Abstract

Currently, the disposal of waste tires is considered one of the priority environmental and public health problems worldwide. Every year, more than 1.4 billion unused tires are placed in landfills. Population growth, economic development, and a strong demand for vehicle production in the automotive industry increase this problem. In Mexico, nearly 36 million unused tires are deposited in landfills or clandestine deposits, the vast majority being burned or accumulated in the open air. The lack of regulations in the handling, disposal, and recycling of tires creates a worrying panorama for environmental care and the problems that this entails. The objective of this work is to propose a viable alternative for the final disposal and recycling of waste tires through the implementation of a company for the manufacture of products based on recycled rubber in the state of Tamaulipas, Mexico, reducing environmental pollution by these wastes and generating sources of employment through a sustainable company. For this purpose, a study was carried out in Tamaulipas, Mexico, through surveys to determine the number of tires that can be obtained and determine the feasibility of the business; subsequently, a prediction was made using simulation software to design and estimate the expected production in the manufacture of parking bumpers using two scenarios with two and four workers. Likewise, specialized software was used to optimize waste tire collection routes from the different tire stores to the company’s location. The results show that with an optimal design of the tire collection routes, up to 483 tons of waste tires can be recovered per year, representing 10% of the total unused tires in Tamaulipas. Because it is an environmental and social problem, installing a company manufacturing products based on recycled rubber is feasible and has a high probability of success for the region studied. According to the simulation, employing four workers increases productivity and decreases manufacturing costs. Through the simulation, three tire collection routes were determined considering the total number of tire stores in the city where the company is located.

1. Introduction

The final disposal of municipal solid waste (MSW) and its recycling is a problem that affects all human beings worldwide and is closely related to environmental pollution, economic development, and social culture. In recent years, waste tire recycling has become one of the most complex MSW in its disposal and represents a serious environmental and public health problem [1,2,3]; for this reason, it is considered among the main ecological challenges worldwide [4,5,6]. Only scrap tires represent over 12% of all the solid waste in the world [7], and due to their size, shape, and physicochemical composition, they have become polymeric materials that are difficult to eliminate naturally. Their complex three-dimensional reticulated structure becomes resistant to many external factors. When deposited in landfills, they cause a high rate of risk to health and pollution of air, water resources, and soil [8,9,10,11].

Today, it is notable that in most developing countries, there is no control over the disposal of municipal solid waste, in addition to the fact that its recycling is significantly lower than in developed countries. In these countries, storage yards and uncontrolled landfills are the main options for disposing of waste tires. However, with the increase in waste rubber coupled with the increment in demand for tires in the world, in addition to the complexity of its recycling and its non-biodegradable chemical nature, in a few years, landfills will become a non-viable alternative for tire waste management [12,13]. Therefore, it is urgent to have regulations on the recycling of tires, disposal of this waste in landfills, sustainable management of these wastes, implementation of effective processes in the treatment of tires for energy generation, and their reuse for manufacturing products.

In most countries, the excessive and uncontrolled accumulation of waste tires is considered a serious environmental and public health problem; however, there is currently no satisfactory response to control this problem on the part of the industrial sector. Therefore, the recycling of waste tires has become a potentially profitable and growing business in the last decade, although still without being adequately exploited [14,15,16,17]. For this reason, governments and environmental organizations in many parts of the world have promoted and established ecological regulations on the management, recovery, and final disposal of waste tires to adopt effective measures that positively impact rubber recycling and environmental care [18,19,20,21,22]. In this sense, many countries in Europe and Asia, as well as the United States, occupy first place in recycling, with regulations and organizations dedicated to the management of end-of-use tires. These countries highlight that the effectiveness and success of the bylaws are due to the participation of all those involved (manufacturers, importers, industries dedicated to collection, consumers, and governments of each country) [23,24].

Although in the main developed countries such as the United Kingdom, Japan, Serbia, Norway, United States, Switzerland, and Turkey, among others, around 95% of the tires at the end of their useful life are collected, stored, and reused in different applications such as civil engineering, energy recovery, and recycling, at the other extreme in developing countries, only between 10 and 20% of their tire waste is properly collected and reused in the production of secondary products, and the rest remains exposed to the environment, causing serious environmental damage and health problems [8,25,26,27].

The growth in demand for global tire production is strongly influenced by population growth, the development of most economies worldwide, and mainly the strong development of the automotive sector [28,29,30]. Automotive industry consumption represents more than 75% of global rubber production, of which approximately 60% is used to manufacture tires for vehicles and trucks [31,32]. The remaining, approximately 15%, is used in producing automotive parts, such as hoses, moldings, rings, and seals, among others [33]. According to several researchers [34,35,36,37], global tire production has grown exponentially over the last 10 years by 17.5% since 2012. Currently, tire manufacturing is greater than 3.3 billion units per year and is forecast to increase to 4.1 billion per year until 2028. Asia-Pacific, Europe, and North America are the largest consumers of automobile tires, with more than 75% of the global production. In the year 2022, countries such as the United States and China were the largest consumers of tires in the world, with 450 and 320 million, respectively [38,39], while in Mexico, tire consumption recorded in 2020 was 33.2 million, maintaining an average growth rate of 1.6% annually in the last 7 years [40].

As a result of the accelerated growth in the automotive industry, pollution from unused tires has become one of the most worrying problems for humanity to solve. Currently, around 1.4 billion tires are disposed of into the environment yearly [41,42]. Several researchers [43,44] mention that the growth of waste tires has increased by around 13% annually, from 300 million in 2016 to more than 1,300 million in 2020. According to data presented in various studies, for every 1 billion tires produced, 3 million tons of rubber waste are generated per year, and it is estimated that the number of tires out of use by 2030 will be 1.2 billion Tons of tires per year [45,46]. Thailand annually generates about 600 thousand tons of waste tires [47], and China discards 112 million tons of tires per year, while the United States exceeds 246 million tons each year [48]. In the same sense, the European Union and Japan are also among the largest generators of tire waste. While Mexico reported 36 million waste tires per year in 2018, if this trend continues, in 5 years, 250 million waste tires will be added, plus another 200 million that have accumulated in the last decade. The above has been attributed mainly to population growth and the increase in vehicle consumption in the country [40,49].

The uncontrolled increase in clandestine landfills worldwide has represented a serious problem of environmental pollution and public health and important technological and scientific challenges for their control and elimination. Therefore, the various technological and research strategies and the circular economy related to sustainable development in the disposal and recycling of waste tires are sufficiently justified, as evidenced by the worldwide growth in research on these topics [50,51,52].

