Abstract

The flotation effect of lean coal is crucial for its clean utilization. Therefore, the flotation characteristics of difficult-to-float lean coal were studied. The analysis results of the feed properties showed that the ash content of the feed was high and the particle size was very fine. The minerals in the gangue mainly included sericite, kaolinite, quartz, white mica, and other substances. After flotation, the functional groups of the coal particles in the tailings decreased, and the absorption peak intensity weakened. Furthermore, the results of multi-factor flotation experiments showed that the dosages of the collector and the frother were significant factors affecting the yield of clean coal. The clean coal yield gradually increased with an increase in the two factors. The ash content of the clean coal increased with an increase in the frother dosage. Within the range of feed concentrations used in this work, the feed concentration was not a significant factor affecting the clean coal’s yield and ash content. Prediction models for the clean coal yield and ash content were proposed. Under optimized experimental conditions, the clean coal yield and the flotation perfection index were 72.15% and 46.63%, respectively, indicating a good flotation effect.

1. Introduction

Coal accounts for approximately 55% of China’s primary energy consumption and is the “ballast stone” of China’s energy security. In 2023, the raw coal output in China was 4.71 billion tons, achieving a year-on-year growth of 3.4% [1]. Hence, promoting the clean and efficient utilization of coal resources is crucial for achieving the goal of carbon neutralization and a carbon peak. As the source technology in the field of clean coal, coal separation is a basic way to achieve clean and efficient coal utilization. After coal separation, the ash and sulfur content of coal can be greatly reduced, the coal quality can be improved, the coal product structure can be optimized, and the utilization efficiency can be improved. The content of fine particles in raw coal gradually increases with the changes in the geological conditions of coal mining and the improved mechanization of coal mining. In general, the content of particle sizes of less than 3 mm ranges from 20% to 45%. Normally, gravity beneficiation and flotation beneficiation are adopted for particle sizes larger than 0.25 mm (or 0.5 mm) and particle sizes smaller than 0.25 mm (or 0.5 mm), respectively [2].

Coal flotation is a complex process for separating different hydrophobic particles. The efficiency of particle separation is typically affected by various factors, such as the properties of feed particles [3,4,5], equipment performance [6,7,8], and process and operating parameters [9,10,11]. Many researchers have performed theoretical and experimental research on flotation, focusing on the influence of the particle size and density of the feed particles [12], the effect of the reagent [13,14], the characteristics and influence of bubbles [15], the influence of high-ash fine slime [16], the adhesion behavior and process of coal particles and bubbles [17,18], etc. Cheng et al. [19] studied the adsorption of several collectors on long-flame coal surfaces using density functional theory calculation and molecular dynamics simulation. They found that an emulsifier can enhance the dispersion of the biodiesel collector during flotation. The number of hydrogen bonds between the biodiesel collector and the long-flame coal surface was increased. Therefore, the migration of water molecules from the long-flame coal surface was accelerated. Xu et al. [20] used vegetable oil 1030# to enhance the flotation performance of low-rank coal. The results showed that 1030# with many polar components was more easily spread on the surface of low-rank coal, thus improving its hydrophobicity. Jia et al. [21] investigated the effect of high-intensity conditioning on the surface hydrophobicity of coal and the possible formation of particle–bubble clusters. Coarse particles required a higher turbulence intensity to increase the collector dispersion. Fine particles required a lower turbulence intensity to reduce the collector’s desorption. Furthermore, the adsorption capacity between the fine particles and the collector was weaker than that for the coarse particles. Sun et al. [22] studied the effect of Na+ on the adsorption behavior of polystyrene nanoparticles onto coal and quartz surfaces. They found that the hydrophobic polystyrene nanoparticles were irreversibly adsorbed onto both amorphous carbon and SiO2 sensors, and their adsorption capacity gradually decreased with an increasing Na+ ion concentration. Zhou et al. [23] studied the dispersion and mixing mechanism of coal slime particles in a jet-mixing flow field. The results showed that the jet flow field can effectively remove the fine mud wrapped on the surface of coal particles. The gas jet mode can promote the reagent acting on the surface of the bubble liquid film to form oil bubbles, which is more suitable for hydrophobic mineral flotation.

