Abstract

By addressing the flexible job shop scheduling problem (FJSP), this paper proposes a new type of algorithm for the FJSP. We named it the hybrid coronavirus population immunity optimization algorithm. Based on the characteristics of the problem, firstly, this paper redefined the discretized two-stage individual encoding and decoding scheme. Secondly, in order to realize the multi-scale search of the solution space, a multi-population update mechanism is designed, and a collaborative learning method is proposed to ensure the diversity of the population. Then, an adaptive mutation operation is introduced to enrich the diversity of the population, relying on the adaptive adjustment of the mutation operator to balance global search and local search capabilities. In order to realize a directional and efficient neighborhood search, this algorithm proposed a knowledge-driven variable neighborhood search strategy. Finally, the algorithm’s performance comparison experiment is carried out. The minimum makespans on the MK06 medium-scale case and MK10 large-scale case are 58 and 201, respectively. The experimental results verify the effectiveness of the hybrid algorithm.

1. Introduction

The flexible job-shop scheduling problem (FJSP) is an extension of the classic job-shop scheduling problem, which is more suitable for the complex production environment faced by advanced modern manufacturing industries. The classic job-shop scheduling problem has been proven to be an NP-hard problem [1]. Based on the classic job-shop scheduling problem, the flexible job-shop scheduling problem relaxes the processing machine constraints of operations. At least one operation is allowed to be processed on two or more machines, and the time required for processing using different machines is different. The production environment represented by the flexible job-shop scheduling problem is more complex. It is necessary to consider the processing sequence of jobs and arrange the processing machines so that the operations can achieve the scheduling goal. Therefore, solving the problem is more difficult, but it can better simulate the current rapid development of the semiconductor manufacturing industry, automobile assembly industry, and other environments [2]. In recent years, this issue has received extensive attention from many researchers. The earliest research on this problem can be traced back to the middle of the last century [3]. Early research methods mainly used scheduling rules, branch and bound methods, etc. However, they were only applicable to small-scale problems. Thanks to the development of computer computing power, the swarm intelligence algorithm has become the current mainstream research method, such as genetic algorithm, gray wolf algorithm, particle swarm algorithm, etc.

The swarm intelligence algorithm can obtain an effective approximate solution to the FJSP within an acceptable time, so it has been extensively studied by many scholars. Zhang et al. [4] proposed a crossover operator that can avoid illegal solutions to optimize different performance indicators of the FJSP. Liu et al. [5] proposed an improved genetic algorithm with an active-schedule decoding mechanism to solve flexible job-shop scheduling problems. Sun et al. [6] proposed a variable neighborhood search strategy to improve the effective search efficiency of the genetic algorithm in order to optimize the makespan’s objective. Jiang [7] proposed a hybrid gray wolf algorithm combined with a variable neighborhood search and genetic operators to optimize the makespan objective of the FJSP. Ding et al. [8] proposed a hybrid algorithm combining the human learning optimization algorithm and particle swarm algorithm to solve the flexible job-shop scheduling problem. Zhang et al. [9] proposed an improved wolf pack algorithm to solve the multi-objective flexible job-shop scheduling problem. In view of the above literature for classical FJSPs, we summarize the contribution and related studies in this study. The results are shown in Table 1.

Table 1.

Summary of related studies on classical FJSPs.

In addition, the actual production environment is complex and changeable, and many scholars have added conditional constraints on the basis of the FJSP to fit a variety of actual processing environments. Chen et al. [10] proposed an elitist genetic algorithm to solve the flexible job-shop scheduling problem with fuzzy processing time. Chen et al. [11] applied the improved particle swarm optimization algorithm to FJSP research by considering the transportation time. Zhang et al. [12] combined the particle swarm optimization algorithm with the simulated annealing algorithm to solve the flexible job-shop batch scheduling problem. Komakia et al. [13] used the improved gray wolf algorithm to solve the two-stage flow-shop scheduling problem with release time constraints.

Hybrid algorithms can reduce the limitations of a single algorithm and can effectively improve the performance of an algorithm. In many research fields, these hybrid algorithms have been extensively studied by many scholars. Coma et al. [14] combined genetic algorithms with gradient-based algorithms to optimize the active flow control problem over airfoils. Devarapalli et al. [15] combined the gray wolf algorithm and the sine cosine algorithm in order to effectively and quickly adjust the parameters of power system stabilizers. Knypinski [16] introduced the Hooke–Jeeves method in the cuckoo search algorithm to search for new cuckoo positions, greatly improving the optimization accuracy of a line-start permanent magnet synchronous motor. The nonlinear convergence factor is an effective method for improving the performance of algorithms. Knypinski [17] proposed a linear convergence factor for the gray wolf algorithm, which greatly improved the performance of the gray wolf algorithm in the line-start permanent magnet motor. Hegazy et al. [18] introduced the inertial weight strategy in the sarp group algorithm, which not only balanced global and local search capabilities but also improved the convergence of the algorithm.

