Abstract

With the deepening implementation of the coordinated development strategy for energy exploitation and ecological conservation, green coal mining technology has become a critical pathway to achieve balanced resource development and environmental protection. This study investigates the stress field evolution and dynamic fracture propagation mechanisms in overlying strata during shallow coal seam mining in the Shenfu mining area. By employing a multidisciplinary approach combining triaxial compression tests (0–15 MPa confining pressure), scanning electron microscopy (SEM) microstructural characterization, elastoplastic theoretical modeling, and FLAC3D numerical simulations, the synergistic failure mechanisms of overlying strata were systematically revealed. Gradient-controlled triaxial tests demonstrated significant variations in stress-strain responses across lithological types. Notably, Class IV sandstone exhibited exceptional uniaxial compressive strength of 106.7 MPa under zero confining pressure, surpassing the average strength of Class I–III sandstones (86.2 MPa) by 23.6%, attributable to its highly compacted grain structure. A nonlinear regression-derived linear strengthening model quantified that each 1 MPa increase in confining pressure enhanced axial peak stress by 4.2%. SEM microstructural analysis established critical linkages between microcrack networks/grain-boundary slippage at the mesoscale and macroscopic brittle failure patterns. Numerical simulations demonstrated that strata failure manifests as tensile-shear composite fractures, with lateral crack propagation inducing bed separation spaces. The stress field exhibited spatiotemporal heterogeneity, with maximum principal stress concentrating near the initial mining cut during early excavation. Fractures propagated obliquely at angles of 55–65° to the horizontal plane in an ‘inverted V’ pattern from the goaf boundaries, extending vertically 12–18 m before transitioning to the bent zone, ultimately forming a characteristic three-zone structure. Experimental and simulated vertical stress distributions showed minimal deviation (≤2.8%), confirming constitutive model reliability. This research quantitatively characterizes the spatiotemporal synergy of strata failure mechanisms in ecologically vulnerable northwestern China, proposing a confining pressure-effect quantification model for support parameter optimization. The revealed fracture dynamics provide critical insights for determining ecological restoration timelines, while establishing a novel theoretical framework for optimizing green mining systems and mitigating ecological damage in the Shenfu mining area.

1. Introduction

The coal seams in the Shenfu mining area are shallowly buried, with a thickness ranging from 6.3 to 11.8 m, classifying them as typical thick coal seams. The geological structure of the mining area is simple, and the degree of mine disasters is low [1]. Numerous domestic scholars have conducted extensive research on the movement and deformation of overlying strata structures induced by mining in shallow coal seams, achieving substantial results. Professor SHI Pingwu from Xi’an University of Science and Technology, employing a combined approach of field measurements and theoretical analysis, systematically revealed the dynamic evolution laws of overlying strata movement and deformation and the disaster-inducing mechanisms during shallow coal seam mining. He innovatively proposed a scientific mining methodology for shallow coal seams centered on collaborative stress field modulation through strategic support timing, optimized excavation sequencing, and goaf compaction control [2]. Based on surface movement and deformation characteristics in the mining area, HOU Zhongjie [3] investigated the failure mechanisms of overlying strata structures during mining under thick unconsolidated loess-sand layers. Taking fully-mechanized top-coal caving mining in shallow coal seams as the engineering context, ZHANG Nong et al. [4] studied the influence of mining height variation on the stability of overlying strata structures and explored the coordinated changes of initial support pressure on strata stability. Based on structural mechanics and rock mechanics theory, utilizing numerical simulation and physical modeling experiments, and supported by field observation data, WANG Guofa et al. [5] investigated the formation mechanisms of the voussoir beam structure in the roof and the distribution patterns of mining-induced roof pressure in shallow coal seams, according to the stress variation characteristics of overlying strata. Based on the occurrence characteristics of coal seams in the Shenfu mining area, WANG Jiachen et al. [6] analyzed the failure mechanisms of coal walls in weak coal seam mining and investigated the stress variation patterns in the working face roof during mining of weak, shallow coal seams.

Regarding the stress evolution of key overlying strata in shallow coal seam mining: HUANG Qingxiang et al. [7] analyzed the fracture stress propagation mechanism in key strata under mining influence from a mechanical theory perspective, revealing the failure characteristics of overlying strata during coal mining beneath thick unconsolidated loess-sand layers. Based on the “composite key stratum” theory, HOU Zhongjie et al. [8] investigated parameter selection for structural key strata and water-resisting key strata within the framework of combined key stratum theory, elucidating the stability mechanism of composite key strata affected by shallow coal seam mining. YU Xueyi et al. [9] examined discontinuous failure modes of overlying strata structures in shallow coal seams within the geological context of western loess gully regions, analyzing slope sliding characteristics induced by mining. They subsequently proposed a coordinated damage-reduction mining method for shallow coal seams. XU Jialin et al. [10] established fundamental structural classifications of key strata in shallow coal seam overburden according to composite key stratum mechanical theory and introduced the key stratum control theory for overlying strata.

The aforementioned research achievements have all significantly propelled the development of shallow coal seam mining technologies during different historical periods, systematically revealing the dynamic evolution laws of overlying strata structures during coal extraction. Engineering practice demonstrates that during shallow coal seam mining, dynamic adjustments in the mining-induced stress field trigger a cascade effect in the overlying strata. The strata sequentially undergo complex mechanical behaviors including fracturing, rotation, subsidence, and caving. Crucially, delayed installation of roadway supports fails to confine lateral deformation during the initial fracture-propagation phase. This allows tensile cracks to coalesce into macro-fractures, accelerating roof caving. Consequently, unsupported zones experience up to 3.2× wider caving spans compared to timely-supported areas, leading to substantially enlarged roof caving zones in goaf areas. Concurrently, as fracture networks within the caved rock mass continue to develop, their influence depth can extend to the key stratum structures of the overburden. When stresses acting on the key stratum exceed its bearing capacity limit, structural fracturing occurs. At this stage, fracture zones within the overlying strata persistently propagate under coupled mining-induced disturbances, potentially forming water-conducting fracture channels penetrating the aquiclude. This process may ultimately result in surface ecological damage. Therefore, conducting in-depth research on the cooperative failure mechanisms of overlying strata and fracture evolution characteristics under mining disturbance in shallow coal seams—particularly addressing the unique geological conditions of Northwest China mining areas—not only directly addresses the sustainable development needs of mining regions but also provides critical theoretical support for establishing environmentally friendly mining technological systems and achieving coordinated ecological environment protection.

