Construction of a Green-Comprehensive Evaluation System for Flotation Collectors

Abstract

:1. Introduction

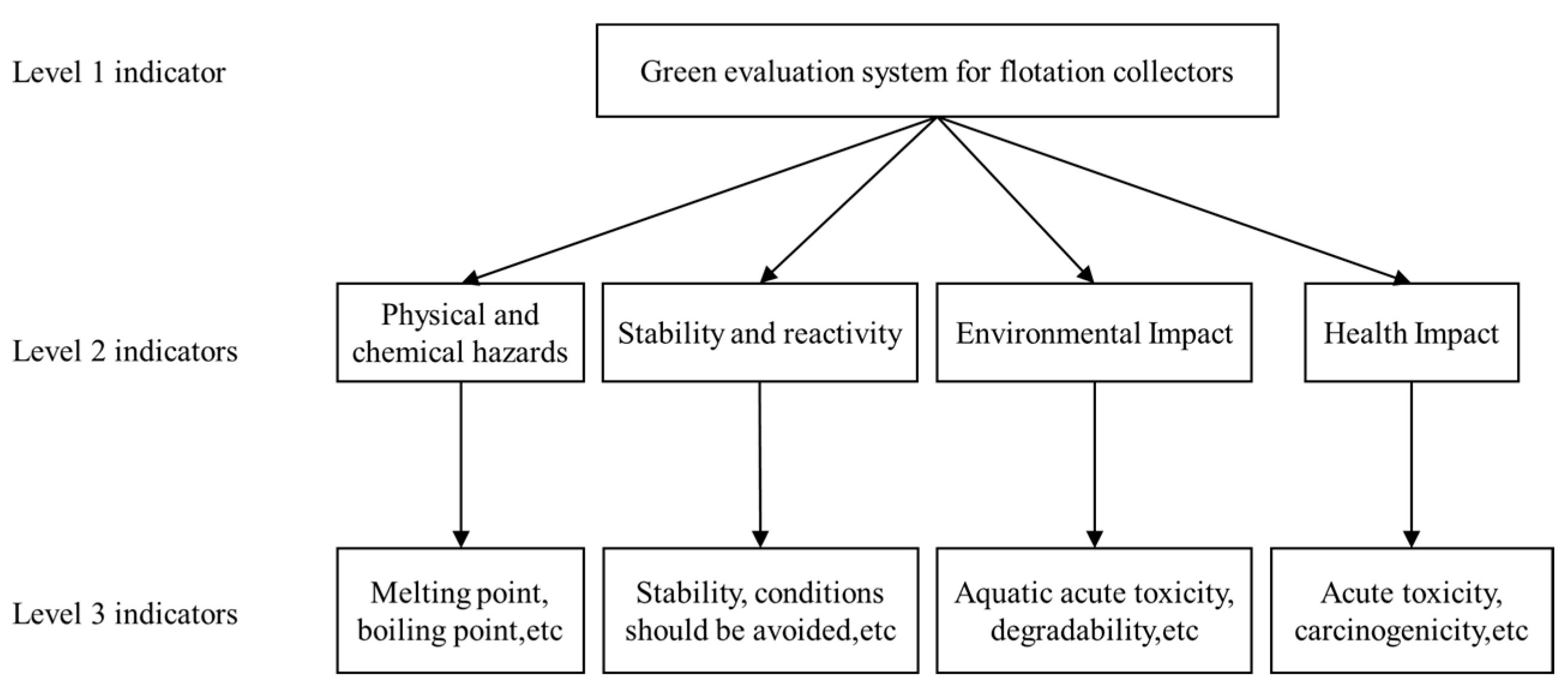

2. Flotation Collector Green Evaluation System

2.1. Selection of Indicators for Different Levels of Flotation Collector Green Evaluation System

2.2. Determination of Index Weight of Flotation Collector Green Evaluation System

- Build a hierarchical model;

- Constructing the judgment matrix;

- Calculate the weights;

- Consistency check.