The research on FJSP is still a focus of research in recent years. Aiming at this problem, the mainly used swarm intelligence algorithms can be divided into four types: genetic algorithm, gray wolf algorithm, particle swarm algorithm, and wolf pack algorithm. On the basis of the original algorithm, scholars have carried out detailed research on the gene update method and the neighborhood search’s structure. However, their populations often use a unified search scale to carry out searches within the solution space, and this cannot achieve refined searches. Additionally, they use a fixed mutation rate, which cannot balance the relationship between global and local searches, and there is a risk of falling into a local optimum. The existing neighborhood structure only comprises a random search, or the machine with the shortest processing time for the process is chosen, which lacks the use of existing knowledge. The solution space of the FJSP is large and complex, and the swarm intelligence algorithm is essentially an approximate solution algorithm. Effective methods for searching for a better solution within an effective time range still comprise a challenging task. Affected by randomness, there is currently no algorithm that can guarantee the optimal solution to this problem every time. To this end, this paper conducts research on the multi-scale solution space search. By summarizing the existing empirical knowledge, the knowledge-driven neighborhood structure search is realized.

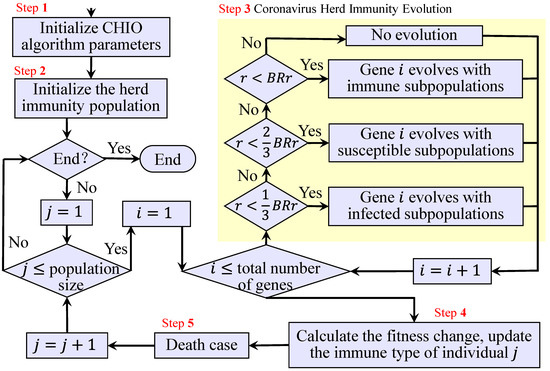

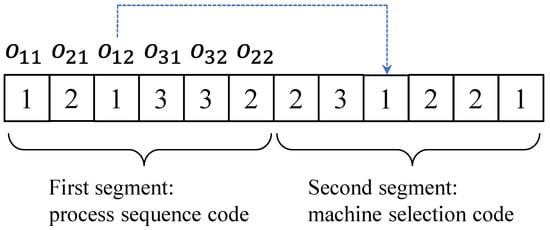

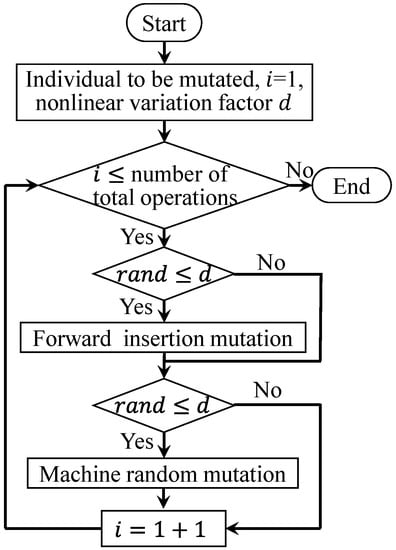

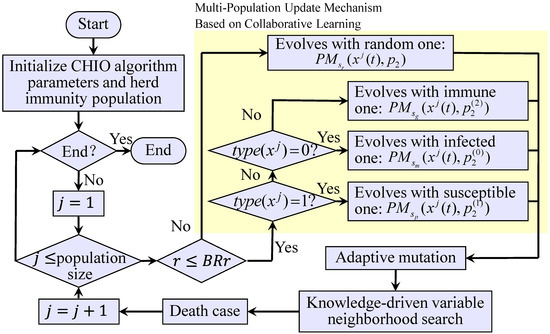

The coronavirus swarm immunity optimization (CHIO) algorithm is an emerging swarm intelligence optimization algorithm proposed by Al-Betar et al. [19] in 2020. Inspired by the novel coronavirus that is widespread around the world, the algorithm proposes an algorithm update theory that simulates the emergence of herd immunity. Although the algorithm appeared late, it has been verified on multiple functions and engineering optimization problems [19,20,21]. The CHIO algorithm proposed the concept of multi-population evolution for the first time. Although this point also exists in the gray wolf algorithm, the gray wolf algorithm mainly comprises the following concept: All individuals of other populations approach the head wolf population. The difference is that the CHIO algorithm performs an iterative update of genes both within the sub-population and between sub-populations, and the update mechanisms within different sub-populations are different, so it has a broader search capability. In addition, the CHIO algorithm adopts the “survival of the fittest” mechanism. If the individual has not been improved in the iteration process, the individual will be replaced by a randomly generated new individual when the maximum age is reached. This update mechanism is beneficial as individuals can escape the local optimal trap. The original CHIO algorithm uses floating-point numbers to encode individuals, so it needs to use a certain mapping method when it is applied to the FJSP. In addition, CHIO is a new algorithm, so there are few studies on the algorithm used in the field of job-shop scheduling. Only one research study [22] applies it to the solution of the replacement flow-shop scheduling problem. Compared with the replacement flow-shop scheduling problem, the FJSP needs to consider two sub-problems—operations arrangement and machine selection—at the same time, so the complexity of the problem is greater. For this reason, this paper attempts to extend the CHIO algorithm to solve the FJSP. In order to improve the global search and local search capabilities of the algorithm, on the basis of the traditional CHIO algorithm, a series of designs and improvements in line with the FJSP were constructed. In order to facilitate the description below, we named the improved algorithm for the FJSP the hybrid coronavirus swarm immunity optimization (HCHIO) algorithm. Combined with the characteristics of the FJSP, the discretized individual encoding and decoding schemes are redefined. FJSP is essentially a combinatorial optimization problem. During the solution process, all possible machine scheduling schemes need to be searched to find the optimal solution. However, in the worst case, the time complexity of this search process is exponential. Thus, the FJSP is an NP-hard problem. The solution space of this problem is large and complex. The difficulty related to producing a fast and efficient search scheme in such a large solution space is a meaningful problem that should be solved. Inspired by the way novel coronavirus spreads, a multi-population mechanism is established within the algorithm, and the discretized update actions of different scales are designed to achieve the efficient search of a solution space. An adaptive mutation operation is introduced to expand the diversity of the population while balancing the global search and local search capabilities of the algorithm.