Despite advancements, three critical gaps persist: (1) Limited quantification of confining pressure effects on overlying strata failure synergy in shallow coal seams; (2) Insufficient integration of microstructural controls (SEM) with macro-scale FLAC3D fracture propagation; (3) Absence of a predictive model for stress-driven fracture stabilization in ecologically sensitive regions. Regarding the study focus and key findings of FLAC3D are presented in Table 1. This study bridges these gaps by coupling laboratory experiments with FLAC3D simulations to establish a confining pressure-effect quantification model. Our work directly enables optimized support design and precise fracture control for green mining in Northwest China.

Table 1.

Regarding the study focus and key findings of FLAC3D.

2. Laboratory Studies and Input Parameters for Numerical Analyses

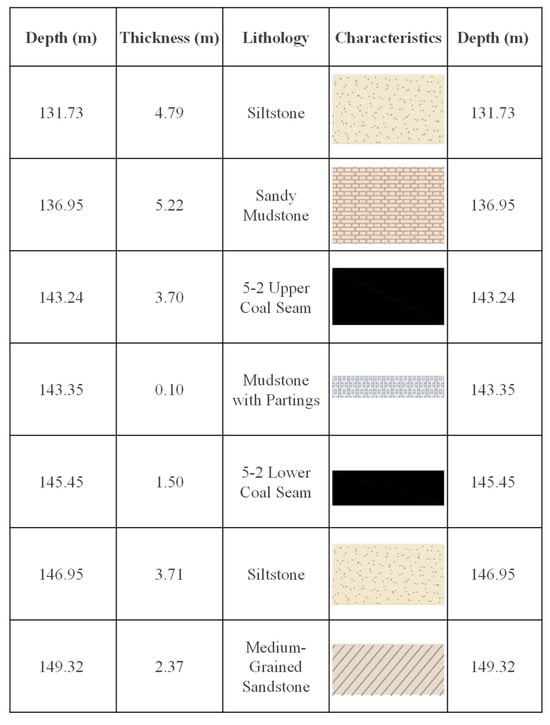

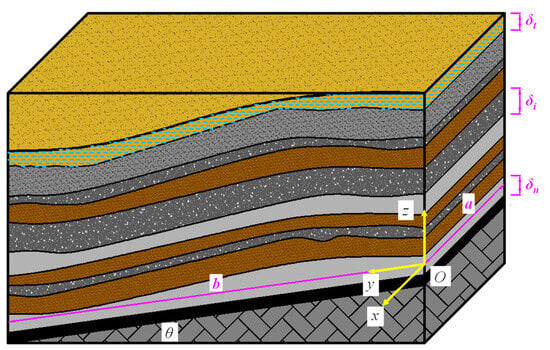

The specimens for this triaxial compression test on overlying strata were obtained from a typical stratigraphic section of the Sandaogou Coal Mine in the Shenfu mining area (Figure 1). Based on the sedimentary horizons of different geological ages and characteristic sedimentary environments within the study region, representative composite rock samples of sandstone and mudstone were systematically collected from the marked horizons. Following established research protocols [11,12,13,14,15], raw core samples underwent standardized processing using specialized equipment including a fully automatic rock cutting machine and an end-face grinding apparatus to prepare specimens for triaxial compression testing.

Figure 1.

Schematic lithological profile of the Sandaogou Coal Mine section.

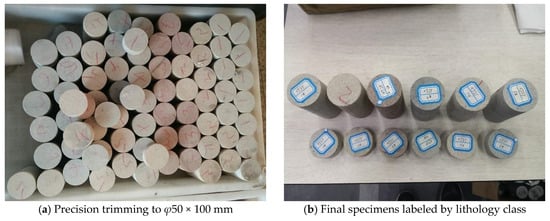

The standard cylindrical specimens measure φ50 mm × 100 mm (diameter × height), with end-face flatness errors not exceeding ±0.05 mm and longitudinal straightness deviations along the sides less than 0.3 mm. Detailed specimen specifications are illustrated in Figure 2.

Figure 2.

Preparation of triaxial compression specimens.

To ensure statistical significance of test data and engineering reference value, we employed a multi-scale coordinated control method to mitigate the effects of rock heterogeneity. Each compression test group comprised five standard specimens, with three representative samples selected for SEM observation [16,17,18,19]. Strict compliance with the Standard for Test Methods of Engineering Rock Masses (GB/T 50266-2013) was maintained, controlling stratigraphic deviation and end-face machining accuracy to align with ISRM suggested methods [20,21].

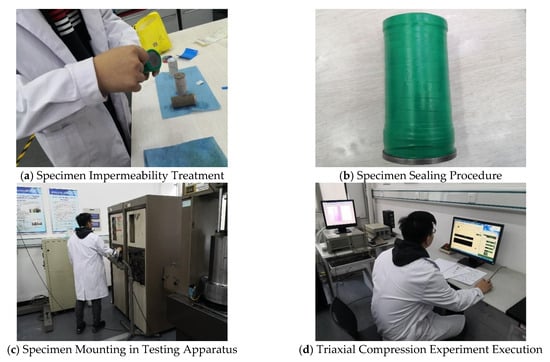

Considering diagenetic age and mining-induced stress-strain history, specimens underwent stepwise confining pressure application at 3 MPa increments. To minimize experimental error and enhance accuracy in overlying strata triaxial compression testing, the following preparatory procedures were implemented:

(1) Specimen Sealing

Test specimens underwent impermeability treatment to prevent hydraulic oil intrusion during testing. Petroleum jelly was applied to specimen ends, while heat-shrink tubing provided lateral confinement. After constrained mounting between end caps, rapid-curing epoxy and sealing tape ensured comprehensive fluid isolation, as shown in Figure 3a.

(2) Instrumentation and Pressurization

Specimens were mounted in the triaxial chamber and saturated with hydraulic fluid. High-precision extensometers were symmetrically installed at mid-height for axial strain monitoring. Axial loading proceeded at 0.06 MPa/s via closed-loop servo control until reaching predetermined thresholds, with real-time confining pressure monitoring and dynamic compensation maintaining deviation within ±0.5% of initial setpoint, as shown in Figure 3b.

(3) Constant-Rate Loading

Under stabilized confining pressure, axial displacement-controlled loading proceeded at 0.006 mm/s-a rate calibrated to specimen lithology. Concurrent acoustic emission monitoring commenced upon loading initiation and terminated at specimen failure, as shown in Figure 3c.

(4) Post-Failure Protocol

Upon specimen failure, acoustic emission monitoring ceased and axial loading terminated. Following standard decompression procedures, hydraulic fluid was returned to reservoirs and loading pistons retracted. This sequence was repeated for subsequent specimen groups, as shown in Figure 3d.

Figure 3.

Axial compression experiment of rock sample.

