprenoid production in microorganisms such as E. coli and S. cerevisiae. These approaches lead to the successful synthesis of triterpenoids like amorpha-4,11-diene and artemisinic acid, which are vital precursors for the antimalarial drug artemisinin. Furthermore, they enable the efficient production of taxa-4(5),11(12)-diene, a key precursor for the potent antineoplastic agent Taxol. Additionally, synthetic bioengineering drives the synthesis of tetraterpenoids, including carotenoids like astaxanthin, showcasing its critical role in advancing these valuable compounds [152,153,154,155,156].

2.5. Six-Carbon Petroleum-Derived Chemicals

2.5.1. Adipic Acid

The adipic acid (1,6-hexanedioic acid) and its derivative, ɛ-caprolactam, are primarily utilized as building blocks for polyamides, including Nylon-6,6 and Nylon-6, respectively. The worldwide yearly preparation of adipic acid and ɛ-caprolactam is calculated at 2.2 and 4 million metric tons, respectively. Industrially, adipic acid is acquired by mixing the oxidation of cyclohexanone and cyclohexanol (ketone-alcohol oil); in contrast, ɛ-caprolactam is built by ɛ-aminocaproic acid cyclization [142]. The International Energy Agency (IEA) considers adipic acid the most significant dicarboxylic acid from an industrial perspective and has identified it as a suitable platform chemical for biobased production. Globally, adipic acid production will increase at a compound annual growth rate of 3–5%. It is being developed to produce adipic acid by microorganism fermentation using complex raw material streams and high concentrations of adipic acid at acidic pH, using a production host that is highly tolerant of complex raw material streams. Biomass must be produced and utilized efficiently in order to achieve a biobased economy. As a result, the raw materials used in a bioeconomy must be produced sustainably [157,158,159].

2.5.2. Anthranilic Acids, Catechols, and Phenols

Anthranilic acids (2-aminobenzoic acid), catechols (1,2-dihydroxybenzene), and phenols are a group of monoaromatic hydrocarbons inferred from the petrochemical industry. These monoaromatics have been produced globally as starting materials and are used extensively in different industries, including plastics, detergents, and pesticides. They also consist of significant constituents of numerous petroleum and fine chemical products [160,161].

2.5.3. Styrene

Styrene is a key monomer derived from benzene and ethylene, essential in the production of polymers and resins, with over 5.8 million metric tons consumed annually in the U.S. As a new drug delivery vehicle, polystyrene-integrated solid foams have also shown promise [162,163]. Styrene traditional synthesis requires more than three metric tons of steam per metric ton, making it the most energy-intensive of all commodity chemical production routes. It consumes nearly 200 trillion BTU of steam annually for domestic production alone, which is an exorbitant amount. Styrene can be biosynthesized using renewable resources like glucose instead of traditional methods. This innovative method harnesses the power of microorganisms to transform renewable resources directly and efficiently into styrene. By embracing this biotechnological approach, we pave the way for a sustainable and environmentally friendly solution that not only minimizes energy consumption but also reduces costs significantly. The use of these tiny biological powerhouses exemplifies how nature can contribute to a greener future, making the production process both eco-conscious and economically viable [84,164,165].

2.5.4. 5-Hydroxymethylfurfural

5-Hydroxymethylfurfural (5-HMF) is an aromatic heterocyclic furan substituted in the 2,5-position by hydroxide and aldehyde functional groups. Due to the 5-HMF’s unique chemical structure, there are large efforts to utilize 5-Hydroxymethylfurfurals as a starting point for the synthesis of chemicals. As its characteristics, 5-Hydroxymethylfurfural is an α,ω-bifunctional molecule with substituents at positions 2 and 5; thus, it could be either oxidized to a dicarboxylic acid or reduced to a diol. Both of them can be used to synthesize polymers. Also, it is a relatively unsaturated compound that can be turned into fuel molecules by hydrogenation [166]. Plastics, pharmaceuticals, food, and chemical industries also use 5-Hydroxymethylfurfural and its derivatives. By oxidizing 5-HMF, 2,5-furandicarboxylic acid (FDCA) is generated. In the same way that terephthalic acid is used to produce PET, FDCA can be used to produce polyethylene furanoate (PEF). By replacing polyethylene terephthalate with PEF, plastic bottles and packaging materials will have a significantly reduced carbon footprint. There is considerable promise in 5-hydroxymethylfurfural as a potential replacement for fossil-derived compounds. It is estimated that more than 175 valuable bio-based products are obtained from 5-Hydroxymethylfurfural [167,168,169]. In recent years, algal biomass has emerged as an ideal material for producing 5-hydroxy-methylfurfural. This is a compound commonly found in lignocellulosic acid hydrolysate, and it is mainly formed by the dehydration of hexose [170]. Gracilaria verrusca, with a solid-acid catalyst, released 5-Hydroxymethylfurfural, and red algae, Gelidium amansii, are also a source of it [71,171,172,173].

2.5.5. Citric Acid

Citric acid (CA) (C6H8O7) is one of the most essential biochemicals produced on an industrial scale. It has a broad range of applications across various industries, such as food and beverage, pharmaceutical, metal, and nutraceutical. It also has roles in cosmetics as a flavoring agent, sequestering agent, buffering agent, etc. [174]. In 2020, the global production of citric acid was estimated at 2.39 million tons. By 2026, the production is forecast to reach 2.91 million tons [175]. Additionally, in 2021, its worldwide sales were approximately $2.8 billion, and the market for citric acid is expected to grow further in the next decade [176]. According to statistical data, pharmaceuticals are responsible for 12% of the global production of this acid, whereas food consumes 70% [177]. For instance, the common medical use of citric acid is in formulations, including intramuscular and subcutaneous injections for parenteral administration, co-amorphous drugs, co-crystals, lyophilization (drug delivery), taste-masking, and effervescence. It is worth noting that the effectiveness of a treatment is heavily reliant on patient compliance. [178]. Following a worldwide increase in demand for biobased products instead of petroleum-derived ones, citric acid is a suitable candidate for replacement, as it is a bio-based monomer with three carboxylic and one hydroxyl group, providing hydrophilicity and crosslinking sites, as well as being non-toxic and cost-effective [179].

Aspergillus niger cultivation on carbohydrate-rich substrates is the primary method of producing citric acid. A study by Ramesh and Kalaiselvam (2011) demonstrated that the red macroalgae Gelidiella acerosa possess a high carbohydrate content (ca. 60% w/w) and can be used for citric acid production (obtained citric acid concentrations varied from 30 to 80 g at different pH) [180].

3. Challenges, Limitations, and Potentials of Petroleum-Derived Platform Chemicals from Marine Sources

This section assesses the commercial potential, scalability challenges, and optimal marine sources for key C2–C6 molecules, highlighting their relevance, technological maturity, and environmental benefits.

3.1. Commercial Potential

Lactic acid, succinic acid, butanol, 5-HMF, and ethylene are the most promising due to their large markets and bio-based production feasibility. Lactic acid, with a significant market (150,000 tons in 2007, likely higher in 2025) [28], SA with EUR 2.5 billion market, and butanol with USD 9 billion by 2026 support polymers, solvents, and biofuels, reducing reliance on energy-intensive petrochemical processes [127,139]. 5-HMF enables PEF, a sustainable PET alternative, while ethylene, 305.9 million tons in 2022, is critical for bioplastics [93,142]. Acetic acid, propionic acid, isoprene, and adipic acid hold potential but are less mature [180,181].

