Theoretical Investigation on the Catalytic Effect and Mechanism of Pure and Cu−Doped SBA−15 Molecular Sieves on the Decomposition of Dimethyl Sulfoxide

Abstract

1. Introduction

2. Computational Method

3. Results and Discussion

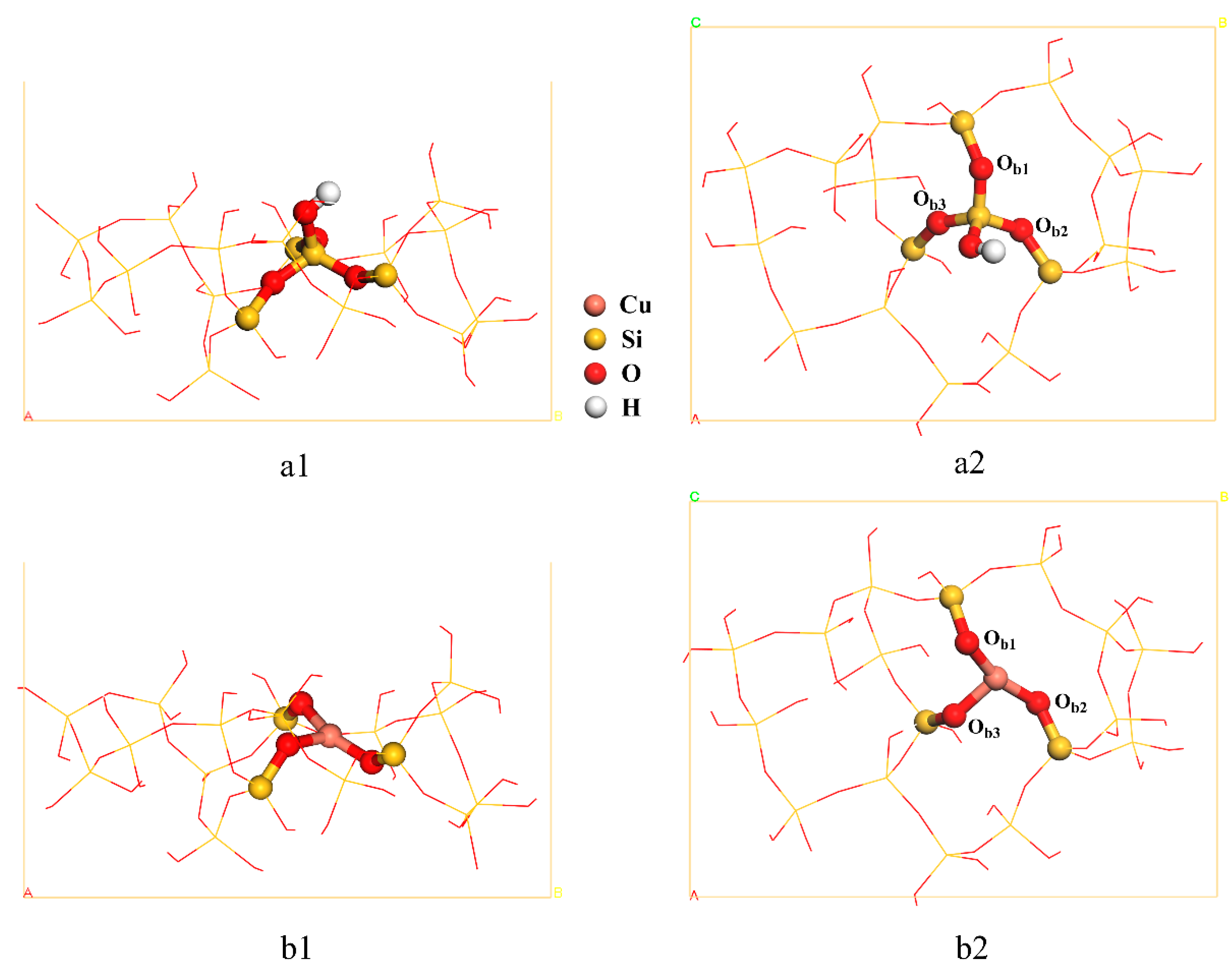

3.1. Structures of the Pure and Cu−Doped SBA−15 Surfaces