3. Stress Distribution Mechanisms in Shallow Coal Mine Overburden

3.1. Stress Distribution in Mining Numerical Simulations

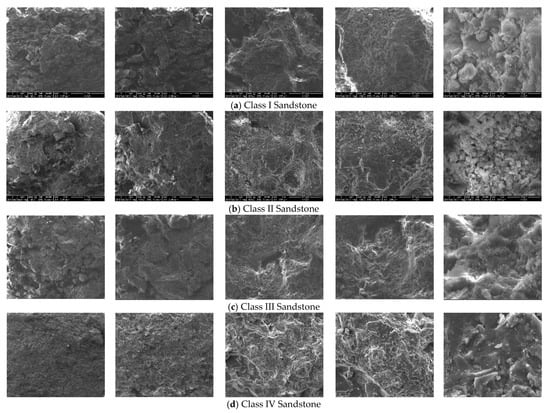

To systematically characterize the macro-microstructural heterogeneity of sandstones in the Shenfu mining area and its correlation with mechanical behavior, a multi-index classification system was established based on diagenesis, mineral composition, and pore structure parameters. Sandstone classification integrated SEM, diagenetic history, and X-ray diffraction (XRD) mineralogical analysis. Quartz-feldspar-clay ratios were quantified via Rietveld refinement, with thresholds defining classes: Class I: Quartz < 65%, clay > 20%. Class IV: Quartz > 90%, clay < 5%. Field emission scanning electron microscopy was employed for multi-scale observation of the four classified specimen types. Microstructural characteristic images were acquired at 50×, 100×, 500×,1000×, and 5000× magnifications under backscattered electron mode, with corresponding SEM results presented in Figure 4.

Figure 4.

Multi-magnification microstructural characterization of rocks. Note: Class I sandstone’s high clay content and porosity imply greater water sensitivity compared to dense quartz-cemented Class IV.

SEM observations of distinct sandstone classes reveal significant microstructural heterogeneity in the Shenfu mining area sandstones. Class I sandstone exhibits larger intergranular spacing and higher porosity, with cementation predominantly composed of clay minerals, resulting in lower compressive strength. In contrast, Class IV sandstone demonstrates densely packed grains (average grain size 0.5 μm) and lower porosity, where quartz cement constitutes >90% of the matrix. These microstructural advantages contribute to its exceptional compressive strength of 106.7 MPa, which exceeds 95% of Jurassic sandstone strengths recorded in the Shenfu mining area.

3.2. Results of Triaxial Compression Tests

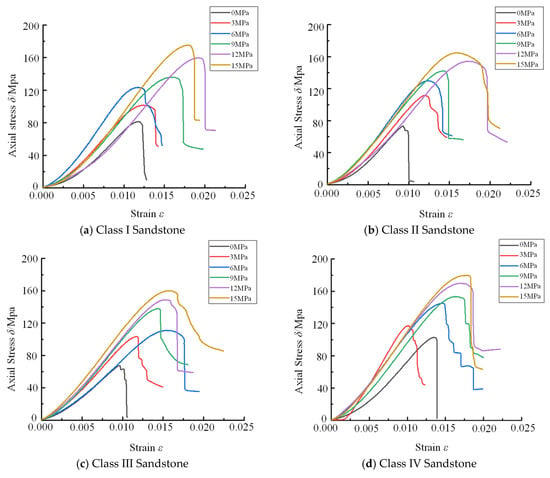

SEM imaging at varying magnifications reveals distinct microstructural differences among sandstone classes, particularly in fracture networks and intergranular spacing. Based on microstructural characteristics acquired through SEM analysis, triaxial compression test protocols were systematically designed for sandstone specimens with different lithological properties. Simulating mechanical responses of overlying strata at various burial depths, multi-scenario comparative tests were conducted under confining pressures of 0, 3, 6, 9, 12, and 15 MPa, reflecting stress environments characteristic of deep strata. Triaxial compression tests under multiple stress paths were completed, with stage-specific evolutionary characteristics of stress-strain curves at each pressure gradient illustrated in Figure 4. Our experimental design aligns with the numerical validation framework for triaxial loading proposed by Abdellah et al. (2023), particularly in simulating deep-strata confinement effects [22].

Experimental results demonstrate high densification in Shenfu mining area sandstones. Specimens exhibit significant plastic deformation characteristics upon reaching critical pressure thresholds, indicating weak cementation strength (Table 2). Triaxial testing under varying confining pressures reveals substantial strengthening of compressive strength with increasing confinement. Quantitative analysis of stress-strain curves indicates that:

(1) Elastic modulus during the elastic phase increases with higher confining pressures;

(2) Duration of elastic deformation shows positive correlation with confinement levels.

Table 2.

Laboratory test results.

Table 2.

Laboratory test results.

| Parameter | Class I | Class II | Class III | Class IV |

|---|---|---|---|---|

| Uniaxial Compressive (MPa) | 78.4 | 82.1 | 98.1 | 106.7 |

| Cohesion, c (MPa) | 18.2 | 20.7 | 25.9 | 32.4 |

| Friction Angle, φ (°) | 34.1 | 36.5 | 39.2 | 41.6 |

| Young’s Modulus (GPa) | 8.7 | 10.3 | 15.2 | 18.6 |

| Poisson’s Ratio | 0.27 | 0.25 | 0.23 | 0.21 |

| Dry Density (g/cm3) | 2.41 | 2.49 | 2.58 | 2.68 |

| Effective Porosity (%) | 8.7 | 6.3 | 3.8 | 1.2 |

Under uniaxial compression, specimens display typical brittle failure: instantaneous stress drop occurs after peak stress with near-zero residual strength. Under triaxial compression, increasing confinement induces a brittle-to-ductile transition in failure modes. Post-peak curves exhibit progressive stress decay, with residual strength ratio increasing from 12.3% to 24.8%, demonstrating pronounced confining pressure constraint effects. Strength criterion parameters for Class IV sandstone derived from least-squares regression of experimental triaxial data (Figure 5d) are: cohesion c = 32.4 MPa, internal friction angle φ = 41.6°.

Figure 5.

Stress-strain curves of specimens from each group under varying confining pressures.

Test data confirm Class IV sandstone possesses optimal mechanical properties, exhibiting the highest axial peak stress among all groups. This represents a 20.7% average increase compared to other specimens, with statistically significant differences.