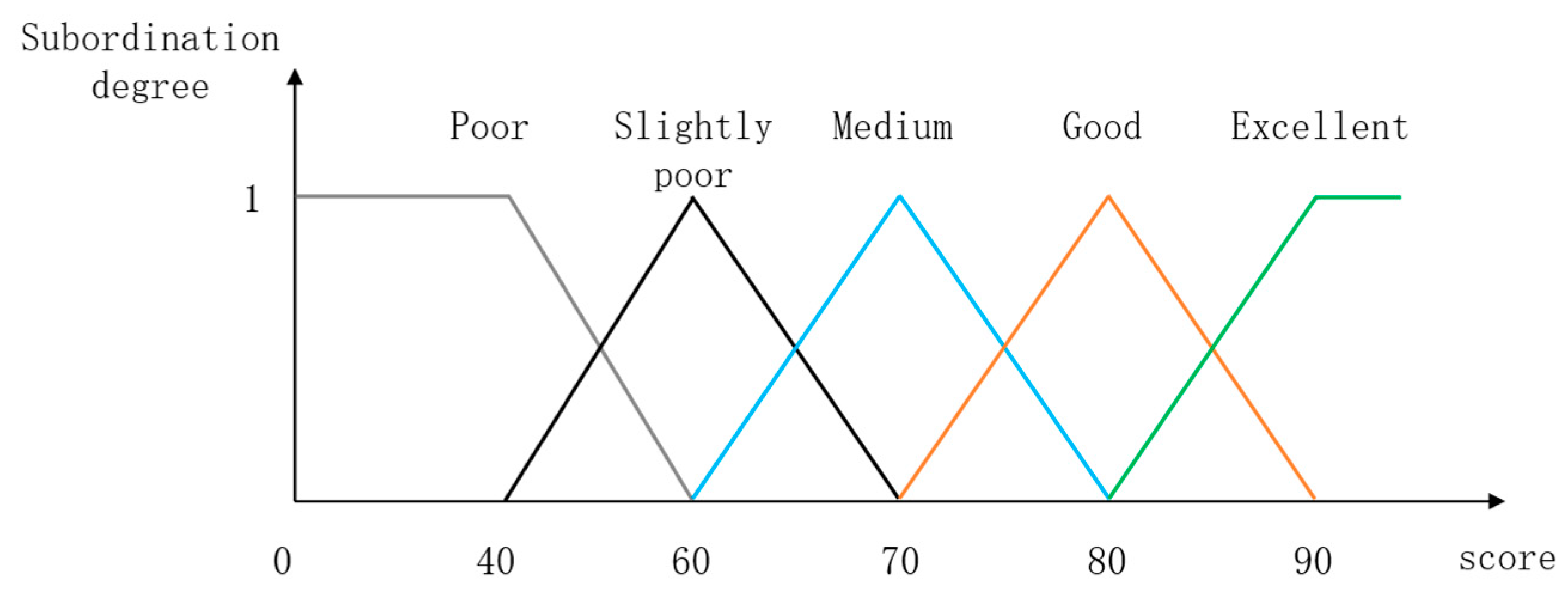

2.3. Index Calculation of Flotation Collector Green Evaluation System

2.3.1. Calculation of Three Levels of Indicators for Green Evaluation System of Flotation Collector

- 1.

- Aquatic acute toxicity

- 2.

- Aquatic slow toxicity

- 3.

- Biodegradability

- 4.

- Acute toxicity

- 5.

- Skin corrosion or irritation

- 6.

- Severe eye injury or eye irritation

- 7.

- Specific target organ toxicity

- 8.

- Carcinogenicity

- 9.

- Germline mutation

- 10.

- Inhalation hazards

- 11.

- Stability

- 12.

- Conditions should be avoided

- 13.

- Polymerization hazards

- 14.

- Decomposition of products

- 15.

