Green Extraction Technologies for Carotenoid Recovery from Citrus Peel: Comparative Study and Encapsulation for Stability Enhancement

Abstract

1. Introduction

- The solvents used are food-grade and biocompatible, eliminating the need for removal and allowing for direct incorporation into bioactive formulations. This simplifies production, reduces energy consumption, and avoids solvent recovery steps. The solvents are composed of edible, Generally Recognized As Safe (GRAS) components, which are already approved by the Food and Drug Administration (FDA) and the European Commission as food colorants or dyes.

- The solvents may be used to create formulations suitable for various industries, including food, pharmaceuticals, and cosmetics, as carriers of natural carotenoids.

- Finally, chickpea protein isolate (CPI) can improve the stability and bioavailability of natural carotenoids in humans. Rich in essential amino acids and possessing excellent emulsifying properties, chickpea protein isolate acts as a protective carrier, preventing carotenoid degradation and enhancing carotenoid absorption. Additionally, its plant-based and sustainable nature makes it an ideal ingredient for functional foods, catering to the growing demand for clean-label and protein-enriched products.

2. Materials and Methods

2.1. Raw Samples

2.2. Cloud Point Extraction (CPE)

2.3. Supramolecular Solvent (SUPRAS)-Based Extraction

2.4. Conventional Water Extraction (CWE)

2.5. Characterization of Citrus Peel Extracts

2.5.1. HPLC Carotenoid Profiling

2.5.2. In Vitro Antioxidant Activity

2.6. Encapsulation of CPE and SUPRAS Citrus Peel Extracts

2.7. Characterization of Citrus Peel Encapsulates

2.7.1. Encapsulation Efficiency (EE)

2.7.2. Color Properties

2.7.3. Morphological Properties

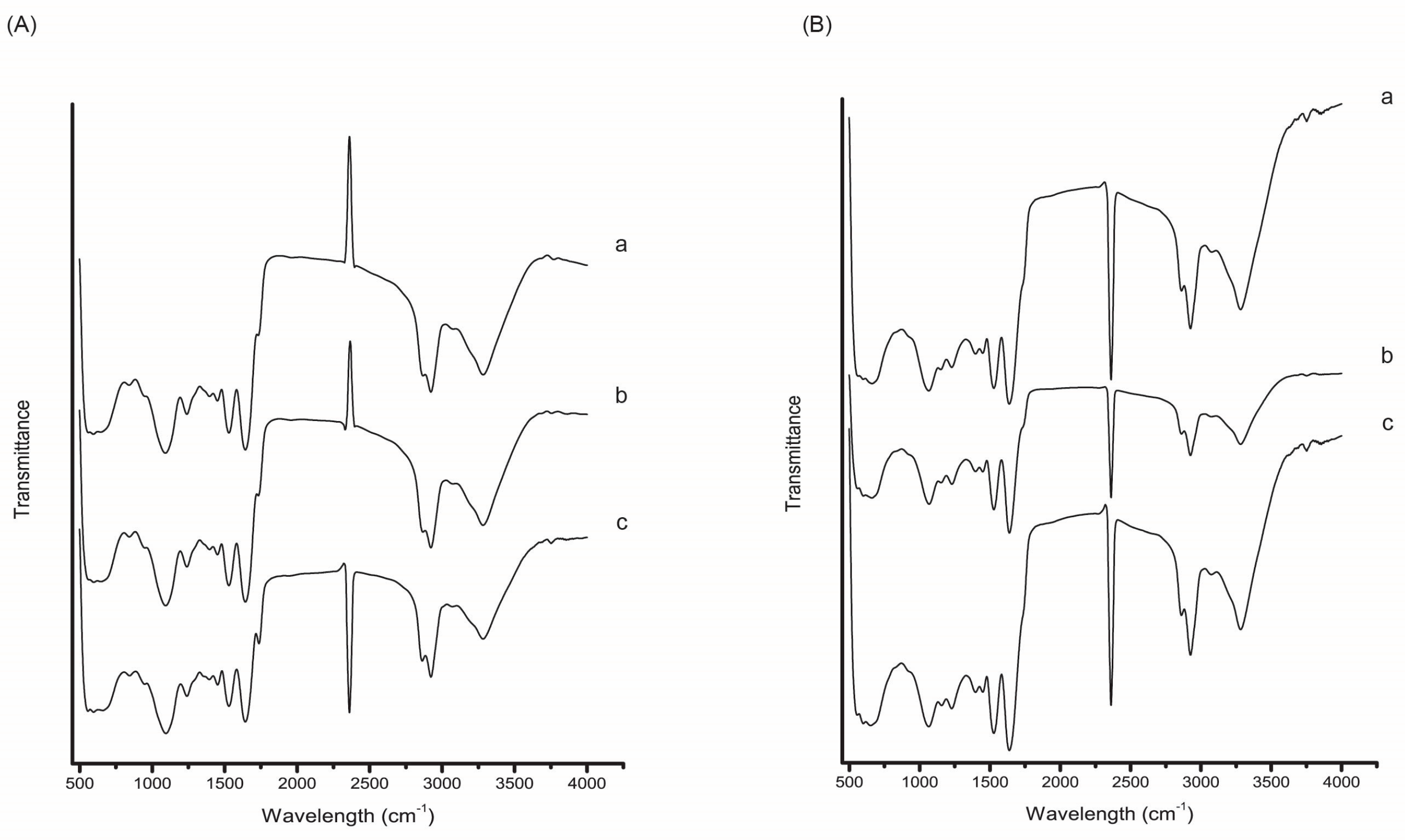

2.7.4. Fourier Transform Infrared Spectroscopy (FTIR) Analysis

2.8. Green Metrics

2.9. Statistical Analysis

3. Results and Discussion

3.1. Characterization of Citrus Peel Extracts

3.1.1. Efficiency of Carotenoid Recovery