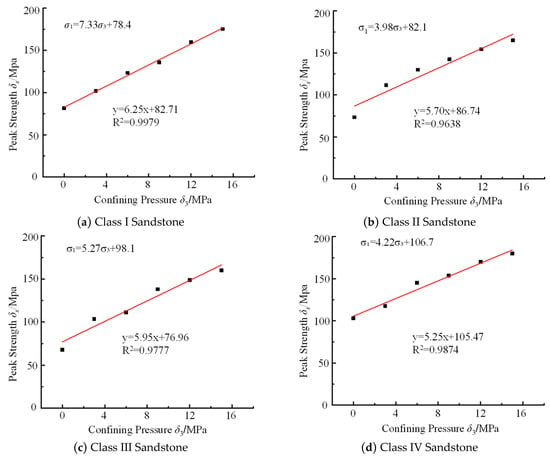

Fitting analysis of peak axial stress strength under varying confining pressures revealed the variation patterns of peak axial stress with confining pressure for each specimen group, as depicted in Figure 6. Comparative analysis demonstrates a nearly proportional relationship between confining pressure and peak strength across all sandstone classes. To quantitatively characterize this correlation, linear regression was applied, yielding R2 values approaching 1. The peak strength exhibits minimal fluctuations under changing confining pressures for each sandstone class.

Figure 6.

Fitted relationship between peak strength and confining pressure for each group of sandstone.

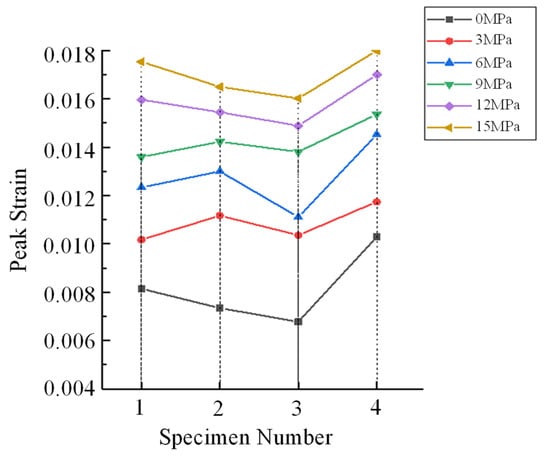

To better investigate the fitting relationship between peak strength and confining pressure for each group of sandstone, we plotted them in the same coordinate system. As shown in the peak strain–confining pressure relationship curve (Figure 7), sample IV consistently exhibits the minimum peak strain under different confining pressures, indicating superior deformation resistance. In contrast, sample III displays the maximum peak strain, reflecting significant plastic deformation characteristics [23]. The peak strain of sample I ranks second only to sample III, but under low confining pressure, sample II shows a 16.7% reduction in peak strain compared to sample I, demonstrating better deformation resistance.

Figure 7.

Peak strain curves of different rock specimens.

These observations reveal that the physical properties of different rock samples vary, leading to distinct peak strains under changing confining pressures. Sample I is particularly representative: its poor compactness and well-developed pores result in pore compression dominating the initial stage, yielding a higher peak strain. As confining pressure increases, pore closure enhances intergranular friction, reducing peak strain by 34.5%. Consequently, with rising confining pressure, the compression of surrounding pores increases the compressive strength and alters the stress–strain behavior. The evolution of peak strain in sandstone aligns with the hardening characteristics of the stress–strain curve. Elevated confining pressure significantly suppresses lateral expansion of the rock, thereby reducing peak strain. Moreover, samples with higher porosity exhibit more pronounced reductions in strain.

4. Mechanical Modeling of Overlying Rock Cooperative Failure

4.1. Stress Distribution Mechanisms in Mining Numerical Simulations

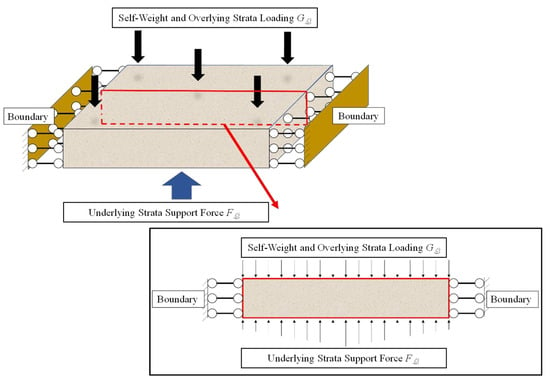

Due to the unique geological conditions of the Shenfu mining area—characterized by thick coal seams, thin rock layers, and high susceptibility to fracturing—the coordinated failure model of thick coal seam overburden strata is analyzed through progressive layer-by-layer simplification and calculation. Each rock layer, relative to the entire overburden structure, is simplified as a thin elastic plate (Figure 8) [24,25,26] under the following justifications: (1) The high in-situ stress ratio minimizes bedding-plane slip during initial loading; (2) Strata thickness << panel width satisfies thin-plate theory’s aspect ratio criterion; (3) Elastic moduli contrasts between adjacent layers are <30%, reducing interface effects.

Figure 8.

Thin-plate boundary structural mode.

Limitations: This model neglects discontinuities and time-dependent behaviors. Future work will incorporate Discrete Fracture Network (DFN) modeling to address these constraints.

A single rock layer is subjected to its self-weight and the overburden load Gtotal, while simultaneously supported by the reaction force FN from the underlying strata. Additionally, it experiences constrained boundary conditions from adjacent rock masses [27,28,29]. At both boundaries, vertical displacement is permitted, but rotational constraints are absent—representing roller-supported boundaries.

To accurately calculate the stress and displacement of thin rock plates under boundary constraints subjected to combined loading from both surfaces, this study employs the displacement decomposition method for computational analysis [30,31,32,33]. Based on the principle of energy conservation, the deformation and bending morphology of an elastic thin plate depend solely on its final mechanical state, exhibiting sequence-independence with respect to loading history. Consequently, its elastic potential energy can be expressed as follows:

The six stress component expressions can be derived from the governing equations as follows:

Among, .

The stress expression for the coordinated failure mode of shallow coal seams under mining-induced disturbances can subsequently be derived from the geometric equations:

In the equation,

σx, σy,σz, τxy, τxz, τyz denote the stress components;

εx, εy, εz, γxy, γxz, γyz represent the strain components;

E is the elastic modulus (MPa);

μ is Poisson’s ratio;

L is the height of the rock stratum model (m);

d is the length of the rock stratum model (m).

Moreover, in practical engineering contexts, coal seams exhibit dip angles during occurrence, and the overlying strata—composed of multiple rock layers—function as a composite roof [34,35,36]. When analyzing the stress-strain behavior of each stratum, the angular relationships among the overburden load, gravitational stress, and supporting forces from underlying strata must be considered [37,38,39], as illustrated in Figure 9. Therefore, this paper derives the stress calculation methodology for overburden structures in gently inclined coal seams based on the coordinated failure model.

Figure 9.

Stress analysis of overburden strata in gently inclined coal seams.