- Ozone layer hazards

2.3.2. Flotation Collector Green Evaluation System II/I Calculation of Primary Indicators

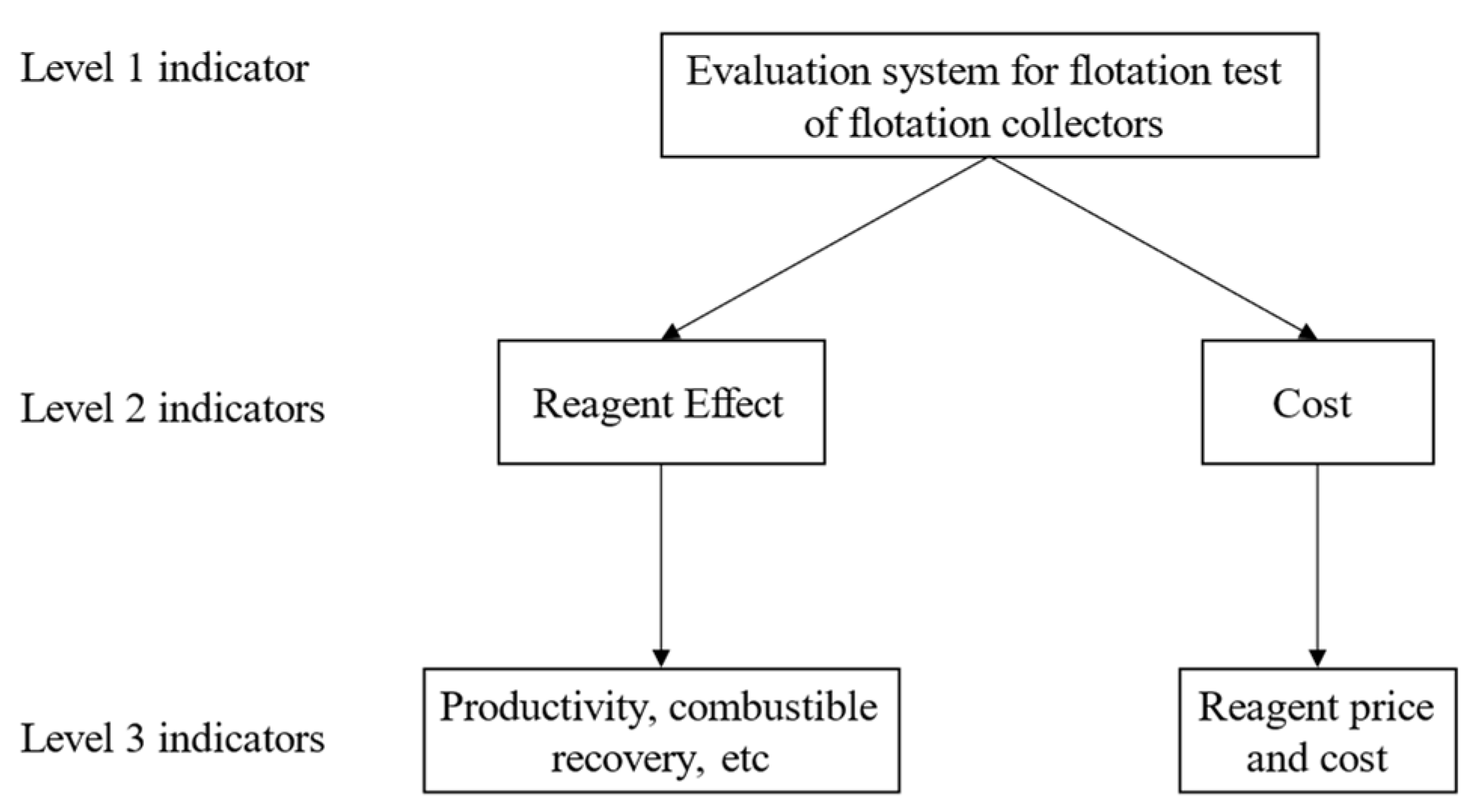

3. Evaluation System of Flotation Effect of Flotation Collector

3.1. Selection of Indicators for the Flotation Effect Evaluation System of the Flotation Collector Based on the Flotation Test

3.2. Determination of Index Weights for the Flotation Effect Evaluation System of the Flotation Collector Based on Flotation Tests

3.3. Calculation of Indicators of Flotation Effect Evaluation System of Flotation Collector Based on Flotation Test

3.3.1. Calculation of Three-Stage Indexes of Flotation Effect Evaluation System of Flotation Collector Based on Flotation Test

3.3.2. The Evaluation System of the Flotation Effect of the Flotation Collector Based on Flotation Test II/I Index Calculation

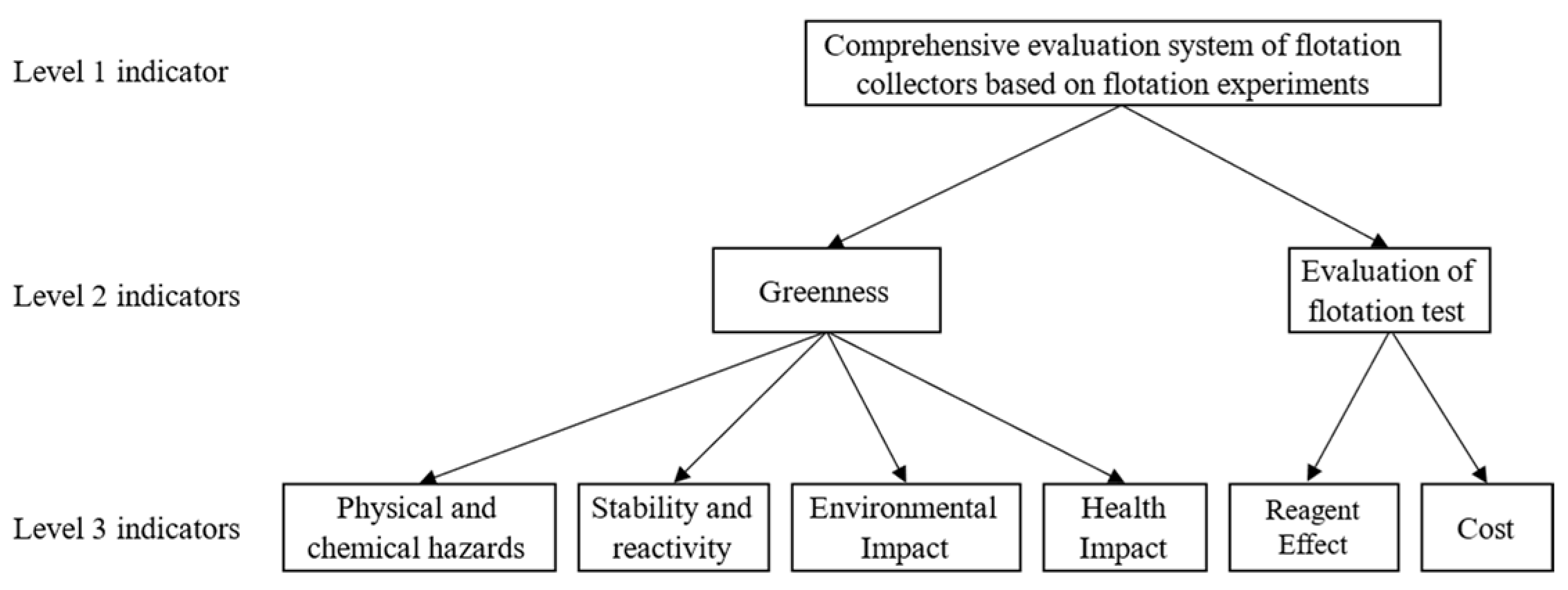

4. The Green-Comprehensive Evaluation System of the Flotation Collector

4.1. Index Determination of Comprehensive Evaluation System of Flotation Collector

4.2. Weight Determination of Flotation Collector Comprehensive Evaluation System

4.3. Comprehensive Evaluation Calculation of Flotation Collector

5. Example Analysis of Comprehensive Evaluation of Flotation Collectors

6. Conclusions

- According to the use of flotation collectors in coal processing plants, the green evaluation system of flotation collectors was constructed by using the analytical method, and the basis for selecting green indicators of flotation collectors was established according to chemical safety technical instructions and Globally Harmonized System of Classification and Labeling of Chemicals (GHS).

- The flotation effect evaluation system based on the flotation test is constructed by using the analytical method, and the indicators are determined by the method of flotation test commonly used in the laboratory: secondary indicators, i.e., the effect and cost of chemicals, and tertiary indicators under the secondary indicators: the yield of fine coal, the recovery of combustible body and the price of chemicals, etc., forming the evaluation system of “1-2-5”.