Waste tires obtained from cars and trucks represent the largest source of waste rubber in the world; its main components are natural and synthetic rubber, carbon black, metal, textile fabrics, and various additives according to the type of tire [4,50,53,54,55,56,57,58]. In Latin American countries and, more specifically, in Mexico, unfortunately, the progress in regulatory laws prohibiting the dumping of waste tires that encourage their reuse and recycling after their useful life is still insufficient, causing this situation to be even worse and increasingly complex. To reduce the problems generated by scrap tires, a significant number of countries in the world are using various efficient methods of reusing rubber due to its properties such as its low density, malleability, resistance to shocks, and moderate temperatures [59,60]; these methods include retreading and various applications in civil engineering [8,37,61], particularly in the production of concrete and asphalt; in the construction of playgrounds and sports surfacing, ground rubber applications, in addition to energy recovery (combustion in cement kilns and pyrolysis); and in blending polymeric types (thermoplastics, thermosets, or virgin rubber) [62,63,64,65,66].

It is of great interest for researchers and the public and private sectors to explore new applications and expand the markets for recycled tire rubber. Recycled rubber is the most used raw material for the subsequent processing of finished or semi-finished parts with a wide industrial application; recycled tire rubber, in addition to the applications mentioned above, is used in agricultural products and recreational and sports applications, in addition to many applications in engineering such as boat protection [67], conveyor belts [65], vibration reduction on railway tracks [68], footwear industry [69], lawn grounds [70], and playground flooring [71].

In the last 10 years, several investigations have focused on issues ranging from recycling to the manufacturing of parts using recycled tire rubber; the reported achievements are promising both environmentally and economically. Some studies have contributed to advances related to the value chain analysis for supply chain management [72]; decision making for waste tire management [73]; in the process of rubber recycling, collection, and processing; and potential customers [74]. Additionally, forecast models have been developed to estimate the volume of collected and the return time of out-of-use tires [75]. Finally, research related to the scenarios of collection, transportation and cutting, packaging, and bailing of products from recycled rubber has also been reported [76].

In Mexico, the final disposal of waste from out-of-use tires is considered a critical problem in public and environmental health issues. Although government institutions and the private sector have made significant efforts to regulate this problem, progress has been insufficient. The main reasons have been attributed to the lack of knowledge on waste management issues; lack of government regulations on final disposal, reuse, and recycling; the high cost of management and disposal; and the lack of knowledge of the population on issues related to environmental care. According to data from [77], from 2010 to 2020, the registration of vehicles and trucks increased from 31 to 51 million units in Mexico, representing an annual average growth of 6.4%. The forecast estimates about 83.5 million vehicles by 2030; the above exposes the inevitable increase in waste tires in landfills, warehouses, or clandestine places [78]. The state of Tamaulipas is in the north of Mexico, and with more than 370 km of border with the USA, it is a strategic state for the country’s economic development. Tamaulipas is divided into three economic zones that are important for the development of the state. The first is the "southern zone," and its main economic activities include the oil industry, energy generation, maritime services, and industrial and petrochemical sectors. Until 2020, the registered vehicle park was 385,217 units. The second corresponds to the "central zone," and its economic activities focus mainly on agriculture and livestock and educational and government services, with the registration of 195,243 vehicles; the third is the "northern zone" which has fourteen international bridges into the USA; its main economic activities focus on the manufacturing industry, international trade, and transportation, with more than 854,514 vehicles in circulation. Additionally, nearly 1.2 million transport units circulate to the United States each month [77]. The above exposes not only the large number of vehicles that circulate in the state and the exponential growth of the automotive industry but also the high volume of waste tires that will be generated and exposed in landfills, causing environmental pollution and health problems public, which require urgent regulation.

The above demonstrates for Tamaulipas important challenges related to the disposal of waste tires both to contribute to improving the prospects and conditions of climate change worldwide and to enter new business markets in tire recycling, positioning Mexico as a country committed to environmental issues and the circular economy.

According to a bibliographic review, waste tires have not only become a significant environmental, economic, and technological challenge but their components are also considered valuable secondary raw materials with a high potential for the manufacture of products and energy resources.

One of the alternatives of most significant interest to the industry in many countries is the recycling of tire rubber for its subsequent use in manufacturing parts and products. In this sense, numerous case studies have been carried out on using waste tires for energy generation, the use of metals, and reusing rubber to manufacture products [47,79,80,81,82,83]. The main contributions have been in establishing future research bases on the management of waste tires, their use as raw material, the generation of new sources of income for the industry, and reducing the serious environmental problems derived from the poor management of the disposal of tires.

The objective of the present study is to make a reliable diagnosis of the current situation that prevails in the state of Tamaulipas, Mexico, regarding the disposal and management issues related to the recycling of waste tires that impact the environment, public health, and economic development. The study also considers a feasibility study and a design proposal for a company to manufacture products based on rubber from recycled tires. Data for the present study were obtained through the published literature, academic sources, and research derived from governments and other sectors, in addition to electronic surveys and interviews with professionals; for the analysis, the population of the three economic zones of Tamaulipas (south, center, and north) was considered. For simulation in the design and evaluation stage of the process, the ProModel® 7.0 software was used, which is a powerful and useful tool for the manufacturing environment, production capacity planning, human resource optimization, and improvement of installation capacity. ArcGIS® 10.3.1 was used in the research because it is a widely used tool to manage, analyze, and visualize geospatial data. The analysis conducted with ArcGIS® 10.3.1 reveals the potential to define the optimal routes for collecting waste tires in the tire stores of the city where the company is installed and to ensure efficiency in collection and reduction in transportation costs.

The study’s results can be used to review and update data trends of out-of-use tires to improve efficiency in management, storage, and effective recycling methods. This will positively impact the quality of the environment and the economic development of Tamaulipas, Mexico.

2. Experimental Procedure

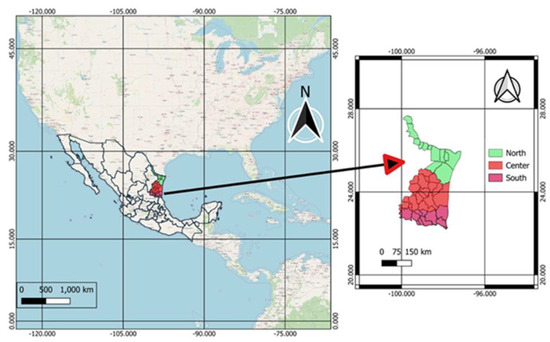

The present investigation was conducted in Tamaulipas, located north of Mexico and on the border with the United States. Tamaulipas is divided into 43 municipalities. For ease of analysis, the study was grouped into three zones (south, center, and north), as shown in Figure 1. According to data from (INEGI 2020), Tamaulipas has a population of 3,572,735 people. The study considerations were the economically active population, considering people between 20 and 60 years old with their own vehicle, the number of people in this range was 2,324,561; the type of vehicle; and the situation of automobile traffic in the areas studied (south, center, and north), in the north it is important to consider the proximity to the United States of America and the current situation of the final disposal of used tires.

Figure 1.

Geographic location of the study zone.