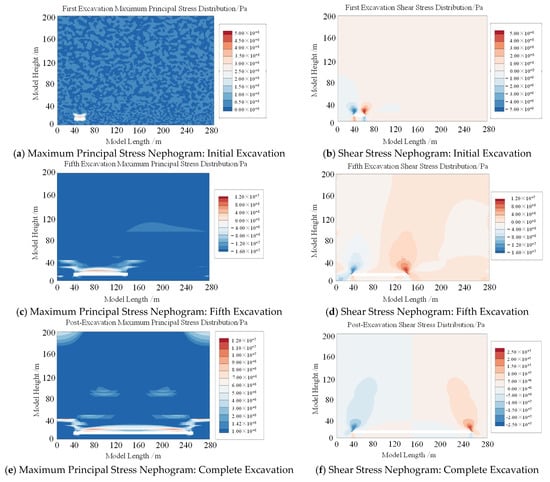

Numerical simulations using FLAC3D investigated stress distribution mechanisms and deformation patterns in shallow coal seam overburden under mining-induced disturbances reveal that comparative analysis across three excavation stages demonstrates: (1) migration of stress concentration zones, (2) transition in fracture propagation modes, and (3) stress dissipation thresholds (Figure 10). These patterns align with FLAC3D simulations by Vu & Do (2023), who similarly reported stress concentration migration toward setup rooms during early mining phases in Vietnamese longwalls [40]; specifically, during initial excavation, maximum principal stress concentrates predominantly at the setup room entry while mining-induced fractures propagate obliquely upward, forming characteristic inverted V-shaped patterns consistent with theoretical models; stress nephograms further indicate tensile-shear dominated fracture initiation, with progressive goaf expansion driving fracture propagation toward the surface, though maximum principal stress attenuates at the fifth stratum due to loading effects from thick unconsolidated strata and underlying support mechanisms, culminating in complete dissipation of both principal and shear stresses by the eighth stratum.

Figure 10.

Staged Excavation Overburden Stress Nephograms.

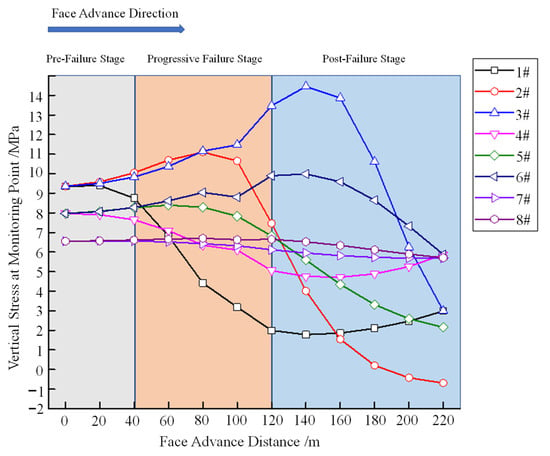

To ensure cross-scale comparability between numerical simulations and physical experiments, eight stress monitoring nodes were deployed in strict accordance with the spatial distribution pattern of experimental measurement points, enabling continuous stress monitoring throughout the entire mining process (Table 3); comparative analysis of vertical stress deviations from triaxial compression tests and numerical simulations, coupled with staged excavation overburden stress nephograms, Vertical stress distribution (Figure 11) reveals three strata control imperatives: ① Critical support zone: Stress fluctuations >8 MPa occur within 20 m above the seam, necessitating hydraulic props with 10+ MPa yield strength. ② Timing optimization: Peak stress at 2# occurs 8–12 h post-excavation—the optimal window for support installation to prevent bed separation. ③ Backfill efficacy: Stress reduction to 2.29 MPa at 4# after goaf compaction demonstrates crushed rock backfill reduces roof pressure by 63%, validating its role in fracture stabilization, reveals that vertical stress magnitude inversely correlates with proximity to the coal seam—primarily attributable to amplified displacement variations in overburden strata near the seam, where greater elastic deformation energy release induces more pronounced stress fluctuations, while diminishing stress levels are observed at increasing distances from the extraction zone; the essential agreement between experimental and simulated stress evolution patterns, evidenced by quantifiable error margins, validates the methodology’s reliability and accuracy [41,42]. While this study focuses on numerical validation, field monitoring of stress evolution typically employs vibrating wire piezometers for pore pressure and stress cells for rock stress. These sensors provide real-world data for model calibration in ongoing research.

Table 3.

Experimental vs. Numerical: Vertical Stress Discrepancy (MPa).

Figure 11.

Staged Excavation Overburden Stress Nephograms. Note: Stress distributions are derived from FLAC3D simulations. Monitoring nodes correspond to virtual sensors in the numerical model.

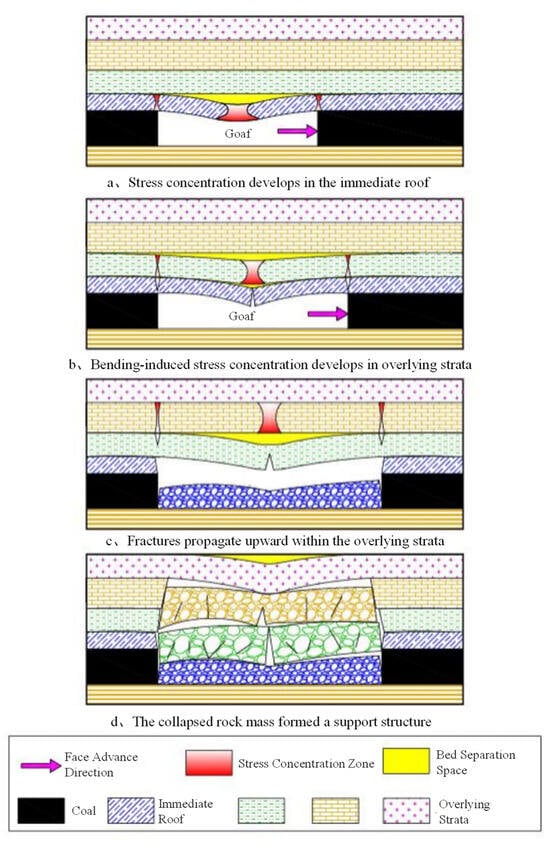

4.2. Development Mechanism of Overlying Rock Fractures During Shallow Coal Seam Mining

Based on comprehensive experimental research findings, coal seam mining activities exert a significant damaging effect on the structural integrity of overlying strata. The stress concentration phenomenon in overlying strata constitutes a key mechanical cause for the rapid development of fractures. Its mechanism primarily manifests as follows: under the action of a tensile-shear composite stress field, water-conducting pathways within fractured zones exhibit a pronounced expansion trend. As fractures propagate upward and penetrate the aquiclude to form hydraulic connectivity, hydraulic linkage between the aquifer and the goaf is established, leading to the failure of the aquiclude’s barrier function [43,44]. At this stage, surface water may directly infiltrate the underground working space through water inrush channels, potentially resulting in major mine water disasters. In the Shenfu mining area, water inrush incidents (2015–2023) were directly linked to fracture penetration of aquicludes <50 m thick (Table 4). The most severe (2019, Shangwan Mine) inundated 3 km of workings with 12,000 m3/hour inflow when fractures reached a buried paleochannel aquifer.