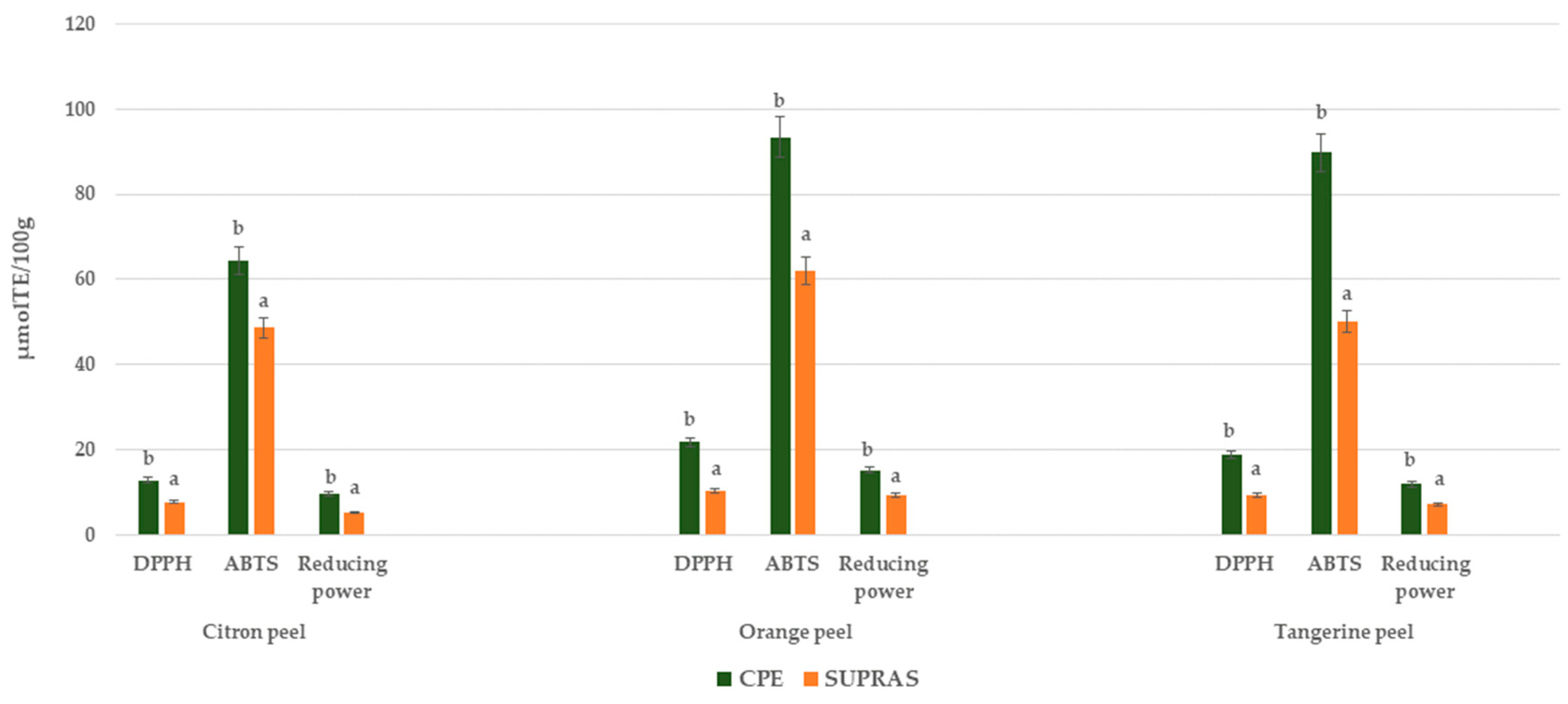

3.1.2. In Vitro Antioxidant Activity

3.2. Characterization of Citrus Peel Encapsulates

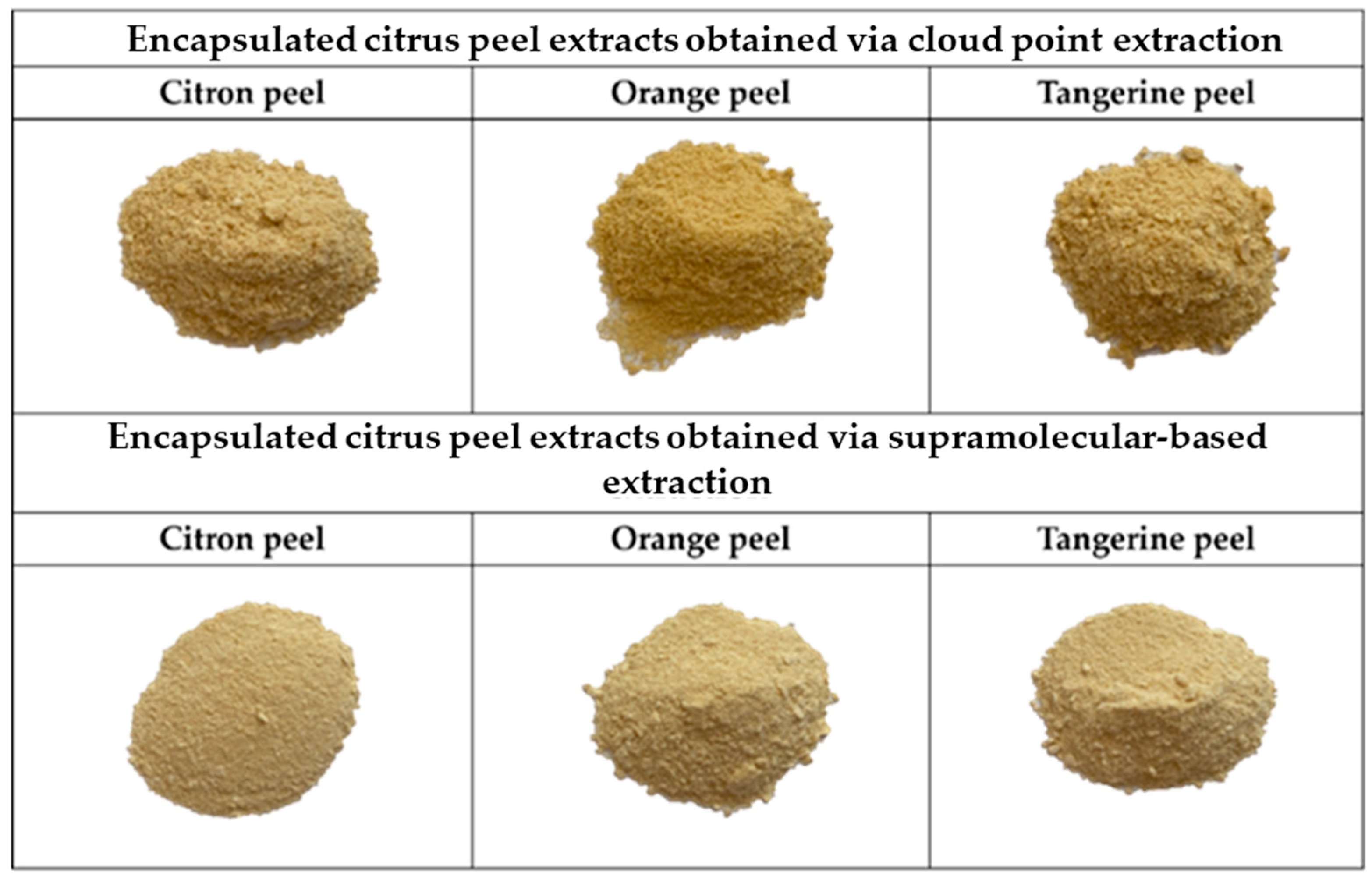

3.2.1. Encapsulation Efficiency and Color Properties

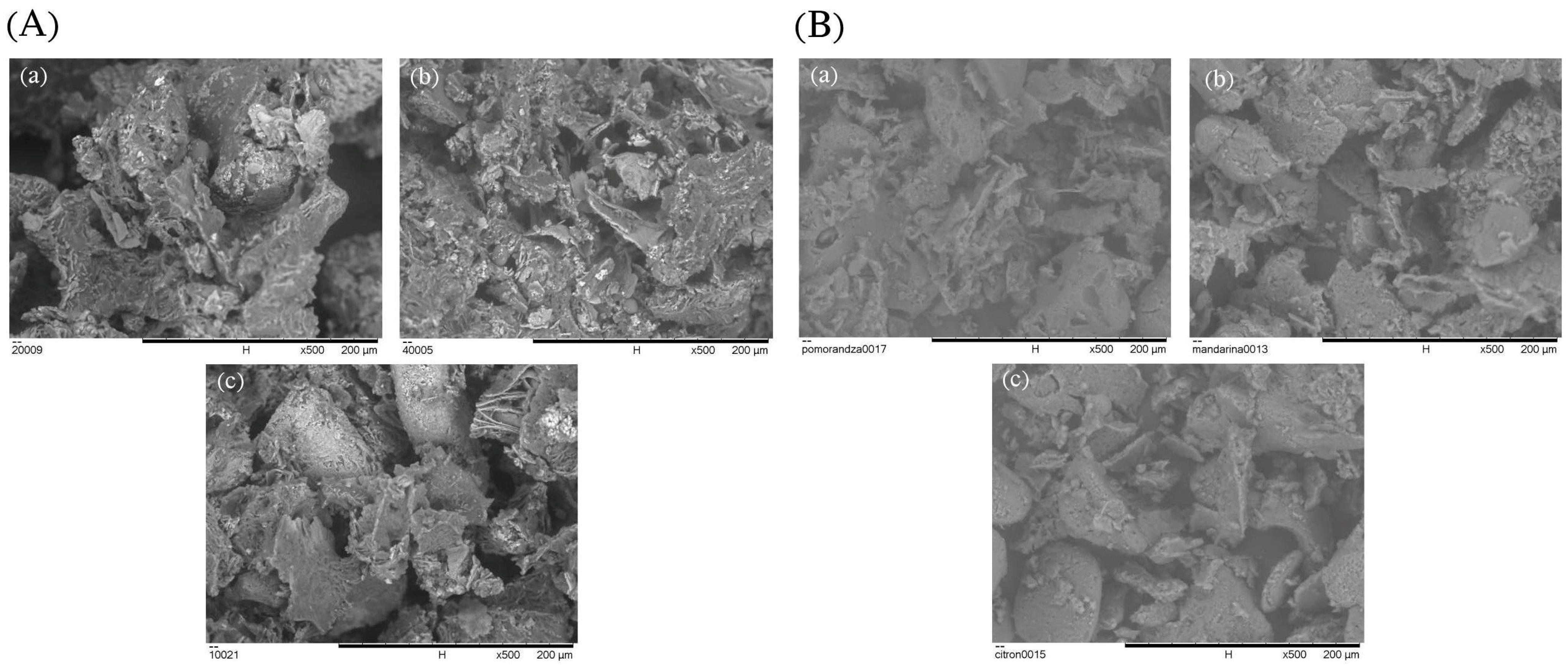

3.2.2. Morphological Properties

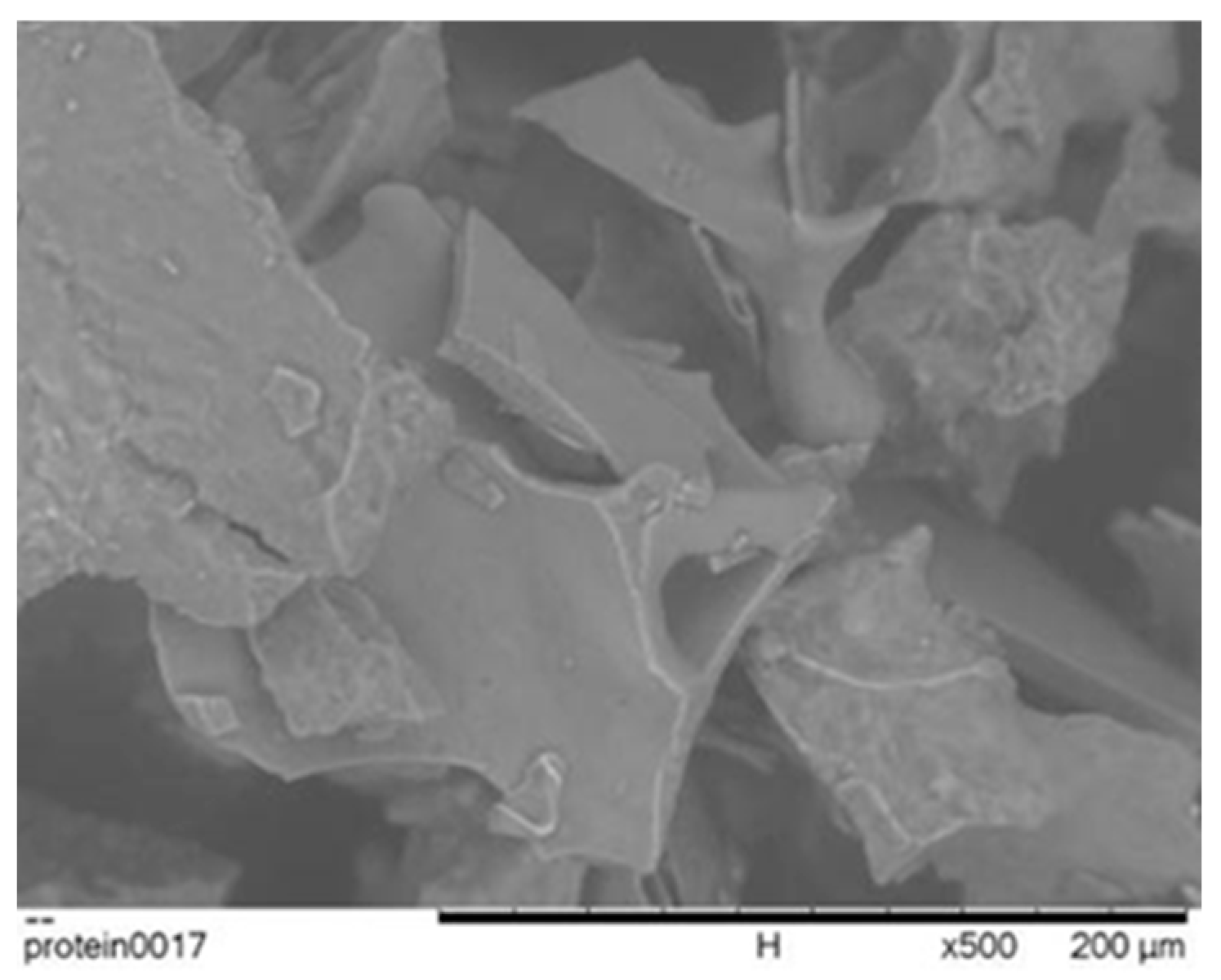

3.2.3. Fourier Transform Infrared Spectroscopy (FTIR) Analysis

3.3. EcoScale

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kato-Noguchi, H.; Kato, M. Pesticidal Activity of Citrus Fruits for the Development of Sustainable Fruit-Processing Waste Management and Agricultural Production. Plants 2025, 14, 754. [Google Scholar] [CrossRef] [PubMed]