The stratified random sample technique was used to select a representative population sample. This technique was used due to the need to obtain information from a particular group of the general population, with specific and clearly defined conditions, and with the objective of obtaining results that provide reliable data in the research. Equation (1) was used to determine the sample size.

where n is the sample size; N is the population size; Z is the value for a 95% confidence level; p is the estimated proportion of the attribute present in the population; and E is the margin of error. Therefore, developing the formula, the result of the sample size is shown in Equation (2):

According to Equation (2), the minimum population to study was 384 to obtain a reliability index of 95% and a margin of error of 5%. Once the sample was determined, the measurement instruments applied were electronic surveys using the Google Forms platform and personal interviews with vehicle owners. The instrument consisted of 6 questions to 634 people from the different zones. The questions were related to the type of vehicles and number of tires used (cars, motorcycles, and heavy load transport), in addition to the number of tires discarded in a period of time and the final disposal of this waste. The data collected in the surveys were analyzed, and tire consumption and disposal trends were calculated.

Simulation Model

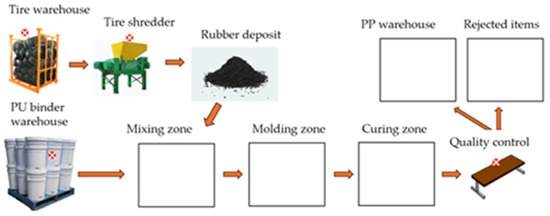

The layout of the production line and the process operations will depend on each product to be manufactured. The considerations for the design in the manufacture of the products based on recycled rubber in the simulation were the place available for the installation of the process; the distribution of the equipment and delimitation of areas for the collection of raw materials, storage, spaces for the equipment and work areas; the capacity of product that can enter the system and this was related to the quantity of products required by the customers; the production capacity of the equipment; the production times; and the amount of human resources and the scheduling of input and output of product. A proposal was made for the design and distribution of a plant for the processing of ground rubber from recycled tires for the manufacture of consumer products. The proposed distribution is shown in Figure 2.

Figure 2.

Facility design and plant layout proposed.

Ciudad Victoria is located in the central area of the state of Tamaulipas and was the study area for the project because this city is where the company that will collect, process, and produce products from recycled tire rubber is located. The growth of the population in recent years and the increase in the use of transportation vehicles has caused a considerable increase in the use of tires that, after their useful life, are deposited in clandestine dumps and open-air places, causing environmental and health problems. However, a significant amount of tires are deposited in tire sales stores after their useful life has expired, and these tires are collected by the businesses and accumulated for later disposal.

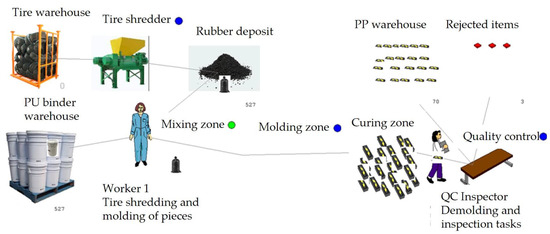

A good vehicle routing design is a key factor in the transportation industry to reduce distances and operating costs. Therefore, in the present investigation, the ArcGis® tool was used to design an optimal collection route for used tires in tire stores. The variables considered in the routing were operational efficiency, improvement in the collection service, environmental impact, and resource optimization. The North American Industrial Classification System, Mexico (SCIAN 2023) platform was used. The code for the filter was "468213," and the result obtained was that 146 businesses had commercial activity in the sale of tires in Ciudad Victoria, Tamaulipas, Mexico. Subsequently, a refinement was carried out considering businesses with more than five workers and a tire sales volume of more than 100 units per month. The result was that 22 businesses were considered for the optimal route design analysis process for the collection of used tires. Understanding the optimal flow of a process for manufacturing products and predicting with high precision the performance of a production system as a function of time makes process modeling and simulation a powerful tool for planning production systems. In this sense, the simulation of the plant production process for the manufacture of products from end-of-life tire rubber and polyurethane-based binder was carried out in the ProModel Student 7.5 ® software. The simulation model is considered from the stage of cutting and shredding tires to obtaining the finished product. The product proposed in the simulation is "parking stops rubber" with a weight of 4.4 Kg, in the proportions of 3.2 Kg (73%) of ground rubber and 1.2 Kg (27%) of commercial polyurethane. The main workstations considered were a rubber crusher or mill, mixing station, molding area, curing area, and quality inspection point, in addition to the warehouses for raw materials and finished products, as shown in Figure 3. A total of two scenarios were established for the product to be manufactured.

Figure 3.

Manufacturing process simulation scheme.

For the first scenario (see Figure 4), the complete manufacturing process is simulated using two workers in a simple process. Worker one first recycles a full batch of tires before performing the mixing and individual molding operation of the parking stop rubber, a resin curing time of 120 minutes is allowed to be able to handle it safely, and quality inspection is carried out, and it finally ends up in the finished product warehouses.

Figure 4.

Simulation of the first scenario of the parking stop rubber production process considering 2 employees.

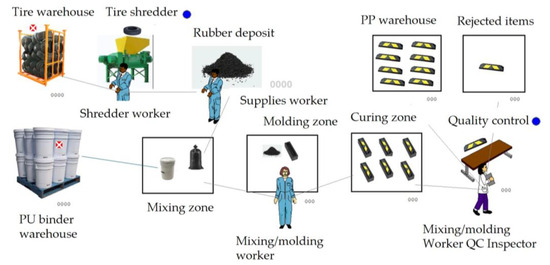

In the second scenario (see Figure 5), the participation of four workers is considered, allowing the continuous operation of the process, and the use of a multiple matrix-type mold is also contemplated that allows the available raw material to be processed in small batches with a fluid speed at the workstations.

Figure 5.

Simulation of the second scenario of the parking stop rubber production process considering 4 employees.

The simulation allows estimating processing times and operating costs for both cases only by modifying the number of workers and the fragmentation of small production batches in a 12-piece mold that has been designed to occupy the space of a standard pallet (1 × 1.2 m) that facilitates its manipulation.

3. Results

Figure 6 shows the results obtained from the surveys applied to the population of Tamaulipas on the use of private vehicles. The data indicate that 78.4% of those surveyed correspond to users who count automobiles as a means of transportation, 7.7% use motorcycles, only 2.4% have trucks or heavy trucks, and 11.5% of those surveyed responded that they do not have any vehicle.

Figure 6.

Distribution of used vehicle types in Tamaulipas.

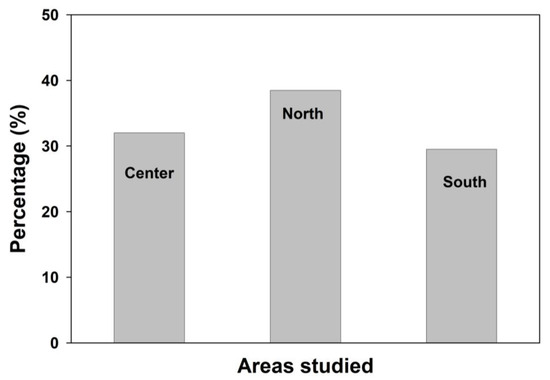

Therefore, it can be mentioned that a considerable percentage of tires that will be out of use over some time will be of medium sizes that correspond to cars whose weight per tire is estimated between 7 and 9 kg. Other data indicate that the generation and accumulation of out-of-use tires are found in greater quantities in the north of the state in the order of 38.5%, this being the area with the largest population, having an extensive border with the USA, and where there is higher vehicular traffic. In the center and south of Tamaulipas, the accumulation of waste tires represents 32 and 29.5%, respectively, as can be seen in Figure 7.