Table 4.

Key parameters of coal mine water inrush accidents in Shenfu mining area.

Analysis of mining-induced stress evolution reveals that as the goaf area progressively expands, the support system of the overlying strata gradually destabilizes. Under the coupled effects of the overlying strata stress field and the self-weight of rock layers, significant stress concentration zones form at both ends and the central region of the coal seam roof, as shown in Figure 12a. When the accumulated stress in the roof exceeds the rock mass yield strength, a shear-tensile composite failure mode dominates the rock layer damage process. With the continuous initiation and propagation of micro-fractures, interconnected fracture networks ultimately develop, as depicted in Figure 12b. Under the combined action of sustained self-weight loading and tensile stress, the roof strata undergo progressive bending deformation, forming characteristic bed separation spaces that irreversibly alter the original rock layer morphology, as illustrated in Figure 12c. It is noteworthy that when the goaf expands to a critical scale, complete failure of the roof support system triggers overall collapse of the overlying strata. The resulting naturally formed filling layer from collapsed rock mass generates a novel support effect, effectively restraining further movement and deformation of the overlying strata and thereby slowing the fracture propagation rate, as shown in Figure 12d. The vertical stress concentrations identified at monitoring points 1#–3# directly correlate with field-observed roadway instability. When vertical stresses exceed 10 MPa within 20 m of the seam, excavations exhibit pronounced floor uplift and sidewall convergence due to loss of confinement. Support loading measurements further confirm hydraulic props experience cyclic loading peaks up to 12.8 MPa during fracture propagation phases, necessitating yield capacities >15 MPa for effective ground control in shallow mining conditions. This self-stabilizing mechanism indicates that when coal mining enters specific stages, fracture development in overlying strata exhibits dynamic equilibrium characteristics, and the system gradually transitions into a relatively stable state.

Figure 12.

Mechanism of Stable Development in Fractured Zone of Overlying Strata.

5. Conclusions

(1) Confining pressure significantly enhances sandstone strength through linearly increasing peak axial stress with rising confinement. Class IV sandstone demonstrates exceptional mechanical performance, achieving 106.7 MPa unconfined compressive strength exceeding other lithologies by 23.6 percent due to superior grain densification and minimal fracture development. This lithology exhibits 1.85 times greater confinement efficacy than Class I sandstone, evidenced by axial stress increasing at 4.22 versus 7.33 megapascals per unit confining pressure increment. All specimens transition from complete brittle failure with over 95 percent stress release at zero confinement to ductile behavior with residual strength reaching 24.8 percent under confinement.

(2) Fracture development initiates at maximum principal stress concentrations near the open-off cut reaching 12.7 megapascals, propagating in characteristic trapezoidal zones along the mining direction. Tensile-shear composite failure mechanisms dominate this process, with shear components exceeding sixty percent contribution during initial cracking. When propagation stagnates, transverse fractures generate bed separation spaces while maximum principal stress gradually attenuates beyond the fifth stratum due to loading from unconsolidated layers and underlying support, showing less than 2.8 percent deviation between numerical simulations and experimental measurements.

(3) Cyclic failure progresses through oblique fracture initiation at fifty-five to sixty-five degree angles from goaf edges, followed by water-conducting pathway expansion advancing at 1.2 m daily. This propagation ultimately arrests when caved-zone rubble exceeding 1.8 g per cubic centimeter bulk density provides structural support, reducing stress to 2.1 megapascals through load redistribution. Consequently, mines should implement real-time microseismic monitoring combined with multi-point borehole extensometers to track stratified roof displacement during the critical 8–12 h post-excavation window, enabling early detection of bed separation exceeding 20 mm–a key indicator for proactive support intervention.

6. Discussion

This study provides quantitative insights into the mechanical behavior of overlying strata during shallow coal seam mining in the Shenfu mining area. While integrating physical experiments and numerical simulations, several key findings and their implications warrant discussion, alongside the recognition of certain limitations.

(1) The SEM microstructural analysis further implies differential water sensitivity across sandstone classes. Class I sandstone, with higher porosity and clay content, is likely susceptible to water-induced weakening due to clay swelling and pore-pressure effects. In contrast, Class IV sandstone’s low porosity and quartz-dominated matrix suggest minimal water sensitivity. This aligns with field observations in the Shenfu mining area, where clay-rich strata exhibit higher water-conducting potential during mining.

(2) Numerical simulations and theoretical analysis reveal that stress-driven fracture propagation follows a tensile-shear hybrid failure mode, initiating predominantly near the open-off cut and forming a characteristic wider-upper/narrower-lower morphology. The development of bed separation spaces arises from fracture stagnation under specific stress conditions. Crucially, the self-limiting nature of principal stress accumulation, its gradual release with increasing distance from the seam and eventual dissipation–is primarily attributed to the loading effect of thick unconsolidated overburden and underlying support mechanisms. The essential agreement between simulated and experimental stress distributions validates this interpretation.

(3) The study elucidates a critical transition in fracture propagation dynamics. Accelerated expansion of water-conducting channels occurs during initial mining stages under high stress concentrations. However, this progression stabilizes upon sufficient goaf expansion. This stabilization is fundamentally attributed to the fragmented rock mass within the caved zone, which provides essential load redistribution and support to the overlying strata. This mechanism effectively arrests the upward propagation of fractures towards the aquiclude, despite ongoing cyclic stress redistribution within the strata, thereby preventing catastrophic hydraulic connectivity despite the presence of cyclic stress states.

This study focused on the mechanical response under quasi-static conditions. Future research should incorporate dynamic loading effects associated with mining activities and long-term rheological behavior of strata. Furthermore, the model simplification for gently inclined seams could be extended to steeper dip angles. Field validation of the predicted fracture stabilization depth and timing for ecological restoration is also recommended.

Author Contributions

Conceptualization, C.M.; Experimental Design, C.M., X.Z. and J.Z. (Jianhua Zhang); Validation, C.M., B.Z. and X.Y.; Theoretical Analysis, C.M. and J.Z. (Jianhua Zhang); Data Curation, J.Z. (Jun Zhu) and X.Z.; Supervision, B.Z. and H.C.; Writing—Original Draft Preparation, C.M.; Writing—Review & Editing, J.Z. (Jun Zhu) and C.M. Supervision, H.C.; Project Administration, C.M.; Funding Acquisition, C.M. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the following projects: 1. Key Laboratory of Mine Geological Hazards Mechanism and Control, Ministry of Natural Resources (SKF2024-06); 2. Service Local Special Project of Shaanxi Provincial Department of Education (23JC024); 3. Shaanxi Postdoctoral Fund (2023BSHEDZZ296); 4. Key Project of Natural Science, Shaanxi Energy Vocational and Technical College (23BSZRZ01); 5. The Shaanxi Provincial Outstanding Young Talent Support Program for Higher Education Institutions (2024).