- The comprehensive evaluation model of the flotation collector based on the flotation test has constructed a four-level evaluation index system of “1-2-6-30” from two dimensions: green and flotation test.

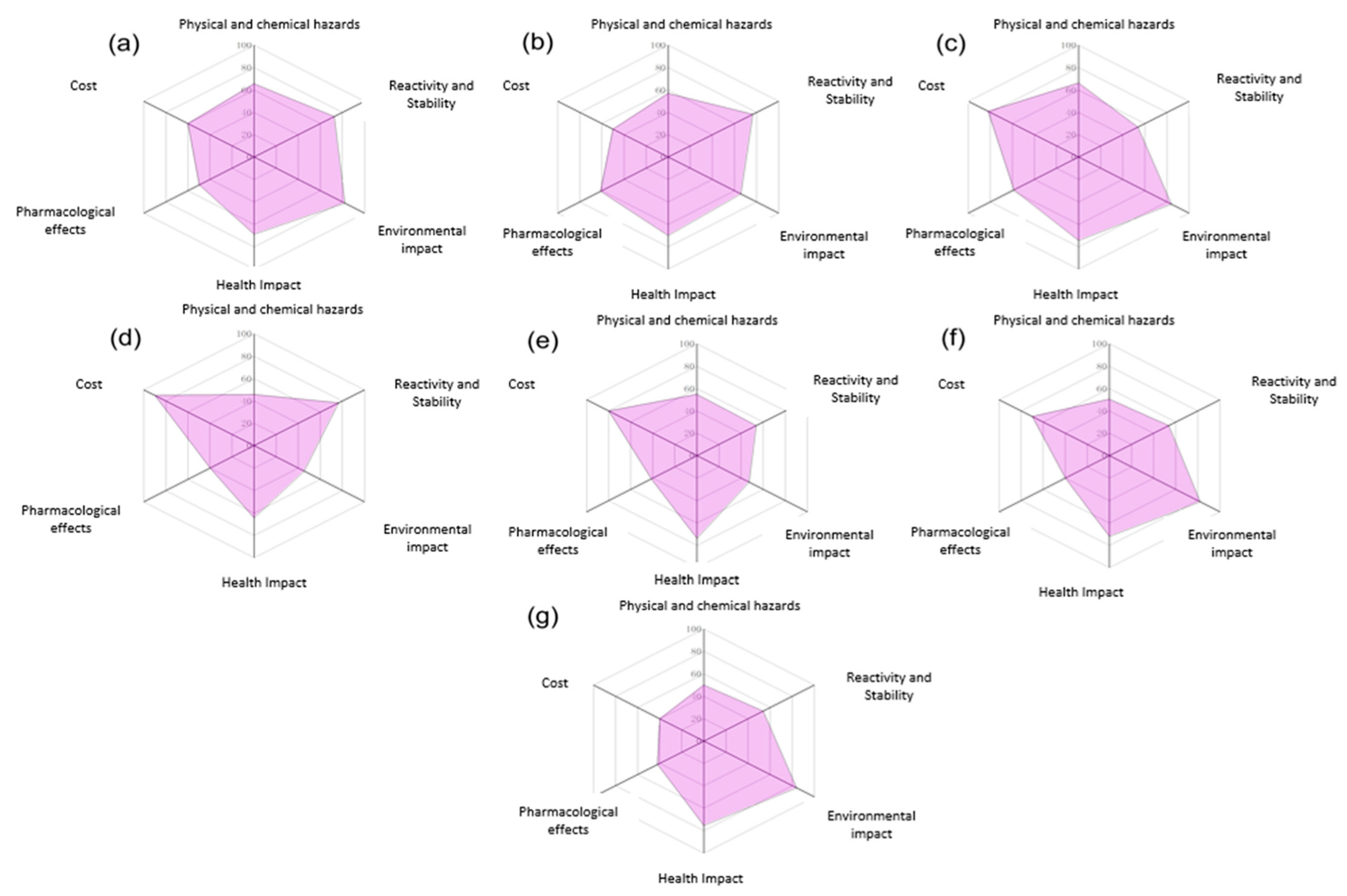

- The reasonableness, intuitiveness, and scientificity of the establishment of the comprehensive evaluation system can be verified by the difference between radar plots of secondary and tertiary indicators. The effectiveness of the evaluation system can be verified by the comparison of radar plots between different reagents, and the comparison of radar plots between different reagents can be used to evaluate different collectors.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Coal Industry Prosperity Index Research Group, YUE Fubin. Research report on the economic situation of China’s coal industry in 2020–2021. Chin. Coal 2021, 47, 9. [Google Scholar]

- Zhang, R.; Qie, X.; Hu, Y.; Chen, X. Does de-capacity policy promote the efficient and green development of the coal industry?—Based on the evidence of China. Resour. Policy 2022, 77, 102717. [Google Scholar] [CrossRef]

- Du, Y.; Liu, Y.; Hossain, M.A.; Chen, S. The decoupling relationship between China’s economic growth and carbon emissions from the perspective of industrial structure. Chin. Resour. Environ. Engl. Version 2022, 20, 10. [Google Scholar] [CrossRef]

- Kondrat’ev, S.A. Selecting Collecting Agents for Flotation. J. Min. Sci. 2023, 58, 796–811. [Google Scholar] [CrossRef]