Figure 7.

Percentage of generation of out-of-use tires in the different areas studied.

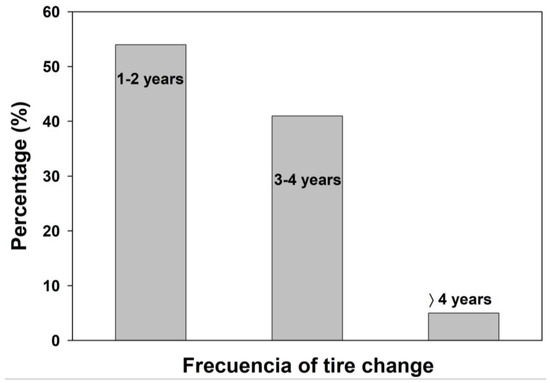

In response to the question related to the frequency of the used tire change period, most people mentioned that they change their tires in 2 years or less, which represents 54% of the population. A total of 41% responded that they change used tires in a period between 3 and 4 years of use, and finally, a small part of the population mentioned that they do it every 4 years or more of use, see Figure 8. It should be noted that the surveys did not consider the kilometers traveled by vehicles after a tire change, which most manufacturers recommend changing when tire wear reaches its lower limit of useful life, which is approximately 50,000 km depending on the type of tire. Likewise, it is important to consider that in addition to the natural wear of the tires, punctures, damage from impacts, and tears cause a decrease in the life of the tires.

Figure 8.

Average time to change used tires.

It is important to mention that of the sample surveyed, only 634 people had a vehicle to transport, generating about 700 out-of-use tires per year (~ one waste tire per person), and the number of people according to the economically active population (between 20 and 65 years) in the state of Tamaulipas is 2,324,561, while the number of vehicles circulating is 1,761,634; if this amount is multiplied by an average of 4 tires per vehicle and 8 kg per tire, the result is 56,372 tons of tire waste per year in Tamaulipas. Due to economic and population growth, Tamaulipas faces significant challenges in the management of used tires. Their disposal through appropriate methods and the use of technologies are priority issues. The generation of this type of project has a positive impact not only on the environment but also on the social sphere, improving the quality of life and economy of the region. In this sense, the results obtained demonstrate the economic potential of the management and recycling of used tires in Tamaulipas.

However, the management of collection, the process of shredding and grinding rubber, and its subsequent processing to transform it into commercial products are important challenges in the recycled rubber transformation industry. Therefore, they were considered in this research. For the collection stage, the study used the ArcGis® 3.10.1 software as a tool to define optimal routes for collecting used tires and focused on the first phase in tire sales businesses. It is important to mention that the tire collection stage is dynamic and requires adjustments to the model to obtain the greatest efficiency in tire collection. The analysis performed with ArcGis® 3.10.1 revealed the potential to determine optimal routes by minimizing distances traveled, reducing operating costs, and increasing the level of service through balanced routes that can effectively cover the businesses selected according to ArcGis® 3.10.1. Table 1 shows the location by coordinates and the volume of tires received on average per week in the selected companies in the study.

Table 1.

Geographic location of companies for the collection of used tires.

Subsequently, using the ArcGlobe 10.8 ® tool, the localization process was carried out using a satellite map of the company in the case study (blue point) and the tire sales businesses selected in the study (red points), see Figure 9.

Figure 9.

ArcGIS map showing the rubber processing company (blue point), and the tire sales businesses and collection site (red points).

After locating the businesses for the collection of used tires and using the rubber processing plant as a starting point, different analyses were carried out using the ArcGis® software to select the tire collection route that presented the greatest advantages in terms of travel times, collection capacity, and fuel consumption. The defined coordinates of the businesses selected in Table 1 were entered into the ArcGis® 3.10.1 software as input data, and within the interface, the variables of impedance, starting and ending points, the distribution of the network points for the route, vehicle characteristics, number of vehicles to be used, load capacity, and tire collection service areas were associated.

Figure 10 shows the results obtained using ArcGis® 3.10.1 for the collection routes for used tires from the selected companies in Ciudad Victoria, Tamaulipas, considering a study area of approximately 77 km2. For the selection of the routes, priority was given to minimizing travel distances and collection time, and reducing the costs related to tire transportation, for which it was proposed to use three collection routes: a heavy transport vehicle with a capacity of 1.5 Ton to collect 210 tires per trip, and a total of 2 trips per route/week would collect 5040 tires per month. The details and characteristics of each route are shown in Table 2.

Figure 10.

Optimal routes for the collection of used tires using ArcGis®.

Table 2.

Details of proposed routes for tire collection.

In just 5 years, Tamaulipas increased its vehicle fleet from 1,225,196 to 1,761,634 (cars, vans, and heavy trucks). This represents a growth of 43.78%, and the trend shows an annual growth of 10%; considering an average of four tires per vehicle and a weight of 8 kg per tire, as well as a useful life period of 4 years per tire, there would be an accumulation per year of 39 thousand tons of out-of-use tires. In the case of Ciudad Victoria (location of the manufacturing company), the number of vehicles increased from 139,435 to 178,207 in the same period of time, which represents an increase of 27.80%. This represents a disposal of 4,461 tons of tires per year. By carrying out the tire collection proposal on the selected routes, more than 60 thousand waste tires can be collected, equivalent to 483 tons per year. This action would represent 10.82% of the collection of used tires in Ciudad Victoria and demonstrate the potential that the tire collection program has, both from an economic perspective and for contributing to reducing the environmental impact.

After collecting used tires, they will be transferred to a storage point within the company, and in the first stage, the process of crushing and separating rubber and other materials will be carried out. Rubber represents the main raw material used in the manufacture of products in the company.

To know an estimate of the production of granulated rubber, the specifications and technical sheets of different brands of crushing machines available on the market were considered, and according to the data consulted, it is possible to generate up to 2000 Kg of granulated rubber in an approximate grinding time of 4 hours, these data being the reference value in the simulation scenarios. This has been the reference batch in the simulations, so 740 kg of binder have also been considered, generating a total of 625 finished pieces. For the first scenario, the manufacturing of the product with a manual procedure and two workers in the process, a total processing time of 112 hours was determined. Therefore, the resulting operating costs were USD 7.92 (see Table 3). In the second scenario, the production batch can be processed in a time of 22 hours with four workers for the process, obtaining an operation cost of USD 2.65 (see Table 4). Therefore, considering a manual production scheme with two workers, production costs are three times higher when compared to the scenario of using four workers in batch production. It is worth mentioning that for both simulation cases, the percentage of tasks for each worker has not been optimized, so in practice, their performance could be improved.

Table 3.

Simulation conditions in the first scenario.