- Mahato, N.; Sinha, M.; Sharma, K.; Koteswararao, R.; Cho, M.H. Modern Extraction and Purification Techniques for Obtaining High Purity Food-Grade Bioactive Compounds and Value-Added Co-Products from Citrus Wastes. Foods 2019, 8, 523. [Google Scholar] [CrossRef] [PubMed]

- Zema, D.A.; Calabrò, P.S.; Folino, A.; Tamburino, V.; Zappia, G.; Zimbone, S.M. Valorisation of Citrus Processing Waste: A Review. Waste Manag. 2018, 80, 252–273. [Google Scholar] [CrossRef]

- Ellouze, I. Citrus Bio-Wastes: A Source of Bioactive, Functional Products and Non-Food Uses. In Mediterranean Fruits Bio-Wastes: Chemistry, Functionality and Technological Applications; Ramadan, M.F., Farag, M.A., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 221–260. ISBN 978-3-030-84436-3. [Google Scholar]

- Andrade, M.A.; Barbosa, C.H.; Shah, M.A.; Ahmad, N.; Vilarinho, F.; Khwaldia, K.; Silva, A.S.; Ramos, F. Citrus By-Products: Valuable Source of Bioactive Compounds for Food Applications. Antioxidants 2023, 12, 38. [Google Scholar] [CrossRef] [PubMed]

- Hoe, B.C.; Priyangaa, A.; Nagarajan, J.; Ooi, C.W.; Ramanan, R.N.; Nagendra Prasad, K. Chapter 8—Carotenoids. In Nutraceutical and Functional Food Components, 2nd ed.; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2017; pp. 313–362. ISBN 978-0-323-85052-0. [Google Scholar]

- Šeregelj, V.; Ćetković, G.; Čanadanović-Brunet, J.; Šaponjac, V.T.; Vulić, J.; Lević, S.; Nedović, V.; Brandolini, A.; Hidalgo, A. Encapsulation of Carrot Waste Extract by Freeze and Spray Drying Techniques: An Optimization Study. LWT 2021, 138, 110696. [Google Scholar] [CrossRef]

- Viñas-Ospino, A.; Rita Jesus, A.; Paiva, A.; Esteve, M.J.; Frígola, A.; Blesa, J.; López-Malo, D. Comparison of Green Solvents for the Revalorization of Orange By-Products: Carotenoid Extraction and in Vitro Antioxidant Activity. Food Chem. 2024, 442, 138530. [Google Scholar] [CrossRef]

- Teramukai, K.; Kakui, S.; Beppu, F.; Hosokawa, M.; Miyashita, K. Effective Extraction of Carotenoids from Brown Seaweeds and Vegetable Leaves with Edible Oils. IFSET 2020, 60, 102302. [Google Scholar] [CrossRef]

- de Andrade Lima, M.; Kestekoglou, I.; Charalampopoulos, D.; Chatzifragkou, A. Supercritical Fluid Extraction of Carotenoids from Vegetable Waste Matrices. Molecules 2019, 24, 466. [Google Scholar] [CrossRef]

- Silva, T.P.; Alves, L.; Salgado, F.; Roseiro, J.C.; Łukasik, R.M.; Paixão, S.M. Ionic Liquids toward Enhanced Carotenoid Extraction from Bacterial Biomass. Molecules 2024, 29, 4132. [Google Scholar] [CrossRef]

- Sportiello, L.; Marchesi, E.; Tolve, R.; Favati, F. Green Extraction of Carotenoids from Pumpkin By-Products Using Natural Hydrophobic Deep Eutectic Solvents: Preliminary Insights. Molecules 2025, 30, 548. [Google Scholar] [CrossRef]

- Giovanoudis, I.; Athanasiadis, V.; Chatzimitakos, T.; Gortzi, O.; Nanos, G.D.; Lalas, S.I. Development of a Cloud Point Extraction Technique Based on Lecithin for the Recovery of Carotenoids from Liquid Tomato Wastewater. Waste 2023, 1, 105–114. [Google Scholar] [CrossRef]

- Travičić, V.; Cvanić, T.; Vidovic, S.; Pezo, L.; Hidalgo, A.; Šovljanski, O.; Ćetković, G. Sustainable Recovery of Polyphenols and Carotenoids from Horned Melon Peel via Cloud Point Extraction. Foods 2024, 13, 2863. [Google Scholar] [CrossRef] [PubMed]

- Cvanić, T.; Sulejmanovic, M.; Perovic, M.; Vulić, J.; Pezo, L.; Ćetković, G.; Travičić, V. Novel Green Strategy to Recover Bioactive Compounds with Different Polarities from Horned Melon Peel. Foods 2024, 13, 2880. [Google Scholar] [CrossRef]

- Vieira, F.A.; Ventura, S.P.M. Efficient Extraction of Carotenoids from Sargassum Muticum Using Aqueous Solutions of Tween 20. Mar. Drugs 2019, 17, 310. [Google Scholar] [CrossRef]