- Moshkin, N.P.; Kondrat’ev, S.A. Foam separation selectivity conditioned by the chemically attached agent. J. Min. Sci. 2014, 50, 780–787. [Google Scholar]

- Vilaso-Cadre, J.E.; Avila-Marquez, D.M.; Reyes-Dominguez, I.A.; Blanco-Flores, A.; Gutierrez-Castaneda, E.J. Coal flotation in a low-rank carbonaceous mineral using 3-phenyl-1-propanol as a collector reagent. Fuel J. Fuel Sci. 2021, 304, 121363. [Google Scholar] [CrossRef]

- Kadagala, M.R.; Nikkam, S.; Tripathy, S.K. A review on flotation of coal using mixed reagent systems. Miner. Eng. 2021, 173, 107217. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhou, J. The Development of Flotation Reagents in 2018. Multipurp. Util. Miner. Resour. 2019, 4, 1–10. [Google Scholar] [CrossRef]

- Xie, K. Reviews of Clean Coal Conversion Technology in China: Situations & Challenges. Chin. J. Chem. Eng. 2021, 35, 62–69. [Google Scholar]

- Liu, Z.; Liao, Y.; An, M.; Lai, Q.; Ma, L.; Qiu, Y. Enhancing low-rank coal flotation using a mixture of dodecane and n-valeraldehyde as a collector. Physicochem. Probl. Miner. Process. 2019, 55, 49–57. [Google Scholar]

- He, G. Essays on the Health Effects of Pollution in China. Ph.D. Dissertation, University of California, Berkeley, CA, USA, 2013. [Google Scholar]

- Ji, Q.; Tabassum, S.; Hena, S.; Silva, C.G.; Yu, G.; Zhang, Z. A review on the coal gasification wastewater treatment technologies: Past, present and future outlook. J. Clean Prod. 2016, 126, 38–55. [Google Scholar] [CrossRef]

- Boening, D.W. Aquatic toxicity and environmental fate of xanthates. Min. Eng. 1998, 50, 65–68. [Google Scholar]

- Naidu, R.; Biswas, B.; Willett, I.R.; Cribb, J.; Aitken, R.J. Chemical pollution: A growing peril and potential catastrophic risk to humanity. Environ. Int. 2021, 156, 106616. [Google Scholar] [CrossRef] [PubMed]

- Hongyu, L.; Chenyang, Q.; Sigang, L.; Yangge, Z.; Runqing, L.; Meirong, W. Study on the influence and mechanism of polyferric sulfate on COD removal and reuse of scheelite flotation wastewater. Miner. Eng. 2023, 191, 107940. [Google Scholar]

- Jacek, R.; Grzegorz, R.; Tomasz, B.; Lukasz, D. The Use of Mining Waste Materials for the Treatment of Acid and Alkaline Mine Wastewater. Minerals 2020, 10, 1061. [Google Scholar]

- Gan, H.-X.; Gu, X.-Z. The Effect of Chemical Pollution on Health & Countermeasures in Scholastic Physical Education; Sanya, China, 2014; pp. 70–73. [Google Scholar]

- An, M.; Liao, Y.; Yang, Z.; Cao, Y.; Hao, X.; Song, X.; Ren, H.; Yang, A.; Chen, L. Energy Feature of Air Bubble Detachment from a Low-Rank Coal Surface in the Presence of a Dodecane-Oleic Acid Collector Mixture. ACS Omega 2022, 7, 18315–18322. [Google Scholar] [CrossRef]

- He, J.; Liu, C.; Yao, Y. Flotation intensification of the coal slime using a new compound collector and the interaction mechanism between the reagent and coal surface. Powder Technol. Int. J. Sci. Technol. Wet Dry Part. Syst. 2018, 325, 333–339. [Google Scholar]

- Ganesh, K.N.; Zhang, D.; Miller, S.J.; Rossen, K.; Chirik, P.J.; Kozlowski, M.C.; Zimmerman, J.B.; Brooks, B.W.; Savage, P.E.; Allen, D.T.; et al. Green Chemistry: A Framework for a Sustainable Future. ACS Omega 2021, 25, 16254–16258. [Google Scholar]

- Van Schoubroeck, S.; Van Dael, M.; Van Passel, S.; Malina, R. A review of sustainability indicators for biobased chemicals. Renew. Sustain. Energy Rev. 2018, 94, 115–126. [Google Scholar]

- Turysbekov, D.; Tussupbayev, N.; Semushkina, L.; Narbekova, S.; Kaldybaeva, Z.; Mukhamedilova, A. Study of the properties of water-air microdispersion of a floatation agent solution. Metalurgija 2022, 61, 363–366. [Google Scholar]

- Melhem, G.A.; Shanley, E.S. On the estimation of hazard potential for chemical substances. Process Saf. Prog. 1996, 15, 168–172. [Google Scholar] [CrossRef]

- United Nations. Globally Harmonized Systems of Classification and Labelling of Chemicals (GHS). 2009. Available online: https://www.cirs-group.com/en/chemicals/un-ghs-globally-harmonized-system-of-classification-and-labeling-of-chemicals (accessed on 12 February 2022).