In order to reduce the algorithm’s invalid neighborhood search, it is necessary to make full use of empirical knowledge. From a mathematical point of view, we can refer to empirical knowledge as the mathematical characteristics of the problem. Math-heuristic algorithms is a well-known method in the study of solving Np-hard problems and comprises using mathematical features. Burke and Brucker et al. [23] proposed a branch and bound algorithm for the cyclic job-shop problem by combining mathematical features and heuristic algorithms. However, there is a certain gap between the knowledge used in this article and the mathematical features in math-heuristic algorithms. The mathematical features in math-heuristic algorithms mostly comprise deep-level, complex linear or nonlinear properties, etc. The difference is that the knowledge used in this paper includes the following: the critical path of the directed acyclic graph and simple mathematical characteristics. The simpleness of the mathematical features used in this article is that the features only involve size comparisons and division operations. In our evolutionary algorithms, the purpose is to direct the neighborhood search, which originally may not involve a change in the scheduling target with respect to the neighborhood search, in such a manner that will inevitably lead to a change in the scheduling target. Thus, this neighborhood structure does not exhibit enough properties to be called a math heuristic. Thus, a variable neighborhood search strategy that is knowledge-driven is proposed to enhance the local search ability of the algorithm and improve the convergence efficiency of the algorithm.

The rest of this paper is organized as follows: Section 2 introduces the description of the FJSP. Section 3 shows the original CHIO algorithm. In Section 4, the proposed HCHIO algorithm is described in detail. The experimental results and analysis of the HCHIO algorithm are shown in Section 5. Section 6 states the conclusions and suggestions for future works.

2. Flexible Job-Shop Scheduling Problem Description and Formulation

The FJSP has been extensively studied by many scholars. In order to clearly describe our processing system of the FJSP and scheduling objective in this paper, this section will introduce the FJSP description and formulation.

2.1. Problem Description

The FJSP of this paper is almost identical to the framework of the flexible job shop in the book by Pinedo [24], but there are also minor differences. The detailed differences are introduced as follows: the flexible job-shop () framework in Pinedo [24] first divides all machines into work centers. When a certain job passes through a certain work center more than once, it becomes a recirculation problem. The FJSP in this paper does not divide the work centers but provides optional processing machines for each operation, so there is no need to consider the recirculation problem. However, the FJSP is essentially derived from the flexible job-shop framework in the Scheduling.

The FJSP studied in this paper can simply be described as follows: In a factory processing workshop, we use machines to process jobs . Each job to be processed contains a certain number of operations , and the number of operations contained in different jobs can vary. Each operation of each job has a corresponding set of optional processing machines where , and the processing time of the operation on different machines can be different. Only when there is at least one or more operations with an optional machine set, , for which its cardinality is greater than or equal to 2 can it be called a flexibility problem; that is, there is process flexibility in the operations [25]. The FJSP requires a reasonable solution to the operation’s sequence and the machine selection of different operations in order to achieve the optimization goal. The FJSP studied in this paper has the following constraints:

- (1)

- The first operations of all jobs can be processed at the initial moment.

- (2)

- All machines are available at the initial moment.

- (3)

- The machine can only process one operation at a time.

- (4)

- The job can only be processed by one machine at the same time.

- (5)

- The process of each operation cannot be interrupted by others; that is, the machine cannot be preempted.

- (6)

- The processing of any job must be carried out in strict accordance with the preset sequence.

2.2. Problem Formulation

In order to clearly describe the flexible job-shop scheduling problem, the notations used for problem formulation are listed below.

- (1)

- Parameters

: total number of machines.

: total number of jobs.

: index of jobs, .

: index of jobs, .

: the total number of operations included in job .

: the total number of operations included in job .

: index of operations included in job , .

: index of operations included in job , .

: index of machines, .

: index of machines, .

: the th operation of job .

: the th operation of job .

: the optional machine set of , .

: machine in the optional machine set of , .

: the processing time of on machine .

: the processing time of on machine .

: the release time of the first operation of job .