3.2. The Adsorption of DMSO on the Pure and Cu−Doped SBA−15 Surfaces

3.2.1. Adsorption Configuration and Energy for DMSO Adsorbed on the Pure SBA−15 Surface

3.2.2. Adsorption Configuration and Energy for DMSO Adsorbed on the Cu−Doped SBA−15 Surface

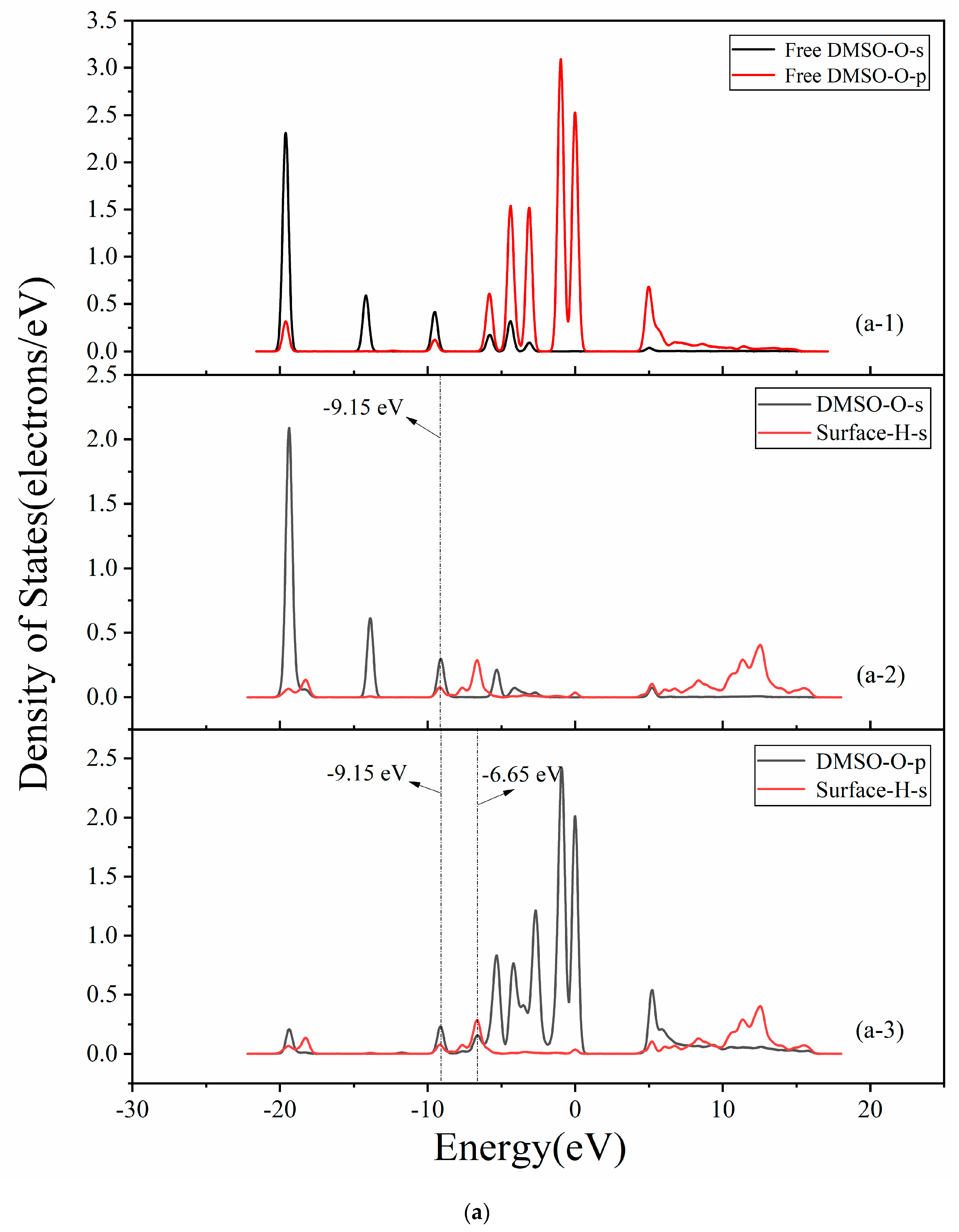

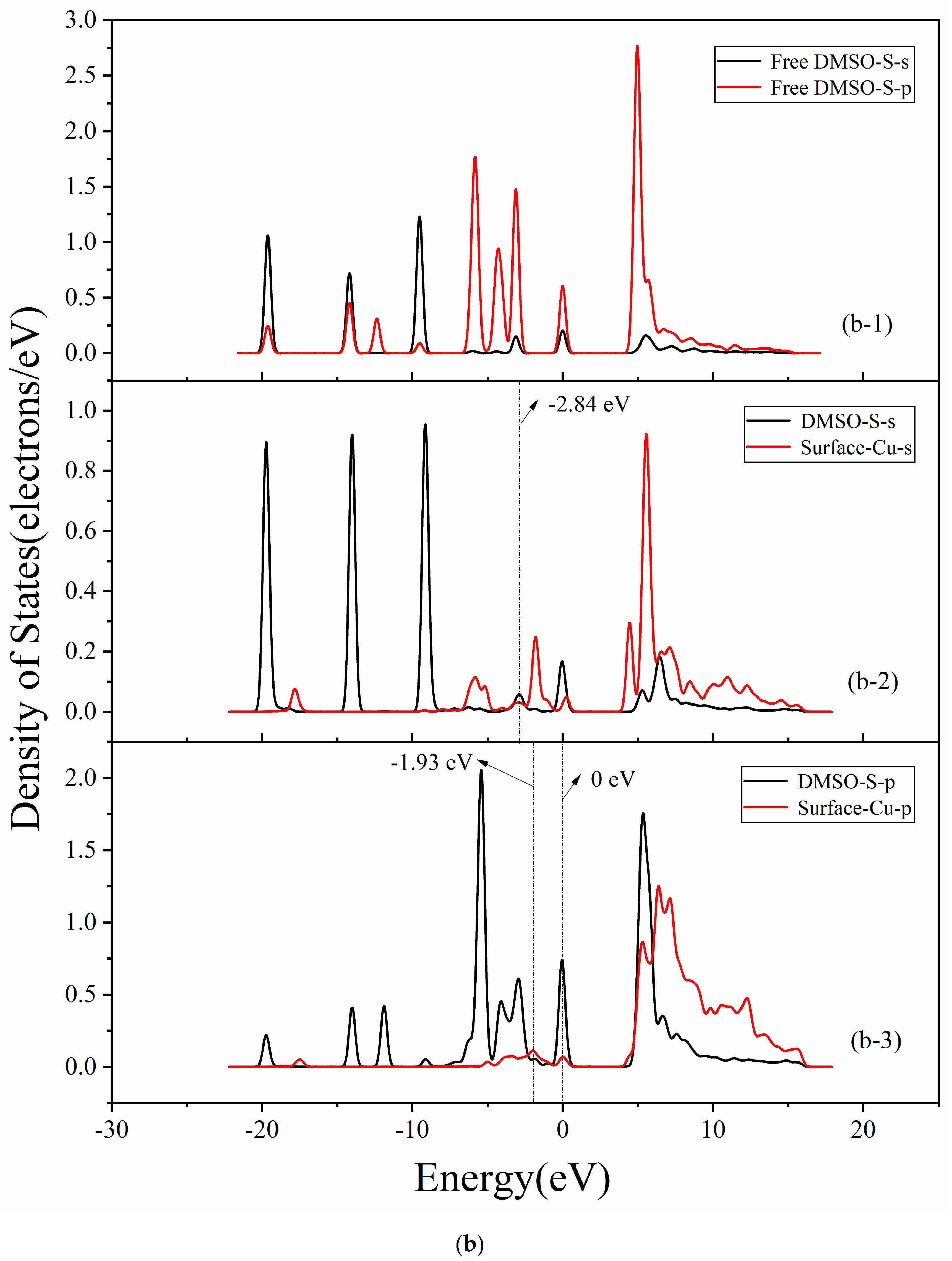

3.2.3. Density of States