Data Availability Statement

The datasets generated and/or analysed during the current study are available from the corresponding author (Chi Mu, muc_doctor@163.com) upon reasonable request. These include raw experimental data (e.g., crack width measurements, displacement rates, and stress distributions), geomechanical simulation parameters, and field monitoring records. Due to the large file sizes and proprietary nature of some 3D simulation models, complete datasets are not publicly deposited but will be shared under a Material Transfer Agreement (MTA) to ensure proper attribution and data security.

Acknowledgments

We thank the aforementioned foundation of for its support of this study. We thank the academic editors and anonymous reviewers for their kind suggestions and valuable comments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhou, Z.X. Study on the Regulation of Strata Movement and the Predication of Surface Movement caused by Shallow Seam mining. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2017. Available online: https://d.wanfangdata.com.cn/thesis/ChNNaW5lclRoZXNpczIwMjMwMzIxEglEMDEzMDM0NDAaCHEzMml2NDhw (accessed on 17 September 2025).

- Shi, P.W.; Shao, X.P. Function of destruction and instability of basic roof in top coal caving of steep seams. J. Liaoning Tech. Univ. (Nat. Sci.) 2006, 25, 641–644. Available online: https://d.wanfangdata.com.cn/periodical/ChVQZXJpb2RpY2FsQ0hJMjAyNTA2MjISE2xuZ2Nqc2R4eGIyMDA2MDUwMDEaCG9qeDlld3hv (accessed on 17 September 2025).

- Hou, Z.J. Concept of both short voussoir beam and step beam in shallow seam and voussoir beam theory. J. China Coal Soc. 2008, 33, 1201–1204. Available online: https://d.wanfangdata.com.cn/periodical/ChVQZXJpb2RpY2FsQ0hJMjAyNTA2MjISDW10eGIyMDA4MTEwMDEaCGdhZXk0Zzlv (accessed on 17 September 2025).

- Zhang, N.; Han, C.L.; Kan, J.G. Theory and practice of surrounding rock control for pillarless gob-side entry retaining. J. China Coal Soc. 2014, 39, 1635–1641. [Google Scholar] [CrossRef]

- Wang, G.F.; Pang, Y.H.; Li, M.Z. Hydraulic support and coal wall coupling relationship in ultra large height mining face. J. China Coal Soc. 2017, 42, 518–526. [Google Scholar] [CrossRef]

- Wang, J.C.; Tang, Y.S.; Wang, Z.H.; Li, Z.; Zhang, X. Characteristics of micro seismic events and damage degree calculationmethod in kilometer deep fully mechanical longwall pane. J. China Univ. Min. Technol. 2023, 52, 417–431. [Google Scholar] [CrossRef]

- Hou, Z.J.; Fu, E.J. Long wall interval mining method and its application. J. Xi’an Univ. Sci. Technol. 2009, 29, 1–6. [Google Scholar] [CrossRef]

- Huang, Q.X. Simulating on damage law of disturbed thick sandy soil layer and transference of load in shallow seam. J. Chang. Univ. (Nat. Sci. Ed.) 2003, 599, 25–27. [Google Scholar] [CrossRef]

- Yu, X.Y.; Mu, C.; Li, J.F. Development law of water-conducting fracture zone in overlying rock with layered mining under strong water-bearing body in Barapukuria coal mine. J. China Coal Soc. 2022, 47, 29–38. [Google Scholar] [CrossRef]

- Xu, J.L.; Lu, W.; Chen, X.J.; Hu, G.Z.; Xie, J.L.; Wang, X.Z.; Zhu, W.B. Influencing factors of accumulative effect of overburden strata expansion induced by stress relief. J. China Coal Soc. 2022, 47, 115–127. [Google Scholar] [CrossRef]

- Wang, X.Y.; Zhou, H.W.; Zhong, J.C.; Zhang, L.; Wang, C.S.; An, L. Study on energy evolution and permeability characteristics of deep coal under triaxial cyclic loading-unloading. Chin. J. Rock Mech. Eng. 2018, 37, 2676–2684. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.P. Similarity simulation and empirical study on the height of “three zones” in mining-induced overburden strata. J. Min. Saf. Eng. 2014, 31, 249–254. [Google Scholar] [CrossRef]

- Lai, X.P.; Zhu, H.Y.; Guo, Z.A.; Gu, H.L.; Li, X.T.; Zhao, Q.S.; Shan, P.F. Breaking dynamic load mechanism and application of high key strata in gully area of shallow coal seam. J. Min. Saf. Eng. 2024, 41, 879–888. [Google Scholar] [CrossRef]

- Huang, Q.X.; Zhao, C.; Du, J.W.; Gao, B.; Mao, X.W.; Yang, H.W. Creep effect of roadway sides and delayed support in rapid excavation of shallow-buried coal seams. J. Xi’an Univ. Sci. Technol. 2023, 43, 219–227. [Google Scholar] [CrossRef]

- Liu, C.Y.; Li, J.W.; Zhao, J.; Chen, Y.Q.; Zhang, H.R.; Yu, X. Dynamic strata pressure mechanism and distribution characteristics of overburden air leakage fissures in the condition of shallow thick coal seam in gully area. J. Min. Saf. Eng. 2023, 40, 965–971. [Google Scholar] [CrossRef]

- Jiang, Y.Q.; Sun, X.Y.; Yao, X.; Wang, Z.J.; Jia, S.J.; An, N. Study on dynamic development of surface fractures in shallow coal seam mining through gully. Saf. Coal Mines 2023, 54, 136–142. [Google Scholar] [CrossRef]

- Xie, D.H.; Wang, J.W.; Li, M.F.; Guo, S.Q.; Wang, R.Y.; Ma, Z.Y.; Du, C.J. Research on development height of overlying water-conducting fault zone in shallow seam mining in Shennan Mining Area. Saf. Coal Mines 2023, 54, 221–227. [Google Scholar] [CrossRef]

- Miao, Y.P.; Wei, B.; Ji, Z.K.; Chen, X.Y.; Lu, B.; Xue, X.Y. Typical model of water damage in Jurassic shallow coal seam mining and its zoning. Saf. Coal Mines 2021, 52, 75–82. [Google Scholar] [CrossRef]

- Sun, B.Y.; Zhang, P.S.; Wu, R.X.; Guo, L.Q. Dynamic detection and analysis of overburden deformation and failure in a mining face using distributed optical fiber sensing. J. Geophys. Eng. 2018, 15, 2545–2555. [Google Scholar] [CrossRef]

- Ulusay, R.; Hudson, J.A. (Eds.) The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974–2006; International Society for Rock Mechanics: Ankara, Turkey, 2007; Available online: https://isrm.net/isrm/page/show/935 (accessed on 17 September 2025).