Table 4.

Simulation conditions in the second scenario.

4. Discussion

Tamaulipas faces significant challenges related to the management of used tire waste that contributes to environmental pollution. The more than 56 thousand tons of tires per year that are deposited in landfills or illegal sites cause not only an environmental problem but also a social and public health problem that primarily affects developing economies. This amount and its negative effects will continue to increase due to population growth and the vehicular flow that is concentrated in the northern area of Tamaulipas due to its proximity to the United States of America. The final disposal of tires using efficient methods and technologies focused on rubber shredding, energy generation, material recovery, retreading, and recycling is a priority issue.

Developed economies such as the United States and the European Union recover between 75% and 92%, respectively, of tire rubber, applied in the recovery of energy for industrial use and materials for applications in civil engineering, manufacturing processes, and road repair [84,85,86]. Although Mexico does not present the same technological advancement and development as these countries, programs for the management of used tires and methods such as recycling that minimize the use of natural rubber for the benefit of future generations are being accepted in society and have a favorable impact on the economy of companies related to rubber processes in the country. In these challenges, the public government sector is involved with the implementation of regulations on the management of tire waste and the application of social programs for the benefit of the environment, society with participation in these programs, and the private sector with economic investment for the implementation of companies that contribute to the reduction in environmental pollution and economic growth.

In this sense, the study carried out for the implementation of a company for the manufacture of products based on recycled rubber arises through private investment, which guarantees the economic sustainability of the project. The feasibility study and financial justification involved aspects such as the number of used tires in the region; the logistics of the collection and transportation, the reception, classification, and storage of tires; and the production and marketing process. The study not only highlighted the challenges and areas of opportunity, such as the optimization of tire collection and the production and sales flow, but also demonstrated the economic potential in the management, recycling, and production of products based on used tires in Tamaulipas, Mexico. The expected benefits in the medium and long term with this type of project are economic growth through the creation of new companies and the increase in jobs, decreased costs of raw materials, reduction in environmental impact, and improvement in public health.

During the development of the project, some important challenges were identified such as (a) the initial investment by a consolidated private company in Tamaulipas, which expects sustainable economic growth; (b) knowledge of the rules and regulations for the treatment of these wastes in the environment; (c) logistics in tire collection, although the simulation using ArcGis® 3.10.1 presented the best option for collection routes, the variables at this stage are dynamic and adjustments must be made based on tire sales at tire shops; (d) marketing and sales, although there are 6,130 companies in Mexico dedicated to the trade in plastic, of which 77 are located in Tamaulipas [87], a small number is dedicated exclusively to the manufacture of products based on recycled rubber, therefore the level of production must be in accordance with the needs of the markets to be competitive at local and national levels; and (e) the manufacturing of products must reduce their impact on the environment, and this requires applying technologies that not only improve the applications and performance of the products, but also use production processes that are more environmentally responsible. In 2023, the international rubber trade and its manufacturing processes reached USD 13,495 million, where Tamaulipas ranked fifth nationwide with sales of USD 396 million, representing 8.35% [88]. This demonstrates an attractive market for this type of company; entering these requires not only manufacturing a good product, but also optimizing each stage in the process to be competitive in these markets.

5. Conclusions

In Tamaulipas, as in many parts of the world, pollution due to out-of-use tires is a serious environmental and public health problem. Currently, around 56,372 tons of waste tires are generated each year, and this trend continues to increase by an average of 10% due to economic development and vehicle growth. The problem of environmental pollution from out-of-use tires is a social responsibility. Currently, most of the government’s actions and management have focused on providing and adapting spaces for the collection of solid waste However, management in the collection and handling of tires in landfills is not sufficient due to the high percentage that is found in illegal sites, which is estimated to be over 60%. In this sense, in addition to implementing efficient strategies and establishing social programs for tire collection, actions must be established with companies that use rubber as raw material and develop technologies that improve their production processes to benefit the environment.

Therefore, the feasibility of implementing a company to manufacture "parking stops rubber" products based on recycled rubber represents an important market opportunity because it will not only generate jobs and economic growth, but will also reduce environmental pollution from out-of-use tires.

To determine the location and selection of strategic companies for the collection of used tires, the ArcGis® tool was first used to perform stratification based on monthly sales in tire stores. Additionally, the distances traveled, travel times, and transportation costs were considered. For the case study, 17 tire shops and 3 collection routes were considered. The simulations predict a collection capacity of 483 tons of tires per year, and although this value only represents 10% of the total waste tires, the consolidation of a company of this type is a starting point for the development of sustainable companies with economic and environmental benefits.

On the other hand, the simulations carried out in ProModel estimate that the mass production process of "parking stops rubber" using four workers is more efficient in terms of increasing production and reducing the cost per finished piece. However, this model will depend on the supply of raw materials, the demand for production, and the capacity of the equipment projected in the first stage. In addition, this proposal has been of interest to some businessmen in the state with whom efforts and agreements are being made to support matters related to the study of potential markets, technical analysis related to the acquisition of equipment and machines, and the process of production to make it a profitable company.

Therefore, as areas of opportunity, it is proposed to continue expanding this research and consolidate work teams with public institutions and the private sector in carrying out campaigns that promote the development of efficient methods and technologies in the collection, treatment, and production of products based on recycled rubber, in addition to promoting effective recycling programs in the community.

Author Contributions

Literature review and state of the art, R.D.L.-G., J.A.R.-G. and A.M-R.; conceptualization, R.D.L.-G., J.A.R.-G. and A.M-R.; methodology, E.R.-R. and M.M.R.-G., online and person to person surveys, C.A.C.-A. and M.M.R.-G.; analysis of statistical data from surveys, R.D.L.-G., J.A.R.-G., A.M-R. and C.A.C.-A.; analysis of the amount of end-of-life tires to be used as raw material, E.R.-R., M.M.R.-G., R.D.L.-G. and J.A.R.-G., formal analysis, R.D.L.-G. and A.M-R.; investigation, R.D.L.-G. and J.A.R.-G.; technical study of the type of equipment and machinery required, E.R.-R., M.M.R.-G. and C.A.C.-A.; resources, E.R.-R. and M.M.R.-G.; design and software simulation of the plant distribution considering equipment and machinery, R.D.L.-G., J.A.R.-G., E.R.-R. and A.M-R.; determination of capacity production of the finished product, C.A.C.-A. and M.M.R.-G.; product manufacturing design, E.R.-R., M.M.R.-G., R.D.L.-G. and J.A.R.-G.; validation, R.D.L.-G. and A.M.-R.; original draft preparation, R.D.L.-G., E.R.-R. and A.M.-R.; writing—review and editing, R.D.L.-G., J.A.R.-G. and A.M.-R.; supervision, R.D.L.-G.; project administration, R.D.L.-G. and A.M.-R.; funding acquisition, M.M.R.-G. and R.D.L.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Tecnológico Nacional de México under the grant number 18585.23-P.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors are very grateful to the Tecnológico Nacional de México campus Ciudad Victoria for the use of its facilities and laboratories and the company “Anuncios y señales” for the facilities for the layout and plant design.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ortíz-Rodríguez, O.; Ocampo-Duque, W.; Duque-Salazar, L. Environmental Impact of End-of-Life Tires: Life Cycle Assessment Comparison of Three Scenarios from a Case Study in Valle del Cauca, Colombia. Energies 2017, 10, 2117–2129. [Google Scholar] [CrossRef]