3.3. The Dissociation of DMSO on the Pure and Cu−Doped SBA−15 Surfaces

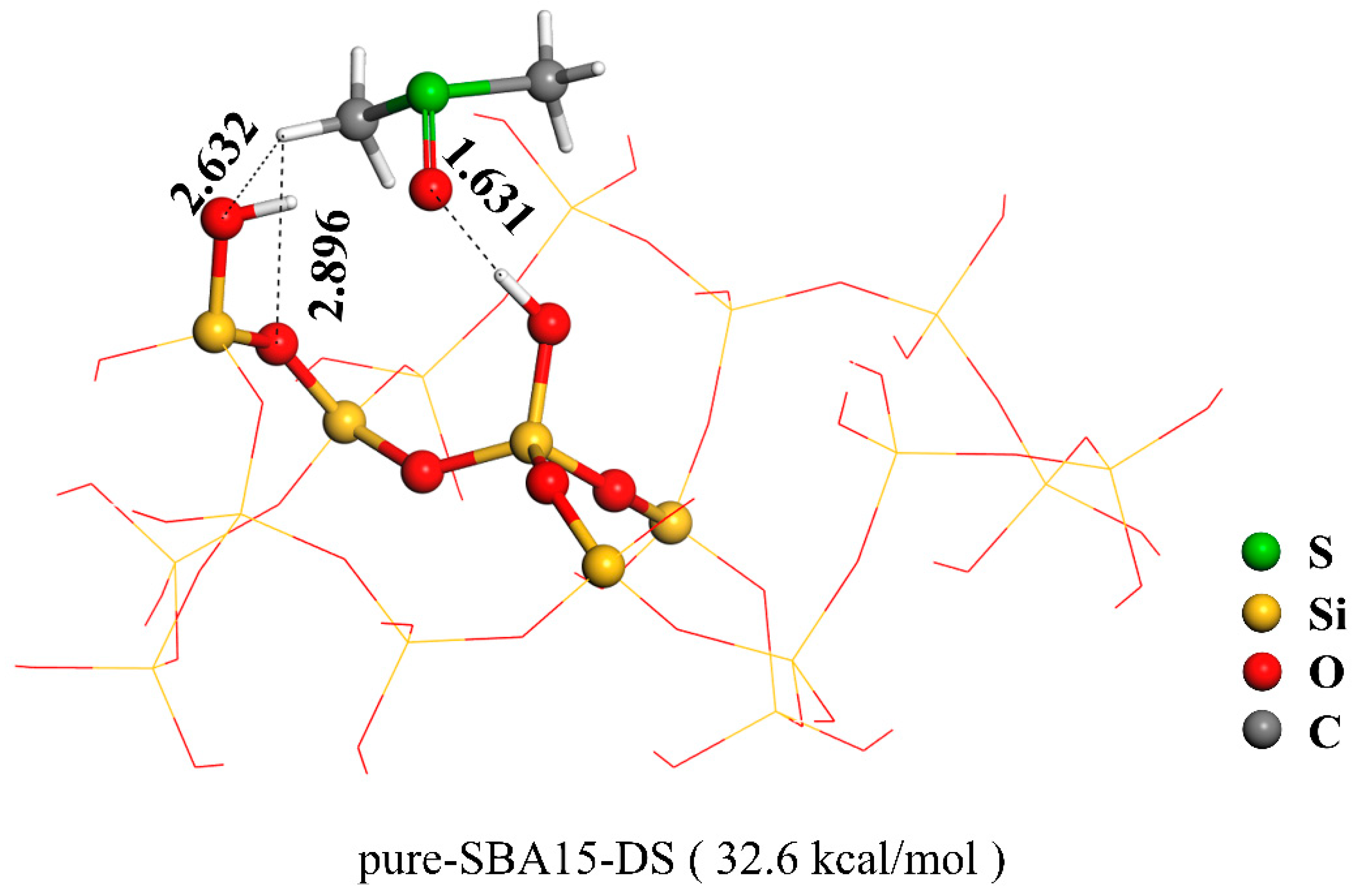

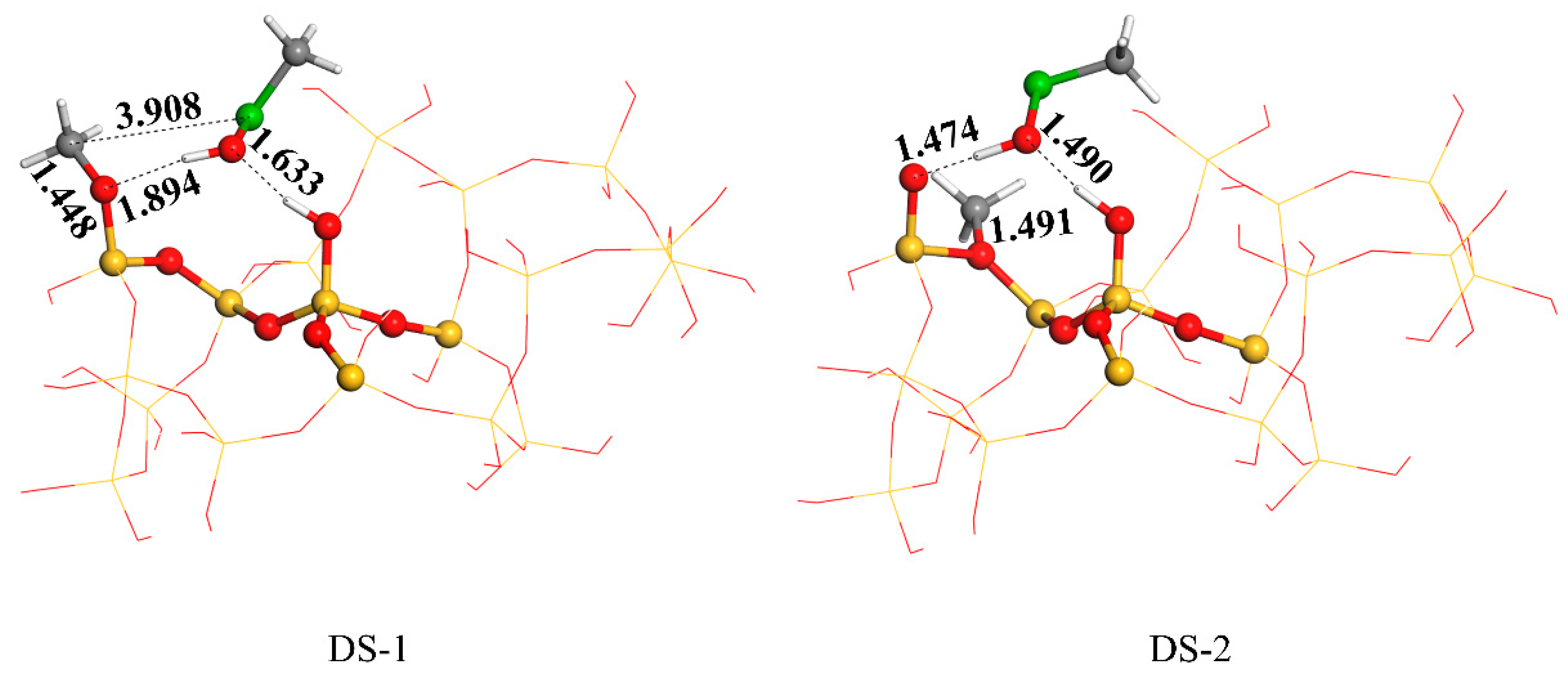

3.3.1. The Dissociation of DMSO on the Pure SBA−15 Surface

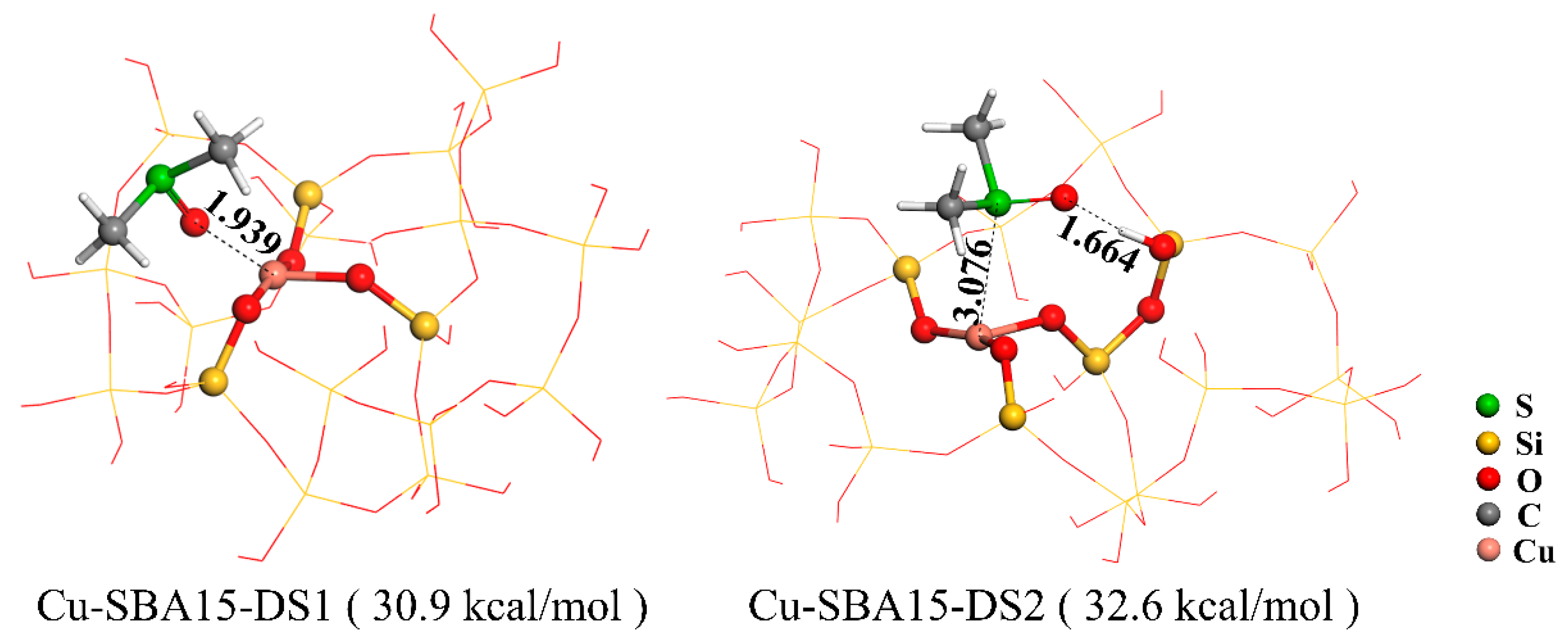

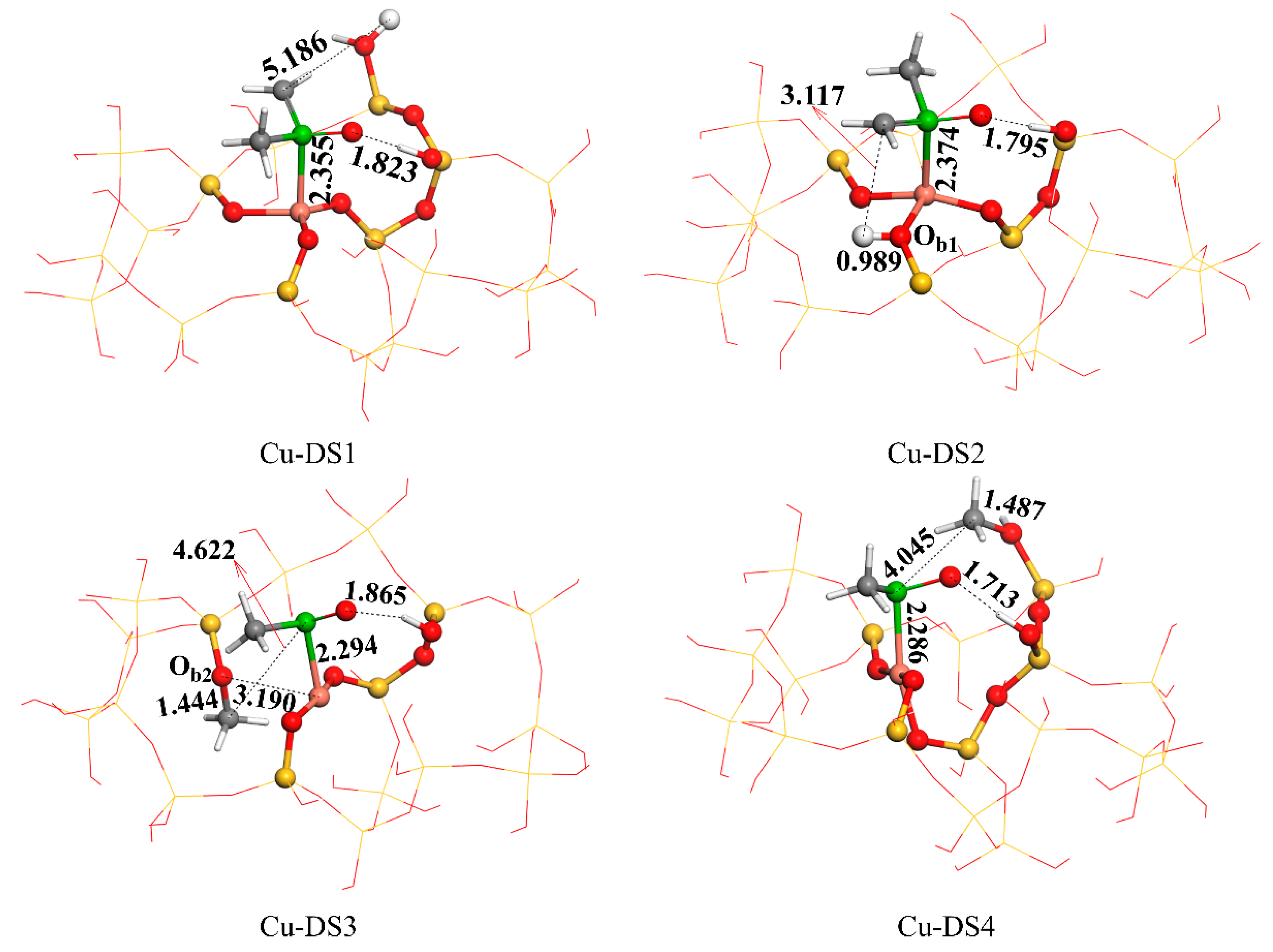

3.3.2. The Dissociation of DMSO on the Cu−Doped SBA−15 Surface