3.2. Scalability Challenges and Limitations

Scaling marine-derived production faces significant hurdles. These include low fermentation yields—such as 0.12–0.50 g g−1 for butanol, 20–40 g L−1 for lactic acid, 62.93 pmol g−1 dry weight h−1 for ethylene. Additionally, high energy costs associated with biomass pretreatment, the formation of by-products like acetic acid and ethanol, and seasonal variability in the composition of marine macro and microorganisms further complicate the process [84,127].

For instance, lactic acid production from Gelidium amansii can reach 30–40 g L−1, but this process is hindered by inhibitors such as 5-HMF. On the other hand, the production of succinic acid and butanol from Laminaria spp. suffers from low conversion efficiencies, with rates of 0.50 g L−1 h−1 and 0.12–0.16 g g−1, respectively [139]. Ethylene production relies on optimized DMSP lyase pathways, while isoprene faces challenges due to enzyme inefficiencies [28]. Techno-economic analyses (TEA) reveal that capital and pre-treatment costs are high. In contrast, life cycle assessments (LCAs) show lower greenhouse gas (GHG) emissions—ranging from 1.5 to 2 kg CO2 kg−1 produced, compared to 3–4 kg CO2 kg−1 from petrochemical processes. However, there are concerns about eutrophication risks [182]. Potential solutions include genetic engineering (such as optimizing Lactobacillus or E. coli), in situ product recovery (ISPR), and integrated biorefineries that enhance the value of co-products. These approaches offer significant industrial-scale potential by 2030 to 2035.

3.3. Sustainable Marine Sources

Macroalgae such as Ulva intestinalis, Gelidium amansii, Saccharina spp., and Laminaria japonica are outstanding choices due to their impressive carbohydrate content, which can reach up to 60% w/w. Their rapid growth and efficient use of land and freshwater make them superior candidates for sustainable applications [183]. Ulva spp. is highly effective for producing ethylene and lactic acid, thanks to its elevated DMSP and sugar content. In contrast, Gelidium and Laminaria play a vital role in supporting the production of 5-HMF, succinic acid, and citric acid [171,180]. Marine microorganisms, such as E. coli, Clostridium spp., and Lactobacillus rhamnosus, effectively utilize algal hydrolysates with fewer inhibitors when compared to terrestrial feedstocks like corn stover. This presents significant sustainability advantages, as confirmed by LCA [182].

In general, lactic acid, succinic acid, and 5-HMF are on the brink of commercial readiness, with a timeline of 5–7 years, thanks to their established fermentation pathways and significant market demand. In contrast, ethylene and butanol need yield improvements to reach similar levels of viability [93,139]. Besides, Acetic acid, propionic acid, isoprene, and adipic acid are currently lagging due to subpar yields and technological shortcomings. However, marine sources clearly outperform terrestrial feedstocks in key environmental metrics, significantly reducing greenhouse gas emissions and land use. To unlock the potential of a decarbonized, bio-based chemical industry, it is essential to overcome scalability challenges through advancements in synthetic biology, effective biorefinery integration, and robust policy incentives such as carbon credits. In the following section, we delve into effective biorefinery processes to tackle existing challenges and drive industrial-scale production forward.

4. Biorefinery

In today’s society, fossil fuel refineries provide most of our energy and consumer products. Our extreme dependence on fossil fuels, largely due to the intensive use of petrochemical derivatives (approximately 4% of oil is used in chemical and plastic production worldwide), releases about two-thirds of GHG into the atmosphere. GHG emissions, including carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O), are detrimentally affecting the Earth’s climate. It is concerning to note that carbon emissions have surged to their highest level in the last seven years. The latest figures show that energy-related carbon emissions have skyrocketed by approximately 2.0%, marking the fastest expansion rate in quite some time [184,185,186,187]. This implies an increment in emissions of approximately 0.6 gigatons, which is a cause for alarm. Moreover, due to the continuous rise in the price of fossil fuels, coupled with their uncertain availability and environmental impact, it is anticipated that the viability of oil exploitation will decline in the coming years. It is essential to promote alternative solutions that can help mitigate climate change and reduce the use of fossil fuels [184,185,186,187]. Globally, it is widely acknowledged that plant-based raw materials (i.e., biomass) can serve as feedstocks for industrial production, thereby replacing a significant portion of fossil resources. In addition to fossil fuels, it is the only source of C available on the planet. Thus, sustainable biomass production is of utmost importance, and expansion to include products from marine algae will be extremely valuable moving forward [188]. In a recent document issued by the IEA Bioenergy, the term “Biorefinery” was defined as a process for the sustainable conversion of biomass into a range of marketable products and energy [188].

The biorefinery concept encompasses various technologies that can extract biomass resources’ essential components (natural products), such as carbohydrates, proteins, and triglycerides. These components can then be transformed into value-added products, biofuels, platform chemicals, and power. Similar to today’s petroleum refineries, which produce a variety of fuels and products from petroleum, this concept is not only relevant but essential across numerous contexts. As we look to the future, we will take a decisive and progressive approach to transform significant sectors of the global economy and industry into a sustainable biobased community that champions environmental responsibility. We are committed to making this vision a reality, and we will succeed in driving this change forward. This will be built on the foundation of bioenergy, biofuels, and biobased products, with biorefineries serving as the backbone. Hence, biological and chemical processes will have to be established in order to replace oil with biomass in today’s production processes of commodities [189,190].

4.1. Biomass vs. Fossils as Source Raw Materials

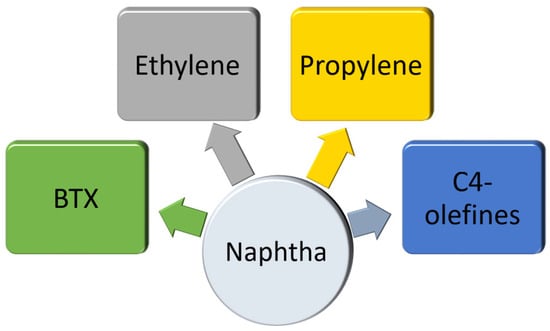

Crude oil consists of a variety of organic hydrocarbon compounds, and the initial refining stage involves eliminating impurities and water. The next step is the distillation process, which separates crude oil into multiple fractions like diesel fuel, gasoline, kerosene, lubricating oils, and asphalts. Afterward, these fractions can undergo chemical transformations to produce a variety of industrial platform chemicals (Figure 1) and end products. Biomass composition differs from petroleum as it is not uniform and consists of a blend of carbon, hydrogen, and oxygen alongside minor components like nitrogen, sulfur, and mineral compounds. It is worth noting that biorefineries that use biomass feedstocks require a more diverse set of processing technologies. However, they are capable of producing a wider variety of products than petroleum refineries and can utilize a broader range of raw materials [191,192]. Naphtha, sourced from crude oil, serves as a raw material that is transformed into a limited number of platform chemicals. These chemicals are then utilized to produce a vast array of bulk chemicals. The critical property of naphtha feedstock is that it contains very little oxygen content, distinguishing it from biomass. As illustrated in Figure 4, a wide range of bulk chemicals can be made using only a handful of platform chemicals, namely, ethylene, propylene, C4-olefins (including butadiene, 1-butene, 2-butene, and isobutene), as well as the aromatics benzene, toluene, and xylene, commonly known as BTX. These platform chemicals containing hydrogen and carbon are utilized as solvents (such as toluene and benzene), as the starting materials for polymers (like ethylene, propylene, and butadiene), or are modified through the addition of elements such as nitrogen, oxygen, or chlorine [193,194,195,196].