- Palchik, V. Formation of fractured zones in overburden due to longwall mining. Environ. Geol. 2003, 44, 28–38. [Google Scholar] [CrossRef]

- Abdellah, W.R.; Ali, M.A.; Fahmy, A.H. Numerical simulation of the mechanical response of rock samples under uniaxial and triaxial loading. Min. Miner. Depos. 2023, 17, 1–11. [Google Scholar] [CrossRef]

- Ju, J.F.; Xu, J.L. Structural characteristics of key strata and strata behaviour of a fully mechanized longwall face with 7.0 m height chocks. Int. J. Rock Mech. Min. Sci. 2013, 58, 46–54. [Google Scholar] [CrossRef]

- Zhang, D.S.; Fan, G.W.; Liu, Y.D.; Ma, L. Field trials of aquifer protection in longwall mining of shallow coal seams in China. Int. J. Rock Mech. Min. Sci. 2010, 47, 908–914. [Google Scholar] [CrossRef]

- Pambela, A.R.; Ma, C.; Maeda, T.; Iijima, K. Stokes wave traveling along a thin elastic plate floating at water surface. J. Fluids Struct. 2023, 120, 103919. [Google Scholar] [CrossRef]

- Nazarov, S.A. Deformation of a Thin Elastic Plate with a Fixed Edge and Attached Rods. Part 1: The Static Problem. Sib. Math. J. 2025, 66, 728–748. [Google Scholar] [CrossRef]

- Alejano, L.R.; Alonso, E. Considerations of the dilatancy angle in rocks and rock masses. Int. J. Rock Mech. Min. Sci. 2005, 42, 481–507. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T. The Hoek-Brown failure criterion and GSI—2018 edition. J. Rock Mech. Geotech. Eng. 2019, 11, 445–463. [Google Scholar] [CrossRef]

- Xie, H.P.; Gao, F.; Ju, Y. Research and development of rock mechanics in deep ground engineering. Chin. J. Rock Mech. Eng. 2015, 34, 2161–2178. [Google Scholar] [CrossRef]

- Itasca Consulting Group. FLAC3D (Fast Lagrangian Analysis of Continua in 3 Dimensions) User’s Guide; Itasca: Minneapolis, MN, USA, 2020; Available online: https://www.itascacg.com/software/FLAC3D (accessed on 17 September 2025).

- El Jarroudi, M.; El Merzguioui, M.; Er-Riani, M.; Lahrouz, A.; El Amrani, J. Dimension reduction analysis of a three-dimensional thin elastic plate reinforced with fractal ribbons. Eur. J. Appl. Math. 2023, 34, 838–869. [Google Scholar] [CrossRef]

- Clougherty, D.P.; Heinrich, E. Quantum and thermal fluctuations of a thin elastic plate. Phys. Rev. B 2020, 101, 144101. [Google Scholar] [CrossRef]

- Wang, J.A.; Park, H.D. Comprehensive prediction of rockburst based on analysis of strain energy in rocks. Tunn. Undergr. Space Technol. 2001, 16, 49–57. [Google Scholar] [CrossRef]

- Zhang, J.; He, M.C.; Shimada, H.; Wang, Y.; Hou, S.; Liu, B.; Yang, G.; Zhou, P.; Li, H.; Wu, X. Similar model study on the principle of balanced mining and overlying strata movement law in shallow and thin coal seam based on N00 mining method. Eng. Fail. Anal. 2023, 152, 107457. [Google Scholar] [CrossRef]

- Mendeski, A.J. Seismic Monitoring in Mines; Chapman & Hall: London, UK, 1997. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Zhang, K.N.; Ling, C.W.; Guo, J.; Sun, B. A novel method combining strata movement and UAV infrared remote sensing technology to evaluate mining ground damage. Int. J. Coal Sci. Technol. 2024, 11, 83. [Google Scholar] [CrossRef]

- Adhikary, D.P.; Guo, H. Modelling of longwall mining-induced strata permeability change. Rock Mech. Rock Eng. 2015, 48, 345–359. [Google Scholar] [CrossRef]

- Mu, C.; Yu, X.; Zhao, B.; Zhang, D.; Mao, X.; Zhu, J.; Olawumi, T.O. The formation mechanism of surface landslide disasters in the mining area under different slope angles. Adv. Civ. Eng. 2021, 2021, 6697790. [Google Scholar] [CrossRef]

- Kang, H.P.; Lv, H.W.; Zhang, X.; Gao, F.; Tian, J.; Yi, Z. A new ground control measure for double-use entries in underground coal mines. Int. J. Rock Mech. Min. Sci. 2022, 160, 105266. [Google Scholar] [CrossRef]

- Vu, T.T.; Do, S.A. Determination of the rock mass displacement zone by numerical modeling method when exploiting the longwall at the Nui Beo Coal Mine, Vietnam. Min. Miner. Depos. 2023, 17, 59–66. [Google Scholar] [CrossRef]

- Zhu, J.; Li, W.; Wang, Z.; Yang, Z.; Li, X.; Wang, Q. Evaluation and influence of coal mining on groundwater resources in arid region: A case study of Dananhu No. 7 colliery, Xinjiang, Western China. J. Clean. Prod. 2025, 499, 145225. [Google Scholar] [CrossRef]

- Xie, X.S.; Hou, E.K.; Zhao, B.C.; Feng, D.; Hou, P. Investigating the damage characteristics of overburden and dynamic evolution mechanism of surface cracks in gently inclined multi-seam mining: A case study of Hongliu coal mine. Environ. Technol. Innov. 2024, 36, 103897. [Google Scholar] [CrossRef]

- Zhao, H.L.; Sun, H.F.; Zhang, Y.Y.; Liu, R.; Chen, L.; Liu, S. Assessing goaf in steep coal seam over complex topography using semi-airborne transient electromagnetic method: A case study in Xinjiang China. Bull. Eng. Geol. Environ. 2025, 84, 342. [Google Scholar] [CrossRef]

- Ning, J.G.; Wang, J.; Tan, Y.L.; Xu, Q. Mechanical mechanism of overlying strata breaking and development of fractured zone during close-distance coal seam group mining. Int. J. Min. Sci. Technol. 2020, 30, 207–215. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).