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Ye, M.; Zhu, W.L.; Xu, S.L.; Liu, Z.M. Coordinated development of coal chemical and petrochemical lndustries in China. Bull. Chin. Acad. Sci. 2019, 34, 417–425. [Google Scholar]

- Jiang, H.; Song, L.; Cheng, Z.; Chen, J.; Zhang, L.; Zhang, M.; Hu, M.; Li, J.; Li, J. Influence of pyrolysis condition and transition metal salt on the product yield and characterization via Huadian oil shale pyrolysis. J. Anal. Appl. Pyrolysis 2015, 112, 230–236. [Google Scholar] [CrossRef]

- Shi, W.; Wang, Z.; Song, W.; Li, S.; Li, X. Pyrolysis of Huadian oil shale under catalysis of shale ash. J. Anal. Appl. Pyrolysis 2017, 123, 160–164. [Google Scholar] [CrossRef]

- Maaten, B.; Loo, L.; Konist, A.; Siirde, A. Mineral matter effect on the decomposition of Ca-rich oil shale. J. Therm. Anal. Calorim. 2018, 131, 2087–2091. [Google Scholar] [CrossRef]

- Yan, J.; Jiang, X.; Han, X.; Liu, J. A TG–FTIR investigation to the catalytic effect of mineral matrix in oil shale on the pyrolysis and combustion of kerogen. Fuel 2013, 104, 307–317. [Google Scholar] [CrossRef]