The flotation of coking coal and low-rank coal has been extensively studied. However, there are relatively few reports on the flotation of difficult-to-float lean coal in China. Lean coal for blast furnace injection can replace some coke, provide iron smelting heat, and play a reducing agent role, thereby reducing the coke ratio and the iron smelting cost. Most of the lean coal preparation plants in China have built flotation systems. However, in many cases, the flotation effect is unsatisfactory. Improving the flotation efficiency of coal slime is crucial for the high-efficiency utilization of lean coal. This study aimed, therefore, to improve coal quality using the slime particles of scarce lean coal as the research object. Both the particle properties and flotation experiments were considered in this work.

2. Materials and Methods

The experimental sample of lean coal used in this study was taken from a coal preparation plant in Shanxi Province. The particle size distribution of the sample is shown in Table 1. The coal slime had a high ash content of 24.07% and consisted primarily of 0.25–0 mm particles (weight fraction: 94.21%). The weight fraction of the particles larger than 0.25 mm was 2.69%, indicating a relatively low classification efficiency before flotation during industrial production. The content of 0.074–0 mm particles reached up to 60.51%, with a relatively high ash content of 28.11%, which indicated that there were large amounts of high-ash fine particles in the coal slime. In addition, 0.045–0 mm particles had a relatively high content of 18.89% and a high ash content of 36.44%, indicating that large amounts of high-ash slime were found in the lean coal sample.

Table 1.

Size distribution of the feed coal for flotation.

An MFDF-2 flotation tester with a volume of 1.5 L and a spindle speed of 1000–3000 rpm watts was used in the flotation experiments. The impeller of this flotation tester was an umbrella-shaped structure with four blades. Octanol was used as a frother agent in this research. Flotilla 111 produced by Kopper Chemical Industry Corp., Ltd., Chongqing, China, was used as a collector agent. The gangue particle properties in the feed coal were analyzed using BGRIMM Process Mineralogy Analyzer (BPMA) produced by BGRIMM Technology Group, Beijing, China. BPMA consisted of a scanning electron microscope (SEM), an X-ray energy-dispersive spectrometer (EDS), and a set of automated testing software for process mineralogy. The functional group characteristics on the surfaces of particles were analyzed using Fourier-transform infrared spectroscopy (Nicolet iS50, Themno Fisher Scientifc, Waltham, MA, USA). A three-factor three-level experimental scheme was designed. The experimental factors included the collector dosage, the frother dosage, and the feed concentration, with minimum values of 750 g/t, 60 g/t, and 60 g/L, respectively. The maximum values of the three factors were 1250 g/t, 120 g/t, and 100 g/L, respectively. The experimental indicators included the clean coal yield, the tailings yield, the clean coal ash content, and the tailings ash content. A total of 27 flotation experiments were performed according to the national standard of China (GB/T 4757-2001) [24] in this study.