: the start time of on machine .

: the finish time of on machine .

: the finish time of on machine .

- (2)

- Decision variables

The decision variables set in this paper are as follows:

determines which machine the operation is assigned on, while means the order of two different operations processed on the same machine.

- (3)

- FJSP formulation

In order to measure a scheduling scheme, makespan has been adopted by many scholars. Makespan is the maximum completion time of all the operations in a processing system, that is, the time required for the system to be completed. The FJSP studied in this paper uses the minimization of makespan as the scheduling objective—it can be expressed as Formula (1). Based on the above symbol definition, the FJSP formulation of this paper is as follows:

Objective:

Subject to:

Equation (2) indicates that all jobs are ready at the initial moment. Equation (3) indicates that the operations can only be processed by one machine. Equation (4) indicates that the operations cannot be interrupted. Equation (5) indicates that the operations of one job can only be processed according to the preset sequential processing operation. Equation (6) indicates that the machine can only process one operation at a time.

5. Experimental Analysis

All experimental algorithms in this paper are programmed using Python language and run in the Windows 10 system and the Python version 3.8 environment. The computer hardware configuration is as follows: Intel Core i7-10700 CPU @2.9GHz and RAM 16GB. This paper chooses Brandimarte’s [33] benchmark and Hurink’s benchmark [34] to verify the performance of the HCHIO algorithm. Brandimarte’s benchmark is used the most in the papers we read, so we have chosen it as the main data set of this article. Brandimarte’s benchmark contains 10 cases named MK01-MK10, including various cases ranging from simple to complex; thus, it has been used by many scholars. The specific details of this benchmark are given in Table 2. Aiming at the problem of large differences in the makespan of different data sets, the relative percentage deviation (relative percentage deviation, RPD) index is introduced to uniformly measure the performance of the algorithm. The calculation formula of RPD is shown in Formula (15).

Table 2.

Specific details of Brandimarte’s benchmark.

In Formula (15), Get is the solution obtained by the current algorithm, and Best is the optimal solution obtained by the algorithm in this paper.

5.1. Parameter Settings

The main parameters in the HCHIO algorithm are epoch, pop_size, BRr, and MA. The variation ratio is set to 0.3 according to the research in the literature [7], and variation degrees and are set to 0.1 and 0.05, respectively. In order to analyze the influence of the main parameters on the performance of the algorithm, an orthogonal table was generated using Mintab software by creating a Taguchi design. According to the orthogonal table, a four-factor three-level orthogonal experiment is carried out, and the parameter level settings are shown in Table 3.

Table 3.

Parameter level.

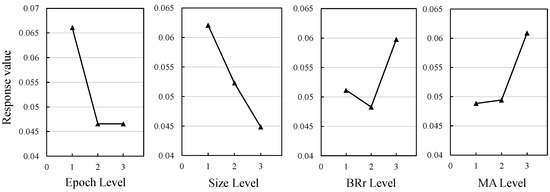

The MK06 data set (Best = 58) with a relatively moderate total number of jobs and machines is selected for orthogonal experiments. Each group runs independently 10 times in the MK06 environment, and the RPD index of the average makespan is calculated. The parameter settings of different experimental groups and the RPD index of the algorithm are shown in Table 4. According to the RPD values of each group of experiments in the orthogonal table, the response values and response graphs of different parameters relative to the algorithm’s performance can be obtained. The results are shown in Table 5 and Figure 7.

Table 4.

Orthogonal tables and RPD values.

Table 5.

Parameter response value.

Figure 7.

Parameter response plot.

From the analysis in Table 4, it is observed that epoch and pop_size have a greater impact on the algorithm, while BBr and MA have less impact. In Figure 7, the parameter levels corresponding to the smaller response value are better. In the Epoch Level diagram, the response values of levels 2 and 3 are smaller than level 1, indicating that a larger epoch is more conducive to optimization. However, the epoch response values of levels 2 and 3 are similar, indicating that at level 2, the performance of the algorithm has converged and stabilized. Similarly, in the size level response value diagram, it can be concluded that the larger the population size, the more conducive it is to finding the optimal solution. However, larger populations require more computing power. The optimal parameter level for BRr is level 2. For the MA parameters, the response values of level 2 and level 1 are not that different, indicating that the performance of the parameters of these two levels is similar to the MK06 data set.

Considering the characteristics of randomness in the swarm intelligence algorithm, the fact that the MK06 data set is a medium data set, and the running time of the algorithm, the parameters of the algorithm in this paper are uniformly set as follows: epoch = 1000, pop_size = 200, BRr = 0.65, and MA = 30. Given the fact that the size of the MK06 data set is 10 × 15 and the size of the MK10 data set is 20 × 15, combined with the analysis of the convergence curve during the experiment, epoch = 1500 of the MK10 data set is reset, and the other parameters are kept unchanged.