- Zubkova, T.; Tagirova, L. Using the hierarchical analysis method for decision making in a business activity. J. Phys. Conf. Ser. 2020, 1553, 012008. [Google Scholar] [CrossRef]

- Barron, M.G.; Lambert, F.N.; Raimondo, S. Assessment of a New Approach Method for Grouped Chemical Hazard Estimation: The Toxicity-Normalized Species Sensitivity Distribution (SSDn). Environ. Sci. Technol. 2022, 56, 8278–8289. [Google Scholar]

- Julie, R.; Aurore, Z.; Nicolas, B.; Laurence, P. From geochemistry to ecotoxicology of rare earth elements in aquatic environments: Diversity and uses of normalization reference materials and anomaly calculation methods. Sci. Total Environ. 2023, 856, 158890. [Google Scholar]

- Gainer, A.; Bresee, K.; Hogan, N.; Siciliano, S.D. Advancing soil ecological risk assessments for petroleum hydrocarbon contaminated soils in Canada: Persistence, organic carbon normalization and relevance of species assemblages. Sci. Total Environ. 2019, 668, 400–410. [Google Scholar] [CrossRef]

- Sivilevicius, H. Application of Expert Evaluation Method to Determine the Importance of Operating Asphalt Mixing Plant Quality Criteria and Rank Correlation. Balt. J. Road Bridge Eng. 2011, 6, 48–58. [Google Scholar] [CrossRef]

- Shen, M.; Zhao, S.; Wang, J.; Ding, L. A Review Expert Recommendation Method Based on Comprehensive Evaluation in Multi-Source Data. In Proceedings of the CCEAI 2021: 5th International Conference on Control Engineering and Artificial Intelligence, Sanya, China, 14–16 January 2021. [Google Scholar]

- Rasol, M.; Rogozov, Y.; Kucherov, S. Development of a Decision-Making Model to Provide Expert Assessment of the State of the Environment. Int. J. Softw. Innov. 2022, 10, 1–15. [Google Scholar] [CrossRef]

- Shengquan, H.; Dazhao, S.; Hani, M.; Xueqiu, H.; Jianqiang, C.; Zhenlei, L.; Yarong, X.; Tuo, C. Integrated rockburst early warning model based on fuzzy comprehensive evaluation method. Int. J. Rock Mech. Min. 2021, 142, 104767. [Google Scholar]

- Yali, C.; Jun, C.; Fanfei, M.; Lujun, W.; Qingdong, S. Research on the flotation efficiency of alcohol/ether alcohol frothers for common collectors: Insight of molecular dynamics simulations. Appl. Surf. Sci. 2023, 614, 156233. [Google Scholar]

- Cheng, G.; Li, Z.; Cao, Y.; Jiang, Z. Research progress in lignite flotation intensification. Int. J. Coal Prep. Util. 2020, 40, 59–76. [Google Scholar] [CrossRef]

- Kim, S. Exploring Chemical Information in PubChem. Curr. Protoc. 2021, 1, e217. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Chen, J.; Cheng, T.; Gindulyte, A.; He, J.; He, S.; Li, Q.; Shoemaker, B.A.; Thiessen, P.A.; Yu, B.; et al. PubChem 2023 update. Nucleic Acids Res. 2023, 51, D1373–D1380. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Xiao, J.; Suzek, T.O.; Zhang, J.; Wang, J.; Bryant, S.H. PubChem: A public information system for analyzing bioactivities of small molecules. Nucleic Acids Res. 2019, 37, W623–W633. [Google Scholar] [CrossRef] [PubMed]

| Evaluating Index | Weight | Evaluating Index | Weight | ||

|---|---|---|---|---|---|

| Physical and chemical hazards B1 | Melting point C1 | 0.0772 | Health impact B4 | Acute toxicity C19 | 0.3421 |

| Boiling point C2 | 0.0808 | Skin corrosion or irritation C20 | 0.2353 | ||

| Water and oil distribution coefficient C3 | 0.0407 | Severe eye injury/eye irritation C21 | 0.1162 | ||

| Relative density C4 | 0.0309 | Characteristic target organ toxicity C22 | 0.0657 | ||

| Molecular weight C5 | 0.0216 | Carcinogenicity C23 | 0.0444 | ||

| Relative vapor density C6 | 0.0267 | Reproductive toxicity C24 | 0.0198 | ||

| Upper explosive limit C7 | 0.1170 | Inhalation hazard C25 | 0.1765 | ||

| Lower explosive limit C8 | 0.1473 | ||||

| Flash point C9 | 0.2626 | ||||

| Autoignition temperature C10 | 0.1952 | ||||

| Stability and reactivity B2 | Stability C11 | 0.0655 | Environmental impact B3 | Acute aquatic toxicity C15 | 0.6528 |

| Conditions to be avoided C12 | 0.5731 | Aquatic chronic toxicity C16 | 0.1655 | ||

| Hazardous polymerization C13 | 0.1082 | Ozone layer hazard C17 | 0.1081 | ||

| Decomposition product C14 | 0.2532 | Degradability C18 | 0.0736 | ||

| Category | Category 1 | Category 2 | Category 3 |

|---|---|---|---|

| Signal word | Warning | Unsignalized word | Unsignalized word |

| Hazard description | Very toxic to aquatic organisms | Toxic to aquatic organisms | Harmful to aquatic organisms |

| Fraction | 0 | 65 | 85 |

| Category | Category 1 | Category 2 | Category 3 |

|---|---|---|---|

| Signal word | Warning | Unsignalized word | Unsignalized word |

| Hazard description | Very toxic to aquatic organisms and has a long-term, lasting impact. | Toxic to aquatic organisms and having long-term, lasting effects. | Harmful to aquatic organisms and having long-term, lasting effects. |