3. Results and Discussion

3.1. Characteristics of Gangue in Feed Coal and Tailings

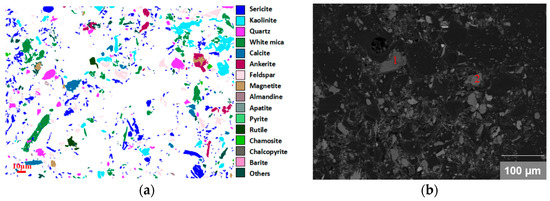

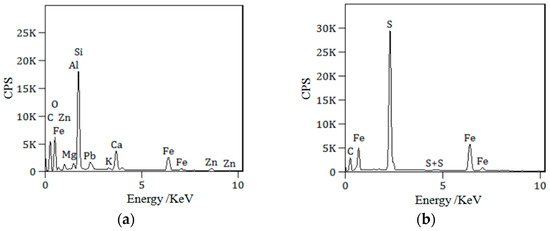

A scanning electron microscope photo of the feed coal slime is shown in Figure 1. According to Figure 1a, the feed coal contained many gangue particles with the main ingredients including sericite, kaolinite, quartz, white mica, and other substances. These particles resulted in a high ash content of raw materials. Consequently, the fine coal should be beneficiated before being used for blast furnace injection. Moreover, many gangue particles had a particle size of less than 0.05 mm. The particle size was relatively small. This follows the results of the particle size composition analysis in Table 1. Fine gangue particles, namely high-ash fine slime, significantly impact the flotation process. These particles adsorb reagents and easily cover the surfaces of bubbles and coal particles due to their large specific surface area, resulting in the loss of coarse clean coal into the tailings. Furthermore, the rising bubble group is likely to cause the mechanical entrainment of fine gangue particles, increasing the ash content in the clean coal. However, during the industrial production process, using mechanically agitated flotation machines, the ash contents in the clean coal and tailings were both relatively low, indicating that the clean coal had a certain loss. This was likely due to the relatively high ash content of low-density particles in the feed. These particles contain a certain number of coal particles and gangue-associated bodies. When the gangue accounts for a large proportion of the associated bodies, these particles are easily mismatched into the tailings. Figure 1b shows a scanning electron microscope photo magnified 500 times. Two points were selected, and the energy spectra of the two particles were analyzed. The results are shown in Figure 2. The main components of gangue particle 1 were oxides of Si, Al, Fe, and Ca. Furthermore, this particle contained small amounts of 0.4% K, 0.19% Mg, 3.81% Zn, and 5.4% Pb elements. The main component of gangue particle 2 was pyrite.

Figure 1.

SEM photos of flotation feed: (a) identification of mineral classification; (b) gray-scale map.

Figure 2.

Energy spectra of gangue particles: (a) particle 1; (b) particle 2.

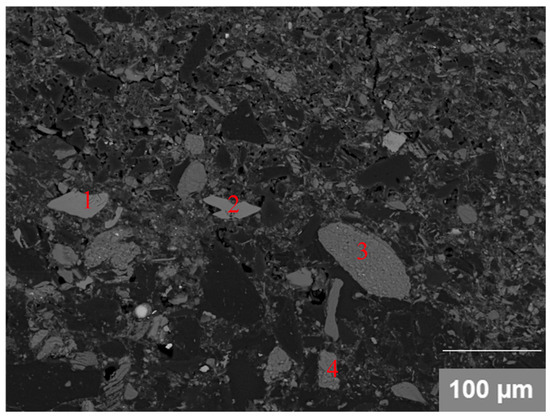

The scanning electron microscope photo of the tailings particles is shown in Figure 3. The tailings contained many gangue particles. This indicates that the gangue particles were greatly enriched after flotation. The ash content of the tailings obtained under optimized experimental conditions was also relatively high, reaching 53.13%. The elemental composition of the gangue particles is shown in Table 2. The main component of gangue particle 1 was iron oxide, with a high Fe content of 63.05%. The main component of gangue particles 2 and 3 was limestone, with Ca contents of 41.39% and 38.35%, respectively. The main components of gangue particle 4 were quartz and alumina, with Si and Al contents of 19.66% and 17.81%, respectively.

Figure 3.

SEM photo of the tailings after flotation.

Table 2.

The elemental compositions of gangue particles.