- Binyu, W.; Li, L.; Jing, L. Research progress on the synthesis of zeolite molecular sieves from industrial solid wastes. Chem. J. Univ. 2021, 42, 40–59. [Google Scholar]

- Vavsari, V.F.; Ziarani, G.M.; Badiei, A. The role of SBA−15 in drug delivery. RSC Adv. 2015, 5, 91686–91707. [Google Scholar] [CrossRef]

- Yan, X.; Zhang, L.; Zhang, Y.; Yang, G.; Yan, Z. Amine-modified SBA−15: Effect of pore structure on the performance for CO2 capture. Ind. Eng. Chem. Res. 2011, 50, 3220–3226. [Google Scholar] [CrossRef]

- Larki, A.; Saghanezhad, S.J.; Ghomi, M. Recent advances of functionalized SBA−15 in the separation/preconcentration of various analytes: A review. Microchem. J. 2021, 169, 106601. [Google Scholar] [CrossRef]

- Byambajav, E.; Ohtsuka, Y. Cracking behavior of asphaltene in the presence of iron catalysts supported on mesoporous molecular sieve with different pore diameters. Fuel 2003, 82, 1571–1577. [Google Scholar] [CrossRef]

- Meng, X.; Bian, J.; Li, J.; Ma, Z.; Long, Q.; Su, J. Porous aluminosilicates catalysts for low and medium matured shale oil in situ upgrading. Energy Sci. Eng. 2020, 8, 2859–2867. [Google Scholar] [CrossRef]

- Erdogan, B.; Arbag, H.; Yasyerli, N. SBA−15 supported mesoporous Ni and Co catalysts with high coke resistance for dry reforming of methane. Int. J. Hydrogen Energy 2015, 43, 1396–1405. [Google Scholar] [CrossRef]

- Yu, C.; Qi, Z.; Guo, Y.; Bian, J.; Meng, X.; Long, Q. Oil shale in situ catalytic conversion over clin/SBA−15 composites under subcritical water. J. Anal. Appl. Pyrolysis 2020, 152, 104942. [Google Scholar] [CrossRef]

- Guan, X.H.; Liu, Y.; Wang, D.; Wang, Q.; Chi, M.S.; Liu, S.; Liu, C.G. Three-dimensional structure of a huadian oil shale kerogen model: An experimental and theoretical study. Energy Fuels 2015, 29, 4122–4136. [Google Scholar] [CrossRef]

- Ye, X.; Jiao, A.; Zhang, H.; Chen, B.; Wang, S.; Shen, J.; Yan, Z.; Deng, S.; Han, X.; Jiang, X.; et al. Quantum chemical calculations for the H free radical chemisorption with different chain models during oil shale pyrolysis. Fuel 2021, 290, 119999. [Google Scholar] [CrossRef]

- Broclawik, E.; Kozyra, P.; Datka, J. IR studies and DFT quantum chemical calculations concerning interaction of some organic molecules with Cu+ sites in zeolites. C. R. Chim. 2005, 8, 491–508. [Google Scholar] [CrossRef]

- Delley, B. From molecules to solids with the DMol3 approach. J. Chem. Phys. 2000, 113, 7756–7764. [Google Scholar] [CrossRef]

- White, J.A.; Bird, D.M. Implementation of gradient-corrected exchange-correlation potentials in Car-Parrinello total-energy calculations. Phys. Rev. B 1994, 50, 4954. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 1996, 77, 3865. [Google Scholar] [CrossRef]

- Grimme, S.; Antony, J.; Ehrlich, S.; Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 2010, 132, 154104. [Google Scholar] [CrossRef] [PubMed]

- Hohenberg, P.; Kohn, W. Inhomogeneous electron gas. Phys. Rev. 1964, 136, B864. [Google Scholar] [CrossRef]

- Becke, A.D. A multicenter numerical integration scheme for polyatomic molecules. J. Chem. Phys. 1988, 88, 2547–2553. [Google Scholar] [CrossRef]

- Fischer, T.H.; Almlof, J. General methods for geometry and wave function optimization. J. Phys. Chem. C 1992, 96, 9768–9774. [Google Scholar] [CrossRef]

- Govind, N.; Petersen, M.; Fitzgerald, G.; King-Smith, D.; Andzelm, J. A generalized synchronous transit method for transition state location. Comput. Mater. Sci. 2003, 28, 250–258. [Google Scholar] [CrossRef]

- Mishra, A.K.; Roldan, A.; de Leeuw, N.H. CuO surfaces and CO2 activation: A dispersion-corrected DFT+ U study. J. Phys. Chem. C 2016, 120, 2198–2214. [Google Scholar] [CrossRef]