- Torres-Valenzuela, L.S.; Ayala-Aponte, A.; Rodriguez, L.; Rodriguez, A.; Navia-Porras, D.P. Supramolecular Solvent Extraction of Bioactive Compounds from Tamarillo (Solanum Betaceum) Byproducts. Discov. Food 2025, 5, 34. [Google Scholar] [CrossRef]

- Ueda, K.M.; Keiser, G.M.; Leal, F.C.; Farias, F.O.; Igarashi-Mafra, L.; Mafra, M.R. A New Single-Step Approach Based on Supramolecular Solvents (SUPRAS) to Extract Bioactive Compounds with Different Polarities from Eugenia Pyriformis Cambess (Uvaia) Pulp. Plant Foods Hum. Nutr. 2024, 79, 242–249. [Google Scholar] [CrossRef]

- Sereti, F.; Alexandri, M.; Papapostolou, H.; Papadaki, A.; Kopsahelis, N. Recent Progress in Carotenoid Encapsulation: Effects on Storage Stability, Bioaccessibility and Bioavailability for Advanced Innovative Food Applications. Food Res. Int. 2025, 203, 115861. [Google Scholar] [CrossRef]

- Ma, D.; Yang, B.; Zhao, J.; Yuan, D.; Li, Q. Advances in Protein-Based Microcapsules and Their Applications: A Review. Int. J. Biol. Macromol. 2024, 263, 129742. [Google Scholar] [CrossRef]

- Vučetić, A.; Pezo, L.; Šovljanski, O.; Vulić, J.; Travičić, V.; Ćetković, G.; Čanadanović-Brunet, J. Supramolecular Solvent-Based Extraction of Microgreens: Taguchi Design Coupled-ANN Multi-Objective Optimization. Processes 2024, 12, 1451. [Google Scholar] [CrossRef]

- Šeregelj, V.; Estivi, L.; Brandolini, A.; Ćetković, G.; Tumbas Šaponjac, V.; Hidalgo, A. Kinetics of Carotenoids Degradation during the Storage of Encapsulated Carrot Waste Extracts. Molecules 2022, 27, 8759. [Google Scholar] [CrossRef]

- Šovljanski, O.; Lončar, B.; Pezo, L.; Saveljić, A.; Tomić, A.; Brunet, S.; Filipović, V.; Filipović, J.; Čanadanović-Brunet, J.; Ćetković, G.; et al. Unlocking the Potential of the ANN Optimization in Sweet Potato Varieties Drying Processes. Foods 2024, 13, 134. [Google Scholar] [CrossRef] [PubMed]

- Perović, M.N.; Antov, M.G. The Influence of Enzymatic Pretreatment of Chickpea on Properties of Protein Nanoparticles Prepared by Heat Treatment. LWT 2022, 163, 113545. [Google Scholar] [CrossRef]

- Barbosa, M.I.M.J.; Borsarelli, C.D.; Mercadante, A.Z. Light Stability of Spray-Dried Bixin Encapsulated with Different Edible Polysaccharide Preparations. Food Res. Int. 2005, 38, 989–994. [Google Scholar] [CrossRef]

- Nagata, M.; Yamashita, I. Simple Method for Simultaneous Determination of Chlorophyll and Carotenoids in Tomato Fruit. J. Food Sci. Technol. 1992, 39, 925–928. [Google Scholar] [CrossRef]

- Aken, K.V.; Strekowski, L.; Patiny, L. EcoScale, a Semi-Quantitative Tool to Select an Organic Preparation Based on Economical and Ecological Parameters. Beilstein J. Org. Chem. 2006, 2, 3. [Google Scholar] [CrossRef]

- Kultys, E.; Kurek, M.A. Green Extraction of Carotenoids from Fruit and Vegetable Byproducts: A Review. Molecules 2022, 27, 518. [Google Scholar] [CrossRef]

- Zuin, V.G.; Ramin, L.Z. Green and Sustainable Separation of Natural Products from Agro-Industrial Waste: Challenges, Potentialities, and Perspectives on Emerging Approaches. Top. Curr. Chem. 2018, 376, 3. [Google Scholar] [CrossRef]

- Kurek, M.A.; Aktaş, H.; Pokorski, P.; Pogorzelska-Nowicka, E.; Custodio-Mendoza, J.A. A Comprehensive Review of Analytical Approaches for Carotenoids Assessment in Plant-Based Foods: Advances, Applications, and Future Directions. Appl. Sci. 2025, 15, 3506. [Google Scholar] [CrossRef]

- Murador, D.C.; Braga, A.R.C.; Martins, P.L.G.; Mercadante, A.Z.; de Rosso, V.V. Ionic Liquid Associated with Ultrasonic-Assisted Extraction: A New Approach to Obtain Carotenoids from Orange Peel. Food Res. Int. 2019, 126, 108653. [Google Scholar] [CrossRef]

- Xu, G.; Liu, D.; Chen, J.; Ye, X.; Ma, Y.; Shi, J. Juice Components and Antioxidant Capacity of Citrus Varieties Cultivated in China. Food Chem. 2008, 106, 545–551. [Google Scholar] [CrossRef]

- Saini, R.K.; Nile, S.H.; Park, S.W. Carotenoids from Fruits and Vegetables: Chemistry, Analysis, Occurrence, Bioavailability and Biological Activities. Food Res. Int. 2015, 76, 735–750. [Google Scholar] [CrossRef] [PubMed]