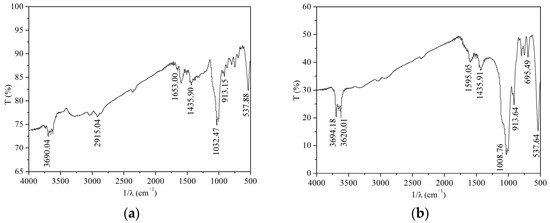

3.2. Characteristics of Particle Surface Functional Groups of Feed and Tailings

The infrared spectra of the feed coal and the tailings are shown in Figure 4. Figure 4a demonstrates that the feed particles feature many absorption peaks with a wave number of less than 913.15 cm−1, especially the absorption peak at 537.88 cm−1. This indicates the presence of benzene ring out-of-plane bending vibrations and ring bending vibrations. The strong absorption peak observed at 1032.47 cm−1 should indicate the C-O vibrational peaks of alcohol, phenol, ether, carboxylic acid, ester, etc. The absorption peaks from 1507.20 to 1716.38 cm−1 are double-bond stretching vibrations. The strong absorption peak at 1596.02 cm−1 is the skeleton vibration of the aromatic ring caused by stretching vibrations between carbon atoms within the ring. The moderate-intensity absorption peak at 1653.00 cm−1 is the C=C vibration of olefin. The absorption peaks at 2915.04–3690.04 cm−1 are in the X-H stretching vibration region (X represents atoms such as C, O, N, S, etc.). Among them, the absorption peak at 2915.04 cm−1 is the C-H stretching vibration of saturated alkanes, and the three absorption peaks greater than 3276.06 cm−1 are the O-H stretching vibration. The surfaces of the feed particles were mainly composed of non-polar benzene rings and aliphatic hydrocarbons, as well as polar C-O functional groups and a small amount of O-H functional groups. Therefore, the overall interaction effect between the particle interface and the collector was relatively good.

Figure 4.

Fourier-transform infrared spectra: (a) the feed; (b) the tailings.

A large amount of clean coal was enriched after flotation. Figure 4b shows that the absorption peaks of the coal particles in the tailings were significantly reduced compared with those of the feed particles. The intensity of the absorption peaks was also weakened, including benzene ring out-of-plane bending vibrations and ring bending vibrations, as well as the aromatic hydrocarbons and O-H functional groups. Furthermore, no absorption peak was observed at 2915.04 cm−1 and 3276.06 cm−1 for the tailings particles. This indicates that C-H functional groups and a small amount of O-H functional groups were enriched in the clean coal. Nevertheless, a certain number of aromatic hydrocarbons and C-O and O-H functional groups were found in the tailings, leading to reduced tailings ash.

3.3. Variation in Flotation Effect

3.3.1. Variation in Clean Coal Yield

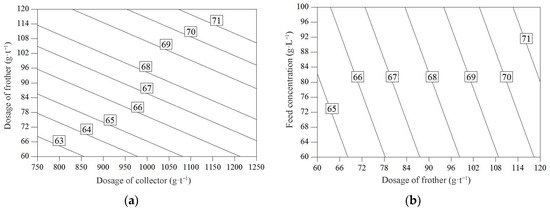

The relationships between the clean coal yield and various factors are presented in Figure 5. The dosages of the collector and frother were significant factors affecting the yield of clean coal. The clean coal yield in the direction of the feed concentration axis slightly rises but does not significantly change. Therefore, for the coal sample, the feed concentration was not a significant factor affecting the clean coal yield within a feed concentration range of 60–100 g/L. Moreover, the clean coal yield gradually increased, reaching above 71%, with an increase in the usage of the collector or frother. This is because more agent molecules were adsorbed by the coal particles or the gangue particles with an increase in the collector dosage. As such, particles were more likely to adhere to and float with the bubbles. Furthermore, a small amount of non-hydrocarbon polar components were contained in the collector. The polar groups of these components could be adsorbed with the hydrophilic oxygen-containing functional groups on the surfaces of the coal particles. The non-polar groups of these components were confronted with water, which further enhanced the hydrophobicity of the coal particles. These components also have foaming and emulsifying effects, which are beneficial for the flotation process. Nevertheless, if the content of these components is too high, reverse adsorption occurs. Subsequently, the hydrophobicity of the coal particles is weakened, and the yield of clean coal is reduced. The rate of increase in the clean coal yield with the frother agent was greater than that with the collector agent. However, if the frother agent is excessively used, it easily carries more high-ash fine slime, resulting in a high ash content in the clean coal, and is unfavorable for the subsequent transportation and dehydration of the clean coal.

Figure 5.

Variation in the clean coal yield with experimental factors: (a) at a feed concentration of 86 g/L; (b) at a collector dosage of 1100 g/t.