| Fraction | 0 | 65 | 85 |

| Category | Category 1 | Category 2 | Category 3 | Category 4 | Category 5 |

|---|---|---|---|---|---|

| Signal word | Hazard | Hazard | Warning | Warning | Warning |

| Hazard description | No degradation | No degradation | Slow degradation | Rapid degradation (<70%) | Rapid degradation (>70%) |

| Fraction | 0 | 20 | 65 | 75 | 85 |

| Category | Category 1 | Category 2 | Category 3 | Category 4 | Category 5 |

|---|---|---|---|---|---|

| Signal word | Hazard | Hazard | Hazard | Warning | Warning |

| Hazard description | Deadly | Deadly | Poisoning | hazardous | May be harmful |

| Fraction | 0 | 20 | 65 | 75 | 85 |

| Category | Category 1A | Category 1B | Category 1C | Category 2 | Category 3 |

|---|---|---|---|---|---|

| Signal word | Hazard | Hazard | Hazard | Warning | Warning |

| Hazard description | Causing severe skin burns and eye injuries | Causing severe skin burns and eye injuries | Causing severe skin burns and eye injuries | Causing skin irritation | Causing mild skin irritation |

| Fraction | 0 | 0 | 0 | 65 | 85 |

| Category | Category 1 | Category 2A | Category 2B |

|---|---|---|---|

| Signal word | Hazard | Warning | Warning |

| Hazard description | Causing severe eye injury | Causing severe eye irritation | Cause eye irritation |

| Fraction | 0 | 65 | 85 |

| Category | Category 1A | Category 2 | Category 3 |

|---|---|---|---|

| Signal word | Hazard | Warning | Warning |

| Hazard description | Can damage organs | May damage organs | May cause respiratory irritation; or may cause drowsiness, or dizziness |

| Fraction | 0 | 65 | 85 |

| Category | Category 1A | Category 1B | Category 2 |

|---|---|---|---|

| Signal word | Hazard | Hazard | Warning |

| Hazard description | May be carcinogenic | May be carcinogenic | Suspected to be carcinogenic |

| Fraction | 0 | 0 | 75 |

| Category | Category 1A | Category 1B | Category 2 |

|---|---|---|---|

| Signal word | Hazard | Hazard | Warning |

| Hazard description | May lead to genetic defects | May lead to genetic defects | Suspicion leads to genetic defects |

| Fraction | 0 | 0 | 75 |

| Category | Category 1 | Category 2 |

|---|---|---|

| Signal word | Hazard | Warning |

| Hazard description | Swallowing and entering the respiratory tract can be fatal | Swallowing and entering the respiratory tract can be harmful |

| Fraction | 0 | 75 |

| Stability | Fraction |

|---|---|

| Yes | 100 |

| No | 0 |

| Number of Conditions to Avoid | Fraction |

|---|---|

| 0 | 100 |

| 1 | 80 |

| 2 | 60 |

| 3 | 40 |

| 4 | 20 |

| Be more 5 | 0 |

| Can Polymerization Occur | Fraction |

|---|---|

| Yes | 0 |

| No | 100 |

| Specify the Type of Decomposition Products | Fraction |

|---|---|

| 0 | 100 |

| 1 | 80 |

| 2 | 60 |

| 3 | 40 |

| 4 | 20 |

| 5 | 0 |

| Harm the Ozone Layer | Whether the Substance Is Specified in the Montreal Protocol | Signal Word | Hazard Description | Fraction |

|---|---|---|---|---|

| Yes | Warning | Destroying ozone in the upper atmosphere | 0 | |

| No | Unsignalized word | No | 100 |

| Evaluation Index | Index Weight | |

|---|---|---|

| Reagent effect B5 | Clean coal yielding rate C26 | 0.5396 |

| Combustible recovery C27 | 0.2970 | |

| Flotation perfection index C28 | 0.1634 | |

| Reagent cost B6 | Reagent price C29 | 1.0000 |

| Collector dosage C30 | ||

| Evaluation Index | Index Weight | |

|---|---|---|

| Green degree A1 | Physical and chemical hazards B1 | 0.0651 |

| Stability and reactivity B2 | 0.0483 | |

| Environmental impact B3 | 0.1445 | |

| Health effect B4 | 0.2547 | |

| Flotation test evaluation system A2 | Reagent effect B5 | 0.3854 |

| Reagent Cost B6 | 0.1022 | |

| Green Index | Dodecane | Dodecyl Aldehyde | Methyl Laurate | N-Octane | 1-Octanol | 2-Octanone | Valeraldehyde |

|---|---|---|---|---|---|---|---|

| C1 | 63.82 | 88.41 | 70.55 | 42.36 | 61.14 | 60.91 | 26.59 |

| C2 | 70.00 | 58.93 | 88.21 | 37.86 | 62.50 | 55.00 | 29.64 |

| C3 | 86.15 | 69.06 | 75.54 | 72.00 | 38.46 | 28.77 | 12.46 |

| C4 | 49.74 | 67.00 | 73.00 | 40.60 | 65.80 | 64.00 | 62.20 |

| C5 | 55.06 | 50.23 | 39.88 | 74.40 | 68.89 | 69.58 | 84.09 |

| C6 | 18.75 | 57.50 | 79.46 | 2.68 | 73.21 | 71.43 | 46.43 |

| C7 | 73.33 | 56.67 | 55.83 | 70.83 | 87.50 | 87.50 | 60.00 |

| C8 | 5.00 | 25.00 | 40.00 | 15.00 | 15.00 | 35.00 | 80.00 |

| C9 | 55.33 | 67.33 | 89.33 | 8.67 | 54.00 | 34.67 | 8.00 |

| C10 | 12.69 | 11.54 | 49.23 | 13.85 | 31.92 | 23.46 | 20.00 |

| C11 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| C12 | 80.00 | 80.00 | 40.00 | 80.00 | 40.00 | 40.00 | 20.00 |