- Marín, F.R.; Soler-Rivas, C.; Benavente-García, O.; Castillo, J.; Pérez-Alvarez, J.A. By-Products from Different Citrus Processes as a Source of Customized Functional Fibres. Food Chem. 2007, 100, 736–741. [Google Scholar] [CrossRef]

- Manzoor, S.; Rashid, R.; Prasad Panda, B.; Sharma, V.; Azhar, M. Green Extraction of Lutein from Marigold Flower Petals, Process Optimization and Its Potential to Improve the Oxidative Stability of Sunflower Oil. Ultrason. Sonochem. 2022, 85, 105994. [Google Scholar] [CrossRef]

- Savic Gajic, I.M.; Savic, I.M.; Gajic, D.G.; Dosic, A. Ultrasound-Assisted Extraction of Carotenoids from Orange Peel Using Olive Oil and Its Encapsulation in Ca-Alginate Beads. Biomolecules 2021, 11, 225. [Google Scholar] [CrossRef] [PubMed]

- Saini, A.; Panesar, P.S.; Bera, M.B. Valuation of Citrus Reticulata (Kinnow) Peel for the Extraction of Lutein Using Ultrasonication Technique. Biomass Conv. Bioref. 2021, 11, 2157–2165. [Google Scholar] [CrossRef]

- Anticona, M.; Blesa, J.; Lopez-Malo, D.; Frigola, A.; Esteve, M.J. Effects of Ultrasound-Assisted Extraction on Physicochemical Properties, Bioactive Compounds, and Antioxidant Capacity for the Valorization of Hybrid Mandarin Peels. Food Biosci. 2021, 42, 101185. [Google Scholar] [CrossRef]

- Karaca, A.C.; Low, N.; Nickerson, M. Emulsifying Properties of Chickpea, Faba Bean, Lentil and Pea Proteins Produced by Isoelectric Precipitation and Salt Extraction. Food Res. Int. 2011, 44, 2742–2750. [Google Scholar] [CrossRef]

- Eun, J.-B.; Maruf, A.; Das, P.R.; Nam, S.-H. A Review of Encapsulation of Carotenoids Using Spray Drying and Freeze Drying. Crit. Rev. Food Sci. Nutr. 2020, 60, 3547–3572. [Google Scholar] [CrossRef]

- da Fonseca Machado, A.P.; Alves Rezende, C.; Alexandre Rodrigues, R.; Fernández Barbero, G.; de Tarso Vieira e Rosa, P.; Martínez, J. Encapsulation of Anthocyanin-Rich Extract from Blackberry Residues by Spray-Drying, Freeze-Drying and Supercritical Antisolvent. Powder Technol. 2018, 340, 553–562. [Google Scholar] [CrossRef]

- Chen, C.; Chi, Y.-J.; Xu, W. Comparisons on the Functional Properties and Antioxidant Activity of Spray-Dried and Freeze-Dried Egg White Protein Hydrolysate. Food Bioprocess Technol. 2012, 5, 2342–2352. [Google Scholar] [CrossRef]

- Guo, N.; Jiang, Y.-W.; Kou, P.; Liu, Z.-M.; Efferth, T.; Li, Y.-Y.; Fu, Y.-J. Application of Integrative Cloud Point Extraction and Concentration for the Analysis of Polyphenols and Alkaloids in Mulberry Leaves. J. Pharm. Biomed. Anal. 2019, 167, 132–139. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.-C.; Shi, M.-Z.; Yu, Y.-L.; Cao, J. Simultaneous Extraction and Enrichment of Alkaloids from Lotus Leaf by In-Situ Cloud Point-Reinforced Ionic Liquid Assisted Mechanochemical Extraction Technology. Ind. Crops Prod. 2022, 183, 114968. [Google Scholar] [CrossRef]

- Algar, L.; Sicilia, M.D.; Rubio, S. Tailoring Supramolecular Solvents with Phosphoryl Groups for Highly Efficient Extraction of Chlorophenols in Natural Waters. Anal. Chim. Acta 2024, 1309, 342688. [Google Scholar] [CrossRef] [PubMed]

- Papoutsis, K.; Golding, J.B.; Vuong, Q.; Pristijono, P.; Stathopoulos, C.E.; Scarlett, C.J.; Bowyer, M. Encapsulation of Citrus By-Product Extracts by Spray-Drying and Freeze-Drying Using Combinations of Maltodextrin with Soybean Protein and ι-Carrageenan. Foods 2018, 7, 115. [Google Scholar] [CrossRef]

- de Lima Petito, N.; da Silva Dias, D.; Costa, V.G.; Falcão, D.Q.; de Lima Araujo, K.G. Increasing Solubility of Red Bell Pepper Carotenoids by Complexation with 2-Hydroxypropyl-β-Cyclodextrin. Food Chem. 2016, 208, 124–131. [Google Scholar] [CrossRef]

- Saha, N.; Samanta, A.K.; Chaudhuri, S.; Dutta, D. Characterization and Antioxidant Potential of a Carotenoid from a Newly Isolated Yeast. Food Sci. Biotechnol. 2015, 24, 117–124. [Google Scholar] [CrossRef]