3.3.2. Variation in Clean Coal Ash

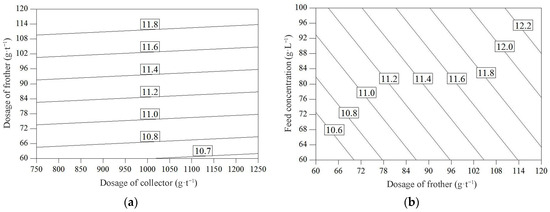

The effects of the experimental factors on the clean coal ash are shown in Figure 6. The ash content in the clean coal could be controlled below 12% under the comprehensive effect of the experimental factors. As the feed concentration increased, the ash content in clean coal gradually increased, but this increase was relatively small. Therefore, within the range of 60–100 g/L used in this study, the feed concentration was not a significant factor affecting the ash content in clean coal. This requires that the amount of water sprayed into the demineralizer and the desliming screen should be well regulated and the classification efficiency of the classification cyclone kept high during the industrial production process to reasonably adjust the amount of water entering the flotation system. If too much water is sprayed, the demineralizer and desliming effects are better, but the feed concentration for flotation is lower. In addition, the effect of the collector on the ash content in clean coal was relatively weak within the range of the collector dosage in this study. However, the ash content in clean coal gradually increased with the increase in the frother dosage. This was mainly because the larger amount of frother produced more bubbles, and the entrainment of the liquid film between the bubbles was enhanced. The feed contained a large amount of high-ash fine slime. A certain amount of high-ash fine slime was carried by the liquid film, thus entering the foam layer.

Figure 6.

Variation in the clean coal ash with experimental factors: (a) at a feed concentration of 75 g/L; (b) at a collector dosage of 870 g/t.

3.4. Prediction and Optimization of Flotation Effect

Coefficient estimates were made for various experimental factors affecting the yield of clean coal based on the experimental results, and a mathematical model for predicting the yield of clean coal could be proposed:

where A is the dosage of the collector, B is the dosage of the collector, and C is the feed concentration.

Clean coal yield = 45.37 + 8.56 × 10−3A + 0.11B + 0.04C

A mathematical model for predicting the ash of clean coal could also be proposed:

Clean coal ash = 8.15 − 1.87 × 10−4A + 0.02B + 0.018C

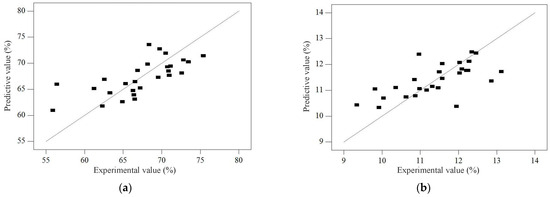

ANOVA was conducted on these two models, as shown in Table 3 and Table 4, respectively. The F-values of the two models were 7.46 and 5.68, respectively. The p-values were both less than 0.005, indicating that the predicted models had a probability of less than 0.5% to reach the F-values. Therefore, these two models are significant and have high credibility for predicting the clean coal yield and clean coal ash content. In addition, the p-values of the collector and frother dosages were both less than 0.03 in the variance analysis of the prediction model for clean coal yield, indicating a significant effect on the clean coal yield. The p-value of the frother dosage was less than 0.002 in the variance analysis of the prediction model for clean coal ash, which significantly impacted the ash content in the clean coal. The effects of the feed concentration on the yield and the ash content in the clean coal were insignificant within the feed concentration range in this study.

Table 3.

ANOVA of the prediction model for the clean coal yield.

Table 4.

ANOVA of the prediction model for the clean coal ash.

A comparison between the predicted values and experimental values is shown in Figure 7. The experimental values for the clean coal yield and the ash content in tail coal agree with the predicted values of the mathematical model, indicating that these two mathematical models have high prediction accuracy for the flotation process of lean coal particles.

Figure 7.

Comparison between experimental values and predicted values: (a) clean coal yield; (b) clean coal ash.

An optimized scheme for the flotation experiment was obtained based on the prediction model, as shown in Table 5. For the average values of each indicator, the clean coal yield was 70.83%, the clean coal ash content was 11.78%, the tailings yield was 29.17%, the tailings ash content was 53.03%, and the flotation perfection index was 46.95%. The experimental scheme with the highest yield of clean coal was taken as the optimal experimental condition to keep the ash content in the clean coal at less than 12%. When the amount of collector was 1206 g/t, the amount of foaming agent was 119 g/t; the feed concentration was 76 g/L; the clean coal yield was the highest, reaching 72.15%; and the flotation perfection index reached 46.63%. The clean coal yield was increased by 1.8 percentage points compared with the industrial production. The flotation perfection index was increased by 0.9 percentage points, achieving good flotation efficiency.

Table 5.