Figure 4.

Schematic of major platform chemicals produced from naphtha at petroleum refineries. Naphtha, as an intermediate hydrocarbon derived from refined crude oil and feedstock, is used for the production of hydrogen, ethylene, propylene, C4-olefins including butadiene, 1-butene, 2-butene, and isobutene; BTX, including aromatics benzene, toluene, and xylene.

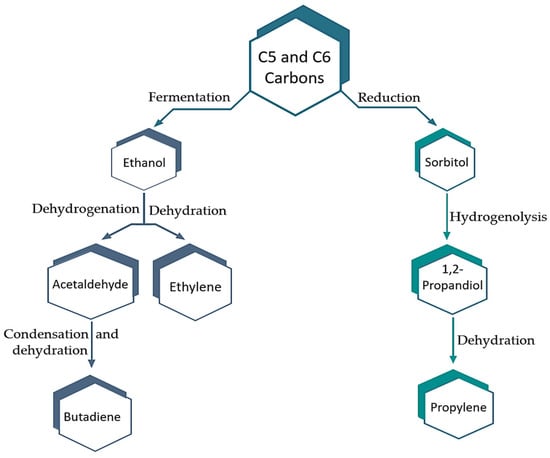

It is forecasted that the biorefinery sector will create several platform chemicals that can be tapped to produce other commodities and bulk chemicals, thereby reducing environmental impact and cutting down on capital expenses (Figure 5 and Figure 6). The manufacture of many C1–C4 chemicals can be accomplished with renewable resources like starch, cellulose, or carbohydrates. In this case, Figure 6 presents some of the chemicals produced by microorganisms as a result of carbohydrate fermentation [197]. An important consideration in the production of biochemical products is the carbohydrate fraction of biomass feedstock, specifically the cellulose and hemicellulose found in lignocellulosic biomass. It is anticipated that this renewable carbon source will have a significant impact on this process. Biomass polysaccharides can be efficiently hydrolyzed into monosaccharides such as glucose, fructose, and xylose. These can be further turned into a variety of bio-platform molecules (bPMs) through fermentation or chemical synthesis. These bio-platform molecules serve as building blocks for numerous value-added chemicals and are similar to the petro-platform molecules found in present-day oil refineries. Also, bPMs have a strikingly higher oxygen content in comparison to platform molecules obtained from oil, such as ethylene and benzene. This will result in an intriguing shift in the chemistry field, where reduction chemistry is becoming more prevalent in comparison to environmentally damaging oxidation procedures. For instance, hydrogen gas is being used with a heterogeneous catalyst, resulting in a greener approach. One example of how one of these biobased platform chemicals can be used is Levulinic acid (C5H8O3), which is produced through the acid hydrolysis of C6 sugars. Due to its high reactivity, it can be transformed into plenty of chemical derivatives. This is possible because it possesses both a ketone carbonyl group and an acidic carboxyl group, allowing it to react as both a ketone and a fatty acid. To begin, cellulose undergoes hydrolysis to produce C6 sugars. Next, HMF is used to obtain levulinic acid efficiently at a 50% rate. Finally, the resulting levulinic acid is converted into either chemicals or fuel additives as desired (Figure 5 and Figure 6) [198,199,200,201,202,203,204,205,206].

Figure 5.

Significant petrochemical platform chemicals are produced from lignocellulosic biomass feedstock [200].

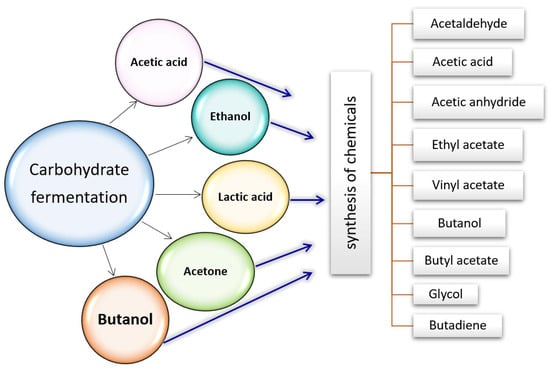

Figure 6.

Some chemicals are derived from carbohydrate fermentation by microorganisms. Ethanol is produced by fermentation of a sugar source (e.g., glucose (C6H12O6)), where one glucose molecule is degraded to two molecules of carbon dioxide and two molecules of ethanol. Ethanol is then converted to acetic acid through the loss of one carbon in the form of CO2 in the glucose–ethanol fermentation. Isomerization of glucose to fructose, the retro-aldol fragmentation of fructose to C3 intermediates, results in lactic acid production. In the side fermentation steps, acetone and butanol are obtained as well. Ultimately, each one of these starting materials is used for the production of other conventional industrial compounds. Lactic acid is a carboxylic acid widely found in nature. It can be converted into various compounds like acetaldehyde, acrylic acid, propanoic acid, 2,3-pentanedione, and dilactide due to its biofunctionality. Ethylene and acetaldehyde can be produced through the fermentation of ethanol. In India, over 20 companies are producing not only ethanol from sugar cane or molasses but also chemicals, such as acetic acid, acetic anhydride, and ethyl acetate, through ethanol fermentation. Vinyl acetate monomer (VAM) is a crucial component in the production of poly(vinyl acetate), which is widely used in the polymer industry for making resins and lattices. This makes VAM a valuable product in the market. To obtain esters such as ethyl acetate and butyl acetate, they are often synthesized from their products, namely ethanol, butanol, and acetic acid. n-butanol, on the other hand, is utilized as a solvent and intermediate for producing acrylates, ethers, and butyl acetate.

4.2. Algal Biorefinery

Marine algae biorefinery provides an eco-friendly way to utilize algae resources for a range of products, including various energy products, platform chemicals, and high-value products [207,208,209]. Indeed, after the extraction of biomolecules (such as bioactive compounds, proteins, gel polymeric materials, and pigments) from the cellulose-rich fraction, the remaining material can be processed into monomeric sugars for fermentation into various products. In recent decades, researchers have been working to reduce the world’s reliance on petrochemicals and petrol fuels. This has led to the development of many bioprocesses that focus on producing biofuels from both marine and freshwater algae. Some species, such as Botryococcus braunii, Nannochloropsis sp., and Schizochytrium sp., have been found to contain more than 700 kg of oil per ton of dry biomass [207,210,211].