5.2. Verification of the Effectiveness of Innovations

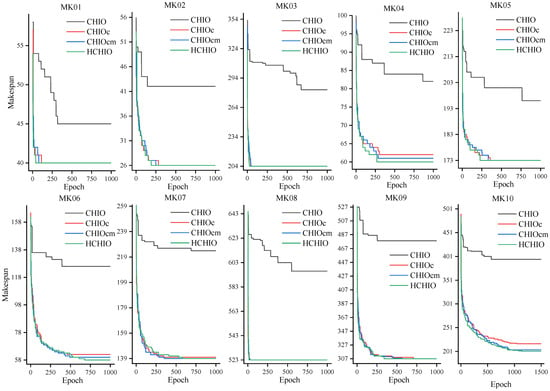

This paper carries out a series of improvements relative to the traditional CHIO algorithm, and these improvements are in line with the characteristics of FJSP. The main innovations include the following: a multi-population update mechanism for collaborative learning, adaptive mutation, and a variable neighborhood search strategy that is knowledge-driven. In order to verify the effectiveness of innovation points, the following algorithm settings are now implemented. CHIO represents the traditional floating-point version of the CHIO algorithm. CHIOc abandons the floating-point number update method and incorporates the CHIO algorithm based on the multi-population update mechanism using collaborative learning. CHIOcm is a CHIOc algorithm with adaptive mutation operations. HCHIO (CHIOcmv) is an added CHIOcm algorithm based on the knowledge-driven variable neighborhood search strategy. The above algorithms are run 10 times (one by one) using Brandimarte’s cases, and the performance of the algorithm is evaluated using the four indicators of Opt, Avg, RPD, and Time. Opt represents the optimal solution obtained by the algorithm, Avg is the average makespan of running 10 times, RPD is the relative percentage deviation of Avg, and Time is the running time required for one iteration of the algorithm (unit: s).

As shown in Table 6, the bold font in the table is the optimal value of Opt and Avg. The traditional CHIO is updated in the floating-point number domain. This paper uses a discrete mapping scheme to convert the floating-point number into a shop-floor scheduling scheme, but the resulting RPD is large, which verifies that the solution space search in the floating-point number domain is unsuitable for the FJSP when using the CHIO algorithm. The main reason is that the floating-point number search method is inefficient, and retaining the characteristics of dominant genes is difficult. Compared with the CHIO algorithm, the RPD index of the CHIOc algorithm is greatly reduced, which fully demonstrates the rationality and effectiveness of the update method designed in this paper, and the update in the discrete domain is less time-consuming and more efficient than the floating-point number domain. After adding the adaptive mutation operation on the CHIOc algorithm to obtain the CHIOcm algorithm, although the RPD value did not decrease significantly, the mutation operation produced better solutions on MK04, 06, 07, and 10, which verified that the mutation operation can produce excellent genes and expand the search space of the current solution. The HCHIO (CHIOcmv) algorithm achieves the optimal mean value in all cases, which fully demonstrates the effectiveness of the neighborhood search knowledge used. As it is different from relying on the random method to introduce good genes, the neighborhood search method in this paper uses knowledge-driven methods to realize the directional search of the solution space in order to achieve the optimal value in all calculation examples. Figure 8 shows the convergence curves of the optimal solutions of all CHIO-based algorithms in each case of Brandimarte’s benchmark. It can be observed from the figure that HCHIO has a stronger searchability for the optimal solution and a faster convergence speed. The convergence details of all the above algorithms are shown in Figure 8.

Table 6.

Verification of the effectiveness of innovation points.

Figure 8.

Convergence curves of the optimal solutions of all CHIO-based algorithms on Brandimarte’s benchmark.

5.3. Algorithm Performance Evaluation

In order to verify the effectiveness of the algorithm proposed in this paper, the algorithm proposed in this paper is compared with the hybrid gray wolf optimization algorithm (HGWO) proposed by Jiang [7], the improved particle swarm optimization algorithm (IPSO) proposed by Ding et al. [35], the mushroom picking framework (MPF) proposed by Jędrzejowicz et al. [36], and the hybrid genetic algorithm (HGA) proposed by Sun et al. [6]. The experimental results of these algorithms are all from the corresponding literature.