- Perez-Beltran, S.; Balbuena, P.B.; Ramírez-Caballero, G.E. Surface structure and acidity properties of mesoporous silica SBA−15 modified with aluminum and titanium: First-principles calculations. J. Phys. Chem. C 2016, 120, 18105–18114. [Google Scholar] [CrossRef]

- Perez-Beltran, S.; Ramírez-Caballero, G.E.; Balbuena, P.B. First-principles calculations of lithiation of a hydroxylated surface of amorphous silicon dioxide. J. Phys. Chem. C 2015, 119, 16424–16431. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, D.; Zhao, Z.; Chen, Y.; Lan, J. A DFT study of the structural units in SBA−15 mesoporous molecular sieve. Comput. Theor. Chem. 2011, 963, 403–411. [Google Scholar] [CrossRef]

- Kang, S.; Sun, Y.; Qiao, M.; Li, S.; Deng, S.; Guo, W.; Li, J.; He, W. The enhancement on oil shale extraction of FeCl3 catalyst in subcritical water. Energy 2022, 238, 121763. [Google Scholar] [CrossRef]

- Tielens, F.; Gervais, C.; Lambert, J.F.; Mauri, F.; Costa, D. Ab initio study of the hydroxylated surface of amorphous silica: A representative model. Chem. Mater. 2008, 20, 3336–3344. [Google Scholar] [CrossRef]

- Dong, X.; Lu, J.; Yu, Y.; Zhang, M. A DFT study on Zr-SBA−15 catalyzed conversion of ethanol to 1, 3-butadiene. Phys. Chem. Chem. Phys. 2018, 20, 12970–12978. [Google Scholar] [CrossRef] [PubMed]

- Shokrlu, Y.H.; Babadagli, T. Viscosity reduction of heavy oil/bitumen using micro-and nano-metal particles during aqueous and non-aqueous thermal applications. J. Pet. Sci. Eng. 2014, 119, 210–220. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, T.; Xu, X.; Xiao, P.; Li, J. Pt nanoparticles supported on SBA−15: Synthesis, characterization and applications in heterogeneous catalysis. Appl. Catal. B 2013, 130, 197–217. [Google Scholar] [CrossRef]

| Bond Type | Bond Length (Å) | Atom | Mulliken (|e|) | ||

|---|---|---|---|---|---|

| Pure-SBA−15 | Cu-SBA−15 | Pure-SBA−15 | Cu-SBA−15 | ||

| D (X−Ob1) | 1.625 | 1.808 | Ob1 | −0.884 | −0.665 |

| D (X−Ob2) | 1.639 | 1.795 | Ob2 | −0.877 | −0.661 |

| D (X−Ob3) | 1.621 | 1.830 | Ob3 | −0.902 | −0.724 |

| Paths | Surface | Product | ΔG (kcal/mol) | ΔE (kcal/mol) |

|---|---|---|---|---|

| CH3→Ob | pure-SBA−15 | DS1 | 14.7 | 81.5 |

| CH3→OH | pure-SBA−15 | DS2 | 56.7 | 74.6 |

| H→OH | Cu-SBA−15 | Cu-DS1 | 21.6 | 62.2 |

| H→Ob | Cu-SBA−15 | Cu-DS2 | 12.1 | 39.8 |

| CH3→OH | Cu-SBA−15 | Cu-DS3 | 6.1 | 63.8 |

| CH3→Ob | Cu-SBA−15 | Cu-DS4 | −16.4 | 31.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, H.; Meng, X.; Jiang, X.; Lu, L.; Wang, Y. Theoretical Investigation on the Catalytic Effect and Mechanism of Pure and Cu−Doped SBA−15 Molecular Sieves on the Decomposition of Dimethyl Sulfoxide. Processes 2023, 11, 1386. https://doi.org/10.3390/pr11051386

Xia H, Meng X, Jiang X, Lu L, Wang Y. Theoretical Investigation on the Catalytic Effect and Mechanism of Pure and Cu−Doped SBA−15 Molecular Sieves on the Decomposition of Dimethyl Sulfoxide. Processes. 2023; 11(5):1386. https://doi.org/10.3390/pr11051386

Chicago/Turabian StyleXia, Haohai, Xianglong Meng, Xingchao Jiang, Lilin Lu, and Yanqun Wang. 2023. "Theoretical Investigation on the Catalytic Effect and Mechanism of Pure and Cu−Doped SBA−15 Molecular Sieves on the Decomposition of Dimethyl Sulfoxide" Processes 11, no. 5: 1386. https://doi.org/10.3390/pr11051386

APA StyleXia, H., Meng, X., Jiang, X., Lu, L., & Wang, Y. (2023). Theoretical Investigation on the Catalytic Effect and Mechanism of Pure and Cu−Doped SBA−15 Molecular Sieves on the Decomposition of Dimethyl Sulfoxide. Processes, 11(5), 1386. https://doi.org/10.3390/pr11051386