Microalgae are considered a potentially important feedstock for a wide range of bio-based products, including biofuels, specialty chemicals, pharmaceuticals, cosmetics, and food products. Algal biomass is being studied worldwide as a sustainable source of simple sugars for bioethanol fermentation [212,213,214]. Carbohydrates obtained from both marine micro- and macroalgae can be used for the production of a variety of biochemicals and biomaterials (Figure 5 and Figure 6). The amount of carbohydrates present in microalgae varies widely from species to species [215]. Microalgae contain abundant amounts of two polysaccharides: cellulose and starch [208]. When broken down into their constituent sugars, glucose is the primary monosaccharide found in microalgae, comprising between 21% and 87% of the total carbohydrate content [216,217,218]. These polysaccharides offer a wide range of properties and potential applications, including biomedical and nutraceutical uses, as well as anti-adhesive, bioflocculant, and drag-reducing properties for ship engineering [219,220]. Compared to terrestrial plants, macroalgae have a major advantage for biorefinery purposes because they lack lignin. This simplifies carbohydrate extraction and saccharification, enabling them to be ideal for use in biotechnology processes ranging from biofuels to biochemicals, building blocks, and biomaterials. Additionally, marine plants such as algae have a high content of easily degradable carbohydrates (25–60% dw) and do not require arable land for growth, making them an attractive renewable feedstock. They grow in seawater, which means they do not compete with terrestrial food crops. Furthermore, the production yields of algae per unit area are higher because they are highly photosynthetic [221]. In summary, seaweeds have the ability to absorb CO2, have a rich carbohydrate content, and lack lignin, thus granting the potential for producing biofuels, biochemicals, and bioproducts [209].

Carbohydrate Bioconversion in Marine Algae

The conversion of carbohydrates from algae can play a significant role in the production of organic chemicals. Specific microbes can ferment sugars obtained from algae to produce commodity chemicals. In 2004, the US Department of Energy (DOE) recognized the potential of biorefinery carbohydrates and declared that a range of building block chemicals could be produced from them through chemical or biological conversion (Figure 5 and Figure 6) [222].

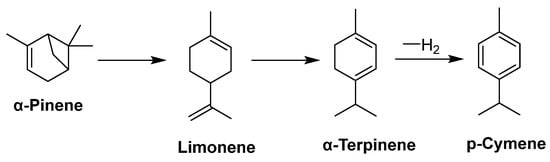

5. Monoterpenes

Monoterpenes (M-terpenes) belong to the terpenes family. Terpenes are a large class of natural products (NPs) produced by both terrestrial and marine organisms. This class of compounds is composed of isoprene units (C5H8) and encompasses innumerable molecules with a variety of structures [223]. Monoterpenes are composed of two linked isoprene units with the molecular formula C10H16 in a fully saturated form. They can be classified into three different subgroups: acyclic (geraniol, linalool, and myrcene), monocyclic (α-terpineol and terpinolene), and bicyclic (α-Pinene, thujone, camphor, and fenchone). These subgroups are further classified as follows: unsaturated hydrocarbons (limonene), alcohols (menthol), aldehydes and ketones (myrtenal, carvone), lactones (iridoids are monoterpene lactones, such as nepetalactone), and tropolones (γ-thujaplicin). Monoterpenes, which contain oxygen-containing functional groups, are also called monoterpenoids. The oxidation and cyclization of these compounds can occur in various ways. In many cases, these substances are found as secondary metabolites because they have such a low molecular weight [224]. In animals, a large percentage of monoterpenes are generally chiral and obtained through enzyme-controlled pathways; their chiral centers are denoted by the R* S* notations (even though chiral natural monoterpene cannot be structurally determined until their stereochemistry is known, the relative stereochemistry of those monocyclic and acyclic monoterpenes is well characterized) [225]. From the viewpoint of biogenesis, M-terpenes are produced by biosynthesis from units of isopentenyl pyrophosphate, which is synthesized from Acetyl-CoA through mevalonic acid in the HMG-CoA reductase pathway. Terpenes of this type are functionalized by molecular oxygen in many aerobic microorganisms. Model organisms such as Pseudomonas and Rhodococcus have been developed for the elucidation of pathways in aerobic bacteria. Microbial cultures have been reported to undergo numerous monoterpene transformations over the last decades, but the biochemical pathways have rarely been described. They have applications in pharmaceuticals, cosmetics, agriculture, food, and biochemistry [226,227,228,229]. Monoterpenes are widely investigated in terrestrial plants, but significantly fewer studies address the marine M-terpenes. Due to the lack of research on monoterpenes derived from marine organisms, structural variations, biosynthetic pathways, and their applications in various industries will be discussed in detail in the next section, and in particular in this review.

5.1. Marine Source Monoterpenes

Marine monoterpenes have shown unprecedented structures compared to their terrestrial counterparts in terms of halogenation and the arrangement of functional groups. These terpenes are produced by a broad range of marine organisms, such as fungi and bacteria [228,230,231,232]. Also, many invertebrates, such as mollusks [233], sponges [234,235], corals [231,236,237,238], ascidians [239,240], etc., have presented terpenes compounds in their secondary metabolites. In particular, over 101 marine monoterpenes have been reported thus far. As mentioned above, a large number of monoterpenes in marine organisms have undergone halogenation; terrestrial organisms do not appear to generate halogenated monoterpenes, and if they occur, they are rare relative to their marine counterparts. These halogen substituents indicate that marine and terrestrial M-terpenes differ significantly. The high chloride (1.99 × 107 µg L−1) and bromide (6.8 × 104 µg L−1) concentrations found in seawater can explain this, as terrestrial environments do not provide similar concentrations of halide ions. Seawater contains many times greater quantities of these ions than the terrestrial environment [225]. Another difference is that most monocyclic monoterpenes that are not halogenated are believed to form as a result of carbonium ion-induced cyclization; halonium ion-induced cyclizations, on the other hand, represent a novel ring-formation mechanism used by marine organisms. In an analogous biosynthetic event, plocamene monocyclics, which are unique carbon frameworks without terrestrial counterparts [225], might be generated. In terms of structural variation, it is estimated that more than 50% of the molecular weight of regular monoterpenoids (here called isoprene dimers) is halogenated. There is a surprising difference between marine sesquiterpenes and diterpenes, with monoterpenes in that only less than 30% of monoterpenes are oxygenated. It is possible to differentiate isoprene dimers (regular monoterpenoids) into four leading structural types (carbon frameworks), namely linear head-to-tail types (type A) and distinguished monocyclic types (types B, C, D). The acyclic compounds could be further subdivided into four groups: monoenes, dienes, trienes, and myrcenes; however, we could not find any evidence of terrestrial counterparts with monocyclic carbon skeletons (C) or (D).

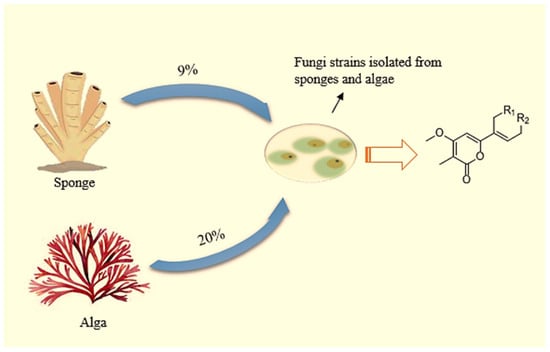

Through biogenesis observations, it has been found that Pseudomonas sp., Aspergillus sp., and Penicillium sp. are responsible for producing these compounds, which are associated with their sponge host. As a result of investigations, 11% of the terpenes derived from marine fungal strains are monoterpenes. Additionally, it has been found that 20% of the fungal strains whose terpene compounds are produced from algae, and 9% are isolated from sponges (as symbionts) (Figure 7) [230].