Optimization schemes of flotation experiments.

4. Conclusions

(1) The ash content in the lean coal used was relatively high, and the particle size was fine. Many gangue particles had a particle size of less than 0.05 mm and were mainly composed of sericite, kaolinite, quartz, white mica, and other minerals. The surface functional groups of the flotation feed particles were mainly non-polar benzene rings and aliphatic hydrocarbon functional groups, as well as polar C-O functional groups and a small amount of O-H functional groups. The functional groups of the coal particles in the tailings decreased, and the absorption peak intensity also weakened.

(2) The dosages of the collector and frother were significant factors affecting the clean coal yield. The clean coal yield gradually increased with the increase in these two factors. The ash content in the tailings increased with an increase in the frother dosage. The feed concentration was not a significant factor affecting the yield and the ash content in the clean coal within the range of feed concentrations used in this work.

(3) Prediction models for the clean coal yield and ash content were proposed. Under the optimized experimental conditions, when the amount of collector was 1206 g/t, the amount of foaming agent was 119 g/t, the feed concentration was 76 g/L, the ash content of the clean coal could be controlled below 12%, the clean coal yield could reach 72.15%, and the flotation perfection index was 46.63%. These two indicators were increased by 1.8 and 0.9 percentage points compared with industrial production indicators, respectively, indicating a good flotation effect.

Author Contributions

Conceptualization, Y.L., L.T. and L.Y.; methodology, Y.L., L.T. and B.G.; validation, Y.L., X.Y. and C.S.; formal analysis, Y.L. and L.T.; investigation, Y.L., L.T., L.Y. and B.G.; data curation, Y.L., X.Y. and C.S.; writing—original draft preparation, Y.L. and L.T.; writing—review and editing, Y.L. and L.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (no. 52274199), the Program for the Top Young Talents of Higher Learning Institutions of Hebei Province of China (no. BJ2018201), and the Fundamental Research Fund for the Central Universities of China (nos. 3142017103, 3142017104, and 3142014081).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

Conflicts of Interest

Author Yihong Li, Lei Yao, Bo Gao and Xue Yuan were employed by Shanxi Xinneng Coal Preparation Technology Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- National Bureau of Statistics of China. Statistical Communique of the People’s Republic of China on the 2023 National Economic and Social Development; China Statistics Press: Beijing, China, 2024; ISBN 978-7-5230-0408-1. [Google Scholar]

- Xie, G.Y. Mineral Beneficiation, 3rd ed.; China University of Mining and Technology Press: Xuzhou, China, 2016; ISBN 978-7-5646-3069-0. [Google Scholar]

- Li, Y.; Li, J.; Chen, P.; Chen, J.; Shen, L.; Zhu, X.; Chen, G. The effect of ultra-fine coal on the flotation behavior of silica in subbituminous coal reverse flotation. Powder Technol. 2019, 342, 457–463. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, Y.; Guo, F.; Luo, J.; Ding, S.; Cao, Y.; Xing, Y.; Gui, X. Effect of surface roughness on floatability of coal slime. Coal Sci. Technol. 2019, 47, 253–258. [Google Scholar]

- Guo, F.; Zhang, Y.; Luo, J.; Xing, Y.; Gui, X. Effect of particle shape on detachment behavior between long flame coal particles and bubble. Coal Sci. Technol. 2020, 48, 217–222. [Google Scholar]

- Hacifazlioglu, H.; Toroglu, I. The recovery of coal from waste coal slurry by cyclojet flotation cell. Energy Source Part A 2012, 34, 1967–1973. [Google Scholar] [CrossRef]

- Hacifazlioglu, H. Recovery of coal from cyclone overflow waste coals by using a combination of Jameson and column flotation. Energy Source Part A 2011, 33, 2044–2057. [Google Scholar] [CrossRef]

- Jena, M.S.; Biswal, S.K.; Das, S.P.; Reddy, P.S.R. Comparative study of the performance of conventional and column flotation when treating coking coal fines. Fuel Process. Technol. 2008, 89, 1409–1415. [Google Scholar] [CrossRef]