- Ziouzios, D.; Baras, N.; Balafas, V.; Dasygenis, M.; Stimoniaris, A. Intelligent and Real-Time Detection and Classification Algorithm for Recycled Materials Using Convolutional Neural Networks. Recycling 2022, 7, 9–22. [Google Scholar] [CrossRef]

- Adhikari, B.; De, D.; Maiti, S. Reclamation and recycling of waste rubber. Prog. Polym. Sci. 2000, 25, 909–948. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Recycling Waste Tires into Ground Tire Rubber (GTR)/Rubber Compounds: A Review. J. Compos. Sci. 2020, 4, 103–145. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B. Recycling of waste tire rubber in asphalt and Portland cement concrete: An overview. Constr. Build. Mater. 2013, 67, 217–224. [Google Scholar] [CrossRef]

- Price, W.; Smith, E.D. Waste tire recycling: Environmental benefits and commercial challenges. Int. J. Environ. Technol. Manag. 2006, 6, 362–374. [Google Scholar] [CrossRef]

- Stevenson, K.; Stallwood, B.; Hart, A. Tire Robber Recycling and Bioremediation: A review. Biorem. J. 2008, 12, 1–11. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.; Alyousef, R.; Mugahed Amran, Y.; Aslani, F.; Alabduljabbar, H. Properties and utilizations of waste tire rubber in concrete: A review. Constr. Build. Mater. 2019, 224, 711–731. [Google Scholar] [CrossRef]

- Sathiskumar, C.; Karthikeyan, S. Recycling of waste tires and its energy storage application of by-products—A review. Sustain. Mater. Technol. 2019, 22, e00125. [Google Scholar] [CrossRef]

- Shakya, P.R.; Shrestha, P.; Tamrakar, C.S.; Bhattarai, P.K. Studies on potential emission of hazardous gases due to uncontrolled open-air burning of waste vehicle tyres and their possible impacts on the environment. Atmos. Environ. 2008, 42, 6555–6559. [Google Scholar] [CrossRef]

- Fiksel, J.; Bakshi, B.; Baral, A.; Guerra, E.; DeQuervain, B. Comparative life cycle assessment of beneficial applications for scrap tires. Clean. Technol. Environ. 2011, 13, 19–35. [Google Scholar] [CrossRef]

- Hejna, A.; Korol, J.; Przybysz-Romatowska, M.; Zedler, Ł.; Chmielnicki, B.; Formela, K. Waste tire rubber as low-cost and environmentally-friendly modifier in thermoset polymers-a review. Waste Manag. 2020, 108, 106–118. [Google Scholar] [CrossRef] [PubMed]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Levlin, J.E.; Read, B.; Grossmann, H.; Hooimeijer, A.; Ervasti, I.; Lozo, B.; Julien Saint Amand, F.; Cochaux, A.; Faul, A.; Ringman, J.; et al. The Future of Paper Recycling in Europe: Opportunities and Limitations; Stawicki, B., Ed.; The Paper Industry Technical Association: Bury, UK, 2010. [Google Scholar]

- Zaman, A.U. A comprehensive study of the environmental and economic benefits of resource recovery from global waste management systems. J. Clean. Prod. 2016, 124, 41–50. [Google Scholar] [CrossRef]

- Galvagno, S.; Casu, S.; Casabianca, T.; Calabrese, A.; Cornacchia, G. Pyrolysis process for the treatment of scrap tyres: Preliminary experimental results. Waste Manag. 2002, 22, 917–923. [Google Scholar] [CrossRef]

- Ruwona, W.; Danha, G.; Muzenda, E. A review on material and energy recovery from waste tyres. Procedia Manuf. 2019, 35, 216–222. [Google Scholar] [CrossRef]

- Malyshkov, G.B.; Nikolaichuk, L.A.; Sinkov, L.S. Legislative regulation of waste management system development in Russian federation. Int. J. Eng. Res. Technol. 2019, 12, 631–635. [Google Scholar]

- Yang, Z.; Ji, R.; Liu, L.; Wang, X.; Zhang, Z. Recycling of municipal solid waste incineration by-product for cement composites preparation. Constr. Build. Mater. 2018, 162, 794–801. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef]

- Ferrāo, P.; Ribeiro, P.; Silva, P. A management system for end-of-life tyres: A Portuguese case study. Waste Manag. 2000, 28, 604–614. [Google Scholar] [CrossRef]

- Gigli, S.; Landi, D.; Germani, M. Cost-benefit analysis of a circular economy project: A study on a recycling system for end-of-life tyres. J. Clean. Prod. 2019, 229, 680–694. [Google Scholar] [CrossRef]

- Alwaeli, M. End-of-life vehicles recovery and recycling and the route to comply with EU directive targets. Environ. Prot. Eng. 2016, 42, 191–202. [Google Scholar] [CrossRef]

- Torreta, V.; Rada, E.C.; Raggazi, M.; Trulli, E.; Istrate, I.E.; Cioca, L.L. Treatment and disposal of tyres: Two EU approaches. A review. Waste Manag. 2015, 45, 152–160. [Google Scholar] [CrossRef] [PubMed]

- European Tyre & Rubber, Manufacturers’ Association. Press Release. 2021. Available online: https://www.etrma.org/wp-content/uploads/2021/05/20210520_ETRMA_PRESS-RELEASE_ELT-2019.pdf (accessed on 11 May 2022).

- Van Beukering, P.J.H.; Janssen, M.A. Trade and recycling of used tyres in Western and Eastern Europe. Resour. Conserv. Recycl. 2001, 33, 235–265. [Google Scholar] [CrossRef]

- Sharma, V.K.; Fortuna, F.; Mincarini, M.; Berillo, M.; Cornacchia, G. Disposal of waste tyres for energy recovery and safe environment. Appl. Energy 2000, 65, 381–394. [Google Scholar] [CrossRef]

- Eriksson, O. Energy and waste management. Energies 2017, 10, 1072–1078. [Google Scholar] [CrossRef]

- Asaro, L.; Gratton, M.; Saghar, S.; Hocine, N.A. Recycling of rubber wastes by devulcanization. Resour. Conserv. Rec. 2018, 133, 250–262. [Google Scholar] [CrossRef]

- Alfayez, S.A.; Suleiman, A.R.; Nehdi, M.L. Recycling Tire Rubber in Asphalt Pavements: State of the Art. Sustainability 2020, 12, 9076. [Google Scholar] [CrossRef]