| C13 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| C14 | 60.00 | 60.00 | 60.00 | 60.00 | 60.00 | 60.00 | 60.00 |

| C15 | 85.00 | 65.00 | 0.00 | 0.00 | 0.00 | 85.00 | 85.00 |

| C16 | 85.00 | 65.00 | 65.00 | 0.00 | 0.00 | 85.00 | 85.00 |

| C17 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| C18 | 0.00 | 65.00 | 75.00 | 0.00 | 65.00 | 0.00 | 65.00 |

| C19 | 85.00 | 85.00 | 75.00 | 75.00 | 75.00 | 75.00 | 85.00 |

| C20 | 65.00 | 65.00 | 65.00 | 65.00 | 85.00 | 65.00 | 65.00 |

| C21 | 85.00 | 65.00 | 85.00 | 65.00 | 65.00 | 65.00 | 65.00 |

| C22 | 65.00 | 65.00 | 85.00 | 85.00 | 0.00 | 85.00 | 85.00 |

| C23 | 0.00 | 75.00 | 75.00 | 0.00 | 75.00 | 75.00 | 75.00 |

| C24 | 75.00 | 75.00 | 75.00 | 75.00 | 75.00 | 75.00 | 75.00 |

| C25 | 0.00 | 75.00 | 75.00 | 0.00 | 75.00 | 75.00 | 75.00 |

| Effect Index | Dodecane | Dodecyl Aldehyde | Methyl Laurate | N-Octane | 1-Octanol | 2-Octanone | Valeraldehyde |

|---|---|---|---|---|---|---|---|

| C26 | 45.41 | 57.05 | 54.26 | 32.29 | 36.48 | 32.05 | 38.24 |

| C27 | 53.30 | 66.55 | 63.68 | 38.25 | 42.83 | 37.77 | 44.79 |

| C28 | 53.76 | 65.46 | 63.96 | 38.10 | 43.60 | 38.76 | 43.70 |

| C29*C30 | 60.00 | 50.00 | 82.00 | 90.00 | 80.00 | 70.00 | 40.00 |

| Collector | A1 | B1 | B2 | B3 | B4 |

|---|---|---|---|---|---|

| Dodecane | 71.56 | 65.69 | 72.67 | 82.32 | 68.84 |

| Dodecyl aldehyde | 70.45 | 57.10 | 76.67 | 67.70 | 74.25 |

| Methyl laurate | 74.19 | 66.38 | 53.75 | 84.06 | 74.47 |

| N-octane | 57.85 | 45.85 | 76.67 | 45.41 | 64.41 |

| 1-octanol | 62.07 | 54.94 | 53.75 | 47.25 | 73.89 |

| 2-octanone | 70.52 | 50.60 | 53.75 | 82.23 | 72.14 |

| Valeraldehyde | 72.66 | 50.04 | 53.75 | 84.07 | 75.56 |

| Collector | A2 | B5 | B6 |

|---|---|---|---|

| Dodecane | 53.14 | 49.71 | 60.00 |

| Dodecyl aldehyde | 57.50 | 61.25 | 50.00 |

| Methyl laurate | 66.43 | 58.64 | 82.00 |

| N-octane | 56.67 | 40.00 | 90.00 |

| 1-octanol | 54.28 | 41.43 | 80.00 |

| 2-octanone | 50.00 | 40.00 | 70.00 |

| Valeraldehyde | 41.35 | 42.03 | 40.00 |

| Collector Name | Overall Score |

|---|---|

| Dodecane | 61.97 |

| Dodecyl aldehyde | 64.83 |

| Methyl laurate | 69.01 |

| N-octane | 54.27 |

| 1-octanol | 55.96 |

| 2-octanone | 58.72 |

| Valeraldehyde | 57.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Cui, J.; Cao, Y.; Ma, L.; Fan, G.; Huang, G.; Ning, K.; Wang, J.; Kang, Y.; Sun, X.; et al. Construction of a Green-Comprehensive Evaluation System for Flotation Collectors. Processes 2023, 11, 1563. https://doi.org/10.3390/pr11051563

Xu H, Cui J, Cao Y, Ma L, Fan G, Huang G, Ning K, Wang J, Kang Y, Sun X, et al. Construction of a Green-Comprehensive Evaluation System for Flotation Collectors. Processes. 2023; 11(5):1563. https://doi.org/10.3390/pr11051563

Chicago/Turabian StyleXu, Hongxiang, Jiahua Cui, Yijun Cao, Lin Ma, Guixia Fan, Gen Huang, Kejia Ning, Jingzheng Wang, Yuntao Kang, Xin Sun, and et al. 2023. "Construction of a Green-Comprehensive Evaluation System for Flotation Collectors" Processes 11, no. 5: 1563. https://doi.org/10.3390/pr11051563

APA StyleXu, H., Cui, J., Cao, Y., Ma, L., Fan, G., Huang, G., Ning, K., Wang, J., Kang, Y., Sun, X., Deng, J., & Li, S. (2023). Construction of a Green-Comprehensive Evaluation System for Flotation Collectors. Processes, 11(5), 1563. https://doi.org/10.3390/pr11051563