- Gui, X.; Cao, Y.; Xing, Y.; Yang, Z.; Wang, D.; Li, C. A two-stage process for fine coal flotation intensification. Powder Technol. 2017, 313, 361–368. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, S.; Chen, F.; Liu, J.; Wang, Y.; Guo, C.; Ni, C. Effect of dry rodmill and ball mill on liberation characteristics of coking middlings and flotation of grinding products. Coal Sci. Technol. 2020, 48, 248–253. [Google Scholar]

- Massinaei, M.; Jahedsaravani, A.; Taheri, E.; Khalilpour, J. Machine vision based monitoring and analysis of a coal column flotation circuit. Powder Technol. 2019, 343, 330–341. [Google Scholar] [CrossRef]

- Ni, C.; Xie, G.; Jin, M.; Peng, Y.; Xia, W. The difference in flotation kinetics of various size fractions of bituminous coal between rougher and cleaner flotation processes. Powder Technol. 2016, 392, 210–216. [Google Scholar] [CrossRef]

- Ren, C.; Li, Z.; Liu, A.; Liu, Y.; Fan, M. Capture performance and quantum chemistry calculation of methyl oleate on long flame coal surface. Coal Sci. Technol. 2020, 48, 197–202. [Google Scholar]

- Ren, C.; Fan, M.; Li, Z.; Qiao, X.; Luo, C.; Yang, H.; Liu, A. Efficiency of compound reagents flotation of low-rank coal slime. Coal Sci. Technol. 2020, 48, 242–247. [Google Scholar]

- Sun, X.; Liu, W.; Wang, W.; Chen, S.; Liu, W. Study on particle size distribution law of air flotation bubble and its influencing factors in coal slime flotation. Coal Sci. Technol. 2019, 47, 205–209. [Google Scholar]

- Arnold, B.J.; Aplan, F.F. The effect of clay slimes on coal flotation, part I: The nature of the clay. Int. J. Miner. Process. 1986, 17, 225–242. [Google Scholar] [CrossRef]

- Ozdemir, O.; Taran, E.; Hampton, M.A.; Karakashev, S.I.; Nguyen, A.V. Surface chemistry aspects of coal flotation in bore water. Int. J. Miner. Process. 2009, 92, 177–183. [Google Scholar] [CrossRef]

- Piñeres, J.; Barraza, J. Energy barrier of aggregates coal particle–bubble through the extended DLVO theory. Int. J. Miner. Process. 2011, 100, 14–20. [Google Scholar] [CrossRef]

- Cheng, G.; Peng, Y.; Lu, Y.; Zhang, M. Adsorption of multi-collector on long-flame coal surface via density functional theory calculation and molecular dynamics simulation. Processes 2023, 11, 2775. [Google Scholar] [CrossRef]

- Xu, M.; Zhou, Y.; Hao, Y.; Cao, Y.; Xing, Y.; Gui, X. Enhancing flotation performance of low-rank coal using environment-friendly vegetable oil. Minerals 2023, 13, 717. [Google Scholar] [CrossRef]

- Jia, X.; Yu, Y.; Liu, J.; Min, C.; Liu, F.; Zhang, N.; Chen, S.; Zhu, Z. Changes in surface hydrophobicity of coal particles and the formation of coarse particle–bubble clusters in the process of high-intensity conditioning. Processes 2023, 11, 1723. [Google Scholar] [CrossRef]

- Sun, Y.; Jiang, N.; Dong, X.; Fan, Y.; Yang, M.; Xiong, P.; Chen, Y. Effect of Na+ on the Adsorption Behavior of Polystyrene Nanoparticles onto Coal and Quartz Surfaces. Separations 2023, 10, 285. [Google Scholar] [CrossRef]

- Zhou, W.; Wang, S.; Wang, L.; Cai, C.; Li, J.; Liu, L.; Zhu, J.; Min, F. Study on dispersion and mixing mechanism of coal slime particles in jet mixing flow field. Minerals 2023, 13, 13. [Google Scholar] [CrossRef]

- GB/T 4757-2001; General Administration of Quality Supervision, Inspection and Quarantine of China. Methods for the batch flotation testing of fine coal; General Administration of Quality Supervision, Inspection and Quarantine of the People Republic of China: Beijing, China, 2001.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).