Figure 7.

A large percentage of monoterpenes are derived from microbial symbionts (e.g., fungi) isolated from sponges and algae.

5.2. Fungi

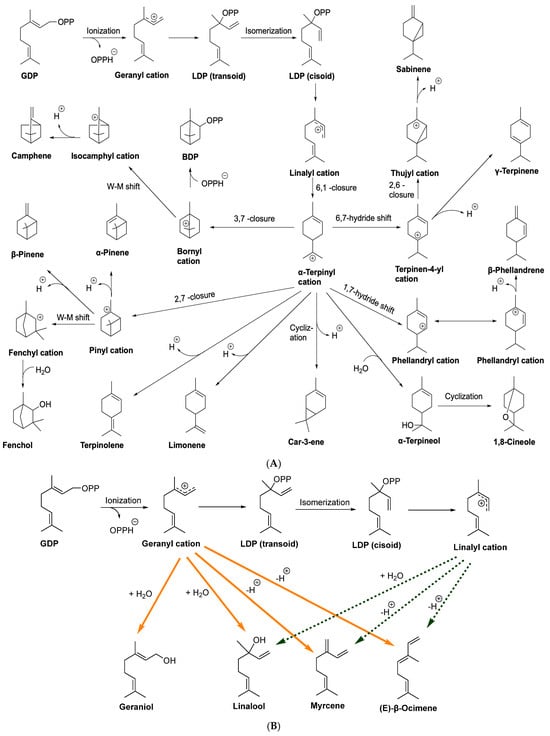

All monoterpene synthases initiate their carbocationic reaction by ionizing the substrate using divalent metal ions. After cyclizations, hydride shifts, or other rearrangements, the cationic intermediate undergoes a series of rearrangements. This reaction proceeds only until a proton loss or the addition of a nucleophile, and then it is terminated (Figure 8) [241]. Analogs of substrates, inhibitors, intermediates, and native enzymes are used to dissect this mechanism. The process converts approximately one-third of the substrate geranyl diphosphate (GDP) into acyclic products. This reaction occurs by ionizing the extended geranyl cation. Due to the (E)-geometry of the 2,3-double bond of the geranyl cation, the formation of cyclic products is hindered. Nevertheless, the cyclization of the geranyl cation into a six-membered ring is facilitated by the preliminary conversion of the geranyl cation into the tertiary linalyl cation. All cyclic monoterpenes are formed from the cisoid, anti-endo conformer of the linalyl cation, resulting in the cyclic α-terpinyl cation through the electrophilic attack of C1 on the C6–C7 double bond. Terpene synthase-mediated Wagner–Meerwein rearrangements are believed to form two other bicyclic monoterpene skeletons. In the case of terpene synthase, for instance, cyclizations, hydride shifts, or rearrangements could be performed in order to convert a single carbocation into a mixture of others [241].

Figure 8.

The general summary of monoterpene synthase reactions to synthesize cyclic monoterpenes (A) and acyclic monoterpenes (B). GDP: geranyldiphosphate; LDP: linalyldiphosphate; BDP: bornyldiphosphate.

5.3. Algae

Cyclic and halogenated monoterpenes are among the most active compounds from this class (largely α-Pinene) [242,243,244,245,246,247,248]. A large portion of these compounds was found in marine algae, and they were synthesized mostly as a chemical defense against herbivores [249]. Macroalgae, which consist of red, Rhodophyta; brown, Phaeophyta; and green, Chlorophyta phyla, and microalgae, which consist of diatoms and cyanobacteria, provide a comprehensive list here are photosynthesizing organisms that sequester CO2 and biosynthesize isoprene and numerous monoterpenes. Marine monoterpenes are synthesized from terrestrial terpene precursors that are speculated to be associated with biological and low-temperature chemical formation mechanisms [250]. As a result, complex cyclic (ring-containing) or acyclic (linear) monoterpenes with unique ring structures (Figure 9) are commonly found in marine organisms that do not exist in terrestrial plants. Monoterpenes are found in marine macroalgae in abundant yields and have been widely observed to possess seasonal and geographical variations. In seawater, bromine and chlorine ions play an important role in the formation of halogenated monoterpenes, which are produced by bromoperoxidase abundant in many red algae [251]. Marine terpenoids differ from their terrestrial counterparts due to the halogen substituents. Investigations showed that red seaweed enzymes produce a variety of halogenated hydrocarbons and ketones during bromide ion addition. Nevertheless, the halogenated monoterpenes’ structures disclosed new patterns in which many compounds contained either only chlorine or a large proportion of chlorine in comparison with bromine [225]. Several of these compounds have been detected in red algae, such as Plocamium, Ochtodes, and Portieria [225,252]. Additionally, brown algae of the genus Dictyopteris contain monoterpenes but are much less concentrated than red algae [248]. Monoterpenes are biosynthesized via mevalonate (MVA) and/or methylerythritol phosphate (MEP) pathways (often involving haloperoxidase action). During the first step, building blocks such as all isopentenyl pyrophosphate (IPP), isoprenoids (considered as active isoprenes), and dimethylallyl pyrophosphate (DMAPP) are formed. In the cytosol, the MVA pathway begins with the condensation of three molecules of acetyl-CoA, followed by enzymatic conversions to produce isopentenyl pyrophosphate. Mevalonate kinase phosphorylates mevalonate as the main reaction in the formation of isopentenyl pyrophosphate (six different enzymes involved), while dimethylallyl pyrophosphate is generated from isopentenyl pyrophosphate by the seventh enzyme methylerythritol phosphate pathway (also referred to as deoxyxylulose-5-phosphate (DXP) pathway) initiates with the reaction between glyceraldehyde-3-phosphate (G3P) and pyruvate [253,254]. In addition to producing isopentenyl pyrophosphate, it can also produce dimethylallyl pyrophosphate because of the presence of the enzyme 4-hydroxy-3-methylbut-2-enyl diphosphate reductase (HDR) [254,255]. A monoterpene precursor, geranyl pyrophosphate (GPP), is formed when isopentenyl pyrophosphate is isomerized to dimethylallyl pyrophosphate [256]. The algae cells can follow each of these pathways. The methylerythritol phosphate pathway is present only in green algae, whereas several red algae can have either both methylerythritol phosphate pathways or only one. In regard to the biosynthesis of cyclic monoterpenes, as mentioned before, geranyl pyrophosphate is converted into the tertiary allylic isomer, linalyl pyrophosphate (LPP), through enzyme-catalyzed cyclization. A key step in this mechanism occurs when the divalent cation helps ionize the pyrophosphate group, allowing rotation around new single bonds and the generation of the highly reactive cyclic α-terpinyl cation (as an intermediate). As a result of several mechanisms such as oxidation, reduction, isomerization, or conjugation, the α-terpinyl cation intermediate will give rise to a wide range of monoterpene cyclic and bicyclic carbon skeletons [257,258]. In a study by Wise et al. (2002), neryl pyrophosphate (NPP), cis-isomer of geranyl pyrophosphate, and linalyl pyrophosphate were evaluated as alternative monoterpene substrates [258]. They found that by using neryl pyrophosphate and linalyl pyrophosphate as substrates, myrcene synthase formed cyclic structures that led to different product profiles. From neryl pyrophosphate, limonene was produced, while from linalyl pyrophosphate, myrcene, cis-ocimene, terpinene, and limonene were produced. Despite its capability to cyclize neryl pyrophosphate and LP, the enzyme is unable to cyclize the isomerization of geranyl pyrophosphate to the cyclization intermediate. It is worth noting that in macroalgae, the formation of acyclic monoterpenes with bromine or chlorine atoms or both is likely to be formed by haloperoxidase acting on either myrcene or ocimene [251,259]. Furthermore, as a result of electrophilic substitution with Cl, Br, and I, chloroperoxidase oxidizes and incorporates these molecules into the substrate [225]. In marine monoterpenes, the ochtodane ring (l-ethylidene-3,3-dimethylcyclohexane) may be created by bromonium ion-initiated cyclization from myrcene [260]. In this way, the C6–C7 olefin ring is closed first by bromination, and then an internal addition is made to the resulting cationic center. In a similar manner, 1,3-dimethyl-l-vinylcyclohexane ring and 2,4-dimethyl-1-vinylcyclohexane ring are precursors to ocimene. Multiple halogen substitutions in the monoterpenes were obtained from red algae, as discussed previously [225]. A mono- or dihalogenated myrcene derivative can be produced by turning geranyl pyrophosphate into myrcene using myrcene synthase. The myrcene derivative is then halogenated with haloperoxidases [261]. Halogenated cyclic compounds can be built from myrcene and ocimene as immediate precursors. Myrcene is a common precursor of halogenated monoterpenes in species from Portieria and Ochtodes, whereas ocimene is in macroalgae of the genus Plocamium (i.e., from Rhizophyllidaceae family, solely halogenated myrcene derivatives were isolated, whereas Plocamiaceae family just contains halogenated ocimene derivatives). Nevertheless, these halogenated substances are not only biologically synthesized by myrcene; enzyme cofactors play a crucial role in their production, and a certain set of enzyme cofactors is required to produce these compounds. The profound fact is that myrcene or ocimene can be directly yielded by HOPP loss from geranyl pyrophosphate [225].