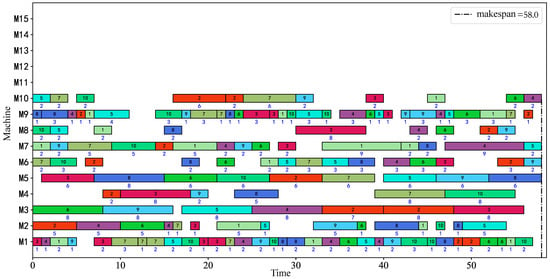

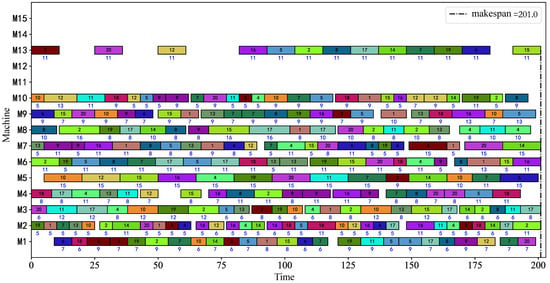

As shown in Table 7, the bold font in the table is the optimal value of Opt and Avg. Compared with other algorithms, the HCHIO algorithm obtained the optimal solution on all examples in the Opt index, which verified that the HCHIO algorithm can effectively learn the dominant genes during the update course and realize the directional and effective search of the current solution neighborhood. Among them, the optimal solution Gantt charts of MK06 and MK10 are shown in Figure 9 and Figure 10. In the Gantt chart, the blue number in the center below each operation is the processing time of the operation. In terms of the Avg index, the average value of the HCHIO algorithm in the nine cases is the best, which reflects the rationality of the HCHIO algorithm’s update mechanism designed in this paper, which can ensure the diversity of the population while maintaining convergence, and it does not easily fall into a local optimum. However, with respect to the MK04 data set, the HGA algorithm obtained a smaller average value. The reason may be that the adjacent excellent solutions of the MK04 example have a large difference, and this is unsuitable for the update mechanism in this paper. The RPD index shows that the HCHIO algorithm in this paper has the best comprehensive performance, which verifies the effectiveness of the algorithm proposed in this paper.

Table 7.

Algorithm performance on Brandimarte’s benchmark.

Figure 9.

Gantt chart of MK06’s optimal solution (One color represents a job. The blue number below the rectangular block is the processing time).

Figure 10.

Gantt chart of MK10’s optimal solution (One color represents a job. The blue number below the rectangular block is the processing time).

Although Brandimarte’s benchmark already includes cases of various complexity, in order to fully verify the effectiveness of the algorithm in this paper, by searching other benchmarks of FJSP articles, we selected the Hurink benchmark to test the performance of the algorithm in this paper. The most complex category in this benchmark is Vdata. Thus, we chose the cases from Vdata_la1 to Vdata_la10 for experimentation. For this benchmark, the algorithm parameters of this paper are set as follows: epoch = 1500, pop_size = 200, BRr = 0.65, and MA = 30. The specific experimental results are shown in Table 8. The result of HCHIO is an average of 10 executions. The average results of the regular genetic algorithm (RGA), two-stage GA (2SGA), and deep reinforcement learning (DRL) in the table are all from the literature [32]. It can be observed in the table that the HCHIO algorithm outperforms the DRL and RGA algorithms in almost all aspects in terms of performance. Moreover, the HCHIO algorithm produces a state-of-the-art solution with respect to the current body of research on the la3-la5 cases. However, the performance in other cases is not as good as 2SGA. However, it is worth mentioning that the maximum number of iterations of the 2SGA algorithm is 3000, while the HCHIO algorithm only iterates 1500 times, which is only half of the 2SGA algorithm. The experimental results show that the gap between the HCHIO algorithm and the 2SGA algorithm is small, which fully demonstrates the effectiveness of our algorithm.

Table 8.

Algorithm performance on Hurink’s benchmark.

6. Conclusions

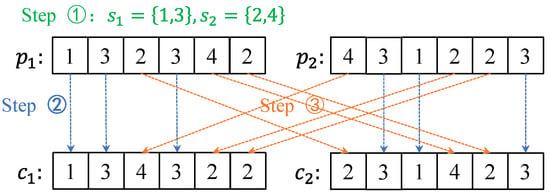

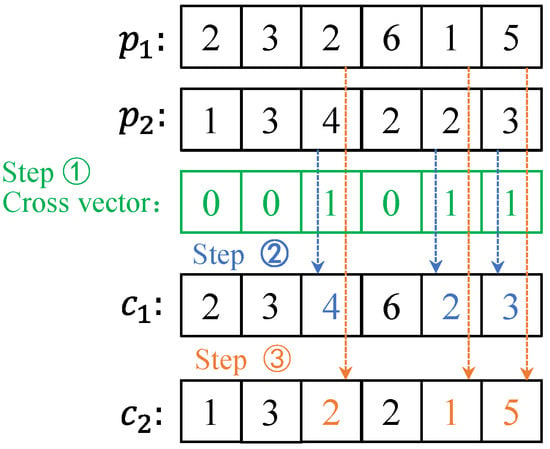

This paper studies the FJSP and proposes an effective HCHIO algorithm based on the traditional CHIO algorithm. Combining the characteristics of the FJSP, this algorithm designs a discretized two-stage encoding and decoding scheme to solve the operation sequencing subproblem and the machine selection subproblem of the FJSP. Then, based on POX and MPX operations, the multi-population update mechanism is redesigned based on collaborative learning so that cross-individuals can collaboratively learn each other’s superior genes. This mechanism can simultaneously ensure the convergence of the algorithm and the diversity of the population. Inspired by the evolution of the new coronavirus, an adaptive mutation operation is proposed to realize dynamic gene mutations and increase the search space of the algorithm. In order to efficiently search for a better solution, this algorithm proposes a variable neighborhood search technology that is knowledge-driven, using the knowledge of critical paths, processing times, and machine utilization to realize the directional and effective search of the neighborhood solution space. Finally, the benchmark calculation example is tested and compared with other algorithms to verify the effectiveness of the algorithm proposed in this paper.