- Chemat, F.; Abert-Vian, M.; Fabiano-Tixier, A.S.; Strube, J.; Uhlenbrock, L.; Gunjevic, V.; Cravotto, G. Green Extraction of Natural Products. Origins, Current Status, and Future Challenges. TrAC 2019, 118, 248–263. [Google Scholar] [CrossRef]

- Benvenutti, L.; Zielinski, A.A.F.; Ferreira, S.R.S. Pressurized Aqueous Solutions of Deep Eutectic Solvent (DES): A Green Emergent Extraction of Anthocyanins from a Brazilian Berry Processing by-Product. Food Chem. X 2022, 13, 100236. [Google Scholar] [CrossRef]

| Carotenoids (mg/100 g) | Citron Peel | Orange Peel | Tangerine Peel |

|---|---|---|---|

| Cloud point extraction | |||

| β-cryptoxanthin | 18.67 ± 0.02 b | 33.01 ± 0.06 b | 27.18 ± 0.03 b |

| Lutein | 4.09 ± 0.01 a | 7.21 ± 0.02 a | 2.65 ± 0.01 a |

| Zeaxanthin | 1.16 ± 0.00 a | nd a | nd a |

| α-carotene | nd a | 1.02 ± 0.00 a | 0.94 ± 0.00 a |

| β-carotene | 0.07 ± 0.00 a | 4.33 ± 0.01 a | 3.31 ± 0.01 a |

| Total carotenoids | 23.99 ± 0.03 b | 45.57 ± 0.09 b | 34.08 ± 0.05 b |

| Supramolecular solvent-based extraction | |||

| β-cryptoxanthin | nd a | 3.78 ± 0.01 a | nd a |

| Lutein | 5.36 ± 0.03 b | 8.69 ± 0.05 b | 5.39 ± 0.04 b |

| Zeaxanthin | 5.87 ± 0.01 b | nd a | nd a |

| α-carotene | 0.06 ± 0.00 b | 1.56 ± 0.00 b | 1.01 ± 0.00 b |

| β-carotene | 0.15 ± 0.00 b | 4.98 ± 0.05 b | 4.47 ± 0.02 b |

| Total carotenoids | 11.44 ± 0.04 a | 19.01 ± 0.11 a | 10.87 ± 0.06 a |

| Conventional water extraction | |||

| Total carotenoids | nd | ||

| Characteristics | Encapsulated CPE Citrus Peel Extracts | Encapsulated SUPRAS Citrus Peel Extracts | ||||

|---|---|---|---|---|---|---|

| Citron Peel | Orange Peel | Tangerine Peel | Citron Peel | Orange Peel | Tangerine Peel | |

| EE (%) | 86.57 ± 1.26 a | 88.97 ± 2.31 b | 85.55 ± 3.47 a | 88.26 ± 1.66 a | 82.40 ± 3.14 a | 88.06 ± 4.79 a |

| CIE Lab | ||||||

| L* | 78.01 ± 0.01 a | 75.28 ± 0.01 a | 76.69 ± 0.01 a | 85.61 ± 0.01 b | 83.25 ± 0.02 b | 85.03 ± 0.02 b |

| a* | −1.07 ± 0.01 b | 0.15 ± 0.01 b | −1.05 ± 0.01 a | −2.25 ± 0.01 a | −1.96 ± 0.01 a | −1.92 ± 0.01 b |

| b* | 18.11 ± 0.01 b | 25.63 ± 0.02 b | 21.15 ± 0.01 b | 10.14 ± 0.01 a | 11.08 ± 0.01 a | 10.25 ± 0.01 a |

| C* | 18.13 ± 0.02 b | 25.63 ± 0.03 b | 21.17 ± 0.02 b | 10.39 ± 0.02 a | 11.25 ± 0.02 a | 10.43 ± 0.02 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Travičić, V.; Cvanić, T.; Vučetić, A.; Kostić, M.; Perović, M.; Pezo, L.; Ćetković, G. Green Extraction Technologies for Carotenoid Recovery from Citrus Peel: Comparative Study and Encapsulation for Stability Enhancement. Processes 2025, 13, 1962. https://doi.org/10.3390/pr13071962

Travičić V, Cvanić T, Vučetić A, Kostić M, Perović M, Pezo L, Ćetković G. Green Extraction Technologies for Carotenoid Recovery from Citrus Peel: Comparative Study and Encapsulation for Stability Enhancement. Processes. 2025; 13(7):1962. https://doi.org/10.3390/pr13071962

Chicago/Turabian StyleTravičić, Vanja, Teodora Cvanić, Anja Vučetić, Marija Kostić, Milica Perović, Lato Pezo, and Gordana Ćetković. 2025. "Green Extraction Technologies for Carotenoid Recovery from Citrus Peel: Comparative Study and Encapsulation for Stability Enhancement" Processes 13, no. 7: 1962. https://doi.org/10.3390/pr13071962

APA StyleTravičić, V., Cvanić, T., Vučetić, A., Kostić, M., Perović, M., Pezo, L., & Ćetković, G. (2025). Green Extraction Technologies for Carotenoid Recovery from Citrus Peel: Comparative Study and Encapsulation for Stability Enhancement. Processes, 13(7), 1962. https://doi.org/10.3390/pr13071962