- Masri, T.; Yagoub, M.; Rouag, A.; Benchabane, A.; Guerira, B. Characterization of a Composite Material Composed by Rubber Tire and Expanded Polystyrene Wastes. J. Compos. Adv. Mater. 2023, 33, 13–19. [Google Scholar] [CrossRef]

- Merkisz-Guranowska, A. Waste recovery of end-of-life vehicles. IOP Conf. Ser. Mater. Sci. Eng. 2018, 421, 032019. [Google Scholar] [CrossRef]

- Shulman, V.L. Tire recycling. In Waste; Academic Press: Cambridge, MA, USA, 2019; pp. 489–515. [Google Scholar]

- Chen, Z.; Liang, Y.; Lin, Y.; Cai, J. Recycling of waste tire rubber as aggregate in impact-resistant engineered cementitious composites. Constr. Build. Mater. 2022, 359, 129477. [Google Scholar] [CrossRef]

- Antony, A.; Provodnikova, A.; Kumar, S.; Balachandan, B. Sustainable Materials in Tire Industry: A comparative Study of Europe and Asian Markets. Glob. J. Bus. Integral Secur. Int. Conf. Bus. Integral Secur. (IBIS) 2021, 1–14. [Google Scholar]

- Sitepu, M.H.; Armayani; Matondang, A.R.; Sembiring, M.T. Used tires recycle management and processing: A review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 801, 012116. [Google Scholar] [CrossRef]

- Roychand, R.; Gravina, R.; Zhuge, Y.; Ma, X.; Youssf, O.; Mills, J. A comprehensive review on the mechanical properties of waste tire rubber concrete. Constr. Build. Mater. 2020, 237, 117651. [Google Scholar] [CrossRef]

- Tsang, H.H. Uses of Scrap Rubber Tires. In Rubber: Types, Properties and Uses, 1st ed.; Popa, G.A., Ed.; Nova Science Publisher, Inc.: New York, NY, USA, 2012; pp. 477–492. [Google Scholar]

- Ramarad, S.; Khalid, M.; Ratnam, C.T.; Luqman Chuah, A.; Rashmi, W. Waste tire rubber in polymer blends: A review on the evolution, properties, and future. Prog. Mater. Sci. 2015, 72, 100–140. [Google Scholar] [CrossRef]

- Asociación de Manejo Responsible de Llantas Usadas, A.C. 2022. Available online: https://reciclallantas.org.mx/ (accessed on 26 January 2025).

- Rogachuk, B.E.; Okolie, J.A. Waste tires based biorefinery for biofuels and value-added materials production. Chem. Eng. J. Adv. 2023, 14, 100476. [Google Scholar] [CrossRef]

- Nanda, S.; Reddy, S.N.; Hunter, H.N.; Vo, D.V.N.; Kozinski, J.A.; Gökalp, I. Catalytic subcritical and supercritical water gasification as a resource recovery approach from waste tires for hydrogen-rich syngas production. J. Supercrit. Fluids 2019, 154, 104627. [Google Scholar] [CrossRef]

- Raffoul, S.; Garcia, R.; Escolano-Margarit, D.; Guadagnini, M.; Hajirasouliha, I.; Pilakoutas, K. Behaviour of unconfined and FRP-confined rubberized concrete in axial compression. Constr. Build. Mater. 2017, 147, 388–397. [Google Scholar] [CrossRef]

- Yadav, J.S.; Tiwari, S.K. Effect of inclusion of crumb rubber on the unconfined compressive strength and wet-dry durability of cement stabilized clayey soil. J. Build. Mater. Struct. 2016, 3, 68–84. [Google Scholar] [CrossRef]

- Liu, L.; Cai, G.; Zhang, J.; Liu, X.; Liu, K. Evaluation of engineering properties and environmental effect of recycled waste tire-sand/soil in geotechnical engineering; A compressive review. Renew. Sustain. Energy Rev. 2020, 126, 109831. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Recycling of waste tire rubber as aggregate in concrete: Durability-related performance. J. Clean. Prod. 2016, 112, 504–513. [Google Scholar] [CrossRef]

- Mereki, D.; Machola, B.; Mokokwe, K. Status of waste tires and management practice in Botswana. J. Air Waste Manag. Assoc. 2019, 69, 1230–1246. [Google Scholar] [CrossRef] [PubMed]

- Berendsohn, R. Our Waste Tire Problem Is Getting Worse. 2018. Available online: https://www.popularmechanics.com/cars/car-technology/a22553570/waste-tires/ (accessed on 18 December 2022).

- Rosagel, S. Reciclaje de Llantas en México. 2013. Available online: http://havelsa.com/reciclaje-de-llantas-unam/ (accessed on 18 January 2024).

- Formela, K. Sustainable development of waste tires recycling technologies recent advances, challenges and future trends. Adv. Ind. Eng. Polym. Res. 2021, 4, 209–222. [Google Scholar] [CrossRef]

- Dabic-Miletic, S.; Simic, V.; Karagoz, S. End-of-life tire management: A critical review. Environ. Sci. Pollut. Res. 2021, 28, 68053–68070. [Google Scholar] [CrossRef]

- Kinnaman, T.C. The economics of municipal solid waste management. Waste Manag. 2009, 29, 2615–2617. [Google Scholar] [CrossRef]

- Topcu, I.B.; Unverdi, A. Scrap tires/crumb rubber. In Waste and Supplementary Cementitious Materials in Concrete; Elsevier: Amsterdam, The Netherlands, 2018; pp. 51–77. [Google Scholar]

- Evans, A.; Evans, R. The Composition of a Tyre: Typical Components; The Waste & Resources Action Programme: Banbury, UK, 2006; p. 5. [Google Scholar]

- Baranwal, K.C. Akron rubber development laboratory, ASTM standards & testing of recycle rubber. In Proceedings of the Rubber Division Meeting, San Francisco, CA, USA, 28–30 April 2003. [Google Scholar]

- Messerle, V.; Ustimenko, A. Plasma processing of rubber powder from end-of-life tires: Numerical analysis and experiment. Processes 2024, 12, 994–1011. [Google Scholar] [CrossRef]

- Ćetković, J.; Lakić, S.; Žarković, M.; Vujadinović, R.; Knežević, M.; Živković, A.; Cvijović, J. Environmental benefits of air emission reduction in the waste tire management practice. Processes 2022, 10, 787–810. [Google Scholar] [CrossRef]

- Sagara, M.; Nibeditab, K.; Manoharb, N.; Raj Kumarb, K.; Suchismitab, S.; Pradnyesha, A.; Babul Reddyc, A.; Rotimi Sadikuc, E.; Guptad, U.N.; Lachitd, P.; et al. A potential utilization of end-of-life tyres as recycled carbon black in EPDM rubber. Waste Manag. 2018, 74, 110–122. [Google Scholar] [CrossRef]

- Khan, S.R.; Zeedhan, M.; Masood, A. Enhancement of hydrocarbons production through co-pyrolysis of acid-treated biomass and waste tire in a fixed bed reactor. Waste Manag. 2020, 106, 21–31. [Google Scholar] [CrossRef]