The next research plan Is as follows: (1) By combining the characteristics of the FJSP, we intend to dig deep into diversified mutation operations and search for dominant genes from different angles; (2) we continue to expand upon the empirical knowledge used in neighborhood search in order to achieve a more efficient neighborhood space search.

Author Contributions

Methodology, writing, editing, and original draft preparation, X.M.; conceptualization, project administration, reviewing, and funding acquisition, L.B. and X.J.; writing—reviewing and editing, J.W. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the National Natural Science Foundation of China (No. 62266034) and the Key R&D projects of Ningxia Hui Autonomous Region (No. 2021BEE03020).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

After the paper is accepted, we will upload the experimental data and all related codes. The following information was supplied regarding data availability: The data set is available on GitHub: https://github.com/YiCai-Guo/HCHIO (accessed on 7 May 2023). The code is available on GitHub: https://github.com/YiCai-Guo/HCHIO (accessed on 7 May 2023).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Garey, M.R.; Johnson, D.S.; Sethi, R. The Complexity of Flowshop and Jobshop Scheduling. Math. Oper. Res. 1976, 1, 117–129. [Google Scholar] [CrossRef]

- Gao, K.Z.; Suganthan, P.N.; Chua, T.J.; Chong, C.S.; Cai, T.X.; Pan, Q.K. A two-stage artificial bee colony algorithm scheduling flexible job-shop scheduling problem with new job insertion. Expert Syst. Appl. 2015, 42, 7652–7663. [Google Scholar] [CrossRef]

- Chang, Y.-L.; Matsuo, H.; Sullivan, R.S. A bottleneck-based beam search for job scheduling in a flexible manufacturing system. Int. J. Prod. Res. 1989, 27, 1949–1961. [Google Scholar] [CrossRef]

- Zhang, G.H.; Gao, L.; Li, P.G.; Zhang, C.Y. Improved Genetic Algorithms for Solving Flexible Job Shop Scheduling Problems. Chin. J. Mech. Eng. 2009, 45, 145–151. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, C.Y.; Rao, Y.Q.; Shao, X.Y. Improved Genetic Algorithm for Flexible Job Shop Scheduling. Ind. Eng. Manag. 2009, 14, 59–66. [Google Scholar]

- Sun, K.X.; Zheng, D.B.; Song, H.H.; Cheng, Z.W.; Lang, X.D.; Yuan, W.D.; Wang, J.Q. Hybrid genetic algorithm with variable neighborhood search for flexible job shop scheduling problem in a machining system. Expert Syst. Appl. 2023, 215, 119359. [Google Scholar] [CrossRef]

- Jiang, T.H. Hybrid Gray Wolf Optimization Algorithm for Solving Flexible Job Shop Scheduling Problems. Control. Decis. Mak. 2018, 33, 503–508. [Google Scholar]

- Ding, H.J.; Gu, X.S. Hybrid of human learning optimization algorithm and particle swarm optimization algorithm with scheduling strategies for the flexible job-shop scheduling problem. Neurocomputing 2020, 414, 313–332. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Xu, L.; Li, J.; Zhao, Y.; He, K. Research on Flexible Job Shop Scheduling Based on Improved Wolf Pack Algorithm. J. Syst. Simul. 2023, 35, 534–543. [Google Scholar]

- Chen, N.L.; Xie, N.M.; Wang, Y.Q. An elite genetic algorithm for flexible job shop scheduling problem with extracted grey processing time. Appl. Soft Comput. 2022, 131, 109783. [Google Scholar] [CrossRef]

- Chen, K.; Bi, L. FJSP research of improved particle swarm optimization algorithm considering transportation time. J. Syst. Simul. 2021, 33, 845–853. [Google Scholar]

- Zhang, J.; Wang, W.L.; Xu, X.L.; Wang, H.Y. Solving the Batch Scheduling Problem of Flexible Job Shops Based on Improved Particle Swarm Optimization Algorithm. Control. Decis. Mak. 2012, 27, 513–518. [Google Scholar]

- Komaki, G.M.; Kayvanfar, V. Grey Wolf Optimizer algorithm for the two-stage assembly flow shop scheduling problem with release time. J. Comput. Sci. 2015, 8, 109–120. [Google Scholar] [CrossRef]

- Coma, M.; Tousi, N.M.; Pons-Prats, J.; Bugeda, G.; Bergada, J.M. A New Hybrid Optimization Method, Application to a Single Objective Active Flow Control Test Case. Appl. Sci. 2022, 12, 3894. [Google Scholar] [CrossRef]

- Devarapalli, R.; Bhattacharyya, B. A hybrid modified grey wolf optimization-sine cosine algorithm-based power system stabilizer parameter tuning in a multimachine power system. Optim. Control. Appl. Methods 2020, 41, 1143–1159. [Google Scholar] [CrossRef]

- Knypinski, L. A novel hybrid cuckoo search algorithm for optimization of a line-start PM synchronous motor. Bull. Pol. Acad. Sci.-Tech. 2023, 71, e144586. [Google Scholar]