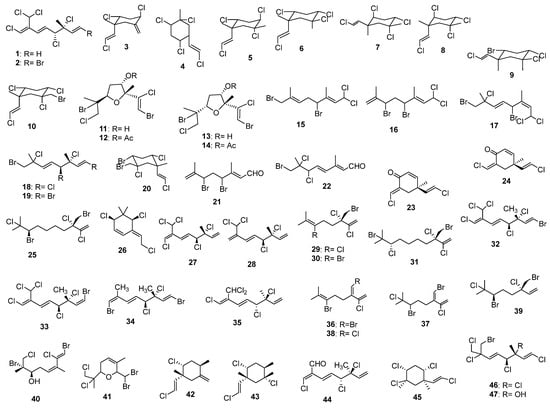

Figure 9.

Algal (a)cyclic monoterpenes 1–77.

5.4. Emission Rates of Isoprenes and Monoterpenes from Marine Photosynthetic Organisms

Isoprene, as mentioned earlier, is a crucial building block precursor for monoterpenes. It is the most common trace gas and is labeled as a biogenic volatile organic compound (BVOC) that has a role in protecting the ozone and atmospheric gases like methane and carbon monoxide [262]. Although isoprene is an important volatile organic compound, it also serves as a precursor to climate change via oxidative chemistry and secondary organic aerosol (SOA) formation [250,263]. Isoprene and monoterpenes emitted by macroalgae and microalgae, such as phytoplankton, are considered “oceanic emissions” due to their contribution as drivers of secondary organic aerosols. These are believed to affect the microphysical and radiational balance of the atmosphere via increasing CO2 and methane concentrations [250,262]. One study investigating marine aerosol production found that the red macroalga, Ochtodes secundiramea, produced the following monoterpene emissions in culture: myrcene, 32.6%; and (E)-10-bromomyrcene, 33.2% [250,258]. In another study, phytoplankton monoculture experiments revealed that marine gas-phase isoprene is produced at a greater scale than monoterpenes emissions. Specifically, during a phytoplankton bloom, the highest observed volatile organic compound emissions were measured at 375 ppt for isoprene but only 125 ppt for monoterpenes [250,264]. Similar laboratory monoculture studies have demonstrated that phytoplankton produce isoprene and monoterpenes, which have emission production rates that are dependent on speciation and environmental factors, such as water temperature, nutrients, and solar radiation [262,264]. Table 2 summarizes isoprene and monoterpene emissions from phytoplankton and other microalgae, which is important as a starting point for assessing their contributions to sustainable platform chemicals.

Many terrestrial monoterpenes are extracted via energy-intensive distillation methods that are nonrenewable and unsustainable in terms of resource consumption and by-product pollution, i.e., CO2. Marine photosynthetic organisms, specifically microalgae and macroalgae, offer an opportunity to utilize prevalent and existing emissions on an industrial scale. The production of marine photosynthetically produced isoprene and monoterpenes only requires CO2 and sunlight, unlike the cultivation of heterotrophic microsymbionts, which are often dependent on exogenous carbohydrate feedstocks [265]. Terrestrial-sourced monoterpenes, such as limonene and pinene extracted from citrus rinds and gum turpentine, can be substituted for marine-sourced monoterpenes (limonene and pinene from photosynthesizing microalgae, Table 2) that are naturally emitted into the environment. A large-scale transition away from the terrestrial production of isoprene and monoterpenes into an algal culture or capture of secondary organic aerosol-driving oceanic emissions will be crucial for combating climate change.

Table 2.

Isoprene and monoterpene emissions produced by macroalgae.

Table 2.

Isoprene and monoterpene emissions produced by macroalgae.

| Compound(s) | Species | Emission Rate | References |

|---|---|---|---|

| Limonene (cyclic monoterpene) | Nereocystis luetkeana, Alaria marginata (Brown algae) | ∼2.1 ppbV and 1.8 ppbV | [266] |

| Isoprene | Laminaria digitata, Ascophylum nodosum, Pelvetia canaliculata, Fucus vesiculosus, Fucus serratus, Halidrys siliquosa, Laminaria saccharina (Brown algae); Chondrus Crispis (Red alga); Asparagopsis armata (Red alga); Ulva intestinalis (Green alga) | 0.3–1.4 pmolesg−1 dry weighthr−1 3.5–5.3 pmolesg−1 dry weighthr−1 | [93,262,267] |

| Myrcene (E)-10-bromomyrcene (short-chained monoterpenes) | Ochtodes secundiramea (Red macroalga) | Myrcene- 32.6% (E)-10-bromomyrcene 33.2%* | [250,258] |

| Monoterpenes—N/A | Chaetoceros neogracilis, Chaetoceros debilis, Phaeodactylum tricornutum, Skeletonema costatum, Fragilariopsis kerguuellensis (Diatoms); Emiliania huxleyi (Coccolithophore); Trichodesmium sp., Synechococcus sp. (Cyanobacteria) | 0.3–68 nmol g [chlorophyll a]−1 day−1) | [250] |