- Mckeen, L.W. The Effect of Long Term Thermal Exposure on Plastic and Elastomers; William Andrew: Norwich, NY, USA, 2004. [Google Scholar]

- Li, Y.; Zhang, S.; Wang, R.; Dang, F. Potential use of waste tire rubber as aggregate in cement concrete—A comprehensive review. Constr. Build. Mater. 2019, 225, 1183–1201. [Google Scholar] [CrossRef]

- Junqing, X.; Jiaxue, Y.; Jianglin, X.; Chenliang, S.; Wenzhi, H.; Juwen, H. High-value utilization of waste tires: A review with focus on modified carbon from pyrolysis. Sci. Total Environ. 2020, 742, 140235. [Google Scholar]

- Czajczynska, D.; Krzyzynska, R.; Jouhara, H.; Spencer, N. Use of pyrolytic gas from waste tire as a fuel: A review. Energy 2017, 134, 1121–1131. [Google Scholar] [CrossRef]

- Hita, I.; Arabiourrutia, M.; Olazar, M.; Bilbao, J.; Arandes, J.M.; Castaño Sánchez, P. Opportunities and barriers for producing high quality fuels from the pyrolysis of scrap tires. Renew. Sustain. Energy Rev. 2016, 56, 745–759. [Google Scholar] [CrossRef]

- Aziz, M.A.; Rahman, M.A.; Molla, H. Design, fabrication and performance test of a fixed bed batch type pyrolysis plant with scrap tire in Bangladesh. J. Radiat. Res. Appl. Sci. 2018, 11, 311–316. [Google Scholar] [CrossRef]

- Machin, E.B.; Pedroso, D.T.; de Carvalho, J.A. Energetic valorization of waste tires. Renew. Sustain. Energy Rev. 2017, 68, 306–315. [Google Scholar] [CrossRef]

- Abdul-Kader, W.; Haque, M.S. Sustainable tyre remanufacturing: An agent-based simulation modelling approach. Int. J. Sustain. Eng. 2011, 4, 330–347. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; Moreno-Navarro, F.; Rubio-Gámez, M. The use of deconstructed tires as elastic elements in railway tracks. Materials 2014, 7, 5903–5919. [Google Scholar] [CrossRef]

- Araujo-Morera, J.; Hernández Santana, M.; Verdejo, R.; López-Manchado, M.A. Giving a second opportunity to tire waste: An alternative path for the development of sustainable self-healingstyrene-butadiene rubber compounds overcoming the magic triangle of tires. Polymers 2019, 11, 2122. [Google Scholar] [CrossRef]

- Symeonides, D.; Loizia, P.; Zorpas, A.A. Tire waste management system in Cyprus in the framework of circular economy strategy. Environ. Sci. Pollut. Res. 2019, 26, 35445–35460. [Google Scholar] [CrossRef]

- Girskas, G.; Nagrockiené, D. Crushed rubber waste impact of concrete basic properties. Constr. Build. Mater. 2017, 140, 36–42. [Google Scholar] [CrossRef]

- De Souza, C.D.R.; D’Agosto, M.D.A. Value chain analysis applied to the scrap tire reverse logistics chain: An applied study of co-processing in the cement industry. Resour. Conserv. Recycl. 2013, 78, 15–25. [Google Scholar] [CrossRef]

- Kannan, D.; Diabat, A.; Shankar, K.M. Analyzing the drivers of end-of-life tire management using interpretive structural modeling (ISM). Int. J. Adv. Manuf. Technol. 2014, 72, 1603–1614. [Google Scholar] [CrossRef]

- Amin, S.H.; Zhang, G.; Akhtar, P. Effects of uncertainty on a tire closed-loop supply chain network. Expert. Syst. Appl. 2017, 73, 82–91. [Google Scholar] [CrossRef]

- Pereira, M.M.; Machado, R.L.; Ignacio Pires, S.R.; Pereira Dantas, M.J.; Zaluski, P.P.; Frazzon, E.M. Forecasting scrap tires returns in closed-loop supply chains in Brazil. J. Clean. Prod. 2018, 188, 741–750. [Google Scholar] [CrossRef]

- Nowakowski, P.; Król, A. The influence of preliminary processing of end-of-life tires on transportation cost and vehicle exhausts emissions. Environ. Sci. Pollut. Res. 2020, 28, 24256–24269. [Google Scholar] [CrossRef]

- Instituto Nacional de Estadística y Geografía (INEGI). Economía y Sectores Productivos. Parque Vehicular. Available online: https://www.inegi.org.mx/temas/vehiculos/ (accessed on 26 January 2025).

- Arciniega, G.M.; Ávila, D.J.; Quintero, O.P. Propuesta de plan de manejo integral de llantas usadas, generadas en la ciudad de los mochis, Sinaloa. Rev. Ra Ximhai 2023, 19, 157–181. [Google Scholar] [CrossRef]

- Mrad, M.; El-Samra, R. Waste Tire Management: Lebanon Case Study. J. Waste Manag. Dispos. 2020, 3, 102–113. [Google Scholar]

- Rumyantseva, A.; Rumyantseva, E.; Berezyuk, M.; Plastinina, J. Waste recycling as an aspect of the transition to a circular economy. Int. Con. Sustain. Clim. Chang. 2020, 534, 012002. [Google Scholar] [CrossRef]

- Dobrota, D.; Dobrota, G.; Dobrescu, T.; Mohora, C. The Redesigning of Tires and the Recycling Process to Maintain an Efficient Circular Economy. Sustainability 2019, 11, 5204. [Google Scholar] [CrossRef]

- Li, W.; Wang, Q.; Jin, J.; Li, S. A life cycle assessment case study of ground rubber production from scrap tires. Int. J. Life Cycle Assess. 2014, 19, 1833–1842. [Google Scholar] [CrossRef]

- Feriha, K.M.; Hussein, R.A.; Ismail, G.A.; El-Naggar, H.M.; El-Sebaie, O.D. Feasibility study for end-of-life tire recycling in new tire production. Egypt. J. Environ. Eng. Ecol. Sci. 2014, 3, 5. [Google Scholar] [CrossRef]

- Martínez, J. An overview of the end-of-life tires status in some Latin American countries: Proposing pyrolysis for a circular economy. Renew. Sustain. Energy. Rev. 2021, 144, 111032. [Google Scholar] [CrossRef]

- European Tyre and Rubber Manufacturers Association (ETRMA). Annual Report. 2017. Available online: https://www.etrma.org/key-topics/materials/natural-rubber/ (accessed on 26 January 2025).

- U.S. Tire Manufacturers Association (USTMA). U.S. Scrap Tire Management Summary. 2019. Available online: https://www.ustires.org/ (accessed on 26 January 2025).

- INEGI. Censo Económico. 2019. Available online: https://www.inegi.org.mx/programas/ce/2019/ (accessed on 31 December 2024).

- Available online: https://www.economia.gob.mx/datamexico/es/profile/product/rubber-and-articles-thereof (accessed on 31 December 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).