- Knypinski, L. Constrained optimization of line-start PM motor based on the gray wolf optimizer. Eksploat Niezawodn. 2021, 23, 1–10. [Google Scholar] [CrossRef]

- Hegazy, A.E.; Makhlouf, M.A.; El-Tawel, G.S. Improved salp swarm algorithm for feature selection. J. King Saud. Univ.-Comput. Inf. Sci. 2020, 32, 335–344. [Google Scholar] [CrossRef]

- Al-Betar, M.A.; Alyasseri, Z.A.A.; Awadallah, M.A.; Abu Doush, I. Coronavirus herd immunity optimizer (CHIO). Neural Comput. Appl. 2021, 33, 5011–5042. [Google Scholar] [CrossRef]

- Rani, N.; Malakar, T. Maximization of Reactive Power Reserve in wind integrated power system using CHIO approach. IFAC-PapersOnLine 2022, 55, 150–155. [Google Scholar] [CrossRef]

- Hosny, K.M.; Khalid, A.M.; Hamza, H.M.; Mirjalili, S. Multilevel segmentation of 2D and volumetric medical images using hybrid Coronavirus Optimization Algorithm. Comput. Biol. Med. 2022, 150, 106003. [Google Scholar] [CrossRef]

- Yang, P.; Qi, X.B.; Yuan, Y.X.; Zhao, Y.S. Hybrid CHIO algorithm optimization for PFSP problems. Comput. Syst. Appl. 2022, 31, 380–387. [Google Scholar]

- Brucker, P.; Burke, E.K.; Groenemeyer, S. A branch and bound algorithm for the cyclic job-shop problem with transportation. Comput. Oper. Res. 2012, 39, 3200–3214. [Google Scholar] [CrossRef]

- Pinedo, M.L. Deterministic Models: Preliminaries. In Scheduling Theory, Algorithms, and Systems, 5th ed.; Springer Science + Business Media: New York, NY, USA, 2016; pp. 15–20. [Google Scholar]

- Hu, R.Q.; Cheng, H.; Zhang, Z.N. Solving Sequential Flexible Shop Scheduling Problems Based on Expression Trees. Computer Integrated Manufacturing Systems, 1–15. Available online: http://kns.cnki.net/kcms/detail/11.5946.tp.20220317.1506.002.html (accessed on 21 March 2022).

- Chen, R.H.; Yang, B.; Li, S.; Wang, S.L. A self-learning genetic algorithm based on reinforcement learning for flexible job-shop scheduling problem. Comput. Ind. Eng. 2020, 149, 106778. [Google Scholar] [CrossRef]

- Li, R.; Gong, W.Y.; Wang, L.; Lu, C.; Jiang, S.N. Two-stage knowledge-driven evolutionary algorithm for distributed green flexible job shop scheduling with type-2 fuzzy processing time. Swarm Evol. Comput. 2022, 74, 101139. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Rao, Y.Q.; Liu, X.J.; Li, P.G. Genetic algorithm based on POX crossover to solve job-shop scheduling problem. China Mech. Eng. 2004, 23, 83–87. [Google Scholar] [CrossRef]

- Gu, J.C.; Jiang, T.H.; Zhu, H.Q. Multi-objective discrete gray wolf optimization algorithm to solve job shop energy-saving scheduling problems. Comput. Integr. Manuf. Syst. 2021, 27, 2295–2306. [Google Scholar]

- Sun, A.H.; Song, Y.C.; Yang, Y.F.; Lei, Q. A dual resource constrained shop scheduling algorithm considering the processing quality of key parts. China Mech. Eng. 2022, 33, 2590–2600. [Google Scholar]

- Chen, K.; Bi, L. Research on Multi-objective Flexible Job Shop Scheduling Considering Transportation Time. Small Microcomput. Syst. 2021, 42, 946–952. [Google Scholar]

- Lei, K.; Guo, P.; Zhao, W.C.; Wang, Y.; Qian, L.M.; Meng, X.Y.; Tang, L.S. A multi-action deep reinforcement learning framework for flexible Job-shop scheduling problem. Expert Syst. Appl. 2022, 205, 117796. [Google Scholar] [CrossRef]

- Brandimarte, P. Routing and scheduling in a flexible job shop by tabu search. Ann. Oper. Res. 1993, 41, 157–183. [Google Scholar] [CrossRef]

- Hurink, J.; Jurisch, B.; Thole, M. Tabu search for the job-shop scheduling problem with multi-purpose machines. OR Spektrum 1994, 15, 205–215. [Google Scholar] [CrossRef]

- Ding, H.J.; Gu, X.S. Improved particle swarm optimization algorithm based novel encoding and decoding schemes for flexible job shop scheduling problem. Comput. Oper. Res. 2020, 121, 104951. [Google Scholar] [CrossRef]

- Jędrzejowicz, P.; Wierzbowska, I.A. Implementation of the Mushroom Picking Framework for Solving Flexible Job Shop Scheduling Problems in Parallel. In Proceedings of the International Conference on Knowledge-Based Intelligent Information & Engineering Systems, Verona, Italy, 7–9 September 2022. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).