| (–)-/(+)-pinene, myrcene, (+)-camphene, (–)-sabinene, (+)-3-carene, (–)-pinene, (–)-limonene, and p-ocimene (37% of total monoterpenes emitted) | Dunaliella tertiolecta (Green alga) | 226 nmol g [chlorophyll a]−1 day−1) | [250] |

| Isoprene | Phaeodactylum tricornutum, Chaetoceros neogracilis (Diatoms); Calcidiscus leptoporus, Emiliania huxleyi (Coccolithophores:); Dunaliella tertiolecta (Green alga | 2.8–28.5 pmol L−1-Chl a−1 (biomass-normalized concentration for C. neogracilis) | [250,262,268] |

| Isoprene | Prochlorococcus, Synechococcus (Cyanobacteria); Micromonas pusilla (Green alga); Pelagomonas calceolata (Flagellate); Emiliania huxleyi (Coccolithophore); Skeletonema costatum (Diatom) | 1–1.6 µmolesg−1 Chlday−1 (0.2–3.8 × 10−19 molescell−1 day−1) | [267] |

| Isoprene | Trichodesmium sp. (Cyanobacteria); Haptophytes, diatoms; Prochlorococcus sp. (Cyanobacteria) | 0–22 µmolesg−1 Chlday−1 | [269] |

| Isoprene | Emiliania huxleyi (Coccolithophor); Thalassiosira weissflogii, Thalassiosira pseudonana, Chaetoceros neogracile (Diatoms) | 0–67 µmolesg−1 Chlday−1 | [270] |

| Isoprene | Dunaliella tertiolecta, Phaeodactylum tricornutum, Thalassiosira pseudonana | 1 × 10−18–8.3 × 10−19 molescell−1 day−1 | [271,272] |

| Isoprene | Diatoms, Emiliania huxleyi, other coccolithophores, and other dinoflagellates | 0–6 × 109 moleculescm-2 sec−1 0.32 TgCyr−1 bottom-up; 11.6 TgCyr−1 top-down | [93,267,269,273,274,275,276,277,278,279,280,281] |

| α-Pinene | Diatoms | 0.013 bottom-up; 29.5 top-down | [281] |

Unit legend: parts per billion (ppb); by volume (V); nanomole (nmol) picomole (pmol); total ion current (TIC); %* as a percentage of TIC in the GC-MS trace; phytoplankton biomass—chlorophyll a (Chl a); biomass normalized concentration- picomol per liter of chlorophyll a (lpmol L−1 Chl a−1); “bottom-up” (sea to-air emission flux measurements); “top-down” (emission source estimate based on simul tion and observation data); tetragrams of carbon per year (TgCyr−1); N/A: not available.

6. Materials Processes of Marine Monoterpenes

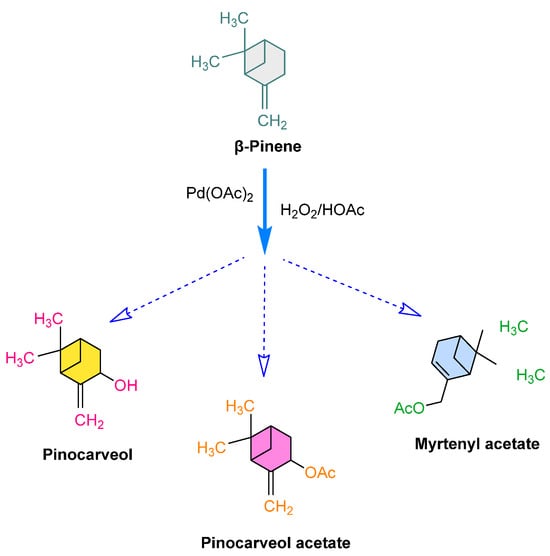

6.1. Biotransformation of Marine Monoterpenes to Produce Biobased-Platform Chemicals

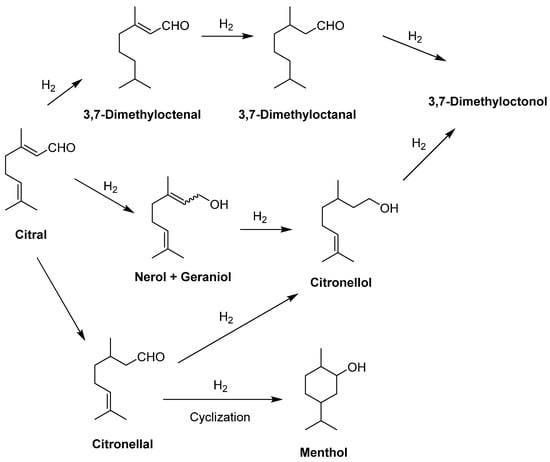

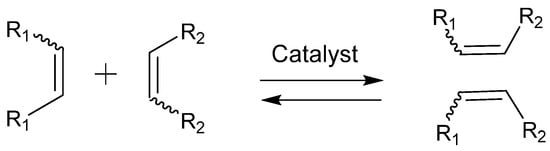

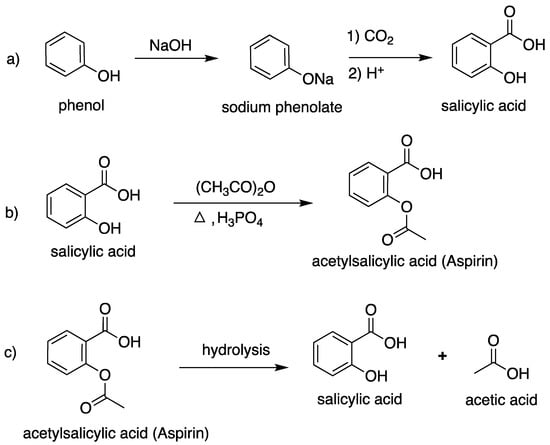

Terpenes such as monoterpenes have chiral centers and diverse functional groups, including olefin, hydroxyl, carboxylic, and carbonyl groups, making them versatile for conversion into various useful fine and bulk chemicals, including flavors, fragrances, solvents, pesticides, pharmaceuticals, and chiral intermediates that possess unique properties. Monoterpene conversion is a valuable process that can yield established industrial building blocks and fine products. Different catalysts and conditions can be employed to achieve the desired properties of the final product based on the terpene feedstock utilized, depending on the specific requirements. M-terpenes can be isomerized and transformed into various terpenoids and chemicals using either homogeneous catalysts (in the same phase) or heterogeneous catalysts (in a separate phase). These catalytic processes can also produce a range of different materials [282,283]. The use of monoterpenes as starting materials for the biotechnological production of natural chemicals has proven to be valuable across various industries. Therefore, the bioconversion of terpenes is of significant importance. Due to their structures, several monoterpenes have gained immense popularity in the industry, such as geraniol, nerol, citral, and limonene derivatives. They are biosynthesized or biotransformed by marine microorganisms. For example, the fungus Penicillium sp. has the ability to transform geraniol, nerol, a mixture of both called citrol, and a mixture of aldehydes known as citral, into 6-methyl-5-hepten-2-one. Citral is an aroma monoterpene that plays a key role in the perfumery industry. It is a cost-effective compound that is frequently used in the synthesis of menthol enantiomers. The other fascinating aroma compound is called (R)-(+)-limonene. Basidiomycete Pleurotus sapidus is capable of biotransforming this monoterpene, resulting in cis/trans-carveol and carvone production as the primary products (Figure 10).

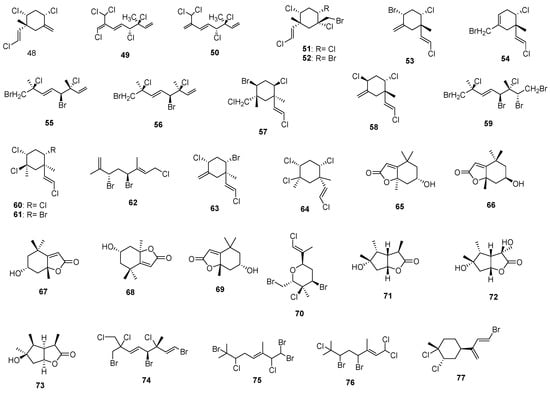

Figure 10.

Biosynthesized monoterpenes are used in various industries, such as the food and perfume industries, as additives used for product smell and taste. Geraniol and neral/nerol derivatives can be found in algae. Limonene is produced from neryl pyrophosphate in algal cells [258,284,285]. Lemon grass’s essential oil contains 75–85% citral, which is produced from geraniol by geraniol dehydrogenase cells [286,287]. Carvone is found in many plant essential oils, such as caraway, spearmint, and dill. However, microorganisms such as Bacillus sp. and their marine counterparts are able to biotransform α- and β-Pinene into carveol and carvone. Also, carvone could be obtained through nitrosochlorination of algal limonene to carvone [228,282].

6.1.1. Homogeneous Catalysts

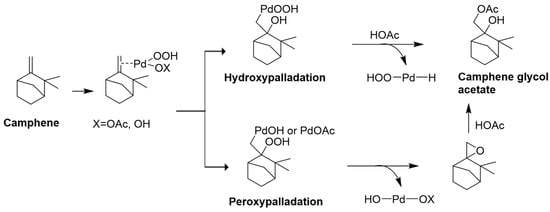

In homogeneous catalysts, palladium (Pd) catalysts are employed for the oxidation (and isomerization) of monoterpenes like α- and β-Pinene and camphene, with hydrogen peroxide serving as the oxidant [288,289]. For instance, β-Pinene, which is a bicyclic monoterpene having an exocyclic alkene, can be transformed into pinocarveol, pinocarveol acetate, and myrtenyl acetate in different proportions based on the reaction conditions (Figure 11).

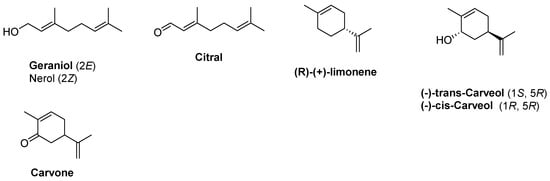

Figure 11.

β-Pinene oxidation in acetic acid solution to produce pinocarveol, pinocarveol acetate, and myrtenyl acetate in the presence of Pd(OAc)2, hydrogen peroxide [288].

Another example is camphene oxidation to camphene glycol acetate in acetic acid, which involves mechanisms such as hydroxypalladation or peroxypalladation with active Pd catalyst species (Figure 12) [283].

Figure 12.

Oxidation of camphene to camphene glycol acetate in acetic acid in the presence of an active palladium catalyst is done with two mechanisms: hydroxypalladation or peroxypalladation.

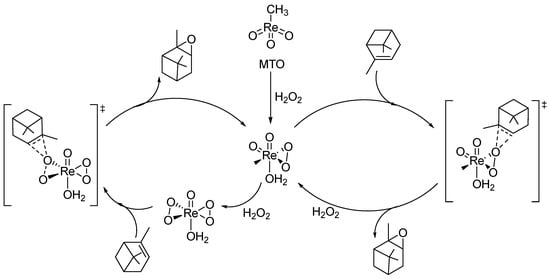

The process of oxidizing monoterpenes is often accomplished through the use of Re catalysts, particularly methyltrioxorhenium (MTO), which is a popular choice for olefin group epoxidation [290,291]. Typically, these reactions are carried out under low temperatures using H2O2 as an oxidant in the presence of a nitrogen base like pyridine (Figure 13). The nitrogen base not only enhances the reaction rate but also helps avoid ring-opening reactions and diol formation and accelerates the stability of the catalyst [292].

Figure 13.

The epoxidation of α-Pinene is effectively carried out using a methyltrioxorhenium (MTO) catalyst in conjunction with H2O2 as the oxidant. Both mono- and bisperoxo catalyst species play a role in this reaction, but the bisperoxo complex is definitely more abundant when excess H2O2 is present.

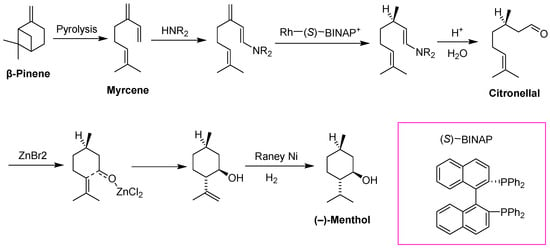

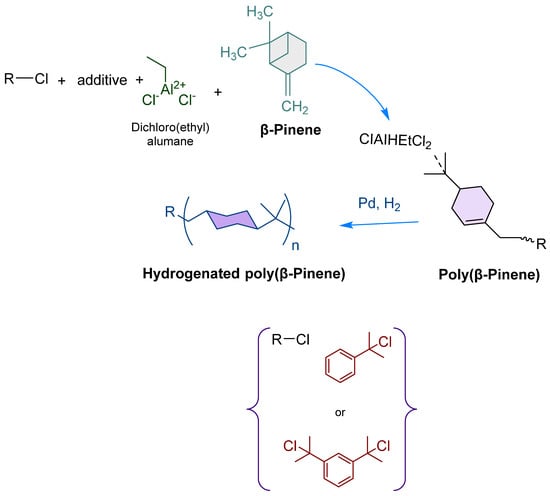

6.1.2. Heterogeneous Catalysts

Another significant process for the production of fine chemicals is the isomerization of olefins found in monoterpenes. Throughout this process, Rh catalysts have been specifically utilized. As an example, myrcene production involves utilizing the pyrolysis of β-Pinene or obtaining myrcene from alternate sources, which is subsequently transformed into geranyldiethylamine through the assistance of a lithium diethyl amide catalyst. In the following step, a Rh(I)–BINAP catalyst (Rh with chelates of either R- or S-2,2′-diphenylphosphino-1,1′-binaphthyl) is tapped to isomerize an alkene, transforming it from allylamine to the (1R,3R,4S) enamine. The enamine is then subjected to hydrolysis (acid) to produce citronellal, with subsequent ring closure catalyzed by ZnCl2 or ZnBr2 (Lewis acid). The remaining alkene is then reduced to yield (−)-menthol (Figure 14) [283].

Figure 14.

(−)-menthol production begins with β-Pinene pyrolysis to myrcene production, according to the Takasago process.